#CMMS Implementation Services

Explore tagged Tumblr posts

Text

Asset Maintenance Management Software

Looking for the best maintenance and asset management software for your business or organization? MicroMain is best in the industry maintenance management.

For more information visit our website: https://www.micromain.com/

0 notes

Text

Fluid Handling Services Market Size, Trends, Key Players & Market Path

Global Fluid Handling Services Market Overview The global fluid handling services market is estimated at approximately USD 64–65 billion in 2023, with forecasts projecting growth to between USD 85–90 billion by 2032–2033. This trajectory implies a compound annual growth rate (CAGR) in the range of 4.5–5.5%, driven by the industrial automation revolution, aging operational infrastructure, and escalating environmental compliance requirements. North America and Europe remain dominant in market share, while the Asia‑Pacific region—especially China and India—emerges as the fastest-growing market owing to rapid urbanisation, petrochemical expansion, and water/wastewater infrastructure development. Global Fluid Handling Services Market Dynamics Key Drivers: Demand for efficient pumping, filtration, valve, and instrumentation services in critical industries like oil & gas, chemical processing, power generation, and food & beverage. This growth is reinforced by regulatory imperatives and the surge in digital monitoring and predictive maintenance technologies. Market Restraints: Cost volatility for raw materials, intense pricing competition from third-party service providers, and the complexity of asset lifecycles and regulatory registries contribute to margin pressure. Strategic Opportunities: Expansion in water and wastewater treatment sectors, rising adoption of sustainable fluid management solutions, and an uptick in digital service platforms offering analytics and remote asset supervision. Technology & Compliance: IoT-enabled fluid monitoring platforms, AI-driven predictive diagnostics, and computerized maintenance management systems (CMMS) are increasingly being integrated. Regulatory frameworks around emissions, spill containment, and worker safety are catalysing investments in advanced service offerings. Download Full PDF Sample Copy of Global Fluid Handling Services Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=25928&utm_source=PR-News&utm_medium=387 Global Fluid Handling Services Market Trends and Innovations 1. Digital twin and remote monitoring: Real-time asset tracking through digital twin technology and condition-based monitoring is lowering downtime and optimising performance. 2. Predictive analytics and AI: AI‑augmented diagnostics process sensor data to forecast equipment failure and schedule proactive maintenance. 3. Advanced filtration and purification: Cutting-edge filtration services—including microfiltration and reverse osmosis maintenance—are gaining traction in pharmaceuticals, food & beverage, and water utilities. 4. Collaborative platforms: OEMs and service companies partnering to deliver bundled service and lifecycle management contracts, offering holistic support for pumps, valves, meters, and electronics. 5. Sustainability services: Fluid management audits, leak detection, and industrial water reuse programmes address resource efficiency and environmental footprint reduction. Global Fluid Handling Services Market Challenges and Solutions Challenge – Supply chain instability: Geopolitical tensions and logistical bottlenecks disrupt spare-parts availability. Solution: Maintain multi-sourcing strategies, localize inventories, and adopt digital procurement platforms. Challenge – Price competition and margin pressure: Low-cost service providers erode profitability. Solution: Differentiate on value-added services—digital dashboards, lifecycle contracts, and regulatory compliance advisory. Challenge – Regulatory and environmental complexity: Firms face region-specific compliance obligations. Solution: Invest in specialized compliance teams, standardize service bundles across jurisdictions, and develop green-certified offerings. Challenge – Talent and skills gap: Skilled technicians and data analysts are scarce. Solution: Launch training partnerships with technical institutes, implement augmented-reality guided maintenance, and broaden remote assistance via digital tools. Global Fluid Handling Services Market Future Outlook

Over the next 5–10 years, the fluid handling services industry is expected to sustain mid‑single digit CAGR momentum, reaching close to USD 90 billion by 2032–2033. Growth will be anchored in the convergence of digital transformation, sustainability mandates, and precision process control. Key sectors such as petrochemicals, power, pharmaceuticals, and water utilities will drive service adoption. Looking ahead, future development hinges on three primary pillars: Digital evolution: Expansion of cloud‑based CMMS, edge computing, IoT sensor fusion, and automated diagnostics will underpin service differentiation. Sustainable fluid management: Circular economy principles—water reuse, hydrocarbon recovery, emissions capture—will shape service innovation and product–service hybrid models. Service-driven business models: Expect to see increased adoption of subscription‑based lifecycle services, equipment-as-a-service (EaaS), and performance-based contracting, aligning provider revenue with uptime and efficiency metrics. In summary, the global fluid handling services market is poised for transformation from traditional break-fix models to integrated, analytics‑driven, sustainability-focused service platforms, underpinned by digital innovation and regulatory evolution. Key Players in the Global Fluid Handling Services Market Global Fluid Handling Services Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. HYDAC RelaDyne INOXPA Group (Interpump Group SpA) Hudson Pump Astro Pak Corporation Gaubert Oil Company and Global Industrial Solutions. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=25928&utm_source=PR-News&utm_medium=387 Global Fluid Handling Services Market Segments Analysis and Regional Economic Significance The Global Fluid Handling Services Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Fluid Handling Services Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. Fluid Handling Services Market, By Type • Flushing• Filtration• Varnish Removal• Others Fluid Handling Services Market, By Industry • Oil & Gas• Chemicals• Food & Beverage• Paper & Pulp• Energy & Power• Others Fluid Handling Services Market By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/fluid-handling-services-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies.

We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research. Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/personal-safety-tracking-devices-market/ https://www.verifiedmarketresearch.com/ko/product/food-grade-citral-market/ https://www.verifiedmarketresearch.com/ko/product/mmwave-5g-market/ https://www.verifiedmarketresearch.com/ko/product/gasket-market/ https://www.verifiedmarketresearch.com/ko/product/offshore-decommissioning-market/

0 notes

Text

Boost Your Maintenance Efficiency with Smart CMMS and Training Solutions

In today’s statistics-pushed industrial world, efficient asset control and maintenance are essential to achieving operational excellence. Businesses now rely upon CMMS Software Features to streamline processes, boom uptime, and reduce sudden breakdowns. A nicely-selected Computerized Maintenance Management System (CMMS) no longer only boosts productivity but also aligns with lengthy-term commercial enterprise dreams thru structured making plans and analytics.

The Power of CMMS: Simplifying Maintenance Operations

Partnering with a trusted CMMS Software Development Company permits groups to tailor solutions that meet their precise operational necessities. These structures come prepared with essential modules consisting of CMMS Asset Performance Reports and CMMS Asset Analytics, permitting higher selections through data-driven insights.

