#Compacted Wire Ropes

Explore tagged Tumblr posts

Text

Compacted Wire Ropes । Rotation Resistant Rope

In the dynamic landscape of heavy-duty industries, the demand for reliable and robust wire ropes has never been higher. Asahi Ropes, a pioneering name in the world of wire rope manufacturing, stands at the forefront of innovation with its exceptional Compacted Wire Ropes and Rotation Resistant Ropes. This article delves into the key features, benefits, and applications of Asahi Ropes' Compacted Wire Ropes, offering insights into why these ropes are the preferred choice for industries globally.

Key Features of Asahi Ropes' Compacted Wire Ropes:

Optimized Strength and Durability:

Asahi Ropes' Compacted Wire Ropes are engineered to deliver superior strength and durability. The compacting process enhances the rope's structural integrity, providing a higher breaking strength and extended service life. This makes them ideal for applications where reliability is paramount.

Reduced Diameter, Increased Flexibility:

The compacting technology employed by Asahi Ropes allows for a reduction in rope diameter without compromising on strength. This results in increased flexibility, making these ropes well-suited for applications that require agility and precision.

Enhanced Resistance to Abrasion and Fatigue:

Compacted Wire Ropes from Asahi are designed to withstand the harsh conditions of heavy-duty industries. Their resistance to abrasion and fatigue ensures longevity, even in challenging environments, minimizing downtime and maintenance costs.

Rotation Resistant Technology:

One of the standout features of Asahi's Compacted Wire Ropes is their rotation resistant design. This unique characteristic makes them particularly well-suited for lifting operations, preventing unwanted twisting and ensuring a stable load during lifting and lowering activities.

Applications of Compacted Wire Ropes:

Construction and Infrastructure:

Asahi's Compacted Wire Ropes find widespread use in construction projects, offering the strength and flexibility required for activities such as crane operations, hoisting, and structural installations.

Oil and Gas Exploration:

In the demanding environments of oil and gas exploration, where equipment is subjected to extreme conditions, Asahi's Compacted Wire Ropes excel, providing reliable and durable solutions for drilling and extraction operations.

Marine and Offshore:

The marine industry benefits from Asahi's Rotation Resistant Ropes, ensuring secure and controlled lifting operations on ships and offshore platforms.

Mining and Material Handling:

Compacted Wire Ropes play a crucial role in mining and material handling applications, offering the strength and durability needed for transporting heavy loads efficiently.

Asahi Ropes' Compacted Wire Ropes, featuring rotation-resistant technology, are setting a new standard for reliability and performance in heavy-duty industries. With a commitment to quality and innovation, Asahi Ropes continues to be a trusted partner for businesses seeking cutting-edge solutions for their wire rope needs. Invest in Asahi Ropes' Compacted Wire Ropes to elevate your operations and experience the strength that goes beyond expectations.

0 notes

Text

Wire rope electric hoist: a powerful assistant for efficient lifting.

#Wire rope electric hoist#Efficient lifting equipment#Industrial construction hoist#Powerful lifting capacity#Multiple lifting heights available#Stable operating speed#Compact structure design#Sturdy and durable materials#Advanced transmission system#Intelligent safety protection#Overload protection device#Travel limiter#Reliable braking system#Intelligent monitoring function#Industrial manufacturing application#Construction application#Logistics and warehousing application#Electric power maintenance application

1 note

·

View note

Text

Lift Installation and Maintenance Services in Raipur: What You Should Know

Introduction

As Raipur grows rapidly as a commercial and residential hub, the demand for reliable and efficient vertical transportation systems—like elevators and lifts—has surged. Whether it’s a residential society, hospital, mall, or office tower, a properly installed and well-maintained lift is not just a convenience but a necessity. This is where understanding Lift Installation and Maintenance Services in Raipur becomes essential for property owners, builders, and facility managers alike. With rising expectations on quality and safety, it is equally important to source equipment from credible Passenger Elevators Manufacturers in Chhattisgarh, who offer high-performance, energy-efficient, and user-friendly elevator systems.

Understanding Lift Installation Services

1. Initial Site Assessment

Before installation, a professional evaluation of the site is carried out. This includes measurements, structural assessment, pit depth, overhead clearance, and shaft space evaluation. Lift engineers ensure that the building complies with IS codes and elevator installation guidelines.

2. Choosing the Right Type of Elevator

Elevators vary based on purpose, load capacity, speed, and usage frequency. Some common types include:

Passenger Elevators – for apartments, offices, and public buildings

Goods Lifts – for warehouses and commercial use

Hospital Elevators – designed for stretchers and medical equipment

Home Lifts – compact and stylish for low-rise buildings

For Raipur’s mixed development landscape, passenger elevators dominate the market due to their high utility in both commercial and residential segments.

3. Installation Process

A typical lift installation includes:

Shaft preparation

Fixing guide rails and brackets

Machine room setup (for traction lifts) or hydraulic system configuration

Installation of the cabin, doors, counterweights, and safety gears

Wiring and integration with control systems

Testing and commissioning

Most Passenger Elevators Manufacturers in Chhattisgarh also provide end-to-end installation services with certified technicians, ensuring adherence to industry safety standards.

Importance of Lift Maintenance Services

Once the lift is installed, regular maintenance ensures it operates safely and efficiently throughout its lifecycle. Here’s why lift maintenance is crucial:

1. Safety and Compliance

Malfunctioning lifts pose serious safety risks. Routine inspections help detect wear and tear in mechanical components and ensure compliance with safety codes like IS 14665 and EN 81.

2. Minimized Downtime

Timely maintenance prevents unexpected breakdowns, keeping the lift operational and reliable for users. Preventive checks on brakes, doors, control panels, ropes, and oil levels can extend the life of the lift.

3. Energy Efficiency

Elevators consume power even when idle. Modern systems with regenerative drives and energy-efficient motors can be optimized further with professional maintenance.

4. Cost Savings

Ignoring maintenance often leads to expensive repairs or part replacements. Annual Maintenance Contracts (AMCs) offered by most companies prove to be cost-effective in the long run.

Key Services Offered by Lift Installation and Maintenance Providers in Raipur

1. Custom Design and Engineering

Manufacturers offer customized solutions based on the architectural layout, load capacity, and usage type. Tailored cabins, speed settings, and automatic rescue devices can be incorporated as per customer needs.

2. 24/7 Emergency Repair

Lift companies in Raipur offer emergency response services to fix breakdowns and ensure user safety. Rapid repair services build customer trust and reduce operational disruptions.

3. Modernization Services

Older lifts can be modernized with new control systems, better energy efficiency, enhanced safety features, and aesthetic upgrades. This is particularly relevant for legacy buildings undergoing refurbishment.

4. Annual Maintenance Contracts (AMCs)

These contracts typically cover monthly or quarterly maintenance visits, emergency repairs, and replacement of minor parts. Most Passenger Elevators Manufacturers in Raipur offer comprehensive AMC plans tailored to different types of buildings.

How to Choose a Reliable Lift Service Provider in Raipur

1. Certifications and Compliance

Ensure the service provider complies with ISO standards, CE certification, and local safety regulations. The technicians should be trained and certified by relevant authorities.

2. Experience and Portfolio

Check their track record. Established companies usually have a portfolio of residential, commercial, and institutional projects in Raipur and nearby regions.

3. After-Sales Support

A lift is a long-term investment. A company with robust after-sales support, quick spare parts availability, and a dedicated service team is a clear advantage.

4. Customer Reviews and Feedback

Online reviews and client testimonials reveal much about a company’s reliability, punctuality, and service quality.

5. Pricing Transparency

Choose a provider that offers clear quotations, no hidden charges, and detailed breakdowns for installation, servicing, and maintenance.

The Role of Manufacturers in Shaping Lift Quality

Reliable performance begins with quality manufacturing. In Raipur, most suppliers source lifts from trusted Passenger Elevators Manufacturers in Raipur, who understand the local building codes and environment-specific requirements.

Local manufacturing reduces lead time for spare parts, enables faster service, and offers better pricing due to lower logistics costs. These manufacturers also bring in technological innovations like IoT-based monitoring, AI-based predictive maintenance, and eco-friendly lifts with low carbon footprints.

