#COMSOL multiphysics

Explore tagged Tumblr posts

Text

What have I been up to? Well more or less more optics.

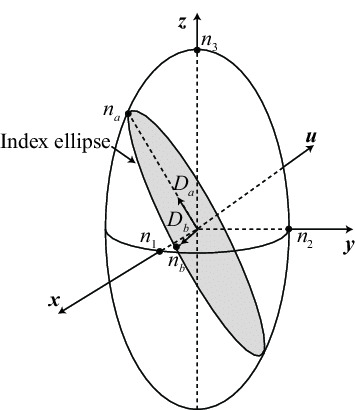

I started to learn about the Index Ellipsoid, and I am beginning to understand how we can quantify a materials allowed polarizations using the "indicatrix" (not going to lie this is a hard word to spell lol)

I now understand that there are two possible electric flux densities (basically the quadratic equations +/- gives two roots, so when you solve for two possible refractive indices, you also get two D solutions) and that these two fluxes are orthogonal.

The index Ellipsoid let's us characterize anisotropic crystals into biaxial (two defined optical axes) and uniaxial (two axes are equal)

But honestly, I'm hitting a bit of a wall here. I just want to be familiar with the material before grad school starts. Since I'm self studying now, I decided to venture off into a related topic: Computational electromagnetics!!

I took numerical methods this winter so when I heard about Finite Difference Method I didn't look like a 🦌 staring at 🚗 lol (honestly I find Runge-Kutta methods scarier haha)

So I learned a bit about collocated grids, recalled Dirichlet boundary conditions, periodic boundary conditions as well as Neuman boundary conditions.

My plan is to use COMSOL multi physics to do a little simulation for my masters thesis, so I'm betting that having a grasp on the numerical side of emag is something I need to accomplish to bear fruitful results.

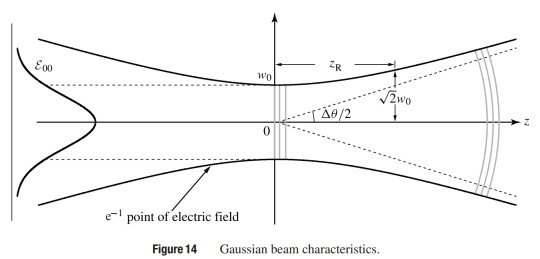

And of course I get hit with the realization exactly *why* plane waves are used to teach us optics: because they are simply a stepping stone towards us learning about Gaussian Beams!

The 🐇 hole just keeps getting deeper and deeper... 🕳️

#anisotropy#optics#physics#math#electromagnetics#gaussian beam#boundary conditions#Neumann#Dirichlet#COMSOL multiphysics#numerical electromagnetics#Finite Difference Methods#SoundCloud

0 notes

Text

a week ago i (full of hubris) thought to myself. you know, this modeling (<- the multiphysics kind u_u) shit is not so bad. maybe i have gotten good at it. and now something fundamentally sinister is occurring with my fucking model and i'm going insane trying to troubleshoot. COMSOL i did not fucking miss you. bitch

9 notes

·

View notes

Text

Understanding Process Engineering Design in Industrial Projects

In any industrial or manufacturing setting, efficiency, safety, and scalability are critical. This is where process engineering design comes into play. It serves as the blueprint for how raw materials and energy flow through systems to create a finished product—safely, economically, and efficiently.

Process engineering design is not just about drawing diagrams. It involves a systematic approach to designing, analyzing, and optimizing processes across chemical, petrochemical, pharmaceutical, food, and other manufacturing industries.

What is Process Engineering Design?

Process engineering design refers to the conceptualization and detailed planning of the processes involved in manufacturing. It ensures that industrial systems are designed to produce the desired product output with minimal waste, cost, and environmental impact.

This discipline combines principles of chemical engineering, mechanical engineering, thermodynamics, fluid dynamics, instrumentation, and control engineering to create safe, reliable, and effective processes.

Importance of Process Engineering Design

Maximizes Efficiency: Well-designed processes ensure minimal raw material usage, optimal energy consumption, and low production costs.

Ensures Safety and Compliance: Designs must meet industry safety codes and environmental regulations.

Enables Scalability: Good design allows systems to be expanded or modified without major overhauls.

Reduces Risk and Downtime: Anticipates operational issues before they occur through simulations and risk analysis.

Key Steps in Process Engineering Design

1. Process Definition

Understanding the product requirements, feedstock, output, and production rates.

2. Process Flow Diagram (PFD)

Creating a high-level diagram that shows major equipment and flow of materials.

3. Piping and Instrumentation Diagram (P&ID)

A detailed diagram showing pipelines, valves, instrumentation, and control systems.

4. Material and Energy Balances

Calculating inputs, outputs, heat loads, and mass flows throughout the process.

5. Equipment Sizing and Specification

Defining size, capacity, material of construction, and operational parameters of equipment like reactors, heat exchangers, and pumps.

6. Process Simulation

Using software like Aspen HYSYS, ChemCAD, or PRO/II to simulate and optimize the process.

7. Hazard and Operability Study (HAZOP)

A structured risk analysis to identify potential safety and operational hazards.

8. Design Documentation

Preparing final documentation for procurement, construction, and regulatory approval.

Industries That Rely on Process Engineering Design

Chemical and Petrochemical Plants

Oil and Gas Refineries

Water and Wastewater Treatment

Food and Beverage Manufacturing

Pharmaceutical Production

Power Generation and Energy Systems

Tools Used in Process Engineering Design

Simulation Software: Aspen Plus, HYSYS, ChemCAD

Design Tools: AutoCAD, SmartPlant, AVEVA

Analysis Software: MATLAB, COMSOL Multiphysics

Process Safety Tools: PHAST, HAZOP Manager

Conclusion

Process engineering design is the foundation of successful industrial operations. A well-designed process leads to safer, cleaner, and more profitable production lines. Whether you're building a new plant or upgrading an existing system, the importance of detailed and accurate process design cannot be overstated.

Investing in proper process engineering design is investing in the long-term success of your operations.

