#Color 3D printer

Explore tagged Tumblr posts

Text

I am planning on printing this but I want to make sure they are all Star Trek Discovery Badges. I know the top row is but I can't fully remember if the bottom row was.

#star trek#star trek discovery#adiraofthetals somehow has a 3d printer#i only have black white and gray filament so these are the colors we get for now

11 notes

·

View notes

Text

need a slutty little shirt that says "I FUCKING LOVE THE LIBRARY"

#free books movies music endless resources and event spaces for rent AND a 3d printer at some locations!!!!!!!!!!!!!!#the only criticism i have is that they do not have any color printing services#there is like one location in the whole city that does it and its downtown...#sorry not spending 40 mins on transit just to print colour pictures of splatoon characters to display in photocard sleeves around my room#is colour printing really that hard to implement at other branches ik ink is expensive but im willing to pay!!#regular print is a dime per page i'll pay a dollar for colour!! maybe two!!#anything to avoid staples i dont need the employees seeing the shit i want printed also FUCK staples#thispost was about loving the library and i just complained in the tags im so sorry library you are nearly perfect to me in every other way#.ε

6 notes

·

View notes

Text

Lil' Dragon fella :]

#My sister's husband got a 3d printer. and he asked us to send stuff he could print with it.#So I sent some dragons I found on some sites. and he printed this one out.#I love it sm and I might try and color in it's eyes a little :]#my thoughts

9 notes

·

View notes

Text

how to F10 with style

#hades 2#video#trace emoji -> 3d print -> sharpie the black part -> print the keycap -> hot glue#I'd make keyring sizes but that would require a fancier printer that can do dual colors#and I'm not going to ask for fancy printer access to only print my own stuff lol

7 notes

·

View notes

Text

guess who is doing gideon nav for halloween!

#the locked tomb#not a super serious cosplay like i would usually do#like im not getting an actual wig and im not doing resin for the knuckle knives etc.#and the clothes will be stuff i allready own or something i can make in like a day#but i am doing the makeup and glasses (also ive ordered colored hairspray)#and im gonna use my 3d-printer for the rapier#im soooo excited#also i totally worded the post that way on purpose

3 notes

·

View notes

Text

He’s too pretty, he’ll never make it in the wild

#snake#mr snake#snake eyes#snek#rainbow snake#3d printer#3d printing#3d printed#Bambu P1P#rainbow filament#PLA#color shift

4 notes

·

View notes

Text

New 3D printing technique creates unique objects quickly and with less waste

New Post has been published on https://thedigitalinsider.com/new-3d-printing-technique-creates-unique-objects-quickly-and-with-less-waste/

New 3D printing technique creates unique objects quickly and with less waste

Multimaterial 3D printing enables makers to fabricate customized devices with multiple colors and varied textures. But the process can be time-consuming and wasteful because existing 3D printers must switch between multiple nozzles, often discarding one material before they can start depositing another.

Researchers from MIT and Delft University of Technology have now introduced a more efficient, less wasteful, and higher-precision technique that leverages heat-responsive materials to print objects that have multiple colors, shades, and textures in one step.

Their method, called speed-modulated ironing, utilizes a dual-nozzle 3D printer. The first nozzle deposits a heat-responsive filament and the second nozzle passes over the printed material to activate certain responses, such as changes in opacity or coarseness, using heat.

In speed-modulated ironing, the first nozzle of a dual-nozzle 3D printer deposits a heat-responsive filament and then the second nozzle passes over the printed material to activate certain responses, such as changes in opacity or coarseness, using heat.

Credit: Courtesy of the researchers

By controlling the speed of the second nozzle, the researchers can heat the material to specific temperatures, finely tuning the color, shade, and roughness of the heat-responsive filaments. Importantly, this method does not require any hardware modifications.

The researchers developed a model that predicts the amount of heat the “ironing” nozzle will transfer to the material based on its speed. They used this model as the foundation for a user interface that automatically generates printing instructions which achieve color, shade, and texture specifications.

One could use speed-modulated ironing to create artistic effects by varying the color on a printed object. The technique could also produce textured handles that would be easier to grasp for individuals with weakness in their hands.

“Today, we have desktop printers that use a smart combination of a few inks to generate a range of shades and textures. We want to be able to do the same thing with a 3D printer — use a limited set of materials to create a much more diverse set of characteristics for 3D-printed objects,” says Mustafa Doğa Doğan PhD ’24, co-author of a paper on speed-modulated ironing.

