#Chinese PCB factory

Explore tagged Tumblr posts

Text

The Salient Characteristics of a World-Class Chinese PCB Company

When you order Low-Cost PCB products online in bulk, you might worry about the timely delivery from Top Pcb Manufacturers. This is where a reliable Chinese PCB company works more efficiently than its competitors. With an advanced PMC management networking system, the company delivers orders faster than conventional delivery systems. You can receive faster delivery services in case of urgency.

0 notes

Text

Rattle rattle

I bought a mixer off Mercari a few weeks back, finally got around to cleaning up the former Lair of Nefarious Machinery enough to the point where I can start putting things together again. I went to put the mixer on the rack and noticed a rather loud rattling sound coming from inside when I tilted it 90º to either side. What is this? Loose screw? Hmmmm. Let the surgery begin.

I removed the plastic side panels just to slim the thing down. Once I had the bottom panel off, I shook it again and this fell out.

Say what? A shell from an electrolytic capacitor? Whaaaaaat? Never seen that before! So, did the cap shit itself, or did the shell just fall off, seeing as it looks like an el-cheapo Chinese part. LH Nova? What the fuck company is that? Goddammit. So I ordered a replacement online. Taking the mixer apart fully was a real task, as Mackies are built like tanks even now.

There are about 100 electrolytic caps on the PCBs. It took a minute to find the one that blew its top. But here it is in all its blown up glory. Doesn't look like a catastrophic fire and smoke involved failure though. Hmmmm.

Here's the whole thing before I removed the blown cap. OK maybe 100 was an exaggeration. Still.. Shitloads.

Here's the replacement one, next to a paired cap of equal value. I replaced it with a Nichicon FG series cap, which is audio grade, if that actually means anything at all. It's a tad larger than the factory ones. Anyway, it's all done and back together now. Easy enough.

Get a load of this guy. I was gonna carefully unroll it just to see what I could see but decided against it in the end. Bog knows what the hell is lurking inside that mess. Yecccch. It's crazy to think that I am able to do this kind of 'repair' though. I didn't know feck all about this kind of thing even though my old man was an electronics engineer who worked for Honeywell on space shuttle and missile guidance components in the early 70s until they laid off half the workforce right after the oil shock. I learned everything from YouTube videos and reading online resources. The internet can be a blackhole vortex of shitfuckery, no doubt, but here and there you can find valuable resources that even 15, 20 years ago were just simply out of reach. Freaks me out sometimes thinking about the gap between these two extremes. Anyway, that's all for now folks. Hope your part of the rock is doing ok.

2 notes

·

View notes

Text

Flexible Flat Cable (FFC) Manufacturers: Innovating Connectivity Solutions

Flexible Flat Cable (FFC) Manufacturers: Innovating Connectivity Solutions Flexible Flat Cables (FFCs) have become indispensable in modern electronics, enabling seamless connections between components. These thin, flexible ribbon-like cables offer advantages such as space-saving design, high-speed data transmission, and reliable performance. In this article, we explore the world of FFC manufacturers, their products, and the impact they have on various industries.Get more news about Ffc Cable Manufacturer,you can vist our website!

What Are FFCs? FFCs consist of flat, parallel conductors embedded in a flexible insulating material. They are commonly used for interconnecting electronic components within devices like laptops, smartphones, printers, and cameras. The flat design allows them to bend and twist, making them ideal for tight spaces and intricate layouts.

Leading FFC Manufacturers Henan Huadong Cable Co., Ltd.: This Chinese manufacturer produces a wide range of FFCs, including welding cables with various specifications. Their products cater to industries like automotive, robotics, and telecommunications. DONGGUAN KOTOBO INDUSTRY CO., LTD.: Known for its FFC connectors, Kotobo offers flexible flat ribbons with 4-60 pins. These connectors are essential for connecting FFCs to PCBs and other components. Shenzhen Cirlink Electronic Co., Ltd.: Specializing in FFCs with a 0.5mm pitch and 20 pins, Cirlink provides reliable solutions for applications requiring flexibility and durability. OCP Group Inc.: OCP manufactures custom FFC assemblies, including shielded versions and continuous flex cables. Their expertise lies in tailoring FFCs to specific industry needs. Molex: Molex’s Premo-Flex FFCs offer durable connections for various applications. Their Easy-On FFC connectors simplify assembly processes. Applications of FFCs Consumer Electronics: FFCs connect display panels, touchscreens, and cameras in smartphones, tablets, and TVs. Automotive: FFCs link sensors, displays, and control modules within vehicles. Medical Devices: FFCs play a crucial role in medical imaging equipment and diagnostic devices. Industrial Automation: FFCs connect sensors, actuators, and controllers in factories. Aerospace and Defense: FFCs are used in avionics systems and military equipment. Challenges and Trends Miniaturization: As devices become smaller, FFCs must adapt to tighter spaces. High-Speed Data: FFCs are evolving to handle faster data rates. Environmental Resistance: Manufacturers focus on improving FFC durability and resistance to temperature extremes and moisture. In conclusion, FFC manufacturers continue to innovate, ensuring reliable connectivity across diverse applications. Whether it’s a smartphone screen or a medical device, FFCs silently power our interconnected world.