0 notes

Text

FRITAR COXINHA

🔬🖍️ Protocolo Experimental Revisado: Simulação Termofísica de Reentrada Hipersônica com Análogos Alimentares

🎯 Título do Projeto

"Validação de Análogos Alimentares para Simulação Termofísica de Reentrada Hipersônica: Modelagem Experimental e Computacional"

1. 🔍 Hipótese Científica Revisada

A fritura profunda de coxinhas padronizadas simula fenômenos termofísicos de reentrada hipersônica, com correlações quantificáveis em:

Formação de camada ablativa (crosta)

Gradientes térmicos multiescalares

Emissividade infravermelha detectável

Perda de massa por ablação

2. ⚙️ Materiais e Equipamentos (Atualizado)

CategoriaItensAmostras- Coxinhas sintéticas (esferas de polimetacrilato Ø50mm revestidas com camadas controladas de farinha: 1mm, 3mm, 5mm) - Coxinhas tradicionais (grupo controle)Sensores- Câmera térmica FLIR A315 (ε ajustável) - Termômetro de imersão ISO-calibrado - Balança analítica (±0.001g)Sistema de Fritura- Banho termostatado com óleo (controle PID de temperatura) - Recipiente fechado com janela de safira (transmissividade IR >90%)Análise- Software COMSOL Multiphysics® (módulo Heat Transfer) - Kit análise de imagem (ImageJ + script Python para rugosidade)

3. 🧪 Procedimentos Experimentais (Aprimorados)

🔬 Etapa 0: Preparação Teórica

Coletar dados de referência de reentrada hipersônica (NASA TP-2022-XXXX)

Simular perfil térmico esperado no COMSOL (condições: Mach 8, ângulo 30°, atmosfera padrão)

⚖️ Etapa A: Padronização de Amostras

Fabricar 30 esferas sintéticas com revestimentos controlados (10 por espessura)

Caracterizar inicial:

Massa (±0.001g)

Rugosidade superficial (Ra via perfilometria)

Emissividade (método ASTM E1933)

🌡️ Etapa B: Perfis Térmicos Dinâmicos

FaseTemperatura ÓleoDuraçãoAnálogo de ReentradaInicial180°C ±2°C90sCamadas atmosféricas superioresCrítica220°C ±2°C60sCamada de máximo aquecimentoFinal190°C ±2°CAté términoFase de desaceleração

Protocolo:

Registrar a cada 15s:

Temperatura superficial (FLIR)

Temperatura interna (sonda)

Massa (balança de imersão)

Monitorar formação de bolhas (taxa de frames: 60fps)

📀 Etapa C: Análise Pós-Experimento

Caracterização da crosta:

Espessura (micrômetro digital)

Porosidade (análise de imagem em corte transversal)

Correlação térmica:# Código para cálculo de similaridade térmica def calcular_similaridade(perfil_coxinha, perfil_reentrada): # Alinhamento dinâmico temporal (DTW) correlation = np.corrcoef(perfil_coxinha, perfil_reentrada)[0,1] rmse = np.sqrt(mean_squared_error(perfil_coxinha, perfil_reentrada)) return correlation, rmse

4. 📊 Matriz de Dados (Expanda)

VariávelMétricaInstrumentoFrequênciaTemperaturaT_superfície, T_núcleoFLIR + Termopar15sMassaΔm (g/s)Balança analítica30sEmissividadeε(λ) 3-5μmFLIR (calibrado)ContínuoMorfologiaEspessura crosta, Ra (μm)Micrômetro + ImageJPós-testeAssinatura IRHistograma térmicoScript PythonPor frame

5. ⚠️ Protocolo de Segurança

Contenção de óleo:

Usar recipiente com fechamento magnético e válvula de alívio

Escudo térmico para operador durante medições FLIR

EPI Obrigatório:

Óculos de proteção IR

Avental resistente a óleo quente

Luvas termorresistentes (Kevlar®)

6. 📈 Análise de Dados (Aprofundada)

Modelos Matemáticos:

Taxa de ablação: m˙=k⋅(Tsurface−T∞)n (Regressão não-linear para determinar k, n)

Eficiência de proteção térmica: η=∫0tqconvdt−ΔHabl∫0tqconvdt Onde:

qconv=h(Toil−Tsurface)

ΔHabl=m˙⋅Lv

Validação Computacional:

Comparar gradientes térmicos experimentais vs. simulação COMSOL

Análise de sensibilidade: espessura de revestimento vs. tempo de falha térmica

7. 🔗 Fundamentação Teórica

Referências-Chave:

Reentrada Hipersônica:

ANDERSON, J. D. (2019). Hypersonic and High-Temperature Gas Dynamics. 3rd ed.

NASA TP-2022-XXXX: Thermal Protection System Modeling for Mars Entry

Materiais Ablativos:

KOO, J. H. (2018). Polymer Nanocomposites as Ablative Materials. Elsevier.

ZHANG, X. et al. (2021). Carbon-Phenolic Composites Ablation under Plasma Torch. J. Spacecraft Rockets.

Metodologias Experimentais:

VOLLMER, M.; MÖLLMANN, K. P. (2017). Infrared Thermal Imaging: Fundamentals, Research and Applications. Wiley-VCH.

ASTM E457: Standard Test Method for Measuring Heat Transfer Rate Using a Thermal Capacitance (Slug) Calorimeter

8. 🧬 Extensão para Modelagem AI

graph LR A[Dados FLIR] --> B(Pré-processamento) B --> C[Redução dimensional - PCA] C --> D{Modelo de Classificação} D --> E[ResNet-50] D --> F[Vision Transformer] E & F --> G[Identificação de padrões críticos] G --> H[Correlação com dados reais de reentrada]

📥 Produtos Esperados

Banco de dados público de termogramas de fritura

Plugin para ImageJ: CrustAnalyzer (quantificação morfológica)

Modelo preditivo open-source de formação de crosta

Protocolo didático para laboratórios de engenharia aeroespacial

"Este protocolo integra metodologias experimentais rigorosas com modelagem computacional, transformando uma analogia culinária em ferramenta válida para estudos termofísicos iniciais."

0 notes

Text

How to Get Started with Computational Fluid Dynamics (CFD)

Have you ever watched water flow from a tap, or seen smoke swirl through the air, and wondered how engineers predict and simulate such movements? That’s exactly where Computational Fluid Dynamics (CFD) comes into play.

CFD is a powerful branch of fluid mechanics that uses computer simulations to analyze and predict how fluids behave under various conditions. If you’re an engineering student curious about design, aerodynamics, energy, or even biomedical applications, learning CFD can be a game-changer for your career. Let’s break down how you can get started with it, step by step.