This project is a collaboration between the research groups of Zjenja Doubrovski, assistant professor at TU Delft, and Stefanie Mueller, the TIBCO Career Development Professor in the Department of Electrical Engineering and Computer Science (EECS) at MIT and a member of the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL). Doğan worked closely with lead author Mehmet Ozdemir of TU Delft; Marwa AlAlawi, a mechanical engineering graduate student at MIT; and Jose Martinez Castro of TU Delft. The research will be presented at the ACM Symposium on User Interface Software and Technology.

Modulating speed to control temperature

The researchers launched the project to explore better ways to achieve multiproperty 3D printing with a single material. The use of heat-responsive filaments was promising, but most existing methods use a single nozzle to do printing and heating. The printer always needs to first heat the nozzle to the desired target temperature before depositing the material.

However, heating and cooling the nozzle takes a long time, and there is a danger that the filament in the nozzle might degrade as it reaches higher temperatures.

To prevent these problems, the team developed an ironing technique where material is printed using one nozzle, then activated by a second, empty nozzle which only reheats it. Instead of adjusting the temperature to trigger the material response, the researchers keep the temperature of the second nozzle constant and vary the speed at which it moves over the printed material, slightly touching the top of the layer.

“As we modulate the speed, that allows the printed layer we are ironing to reach different temperatures. It is similar to what happens if you move your finger over a flame. If you move it quickly, you might not be burned, but if you drag it across the flame slowly, your finger will reach a higher temperature,” AlAlawi says.

The MIT team collaborated with the TU Delft researchers to develop the theoretical model that predicts how fast the second nozzle must move to heat the material to a specific temperature.

The model correlates a material’s output temperature with its heat-responsive properties to determine the exact nozzle speed which will achieve certain colors, shades, or textures in the printed object.

“There are a lot of inputs that can affect the results we get. We are modeling something that is very complicated, but we also want to make sure the results are fine-grained,” AlAlawi says.

The team dug into scientific literature to determine proper heat transfer coefficients for a set of unique materials, which they built into their model. They also had to contend with an array of unpredictable variables, such as heat that may be dissipated by fans and the air temperature in the room where the object is being printed.

They incorporated the model into a user-friendly interface that simplifies the scientific process, automatically translating the pixels in a maker’s 3D model into a set of machine instructions that control the speed at which the object is printed and ironed by the dual nozzles.

Faster, finer fabrication

They tested their approach with three heat-responsive filaments. The first, a foaming polymer with particles that expand as they are heated, yields different shades, translucencies, and textures. They also experimented with a filament filled with wood fibers and one with cork fibers, both of which can be charred to produce increasingly darker shades.

The researchers demonstrated how their method could produce objects like water bottles that are partially translucent. To make the water bottles, they ironed the foaming polymer at low speeds to create opaque regions and higher speeds to create translucent ones. They also utilized the foaming polymer to fabricate a bike handle with varied roughness to improve a rider’s grip.

Trying to produce similar objects using traditional multimaterial 3D printing took far more time, sometimes adding hours to the printing process, and consumed more energy and material. In addition, speed-modulated ironing could produce fine-grained shade and texture gradients that other methods could not achieve.

In the future, the researchers want to experiment with other thermally responsive materials, such as plastics. They also hope to explore the use of speed-modulated ironing to modify the mechanical and acoustic properties of certain materials.

#3-D printing#3d#3D model#3D printers#3D printing#additive manufacturing#air#approach#artificial#Artificial Intelligence#author#career#career development#Collaboration#Color#colors#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#cooling#desktop#development#devices#effects#Electrical engineering and computer science (EECS)#energy#engineering#fibers#Foundation#Future

0 notes

Text

I've been staring at this too long bro this is yummy I love these

Febuwhump Day 9: Bees “Human” Weapon

“Weapon? I have a whole arsenal now!”

I figured I would continue this prompt!

Poor Jace is off camera peeing his pants. Like Kendra wasn’t scary enough before she brainwashed a 3-D printer for any weapon imaginable.