Safety Standards and Regulations to Be Aware Of

Lift installations must conform to multiple national and international safety codes, such as:

IS 14665 – Indian standard for lift components and installation

EN 81 – European safety standards for elevator design and performance

NBC India – National Building Code provisions for vertical transportation

A responsible service provider ensures regular inspections, insurance coverage, emergency phone systems in cabins, and annual third-party safety audits.

Technological Advancements in Lift Systems

Lift manufacturers and service providers are now integrating cutting-edge technology into their systems:

IoT Integration: Enables real-time monitoring, predictive maintenance, and alerts for breakdowns

Touchless Controls: Especially post-COVID, lifts now come with app-based or voice-controlled operations

AI-Powered Optimization: Smart lifts reduce wait time and energy consumption in multi-floor buildings

Regenerative Drives: These recover energy during the downward travel and save power

Destination Control Systems: Enhance traffic handling efficiency in high-rise buildings

Partnering with advanced Passenger Elevators Manufacturers in Raipur ensures your building remains future-ready and competitive.

Lift Maintenance Trends in Bilaspur and Nearby Regions

While Raipur remains the capital city and core of elevator demand, nearby cities like Bilaspur are catching up quickly. There’s a rising focus on smart infrastructure in Bilaspur, especially in malls, educational institutions, and healthcare facilities. This has increased the demand for expert Passenger Elevators Manufacturers in Bilaspur who can deliver modern lifts and reliable maintenance solutions.

These manufacturers are not just supplying hardware but also offering remote monitoring tools, app-based service tracking, and digitized AMC plans for improved user experience and system transparency.

Final Thoughts

Elevators are no longer just vertical mobility tools—they are integral to a building’s functionality, safety, and aesthetics. Understanding Lift Installation and Maintenance Services in Raipur allows building owners and developers to make informed decisions, ensuring long-term safety, convenience, and efficiency.

Collaborating with reputable Passenger Elevators Manufacturers in Chhattisgarh, leveraging modern technologies, and ensuring rigorous maintenance protocols can elevate not just people—but the entire value of your property.

#Capsule Lift Manufacturers in Chhattisgarh#Hospital Lift Manufacturers in Chhattisgarh#Passenger Elevators Manufacturers in Chhattisgarh#Hydraulic elevator Manufacturers in Chhattisgarh#Car Elevator Manufacturers in Chhattisgarh

0 notes

Text

Say Goodbye to Cluttered Balconies with the Modern Cloth Drying Hanger

In the fast-paced world of urban living, space is precious and efficiency is essential. Whether you live in a high-rise apartment or a compact home, managing laundry can often become a frustrating chore. This is where the cloth drying hanger comes in as a game-changing solution. Designed for convenience, style, and practicality, the cloth drying hanger is no longer just a household accessory — it’s a smart upgrade for every home.

Why Choose a Cloth Drying Hanger

The traditional methods of drying clothes — using ropes, wires, or flimsy stands — come with multiple problems: sagging lines, uneven drying, blocked balconies, and constant tangles. But a cloth drying hanger offers:

Neatness: Keeps your balcony or indoor space looking organized.

Space-saving: Ideal for small flats or homes with limited open areas.

Durability: Built with strong materials like stainless steel or rust-proof aluminum.

Ease of use: Operates with pulleys, sliders, or collapsible rods for smooth drying.

It’s not just about drying clothes anymore — it’s about doing it smartly.

Types of Cloth Drying Hangers Available

There are a variety of cloth drying hangers designed to suit different needs and home setups. Some of the most popular types include:

1. Ceiling Mounted Cloth Drying Hanger

Perfect for balconies or utility areas, this system hangs from the ceiling and operates with a pulley mechanism. You can lower or raise the rods easily to hang or remove clothes, saving time and effort.

2. Wall-Mounted Foldable Hanger

If you’re short on ceiling space, a foldable wall hanger is a great alternative. It folds back against the wall when not in use, keeping your area clear.

3. Portable Cloth Drying Stand

Best for renters or frequent movers. Lightweight, collapsible, and mobile — just unfold when needed and store away when done.

4. Pull & Dry Pulley Hanger

Combining ceiling and pulley advantages, this system features individual stainless steel rods that move up and down independently. You can adjust each rod as per your need.

Benefits of Installing a Cloth Drying Hanger

Here’s why thousands of homeowners are switching to modern cloth drying hangers:

☑ No More Bending or Stretching

Say goodbye to back pain. The pulley system allows you to bring the rods to your level, eliminating the need to stretch or bend.

☑ All-Weather Drying

Rain or shine, you can dry your clothes indoors without worrying about the weather ruining your laundry routine.

☑ Aesthetic Appeal

Modern designs blend seamlessly with your home decor. Whether it’s matte-finished rods or stainless-steel elegance, they enhance the overall look of your space.

☑ Maximum Load Capacity

Sturdy designs allow you to hang heavy clothes, bedsheets, and towels with ease.

Who Should Use a Cloth Drying Hanger

Apartment Residents: Maximize balcony or utility space.

Working Professionals: Dry laundry fast and efficiently after a busy day.

Senior Citizens: Reduce physical strain during daily chores.

Families: Dry more clothes in less time with multiple rods or tiers.

How to Choose the Right Cloth Drying Hanger

Here are a few tips to help you pick the perfect one:

Measure your space: Ensure enough clearance for rods or folding units.

Material matters: Go for stainless steel or powder-coated metal for longevity.

Mechanism preference: Choose between pulley-based or foldable models based on your convenience.

Weight load: Check the maximum weight each rod or unit can handle.

Why Customers Love the Cloth Drying Hanger

Many customers report that using a cloth drying hanger transformed how they manage their daily laundry. They save time, effort, and even electricity by reducing dependency on electric dryers.

⭐ “This is the best home upgrade I’ve made in years. No more messy wires or rusted rods.” – Priya, Hyderabad ⭐ “It blends so well with my balcony design. Functional and beautiful.” – Rohan, Bangalore ⭐ “I gifted one to my parents, and they are in love with the comfort it provides.” – Sneha, Mumbai

Final Thoughts

In modern homes where every inch counts, a cloth drying hanger is not just a utility — it’s a lifestyle choice. Whether you live in a cozy studio or a large family apartment, this innovative solution ensures that your laundry days are smooth, stylish, and stress-free. With easy installation and long-lasting benefits, it’s time to upgrade how you dry your clothes.

0 notes

Text

Elevator Ropes Market Size, Drivers & Innovations Forecast 2032

Global Elevator Ropes Market Overview The global elevator ropes market is witnessing consistent growth, driven by urbanization, infrastructure development, and advancements in vertical transportation technologies. As of 2024, the market is valued at approximately USD 730 million and is projected to reach around USD 1.1 billion by 2030, expanding at a CAGR of 6.8% over the forecast period. The demand is being fueled by increasing high-rise construction activities, modernization of aging infrastructure, and growth in commercial and residential buildings worldwide. Technological improvements in elevator systems, such as machine-room-less (MRL) elevators and energy-efficient traction elevators, are reshaping the dynamics of the market. With safety and performance at the forefront, manufacturers are focusing on the development of high-tensile, corrosion-resistant, and lightweight rope materials, including compacted wire ropes and synthetic alternatives, to enhance ride quality and longevity. Global Elevator Ropes Market Dynamics Market Drivers: Key drivers include the surge in urban population, expansion of the construction sector, and the retrofitting of outdated elevator systems in mature markets like Europe and North America. The growth of smart buildings and the integration of IoT-based elevator technologies are also pushing demand for advanced elevator ropes. Market Restraints: The market faces challenges from raw material price fluctuations, particularly in steel and specialty alloys. Additionally, the high cost of R&D in developing new materials and compliance with stringent safety and performance regulations can limit growth in emerging economies. Opportunities: Opportunities abound in Asia-Pacific and the Middle East, where mega infrastructure projects, smart city developments, and rapid urbanization are driving the need for robust and efficient elevator systems. There's also a rising demand for eco-friendly ropes aligned with green building standards, supporting the shift toward sustainability. Technology and Regulation: Technological innovations such as carbon fiber-based ropes and AI-powered predictive maintenance systems are transforming operational efficiency. Regulatory bodies like EN 12385 and ISO 4344 ensure safety compliance, while sustainability initiatives are encouraging the use of recyclable materials and low-energy manufacturing processes. Download Full PDF Sample Copy of Global Elevator Ropes Market Report @ https://www.verifiedmarketresearch.com/download-sample?rid=75025&utm_source=PR-News&utm_medium=378 Global Elevator Ropes Market Trends and Innovations The industry is witnessing significant shifts due to emerging technologies such as lightweight synthetic ropes, nanostructured coatings for corrosion resistance, and embedded sensors for real-time monitoring of tension and wear. Market leaders are focusing on strategic partnerships and mergers & acquisitions to enhance production capabilities and global reach. Collaborations between OEMs and rope manufacturers are fostering the co-development of smart, high-durability solutions that meet evolving safety standards. Additionally, 3D printing technologies are being explored for precision manufacturing of rope components, potentially reducing lead times and enhancing customization. Global Elevator Ropes Market Challenges and Solutions Challenges: Key obstacles include supply chain disruptions, particularly in steel procurement, which affect production cycles and pricing. Labor shortages and energy costs also pose operational risks. Regulatory variations across regions may create hurdles for global players aiming for standardization. Solutions: To overcome these issues, companies are adopting digital supply chain management systems, investing in local manufacturing hubs, and embracing lean production techniques. Diversification of raw material sources and investing in recycling capabilities for metal ropes can help mitigate cost pressures and environmental concerns.