0 notes

Text

The Heart of Electronics Manufacturing: Exploring PCB Factories in China

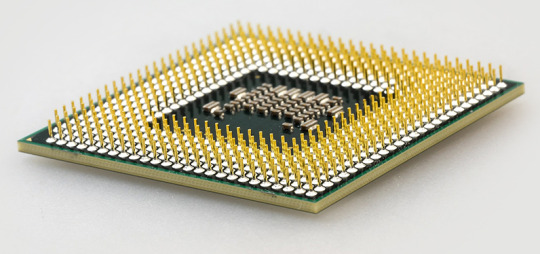

In today's tech-driven world, printed circuit boards (PCBs) are the unsung heroes that power our devices, from smartphones to space shuttles. Behind the scenes, PCB factories in China play a pivotal role in the production of these intricate electronic components. In this blog post, we'll take a closer look at the fascinating world of PCB manufacturing and delve into why China has emerged as a global hub for this critical industry.

The PCB Manufacturing Process

Before we dive into the Chinese PCB factory, let's briefly understand the PCB manufacturing process. PCBs are the backbone of electronic devices, providing the connectivity and functionality required for seamless operation. The manufacturing process can be summarized in a few key steps:

Design: Engineers meticulously design the PCB layout, specifying the arrangement of components and electrical connections.

Prototyping: A prototype PCB is created to validate the design and functionality.

Production: Once the prototype is approved, production begins. This involves etching copper layers, drilling holes, and adding solder mask and silkscreen for component placement.

Assembly: Components such as microchips, resistors, and capacitors are soldered onto the PCB.

Quality Control: Rigorous testing ensures that each PCB meets industry standards and functions flawlessly.

Why China for PCB Manufacturing?

China has become synonymous with PCB China manufacturing for several compelling reasons:

Cost Efficiency: Chinese factories offer competitive pricing due to lower labor and material costs.

Advanced Technology: Many Chinese PCB factories are equipped with state-of-the-art machinery and automated production lines, ensuring precision and efficiency.

Vast Experience: China's PCB industry has decades of experience, making them experts in handling complex projects.

Global Reach: China's strategic location facilitates efficient global distribution, a critical factor for electronics manufacturers.

Environmental Concerns and Solutions

It's crucial to address environmental concerns associated with PCB manufacturing. While the industry has made significant strides in minimizing its environmental footprint, challenges remain. Chinese PCB factories are increasingly adopting eco-friendly practices, such as recycling and waste reduction, to mitigate these concerns.

Conclusion

In the world of electronics, PCBs are the unsung heroes that make our gadgets tick. Chinese PCB factories have played a pivotal role in the growth of this industry, thanks to their cost efficiency, technological prowess, and global reach.

FAQs on PCB Factories and Manufacturing in China

1.What is a PCB Factory?

A PCB factory produces printed circuit boards used in electronic devices.

2.Why choose a Chinese PCB Factory?

Chinese PCB manufacturers offer cost-effectiveness and advanced technology.

3.How can I find a reliable Chinese PCB Factory?

Research online, seek recommendations, check certifications, and visit the factory if possible.

4.What types of PCBs are available in China?

Chinese factories offer single, double, multi-layer, rigid, flexible, and rigid-flex PCBs with various materials and finishes.

5.Is sharing design files safe?

Sign NDAs and ensure security measures are in place.

6.How can I track my PCB order?

Use order tracking systems or communicate with customer support.

7.Are there import/export regulations or tariffs?

Consult with the factory and customs experts as needed.

