#Capacitive Touch Controllers

Explore tagged Tumblr posts

Text

Controladores táctiles capacitivos, previsión del tamaño del mercado mundial, clasificación y cuota de mercado de las 23 principales empresas

Según el nuevo informe de investigación de mercado “Informe del Mercado Global del Controladores táctiles capacitivos 2024-2030”, publicado por QYResearch, se prevé que el tamaño del mercado mundial del Controladores táctiles capacitivos alcance 2.11 mil millones de USD en 2030, con una tasa de crecimiento anual constante del 4.9% durante el período de previsión.

Figure 1. Tamaño del mercado de Controladores táctiles capacitivos global (US$ Millión), 2019-2030

Según QYResearch, los principales fabricantes mundiales de Controladores táctiles capacitivos incluyen Infineon, Goodix, FocalTech Systems, MicroChip, Renesas, Synaptics, ELAN Microelectronics, Sitronix Technology, GigaDevice, Silicon Labs, etc. En 2023, las diez principales entidades mundiales tenían una cuota de aproximadamente 64.0% en términos de ingresos.

Figure 2. Clasificación y cuota de mercado de las 23 principales entidades globales de Controladores táctiles capacitivos (la clasificación se basa en los ingresos de 2023, actualizados continuamente)

Sobre QYResearch

QYResearch se fundó en California (EE.UU.) en 2007 y es una empresa líder mundial en consultoría e investigación de mercados. Con más de 17 años de experiencia y un equipo de investigación profesional en varias ciudades del mundo, QY Research se centra en la consultoría de gestión, los servicios de bases de datos y seminarios, la consultoría de OPI, la investigación de la cadena industrial y la investigación personalizada para ayudar a nuestros clientes a proporcionar un modelo de ingresos no lineal y hacer que tengan éxito. Gozamos de reconocimiento mundial por nuestra amplia cartera de servicios, nuestra buena ciudadanía corporativa y nuestro firme compromiso con la sostenibilidad. Hasta ahora, hemos colaborado con más de 60.000 clientes en los cinco continentes. Trabajemos estrechamente con usted y construyamos un futuro audaz y mejor.

QYResearch es una empresa de consultoría a gran escala de renombre mundial. La industria cubre varios segmentos de mercado de la cadena de la industria de alta tecnología, que abarca la cadena de la industria de semiconductores (equipos y piezas de semiconductores, materiales semiconductores, circuitos integrados, fundición, embalaje y pruebas, dispositivos discretos, sensores, dispositivos optoelectrónicos), cadena de la industria fotovoltaica (equipos, células, módulos, soportes de materiales auxiliares, inversores, terminales de centrales eléctricas), nueva cadena de la industria del automóvil de energía (baterías y materiales, piezas de automóviles, baterías, motores, control electrónico, semiconductores de automoción, etc.. ), cadena de la industria de la comunicación (equipos de sistemas de comunicación, equipos terminales, componentes electrónicos, front-end de RF, módulos ópticos, 4G/5G/6G, banda ancha, IoT, economía digital, IA), cadena de la industria de materiales avanzados (materiales metálicos, materiales poliméricos, materiales cerámicos, nanomateriales, etc.), cadena de la industria de fabricación de maquinaria (máquinas herramienta CNC, maquinaria de construcción, maquinaria eléctrica, automatización 3C, robots industriales, láser, control industrial, drones), alimentación, bebidas y productos farmacéuticos, equipos médicos, agricultura, etc.

0 notes

Text

I went to Lowe’s to look at refrigerators with my mom because her’s is having issues, and I saw a Samsung model that had capacitive buttons to open the doors.

Like, you could still reach into the handle, not touch the control, and pull it open, normally. But for some reason, there was also this little pad inside the handle where, if your touched it, the door would pop itself open.

Like what????? In what world are people complaining about the “strength” it requires to open a refrigerator door?? And all the unreliable mechanical complexity that adds?? Not to mention, it wasn’t very useful because of the slight delay between touching it, opening itself, and then you opening it the rest of the way was longer than just opening it by brute force. Like… what’s even the point? Companies are really scraping the bottom of the barrel, these days, ffs.

9 notes

·

View notes

Text

A Practical Guide to Customizing TFT LCD Displays for Embedded Projects

When designing an embedded system, picking the right display module is more than a technical choice — it directly shapes how users interact with your product.

From medical devices and HMIs to industrial controllers and smart panels, standard TFT LCD modules may not always be enough. That’s where custom displays come in — offering flexibility in electrical interface, mechanical layout, and visual performance.

This guide covers the five key areas you should consider when customizing a TFT LCD for your embedded project.

1. FPC Layout and Pin Mapping

The Flexible Printed Circuit (FPC) connects your LCD module to the mainboard, and in custom designs, this interface is often the first thing to change.

Ask yourself:

Do you need a uniquely shaped or angled FPC to fit inside your housing?

Are there ICs, resistors, or other components on the backlight or CTP that require mechanical clearance?

Is your SBC’s connector pinout compatible with the LCD’s FPC layout?

A mismatch here can lead to signal errors, mechanical stress, or even damage to components.

2. Backlight Brightness and Color Temperature

Not all embedded devices live under the same lighting.