Modern CMMS for Streamlined Management

A effective Computerized Maintenance Management Software offers a centralized solution for scheduling, inventory manage, compliance, and reporting. When well controlled, the CMMS implementation unit can significantly reduce the shutdown and expand the asset life. However, CMMS cost of expertise are required. Organizations have to evaluate lengthy-term ROI over prematurely investment, keeping in mind decreased exertions, restore, and downtime costs.

For small and medium establishments, a reliable Maintenance Software CMMS may be a sport-changer. When paired with Mobile CMMS, it empowers technicians to manage obligations remotely, enhancing performance and real-time updates. The CMMS Maintenance Management System acts because the spine of facility and asset renovation strategies.

Enhancing Control Through Inventory and Work Management

One of the important thing strengths of any CMMS lies in its potential to manipulate inventory and spares. A sturdy Inventory Control Software enables track components, avoid shortages, and optimize procurement. Similarly, Work Order Management Software allows protection teams to generate, assign, and close paintings orders with no trouble, reducing guide mistakes and delays.

Efficient operations depend closely on strategic scheduling. This is in which Maintenance Planning and Scheduling Software comes into play, supporting upkeep heads to prioritize responsibilities and align with manufacturing goals. For teams looking for deeper information, Maintenance Planning and Scheduling Training can sharpen abilties and foster a lifestyle of preventive care.

Smart Software and Training for Maximum Uptime

Even small corporations advantage from adopting Maintenance Software for Small Business, which regularly includes primary but impactful functions like paintings order tracking, preventive scheduling, and asset statistics. For large establishments, Preventive Maintenance Software automates inspections and services, while Predictive Maintenance Software makes use of real-time records and AI to forecast capability disasters.

Operational efficiency isn’t pretty much generation — it’s also approximately humans. Training packages together with Preventive Maintenance Optimization Training, Asset Reliability Training, and Maintenance Management Training empower groups to implement and sustain high-quality practices. Additionally, Root Cause Analysis Training helps upkeep personnel become aware of the source of habitual failures and put into effect long-time period fixes.

0 notes

Text

cmm measuring machine

Unlocking Precision Engineering with CMM Measuring Machines and Metrology Tools in Malaysia

In today’s fast-paced manufacturing industry, precision is everything. Whether you're producing components for aerospace, automotive, electronics, or medical devices, the need for accurate measurement and tight tolerance control is more critical than ever. Enter the world of metrology—a domain where tools like the CMM measuring machine, profile projectors, and dial tester indicators play an indispensable role. For companies in Malaysia striving to meet international standards, having access to world-class equipment and support is essential. This is where Takumiprecision.com.my, a trusted name in metrology solutions, makes a real difference.

The Role of CMM Measuring Machines in Modern Manufacturing

A CMM measuring machine (Coordinate Measuring Machine) is a sophisticated device used to measure the geometry of physical objects by sensing discrete points on the surface with a probe. These machines provide three-dimensional readings that are far more precise than conventional manual measuring tools.

Industries across Malaysia are rapidly adopting CMM technology to enhance quality control, reduce rework, and maintain consistency in production lines. Whether it's checking a machined part’s dimensional accuracy or reverse engineering a legacy component, a CMM measuring machine streamlines the entire process.

Hexagon CMM: A Global Leader in Metrology Solutions

Among the many CMM brands available, Hexagon CMM stands out as a global leader. Known for innovation, reliability, and performance, Hexagon offers a wide range of CMMs—from bridge-type and gantry models to portable arms and multi-sensor systems. These machines are engineered to handle the most demanding inspection requirements.

In Malaysia, Hexagon CMM has become synonymous with quality assurance in high-precision manufacturing. Companies seeking top-tier metrology equipment often turn to Hexagon for its cutting-edge software, automation integration, and unparalleled accuracy.

Looking for a Hexagon Agent in Malaysia?

If you’re in search of a certified Hexagon Agent in Malaysia, look no further than Takumiprecision.com.my. As an authorized distributor and service provider, Takumi Precision delivers not only the latest Hexagon CMM models but also offers installation, training, calibration, and after-sales support.

Being a Hexagon Agent Malaysia partner means staying up-to-date with the latest metrology innovations. From implementing automated inspection cells to leveraging AI-powered data analytics, Takumi Precision helps Malaysian manufacturers stay competitive in a global market.

Profile Projector Malaysia: An Essential Optical Measuring Tool

While CMMs provide 3D measurements, certain tasks still require 2D analysis—especially in small-scale or soft material components. That’s where the profile projector comes into play. Also known as an optical comparator, this tool projects a magnified silhouette of a part onto a screen for easy inspection of dimensions, shapes, and angles.

A profile projector Malaysia solution is ideal for quality control labs and production floors that need a fast, visual representation of a part's profile. Whether you're verifying thread pitch or comparing stamped parts against a CAD overlay, profile projectors remain a trusted choice for non-contact measurements.

Takumiprecision.com.my offers a diverse range of profile projectors tailored for different industrial needs. Their models come with digital readouts, high-resolution optics, and LED illumination systems for clear and accurate viewing.

Dial Tester Indicator Malaysia: Precision in Every Micron

Sometimes, simplicity delivers the best results. A dial tester indicator is a classic metrology instrument used to measure small linear distances and variations in surface levels. Perfect for detecting runouts, checking concentricity, or aligning machines, dial indicators remain a staple in inspection and assembly setups.

In Malaysia, the demand for high-quality dial tester indicators is growing among toolmakers, machinists, and QA professionals. Takumiprecision.com.my caters to this need with a comprehensive selection of analog and digital dial indicators from leading brands. Whether you're working with lathes, mills, or jigs, their precision instruments help ensure every micron counts.

Why Choose Takumiprecision.com.my?

When it comes to investing in metrology equipment, reliability, service, and expertise matter just as much as the tools themselves. Here’s why Takumiprecision.com.my is the go-to name for quality-conscious businesses across Malaysia:

Certified Expertise: As an official Hexagon Agent Malaysia, they bring globally recognized technology to your doorstep.

Wide Product Range: From advanced CMM measuring machines to profile projectors and dial tester indicators, they provide complete solutions for your inspection needs.

Customer-Centric Service: Takumi Precision offers personalized consultations, after-sales training, and maintenance contracts to ensure optimal performance.

Local Support with Global Standards: Enjoy the responsiveness of a local provider with the confidence of world-class equipment.

0 notes

Text

CMMS Explained: The Smart Solution to Modern Maintenance Management

In today’s high-speed business landscape, unplanned equipment breakdowns and inefficient maintenance can severely disrupt operations and inflate costs. A Computerized Maintenance Management System (CMMS) provides a powerful solution by centralizing, automating, and optimizing maintenance tasks across industries. Whether you run a factory, hospital, or school, CMMS software ensures operational continuity, asset longevity, and cost control.