What Exactly Is CFD?

Before diving into the how, let’s clear up the what.

CFD is the art and science of solving and analyzing fluid flows using numerical methods and algorithms. Instead of doing real-world experiments (which can be expensive and time-consuming), engineers use CFD to simulate fluid behavior digitally. This includes everything from how air flows around a car to how blood moves through arteries.

The core of CFD involves three main elements:

Pre-processing – setting up the problem, geometry, and mesh

Solving – applying equations to simulate the flow

Post-processing – analyzing and visualizing the results

Why Should You Care About CFD?

Good question. CFD isn’t just for aerospace engineers or scientists. It’s used across a variety of industries:

Automotive: Improving aerodynamics and fuel efficiency

Civil Engineering: Designing ventilation systems in tunnels

Biomedical Engineering: Simulating blood flow for stent design

Energy Sector: Analyzing wind patterns for turbine placement

In short, CFD is everywhere fluids exist—air, water, gas, even oil—and learning it makes you a valuable asset in industries that value precision and innovation.

What You Need to Get Started

Now, how do you actually start learning CFD? Here’s what I suggest:

1. Get a Strong Foundation in Fluid Mechanics

Before diving into simulation tools, make sure your basics are solid. Understand the fundamental equations—continuity, momentum, and energy. These are often taught in core mechanical or aerospace engineering courses.

If you're still deciding where to study, it helps to pick a college with a strong practical orientation. I was recently reviewing the curriculum at NMIET in Bhubaneswar, and noticed how they integrate hands-on labs with subjects like Thermodynamics and Fluid Mechanics. That kind of exposure can really help.

2. Learn the Mathematics Behind It

You don’t need to be a math genius, but you do need to be comfortable with:

Differential equations

Linear algebra

Numerical methods

These are the tools CFD software uses behind the scenes to simulate reality.

3. Get Familiar with CFD Software

There are many popular CFD tools available:

ANSYS Fluent

OpenFOAM (open-source)

COMSOL Multiphysics

SimScale (cloud-based)

Start with student versions or open-source platforms. OpenFOAM is great if you’re okay with some coding, while ANSYS Fluent offers a more visual, drag-and-drop interface.

4. Take Online Courses or Certification Programs

CFD can be complex, so guided learning really helps. Platforms like NPTEL, Coursera, or edX offer beginner-friendly CFD courses. Some engineering colleges in Odisha have also begun integrating these tools into their regular curriculum, which is a big plus.

How to Practice What You Learn

Theory alone won’t make you a CFD expert. Try to:

Take up mini projects: Simulate airflow over an airfoil, or cooling in an electronics system.

Participate in competitions: Some colleges encourage participation in technical fests and simulation challenges.

Intern with companies: Many industries use CFD daily. A short internship can give you exposure to real-world applications.

Which College Can Support Your CFD Learning?

If you're serious about CFD, the environment you study in matters. Look for institutes that offer strong lab facilities, experienced faculty, and industry collaboration. Some of the best engineering colleges in Odisha include departments that focus on mechanical, civil, and aerospace disciplines—all key areas where CFD is relevant.

During my interactions with students from various institutes, I’ve noticed that colleges like NMIET provide access to digital labs, industry tie-ups with companies like IBM and Cognizant, and even R&D opportunities. These are the things that matter when you want to get practical exposure alongside theory.

Final Thoughts: CFD Is a Journey, Not a Shortcut

It’s okay if CFD feels overwhelming at first. It’s a complex field that blends physics, math, and computer science. But the good news? With consistent effort, curiosity, and the right guidance, anyone can learn it.

Whether you're a first-year student just discovering the world of engineering or a senior looking to specialize, starting your CFD journey today can open up exciting opportunities in both academia and industry.Remember, tools can be learned—but the mindset to explore, question, and simulate the real world? That’s something you start building now. And if you’re studying at one of the best engineering colleges in Odisha, you already have a head start.

#bhubaneswar b tech colleges#college of engineering bhubaneswar#best engineering colleges in orissa#best engineering colleges in bhubaneswar#best private engineering colleges in odisha#best engineering colleges in odisha

0 notes

Text

Servotech FEA Services for Smarter Engineering

In today’s competitive engineering landscape, staying ahead means designing smarter, safer, and more efficient products—faster than ever before. Servotech, a leader in simulation and digital engineering, delivers top-tier Finite Element Analysis (FEA) services to empower engineers, manufacturers, and innovators to make better design decisions early in the product development cycle. With cutting-edge tools and a deep understanding of structural mechanics, Servotech is revolutionizing how companies approach complex engineering challenges.

What is FEA and Why It Matters

Finite Element Analysis (FEA) is a computer-based simulation technique used to predict how products will react to real-world forces like heat, vibration, stress, and motion. By creating a virtual model and breaking it down into small finite elements, engineers can evaluate structural performance and identify weak points without the cost or time of building physical prototypes.

FEA plays a critical role in industries such as:

Automotive and aerospace

Electronics and consumer products

Energy and utilities

Heavy machinery and industrial equipment

Biomedical and healthcare devices

For companies seeking reliability, safety, and regulatory compliance, FEA is not just a tool—it’s an essential part of modern engineering.

Why Choose Servotech for FEA?

Servotech brings more than just simulation software to the table. Their FEA services combine technical precision, industry experience, and engineering intelligence to deliver results that matter.

1. Expertise Across Multiple Domains

Servotech’s team of certified FEA engineers have experience across mechanical, thermal, structural, and dynamic analysis. Whether it's crash simulation for an automobile or thermal stress in electronics, Servotech delivers multi-physics solutions that integrate seamlessly into your workflow.

2. Customized Simulation Solutions

No two projects are the same. Servotech tailors its FEA services to meet the unique demands of your product, industry, and design constraints. From linear static analysis to non-linear and dynamic simulations, the team adapts the modeling techniques and software tools to provide actionable insights specific to your needs.

3. Advanced Software Capabilities

Servotech utilizes industry-standard FEA software tools such as:

ANSYS

Abaqus

HyperMesh

SolidWorks Simulation

COMSOL Multiphysics

These tools allow them to offer high-fidelity simulation, mesh optimization, and fast computation, resulting in more accurate and reliable predictions.