If your product is used outdoors or in industrial lighting, consider high-brightness backlights (≥800 nits). For environments where aesthetics and color warmth matter (like smart mirrors or indoor kiosks), choose the right LED color temperature:

3000K (Warm White): Soft, suitable for medical or ambient lighting

5000K (Neutral White): Balanced tone, accurate colors

6500K+ (Cool White): Sharper, more industrial feel

A poorly lit display can make a great device feel underwhelming.

3. Touch Panel Shape and Bonding Options

If your display includes a touch interface, customizing the Capacitive Touch Panel (CTP) is critical.

Typical customizations include:

Round corners, logo cutouts, button holes

Bonding methods:

Optical bonding: Improves visibility, reduces reflections, stronger seal

Air bonding: More affordable and easier to assemble

The bonding method directly impacts touch accuracy, display clarity, and long-term reliability.

4. Surface Treatments: AG, AR, and AF

For devices exposed to bright light or frequent finger contact, display surface treatments make a noticeable difference.

AG (Anti-Glare): Scatters reflected light, improving readability

AR (Anti-Reflection): Enhances contrast in sunlight or strong lighting

AF (Anti-Fingerprint): Reduces smudges, improves touch feel

Combining AG+AF is a common choice for public-facing touchscreen displays.

5. Want to Learn More?

If you’re building with platforms like RK3566, PX30, or Allwinner boards and need a reliable display solution — including driver compatibility and electrical tuning — check out our full technical article:

👉 Read the Full Custom TFT LCD Guide

You can also browse driver/device tree examples on GitHub:

📂 rocktech-tft-display-configs

1 note

·

View note

Text

Industrial Displays for Smart Operations

In today’s fast-paced manufacturing and automation environments, having the right technology is crucial to maintain productivity and efficiency. Two essential tools that continue to shape industrial innovation are the industrial monitor and the touchscreen embedded PC. These devices are not only revolutionizing how operators interact with systems but also how industries achieve operational accuracy and control.

𝑷𝒐𝒘𝒆𝒓 𝒂𝒏𝒅 𝑹𝒆𝒔𝒊𝒍𝒊𝒆𝒏𝒄𝒆 𝒐𝒇 𝑰𝒏𝒅𝒖𝒔𝒕𝒓𝒊𝒂𝒍 𝑴𝒐𝒏𝒊𝒕𝒐𝒓𝒔

Unlike traditional consumer-grade screens, industrial monitors are purpose-built to withstand challenging environments. From high-vibration settings in factories to exposure to dust, moisture, and extreme temperatures, these monitors are designed with rugged durability in mind. Their ability to deliver clear visuals under harsh lighting or variable weather conditions makes them invaluable for both indoor and outdoor industrial applications.

Furthermore, industrial monitors are often integrated with mounting options such as panel, VESA, or rack mounts, which offer flexibility for installation across a variety of settings including control panels, production lines, and inspection stations. Their long product lifecycles and minimal maintenance requirements make them a cost-effective choice for industries ranging from oil and gas to pharmaceuticals and logistics.

𝑬𝒏𝒉𝒂𝒏𝒄𝒊𝒏𝒈 𝑰𝑶𝑻 𝒘𝒊𝒕𝒉 𝑻𝒐𝒖𝒄𝒉𝒔𝒄𝒓𝒆𝒆𝒏 𝑬𝒎𝒃𝒆𝒅𝒅𝒆𝒅 𝑷𝑪𝒔

As industries shift toward automation and digitization, the demand for advanced computing systems has grown significantly. A touchscreen embedded PC offers a compact, efficient solution for managing machinery and data input directly from the production floor. These systems combine processing power with space-saving design, allowing them to be installed directly into operator panels or machine enclosures.

What makes touchscreen embedded PCs especially valuable is their versatility. They are built to handle data-intensive operations, integrate with sensors, and communicate with cloud-based platforms for real-time monitoring and analytics. Whether used in a warehouse to track inventory or in a manufacturing unit to control robotic arms, they provide an intuitive, touch-based interface that simplifies operations for users.

Modern touchscreen embedded PC often run on energy-efficient processors and support various operating systems such as Windows, Linux, or Android. Their robust design includes fanless architecture, which reduces the risk of contamination and failure in sensitive environments like food processing or clean rooms.

𝑰𝒏𝒕𝒆𝒈𝒓𝒂𝒕𝒆𝒅 𝑺𝒐𝒍𝒖𝒕𝒊𝒐𝒏𝒔 𝒇𝒐𝒓 𝑴𝒐𝒅𝒆𝒓𝒏 𝑰𝒏𝒅𝒖𝒔𝒕𝒓𝒚

The combination of an industrial monitor and a touchscreen embedded PC creates a powerful human-machine interface (HMI) solution. This setup not only allows operators to visualize data in real-time but also to interact with machines using easy-to-use graphical interfaces. This human-centric design leads to faster decision-making and reduces the learning curve for technicians and engineers.

These integrated systems are scalable, enabling industries to expand or upgrade their operations without significant downtime. Additionally, with increased focus on cybersecurity and remote access, many touchscreen embedded PCs now come with enhanced security protocols, ensuring data protection and safe remote troubleshooting.

𝑭𝒖𝒕𝒖𝒓𝒆-𝑹𝒆𝒂𝒅𝒚 𝑻𝒆𝒄𝒉𝒏𝒐𝒍𝒐𝒈𝒚

As industrial ecosystems grow more interconnected, choosing devices that are future-ready is vital. The industrial monitor continues to evolve with features like 4K resolution, sunlight-readable displays, and capacitive touch options. Meanwhile, touchscreen embedded PCs are becoming smarter, integrating AI capabilities and edge computing functions that allow real-time decision-making without relying on cloud latency.