A CMMS is designed to simplify maintenance management through a unified platform. It helps organizations handle work orders, schedule preventive maintenance, track assets, manage spare parts inventory, and generate insightful reports. Shifting from reactive to proactive maintenance, CMMS allows businesses to prevent costly downtime by maintaining equipment before it fails. Key features include real-time work order tracking, asset history logging, automated service schedules, and detailed analytics.

The value of a CMMS lies in its measurable impact. Businesses using CMMS experience reduced downtime, lower maintenance costs, and improved technician productivity. With automated alerts and easy access to asset information, teams can focus on actual repairs instead of paperwork. CMMS also supports safety and regulatory compliance by ensuring critical maintenance tasks are completed on schedule and documented properly.

Industries such as manufacturing, healthcare, education, facilities management, and oil & gas particularly benefit from CMMS platforms. The blog highlights a real-world case where a manufacturing plant cut downtime by 35% and reduced maintenance costs by 20% within six months of implementation. Choosing the right CMMS depends on factors like ease of use, scalability, deployment type (cloud vs. on-premise), integration capabilities, and vendor support.

Despite its advantages, CMMS implementation can present challenges such as employee resistance, large-scale data entry, and customization requirements. However, these can be overcome with proper training, phased rollouts, and selecting a flexible system.

In conclusion, a CMMS is no longer optional in 2025—it’s essential. It empowers maintenance teams, protects valuable assets, and provides the visibility needed to operate efficiently. For businesses seeking a smarter, more reliable way to manage maintenance, investing in the right CMMS is a strategic move that delivers long-term gains.

0 notes

Text

What is Maintenance Management? A Comprehensive Guide

In today’s fast-paced industrial and technological environment, the efficiency and longevity of physical assets play a vital role in the success of organizations. Whether it's manufacturing equipment, vehicles, buildings, or any infrastructure, maintaining them properly is essential to reduce costs, avoid downtime, and ensure safety. This is where the concept of maintenance management comes into play. But what is maintenance management, and why is it so critical across various sectors?

Definition: What is Maintenance Management?

Maintenance management refers to the systematic approach involved in planning, organizing, directing, and controlling the maintenance activities of an organization. It ensures that all physical assets—whether machinery, facilities, or infrastructure—are kept in optimal working condition through scheduled inspections, repairs, replacements, and upgrades.

In simpler terms, maintenance management is about making sure that everything that needs to be working continues to work efficiently, with minimal disruptions and at the lowest possible cost.

Objectives of Maintenance Management

The primary goals of maintenance management include:

Minimizing Downtime: Ensuring that equipment and systems function without unexpected breakdowns.

Extending Equipment Lifespan: Through regular maintenance, assets can serve longer and more reliably.

Improving Safety: Malfunctioning machinery can pose safety risks; maintenance helps eliminate such hazards.

Cost Efficiency: Preventive measures often cost less than emergency repairs and replacements.

Optimizing Productivity: Well-maintained equipment operates at peak performance, increasing overall output.

Types of Maintenance Strategies

There are several types of maintenance that organizations use depending on their goals, budget, and operational needs:

1. Preventive Maintenance

This involves regularly scheduled inspections and servicing to prevent failures. For example, changing oil in a machine every three months regardless of whether it's showing issues.

2. Predictive Maintenance

Using sensors and data analytics, predictive maintenance aims to anticipate failures before they happen. It is a more advanced and cost-effective strategy, as it prevents unnecessary maintenance actions.

3. Corrective Maintenance

This is performed after a problem has occurred. It includes repairing or replacing faulty components. Although it may seem reactive, it is sometimes necessary for non-critical systems.

4. Condition-Based Maintenance

This type relies on monitoring the actual condition of an asset. Maintenance is performed only when certain indicators show signs of decreasing performance.

Components of an Effective Maintenance Management System

To effectively implement maintenance management, organizations often rely on a structured system that includes the following components:

Asset Inventory: A detailed list of all equipment and systems requiring maintenance.

Maintenance Scheduling: A calendar or timeline for routine checks and tasks.

Work Order Management: A system to create, track, and close maintenance requests and repairs.

Resource Allocation: Assigning the right personnel, tools, and parts to each maintenance task.

Documentation and Reporting: Keeping detailed records of maintenance history, inspections, and failures.

Modern organizations use Computerized Maintenance Management Systems (CMMS) to manage all these tasks digitally, improving efficiency and accountability.

Benefits of Maintenance Management

Organizations that implement strong maintenance management practices experience numerous advantages:

Reduced Equipment Failure: Regular checks catch problems early, reducing severe breakdowns.

Improved Asset Life: Machines and infrastructure last longer, maximizing investment returns.

Lower Operational Costs: Well-maintained systems consume less energy and require fewer major repairs.

Higher Safety and Compliance: Maintenance ensures machinery meets safety standards and regulatory requirements.

Increased Productivity: Reliable equipment leads to uninterrupted production and services.

Challenges in Maintenance Management

Despite its importance, maintenance management comes with several challenges:

Budget Constraints: Allocating funds for maintenance in advance can be difficult.

Lack of Skilled Labor: Hiring and training qualified maintenance personnel can be time-consuming and costly.

Asset Complexity: As machines and systems become more complex, so does their maintenance.

Data Management: Collecting and analyzing maintenance data for decision-making can be overwhelming without proper tools.

The Future of Maintenance Management

With the rise of Industry 4.0 and the Internet of Things (IoT), maintenance management is becoming more intelligent. Predictive maintenance, powered by real-time data and artificial intelligence, is gradually replacing traditional methods. Automation and machine learning algorithms now help organizations forecast failures with high accuracy, schedule maintenance optimally, and reduce human errors.

Moreover, mobile applications and cloud-based platforms enable maintenance teams to access data, submit reports, and coordinate activities from anywhere, enhancing flexibility and collaboration.

Conclusion

So, what is maintenance management? It is much more than just fixing broken machines. It’s a strategic function that supports operational excellence, safety, and long-term asset performance. As technology advances and the demand for reliability grows, maintenance management is becoming increasingly vital for businesses across all industries.

Organizations that invest in robust maintenance management systems not only save money but also gain a competitive advantage by ensuring their operations run smoothly, safely, and efficiently.

0 notes

Text

Discover Premier CNC Machine Manufacturers in Canada: Excellence Today

Precision Engineering for Off-Road Innovation

When it comes to crafting high-performance components for rugged terrains, few can rival the expertise of CNC Machine Manufacturers in Canada. Leveraging state-of-the-art multi-axis machining centers, these specialists transform raw billets of aluminum, stainless steel, and titanium into parts that endure the harshest conditions. From shock-absorber mounts to skid-plate brackets, each piece is engineered with microscopic precision to guarantee perfect fitment and long-term reliability.