4. Focus on Design Optimization

FEA isn’t just about identifying problems—it’s about solving them. Servotech’s engineers work collaboratively with your design team to recommend geometry improvements, material selection, and load optimization strategies that enhance performance while minimizing cost and weight.

5. Accelerated Time to Market

By integrating FEA early in the product development lifecycle, Servotech helps clients reduce prototyping cycles, prevent late-stage design changes, and accelerate time to market. This early detection of issues leads to significant cost savings and improved product reliability.

Key FEA Services Offered by Servotech

Structural Analysis

This includes static, dynamic, and non-linear stress analysis for components and assemblies. Servotech helps clients determine deformation, fatigue, failure risk, and load distribution across materials and structures.

Thermal Analysis

Heat management is crucial, especially in electronics, automotive, and aerospace applications. Servotech performs steady-state and transient thermal analysis to understand how temperature affects structural integrity and material behavior.

Modal and Vibration Analysis

Servotech simulates natural frequencies, mode shapes, and harmonic response to evaluate how components behave under dynamic loading. This is vital for rotating machinery, engines, and structural components prone to vibration.

Buckling and Stability

For slender structures under compressive loads, Servotech conducts buckling analysis to determine critical loads and ensure structural stability in columns, panels, and frameworks.

Fatigue and Lifecycle Prediction

Using industry-standard fatigue models, Servotech estimates product lifespan under cyclic loading and recommends design modifications to enhance durability and longevity.

Multi-Physics Simulations

Combining FEA with other domains like CFD (Computational Fluid Dynamics) and electromagnetics, Servotech performs multi-physics analysis for advanced applications such as battery systems, thermal-fluid systems, and smart electronics.

Industries Benefiting from Servotech’s FEA Expertise

Automotive

From chassis design to crashworthiness analysis, Servotech assists automotive OEMs and suppliers in designing vehicles that are lighter, safer, and more efficient.

Aerospace

In a field where weight optimization and safety are paramount, Servotech offers structural, thermal, and vibration analysis for aircraft components and space systems.

Consumer Electronics

With the miniaturization of electronics, thermal and structural integrity becomes critical. Servotech helps design heat-resistant and robust enclosures, PCBs, and connectors.

Medical Devices

For surgical tools, implants, and diagnostic equipment, Servotech ensures mechanical safety and regulatory compliance through simulation-backed development.

Energy and Utilities

Whether it's stress testing of wind turbine blades or thermal analysis of power distribution systems, Servotech supports the renewable and conventional energy sectors in designing more reliable systems.

The Servotech Advantage: Smarter Engineering, Delivered

Choosing Servotech means you’re not just outsourcing a simulation—you’re gaining a partner who understands the end goal: better performance, lower costs, and faster innovation. Their collaborative approach ensures that simulation insights directly inform design improvements and product strategy.

Key differentiators include:

In-house expertise and fast turnaround

Cross-disciplinary engineering support

Proven track record across diverse industries

Confidential, secure handling of proprietary data

Transparent reporting and clear interpretation of simulation results

Client Success Stories

Case Study 1: Automotive Suspension Design Servotech helped a leading auto parts supplier reduce component weight by 15% without compromising safety by using dynamic and fatigue FEA to optimize geometry and material.

Case Study 2: Medical Device Durability A medical device startup collaborated with Servotech to validate a new surgical tool design. Using non-linear FEA, Servotech identified potential fracture points, allowing the client to redesign for longer lifespan and pass FDA testing faster.

Conclusion

In a world driven by innovation and efficiency, Servotech’s FEA services are redefining what’s possible in engineering. By integrating high-fidelity simulation with engineering know-how, they help businesses transform bold ideas into high-performance products.

0 notes

Text

Best CFD Courses in the UK — Learn with FlowThermoLab

Computational Fluid Dynamics (CFD) and engineering simulation play a crucial role in industries such as aerospace, automotive, energy, and manufacturing. Whether you’re an engineer, researcher, or student, mastering tools like ANSYS Fluent, OpenFOAM, and STAR-CCM+ can significantly enhance your career prospects. FlowThermoLab, a leading provider of CFD and thermal analysis solutions, offers specialized training programs in the UK to help professionals gain hands-on expertise in these advanced simulation tools.

1. ANSYS Fluent Course & Training in the UK

ANSYS Fluent is one of the most widely used CFD software for fluid flow, heat transfer, and combustion simulations. FlowThermoLab provides industry-focused ANSYS Fluent training, covering topics such as turbulence modeling, multiphase flows, and meshing techniques. Whether you’re a beginner or an advanced user, our courses are designed to help you apply ANSYS Fluent to real-world engineering problems.

2. Scientific Programming with Python for CFD in the UK

Python is an essential tool for automating CFD simulations, post-processing data, and integrating with software like OpenFOAM and ANSYS. FlowThermoLab’s Scientific Programming with Python course is tailored for engineers and researchers looking to enhance their coding skills for computational modeling and analysis.

3. Advanced Fluid Dynamics Training in the UK

Understanding the fundamental principles of fluid mechanics is essential for accurate CFD simulations. FlowThermoLab’s Advanced Fluid Dynamics course dives deep into topics like turbulence modeling, compressible and incompressible flows, and boundary layer theory. This course is ideal for professionals aiming to strengthen their theoretical knowledge and apply it in industry settings.

4. OpenFOAM Course in the UK

OpenFOAM is a powerful open-source CFD toolbox, widely used in academia and industries for flow simulations. FlowThermoLab’s OpenFOAM training program provides hands-on experience in setting up cases, mesh generation, solver selection, and post-processing results. Our course is designed to help engineers master OpenFOAM and implement it effectively in research and industrial applications.

5. CFD and FEM Courses in the UK

Flow and structural analysis often go hand in hand in engineering simulations. FlowThermoLab offers integrated CFD and Finite Element Method (FEM) courses, teaching engineers how to analyze fluid-structure interactions, thermal stresses, and mechanical deformations using industry-standard software.

6. CAE Courses for Mechanical Engineers in the UK

Computer-Aided Engineering (CAE) is essential for optimizing product design and performance. FlowThermoLab provides CAE training for mechanical engineers, covering simulation techniques for heat transfer, structural integrity, and aerodynamics using software like ANSYS, Abaqus, and COMSOL.

7. STAR-CCM+ Course in the UK

STAR-CCM+ is widely used for multiphysics simulations in industries like automotive and aerospace. FlowThermoLab’s STAR-CCM+ course��teaches engineers how to perform high-fidelity simulations, optimize designs, and analyze complex physics using state-of-the-art solvers and visualization tools.