Global Elevator Ropes Market Future Outlook The market is expected to maintain strong momentum, propelled by the rise of high-speed elevators in megacities and increasing focus on sustainable building practices. With growing investments in infrastructure and transportation hubs, the demand for durable, low-maintenance elevator ropes will remain high. Furthermore, the integration of AI and IoT into elevator monitoring will drive the need for smart ropes capable of delivering real-time diagnostics. By 2035, the elevator ropes industry is poised to evolve into a more tech-driven, environmentally responsible sector with heightened emphasis on safety, energy efficiency, and innovation. Key Players in the Global Elevator Ropes Market Global Elevator Ropes Market are renowned for their innovative approach, blending advanced technology with traditional expertise. Major players focus on high-quality production standards, often emphasizing sustainability and energy efficiency. These companies dominate both domestic and international markets through continuous product development, strategic partnerships, and cutting-edge research. Leading manufacturers prioritize consumer demands and evolving trends, ensuring compliance with regulatory standards. Their competitive edge is often maintained through robust R&D investments and a strong focus on exporting premium products globally. BRUGG Lifting AG WireCo WorldGroup Gustav Wolf GmbH Bharat Wire Ropes Limited PFEIFER DRAKO Drahtseilwerk GmbH Usha Martin Tokyo Rope Mfg. Co. Ltd. Alps Wire Rope Corporation Jiangsu Safety Steel Wire Rope Co. Ltd Loos & Co. Inc. Mak Kee International H.K. Limited Santini Funi Srl KISWIRE LTD. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount?rid=75025&utm_source=PR-News&utm_medium=378 Global Elevator Ropes Market Segments Analysis and Regional Economic Significance The Global Elevator Ropes Market is segmented based on key parameters such as product type, application, end-user, and geography. Product segmentation highlights diverse offerings catering to specific industry needs, while application-based segmentation emphasizes varied usage across sectors. End-user segmentation identifies target industries driving demand, including healthcare, manufacturing, and consumer goods. These segments collectively offer valuable insights into market dynamics, enabling businesses to tailor strategies, enhance market positioning, and capitalize on emerging opportunities. The Global Elevator Ropes Market showcases significant regional diversity, with key markets spread across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Each region contributes uniquely, driven by factors such as technological advancements, resource availability, regulatory frameworks, and consumer demand. Elevator Ropes Market, By Product Type • Fiber core (FC)• Independent wire rope core (IWRC) Elevator Ropes Market, By Functionality • Traction/Hoist• Governor• Compensation Elevator Ropes Market By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/elevator-ropes-market/ About Us: Verified Market Research Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ global clients. We provide advanced analytical research solutions while offering information-enriched research studies. We also offer insights into strategic and growth analyses and data necessary to achieve corporate goals and critical revenue decisions. Our 250 Analysts and SMEs offer a high level of expertise in data collection and governance using industrial techniques to collect and analyze data on more than 25,000 high-impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise, and years of collective experience to produce informative and accurate research.

Contact us: Mr. Edwyne Fernandes US: +1 (650)-781-4080 US Toll-Free: +1 (800)-782-1768 Website: https://www.verifiedmarketresearch.com/ Top Trending Reports https://www.verifiedmarketresearch.com/ko/product/north-america-autoinjectors-market/ https://www.verifiedmarketresearch.com/ko/product/wood-lathe-market/ https://www.verifiedmarketresearch.com/ko/product/medical-grade-stainless-steel-tube-market/ https://www.verifiedmarketresearch.com/ko/product/brazil-heavy-equipment-spare-parts-market/ https://www.verifiedmarketresearch.com/ko/product/insulation-monitoring-equipment-market/

0 notes

Text

Winch Upgrade Made Easy for DIYers

Upgrading your winch system doesn’t have to be an intimidating project, even for those tackling it solo. For 4x4 enthusiasts, off-road adventurers, or anyone relying on recovery gear, optimizing your winch setup can significantly enhance performance and reliability. This blog unpacks what DIYers need to know to complete a winch upgrade with confidence and clarity, all while staying aligned with industry best practices.

Understanding the Purpose of a Winch Upgrade

A winch upgrade involves more than just replacing worn-out parts—it’s about improving pulling power, responsiveness, and system durability. Whether it’s for recovering vehicles in harsh terrain or hauling heavy equipment, a well-upgraded winch ensures that you're never left stranded.

DIYers often seek upgrades for several key reasons:

Enhanced load capacity

Faster line speed

Increased resistance to wear

Better compatibility with modern accessories

Recognizing these performance gaps early on can help guide the selection of the right components and streamline the entire process.

Choosing the Right High Mount Winch

One of the most impactful changes in a winch upgrade is transitioning to a high mount winch. Unlike low mount systems that are common in factory setups, high mounts are designed for heavy-duty use and offer a distinct mechanical advantage.

Why Go High Mount?

A high mount winch typically features:

Greater line speed under load, reducing time in recovery situations

Mechanical efficiency, especially in extended recovery tasks

Robust cooling and gearing, ideal for challenging conditions

While initially developed for military and competition use, high mount systems have become increasingly popular in the DIY community due to their reliability and ease of servicing.

Key Components to Focus On

When planning a winch upgrade, attention to detail is everything. Below are the main elements worth evaluating and possibly replacing:

1. Winch Motor

A more powerful motor ensures smoother operation and faster line speed. Ensure that the upgraded motor matches your power source and vehicle requirements.

2. Gear Train

Switching to a gear ratio that complements your needs—whether speed or torque—can drastically affect the winch's usability. Many high mount winch systems offer customizable gear options.

3. Drum and Cable

Consider synthetic rope for safety and ease of use. Also, check if the drum size accommodates your rope of choice without compromising on strength.

4. Solenoids and Electricals

Aging solenoids are a common point of failure. Upgrading to solid-state or waterproof options enhances reliability in all-weather conditions.

Tips for a Smooth DIY Winch Upgrade

Upgrading your winch doesn't have to mean weeks in the garage. Here are some practical tips:

Plan ahead by reviewing the specs of your current winch and identifying its limitations

Use vehicle-specific brackets and mounts to avoid custom fabrication

Label wires and take reference photos before disassembly

Upgrade your battery or alternator if needed to handle higher power loads

Double-check weight distribution to maintain vehicle handling

Above all, safety must be your priority. Always disconnect the battery, wear protective gear, and follow the manufacturer’s guidelines closely.

Frequently Asked Questions (FAQ)

What’s the difference between a high mount and low mount winch?

A high mount winch offers mechanical gearing advantages, faster recovery times under load, and is typically easier to service. Low mount winches are compact and factory-installed but may lack the power for heavy-duty use.

Can I install a high mount winch on any vehicle?

Most 4x4s and utility vehicles can accommodate a high mount winch with the correct mounting kit. However, it's essential to verify clearance, power compatibility, and front-end weight limits.

Do I need to replace my existing winch or can I upgrade parts?