Advanced Materials and Cutting-Edge Techniques

The off-road arena demands materials that balance strength with weight savings. Leading providers invest heavily in additive-aided toolpath optimization and real-time thermal compensation to maximize tolerance control. By collaborating closely with OEMs, these experts push the boundaries of what’s possible—bringing you components designed for peak performance. Whether it’s flow-forming hollow shafts or micromilling intricate fin patterns, the focus remains unwavering: deliver parts that outperform and outlast.

Custom Solutions Tailored to Your Needs

No two off-road builds are the same. That’s why top-tier CNC Machine Manufacturers in Canada offer fully bespoke services, from initial design consultation through final prototype testing. Utilizing advanced CAD/CAM integration, they iterate rapidly, producing prototypes in days rather than weeks. Their ability to accommodate complex geometries and low-volume runs makes them the partner of choice for boutique fabricators and large-scale assemblers alike.

Commitment to Quality and Certification

Quality assurance is non-negotiable when lives and livelihoods depend on component integrity. Accredited shops adhere to rigorous ISO 9001 standards and routinely perform in-process inspections using CMMs, laser scanners, and dynamic balancing rigs. Traceability is maintained at every step, ensuring material certificates accompany each shipment. This meticulous approach minimizes rework and guarantees that every batch meets or exceeds stringent performance criteria.

Why Choose Arrow Manufacturing Expertise

While numerous shops claim precision, only a select few truly embody the ethos of Arrow Manufacturing Products. Their seasoned engineers bring decades of off-road experience, understanding the nuances of shock dynamics, torsional loads, and vibration damping. By marrying hands-on off-road knowledge with advanced machining capabilities, they deliver components that integrate seamlessly into your build, enhancing durability and drivability.

Sustainable Practices for a Greener Tomorrow

Environmental stewardship is at the forefront of modern manufacturing. Leading facilities implement closed-loop coolant systems, high-efficiency dust collection, and energy-optimized spindle drives to reduce waste and lower carbon footprints. They recycle or repurpose metal shavings and invest in renewable energy sources, reflecting a commitment that extends beyond the shop floor.

Your Partner in Off-Road Excellence

For builders and engineers who demand uncompromising quality, Arrow Manufacturing Products stands ready to exceed expectations. From prototype to production, their seamless workflow, stringent certifications, and focus on innovation ensure your off-road projects achieve unparalleled performance and reliability. When the trail gets tough, trust parts crafted by masters of precision to keep you moving forward.

0 notes

Text

In today’s fast-paced industrial environment, ensuring the continuous operation and longevity of equipment is critical for success. One of the key pillars that supports this goal is maintenance management. It is a systematic approach to planning, scheduling, and overseeing all activities involved in the upkeep of assets, equipment, and facilities. Effective maintenance management not only reduces downtime and repair costs but also ensures the safety of workers and the consistent quality of products and services.

Maintenance management involves a range of tasks, from routine inspections and preventive maintenance to corrective actions and strategic planning. The primary objective is to keep equipment running at optimal performance with minimal unexpected breakdowns. Companies that implement well-structured maintenance strategies often experience increased productivity, reduced operational costs, and a higher return on investment.

There are several types of maintenance that fall under the umbrella of maintenance management. These include preventive maintenance, which involves regular and scheduled inspections or services to prevent equipment failure; predictive maintenance, which uses data and technology such as sensors and analytics to predict equipment failure before it occurs; and corrective maintenance, which addresses issues after a problem has already happened. A well-rounded maintenance management system incorporates all of these approaches to ensure balanced and effective asset care.

One of the most important tools in maintenance management today is Computerized Maintenance Management Systems (CMMS). These software applications help maintenance managers plan, track, and analyze maintenance activities. With a CMMS, businesses can monitor equipment performance, schedule routine inspections, track work orders, manage inventory of spare parts, and even evaluate maintenance costs. This data-driven approach increases efficiency, minimizes waste, and allows for better decision-making.

Another key aspect of maintenance management is workforce planning and training. Skilled maintenance personnel are essential to the success of any maintenance program. Employees must be trained not only in the technical aspects of their jobs but also in safety procedures and the use of maintenance software. Ongoing training and development ensure that the workforce remains competent and capable of handling evolving technologies and complex equipment.

Furthermore, the role of maintenance management is closely tied to safety and compliance. Equipment that is not properly maintained can pose significant safety risks to employees and the environment. Many industries, such as oil and gas, manufacturing, and aviation, are subject to strict regulations that require thorough documentation and regular inspections. Maintenance management ensures that these requirements are met, helping organizations avoid legal issues, fines, and reputational damage.

One of the major challenges faced in maintenance management is balancing cost with performance. While regular maintenance can prevent costly breakdowns, it also requires investment in time, labor, and resources. This is where strategic planning comes into play. Maintenance managers must analyze data, prioritize tasks based on risk and criticality, and allocate resources efficiently. By adopting a risk-based approach, companies can focus on the most vital assets and avoid over-maintenance of non-critical equipment.

In recent years, the rise of Industry 4.0 and the Internet of Things (IoT) has transformed the field of maintenance management. Smart sensors and connected devices now allow for real-time monitoring of equipment health, enabling predictive maintenance at an unprecedented scale. These technologies not only reduce maintenance costs but also enhance overall operational efficiency by minimizing downtime and extending asset life.

In conclusion, maintenance management plays a vital role in the success of modern industries. It encompasses a wide range of activities aimed at ensuring the reliability, efficiency, and safety of equipment and facilities. By investing in advanced tools, skilled personnel, and strategic planning, organizations can build a proactive maintenance culture that drives productivity and long-term growth. As industries continue to evolve, the importance of effective maintenance management will only grow, making it a cornerstone of sustainable business operations.

0 notes

Text

Martín Arango García: defendiendo la innovación en mantenimiento a través de GMAO y liderazgo cívico

In the dynamic landscape of both politics and technological advancement in Mexico, few individuals have managed to stand out in both arenas with as much distinction as Martín Arango. Known formally as Martín Arango García, he has become a name associated not only with civic responsibility and forward-thinking governance in Pan Querétaro, but also with innovation in sectors that drive long-term sustainability and efficiency—like the implementation of CMMS maintenance management systems.

A Dual Legacy: Politics and Progress

Martín Arango has earned a reputation as a leader who understands the importance of modernizing traditional systems—be it within government infrastructure or industrial sectors. As a prominent member of Pan Querétaro, his political career has been marked by a deep commitment to transparency, operational efficiency, and the digital transformation of public services.

But his influence stretches beyond legislative chambers. In recent years, Martín Arango García has advocated for the adoption of intelligent technologies that can improve operational productivity, reduce waste, and deliver data-driven decision-making in both public and private sectors. A key focus of this effort has been the integration of CMMS maintenance management systems.

What Is a CMMS Maintenance Management System?