These technologies are not just passive tools; they are proactive elements in driving digital transformation. From smart manufacturing plants to intelligent transportation systems, their role in the industrial landscape is indispensable.

For more info :- 1.Facebook

2.Youtube

1 note

·

View note

Text

⚠️ CW: Mention of Meta products, mining accident, mild gore ⚠️

Hitting Delete rather than Disable on your Threads and Facebook accounts really does feel like this.

To run with the American Psycho reference, read this in a cinematic Patrick Bateman voice: "I clicked Delete using an Apple Magic Mouse with capacitive touch controls that create an elegant, unified, single top-surface, with no unsightly button seams. It's customized with hand-trimmed Teflon tape placed over the glide pads, for nearly silent movement across my desk. My mouse pad; a virtually paper-thin optical precision pad by 3M, squared perfectly to the edge of my desk. I watch as it takes 30 days for the accounts to die."

2 notes

·

View notes

Text

Every time I hear about a new development in cars I get more disappointed. Capacitive touch without a screen? Absolutely disgusting. Things I want in a car:

Steering wheel: Big, taken from a bus

Shift knob: Train throttle

Parking brake (redundant braking systems don't require an emergency brake):

Clock:

AC fan control:

AC temperature adjustment: (3 position marine toggle switch that returns to center)

By no means a complete list, add your own. Perhaps instead of a breathalyzer, you have to score 20 on bop it. All I'm saying is that a car is a tool and tools should feel so natural to use that they become a part of the worker, moving together and enhancing one a other's skills. A smith is just as incapable of shaping metal as a hammer is of swinging itself. The two must agree to move as one for a mutual goal

3 notes

·

View notes

Text

Nothing I love more, and nothing that less inclines me to commit acts of domestic terrorism, than when I'm trying to fill out health insurance intake forms and both my insurer and the provider add fun little surprises to the web UX like turning the control key into a reload button or using JavaScript to keep my group ID extra secure from ne'er-do-wells who want to trick me into copying and pasting it.

Honestly, I've never had so much faith in the ingenuity, fearless willingness to tackle challenging technical problems in the service of me the user, and sense of mission of my fellow software engineers, nor so much confidence in the thoughtfulness and humanity of large organizations a badly confused person might mistake for the point at infinity where the parallel lines of greed and sheer incompetence finally meet.

And, lest this all be so easy that it feels boring, in the same way that playing tic tac toe is, I can always count on the track pad of my contracting employer (whom I'm not taking insurance from since they understandably thought defaulting a six figure professional into an ACA-complaint plan that actually covers things like catastrophes was rather austentatious indeed—what next, flying around on Air Force jets on the taxpayer dime like John fucking Sununu?) operating in some truly interesting ways that challenge both the process of filling out said forms and my understanding of just what sorts of properties human beings have been able to wring out of things like the Hall effect and capacitive touch sensors.

4 notes

·

View notes

Text

Terry and Julia Group Project 1

Video Walkthrough LinkImage of the Project

The last two weeks Terry and I worked on our project called “Hit the Dick” (see video walkthrough above).

Aim of the Game:Each player has one strap-on game controller containing an Airpump, a rgb-LED, as well as a capacitive touch sensor attached to the tip. The game starts by randomly choosing one player whose strap-on will light up green after a random delay. That player has to hit the other players strap on within 3 seconds. If the player succeeds in hitting it before the opponent has dodged, the players starp-on will fill with a little bit of air. Players then take turn until one of the players has gained 5 points.

Hardware:LED: serves to indicate the current state of the game: Who is hitting, who has to dodge. AirPump that fills Silicone strap-on with air: Serves as a funny way to indicate the players points. The higher the Point count, the “higher” the strap-on will be (lol).Capacitive Touch Sensor: detects the slapping

Process:Terry and I ran into a few difficulties during building this project: Here are some interesting findings summed up:

Building the silicone strap-ons: It was really challenging to create 3D printed negatives that would serve as the mold for the strap-ons because we needed to make sure we had enough hallow space for the air to fill.

Getting the Airpumps to work: After some testing, we realized that the Arduino does not have enough power to power the Airpumps using the GPIO pins. Hence, we ended up using a Relay connected to an external 5V 2A power source!

3 notes

·

View notes

Text

The TTP224 is a 4-Channel Touch Sensor, meaning it has four touchpads. Whenever a capacitive load such as human hands is brought in proximity with the sense pad, the sensor then senses the change in capacitance and activates the switch. Custom sense-pads can be made from nearly any conductive material and these sensors can detect touch through thin layers of non-conductive materials such as glass, plastic, fabric or even wood. Each Touchpad has its respective output pin when the user touches a pad, the corresponding output pin will go high. It is very easy to interface with microcontrollers like Arduino to control different applications as a switch. It can be used in home automation, motor control, Relay control, etc. the module basically gets rid of the push button troubles.

