#CompressedAir

Explore tagged Tumblr posts

Text

It is time to connect to your docking station

#dronification#rubberman#gay gear#gas mask#rubberdrone#gay rubber#transformation#gay men#scubadiving#scuba gear#compressedair#ai generated#gearfetish

233 notes

·

View notes

Text

Air Compressor Market Anticipated to Grow to USD 39.52 Billion by 2034 | CAGR: 5.60%

Air Compressor market Analysis: Opportunities, Innovations, and Growth Potential Through [Forecast Period] The global air compressor market was worth USD 25.32 billion in 2024 and is predicted to register a CAGR of 5.60% between 2025 and 2034. Market Definition The air compressor market encompasses machines that convert power into potential energy stored in pressurized air. These compressors are…

#AirCompressorMarket#CompressedAir#CompressorTechnology#EnergyEfficiency#HVACSystems#IndustrialMachinery#ManufacturingEquipment#PneumaticTools#ReciprocatingCompressors#RotaryCompressors

0 notes

Text

Loitha | Top Compressor Manufacturers – Reliable Industrial Air Compressors

Loitha: Leading the Way Among Compressor Manufacturers

In the vast and competitive world of industrial equipment, compressor manufacturers play a crucial role in powering multiple industries — from automotive to food processing. Among them, Loitha stands tall as one of the most trusted and innovative names. With an unwavering focus on quality, durability, and performance, Loitha has become a household name in the compressor manufacturing industry.

Why Choose Loitha Over Other Compressor Manufacturers?

When businesses search for compressor manufacturers, they want reliability, advanced technology, and exceptional service. Loitha provides all this and more. With decades of experience and a customer-centric approach, Loitha delivers world-class compressor solutions tailored to meet specific industrial needs.

Loitha’s Range of Compressors

Rotary Screw Compressors

Loitha offers an advanced line of rotary screw compressors that are ideal for continuous use. As leading compressor manufacturers, Loitha designs these machines for energy efficiency, quiet operation, and minimal maintenance.

Reciprocating Compressors

For businesses needing high-pressure performance, Loitha reciprocating compressors deliver unmatched reliability. Many compressor manufacturers ignore this niche, but Loitha continues to excel here.

Oil-Free Compressors

Industries like food, pharmaceuticals, and electronics require clean air. As one of the top compressor manufacturers, Loitha provides oil-free solutions that meet ISO certifications and environmental standards.

What Makes Loitha Unique Among Compressor Manufacturers?

Advanced R&D Facilities

Unlike many traditional compressor manufacturers, Loitha invests heavily in research and development to stay ahead of the curve.

Customization and Flexibility

Loitha understands that one-size-fits-all doesn’t work for everyone. That’s why, compared to other compressor manufacturers, Loitha offers a highly customizable product lineup.

Energy Efficiency

Energy costs can burden businesses, which is why Loitha compressors are designed to be among the most energy-efficient among all compressor manufacturers.

Industries Served by Loitha – Top Compressor Manufacturers

Automotive Industry

Loitha compressors are widely used in automotive manufacturing for everything from painting to tire inflation.

Textile Industry

The textile sector relies on Loitha, one of the most trusted compressor manufacturers, for spinning, weaving, and dyeing processes.

Food & Beverage

Clean, contaminant-free compressed air is vital in this industry, and Loitha delivers with its oil-free series.

Construction

Heavy-duty compressors by Loitha help power tools and machinery on construction sites globally.

Global Presence of Loitha

Unlike local compressor manufacturers, Loitha has expanded across continents with a strong distribution and service network in Asia, Europe, and Africa.

Customer-Centric Approach by Loitha

While many compressor manufacturers focus solely on sales, Loitha focuses on long-term relationships through after-sales service, maintenance, and technical support.

Certifications and Quality Standards

ISO Certified

Loitha is ISO 9001 and ISO 14001 certified, proving its commitment to quality and environmental responsibility — a trait not all compressor manufacturers can claim.