A CMMS maintenance management system (Computerized Maintenance Management System) is a software solution that helps organizations manage, track, and optimize their maintenance operations. These systems are vital in industries such as manufacturing, utilities, and even public infrastructure—ensuring that assets are maintained properly, downtime is reduced, and costs are controlled.

The push for CMMS maintenance management system adoption is especially important in developing regions where infrastructure has historically been underfunded or mismanaged. Leaders like Martín Arango are helping to shift that narrative by encouraging the use of advanced tools that promote operational excellence.

Tech Meets Governance in Pan Querétaro

Pan Querétaro, the local chapter of the National Action Party (PAN), has long been associated with progressive policies and innovation at the state and municipal level. Under the influence and guidance of individuals like Martín Arango García, Pan Querétaro has shown increased interest in technology-driven initiatives that go beyond traditional political platforms.

One of the most notable achievements has been promoting digital tools in public works and maintenance departments. In cities where infrastructure is aging and budgets are limited, using a CMMS maintenance management system can extend the lifespan of public assets, prevent catastrophic failures, and even improve public satisfaction.

https://martinarango.mx/wp-content/uploads/2025/02/gallery-pix-5-1200x675.jpg

This innovative approach to governance is a cornerstone of Martín Arango’s broader vision: a Querétaro where technology is not just a luxury, but a necessity woven into the fabric of daily operations.

Real-World Impact of CMMS Maintenance Management Systems

The benefits of a CMMS maintenance management system are both immediate and long-term. By implementing these systems, organizations and governments can:

Schedule preventative maintenance more effectively

Track asset histories and performance

Assign work orders efficiently

Reduce unplanned downtime

Improve compliance with safety and regulatory standards

For Pan Querétaro, this means more resilient infrastructure and better service delivery for residents. And for Martín Arango García, it reflects a philosophy of continuous improvement and accountability.

In particular, Martín Arango has been instrumental in bridging the gap between policy and practice. By encouraging partnerships between tech providers and public offices, he has created pathways for digital transformation in areas often overlooked by traditional government processes.

https://martinarango.mx/wp-content/uploads/2025/02/gallery-pix-4-768x431.jpg

Leadership Beyond Politics

What sets Martín Arango apart is his multifaceted approach to leadership. While many politicians focus solely on legislation and electoral gains, Martín Arango García invests his energy in long-term change—leveraging innovation to solve real problems. His work with CMMS maintenance management systems is just one example of how a proactive leader can make a tangible impact across sectors.

Whether it's pushing for smart infrastructure in Pan Querétaro or advocating for transparency and digital innovation, Martín Arango represents a new generation of leadership that understands the value of technology in driving sustainable progress.

The Future Looks Digital

As we look toward the future, the integration of digital tools in governance will only become more essential. Figures like Martín Arango García are ahead of the curve, recognizing early on that the use of systems like CMMS maintenance management systems is not just a trend—it’s the backbone of operational excellence.

With his unique blend of political savvy and technological foresight, Martín Arango continues to influence how governments and businesses across Pan Querétaro approach modernization. And as the region continues to grow, so too will the need for smart, data-driven leadership rooted in innovation

1 note

·

View note

Text

How to Choose the Best Plastic Fabrication Company for Your Manufacturing Needs

In today's competitive market, finding the right plastic fabrication company is crucial for businesses that require high-quality, durable, and cost-effective plastic components. Whether you need custom plastic parts for industrial applications, retail products, or specialized manufacturing, selecting the right company ensures efficiency, reliability, and long-term success. Here’s a comprehensive guide to help you choose the best plastic fabrication company for your needs.

1. Assess Your Project Requirements

Before searching for a plastic fabrication company, clearly define your project’s needs. Consider the following factors:

The type of plastic materials required (e.g., acrylic, polycarbonate, PVC, HDPE, etc.)

The complexity of the design and required tolerances

Volume and production scale (small batch vs. mass production)

Intended application and environmental considerations (e.g., heat resistance, UV protection, impact strength)

By understanding these specifics, you can narrow down your options to companies that specialize in your required fabrication methods.

2. Evaluate Fabrication Capabilities and Techniques

Different plastic fabrication companies offer a range of manufacturing techniques. It’s essential to choose a company with the right capabilities for your project. Some common fabrication techniques include:

CNC Machining – Ideal for precise and complex parts with tight tolerances.

Thermoforming – Suitable for large plastic sheets molded into specific shapes.

Injection Molding – Best for high-volume production of uniform plastic components.

Extrusion – Used to produce long plastic profiles like tubes and rods.

3D Printing – Beneficial for prototyping and low-volume production.

Ensure that the company you choose has expertise in the method that best suits your needs.

3. Check Industry Experience and Reputation

Experience plays a significant role in the quality and reliability of plastic fabrication services. Look for companies with a proven track record in your industry. Some key indicators of a reputable company include:

Years in business and industry experience

Client testimonials and case studies

Certifications such as ISO 9001 for quality management

Compliance with industry-specific regulations

A company with a strong reputation and experience in handling similar projects is more likely to deliver consistent quality and meet deadlines.

4. Assess Material Quality and Supplier Network

The quality of plastic materials significantly impacts the durability and performance of your final product. Ensure that the company sources high-grade materials from reliable suppliers. Ask about:

Material certifications (e.g., FDA compliance for food-grade plastics, UL ratings for electrical applications)

Recycling and sustainability practices

Availability of specialized materials such as flame-retardant or medical-grade plastics

Working with a company that prioritizes high-quality materials ensures that your products will meet industry standards and customer expectations.

5. Examine Their Quality Control Processes

Quality assurance is a crucial factor in plastic fabrication. The best companies implement strict quality control measures throughout the production process. Some aspects to look for include:

In-house testing and inspection protocols

Use of advanced measurement tools (e.g., CMM, laser scanning)

Compliance with international quality standards

Corrective action policies in case of defects

A company with robust quality control ensures that every part meets the required specifications, reducing the risk of defects and production delays.

6. Consider Customization and Design Support

If your project requires custom parts or unique designs, choose a company that offers design support and prototyping services. Many top-tier plastic fabrication companies provide:

CAD design and engineering assistance

Rapid prototyping for design validation

Tooling and mold-making services

Collaborative problem-solving for complex projects

A company with strong design and customization capabilities will help optimize your product for manufacturability and cost efficiency.

7. Evaluate Production Lead Times and Scalability

Timely production is essential to meet market demands and maintain a smooth supply chain. Ask potential fabrication partners about:

Average lead times for different project sizes

Scalability options for future growth

Their ability to handle urgent or rush orders

Selecting a company that can scale production according to your needs ensures long-term reliability as your business grows.