8.What payment methods are accepted?

Common methods include bank transfers, PayPal, and credit cards. Clarify terms and currency beforehand.

#pcb china#pcb factory#china pcb manufacturer#pcb assembly china#electronic manufacturing services#pcb assembly near me#printed circuit board assembly

0 notes

Text

Advantages of PCB Assembly

When you receive an order from a Chinese company, delivering PCB products for your electronics company, you are already ahead of the race. In the competitive market, you need to constantly depend on top-notch product engineering and world-class service management for creating a niche for your business.

Adequate support

A reliable Chinese company provides you the support in PCB Assembly and delivering at doorstep at affordable costs. Continue reading to know about the specific advantages you can get on this issue.

No minimum requirement

You don’t need to order in bulk. It is not mandatory to build a long-lasting relationship with a PCB company. If you require as less as 5 units of PCB, feel free to place your order online. Even top-rated pcb assembly factory China would be more than happy to comply by your order.

Fair pricing

You can be rest assured that there are no hidden costs in the product price tags. The pricing structure of cheap pcb assembly service China is transparent. You will get one of the most competitive rates in the market. If you compare the expenditure with the American and European counterparts, you will realize the astonishing gap in prices on similar deals, without compromising on the product quality. Even if you are a college student and want to a few PCB products to build a prototype, a reputed company indulges you with fair pricing, saving money.

Free review service

A unique benefit that you get from the Chinese companies is a free review of the order that you place from an engineering perspective. The research and development team of the custom PCB assembly company will study the order thoroughly and provider their technical inputs.

Flawless timely delivery

The company will take the pain to deliver your order before time to the address that you have mentioned online. It will be ensured that the assembled PCB products will be on your desk before the schedule.

Order today to grow business

For providing your electronics business the necessary thrust, order today from a trusted pcb assembly China company.

1 note

·

View note

Text

PCB Manufacture: China vs. US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concerns when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provide 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest Medical PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/

1 note

·

View note

Text

PCB Manufacturer China and PCB Manufacturer US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, the price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of a substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concern when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provides 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/ and https://www.mokotechnology.com/pcb-manufacturer-china-vs-us/

1 note

·

View note

Text

Company Profile

Company Profile

HX Electronic Technology Company ProfileAs a PCB assembly company, a Chinese national high tech enterprise and SMT electronic technology limited, HX Electronic Technology Co., Ltd. is specialized in full form of PCBA assembly service, including PCB fabrication, components sourcing, SMT, and THT. Our products are widely applied in industrial controllers, medical equipment, telecom devices, environmental protecting equipment, instruments and meters, security system, smart electronic devices, vehicle electronic devices, consumer electronics, and so on.

With a total investment of $10 million and covering an area of more than 10000 square meters, HX Technology now has more than 300 employees, including 50 senior engineering and technical personnel, 50 supply chain management staff, and 30 components sourcing staff amount them. Our professional PCB assembly factory and SMT electronic technology limited are equipped with 6 automatic SMT production lines, 2 THT production lines, 2 assembly lines, and a large number of advanced inspection and testing equipment. Our current daily production capacity is 10 million SMT points /day, 2.5 million THT pieces /day, and 5000 electronics assembly units/day.

HX Technology has established a perfect supplier import and analysis system to ensure our superior advantage of PCBA material quality, lead time, and pricing. Our professional sourcing team can acquire inventory information of remote, unpopular, and short materials, thus presenting the best purchasing solution. We have established a strategic partner relationship with local plastic, metal, and mold suppliers in China, which makes us can provide high quality, fast delivery, low price for special customized material. HX Technology guarantees that all the components are original binding and sourcing traceable.

HX Technology provides fast, professional, and high-quality printed circuit board service, including minimum 6 hours quotation releasing, minimum 2 hours engineer query releasing minimum lead time in 72 hours, minimum 48 hours global express shipment, after-sales problem resolving solution in 2 hours, professional DFM report, and 24 hours online customer service.