In many cases, you can enhance performance by replacing key components like the motor, solenoid, or rope. However, switching from a low mount to a high mount winch usually requires a full unit replacement and potential bracket modifications.

How often should a winch system be serviced?

Inspect your winch system every six months, especially after heavy use. Check the rope, grease points, connections, and electricals to ensure optimal operation.

Conclusion

A winch upgrade is one of the most rewarding projects for off-road and recovery-focused DIYers. It enhances not only performance but also confidence in remote or demanding environments. By carefully selecting components—particularly considering the advantages of a high mount winch—DIY enthusiasts can achieve professional-grade results without the need for expensive workshops or specialized labor.

With the right preparation and a methodical approach, upgrading your winch system can be straightforward, safe, and surprisingly satisfying. Whether you're heading into rugged backcountry or simply preparing for the unexpected, a smarter winch setup makes all the difference.

0 notes

Text

Crafted from high-quality 304 stainless steel, this drying rack is designed for both indoor and outdoor use, ensuring durability and resistance to rust and corrosion. Its innovative telescopic design allows for easy adjustment to fit various spaces, making it perfect for any home. Key Features: Durable Construction: Made from premium 304 stainless steel, this drying rack is built to last, providing strength and stability while resisting rust and wear over time. Telescopic Design: The adjustable telescopic feature allows you to extend or retract the rack to suit your drying needs, accommodating everything from small garments to larger items like towels and bedding. Punch-Free Installation: Enjoy hassle-free setup with the punch-free installation method. Simply adhere the rack to your wall or desired surface without the need for drilling, preserving the integrity of your walls. Invisible Aesthetic: The sleek and minimalist design ensures that the drying rack blends seamlessly into your home decor, providing a clean and unobtrusive look when not in use. Versatile Use: Ideal for drying clothes, towels, and delicate items, this rack can be used in various settings, including laundry rooms, bathrooms, balconies, and patios. Space-Saving Solution: When not in use, the rack can be easily collapsed and stored away, making it an excellent choice for small spaces or apartments. Specifications: Material: 304 Stainless Steel Installation: Punch-Free Assortment of colors Why Choose Our Drying Rack? The Telescopic Punch-Free Invisible Drying Rack combines functionality with modern design, making it an essential addition to any home. Whether you’re drying laundry indoors or enjoying the fresh air outdoors, this drying rack offers convenience and style in one compact solution. Upgrade your drying experience today!

0 notes

Text

Hoist Manufacturers: Powering Industrial Lifts with Precision and Safety

In the age of automation and speedy industrialization, hoists have emerged as an crucial component for lifting, lowering, and positioning heavy substances throughout multiple sectors. Whether it’s in factories, warehouses, strength flora, or construction sites, deciding on the proper hoist producers can significantly influence operational safety, efficiency, and lengthy-time period performance.

Hoists are now not just mechanical gadgets—they may be clever, engineered answers built to deal with intense workloads with utmost reliability. In this newsletter, we explore the position of present day hoist producers, what makes a terrific one, and how to pick out the first-class partner for your business desires.

What Do Hoist Manufacturers Offer?

Hoist manufacturers layout, engineer, and deliver numerous varieties of hoisting systems, custom designed to particular lifting requirements. These systems may be electric powered, guide, or pneumatic, and are engineered to provide safe and seamless vertical motion of masses in various environments.

Core services from leading hoist producers commonly encompass:

Custom layout and engineering

Electric wire rope and chain hoists

Manual hoists and lever blocks

Pneumatic hoists for risky regions

Overload safety and protection systems

Spare elements and accessories

Installation and commissioning

Annual renovation and servicing

From compact workshop fashions to heavy-obligation hoists for steel flora, cutting-edge producers build structures that are rugged, precise, and built for longevity.

Why Choosing the Right Hoist Manufacturer Matters

The performance of your lifting device heavily depends at the fine and design precision presented by the manufacturer. Here’s why choosing the right hoist manufacturer is vital:

1. Safety First

Certified manufacturers make certain that each hoist meets countrywide and international protection standards, decreasing the threat of mechanical failures and place of business accidents.

2. Tailored Engineering

Good hoist producers customise their systems in step with lifting top, load potential, frequency of use, and placement constraints—ensuring you get a solution that fits your workflow.

3. Higher Efficiency

Electric and automated hoists designed with the aid of pinnacle producers enhance handling velocity, lessen manual effort, and improve productiveness on the shop floor.

4. Longer Equipment Life

Well-manufactured hoists use superb materials, sealed bearings, and durable automobiles to make certain long lifestyles with minimal preservation.

5. Reliable Support

Top producers offer installation help, person education, spares, and AMC help, ensuring clean operations even after purchase.

Industries That Rely on Hoist Manufacturers

Hoists are imperative across a extensive style of sectors. Trusted hoist producers serve industries together with:

Automotive and Auto Components

Steel and Metal Processing

Oil & Gas and Chemical Industries

Textile and Food Processing

Power Generation and Substations

Construction and Infrastructure

Warehousing and Logistics

Each of those industries demands distinctive hoisting specifications—from cleanroom requirements in pharma to explosion-proof structures in oil refineries. This makes specialised manufacturing expertise crucial.

Popular Types of Hoists Offered

Modern hoist manufacturers provide a complete range of system to fulfill precise lifting desires. Some of the important thing types include:

1. Electric Wire Rope Hoists

Ideal for high-load, high-speed programs in factories and massive workshops. These hoists offer easy operation and advanced protection capabilities.

2. Electric Chain Hoists

Compact and dependable, suitable for medium-obligation use in manufacturing strains, assembly shops, and packaging devices.

3. Manual Chain Pulley Blocks

Economical and smooth to perform, perfect for low-frequency lifting duties or faraway activity web sites.

4. Pneumatic Hoists

Designed for use in explosive or high-temperature environments—common in oil and chemical industries.

5. Custom Built Hoists

Manufactured to meet non-wellknown lifting heights, unconventional mounting, or extreme load coping with requirements.

What to Look for in a Hoist Manufacturer

To make certain protection, reliability, and an excellent return on investment, examine a hoist manufacturer primarily based on the following:

Engineering Capability: Can they layout according to your custom specs?

Certifications: Look for ISO 9001, IS requirements, CE mark, and different enterprise compliance.

Material Quality: High-grade metal, automobiles, and gearboxes imply higher sturdiness.

Service Network: Are they able to imparting quick servicing and guide at your vicinity?

Experience: Years in enterprise, consumer list, and enterprise reputation all rely.

Safety Features: Does the hoist include brakes, restriction switches, and overload safety?

Final Thoughts

The right hoist can redefine how your facility handles substances. But a terrific hoist starts with a depended on producer—one that combines innovation, precision, and a deep knowledge of lifting dynamics. Whether you are putting in a brand new plant or upgrading your present structures, choosing the proper hoist producer is a strategic choice that impacts productiveness, protection, and fee-performance.

From fashionable chain hoists to custom-engineered wire rope structures, dependable producers make sure that your lifting answer is not simply purposeful—but destiny-prepared.

0 notes

Text

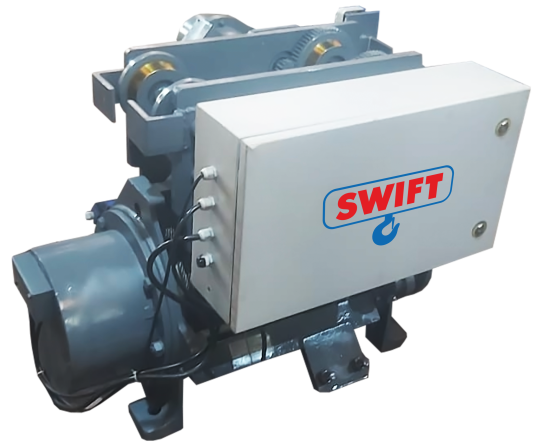

Wire Rope Hoist – Consolidated Swift Industries Limited

Consolidated Swift Industries Limited offers reliable wire rope hoists with capacities ranging from 0.25 to 40 tons and lift heights up to 75 meters. Designed for diverse industrial needs, these hoists feature compact designs, high-torque induction motors, and advanced control panels with overload protection, ensuring efficient and safe material handling.