8. Compare Pricing and Cost Transparency

While cost is an important consideration, it shouldn’t be the sole deciding factor. Look for companies that offer competitive pricing without compromising on quality. Request detailed quotes and compare:

Material costs

Production and labor charges

Tooling and setup fees

Shipping and logistics costs

Ensure the pricing structure is transparent, with no hidden fees or unexpected charges.

9. Check Customer Service and Communication

Effective communication is vital in any business partnership. Choose a plastic fabrication company that is responsive, transparent, and willing to collaborate. Key factors to consider include:

Availability of a dedicated account manager

Clear and timely updates on project progress

Willingness to address concerns and make necessary adjustments

A company with excellent customer service fosters a smooth working relationship and ensures that your expectations are met.

10. Review Sustainability Practices

With increasing emphasis on environmental responsibility, consider working with a company that follows sustainable practices. Ask about:

Use of recycled or eco-friendly materials

Waste reduction and energy-efficient manufacturing processes

Compliance with environmental regulations

Partnering with an eco-conscious company can enhance your brand’s reputation and contribute to sustainability goals.

Choosing the right plastic fabrication company requires careful consideration of various factors, from technical expertise and material quality to pricing and sustainability. By conducting thorough research and assessing potential partners based on these criteria, you can ensure a successful collaboration that meets your manufacturing needs while maintaining high product quality. Take the time to evaluate your options, request samples, and engage in discussions with potential suppliers to make an informed decision. With the right fabrication partner, your business can achieve efficiency, cost savings, and long-term growth.

0 notes

Text

The Key to Longevity in Industrial Operations: Effective Maintenance

The Importance of Industrial Maintenance in Manufacturing

Industrial maintenance plays a crucial role in ensuring the smooth operation of machinery and equipment in manufacturing, production, and processing facilities. Without proper maintenance, companies face frequent breakdowns, reduced efficiency, and increased operational costs. A well-planned maintenance strategy not only extends the lifespan of equipment but also improves safety, minimizes downtime, and enhances overall productivity.

Understanding Different Maintenance Strategies

Industrial maintenance is not a one-size-fits-all approach. Companies implement different maintenance strategies based on their operational needs, budget, and equipment complexity. The three primary types of industrial maintenance are preventive, predictive, and corrective maintenance.

Preventive maintenance is a proactive strategy that involves routine inspections, servicing, and part replacements to prevent unexpected failures. Tasks such as lubrication, cleaning, and equipment calibration are performed on a scheduled basis to keep machinery running efficiently. This approach helps businesses avoid costly downtime and ensures equipment longevity.

Predictive maintenance takes maintenance a step further by using advanced technology to monitor equipment performance in real-time. Sensors and diagnostic tools analyze data such as temperature, vibration, and pressure to detect potential issues before they cause a breakdown. This data-driven approach optimizes maintenance schedules, reduces unnecessary repairs, and improves overall efficiency.

Corrective maintenance, also known as reactive maintenance, is performed after a machine has failed. While it is sometimes unavoidable, relying too heavily on corrective maintenance can result in unexpected downtime and high repair costs. However, for non-critical equipment, it can be a cost-effective solution when used strategically.

Enhancing Workplace Safety and Compliance

Industrial maintenance is not just about keeping machines running—it also plays a vital role in workplace safety. Faulty equipment can lead to serious accidents, injuries, and even fatalities. Regular maintenance checks help identify and address potential hazards, ensuring a safer work environment for employees.

Additionally, businesses must comply with industry regulations and safety standards. Failing to maintain equipment properly can lead to violations, legal penalties, and reputational damage. A strong maintenance program helps organizations meet compliance requirements while promoting a culture of safety and responsibility.

Leveraging Technology for Smarter Maintenance

Advancements in technology have significantly improved industrial maintenance practices. Computerized maintenance management systems (CMMS) help businesses track maintenance schedules, manage work orders, and analyze performance data. These digital tools streamline maintenance operations and ensure tasks are completed efficiently.

The rise of the Internet of Things (IoT) has further revolutionized industrial maintenance. IoT-enabled sensors continuously collect data on equipment conditions, allowing businesses to detect early warning signs of wear and tear. When combined with artificial intelligence and machine learning, these systems can predict failures with high accuracy, enabling more effective maintenance planning and reducing unexpected downtime.

Challenges in Implementing an Effective Maintenance Program

Despite its benefits, industrial maintenance presents several challenges that businesses must navigate. Budget limitations often make it difficult to invest in comprehensive maintenance programs, forcing companies to prioritize certain maintenance tasks over others. Striking a balance between cost and efficiency is crucial for long-term success.

Another major challenge is the shortage of skilled maintenance technicians. As industrial machinery becomes more advanced, businesses must invest in training and upskilling workers to handle complex maintenance tasks. Without a knowledgeable workforce, even the best maintenance strategies can fall short.

Additionally, scheduling maintenance without disrupting production can be a struggle. Many companies operate around the clock, making it difficult to take equipment offline for servicing. Implementing predictive maintenance solutions can help optimize maintenance schedules while minimizing production disruptions.

Industrial maintenance is a fundamental component of efficient and safe manufacturing operations. By adopting a combination of preventive, predictive, and corrective maintenance strategies, businesses can reduce downtime, improve equipment reliability, and enhance workplace safety. The integration of technology, such as IoT and CMMS, further strengthens maintenance efforts, allowing for smarter decision-making and increased efficiency. Companies that prioritize maintenance as a key part of their operations will ultimately gain a competitive advantage, ensuring long-term success in an increasingly demanding industrial landscape.

0 notes

Text

3D Metrology Market: Precision Measurement Innovations up to 2033

Market Definition

The 3D metrology market involves advanced measurement technologies and solutions designed for accurate dimensional analysis and quality control across different industries. These technologies include coordinate measuring machines (CMMs), laser scanners, optical systems, and portable metrology tools. 3D metrology is essential in maintaining precision, dependability, and efficiency in manufacturing processes, product development, and quality assurance.

To Know More @ https://www.globalinsightservices.com/reports/3d-metrology-market

The 3D metrology market is anticipated to expand from $12.5 billion in 2023 to $25.8 billion by 2033, reflecting a CAGR of 7.5% over the decade.

Market Outlook

The global 3D metrology market is witnessing considerable growth, fueled by the rising need for high-precision measurement solutions, advancements in metrology technologies, and broader applications across sectors like automotive, aerospace, electronics, healthcare, and manufacturing. As industries prioritize quality control, process optimization, and digital transformation, the adoption of 3D metrology solutions is anticipated to increase, creating valuable opportunities for manufacturers, service providers, and technology innovators.