#poor guy lmao#i love kendra#and the colors???#they're so yummy#goodness gracious#3d printer 😭#a little horrifying :33#/pos#god- woman- women- ww-wwomen- evil- evil women--

3K notes

·

View notes

Text

youtube

HOLY CHRIST, SHE'S A SAINT!!!! THIS VIDEO CARRYS ALL MY WORRIES!! THANK GOD AND ALL THE HIGHER BEINGS ABOVE!!!😇🙏

#I've been researching for so long on crystal making#Some were for 3d printing#Paper modeling with a crap ton of expensive stuff involved#there was just a lot that required expensive purchases#Or shit that take a long time#It's like those tutorials where it states it's easy#but then during the process of the project#they pull out the “WungTong” electrical machine that's “necessary”#or that's the very important essential to the whole project#does it seem like I carry those expensive 3d printers???#Or a big machine for making cosplay??#no!!!#I just want to do this in a simple and productive way#I need to use things that are lying around near me#like the pole that my own dad gave me.#that metal pole was just sitting there#collecting dust in the garage and I'm finally using it for something useful and productive#The fact the staff is already at the shape and color I want it to be is already great#Anyways#so what I can tell from the video#I need clear folder binder sheets or dividers#hot glue gun#scissors#masking tape#Some type of plastic to help create a rustic look when applying the pieces together???#I don't have a hot glue gun but I can get it at the crafting store easily#Especially the plastic folder dividers#But yeah......#I have finally completed the necessary brainstorming on the crystal#wh fantasy au

1 note

·

View note

Text

I think 2024 will have more text musings from me. Idk tho.

But here is one anyways:

The dream would be 3d modeling on pc and producing 3d print works like figurines but painting is legit impossible for me due to health now lol, guess I have to wait until the Statasys PolyJet/BJP patent expires in a decade+, so that consumer level color/transparency/multimaterial printers can become available. $50,000 for the base machine is not affordable lmafo.

Honestly with the rate at which certain tech advances, it truely feels like patents in those specific fields stunt global advancement for decades. Feels criminal.

For things like 3d printers that are able to print with different materials, colors, and transparencies, it could truely save lives and at minimum drastically improve livelihoods, so it is so bizarre that tech like this is gatekept and not shared to be expanded on and innovated on by others.

This is also a problem in the gaming industry, (albeit at less severity, but still ridiculous). Tell me why there was a DECADES long patent on "mini games during loading screens" that was barely even used before it expired? And the nemesis system...

Obviously, patents have a use and can be very important in making sure creators are not taken advantage of or ripped off (in fact it will likely be a saving grace for taking down unethically sourced data for the current scummy unregulated generative ai models out there), but in certain situations like 3d printing it is straight up detrimental gatekeeping that benefits no one.

#text#musings#certified old fart yells at clouds#tell me that 3d printing full color flexible or transparent merch that looks like mold injection quality at home wouldn't be cool as hell.#with the bs 2d ink printers have now with subscriptions and other bs... i am not looking forward#to that monetization model.#designing and wearing 3d printed shoes that accommodate you sounds cool as hell too.#3d printing

1 note

·

View note

Text

i mean the truth is that we do not need and should not have all this stupid plastic clutter in or houses. no one should be producing or selling this shit. everyone make your own merchandise and charge a living hourly wage to sell it 🤷 sorry to be so simplistic about this but it's one of the results of the lack of class unity specifically in the means of production-owning creative class, who is not mentioned or dealt with by the core Marxist texts as far as I know (i asked about this earlier on here, did marx ever address in his analysis people like, for example, a professional photographer who owns a camera ans prints his own dagguereotypes? or a portrait painter or idk, independent milliner or seamstress? these people all own the means of production and do not employ anyone, and the answer from better educated people than I was that no, Marx didn't mention them), I'm not well read on this at all, there is just a big void where leftist analysis of what modern economists call "the creative class"

I'm getting off topic. my point is make your own keychains in your kitchen. it's actually not hard. you can even mass produce (on a small scale) little plastic crap if you want, with resin and a UV lamp, or a 3d printer, or a laser cutter and acrylic sheets (or just use balsa wood damn, at least its biodegradable and less tacky).

all this stuff is available to little creators AND there are hundreds of people who already own these machines who will take work for you and produce your designs. you just have to actually find them and know them and email them. that's what I mean about the class unity issue with creatives. we have no large scale union, we have no large scale class consciousness, and we're all sending our orders for little plastic crap to sweatshops instead of emailing a guy with a laser cutter in his garage and saying "hey Keith can I get uhhhhhhhhhhh 50 laser cut keychains of this twerking Diggler design I made, like how much would that cost" and he's like sure here's the work and materials cost and tbh it's always always less than i think it's going to be. you just have to do some basic arithmetic and then order shipping, and I hate order fulfillment with my life but you can actually pay or barter with someone to do that for you too. learn to delegate and then factor that into your unit cost. this is basic shit every commercial creator needs to know. they should teach you this in art school but they dont

don't give me crap about "I can't afford a laser cutter" either because I just told you to email Keith. and all these machines get sold secondhand when a manufacturer or hobbyist needs to upgrade. i got a color laser printer perfect for making zines and wheatpastes and shipping labels from a retired lesbian on capital hill for $75 and it was still full of ink. my friend gave me her 20 year old canon dslr because she just didn't need it and didn't want to bother selling it. it works fine because I spent the time finding the right drivers and shit for my computer. and card readers exist. Craigslist. Facebook marketplace. nextdoor sales section. eBay. everyone always forgets eBay. eBay lets you save searches and will email you when it finds a guy selling his vinyl plotter in your city with local pickup. I'm serious