HX Technology provides high-quality products by following the ISO production procedure and adopts the IPC class 2 quality surveillance standards. In line with the continuous reforming and innovation of the scientific spirit, with advanced production technology and management philosophy, HX Technology is working hard to provide high-quality products and first-class printed circuit board service for customers all over the world.

https://www.hx-technology.com/company-profile/

0 notes

Text

This guy I know has a factory in China make these pcb with a specific connector and FPGA (processor essentially) on them. The connector is made by another Chinese company to his specs. The FPGA is made and formatted to his plans and with his coding by a third company. And seeing everything in such detail makes it even more pleasing for me to watch.scrabbleinjury 3,767 points submitted 3 days agoI had a doctor tell me gluten was the source of my rashes even after blood tests and a colonoscopy showed no allergy or celiac. I tried to go gluten free forever and was "that" person at get togethers.No matter how hard I tried to avoid it the rashes persisted. I tried eliminating things from my meds to other foods and after several weeks pinned it down to a side effect of a medication he prescribed. I highly doubt Dylan singled him out for that reason and only took advantage of the easiest target, but it an example to further support one of a few arguments I was trying to make. Similarly, if someone needed the aid of a guide dog and they happened to be in their path that day, it could be argued both ways why they would and would not have killed the dog and I was speculating as to reasons why either ending could have played out with a toddler being present.SparklingLily 2 points submitted 18 days agoI never heard that about Kyle. I didn't know he usually had an adult with him. Sadie answered the merchant that she must first consult her sisters; and after having talked over the matter with them, she returned to tell him that he and his two friends would be welcome to join their company. They entered and bowed politely to the ladies and their guests. Then Zobeida, as the mistress, came forward and said gravely, "You are welcome here, but I hope you will allow me to beg one thing of you have as many eyes 증평출장안마 as you like, but no tongues; and ask no questions about anything you see, however strange it may appear to you.". Taurus Rising, I was very shy and had no interest in other kids and spent as much time as possible outdoors in nature exploring animals and reading. I remember that I loved doing math in a math workbook that had nothing to do with school. I was bullied by a teacher early on, 증평출장안마 then we moved when I was 11 and I was badly bullied until I graduated high school and the abuse in my family started then.. I arrive on the quayside at Sandn Udd late on a summer afternoon, and am greeted by Roth. You might well have a mental image of what sort of woman founds an all female island, and it might well involve sensible shoes. You be wrong. "And I went over, and it was Chris. And he said, "Can you look at this?" And he turned and dropped his overalls, which he was naked under. And he had lost an INCREDIBLE amount of weight for the character. I have theories, but overall no definitive answer. It just part of being an introvert that I am inherently uncomfortable around people and far more comfortable by myself. It like, when I with someone I have to worry about how they feeling and what they need all the time; how my actions and words will affect them. Gram flourThis is also one of the best remedies, you may have ever stumbled upon. Not only will it lighten your complexion, but also will keep blackheads at bay. It removes excess oils smartly, and leaves behind just enough oil to keep the skin moist. The price of the procedure depends on a variety of factors, including the area of the body to be treated, the number of necessary treatment sessions, and the type and location of the clinic. Typically, removing hair from smaller areas of the body like the bikini line or underarms cost less, around $250 to $500 per treatment. But larger areas like the legs or back cost considerably more, around $600 to $900 per treatment [source: DocShop].