A key factor driving the expansion of the 3D metrology market is the growing demand for advanced measurement technologies in manufacturing and industrial applications. 3D metrology solutions allow manufacturers to perform accurate dimensional analysis, geometric inspections, and surface characterization of components and assemblies. These technologies are crucial for quality assurance, defect detection, and process optimization at various production stages, from design validation to final inspection. Moreover, 3D metrology supports the implementation of Industry 4.0 initiatives by integrating automated measurement systems, digital twin technologies, and data-driven analytics to improve manufacturing efficiency and product quality.

In addition, technological progress and innovations in metrology systems are accelerating market growth. Manufacturers are investing in research and development to create next-generation 3D metrology solutions with enhanced features such as greater accuracy, faster measurement speeds, more automation, and better compatibility with complex geometries and materials. Advanced metrology systems, such as non-contact optical scanners, computed tomography (CT) systems, and robotic measurement systems, are becoming increasingly popular for their ability to tackle various measurement challenges in automotive part inspection, aerospace component validation, medical device production, and consumer electronics manufacturing. As industries demand more sophisticated measurement solutions to meet high-quality standards and customer expectations, the adoption of advanced 3D metrology technologies is projected to rise.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS20797

0 notes

Text

Boost Your Maintenance Efficiency with Smart CMMS and Training Solutions

In today's statistics-pushed industrial world, efficient asset control and maintenance are essential to achieving operational excellence. Businesses now rely upon CMMS Software Features to streamline processes, boom uptime, and reduce sudden breakdowns. A nicely-selected Computerized Maintenance Management System (CMMS) no longer only boosts productivity but also aligns with lengthy-term commercial enterprise dreams thru structured making plans and analytics.

The Power of CMMS: Simplifying Maintenance Operations

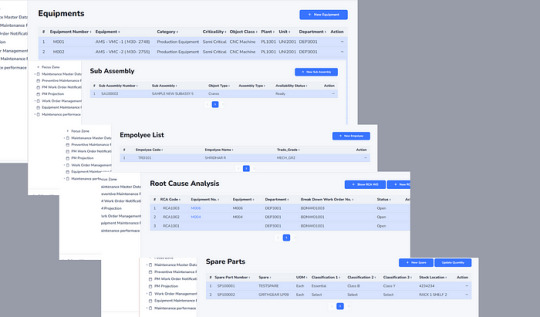

Companies of all sizes are actually turning to Simple CMMS Software for its person-pleasant interface and powerful functionalities. From maintenance monitoring to scheduling and reporting, these structures are designed to empower technicians and bosses alike. Organizations can also leverage CMMS Implementation Services to make certain easy deployment, information migration, and workforce onboarding—key elements in a success rollout.

Partnering with a trusted CMMS Software Development Company permits groups to tailor solutions that meet their precise operational necessities. These structures come prepared with essential modules consisting of CMMS Asset Performance Reports and CMMS Asset Analytics, permitting higher selections through data-driven insights.

Modern CMMS for Streamlined Management

A effective Computerized Maintenance Management Software offers a centralized solution for scheduling, inventory manage, compliance, and reporting. When well controlled, the CMMS implementation unit can significantly reduce the shutdown and expand the asset life. However, CMMS cost of expertise are required. Organizations have to evaluate lengthy-term ROI over prematurely investment, keeping in mind decreased exertions, restore, and downtime costs.

For small and medium establishments, a reliable Maintenance Software CMMS may be a sport-changer. When paired with Mobile CMMS, it empowers technicians to manage obligations remotely, enhancing performance and real-time updates. The CMMS Maintenance Management System acts because the spine of facility and asset renovation strategies.

Enhancing Control Through Inventory and Work Management

One of the important thing strengths of any CMMS lies in its potential to manipulate inventory and spares. A sturdy Inventory Control Software enables track components, avoid shortages, and optimize procurement. Similarly, Work Order Management Software allows protection teams to generate, assign, and close paintings orders with no trouble, reducing guide mistakes and delays.

Efficient operations depend closely on strategic scheduling. This is in which Maintenance Planning and Scheduling Software comes into play, supporting upkeep heads to prioritize responsibilities and align with manufacturing goals. For teams looking for deeper information, Maintenance Planning and Scheduling Training can sharpen abilties and foster a lifestyle of preventive care.

Smart Software and Training for Maximum Uptime

Even small corporations advantage from adopting Maintenance Software for Small Business, which regularly includes primary but impactful functions like paintings order tracking, preventive scheduling, and asset statistics. For large establishments, Preventive Maintenance Software automates inspections and services, while Predictive Maintenance Software makes use of real-time records and AI to forecast capability disasters.

Operational efficiency isn’t pretty much generation—it’s also approximately humans. Training packages together with Preventive Maintenance Optimization Training, Asset Reliability Training, and Maintenance Management Training empower groups to implement and sustain high-quality practices. Additionally, Root Cause Analysis Training helps upkeep personnel become aware of the source of habitual failures and put into effect long-time period fixes.

0 notes

Text

cmm measuring machine

Unlocking Precision Engineering with CMM Measuring Machines and Metrology Tools in Malaysia

In today’s fast-paced manufacturing industry, precision is everything. Whether you're producing components for aerospace, automotive, electronics, or medical devices, the need for accurate measurement and tight tolerance control is more critical than ever. Enter the world of metrology—a domain where tools like the CMM measuring machine, profile projectors, and dial tester indicators play an indispensable role. For companies in Malaysia striving to meet international standards, having access to world-class equipment and support is essential. This is where Takumiprecision.com.my, a trusted name in metrology solutions, makes a real difference.

The Role of CMM Measuring Machines in Modern Manufacturing

A CMM measuring machine (Coordinate Measuring Machine) is a sophisticated device used to measure the geometry of physical objects by sensing discrete points on the surface with a probe. These machines provide three-dimensional readings that are far more precise than conventional manual measuring tools.

Industries across Malaysia are rapidly adopting CMM technology to enhance quality control, reduce rework, and maintain consistency in production lines. Whether it's checking a machined part’s dimensional accuracy or reverse engineering a legacy component, a CMM measuring machine streamlines the entire process.

Hexagon CMM: A Global Leader in Metrology Solutions

Among the many CMM brands available, Hexagon CMM stands out as a global leader. Known for innovation, reliability, and performance, Hexagon offers a wide range of CMMs—from bridge-type and gantry models to portable arms and multi-sensor systems. These machines are engineered to handle the most demanding inspection requirements.

In Malaysia, Hexagon CMM has become synonymous with quality assurance in high-precision manufacturing. Companies seeking top-tier metrology equipment often turn to Hexagon for its cutting-edge software, automation integration, and unparalleled accuracy.

Looking for a Hexagon Agent in Malaysia?

If you’re in search of a certified Hexagon Agent in Malaysia, look no further than Takumiprecision.com.my. As an authorized distributor and service provider, Takumi Precision delivers not only the latest Hexagon CMM models but also offers installation, training, calibration, and after-sales support.