6 notes

·

View notes

Text

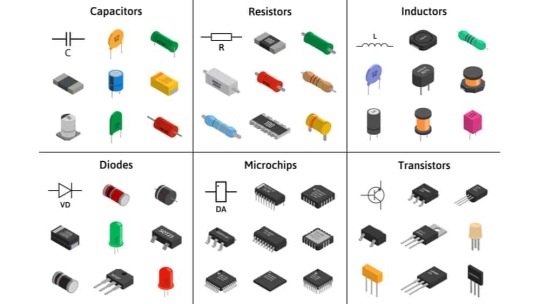

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

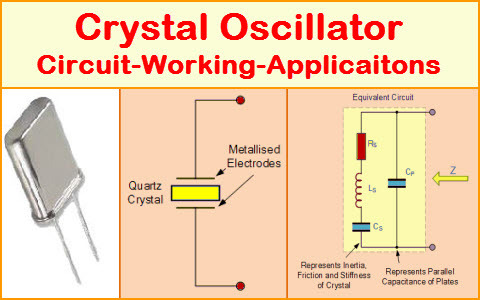

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

LCD Displays in Intelligent Manufacturing and Machine Tools

In the era of Industry 4.0, intelligent manufacturing is revolutionizing how products are designed, fabricated, and inspected. At the core of this transformation is the integration of advanced digital interfaces that bridge human operators with smart machinery. Among these interfaces, LCD display screens—particularly TFT LCD panels—play a pivotal role in enabling seamless machine-to-human communication across a wide range of manufacturing and machining environments.

Digital Interfaces for Smart Machines

Modern machine tools such as CNC milling machines, lathes, and automated inspection stations rely on fast, accurate feedback to maintain performance and precision. Here, high-resolution TFT display modules shine by providing real-time data visualization. These LCD display modules serve as interactive control panels, live status monitors, and diagnostic dashboards that allow users to track and manage everything from spindle speed and tool position to error codes and maintenance alerts.

With the push toward smarter production systems, touch-enabled LCD screens offer major advantages. They simplify interaction by reducing reliance on physical buttons, allowing for faster setup, intuitive navigation, and quicker adjustments. This streamlining directly minimizes the likelihood of human error and significantly reduces downtime—two critical factors in maintaining competitive production output.

Additionally, LCD display solutions often come with plug-and-play capabilities, supporting easy integration with embedded controllers, PLCs, and industrial PCs. For OEMs and system integrators, this means lower development costs and faster deployment of intelligent machinery.

Key Advantages in Smart Manufacturing Environments

The use of TFT LCD panels in intelligent manufacturing environments brings several tangible benefits:

Space-Efficient Design: Many panel LCD displays are slim and compact, allowing them to fit into tight spaces on control cabinets or machine frames without compromising screen size or visibility.

Real-Time Visualization: High brightness and contrast levels ensure the data is readable under varying lighting conditions—critical for factory floors that operate around the clock.

Touch Interfaces: Capacitive or resistive touch screen LCD panels enable direct input, which simplifies configuration tasks and enhances responsiveness during machine operation.

Custom Form Factors: Machine tool manufacturers can choose custom LCD displays that match specific mechanical or ergonomic requirements, supporting seamless housing design without the need for extensive reengineering.

Enhanced Reliability: Industrial-grade LCD modules are designed to withstand vibrations, electrical noise, and temperature fluctuations typically found in heavy-duty manufacturing environments.

For more LCD display information,click here.

#lcd display screen#display modules#replacement lcd screen#screen displays#display lcd#panel display#replacement screen#7 inch display#tft lcd module#panel lcd#tft lcd#lcd module tft#touch lcd#lcd display 7 inch#screen module#tft lcd screen#lcd supplier

0 notes

Text

High-Performance Tactile Sensor market CAGR : Growth, Share, Value, Size and Analysis

According to the latest industry analysis from Intel Market Research, the global High-Performance Tactile Sensor market was valued at USD 25.5 million in 2024 and is projected to reach USD 59.9 million by 2031, growing at an impressive CAGR of 12.1% during the forecast period. This growth trajectory is fueled by accelerating adoption across robotics, medical devices, and next-generation consumer electronics, coupled with technological breakthroughs in sensor sensitivity and miniaturization.

What are High-Performance Tactile Sensors?

High-performance tactile sensors represent a revolutionary class of sensing devices that precisely detect and measure physical interactions - including touch, pressure, vibration, and texture - converting these stimuli into electrical signals. These advanced sensors achieve what engineers call "electronic skin" functionality, mirroring the nuanced perception capabilities of human touch through:

Microscale resolution (detecting forces as low as 0.1 Newtons)

Sub-millisecond response times

Multidimensional force measurement (normal, shear, torsional)

Unlike conventional touch sensors, high-performance variants leverage diverse operating principles including piezoelectric effects, capacitive changes, and optical fiber sensing, making them indispensable in applications demanding human-like tactile feedback.