Why Choose FlowThermoLab for CFD Training in the UK?

Expert Instructors: Learn from experienced CFD professionals with industry expertise.

Hands-on Training: Practical exercises and real-world case studies.

Flexible Learning: Online and in-person training options available.

Industry-Relevant Skills: Gain skills applicable to aerospace, automotive, and energy sectors.

Conclusion

Investing in CFD, FEM, and CAE training can open new career opportunities and improve your technical expertise. FlowThermoLab’s specialized courses in the UK provide hands-on learning to help engineers, researchers, and students excel in engineering simulation.

Enroll today with FlowThermoLab and take your CFD skills to the next level!

0 notes

Text

Computational Fluid Dynamics (CFD) has become an essential tool for engineers and researchers who need to simulate and analyze fluid flow, heat transfer, and other related physical processes. Accurate CFD simulations can save time, reduce costs, and improve product design across industries such as aerospace, automotive, energy, and manufacturing. In this blog, we’ll explore some of the top CFD simulation software options available today that can significantly enhance the accuracy and efficiency of your simulations.

1. ANSYS Fluent

One of the most widely used CFD software solutions, ANSYS Fluent is known for its versatility and comprehensive range of simulation capabilities. It allows users to simulate complex fluid flow, turbulence, heat transfer, and chemical reactions. Fluent is popular because of its ability to handle both steady and transient flow scenarios, as well as its advanced meshing tools that improve the accuracy of simulations. Additionally, the software is highly customizable, with a user-friendly interface and detailed post-processing features that help you gain deeper insights from your results.

Key Features:

Wide range of physical models for complex flows

Advanced turbulence models

High-performance computing (HPC) support

Easy integration with other ANSYS tools

2. Siemens STAR-CCM+

STAR-CCM+, part of Siemens’ Simcenter suite, is another leading CFD simulation software known for its flexibility and integration with other simulation tools. It provides a multidisciplinary approach, allowing users to perform CFD simulations alongside structural and thermal analysis. One of STAR-CCM+'s biggest strengths is its ability to solve complex real-world engineering problems with high accuracy. The software also supports automated workflows, making it an excellent choice for users who require quick turnaround times for multiple simulations.

Key Features:

Multidisciplinary simulation environment

Automated meshing and simulation setup

Ability to handle large, complex models

Efficient solvers for faster simulations

3. OpenFOAM

OpenFOAM is an open-source CFD software that has gained significant popularity due to its flexibility, customizability, and cost-effectiveness. Unlike proprietary software, OpenFOAM allows users to tailor the code to their specific simulation needs. It is particularly favored by academic researchers and institutions for its ability to handle custom and unconventional simulations. While it may not be as user-friendly as other commercial software, OpenFOAM's vast array of solvers and utilities makes it a powerful tool for those who require more control over their simulations.

Key Features:

Open-source and free to use

Highly customizable with user-written code

A wide range of solvers for various CFD applications

Strong community support and active development

4. COMSOL Multiphysics

While COMSOL Multiphysics is primarily known for its multiphysics capabilities, it also offers robust CFD simulation tools. It is especially useful when you need to simulate fluid dynamics alongside other physical phenomena, such as structural mechanics or electromagnetics. COMSOL’s intuitive user interface makes it easier for users to set up complex simulations, and its built-in post-processing tools provide detailed visualization options for analyzing results.

Key Features:

Seamless coupling of CFD with other physics simulations

Easy-to-use interface for faster setup

Excellent post-processing and visualization tools

Supports various fluid dynamics applications

5. Altair AcuSolve

AcuSolve by Altair is a powerful CFD solver that excels in solving fluid dynamics problems quickly and accurately. Its advantage lies in its unique solution algorithms that ensure fast convergence, making it ideal for simulations where time is a critical factor. AcuSolve also integrates well with other Altair products, offering a streamlined experience for users working on multidisciplinary projects.

Key Features:

Fast and robust solvers

Accurate simulations with minimal meshing effort

Excellent integration with other Altair tools

Ideal for transient and steady-state simulations

Conclusion

Choosing the right CFD simulation software depends on your specific needs, such as the complexity of your simulations, the required accuracy, and your budget. Whether you're looking for a user-friendly platform like ANSYS Fluent or a cost-effective solution like OpenFOAM, each software package offers distinct advantages that can help you optimize your fluid dynamics simulations. By leveraging the right tools, you can improve the accuracy and efficiency of your simulations, leading to better insights and more informed engineering decisions.

Visit us to Know More Website:https://www.cfdsupport.com/ Location:CFD support, s.r.o., Sokolovská 270/201, 19000 Praha 9, Czech Republic. Contact Us:+420 212 243 883 Email:[email protected]

0 notes

Text

Top IT Companies that Hire Mechanical Engineers in India

IT companies value several specific skills from mechanical engineering, which are essential for various roles and projects within the IT sector. These skills include:

Technical Skills

1. Computer-Aided Design (CAD) and Solid Modeling:

• CAD software: Tools like SolidWorks, AutoCAD, and CATIA are used to create 2D and 3D models of mechanical objects, which are crucial for designing, analyzing, and simulating products.

• Solid modeling: This involves creating detailed components and models of mechanical parts, which is vital for designing specialty machines and validating form, fit, and function.

2. Finite Element Analysis (FEA):

• FEA software: Tools like ANSYS, Abaqus, and COMSOL Multiphysics are used to analyze the structural and thermal behavior of mechanical objects, simulating stresses, strains, and deformations under different loading conditions.

3. Programming Skills:

• Programming languages: Mechanical engineers often need to automate tasks, control machines, and develop simulations using programming languages like Python, MATLAB, and C++.

4. Mathematics:

• Calculus, differential equations, and linear algebra: These skills are essential for understanding the behavior of mechanical systems and designing safe and efficient products.

5. Problem-Solving Skills:

• Creative problem-solving: Mechanical engineers need to identify and solve complex problems, often requiring innovative solutions.

6. System Analysis and Integration:

• Systems engineering: This involves designing, analyzing, and integrating complex systems, which is valuable in IT for designing and managing software systems.

7. Materials Science and Engineering:

• Materials expertise: Understanding the properties and behavior of materials is crucial for designing and optimizing mechanical systems and products.