#wireropehoist#heavylifting#safehoisting#factoryequipment#workshopequipment#constructionsitehoist#materialhandling#industrialhoist#durablehoist#liftingequipment

0 notes

Text

Common Causes of Steel Wire Rope Failure and How to Prevent Them

Steel wire ropes are essential components in industries such as construction, mining, marine, oil & gas, and manufacturing. Their ability to withstand enormous loads and harsh environmental conditions makes them irreplaceable. However, even the most durable wire ropes are vulnerable to failure if not properly used, maintained, and inspected.

In this article, we explore the common causes of steel wire rope failure and provide practical, expert-backed prevention strategies to help you maximize rope life, reduce downtime, and ensure operational safety.

What is Steel Wire Rope Failure?

Steel wire rope failure refers to the point at which the rope can no longer perform its intended function due to structural degradation, breakage, or reduced strength. This can result from various mechanical, environmental, or handling issues.

Common Causes of Steel Wire Rope Failure

1. Fatigue from Repeated Bending

Wire ropes frequently bend over drums, pulleys, and sheaves, especially in cranes and elevators. This repeated flexing leads to metal fatigue, especially near the outer strands.

Signs:

Small broken wires on the outer layer.

Abrasions or flattening at bending points.

Prevention:

Use sheaves with the proper groove size and diameter.

Replace sheaves with worn grooves.

Choose ropes with fatigue-resistant construction like rotation-resistant ropes or those with compacted strands.

2. Corrosion

Corrosion occurs when ropes are exposed to moisture, chemicals, or salty environments (e.g., marine operations). It weakens internal wires, often without visible external damage.

Signs:

Reddish or greenish powder on strands.

Loss of metallic sheen.

Hidden internal rust leading to unexpected breakage.

Prevention:

Use galvanized or stainless steel wire ropes in corrosive environments.

Regularly apply lubricants with corrosion inhibitors.

Inspect and clean ropes frequently.

Store ropes in dry, covered conditions.

3. Overloading

Using a wire rope beyond its rated capacity causes internal and external wire damage. Even one instance of overloading can significantly reduce its lifespan.

Signs:

Flattened, kinked, or bird-caged sections.

Broken strands.

Elongation or core protrusion.

Prevention:

Always adhere to the Working Load Limit (WLL).

Use load monitoring devices in lifting operations.

Train operators on load rating charts.

Select a rope with a safety factor appropriate for dynamic loads.

4. Abrasion

Friction between the wire rope and contact surfaces can wear away the outer wires. This is especially common in sliding applications or when ropes rub against sharp edges.

Signs:

Shiny, polished sections.

Flattened strands.

Strand distortion.

Prevention:

Install proper guards and fairleads.

Use sheaves and drums of appropriate size and smoothness.

Apply lubrication to reduce friction.

Use plastic-coated wire ropes in high-abrasion areas.

5. Kinking and Improper Handling

Wire ropes are sensitive to improper uncoiling or sudden jerks during installation. Kinks deform the structure and weaken the core.

Signs:

Sharp bends or permanent deformation.

Uneven winding on drums.

Loss of flexibility.

Prevention:

Use rotating turntables or reels to uncoil rope properly.

Avoid dragging ropes over obstacles or rough surfaces.

Train staff in correct handling and coiling techniques.

6. Lack of Lubrication

Steel wire ropes need lubrication to reduce friction between wires and strands. Without proper lubrication, ropes deteriorate quickly under stress and environmental exposure.

Signs:

Squeaking sounds during movement.

Dry or rusted appearance.

Brittle wire breaks.

Prevention:

Use compatible wire rope lubricants (penetrating and coating types).

Schedule periodic lubrication based on usage and environment.

Use automatic lubrication systems for continuous operations.

7. Improper Storage

Storing ropes in damp, uncovered, or chemically reactive areas can accelerate corrosion and damage the rope structure before it's even used.

Signs:

Surface rust before deployment.

Flattened coils or kinks.

Mold, chemical stains, or mechanical damage.

Prevention:

Store wire ropes in covered, dry, and ventilated areas.

Keep ropes on reels or suspended above the ground.

Apply protective coatings if stored for extended periods.

8. Poor Installation or Termination

Improper splicing, socketing, or end-fittings can concentrate stress at weak points and lead to failure under tension.

Signs:

Rope slippage at terminations.

Loosened end fittings.

Fraying at splice points.

Prevention:

Use certified end fittings and proper splicing methods.

Ensure terminations match load requirements.

Conduct pull tests after installation.

How to Prevent Steel Wire Rope Failure: Best Practices

Preventing steel wire rope failure is not just about addressing one factor—it’s about creating a culture of maintenance, training, and proper usage.

1. Regular Inspections

Inspect ropes visually and with tools (e.g., magnetic flux leakage detectors) before every use, especially in lifting and critical load applications.

Inspection checklist includes:

Broken wires

Rust/corrosion

Core protrusion

Diameter reduction

Deformation

Follow industry standards like ISO 4309 or ASME B30.9 for wire rope inspection criteria.

2. Proper Rope Selection

Choosing the correct type of steel wire rope based on application, load, bend radius, and environment is crucial.

Factors to consider:

Construction (e.g., 6x36, 8x19, compacted, swaged)

Core type (FC, IWRC)

Coating (Galvanized, PVC, stainless steel)

Flexibility and fatigue resistance

Consult with Wire Rope Manufacturers in India for customized recommendations.

3. Operator Training

Even the best equipment fails when improperly used. Train operators in:

Load limits

Rigging techniques

Rope inspection

Handling and coiling

4. Use of Rope Accessories

Enhance performance and lifespan with:

Thimbles

Pulley guards

Winch drums with proper grooves

Tension indicators

5. Documentation and Monitoring

Maintain records of:

Inspection logs

Maintenance schedules

Load history

Environmental exposure

Use digital tools or CMMS (Computerized Maintenance Management Systems) to track rope performance and replacements.

Partner With the Right Wire Rope Company

Reliable wire rope manufacturers in India offer not just quality products but also technical support, training, and post-sales service. Look for manufacturers who:

Provide certified and tested ropes.

Offer application-specific advice.

Have strong quality control and R&D practices.

Steel wire rope failure is preventable with the right knowledge, practices, and partnerships. By addressing the common causes—fatigue, corrosion, overloading, abrasion, and more—you can extend the lifespan of your ropes and improve workplace safety.

Whether you're working with cranes, elevators, marine applications, or heavy industrial equipment, prevention starts with:

Choosing the right rope,

Ensuring proper handling,

Regular inspections, and

Working with reputable Steel Wire Ropes manufacturers.

#wireropecompanyinindia#wireropemanufacturersinindia#steelwiremanufacturers#steelwireropeindustry#steelwireropesuppliers#steelwireropes#steelwirerope#steelwireropesmanufacturers#steelwireropescompanies#steelwireropescompany

0 notes

Text

Common Causes of Steel Wire Rope Failure and How to Prevent Them

Steel wire ropes are essential components in industries such as construction, mining, marine, oil & gas, and manufacturing. Their ability to withstand enormous loads and harsh environmental conditions makes them irreplaceable. However, even the most durable wire ropes are vulnerable to failure if not properly used, maintained, and inspected.

In this article, we explore the common causes of steel wire rope failure and provide practical, expert-backed prevention strategies to help you maximize rope life, reduce downtime, and ensure operational safety.

What is Steel Wire Rope Failure?

Steel wire rope failure refers to the point at which the rope can no longer perform its intended function due to structural degradation, breakage, or reduced strength. This can result from various mechanical, environmental, or handling issues.

Common Causes of Steel Wire Rope Failure

1. Fatigue from Repeated Bending

Wire ropes frequently bend over drums, pulleys, and sheaves, especially in cranes and elevators. This repeated flexing leads to metal fatigue, especially near the outer strands.

Signs:

Small broken wires on the outer layer.

Abrasions or flattening at bending points.

Prevention:

Use sheaves with the proper groove size and diameter.

Replace sheaves with worn grooves.

Choose ropes with fatigue-resistant construction like rotation-resistant ropes or those with compacted strands.

2. Corrosion

Corrosion occurs when ropes are exposed to moisture, chemicals, or salty environments (e.g., marine operations). It weakens internal wires, often without visible external damage.

Signs:

Reddish or greenish powder on strands.