📥 Download Sample Report: High-Performance Tactile Sensor Market - View in Detailed Research Report

Key Market Drivers

1. Robotics Revolution Demands Human-Like Dexterity

The robotics sector accounts for 38% of tactile sensor demand as collaborative robots (cobots) require sophisticated touch feedback for:

Precision object handling (<1mm positioning accuracy)

Adaptive grip force control (preventing damage to fragile items)

Safety compliance (instant collision detection)

2. Medical Technology Advancements

Surgical robots and smart prosthetics are leveraging tactile sensors for:

Haptic feedback in minimally invasive surgery (enabling tissue differentiation)

Prosthetic limb pressure mapping (preventing skin ulcers)

Wearable health monitors tracking vital signs through pulse detection

3. Consumer Electronics Innovation

Next-generation devices integrate tactile sensors for:

Pressure-sensitive touchscreens (detecting light taps vs firm presses)

Gaming controllers with dynamic resistance feedback

VR gloves providing realistic texture simulation

Market Challenges

Despite strong growth prospects, several hurdles persist:

Manufacturing complexity: Achieving micron-level precision increases production costs by 25-40% compared to conventional sensors

Material limitations: Few flexible conductive materials maintain stability after 1+ million actuation cycles

Standardization gaps: Absence of universal protocols for tactile data interpretation across industries

Technological Breakthroughs

Recent innovations are overcoming these challenges:

Graphene-based sensors achieving 99.7% conductivity retention after prolonged use

Self-healing polymers automatically repairing minor physical damage

AI integration enabling real-time surface texture classification with 92% accuracy

Regional Market Landscape

North America: Leading in medical and military applications (35% market share)

Europe: Strong in industrial automation with 28% adoption in manufacturing robots

Asia-Pacific: Fastest growing (16.8% CAGR) driven by electronics and automotive sectors

Competitive Environment

The market features both established players and innovative startups:

Tekscan: Pioneer in medical pressure mapping systems

Pressure Profile Systems: Specialists in robotic tactile feedback

Weiss Robotics: Leaders in industrial gripper integration

SynTouch: Innovators in biomimetic sensor technology

📥 Download Sample Report: High-Performance Tactile Sensor Market - View in Detailed Research Report

Market Segmentation

By Technology

Piezoelectric Tactile Sensors

Capacitive Tactile Sensors

Resistive Tactile Sensors

Optical Tactile Sensors

By Application

Robotics

Medical Devices

Consumer Electronics

Automotive

Industrial Automation

📘 Get Full Report Here: High-Performance Tactile Sensor Market - View in Detailed Research Report

About Intel Market Research

Intel Market Research is a leading provider of strategic intelligence, offering actionable insights in industrial automation, medical technology, and emerging sensors. Our research capabilities include:

Real-time competitive benchmarking

Technology adoption trend analysis

Patent and innovation tracking

250+ industrial automation reports annually

Trusted by Fortune 500 manufacturers, our insights enable informed strategic planning.

🌐 Website: https://www.intelmarketresearch.com 📞 International: +1 (332) 2424 294 📞 Asia-Pacific: +91 9169164321 🔗 LinkedIn: Follow Us

0 notes

Text

Fingerprint Recognition Sensor Chip Market: Growth Opportunities Across Biometric Security Applications, 2025-2032

Fingerprint Recognition Sensor Chip Market, Trends, Business Strategies 2025-2032

Fingerprint Recognition Sensor Chip Market size was valued at USD 3.2 billion in 2024 and is projected to reach USD 8.7 billion by 2032, exhibiting a CAGR of 13.4% during the forecast period

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=108070

MARKET INSIGHTS

The Global Fingerprint Recognition Sensor Chip Market size was valued at USD 3.2 billion in 2024 and is projected to reach USD 8.7 billion by 2032, exhibiting a CAGR of 13.4% during the forecast period.

Fingerprint recognition sensor chips are semiconductor devices that capture and process fingerprint data for biometric authentication. These chips utilize three dominant technologies: optical sensors (cost-effective but bulkier), semiconductor sensors (dominant in smartphones with capacitive or thermal solutions), and ultrasonic sensors (emerging high-security alternative). The semiconductor segment currently holds over 65% market share, driven by smartphone adoption where these sensors enable secure yet compact designs.

The market growth is fueled by increasing smartphone biometric integration, with over 85% of flagship devices now featuring in-display fingerprint sensors. However, supply chain disruptions in 2022 impacted semiconductor availability, with the broader sensor market growing only 16.3% despite earlier projections. Asia-Pacific remains the production hub, though recent geopolitical tensions have prompted manufacturers like Goodix and Synaptics to diversify manufacturing beyond China. Emerging applications in automotive access control and IoT devices are expected to drive the next phase of growth, particularly for ultrasonic sensors with higher spoof detection capabilities.

List of Key Fingerprint Recognition Sensor Chip Companies

Synaptics Incorporated (U.S.)

Apple Inc. (U.S.)

Fingerprint Cards AB (Sweden)

Shenzhen Goodix Technology (China)

FocalTech Systems (Taiwan)

Shanghai Sileadinc (China)

Elan Microelectronics Corp (Taiwan)

Qualcomm Technologies (U.S.)

EGIS TECHNOLOGY INC (Taiwan)

ShenZhen Betterlife Electronic Science and Technology (China)

Segment Analysis:

By Type

Semiconductor Sensor Segment Leads Due to Dominance in Smartphone Applications

The market is segmented based on type into:

Optical Sensor

Subtypes: Capacitive Optical, Reflective Optical, and others

Semiconductor Sensor

Ultrasonic Sensor

Subtypes: Piezoelectric Ultrasonic, Capacitive Ultrasonic, and others

By Application

Smartphone Application Segment Dominates Driven by Biometric Security Demand

The market is segmented based on application into:

Smart Phone

Tablet

Electronic Lock

Automotive Electronics

Financial and Medical Devices

By Technology

Touch-based Technology Holds Major Market Share

The market is segmented based on technology into:

Touch-based

Swipe-based

Regional Analysis: Fingerprint Recognition Sensor Chip Market

North America North America remains a critical market for fingerprint recognition sensor chips, driven by strong demand in consumer electronics and security applications. The U.S. leads the region due to high adoption of smartphones with advanced biometric features and stringent security regulations in financial and government sectors. Semiconductor-based sensors dominate the market, with major OEMs like Apple integrating them into flagship devices. The market benefits from R&D investments in ultrasonic and under-display technologies, although cost sensitivity and competition from Asian suppliers remain challenges. Regulatory frameworks around data protection also influence product development trends.