8. 3D Printing and Additive Manufacturing:

• 3D printing: This technology is increasingly used in IT for rapid prototyping and manufacturing, making mechanical engineers with this skillset highly valuable.

Soft Skills

1. Communication:

• Effective communication: Mechanical engineers need to convey technical concepts clearly to various stakeholders, including engineers, technicians, and customers.

2. Teamwork:

• Collaboration: Mechanical engineers often work in teams, requiring strong collaboration and teamwork skills to share ideas, listen to feedback, and compromise.

3. Critical Thinking and Logical Thinking:

• Analytical thinking: Mechanical engineers must approach problems systematically, understand the end goal, note constraints, and use knowledge to find solutions.

4. Project Management:

• Project management: Mechanical engineers are often involved in managing projects, including budgeting, scheduling, and coordinating tasks with stakeholders.

5. Adaptability and Flexibility:

• Adaptability: Mechanical engineers need to be flexible and adapt to new technologies and methodologies, which is crucial in the rapidly evolving IT sector.

6. Data Analysis and Optimization:

• Data analysis: Mechanical engineers need to analyze data to optimize systems and processes, which is increasingly important in IT for data-driven decision-making.

These skills are highly valued by IT companies because they enable mechanical engineers to contribute effectively to various aspects of software development, system architecture, and project management, ultimately enhancing the efficiency and innovation of IT projects.

An IT company might hire a mechanical engineer for their expertise in problem-solving, analytical skills, and understanding of mechanical systems, which are valuable for various IT projects, such as hardware development, robotics, and systems integration. Graduates from Top Engineering Colleges, including Arya College of Engineering and IT, bring a solid foundation in engineering principles and innovative thinking, making them an asset in multidisciplinary IT teams. This blend of mechanical and IT knowledge can drive technological advancements and improve overall project outcomes.

0 notes

Text

Multiphysics Software Market looks to expand its size in Overseas Marketplace

According to HTF Market Intelligence, theGlobal Multiphysics Software market to witness a CAGR of 11.33% during forecast period of 2024-2030. North America Multiphysics Software Market Breakdown by Application (Individual, Enterprise) by End User (Schools, Research Institutes, Engineering, Construction, Others) by Deployment (Cloud, On Premise) and by Geography (United States, Canada, Mexico). The Multiphysics Software market size is estimated to increase by USD Billion at a CAGR of 11.33% from 2024 to 2030.. Currently, market value is pegged at USD 16.55 Billion.

Get Detailed TOC and Overview of Report @

Multiphysics software refers to computational tools that simulate and analyze physical phenomena involving multiple interconnected physics or engineering disciplines. These software packages enable engineers and scientists to model complex systems where different physical processes interact.

Some of the key players profiled in the study are Altair Engineering, Inc. (United States), ANSYS, Inc (United States), COMSOL (Sweden), Dassault Systèmes (France), ElectroMagneticWorks, Inc. (Canada), ESI Group (France), IronCAD, LLC. (United States), LiuRG@MTU (Germany), MATLAB (United States), Siemens (Germany).

Book Latest Edition of Global Multiphysics Software Market Study @ https://www.htfmarketintelligence.com/buy-now?format=1&report=6902

About Us:

HTF Market Intelligence is a leading market research company providing end-to-end syndicated and custom market reports, consulting services, and insightful information across the globe. HTF MI integrates History, Trends, and Forecasts to identify the highest value opportunities, cope with the most critical business challenges and transform the businesses. Analysts at HTF MI focuses on comprehending the unique needs of each client to deliver insights that are most suited to his particular requirements.

Contact Us:

Craig Francis (PR & Marketing Manager) HTF Market Intelligence Consulting Private Limited Phone: +15075562445 [email protected]

0 notes

Text

KIIT School Of Mechanical Engineering Conducts International Conference On Thermofluids And Manufacturing Science

The 3rdInternational Conference on Thermofluids and Manufacturing Science (ICTMS) 2024 was held on March 7th-8th, 2024 at the School of Mechanical Engineering, KIIT-DU. Sponsored by the Science and Engineering Research Board (SERB) of the Government of India, the event brought together delegates pan India and the faculties/students from the School of Mechanical Engineering, KIIT.

Speaking at the inaugural session, the chief guest Prof. Uday Shanker Dixit from IIT Guwahati emphasized the need for striving towards excellence in one’s area of interest. He also noted the need for avoiding unnecessary complexity in research. Dr. Krishnagoud Manda, a leading scientist in biomechanics from Queen's University Belfast UK, spoke about how interdisciplinary collaboration fosters innovation in breakthrough research. Dr. Spandan Guha, Convener, expressed gratitude to the sponsors: SERB, industry partners COMSOL Multiphysics and Linseis India, and IOP Science for publication support.

Prof. Dixit in his keynote speech deliberated on “Heat transfer modelling of manufacturing process”. Prof. Manda's captivating presentation on “Composite Scaffolds for Regeneration of Articular Cartilage” resonated with the audience due to its potential impact on human health. The conference included eight technical sessions, half of which were conducted online. Delegates from various locations presented their research virtually. Prof. Santanu Das, a leading researcher in manufacturing science from Kalyani Government Engineering College, delivered a well-received talk on “Green Cutting Fluid in Machining Hard Steel”.

Prof. Saptarshi Basu, a prominent scientist in shock wave research from the Indian Institute of Science, presented a lecture on “Shock Droplet Interaction”, emphasizing heat transfer in molten metal during manufacturing processes. Other noteworthy presentations included Prof. Satish Kumar's (NIT Jamshedpur) talk on “Multiphase modeling of ash water flow through a centrifugal pump” and Dr. Anties K. Martin's talk on COMSOL and its application in thermofluids and manufacturing.

The inauguration ceremony welcomed attendees both in person and virtually. Prof. Saranjit Singh, Vice Chancellor, KIIT-DU; Prof. Bharat Chandra Routara, Conference Chair; Dr. Debjyoti Sahu, Convener of ICTMS 2024; and Prof. Ashok Kumar Sahoo, Director R&D (Technology) also spoke at the inaugural session.