Loss of metallic sheen.

Hidden internal rust leading to unexpected breakage.

Prevention:

Use galvanized or stainless steel wire ropes in corrosive environments.

Regularly apply lubricants with corrosion inhibitors.

Inspect and clean ropes frequently.

Store ropes in dry, covered conditions.

3. Overloading

Using a wire rope beyond its rated capacity causes internal and external wire damage. Even one instance of overloading can significantly reduce its lifespan.

Signs:

Flattened, kinked, or bird-caged sections.

Broken strands.

Elongation or core protrusion.

Prevention:

Always adhere to the Working Load Limit (WLL).

Use load monitoring devices in lifting operations.

Train operators on load rating charts.

Select a rope with a safety factor appropriate for dynamic loads.

4. Abrasion

Friction between the wire rope and contact surfaces can wear away the outer wires. This is especially common in sliding applications or when ropes rub against sharp edges.

Signs:

Shiny, polished sections.

Flattened strands.

Strand distortion.

Prevention:

Install proper guards and fairleads.

Use sheaves and drums of appropriate size and smoothness.

Apply lubrication to reduce friction.

Use plastic-coated wire ropes in high-abrasion areas.

5. Kinking and Improper Handling

Wire ropes are sensitive to improper uncoiling or sudden jerks during installation. Kinks deform the structure and weaken the core.

Signs:

Sharp bends or permanent deformation.

Uneven winding on drums.

Loss of flexibility.

Prevention:

Use rotating turntables or reels to uncoil rope properly.

Avoid dragging ropes over obstacles or rough surfaces.

Train staff in correct handling and coiling techniques.

6. Lack of Lubrication

Steel wire ropes need lubrication to reduce friction between wires and strands. Without proper lubrication, ropes deteriorate quickly under stress and environmental exposure.

Signs:

Squeaking sounds during movement.

Dry or rusted appearance.

Brittle wire breaks.

Prevention:

Use compatible wire rope lubricants (penetrating and coating types).

Schedule periodic lubrication based on usage and environment.

Use automatic lubrication systems for continuous operations.

7. Improper Storage

Storing ropes in damp, uncovered, or chemically reactive areas can accelerate corrosion and damage the rope structure before it's even used.

Signs:

Surface rust before deployment.

Flattened coils or kinks.

Mold, chemical stains, or mechanical damage.

Prevention:

Store wire ropes in covered, dry, and ventilated areas.

Keep ropes on reels or suspended above the ground.

Apply protective coatings if stored for extended periods.

8. Poor Installation or Termination

Improper splicing, socketing, or end-fittings can concentrate stress at weak points and lead to failure under tension.

Signs:

Rope slippage at terminations.

Loosened end fittings.

Fraying at splice points.

Prevention:

Use certified end fittings and proper splicing methods.

Ensure terminations match load requirements.

Conduct pull tests after installation.

How to Prevent Steel Wire Rope Failure: Best Practices

Preventing steel wire rope failure is not just about addressing one factor—it’s about creating a culture of maintenance, training, and proper usage.

1. Regular Inspections

Inspect ropes visually and with tools (e.g., magnetic flux leakage detectors) before every use, especially in lifting and critical load applications.

Inspection checklist includes:

Broken wires

Rust/corrosion

Core protrusion

Diameter reduction

Deformation

Follow industry standards like ISO 4309 or ASME B30.9 for wire rope inspection criteria.

2. Proper Rope Selection

Choosing the correct type of steel wire rope based on application, load, bend radius, and environment is crucial.

Factors to consider:

Construction (e.g., 6x36, 8x19, compacted, swaged)

Core type (FC, IWRC)

Coating (Galvanized, PVC, stainless steel)

Flexibility and fatigue resistance

Consult with Wire Rope Manufacturers in India for customized recommendations.

3. Operator Training

Even the best equipment fails when improperly used. Train operators in:

Load limits

Rigging techniques

Rope inspection

Handling and coiling

4. Use of Rope Accessories

Enhance performance and lifespan with:

Thimbles

Pulley guards

Winch drums with proper grooves

Tension indicators

5. Documentation and Monitoring

Maintain records of:

Inspection logs

Maintenance schedules

Load history

Environmental exposure

Use digital tools or CMMS (Computerized Maintenance Management Systems) to track rope performance and replacements.

Partner With the Right Wire Rope Company

Reliable wire rope manufacturers in India offer not just quality products but also technical support, training, and post-sales service. Look for manufacturers who:

Provide certified and tested ropes.

Offer application-specific advice.

Have strong quality control and R&D practices.

Steel wire rope failure is preventable with the right knowledge, practices, and partnerships. By addressing the common causes—fatigue, corrosion, overloading, abrasion, and more—you can extend the lifespan of your ropes and improve workplace safety.

Whether you're working with cranes, elevators, marine applications, or heavy industrial equipment, prevention starts with:

Choosing the right rope,

Ensuring proper handling,

Regular inspections, and

Working with reputable Steel Wire Ropes manufacturers.

#wire rope company in india#material handling equipment#lifting solutions#rigging#steelwirerope#steelwireropescompan#alloy steel chain#manufacturers#infrastructure#stainless steel#steelwireropesuppliers#steelwireropeindustry#steelwireropemanufactures#steel#steelwireropecompany#wire rope hoist#industrialwirerope

0 notes

Text

The Hoists That Keep Our Shop Moving

In any fabrication or industrial environment, the equipment you choose isn’t just about specs, it’s about reliability, safety, and long-term performance. Over the years, we’ve used a range of hoists in our shop, some we’ve kept, some we’ve retired, and a few have become permanent fixtures in our day-to-day work.

Here are the hoists we rely on the most, along with our honest thoughts on each:

R&M Spacemaster SX Wire Rope Hoist

This has become one of our most trusted hoists. It's well-engineered, doesn’t require a lot of maintenance, and has a compact trolley design that fits seamlessly into our existing framework. The control is smooth, and load stability is top-notch. It's definitely earned its place.

CM Lodestar Electric Chain Hoist

CM’s Lodestar is a classic for a reason. We’ve used it for everything from lifting structural steel to positioning smaller assemblies. It’s rugged, parts are easy to find, and it just works. No frills, just dependable performance.

Harrington NER Electric Chain Hoist

Harrington brings some nice refinements, we especially like the dual speed and quiet operation. It’s a great option when precision is key or when working indoors where noise matters more.

Konecranes CLX Chain Hoist

We use this in tighter areas of the shop where space is limited. It’s small but strong and has a user-friendly interface. Konecranes does a great job blending power and ergonomics with this one.

Demag DCS Pro Chain Hoist

This hoist gives you a more refined lift , especially helpful for sensitive or more technical projects. The variable speed and quick-response controls are what make it stand out. We don't use it for everything, but for the right job, it's a game changer.

#fabricationlife#industrialequipment#hoists#overheadcrane#rmhoist#manufacturingtools#workshopsetup#heavylifting#shopgear#engineeringtools#cmhoist#harringtonhoists#konecranes#demaghoist#materialhandling#shoplife#toolreview#machineryblog

0 notes

Text

A Comprehensive Look at Tools & Hardware, Hand Tools, and Knives

The Backbone of Every Build: Tools & Hardware

No project can stand without a solid foundation and that foundation starts with quality tools and hardware. From home renovations to professional construction sites, the right gear ensures strength, durability, and clean finishes.

The Tools & Hardware category includes:

Power tools: Drills, saws, sanders, and other motorized essentials.

Measuring instruments: Tape measures, calipers, levels, and more.

Fasteners: Screws, nails, bolts, anchors—everything that holds things together.

Safety gear: Helmets, gloves, goggles, and protective apparel.

Hand Tools: Timeless Precision in Your Hands

Long before electricity powered our tools, everything was built by hand. Today, hand tools remain indispensable thanks to their unmatched precision and reliability. They’re often the first tools we reach for when delicate, detailed, or quick jobs arise.

Essential hand tools include:

Screwdrivers: From electronics to cabinetry, screwdrivers are a must-have.

Wrenches & pliers: For gripping, turning, and adjusting nuts, bolts, and fittings.

Hammers: Including claw hammers, mallets, and specialty types for framing or finishing.

Chisels: Ideal for woodworking, carving, and shaping materials with accuracy.