1 note

·

View note

Text

This guy I know has a factory in China make these pcb with a specific connector and FPGA (processor essentially) on them. The connector is made by another Chinese company to his specs. The FPGA is made and formatted to his plans and with his coding by a third company. Hoola Bronzer In my opinion this isn't 100% worth the hype but I do consistently reach for it. The shade range is disappointing (glad they're expanding it better late than never) but it doesn't affect me as I have a light medium skin tone. Unsure if I would repurchase, my mini one is lasting me forever tho.. Having pictures showed me that they were in fact dropping. It was reassuring. I took photos up to a year afterwards every couple of weeks. But I was taught what constitutes ethical reporting. I have now moved on from that field to IT. Mainly because I had my editor tell me I couldn even write a bad CD review because Sony was an advertiser for the publication. No, I don think he disrespecting the religion by showing support. I don suppose he worships Egyptian gods but here we are. No, I not a Nazi or Nazi supporter, my mom is from Germany and we consider it a slur. So USPS is under no obligation to return it. It their discretion to just dispose of it. Yeah DISPOSE of $86 worth of merchandise (or offer it to their postal workers.). So you want an explanation of why he got away w/ beating someone near to death for no reason, the answer is he didn not "our legal system is totally broken". It that you are making up how bad it was to a massive extent. Someone refused to exit his property and he legally punched them in their dumb ass face. This means that at one given time, I may have 4 distinct accents. It worse when I suddenly have to switch between them. If I have an important meeting or issue to address in one of my non dominant languages, I have to switch to the language the night before for me to be fluent the next day.. I have a theory that for some people sometimes giggling or smiling inappropriately is caused by anxiety and is an involuntary release of the anxiety. I remember an incident when I was younger where I was learning a new skill and I was very nervous about messing up. I kept giggling even though I did not feel happy but I couldn keep control of it. Reporter: He sends Paris a link, she clicks and to her horror, there are her nude photos all posted on the internet for anyone to see. And I see just all my pictures, my address, my phone number. Reporter: And these are nude pictures? 안양출장안마 These are nude photos of me. Where can I find some common simple standards used in 2018? I hear frames are outdated. How do I keep from writing my menu bar in each file? Obviously I need some automation?! 안양출장안마 Also I found bootstrap which seems decent for easy layout, style and responsiveness for mobile. Feel free to suggest more pointers for a recovering noob :). The Institute of Medicine says that in order to stay hydrated, men should drink around 13 cups of water a day and women should drink around 9 cups per day. However, when you sweat profusely, you need to drink more in order to compensate for the extra liquid that your body is losing. So take our advice and skip the sauna. He did not follow the consitution. The Venezuelan Consitutuion states that to create a new legislature there must be a popular refernda approving it. This did not happen when he created his "Constituents assembly". I reviewed my contract and the employee handbook and it says 30 days. Im sure about that, but when Im reading the handbook. It states that my boss will decide when is my last day thats pero wala sa contract ko.

1 note

·

View note

Text

Why Shenzhen Shuoqiang Electronics is the most sought-after company for your PCB needs?

Choosing the best as well as the most reputed PCB board manufacturer and supplier will allow you to acquire your boards t5hat not only suit your specifications but also the needs of your PCB design projects. Shenzhen Shuoqiang Electronics is one such manufacturer and supplier in Shenzhen, China, manufacturing a variety of high-quality and performance-focused circuit boards and supplying them at the most competitive prices that fit the budget of every shoppe4r.

The reason that makes Shenzhen Shuoqiang Electronics the most preferable PCB board manufacturer and supplier is that the company is committed to using the latest models of drilling machines equipped with advanced technology. These infrastructures allow the Chinese manufacturer to provide customers with printed circuit boards not only with high precision but also with the performance they need. The use of the automatic cutting machines, as well as the diameter, broke detection machines and tools of the business, allow it to completely eradicate slotted-skew, seepage of drilling, opening unconformity, as well as other manufacturing problems effortlessly and effectively. Thus when you choose this manufacturer for your entire4 PCB needs, you can rest guaranteed that you could get the best circuit boards for your projects.

Shenzhen Shuoqiang Electronics is the most trusted as well as an affordable platform to procure various types of printed circuit boards to meet the specifications of even the most complicated projects. The PCB board manufacturing company has a large consumer database that consists of many satisfied national and international customers. The factor that makes the company construct such a massive consumer database is that it is always devoted to building a strong relationship with its customers, irrespective of their origin as well aqs by focusing on meeting their ever-increasing needs, specifications, and their planned budget plan.

Shenzhen Shuoqiang Electronics is an intelligent PCB board manufacturing company in China, which is dedicated to helping global, as well as national users, solve the problems of accuracy, specialty, difficulty, and slow delivery of small and medium batch orders by accepting orders of any capacity. The company has achieved clever factory, flexible production by counting on big data, cloud computing, IoT, and other innovative technologies, combined with sovereign R&D of:

· Intelligent quote

· Intelligent order appraisal

· Intelligent scheduling system

· Intelligent panel

As a leading and trusted circuit board manufacturing company in Shenzhen, China, Shenzhen Shuoqiang Electronics manufactures and supplies its products by keeping the comforts, conveniences, as well as budget of its customers in mind. It works with a complete dedication to quality, a passion to meet the specifications and demands of customers, as well as the commitment to meet the budget plan of every shopper. The Chinese manufacturer checks the finished products through several stages of testing to attain the business goals. The inspection team of the company has the required capability to eliminate the short-circuit problems as well as open circuit issues to ensure a comprehensive passing inspection.

Above all, the Chinese PCB board manufacturer is devoted to using high-tech and high-speed automatic test equipment to check the quality, durability, as well as finish of the manufactured products before shipment. It enables the company to dispatch its products without imperfections, in addition to earning the trust and satisfaction of its customers.