The valedictory session was held on March 8th 2024. Three best papers were awarded: one each from Manipal University, Karnataka; NIT Jamshedpur; and BIT Mesra. COMSOL presented gifts worth Rs. 3000/- each to the best paper presenters. Prof. Kunja Bihari Sahu, Dean of UG programs at KIIT-DU, acknowledged the organizers' efforts. The chief guest of the valedictory function, Prof. Santanu Das, provided constructive feedback for improvement in future conferences. The guests of honor, Prof. Saptarshi Basu, IISC Bangalore and Prof. Purna Chandra Mishra, Dean (Research), SME, KIIT both emphasized the importance of continued collaboration for interdisciplinary research. Feedback from participating delegates praised the hospitality, CRF facilities, and the visit to KIIT. Dr. Gyan Sagar Sinha, Conference Secretary, delivered the closing vote of thanks.

0 notes

Text

Relatório Técnico-Científico: Avanços na Modelagem Físico-Computacional do VERAGEL-X e Caminhos para Superar Gargalos

Projeto: VERAGEL-X – Gel Funcional Bioinspirado para Refrigeração Computacional em Ambientes Extremos

Pesquisador Responsável: Renato Ferreira da Silva

Período: Maio–Junho de 2025

Versão: 2.0 (última atualização: 10/06/2025)

1. Resumo Executivo

Este relatório detalha os avanços significativos na pesquisa e modelagem do VERAGEL-X, um gel funcional bioinspirado projetado para sistemas de refrigeração computacional sustentáveis. A fase inicial focou na compreensão fundamental do comportamento termo-hidrodinâmico de fluidos não-newtonianos em microcanais. Foi estabelecida uma base sólida em simulação computacional, desde um modelo conceitual inicial no COMSOL até a configuração detalhada de um ambiente de simulação avançada no OpenFOAM.

Avançamos na formulação de um problema de física dos fluidos de alto nível, incorporando tixotropia e geometrias 3D complexas. Apesar do progresso, gargalos relacionados à modelagem reológica avançada e à validação experimental foram claramente identificados, pavimentando o caminho para futuras investigações cruciais que serão abordadas por um novo problema de alto nível.

2. Introdução

A crescente demanda por poder computacional em data centers, dispositivos espaciais e ambientes extremos impõe desafios substanciais aos sistemas de refrigeração. O VERAGEL-X propõe uma solução inovadora: um gel funcional híbrido à base de Aloe vera, projetado para alta eficiência térmica, segurança e sustentabilidade. Este material promete substituir fluidos convencionais, eliminando o uso de água líquida e refrigeração ativa contínua.

A compreensão e otimização do comportamento deste gel, que exibe características não-newtonianas(dependência da viscosidade com taxa de cisalhamento e temperatura) e potenciais efeitos tixotrópicos(dependência com o tempo), são cruciais para o seu sucesso. Este relatório consolida as descobertas científicas e os avanços na modelagem físico-computacional até o momento.

3. Avanços Científicos Concretos

A pesquisa progrediu através de uma abordagem sistemática e multiescala:

3.1. Formulação Multi-Escala e Interdisciplinar do Problema

O projeto VERAGEL-X foi decomposto em subproblemas disciplinares que abrangem desde a Bioquímica e Biotecnologia Vegetal (extração e modificação de biopolímeros da Aloe vera) até a Engenharia de Sistemas Computacionais (integração em racks reais) e Sustentabilidade/Avaliação de Ciclo de Vida. Esta abordagem holística valida a complexidade e a abrangência do projeto, essencial para captação de recursos e parcerias.

Dentro da Mecânica dos Fluidos, o problema inicial de alto nível focou na transferência de calor conjugada, dinâmica de fluido confinado e convecção em superfícies bioinspiradas, preparando o terreno para a introdução da natureza não-newtoniana do gel.

3.2. Modelagem Termo-Hidrodinâmica de Géis Não-Newtonianos (COMSOL)

Configuração Inicial: Um modelo 2D simplificado foi desenvolvido no COMSOL Multiphysics, representando um módulo eletrônico (fonte de calor), uma capa de VERAGEL-X como meio poroso (Equações de Brinkman) e um domínio de ar para convecção natural. Esta fase inicial permitiu a visualização dos campos básicos de temperatura e velocidade e a validação conceitual do acoplamento térmico e de fluxo.

Transição para Microcanais e Modelagem Não-Newtoniana: O foco evoluiu para o escoamento do gel em microcanais fechados, mais representativos de um sistema de resfriamento. Um modelo de viscosidade Carreau-Yasuda com dependência da temperatura foi implementado diretamente na física de Laminar Flow do COMSOL. Isso permitiu simular:

Perfis de Velocidade: Alterados pela viscosidade variável (efeito shear-thinning).

Variação de Viscosidade: Demonstrou como a viscosidade local do gel muda significativamente (Δη de até 10x) em função da taxa de cisalhamento e do gradiente térmico (próximo a um hot spot).

Transferência de Calor e Queda de Pressão: Análise inicial da eficácia do resfriamento e da energia necessária para o bombeamento do gel.

3.3. Configuração de Ambiente de Simulação Avançada (OpenFOAM)

Para superar as limitações de customização de modelos reológicos do COMSOL e preparar o terreno para simulações 3D de larga escala e otimização topológica, foi realizada uma transição estratégica para o OpenFOAM.

Justificativa: A flexibilidade do OpenFOAM para modificação do código-fonte permite a implementação de modelos constitutivos de fluidos não-newtonianos mais complexos, como os que incluem tixotropia e histerese.

Setup do Caso Básico: Uma estrutura completa de um "case" do OpenFOAM foi configurada para um escoamento em uma geometria 3D simplificada em "Y" (representando uma bifurcação de microcanais). Isso incluiu:

Diretórios Padrão: 0, constant, system.

Condições Iniciais e de Contorno: Arquivos U, p, T com configurações para entrada de velocidade, saídas de pressão e temperatura, paredes de não-escorregamento, e um hotSpotWall com temperatura fixa.

Propriedades Físicas: thermophysicalProperties e transportProperties com propriedades do gel (densidade, calor específico, condutividade térmica) e placeholders para a viscosidade que será customizada.

Malha (blockMeshDict): Um arquivo blockMeshDict foi construído para criar a geometria 3D simplificada em "Y" (blocos retos formando a bifurcação).

Controle da Simulação: controlDict configurado para um solver estacionário (buoyantSimpleFoam), com funções de monitoramento para perda de pressão, temperatura média nas saídas e número de Reynolds local.