Utility knives: Compact yet powerful, perfect for cutting insulation, drywall, or rope.

Unlike their powered counterparts, hand tools require no batteries or outlets—making them reliable even in remote locations or during power outages.

Knives: Cutting Tools That Define Precision

Among hand tools, knives deserve special attention. Far beyond kitchen duty, these tools are designed for jobsite performance—combining sharpness, control, and durability in one compact form.

Common types of work knives:

Utility knives: Featuring retractable or replaceable blades, these are ideal for cutting drywall, packaging, and carpet.

Fixed-blade knives: Sturdier and often used in tougher, repetitive applications.

Electricians’ knives: Built with non-conductive handles and specialized blades for electrical work.

Precision knives: Small, sharp, and perfect for crafts, models, or intricate details.

When selecting a knife, consider blade type (stainless vs. carbon steel), ergonomics, safety features, and whether the blade is fixed, folding, or replaceable. The right knife enhances speed, accuracy, and safety on any job.

Why Quality Tools Make a Difference

With tools, quality is never optional. Cheap tools might seem like a bargain, but they can fail quickly, compromise your work, or even cause injury. Investing in well-made tools ensures longevity, superior performance, and peace of mind.

What makes quality tools worth it?

A premium wrench won’t strip fasteners.

A durable knife won’t break during heavy use.

A precision screwdriver fits snugly, reducing wear on both tool and screw.

High-end tools also tend to offer better ergonomics, reducing fatigue and improving accuracy over long periods.

Keeping Tools in Top Condition

Proper care keeps your tools working hard for years to come. Whether you’re maintaining a utility knife or a full power tool collection, these tips can extend tool life and boost safety:

Wipe down tools after use to prevent corrosion.

Regularly sharpen knives and blades for optimal cutting performance.

Store tools neatly—use racks, toolboxes, or wall mounts to avoid damage.

Lubricate joints and moving parts periodically.

Inspect tools often; replace or repair anything showing signs of wear.

Pro Tip: A dull knife is more dangerous than a sharp one—apply more force, and you're more likely to slip.

Building Your Toolkit: Start Smart, Grow with Experience

The ideal toolkit depends on your trade or tasks. Carpenters might prioritize saws and chisels, while electricians focus on insulated pliers and wire strippers. That said, a core collection of hand tools is useful in nearly every field:

Multi-bit screwdriver

Adjustable wrench

Tape measure

Claw hammer

Utility knife

Allen key set

Level

Handsaw

Start with these essentials and expand as your projects demand. Many brands now offer modular systems—toolkits and accessories designed to work together across a common platform, simplifying your setup.

Where to Buy: Online vs. In-Store

With e-commerce on the rise, it’s easier than ever to explore a wide selection of tools and compare reviews before you buy. But there’s still value in visiting a hardware store, where you can test a tool’s grip, weight, and balance firsthand.

Shop smart by looking for:

Trusted brands like DeWalt, Bosch, Milwaukee, and Stanley

Strong warranties and return policies

Bundled toolkits or multi-tool deals

Verified customer reviews for real-world feedback

Conclusion: Tools That Build More Than Just Projects

Every tool you choose shapes the outcome of your work—and your experience along the way. By investing in the right Tools & Hardware, understanding the power of Hand Tools, and selecting high-quality Knives, you’re not just completing tasks; you’re building skills, confidence, and capability.

The right tools can turn a challenge into an achievement. Keep your gear sharp, your standards high, and your toolbox ready—you'll be prepared for whatever project comes next.

0 notes

Text

Elevate Your Drying Experience with a Ceiling Cloth Hanger

When it comes to saving space and keeping your home organized, one underrated yet incredibly useful solution is the Ceiling Cloth Hanger. Gone are the days of tangled wires, rusted stands, or cluttered balconies. This modern drying solution combines functionality with style, perfectly fitting into today’s compact homes and busy lifestyles.

Whether you live in an apartment or a bungalow, drying clothes can often be a challenge — especially during monsoons or in small spaces. That’s where a ceiling cloth hanger becomes your smart drying companion.

What is a Ceiling Cloth Hanger

A Ceiling Cloth Hanger is a ceiling-mounted drying system with a pulley mechanism that allows you to raise and lower rods for easy hanging and drying of clothes. Designed to be installed on the ceiling — whether in your balcony, utility area, or bathroom — it frees up valuable floor space while giving you the flexibility to dry clothes efficiently.

Side points:

Uses vertical space effectively

Keeps your floor area clean and open

Ideal for all weather drying

Why Choose a Ceiling Cloth Hanger for Your Home

From saving space to making daily chores easier, a ceiling cloth hanger offers plenty of benefits. Let’s look at why thousands of homeowners are switching to this smart solution.

Effortless Operation With its pulley system, you don’t need to bend or stretch. Simply pull the ropes to lower the rods, hang your clothes, and lift them back up. No more back pain or inconvenience.

Strong and Durable Our ceiling cloth hangers are made of rust-proof stainless steel or powder-coated aluminum, making them long-lasting and weather-resistant — perfect for indoor or semi-outdoor usage.

Space Optimization Whether you have a tiny balcony or a compact utility area, this hanger fits snugly on your ceiling, giving you complete freedom below.

Side points:

Pain-free usage for elders

No tools needed for everyday handling

Withstands heavy laundry loads

Types of Ceiling Cloth Hangers Available

At Jindal Hanger, we offer various options tailored for every kind of home setup.

Single Rod System Perfect for small families or studio apartments. Compact yet efficient.

Multiple Rod System (4 to 6 Rods) Ideal for medium to large families, offering more drying space. Each rod can be moved independently.

Balcony Models Specially designed for balconies with aesthetic finishes and weather-resistant materials.

Side points:

Available in different lengths and finishes

Custom installations based on ceiling height

UV and corrosion-resistant designs

Where to Install Your Ceiling Cloth Hanger

The beauty of a Ceiling Cloth Hanger lies in its versatility. You can install it in multiple areas of your home depending on your layout and space.

Balcony This is the most popular location. Fresh air speeds up drying, and you can keep your living areas free from moisture.

Utility Room or Laundry Area Dry clothes directly after washing, and keep them out of sight.

Bathroom Great for small clothing items or towels. Also helpful during monsoons when outdoor drying isn’t feasible.

Side points:

Maintains aesthetics of your home

Can be moved easily during renovation

No obstruction in daily movement

Why Hyderabad Trusts Jindal Hanger

If you're looking for the best Ceiling Cloth Hanger in Hyderabad, Jindal Hanger is your go-to expert. Our products are crafted for durability, convenience, and style. And here’s what we offer exclusively in Hyderabad:

✅ Free Installation ✅ Free Delivery ✅ Lifetime Warranty

With our trained technicians and premium-quality materials, we make sure your drying solution is smooth and long-lasting.

Side points:

On-time doorstep service

Hyderabad-wide support

10000+ happy customers and counting

How to Maintain Your Ceiling Cloth Hanger

Maintenance is minimal, but a little care ensures it lasts for years.

Clean rods once a month with a soft cloth to avoid dust build-up

Check pulleys for smooth movement

Use the system gently to avoid unnecessary tension on ropes

Side points:

No need for regular servicing

Works even after years of heavy use

User-friendly even for kids and elders

Final Thoughts

A Ceiling Cloth Hanger is not just a utility item, it’s a lifestyle upgrade. It helps you save space, reduce physical effort, and maintain a neat and organized home. If you’re in Hyderabad and looking for the best quality and service, Jindal Hanger is here to transform your laundry routine.

0 notes

Text

5 Heavy Duty Lifting Equipments for Industries and Construction

The construction and industrial sectors rely on Heavy Duty Lifting Equipments to handle large, heavy materials with efficiency and safety. From moving steel beams on construction sites to lifting heavy machinery in warehouses, the right equipment ensures smooth operations, reduces manual labor, and minimizes workplace risks.

Choosing the correct lifting equipment is essential for ensuring workplace safety, operational efficiency, and compliance with industrial standards. This guide explores five of the most reliable heavy-duty lifting equipments that are widely used in industries and construction.

5 Heavy Duty Lifting Equipments for Industries and Construction

1. Electric Hoists

Electric hoists are among the most versatile and commonly used lifting solutions in industrial and construction environments. These motorized devices lift and lower heavy loads with precision, making them ideal for warehouses, construction sites, and manufacturing facilities.