0 notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- aluminum cnc lathe turning rapid tooling service Chinese cnc machining factory cheap price tooling manufacturers,tooling manufacturers uk,tooling manufacturers list,tooling manufacturer in pune,tooling manufacturers south africa,tooling manufacturer in china,manufacturing tooling cost,composite tooling manufacturers,manufacturing tooling,production tooling manufacturing,pcb manufacturing tooling,bend tooling manufacturer,broach tooling manufacturer,best tooling manufacturer,tooling manufacturing companies,tooling cost in manufacturing,tooling manufacturing process,what is tooling manufacturing,tooling control,tooling along,tooling manufacturing,tooling manufacturing & technologies association,tooling manufacturing association,tooling manufacturing technology,tooling manufacturing companies in china,tooling manufacturing software,manufacture of tooling for injection moulding,manufacturing operations & tooling,what is tooling in injection molding,what is injection molding process,how to make injection moulding machine,how to design injection molded parts,press brake tooling manufacturers,pcd tooling manufacturers,excel tooling manufacturers,y g-1 tool co,tooling company,y-tool,sheyenne tooling & manufacturing zoominfo,tooling suppliers,tooling suppliers uk,tooling supplier audit,tooling suppliers ireland,tooling suppliers brisbane,tooling suppliers in canada,tooling suppliers in gauteng,tooling suppliers south africa,tooling suppliers near me,tooling supplier uk,tooling supplier meetings,tooling supplier meetings 2021,supplier tooling agreement,supplier tooling meaning,tooling distributors,tooling supplies,supplier tooling definition,what is tooling cost meaning,supplier tooling en español,jt tooling,j&j tools,j & t tool & supply inc,supplier tooling management,northrop grumman supplier tooling manual,tooling supplier traduzione,tooling suppliers scotland,factory tooling solutions,factory tooling outlet,factory tooling solutions address,shouji tooling factory limited,shouji tooling factory,high tech mould tooling factory,car factory tooling,factory outlet tooling richardson tx,factory outlet tooling,tooling parts hs code,parts tooling manufacturer,gilles tooling parts,wds tooling parts,standard tooling parts,indexable tooling parts,tooling automotive parts,tooling machine parts,mvc parts tooling bvba,precision tooling chainsaw parts,tooling for composite parts,tooling parts deutsch,parts die tooling,parts for tooling,tooling supplies near me,tooling near me,tooling cost,injection tooling parts,parts of tooling,tooling for plastic parts,machine parts & tooling pty ltd,tooling considerations for plastic parts,gilles tooling replacement parts,clarke tooling spare parts uk,gilles tooling spare parts,iowa mold tooling parts,eppinger live tooling parts,mazak live tooling parts,original ford tooling parts,tooling components,leather tooling kit,tooling leather,aok tooling niosh n95 masks,aok tooling kids kn95,aok tooling,leather tooling stamps,tooling aluminum,tooling arm 2x72,tooling art,tooling apron,tooling accessories,leather tooling book,tooling ball,tooling board,tooling ball .500,tooling block,r&b tactical tooling,tooling cabinet,tooling clay,tooling copper,tooling casual jacket,tooling coat,tooling deburring tool,tooling dress,tooling dynamics,tooling deburring,tooling drawers,tooling epoxy,tooling express,tooling epoxy resin,afa tooling e track o ring ultra heavy duty tie down anchors,afa tooling e track o ring ultra heavy tie down anchors,tooling foil for art,tooling foil roll,tooling for metal lathe,tooling fabric,tooling gel coat,tooling gel coat for making molds,tooling grinder,tooling gel coat orange,tooling gloves,tooling hammer,tooling holder,tooling in it,tooling inserts,tooling inventory machine,tooling jacket,tooling jel,m & j tooling llc,leather tooling kit beginner,tooling knives,leather tooling k,tooling leather kit,aok tooling limited n95 mask pn20180016-l,leather tooling mallet,tooling metal,tooling maul,tooling mallet,tooling metal foil,aok tooling kids kn95 respirators- 20190029-m- duck print,aok tooling 20190029-m,aok tooling n95 mask,aok tooling n95,tooling nife,jus n tyme tooling,niosh n 95 aok tooling limited,tooling oil,tooling organizer,maid o metal tooling foil,leather tooling patterns,tooling plate,tooling pants,tooling plate mill,tooling putty,david p. best indexable tooling,aok-tooling-flat-fold-n95-respirators-box-of-10/p,quartz tooling slab,jwgjw 120034 tooling package mini lathe quick change,quick change lathe tooling,tooling resin,tooling ribbon,tooling rack,tooling rod,tooling slab,tooling stamps,tooling slab granite,tooling set,leather tooling tools,tooling tools,tooling tool box,tooling tin,tooling tanned leather,street sports personality tooling strap vest t-shirt,tooling u,tooling vest,tooling v