Being a Hexagon Agent Malaysia partner means staying up-to-date with the latest metrology innovations. From implementing automated inspection cells to leveraging AI-powered data analytics, Takumi Precision helps Malaysian manufacturers stay competitive in a global market.

Profile Projector Malaysia: An Essential Optical Measuring Tool

While CMMs provide 3D measurements, certain tasks still require 2D analysis—especially in small-scale or soft material components. That’s where the profile projector comes into play. Also known as an optical comparator, this tool projects a magnified silhouette of a part onto a screen for easy inspection of dimensions, shapes, and angles.

A profile projector Malaysia solution is ideal for quality control labs and production floors that need a fast, visual representation of a part's profile. Whether you're verifying thread pitch or comparing stamped parts against a CAD overlay, profile projectors remain a trusted choice for non-contact measurements.

Takumiprecision.com.my offers a diverse range of profile projectors tailored for different industrial needs. Their models come with digital readouts, high-resolution optics, and LED illumination systems for clear and accurate viewing.

Dial Tester Indicator Malaysia: Precision in Every Micron

Sometimes, simplicity delivers the best results. A dial tester indicator is a classic metrology instrument used to measure small linear distances and variations in surface levels. Perfect for detecting runouts, checking concentricity, or aligning machines, dial indicators remain a staple in inspection and assembly setups.

In Malaysia, the demand for high-quality dial tester indicators is growing among toolmakers, machinists, and QA professionals. Takumiprecision.com.my caters to this need with a comprehensive selection of analog and digital dial indicators from leading brands. Whether you're working with lathes, mills, or jigs, their precision instruments help ensure every micron counts.

Why Choose Takumiprecision.com.my?

When it comes to investing in metrology equipment, reliability, service, and expertise matter just as much as the tools themselves. Here’s why Takumiprecision.com.my is the go-to name for quality-conscious businesses across Malaysia:

Certified Expertise: As an official Hexagon Agent Malaysia, they bring globally recognized technology to your doorstep.

Wide Product Range: From advanced CMM measuring machines to profile projectors and dial tester indicators, they provide complete solutions for your inspection needs.

Customer-Centric Service: Takumi Precision offers personalized consultations, after-sales training, and maintenance contracts to ensure optimal performance.

Local Support with Global Standards: Enjoy the responsiveness of a local provider with the confidence of world-class equipment.

0 notes

Text

Maintenance Management: A Comprehensive Guide to Improving Operations and Efficiency

Maintenance management plays a critical role in ensuring the smooth functioning of facilities, equipment, and assets in any organization. It involves planning, organizing, and overseeing maintenance activities to maximize efficiency, minimize downtime, and reduce costs. In this article, we will explore how effective maintenance management can transform operations and provide a comprehensive guide to improving operations and efficiency.

The Importance of Maintenance Management Effective maintenance management is essential for maintaining operational efficiency. It ensures that equipment and facilities are kept in optimal condition, reducing the risk of unexpected breakdowns. This proactive approach not only enhances productivity but also prolongs the lifespan of assets, leading to significant cost savings in the long term.

By implementing Maintenance Management: A Comprehensive Guide to Improving Operations and Efficiency, organizations can establish a structured framework to address their maintenance needs. This guide emphasizes the importance of scheduling regular inspections, using modern tools for predictive maintenance, and training staff to handle advanced systems.

Key Components of Maintenance Management Preventive Maintenance Preventive maintenance involves routine checks and servicing to prevent equipment failures. This proactive approach minimizes unplanned downtime and keeps operations running smoothly.

Predictive Maintenance Leveraging data analytics and sensors, predictive maintenance identifies potential issues before they occur. This method enhances efficiency by addressing problems during scheduled maintenance windows.

Computerized Maintenance Management Systems (CMMS) CMMS software helps track maintenance tasks, schedules, and asset history. It streamlines processes, ensuring timely interventions and detailed reporting for informed decision-making.

Staff Training and Development Skilled personnel are the backbone of effective maintenance management. Regular training ensures that staff can handle modern machinery and follow best practices for safety and efficiency.

Benefits of Effective Maintenance Management Reduced Downtime Proactive maintenance minimizes unexpected disruptions, allowing organizations to maintain high productivity levels.

Cost Savings Regular upkeep reduces the need for expensive emergency repairs and extends the lifespan of equipment.

Enhanced Safety Properly maintained equipment reduces the risk of workplace accidents, fostering a safer environment for employees.

Sustainability Efficient maintenance practices reduce energy consumption and waste, contributing to environmental sustainability.

Implementing the Guide to Success To implement Maintenance Management: A Comprehensive Guide to Improving Operations and Efficiency, organizations should start by assessing their current processes and identifying areas for improvement. Establishing clear goals, adopting modern technology, and fostering a culture of continuous improvement are essential steps toward achieving excellence.

By following these principles, businesses can enhance their operational capabilities, reduce costs, and create a sustainable framework for future growth. Maintenance management is not just a reactive process; it is a strategic investment in the organization's success.

In conclusion, Maintenance Management: A Comprehensive Guide to Improving Operations and Efficiency serves as an invaluable resource for organizations aiming to optimize their maintenance practices. By adopting this comprehensive approach, businesses can unlock new levels of performance, reliability, and efficiency.

0 notes

Text

Maintenance management is a crucial aspect of any industry that relies on machinery, equipment, or infrastructure. It involves the systematic planning, execution, and monitoring of maintenance activities to ensure that assets function efficiently and reliably. Proper maintenance management helps prevent unexpected failures, reduces downtime, and extends the lifespan of equipment, ultimately contributing to cost savings and productivity.

One of the key objectives of maintenance management is to implement preventive and predictive maintenance strategies. Preventive maintenance involves routine inspections and servicing to prevent breakdowns, while predictive maintenance uses data analysis and condition monitoring to anticipate failures before they occur. Both approaches minimize disruptions and enhance operational efficiency.

In addition to improving equipment performance, maintenance management also plays a critical role in ensuring workplace safety. Well-maintained machinery reduces the risk of accidents, protecting employees and preventing costly liabilities. Furthermore, compliance with industry regulations and safety standards is easier to achieve when maintenance practices are systematically managed.

Modern maintenance management systems utilize advanced technologies such as computerized maintenance management systems (CMMS) and the Internet of Things (IoT) to streamline operations. These tools enable real-time tracking of asset conditions, automate maintenance scheduling, and enhance decision-making processes. As a result, organizations can optimize resources and improve overall efficiency.

In conclusion, maintenance management is essential for maintaining the reliability, safety, and cost-effectiveness of industrial operations. By adopting proactive maintenance strategies and leveraging modern technology, businesses can enhance productivity and ensure long-term success.

0 notes