Europe Europe showcases steady growth in fingerprint sensor adoption, particularly in smart payment systems and IoT devices. The region emphasizes privacy and security compliance under GDPR, pushing manufacturers to develop secure authentication solutions. While smartphone penetration is high, growth opportunities lie in automotive and industrial applications. European manufacturers focus on differentiation through energy-efficient and high-accuracy sensors, though they face pricing pressure from Asian competitors. Collaborative initiatives between academia and industry aim to advance capacitive and optical sensing technologies for niche applications.

Asia-Pacific As the largest and fastest-growing market, Asia-Pacific accounts for over 60% of global fingerprint sensor demand, fueled by massive smartphone production in China and India. Chinese manufacturers like Goodix and Silead lead in cost-competitive semiconductor sensors, catering to both local and global OEMs. While ultrasonic sensors gain traction in premium devices, optical sensors remain popular for budget smartphones and IoT applications. The region’s electronics manufacturing ecosystem and government support for biometric adoption in digital identification programs create long-term growth potential, though intellectual property concerns persist.

South America The South American market shows gradual adoption of fingerprint sensors, primarily in banking and mobile devices. Brazil represents the largest market, where smartphone manufacturers integrate basic capacitive sensors to meet security demands at accessible price points. Economic volatility and currency fluctuations hinder widespread adoption of advanced ultrasonic technologies. However, growing smartphone penetration and fintech adoption create opportunities for sensor manufacturers willing to navigate the region’s complex supply chains and trade policies. Local partnerships with Chinese suppliers are becoming increasingly common to balance cost and performance requirements.

Middle East & Africa This emerging market demonstrates growing interest in fingerprint sensors for government ID programs and secure payment solutions. Gulf countries like UAE and Saudi Arabia lead in adopting advanced biometric systems for smart city initiatives. While semiconductor sensors dominate, the market shows early interest in under-display technologies for flagship smartphones. Infrastructure limitations and budget constraints in African nations favor optical sensor solutions for basic authentication needs. The region presents long-term potential as digital transformation accelerates, though political instability in certain areas creates supply chain uncertainties.

MARKET DYNAMICS

The fingerprint sensor market has become increasingly commoditized, particularly in the smartphone sector, where component prices have declined by over 60% since 2018. Chinese manufacturers now offer capacitive sensors at prices that established players struggle to match, triggering brutal price wars. With gross margins for standard sensors falling below 15%, manufacturers face painful choices between maintaining market share and preserving profitability. This pricing pressure extends throughout the supply chain, discouraging R&D investment in next-generation technologies that could command premium pricing.

Technological obsolescence represents an existential challenge as alternative biometric methods gain traction. Facial recognition systems now surpass fingerprint sensors in several flagship devices, offering comparable security with superior user experience. While fingerprint technology maintains advantages in cost and power efficiency for mid-range devices, its position as the dominant biometric solution faces sustained pressure from emerging modalities.

The automotive industry’s digital transformation creates substantial opportunities for fingerprint sensor integration. Modern vehicles increasingly incorporate biometric authentication for personalized settings, secure access, and payment systems. Luxury automakers now feature fingerprint sensors in door handles, start buttons, and infotainment systems, with mid-range models expected to follow suit as costs decline. This emerging application could add over 150 million potential sensor placements annually by 2027, representing one of the fastest-growing segments outside mobile devices.

The industrial IoT sector offers another promising avenue, particularly for ruggedized sensor solutions. Manufacturing facilities, warehouses, and logistics operations require durable authentication systems that function in harsh environments where gloves, moisture, or contaminants render conventional sensors ineffective. Specialized industrial-grade fingerprint modules command significantly higher ASPs than consumer variants, providing manufacturers with much-needed margin improvement opportunities.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=108070

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Fingerprint Recognition Sensor Chip Market?

Which key companies dominate this market?

What drives market growth?

Which region leads in adoption?

What are emerging technology trends?

Related Reports:

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Revolutionizing Industrial Operations with Cutting-Edge Display Technology

The Growing Demand for Advanced Display Solutions In today’s rapidly evolving industrial landscape, the need for reliable and robust display systems has never been more critical. As industries embrace automation, digitization, and the Industrial Internet of Things (IIoT), devices like the panel pc and the industrial monitor are becoming indispensable tools on factory floors and within control rooms. Designed to withstand harsh environments while offering seamless user interaction, these technologies are redefining how businesses operate in manufacturing, logistics, and process control. Both a panel pc and an industrial monitor bring efficiency and resilience to operations that require continuous, high-performance functionality.