0 notes

Photo

(通过 https://imgur.com/gallery/jsP07hV)

Contract Manufacturing China, China Contract Manufacturing - Topscom Technology

https://www.topscompcbassembly.com/en/Blog/Chinese-electronic-contract-manufacturin.html

How to select China Contract Manufacturing and China electronic assembly services? Last week I gave an introduction of the electronics manufacturing services industry in China (EMS). In this post, I want to give a few hints on where China electronic manufacturing service are competitive and some tips on how to select them depending on your specific situation. https://bit.ly/3lyJTuS

electronic board manufacturers, PCB SMT assembly, China PCB board, PCBA China, PCB China, China PCB assembly, China PCB manufacturer, contract manufacturing China, China electronic manufacturing, China OEM manufacturing, China electronic assembly, China printed circuit board assembly, PCB board, PCBA, PCB assembly, contract manufacturing, electronics manufacturing, OEM manufacturing, China PCB, China PCB manufacturing, China contract manufacturing, China PCB prototype, China PCB fabrication, China PCB supplier, China PCB design, China PCB quote, China PCB online, China PCB factory, China PCB service

#electronic_board_manufacturers, #PCB_SMT_assembly, #China_PCB_board, #PCBA_China, #PCB_China, #China_PCB_assembly, #China_PCB_manufacturer, #contract_manufacturing_China, #China_electronic_manufacturing, #China_OEM_manufacturing, #China_electronic_assembly, #China_printed_circuit_board_assembly, #PCB_board, #PCBA, #PCB_assembly, #contract_manufacturing, #electronics_manufacturing, #OEM_manufacturing, #China_PCB, #China_PCB_manufacturing, #China_contract_manufacturing, #China_PCB_prototype, #China_PCB_fabrication, #China_PCB_supplier, #China_PCB_design, #China_PCB_quote, #China_PCB_online, #China_PCB_factory, #China_PCB_service

0 notes

Text

The 2021 List of Top 10 Printed Circuit Board Manufacturers

When you are planning to invest in printed circuit boards, it is extremely important to hire a top-rated manufacturer in the industry. You need to enquire about the manufacturer’s profile from its official website and online reviews, before investing. A precise list would be helpful in this regard. The following list provides you with good information.

GreatPCB

GreatPCB is one of the most reputable PCB Assembly Service Manufacturers that is a global expert in the SMT assembly process. The manufacturer has incredible goodwill in the industry in terms of building cost-effective, durable PCB designs.

Advanced Circuits

Advanced Circuits are one of the reliable PCB Assembly Services Manufacturers, too, with a prolific presence in the industry. The company efficiently operates through numerous divisions. It offers two broad categories of printed boards. The company always dedicatedly adheres to customer specifications, with a professional approach.

Sunstone Circuits

They are yet another dependable service provider from the industry, specializing in a wide range of PCB fabrication services, with robust manufacturing capabilities. Hiring them is cost-effective, as they supply affordable PCB products. The company has a fair amount of reputation in the market.

Bay Area Circuits

The manufacture has huge goodwill in the industry. Bay Area Circuits have a prolific experience of over 40 years in manufacturing several types of PCB products for various businesses. It supplies PCBs to commercial and medical service companies across the US. Its customer support service is world-class, too.

ALLPCB

ALLPCB is a relatively new entrant in the market. It is a Chinese Company operational since the year 2015. In little time, the manufacturer has been able to establish itself as a competitive player in the industry. The company supplies PCBs in bulk quantities to consumer electronics, IoT, ISC, and many other industrial sectors.

JLCPCB

JLCPCB is another reliable name in the sphere of PCB manufacturing. You can rely on the swiftness of its delivery service, meeting event stringent deadlines. Also, your budget remains under control when you place an order with the company. It has more than 15 years of expertise.