CE Marking

All Loitha compressors comply with EU regulations, making it a top choice among global compressor manufacturers.

Innovation at the Heart of Loitha

IoT Integration

Loitha leads among compressor manufacturers by offering IoT-enabled compressors that allow for real-time monitoring and analytics.

Noise Reduction Technology

Loitha is committed to workplace safety and comfort. Their machines are quieter than most other compressor manufacturers can offer

Environmental Commitment

As responsible compressor manufacturers, Loitha uses sustainable practices and recyclable materials to lower carbon footprint across its operations.

Loitha’s Service Network

A product is only as good as the support behind it. That’s why Loitha maintains a strong service network — another area where most compressor manufacturers fall short.

How to Contact Loitha – The Top Name Among Compressor Manufacturers

Looking for the best compressor solutions? Reach out to Loitha today and get expert consultation tailored to your business. No other compressor manufacturers will understand your needs like Loitha does.

Final Words

When you choose Loitha, you're choosing one of the most forward-thinking and reliable compressor manufacturers in the market. From innovation to sustainability, Loitha ticks all the right boxes.

Summary of Loitha's Advantages:

Trusted brand in compressor manufacturing

Wide range of compressor models

ISO-certified and CE-marked

Global distribution and service

Industry-leading customer support

Follow Us:

Contact No. : +91 9601415434

Email ID: [email protected]

website: https://www.loitha.com/

Facebook: LothAir/

Instagram:/loitha_Air/

Youtube: @LOITHAAir

#CompressorManufacturers#IndustrialCompressors#AirCompressors#RotaryScrewCompressor#ReciprocatingCompressor#OilFreeCompressor#MadeByLoitha#LoithaCompressors#EngineeringExcellence#IndustrialSolutions#EnergyEfficientCompressors#CompressedAir#ManufacturingIndustry#SmartCompressors#GlobalManufacturing#HeavyMachinery#IndustrialTechnology#LoithaInnovation#LoithaPerformance

0 notes

Text

Air Knife Blower – Industrial-Grade Efficiency

EXAIR’s Air Knife Blower uses a high-velocity sheet of air to efficiently dry, clean, or cool parts and processes. With low air consumption and quiet operation, it’s an ideal solution for blowing off water, debris, or excess materials in industrial settings.

0 notes

Text

TVSPL High Pressure Diffuser

For Total Air Particulate of Compressed Air/Gas we can use it in conjunction with a 1CFM, 28.3LPM, 50LPM, 75LPM, or 100 LPM Optical Particle Counters of all makes.

TECHNICAL SPECIFICATIONS

Material of Construction: SS 316 (Stainless Steel)

Output Flow/Use: 1 CFM, 28.3 LPM, 50 LPM, 75 LPM, or 100 LPM

Requirements Suitable For: All Makes Optical/Laser Particle Counters

Inlet Pressure Required: 25 to 125 PSI (approx for HPD)

HPD Dimensions (Approx): 140mm x 32mm QD

HPD for 1 CFM/28.3 LPM OPC: Model No. TVS HPD SS6 001 (TVSPL High Pressure Diffuser)

HPD for 50 LPM OPC: Model No. TVS HPD SS6 050

HPD for 75 LPM/100 LPM OPC: Model No. TVS HPD SS6 100

HPD for 28.3/50/100 LPM OPC: Model No. TVS HPD SS6 002*

Visit www.twchnovale.in for more info.

#CompressedAir#ParticleCounting#OpticalParticleCounter#CleanroomMonitoring#AirQuality#HighPressureDiffuser#SS316#ContaminationControl#IndustrialEquipment#FlowMeasurement#LaserParticleCounter#AirMonitoring#PharmaManufacturing#CleanAirSolutions#EnvironmentalMonitoring

0 notes

Text

Moisture Separator for Steam & Air Compressors – Types, Prices & Delhi Supplier Guide by Udhhyog

In steam and compressed air systems, moisture causes reduced efficiency, corrosion, and equipment damage. That’s where moisture separators (also called water separators or moisture traps) come into play. These devices remove water vapor or condensate from the system before it affects performance.