Understanding the Role of Panel PCs in Industrial Automation A panel pc serves as an all-in-one computing device that integrates a touchscreen with powerful internal hardware, all encased in a compact and rugged enclosure. These devices are widely used in sectors such as automotive manufacturing, pharmaceuticals, and food processing due to their ability to perform complex computations while withstanding dust, moisture, and extreme temperatures. Unlike conventional computers, panel PCs are optimized for long-term use in demanding conditions. Their integration into machinery and workstations allows for real-time monitoring, data input, and machine control, improving productivity and reducing downtime.

Why Industrial Monitors Are Crucial for Modern Workflows An industrial monitor differs from standard consumer displays by its enhanced durability and flexibility. These monitors are specifically built to endure physical impacts, temperature fluctuations, and continuous usage. With industrial monitors, engineers and technicians have a clear, high-resolution interface to oversee processes, visualize data trends, and interact with automation systems. Whether mounted on a control panel or used as part of a larger system, industrial monitors ensure reliable performance across various operational scenarios. Their adaptability and compatibility with different interfaces make them an essential component in any technologically advanced facility.

Integration of Panel PC and Industrial Monitor in System Architecture When used together, a panel pc and an industrial monitor create a cohesive and efficient control environment. The panel PC offers computation and input capabilities, while the industrial monitor provides an extended or alternative display for better visualization. This combination allows for distributed control systems and multi-user interfaces, enhancing workflow efficiency and safety. By supporting different operating systems and connectivity protocols, these devices can seamlessly integrate into existing infrastructures, making upgrades and scalability much easier for industrial organizations.

Technological Advancements Driving Performance and Reliability The evolution of both panel PCs and industrial monitors has led to significant improvements in processing power, touchscreen responsiveness, and energy efficiency. Many panel PCs now come equipped with fanless cooling systems, solid-state drives, and capacitive multi-touch displays, ensuring quiet operation and longevity. Industrial monitors, on the other hand, offer wider viewing angles, anti-glare coatings, and customizable screen sizes, making them suitable for different user requirements. The use of high-grade materials in their construction also guarantees resistance to corrosion, vibration, and electromagnetic interference.

Industries Benefiting from Rugged Display Solutions Numerous industries have adopted these ruggedized technologies to streamline their operations. In the transportation sector, they are used for fleet management and scheduling systems. The oil and gas industry uses them in exploration and monitoring equipment, where precision and safety are paramount. In logistics and warehousing, panel PCs help manage inventory through barcode scanning and order tracking. Industrial monitors play a critical role in monitoring conveyor belts, robotic arms, and quality assurance systems. These technologies are also being used in smart city infrastructure, where dependable performance is key to managing public utilities and surveillance.

Selecting the Right Panel PC and Industrial Monitor for Your Application Choosing the appropriate panel pc or industrial monitor requires a detailed understanding of the specific environmental and functional needs of your facility. Factors such as screen size, mounting options, touch technology, and input/output configurations should be evaluated. Additionally, compliance with industry-specific certifications and standards is essential for ensuring safety and interoperability. Working with a trusted provider like GDCompt ensures you receive devices tailored to your operational requirements and long-term goals.

Driving Digital Transformation with Reliable Display Equipment As industries continue to digitize and modernize their systems, the demand for high-quality display solutions like the panel pc and the industrial monitor will keep rising. Their contribution to improving operational efficiency, reducing human error, and ensuring real-time data access cannot be overstated. Businesses that invest in these technologies position themselves at the forefront of innovation, ready to face both current and future industrial challenges with confidence.

0 notes

Text

AUO TFT LCD – Best Display Solution for Industrial & Commercial Use

In today’s digital and industrial world, the demand for reliable and high-performance display technology is rapidly growing. One of the most trusted names in this field is AUO TFT LCD. Whether you're building industrial equipment, medical devices, or consumer electronics, AUO TFT LCD displays offer a proven solution that combines quality, performance, and longevity.

If you are looking for a reliable distributor of AUO TFT LCD displays in China or globally, Shenzhen Longwin Technology Co., Ltd. is your trusted partner.

What is AUO TFT LCD?

AUO TFT LCD stands for AU Optronics Thin-Film Transistor Liquid Crystal Display. AU Optronics (AUO) is one of the leading global manufacturers known for their innovative and high-quality LCD panels.

High resolution and color accuracy

Wide viewing angles

Excellent sunlight readability

Long operating life

Energy efficient

Available in sizes from 1.3” to 32”+

Explore a wide range of AUO TFT LCD products on their official website.

Industrial Applications of AUO TFT LCD

AUO TFT LCD displays are widely used in:

Industrial control systems

Smart kiosks and vending machines

Automotive dashboards

Medical monitors and diagnostic tools

ATM machines and POS systems

Check out all AUO TFT LCD modules at Shenzhen Longwin’s website.

Why Choose Shenzhen Longwin for AUO TFT LCD?

Shenzhen Longwin Technology Co., Ltd. is an authorized distributor of AUO TFT LCD products, offering:

100% original AUO modules

Custom touch panel integration

OEM/ODM services with logo support

Technical assistance and fast delivery

Global shipping at competitive pricing

For premium quality AUO TFT LCD displays, contact Shenzhen Longwin today.

Custom Solutions for AUO TFT LCD

Shenzhen Longwin also provides customized services such as:

Custom screen sizes and resolutions

Touch panels with your company logo

Ruggedized displays for harsh environments

Capacitive and resistive touch interfaces

Need tailored AUO TFT LCD modules? Get in touch with Shenzhen Longwin’s expert team today.