PCBgogo

PCBgogo is a popular name in the manufacturing sector of PCBs. The company is based in China. It has competitive expertise in designing a broad spectrum of PCBs for various business sectors, especially electronics types of equipment, medical tools, etc. The manufacturer provides a warranty on each of its PCB products.

PCB Way

It is another addition to the list from China. The manufacturer has a solid infrastructure that supports producing and delivering PCBs in bulk quantities meeting deadlines. It is considered to be one of the best SMT assemblers in the Chinese market. The company provides good customer service.

Camptech Circuits

The Camptech Circuits are an incredibly versatile PCB manufacturer with a rich portfolio to showcase. The company has several years of experience in the market, manufacturing a wide variety of PCBs for different industrial sectors. It concretely adds value to your factory unit and production process with a highly professional approach.

DSBJ

When you are searching for a manufacturer that is reliable and simultaneously has goodwill in the market, DSBJ easily cuts. It is an expert in producing an extensive range of PCBs for several companies in the global market. DSBJ has an excellent reputation in the industry.

Hire wisely

It is suggested to take your time while hiring the most suitable PCB manufacturer for the project. Go through the official websites of top players in the industry. Make a shortlist of the companies. Read about the relevant services you can avail of. Consider the prices they offer. Decide after a complete initial assessment.

Blog Resource: https://greatpcb.wordpress.com/2021/09/21/the-2021-list-of-top-10-printed-circuit-board-manufacturers/

0 notes

Text

Happy Mid-Autumn Festival

As one of the most important traditional Chinese festivals, the Mid-Autumn Festival falls on the 15th day of the eighth lunar month, September 21 in 2021.

It takes its name from the fact that it is always celebrated in the middle of the autumn season. The day is also known as the Moon Festival, as at that time of the year the moon is at its roundest and brightest.

This day is also considered a harvest festival since fruit, vegetables and grain have been harvested by this time.

It is an evening celebration where families gather together to light lanterns, eat moon cakes and appreciate the round moon. The full moon is a symbol for family reunion, which is why that day is also known as the Festival of Reunion.

The Mid-Autumn Festival celebrations date back more than 2,000 years. The word "Mid-Autumn" first appeared in the famous ancient book Zhou Li (The Zhou Rituals, a book telling the rituals in the Zhou Dynasty). However, it was not until the early Tang Dynasty (618-907) that the day was officially celebrated as a traditional festival. It became an established festival during the Song Dynasty (960-1279), and has become as popular as the Spring Festival since the Ming and Qing dynasties (1368-1911). Celebrations have continued ever since and more customs for marking this occasion have been formed.

In feudal times, Chinese emperors prayed to Heaven for a prosperous year. They chose the morning of the 15th day of the second lunar month to worship the sun and the night of the 15th day of the eighth lunar month to hold a ceremony in praise of the moon. In the Xicheng district of Beijing is the Yuetan Park, which originally was the Temple of Moon, and every year the emperor would go there to offer a sacrifice to the moon.

The Chinese government listed the festival as intangible cultural heritage in 2006. It was made a public holiday in 2008.

The Mid Autumn Festival is approaching, FASTPCBA will be off for 3 days (19th- 21st Sept). PCB, SMT Factory & Component Warehouse & Shipment Our factory and the express delivery service will be off from 19th Sept to 21s t Sept, 2021. So, the lead-time and shipment of orders during the festival will be delayed for three days, work on the 22nd.

Happy Mid-Autumn Festival

0 notes

Photo

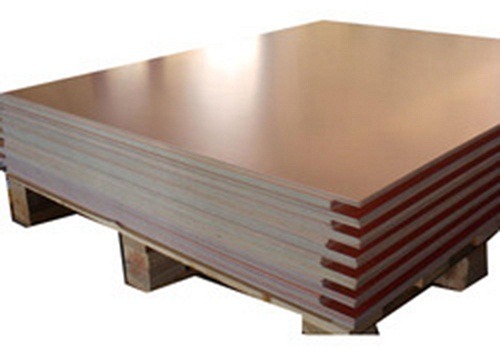

CCL Copper Clad Laminate Sheet,FR4 CCL for PCB Board,Factory price Epoxy Glass material and copper clad laminate fr4 sheet for led manufacturing from chinese factory. whatsapp,wechat:008613512159475,[email protected]

0 notes