Udhhyog, a trusted name in industrial supply, offers high-quality moisture separators for both steam lines and air compressors – backed by fast delivery across Delhi and North India.

What is a Moisture Separator?

A moisture separator is a device installed in a pipeline to remove water droplets or condensate from steam or compressed air before it reaches machinery, dryers, or control valves.

Moisture separators improve:

Efficiency of compressors

Lifespan of pneumatic tools

Steam quality

Heat transfer rates

Types of Moisture Separators Supplied by Udhhyog

🔹 1. Steam Line Moisture Separator

Removes condensate from steam

Centrifugal or baffle type designs

Used in process heating, boilers, autoclaves

🔹 2. Air Compressor Moisture Trap

Removes water from compressed air

Inline design fits directly into the airline

Used in manufacturing, paint booths, CNC machines

🔹 3. Oil & Water Separator for Condensate

Removes oil mixed with water from compressors

Compliant with environmental discharge norms

🔹 4. Centrifugal Water Separator

Uses centrifugal force to separate heavier water from air

Ideal for high-pressure compressors

Popular Brands & Compatibility

✅ Compatible with: Ingersoll Rand, Hydint, Forbes Marshall

✅ Udhhyog supplies OEM-grade replacements

✅ Custom size & flange options available

Technical Specifications

ApplicationTypePressure RangeMaterialSize RangeSteam LinesBaffle / CentrifugalUp to 20 barSS / Cast Iron15mm – 100mmAir CompressorsInline / Bowl TrapUp to 16 barMS / Brass¼" – 2" BSP/NPTCondensate OutletOil/Water SeparatorUp to 12 barPlastic/Metal½" – 1½"

Moisture Separator Price List (Delhi Market – 2024)

Product TypeSizePrice Range (INR)Steam Moisture Separator1”–2”₹850 – ₹3,500In-Line Air Moisture Trap¼”–1”₹450 – ₹1,500Oil-Water Separator (Compressor)½”–1½”₹1,200 – ₹2,800

📥 Download full product list: https://udhhyog.com/valves

Applications of Udhhyog Moisture Separators

🏭 Compressed air networks in industries

♨️ Boiler and autoclave steam lines

🧪 Laboratories with pneumatic setups

🛠️ CNC, sandblasting, painting and tool shops

Why Choose Udhhyog for Moisture Separators in Delhi?

✅ Product Benefits:

High water-removal efficiency

Rust-proof materials and long life

Easy to install and service

🚚 Delivery:

Fast shipping to Delhi, Punjab, Haryana, Rajasthan, UP, J&K

In-stock options for same-day dispatch

💰 Value:

Direct-from-manufacturer pricing

Volume discounts for contractors and OEMs

FAQs

Q1: Are Udhhyog separators suitable for Ingersoll Rand compressors? Yes, we offer compatible models for top brands.

Q2: Do I need a moisture separator if I already use a dryer? Yes, separators catch water earlier and reduce dryer load.

Q3: Can I use the same separator for steam and air? No, steam separators are pressure-rated and material-specific.

How to Order

📞 Call: +91-XXXXXXXXXX 🌐 Visit: https://udhhyog.com 📩 Email: [email protected] / Contact Form

#MoistureSeparator#SteamTrap#OilWaterSeparator#AirCompressorTrap#WaterTrap#Udhhyog#DelhiValveSupplier#IndustrialFiltration#CompressedAir

1 note

·

View note

Text

Moisture Separator for Steam & Air Compressors – Types, Prices & Delhi Supplier Guide by Udhhyog

In steam and compressed air systems, moisture causes reduced efficiency, corrosion, and equipment damage. That’s where moisture separators (also called water separators or moisture traps) come into play. These devices remove water vapor or condensate from the system before it affects performance.