Your Trusted AUO TFT LCD Distributor in China

When sourcing AUO TFT LCD China products, Shenzhen Longwin is the name you can rely on for authenticity, quality, and service.

Start your journey with Shenzhen Longwin Technology Co., Ltd. today!

1 note

·

View note

Text

LCD Laminating Machine: The Ultimate Guide to Precision Display Manufacturing

The LCD laminating machine is a critical piece of equipment in the production of high-quality display panels. Used in smartphones, tablets, televisions, and automotive displays, this machine ensures flawless bonding between layers, enhancing durability and visual performance. This guide explores the working principles, types, applications, and benefits of LCD laminating machines, providing a comprehensive understanding of their role in modern display manufacturing.

What Is an LCD Laminating Machine?

An LCD laminating machine is a specialized device designed to bond multiple layers of an LCD panel together under controlled pressure, temperature, and vacuum conditions. The process eliminates air bubbles, dust particles, and misalignments, resulting in a seamless and durable display.

Key Components of an LCD Laminating Machine

Vacuum Chamber – Removes air to prevent bubbles during lamination.

Heating System – Activates adhesive materials for optimal bonding.

Pressure Mechanism – Ensures even distribution of force across the panel.

Alignment System – Precisely positions layers to avoid misalignment.

Control Panel – Allows operators to adjust parameters like temperature, pressure, and time.

How Does an LCD Laminating Machine Work?

The lamination process involves several precise steps:

Layer Preparation – The LCD panel, touch film, and protective cover are cleaned to remove contaminants.

Adhesive Application – Optical Clear Adhesive (OCA) or Liquid Optically Clear Adhesive (LOCA) is applied.

Alignment – Layers are carefully positioned to ensure perfect overlap.

Vacuum Sealing – The assembly is placed in a vacuum chamber to remove air pockets.

Heat and Pressure Bonding – Controlled heat and pressure activate the adhesive, creating a permanent bond.

Curing – UV light or heat is used to fully harden the adhesive.

This process ensures a bubble-free, high-clarity display with enhanced touch sensitivity and durability.

Types of LCD Laminating Machines

Different applications require specific types of LCD laminating machines. The main categories include:

1. Manual LCD Laminating Machines

Operated by hand, suitable for small-scale production or repairs.

Cost-effective but less precise than automated systems.

2. Semi-Automatic LCD Laminating Machines

Combines manual loading with automated lamination.

Ideal for medium-scale production with moderate precision.

3. Fully Automatic LCD Laminating Machines

Fully automated with robotic handling and precision alignment.

Used in high-volume manufacturing for smartphones and tablets.

4. OCA vs. LOCA Laminating Machines

OCA Laminators use pre-cut adhesive films for dry bonding.

LOCA Laminators apply liquid adhesive, requiring UV curing for a bubble-free finish.

Applications of LCD Laminating Machines

The LCD laminating machine is essential in various industries:

1. Consumer Electronics

Smartphones, tablets, and laptops require flawless display bonding for touch sensitivity and durability.

2. Automotive Displays

Dashboard screens and infotainment systems must withstand vibrations and temperature changes.

3. Medical Devices

High-precision displays for diagnostic equipment rely on bubble-free lamination.

4. Industrial Control Panels

Rugged displays for machinery need strong lamination to resist harsh environments.

Benefits of Using an LCD Laminating Machine

Investing in a high-quality LCD laminating machine offers several advantages:

1. Improved Display Quality

Eliminates air bubbles and dust, ensuring crystal-clear visuals.

2. Enhanced Durability

Strong bonding prevents delamination from impacts or temperature fluctuations.

3. Increased Touch Sensitivity

Proper lamination ensures smooth touch response in capacitive screens.

4. Higher Production Efficiency

Automated machines reduce labor costs and increase output consistency.

5. Reduced Defect Rates

Precision alignment and vacuum sealing minimize rework and waste.

Choosing the Right LCD Laminating Machine

Selecting the best LCD laminating machine depends on production needs:

1. Production Volume

Small workshops may prefer manual or semi-automatic machines.

Large manufacturers should opt for fully automated systems.

2. Adhesive Type

OCA is easier to handle, while LOCA offers better optical clarity.

3. Precision Requirements

High-end displays need machines with advanced alignment systems.

4. Budget Considerations

Manual machines are affordable, while automated systems require higher investment.

Maintenance and Troubleshooting Tips

To ensure long-term performance of an LCD laminating machine, follow these best practices:

1. Regular Cleaning

Keep the vacuum chamber and rollers free from adhesive residue.

2. Calibration Checks

Periodically verify alignment and pressure settings for accuracy.

3. Adhesive Quality Control

Use high-grade OCA/LOCA to prevent bonding failures.

4. Common Issues & Solutions

Bubbles in Display → Check vacuum pressure and adhesive application.

Misaligned Layers → Recalibrate the alignment system.

Weak Bonding → Adjust temperature and curing time.

Future Trends in LCD Lamination Technology

The LCD laminating machine industry is evolving with new innovations:

1. Flexible Display Lamination

Machines capable of bonding foldable and rollable screens.

2. AI-Driven Quality Control

Automated defect detection using machine learning.

3. Eco-Friendly Adhesives

Development of sustainable bonding materials.

4. Faster Curing Methods

Advanced UV-LED systems for quicker production cycles.

1 note

·

View note