#long post#pro doom strats#leather embossing is another one#risograph prints#woodblock prints#rubber prints#etchings even#silicon molds for sculpey or resin or clay#local pottery studios#local photography studios#professional art printers with giclee printers!#ive used all these techniques to make merch#none of them are difficult or out of reach its just EASIER and adverised more to order shit from china#oh my god i forgot button presses#ALSO WE NEED A UNION AND STANDARDIZED HOURLY WAGES BTW#TIRED OF THIS BICKERING ABOUT PRICE UNDERCUTTING

406 notes

·

View notes

Text

crispy 3d renders of a Casio Loopy My Seal Computer SV-100 // video game console / color printer combo (Japan, 1995)

by Camila da Mata

284 notes

·

View notes

Note

This is a set of dice that I made for my nephew, he likes spooky things, so I included moss and some blue-green 3D printed skulls.

I was really disappointed when I pulled them out of the molds, because the skulls were too close in color to the resin I had used for the rest of the dice. Or I was disappointed until I thought to shine a blacklight on them.

The 3D printer resin I used fluoresces under UV light, so using a blacklight pen reveals the invisible skulls inside the dice. I wish I had some better pictures, but I gave these to my nephew who keeps them in his personal treasure chest.

305 notes

·

View notes

Text

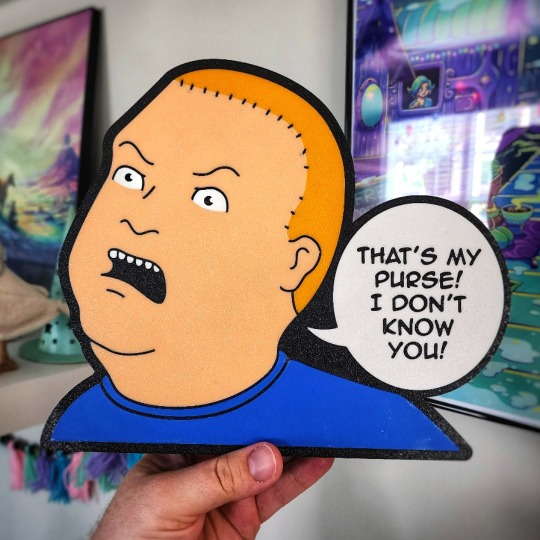

I've been adding more free 3D printables over on my MakerWorld account.

You don't have to have an account to download files, but if you do have an account, you can save designs to specific categories (a tip from me though, if you're really interested in something, download the files because they may be removed in the future for a variety of reasons).

Anyways, I'm most happy with my Tic-Tac-Totoro set since I feel, while not super complicated, is a decent achievement. All of the colors print separately, so if you only have a single color printer, you can print it "in color". Totoro works as a container for the soot sprite and acorn play pieces and the tummy lid flips to reveal the play grid.

The other designs rely on a multi-color printer setup though to print as shown, but you could always print them in a single color and paint them!

#totoro#pikachu#dragon#bobby hill#king of the hill#studio ghibli#3d printing#3d design#makerworld#bambulab

65 notes

·

View notes

Text

Looking for some custom flair of your favorite character / sona? 🐾

I've been using my 3d printer a lot lately, and having a bunch of fun! Designing something digitally and then holding it in your hands on the same day is super satisfying💖

I have a few colors available, but if you're looking for something I don't have, let me know! I'm willing to paint pieces or get extra filament if needed c:

Available here!

462 notes

·

View notes

Text

My friend made a figure of Nathaniel based on my character design. A wonderful surprise gift!! He said he created a 3D model of Nathaniel, printed it on a 3D printer, polished it, and finished it off with a coat of color. What a workmanship! I have nothing but respect for him because I am not good at 3D.

I took this photo side by side with a plush toy of BartNat that I had another friend make for me before and an acrylic stand that I made myself. I'm soooo happy!!

87 notes

·

View notes