Udhhyog, a trusted name in industrial supply, offers high-quality moisture separators for both steam lines and air compressors – backed by fast delivery across Delhi and North India.

What is a Moisture Separator?

A moisture separator is a device installed in a pipeline to remove water droplets or condensate from steam or compressed air before it reaches machinery, dryers, or control valves.

Moisture separators improve:

Efficiency of compressors

Lifespan of pneumatic tools

Steam quality

Heat transfer rates

Types of Moisture Separators Supplied by Udhhyog

🔹 1. Steam Line Moisture Separator

Removes condensate from steam

Centrifugal or baffle type designs

Used in process heating, boilers, autoclaves

🔹 2. Air Compressor Moisture Trap

Removes water from compressed air

Inline design fits directly into the airline

Used in manufacturing, paint booths, CNC machines

🔹 3. Oil & Water Separator for Condensate

Removes oil mixed with water from compressors

Compliant with environmental discharge norms

🔹 4. Centrifugal Water Separator

Uses centrifugal force to separate heavier water from air

Ideal for high-pressure compressors

Popular Brands & Compatibility

✅ Compatible with: Ingersoll Rand, Hydint, Forbes Marshall

✅ Udhhyog supplies OEM-grade replacements

✅ Custom size & flange options available

Technical Specifications

ApplicationTypePressure RangeMaterialSize RangeSteam LinesBaffle / CentrifugalUp to 20 barSS / Cast Iron15mm – 100mmAir CompressorsInline / Bowl TrapUp to 16 barMS / Brass¼" – 2" BSP/NPTCondensate OutletOil/Water SeparatorUp to 12 barPlastic/Metal½" – 1½"

Moisture Separator Price List (Delhi Market – 2024)

Product TypeSizePrice Range (INR)Steam Moisture Separator1”–2”₹850 – ₹3,500In-Line Air Moisture Trap¼”–1”₹450 – ₹1,500Oil-Water Separator (Compressor)½”–1½”₹1,200 – ₹2,800

📥 Download full product list: https://udhhyog.com/valves

Applications of Udhhyog Moisture Separators

🏭 Compressed air networks in industries

♨️ Boiler and autoclave steam lines

🧪 Laboratories with pneumatic setups

🛠️ CNC, sandblasting, painting and tool shops

Why Choose Udhhyog for Moisture Separators in Delhi?

✅ Product Benefits:

High water-removal efficiency

Rust-proof materials and long life

Easy to install and service

🚚 Delivery:

Fast shipping to Delhi, Punjab, Haryana, Rajasthan, UP, J&K

In-stock options for same-day dispatch

💰 Value:

Direct-from-manufacturer pricing

Volume discounts for contractors and OEMs

FAQs

Q1: Are Udhhyog separators suitable for Ingersoll Rand compressors? Yes, we offer compatible models for top brands.

Q2: Do I need a moisture separator if I already use a dryer? Yes, separators catch water earlier and reduce dryer load.

Q3: Can I use the same separator for steam and air? No, steam separators are pressure-rated and material-specific.

How to Order

📞 Call: +91-XXXXXXXXXX 🌐 Visit: https://udhhyog.com 📩 Email: [email protected] / Contact Form

#MoistureSeparator#SteamTrap#OilWaterSeparator#AirCompressorTrap#WaterTrap#Udhhyog#DelhiValveSupplier#IndustrialFiltration#CompressedAir

1 note

·

View note

Text

Moisture Separator for Steam & Air Compressors – Types, Prices & Delhi Supplier Guide by Udhhyog

In steam and compressed air systems, moisture causes reduced efficiency, corrosion, and equipment damage. That’s where moisture separators (also called water separators or moisture traps) come into play. These devices remove water vapor or condensate from the system before it affects performance.