Key Benefits:

High Load Capacity: Electric hoists can lift several tons of weight, making them suitable for various applications.

Efficient Operation: The motorized function eliminates manual effort, improving productivity.

Precision Lifting: Many electric hoists come with adjustable speed controls for safe and precise lifting.

For businesses looking to upgrade their lifting capabilities, it is easy to buy electric hoists online, ensuring quick access to high-quality equipment designed for industrial use.

2. Crane Systems

Cranes are essential for large-scale construction and industrial projects. These heavy-duty lifting equipments are designed to lift, move, and position massive loads across different areas of a job site.

Types of Cranes Used in Construction & Industry:

Tower Cranes: Used in high-rise construction for lifting steel, concrete, and heavy machinery.

Mobile Cranes: Versatile and easy to transport, mobile cranes are suitable for various lifting tasks.

Overhead Cranes: Common in warehouses and manufacturing units for lifting and moving loads along a fixed path.

Cranes play a vital role in enhancing efficiency and ensuring worker safety, making them an indispensable asset for large-scale projects.

3. Forklifts

Forklifts are compact yet powerful lifting machines widely used in warehouses, factories, and construction sites. They are designed to lift, transport, and stack heavy materials efficiently.

Why Forklifts are Essential:

Quick Material Handling: Forklifts can transport heavy loads across short distances with ease.

Multiple Attachments Available: Various attachments, such as pallet forks and clamps, make forklifts adaptable for different tasks.

Ideal for Indoor & Outdoor Use: They are used in both warehouse storage and open construction sites.

Forklifts are an integral part of construction toolkits for professionals, enabling seamless transportation of materials in demanding industrial environments.

4. Lifting Slings and Chains

When it comes to securing and lifting heavy loads, reliable lifting slings and chains are crucial. These accessories are used alongside cranes, hoists, and other lifting devices to ensure safe and stable load handling.

Types of Lifting Slings & Chains:

Chain Slings: Heavy-duty chains designed for lifting steel beams, pipes, and machinery.

Wire Rope Slings: Strong and durable, ideal for high-tension applications.

Synthetic Slings: Made from polyester or nylon, offering flexibility and lightweight handling.

Using high-quality slings and chains is essential for reducing the risk of accidents and ensuring secure lifting operations.

5. Hydraulic Jacks and Winches

Hydraulic jacks and winches are compact yet powerful heavy-duty lifting equipments used for lifting, pulling, and positioning heavy objects.

Advantages of Hydraulic Jacks & Winches:

High Lifting Capacity: Can lift extremely heavy loads with minimal effort.

Portable & Versatile: Used in construction, automotive repair, and industrial settings.

Reliable Performance: Provides a safe and controlled lifting process.

These tools are often found in multi-purpose screwdrivers and wrenches kits, making them a practical choice for professionals in construction, repair, and industrial maintenance.

Conclusion – Heavy Duty Lifting Equipments

Industries and construction sites depend on heavy-duty lifting equipment to increase productivity, improve workplace safety, and handle large materials efficiently. Whether it’s electric hoists, crane systems, forklifts, lifting slings, or hydraulic jacks, investing in the right lifting solutions is crucial for operational success.

For businesses looking to upgrade their lifting tools, AHM Building Materials offers a wide range of high-quality lifting equipment. Visit AHM Building Materials to explore premium lifting solutions designed for industrial and construction needs.

0 notes

Text

SCAR 10S Winch Built for Real Off Road Gear and Recovery Use

When we talk about off-road recovery, there’s no room for second-guessing your gear. That’s why we rely on tools that prove themselves every time we hit the trail. One product we stand behind is the SCAR 10S 10,000 LB Synthetic Rope Winch—a solid piece of off road gear that’s all about strength, reliability, and simplicity. Whether you're stuck in the mud, tangled in a ditch, or pulling a buddy to safety, this winch doesn’t flinch.

Let’s break down why this product has become one of our go-to recovery tools.

Product Information

The SCAR 10S Synthetic Rope Winch is built to perform under pressure. Designed to handle up to 10,000 lbs of pulling force, it uses high-strength synthetic rope to keep things light, safe, and manageable without sacrificing power. With a focus on functionality and trail-ready design, this winch fits right in with serious off road gear.

Key specs include:

Rated line pull: 10,000 lbs (single line)

100 ft of 3/8” synthetic rope

6.0 HP series wound motor

IP68-rated waterproofing

Wireless and wired remote options

Black powder-coated finish for added durability

It’s designed to blend form and function, giving you everything you need in a recovery system without unnecessary bells and whistles.

The Off-Road Essential You Can Count On

What makes the SCAR 10S stand out is its dependability. When you're navigating tough terrain, you don’t want to worry about your winch stalling out or fraying under pressure. We’ve tested it in real-world trail conditions, and it’s proven itself time and again.

We chose synthetic rope because it's lighter, safer, and easier to handle than steel cable. If it snaps, there’s less snapback force. It's a smart solution for modern off road gear setups that need to be efficient and safe without cutting corners.

This winch is also compact enough to mount cleanly on most bumpers while still delivering a serious amount of pulling strength. It’s ready for action whenever and wherever we need it.

Everything You Need

When you purchase the SCAR 10S 10,000 LB Synthetic Rope Winch, here’s what’s in the package:

Winch body with 6.0 HP motor

100 ft of synthetic rope (3/8”)

Aluminum hawse fairlead

Wireless remote controller

Wired remote controller

Control box

Mounting hardware

Hook with safety strap

Installation and user manual

Everything comes neatly packed and ready to bolt on. Whether you're upgrading your current setup or building a new rig, it’s an easy fit.

For Every Off-Roader

If you’re someone who heads off pavement more than once in a while, you already know that recovery gear is non-negotiable. We’ve seen this winch become a staple for:

Overlanders building self-reliant rigs

Weekend warriors tackling backwoods trails

Off-road enthusiasts heading into rocky, muddy, or snowy areas

Truck owners who haul or tow through unpredictable terrain

Anyone who travels solo and wants a reliable backup

This winch gives you a solid safety net—and in many cases, it can be the difference between a long wait for help and a quick self-recovery.

Key Features and Benefits

Let’s talk features—the SCAR 10S doesn’t cut corners:

1. 10,000 LB Capacity

It’s got serious pulling power, enough to handle mid-size trucks, SUVs, and overland rigs with ease.

2. Synthetic Rope

Strong yet lightweight, synthetic rope is easier to spool, safer to handle, and floats in water. It’s a smart upgrade over traditional steel cables.

3. IP68 Waterproof Rating

Trail conditions don’t stop for weather, so we don’t either. This winch is built to keep working through rain, mud, and snow.

4. Dual Remote Options

Choose between wired or wireless operation. Whether you’re stuck on a tight trail or need space to maneuver, both options come in handy.

5. Aluminum Hawse Fairlead

Designed for use with synthetic rope, it reduces wear and keeps your rope running smoothly.

6. Easy Installation

With all necessary hardware included, setup is simple and clean. We’ve mounted plenty of winches, and this one’s been among the easiest.

For the Bold and Adventurous

The SCAR 10S is made for people who take off-road preparedness seriously. It fits right into a wide range of vehicles and lifestyles:

4x4 owners: Jeep, Toyota, Ford, and Chevy owners who want rugged, trail-ready performance.

Overlanders: Folks who camp off-grid and travel remote routes will appreciate the peace of mind this winch offers.

Outdoor pros: Hunters, land managers, and rural workers who need dependable off road gear.

Clubs and off-road groups: Perfect for shared rigs or trail support vehicles that tackle group recoveries.

What You Get

Here’s a recap of what you’ll receive with your SCAR 10S order:

1x Winch with synthetic rope installed

1x Aluminum hawse fairlead

1x Hook with safety strap

1x Wireless remote

1x Wired remote

1x Control box and mounting hardware

Detailed instructions for setup

We made sure every part is ready to go—right out of the box.

Gear Made for Real Life

At C4 Fabrication, we build gear that we’d use on our own trucks. Located right in Sturgis, South Dakota, we design, test, and manufacture with trail durability in mind. We’re not just selling parts—we’re building tools that support real people in real situations.