Esquemas e Solvers: fvSchemes e fvSolution foram ajustados para discretização e solução do problema.

Status Atual: O ambiente OpenFOAM está configurado e o case básico (com viscosidade Newtoniana temporária) está pronto para execução, permitindo a verificação da malha e a análise dos campos de velocidade e temperatura nesta geometria 3D simplificada.

4. Gargalos Atuais e Caminhos de Investigação Futura

Apesar do notável progresso, desafios inerentes à complexidade do VERAGEL-X e suas aplicações em ambientes reais foram identificados. Superar estes gargalos é o foco para as próximas fases de pesquisa:

4.1. Modelagem Reológica Avançada e Inclusão de Tixotropia

Gargalo: A viscosidade do VERAGEL-X não depende apenas da taxa de cisalhamento e temperatura, mas também do tempo de exposição ao cisalhamento (tixotropia). O modelo Carreau-Yasuda implementado no COMSOL é um avanço, mas não captura essa dependência temporal ou histerese. A implementação no OpenFOAM ainda opera com um modelo Newtoniano placeholder.

Caminho para Superação:

Desenvolvimento de um Modelo de Viscosidade Tixotrópica Customizado: Esta é a prioridade imediata. Requer programação em C++ dentro da arquitetura do OpenFOAM (e.g., criando um novo modelo em src/transportModels/viscosityModels), que incluirá a evolução temporal da estrutura do gel e sua influência na viscosidade. Modelos como Herschel-Bulkley estendido com dependência de tempo, ou outros modelos de estrutura tixotrópica, devem ser investigados.

Inclusão de Efeitos Elásticos: Avaliar a importância do Número de Deborah (De) para incorporar a elasticidade do gel em regimes de alto cisalhamento e curtos tempos de residência.

4.2. Geometrias 3D Complexas e Otimização Topológica

Gargalo: A geometria "Y" simplificada é um bom início, mas redes de microcanais reais em racks de data center são muito mais intrincadas, com múltiplas bifurcações, curvaturas e otimizações de espaço.

Caminho para Superação:

Refinamento da Malha 3D: Transitar de blockMesh para ferramentas mais robustas como snappyHexMesh (utilizando arquivos STL de geometrias complexas) ou outras ferramentas de CAD/malha (e.g., Salome, Gmsh) para gerar malhas de alta qualidade de redes de microcanais realistas.

Otimização Topológica: Integrar o solver OpenFOAM com algoritmos de otimização topológica (e.g., baseados no método SIMP) para projetar automaticamente as formas mais eficientes de dissipadores e canais que maximizem a transferência de calor e minimizem a perda de pressão.

4.3. Comportamento Dinâmico e Estabilidade a Longo Prazo

Gargalo: As simulações atuais são estacionárias, mas o VERAGEL-X operará sob cargas térmicas variáveis e ciclos contínuos, que podem induzir flutuações reológicas e degradação do gel.

Caminho para Superação:

Simulações Transientes: Migrar para solvers transientes do OpenFOAM (buoyantPimpleFoam ou um solver customizado) para simular a resposta do sistema a flutuações de potência dos hot spots e avaliar o tempo de resposta térmica e reológica do gel.

Modelagem de Degradação: Desenvolver sub-modelos que representem a degradação térmica e mecânica do gel (e.g., perda de propriedades biofuncionais, alteração de Cp, k, Aarrh) ao longo do tempo de operação e ciclos de cisalhamento/temperatura.

4.4. Validação Experimental (Crucial)

Gargalo: A validação dos modelos numéricos complexos (especialmente os tixotrópicos e em geometrias 3D) depende criticamente de dados experimentais. Atualmente, a validação é teórica e comparativa.

Caminho para Superação:

Construção de Bancada Experimental: Projetar e construir uma bancada hidrotérmica que permita o fluxo do VERAGEL-X em microcanais (e.g., fabricados via microfabricação).

Instrumentação Avançada: Equipar a bancada com sensores de temperatura de alta resolução, transdutores de pressão e, crucialmente, sistemas de velocimetria por imagem (PIV) para medir os campos de velocidade e, indiretamente, as taxas de cisalhamento e viscosidade local do gel. Isso fornecerá os dados necessários para calibrar e validar os modelos CFD.

5. Conclusão

Os avanços na modelagem físico-computacional do VERAGEL-X são robustos e estabeleceram uma base sólida para a compreensão do seu comportamento termo-hidrodinâmico. A transição para o OpenFOAM e a formulação de problemas de alto nível para modelagem tixotrópica e geometrias 3D complexas posicionam o projeto na vanguarda da pesquisa em fluidos não-newtonianos para aplicações de engenharia.

A superação dos gargalos identificados – notadamente a implementação de modelos reológicos avançados e a validação experimental rigorosa – será o foco das próximas etapas, abrindo caminho para a otimização de protótipos funcionais e a realização do potencial de resfriamento sustentável do VERAGEL-X.

0 notes

Text

Webseminar: Batterien modellieren mit Comsol Multiphysics

Kostenloses Webseminar Dienstag, 20. Februar 2024, 11:00 – 12:00 Uhr Die Entwicklung von leistungsstarken, langlebigen und sicheren Akkus erfordert ein detailliertes Verständnis der Akkutechnologie und der zugrunde liegenden physikalischen und elektrochemischen Prozesse. Simulationssoftware hilft Forschern und Entwicklern, einen Blick in das Innere des Akkus zu werfen, wie es mit Experimenten…

View On WordPress

0 notes

Video

youtube

Python Scripting for COMSOL Multiphysics - COMSOL Programming

0 notes

Text

COMSOL releases version 6.2 of COMSOL Multiphysics

COMSOL announced the release of COMSOL Multiphysics version 6.2, adding data-driven surrogate model functionality for efficient standalone simulation apps and multiphysics-based digital twins. It also features high-performance multiphysics solvers for the analysis of electric motors, up to 40% faster turbulent CFD simulations, and an order of magnitude faster impulse response calculations for…

View On WordPress

0 notes

Text

disoriented by someone else reblogging this out of nowhere over six months later but i hope they find comfort and enjoyment in Norwegian pop icon Sigrid's absolute fucking bop "High Five" for all their COMSOL Multiphysics needs. time for me to return to this song since i'm still fucking being tormented by COMSOL

songs to be tormented by COMSOL to

4 notes

·

View notes