Udhhyog, a trusted name in industrial supply, offers high-quality moisture separators for both steam lines and air compressors – backed by fast delivery across Delhi and North India.

What is a Moisture Separator?

A moisture separator is a device installed in a pipeline to remove water droplets or condensate from steam or compressed air before it reaches machinery, dryers, or control valves.

Moisture separators improve:

Efficiency of compressors

Lifespan of pneumatic tools

Steam quality

Heat transfer rates

Types of Moisture Separators Supplied by Udhhyog

🔹 1. Steam Line Moisture Separator

Removes condensate from steam

Centrifugal or baffle type designs

Used in process heating, boilers, autoclaves

🔹 2. Air Compressor Moisture Trap

Removes water from compressed air

Inline design fits directly into the airline

Used in manufacturing, paint booths, CNC machines

🔹 3. Oil & Water Separator for Condensate

Removes oil mixed with water from compressors

Compliant with environmental discharge norms

🔹 4. Centrifugal Water Separator

Uses centrifugal force to separate heavier water from air

Ideal for high-pressure compressors

Popular Brands & Compatibility

✅ Compatible with: Ingersoll Rand, Hydint, Forbes Marshall

✅ Udhhyog supplies OEM-grade replacements

✅ Custom size & flange options available

Technical Specifications

ApplicationTypePressure RangeMaterialSize RangeSteam LinesBaffle / CentrifugalUp to 20 barSS / Cast Iron15mm – 100mmAir CompressorsInline / Bowl TrapUp to 16 barMS / Brass¼" – 2" BSP/NPTCondensate OutletOil/Water SeparatorUp to 12 barPlastic/Metal½" – 1½"

Moisture Separator Price List (Delhi Market – 2024)

Product TypeSizePrice Range (INR)Steam Moisture Separator1”–2”₹850 – ₹3,500In-Line Air Moisture Trap¼”–1”₹450 – ₹1,500Oil-Water Separator (Compressor)½”–1½”₹1,200 – ₹2,800

📥 Download full product list: https://udhhyog.com/valves

Applications of Udhhyog Moisture Separators

🏭 Compressed air networks in industries

♨️ Boiler and autoclave steam lines

🧪 Laboratories with pneumatic setups

🛠️ CNC, sandblasting, painting and tool shops

Why Choose Udhhyog for Moisture Separators in Delhi?

✅ Product Benefits:

High water-removal efficiency

Rust-proof materials and long life

Easy to install and service

🚚 Delivery:

Fast shipping to Delhi, Punjab, Haryana, Rajasthan, UP, J&K

In-stock options for same-day dispatch

💰 Value:

Direct-from-manufacturer pricing

Volume discounts for contractors and OEMs

FAQs

Q1: Are Udhhyog separators suitable for Ingersoll Rand compressors? Yes, we offer compatible models for top brands.

Q2: Do I need a moisture separator if I already use a dryer? Yes, separators catch water earlier and reduce dryer load.

Q3: Can I use the same separator for steam and air? No, steam separators are pressure-rated and material-specific.

How to Order

📞 Call: +91-XXXXXXXXXX 🌐 Visit: https://udhhyog.com 📩 Email: [email protected] / Contact Form

#MoistureSeparator#SteamTrap#OilWaterSeparator#AirCompressorTrap#WaterTrap#Udhhyog#DelhiValveSupplier#IndustrialFiltration#CompressedAir

0 notes

Text

Is Compressed Air Inexpensive Enough To Ignore Measurement?

Ignoring Compressed Air Measurement can increase costs and reduce efficiency. Measuring Compressed Air ensures optimal energy use, lowers expenses, and improves system performance, making it essential for industrial operations.

0 notes

Text

How to Maintain Your Compressed Air Hose: Tips for Longer Hose Life

Compressed air hoses are an essential part of many industrial and workshop environments, providing a reliable means of transporting air to power tools and equipment. However, without proper maintenance, these hoses can wear out, leading to costly repairs or replacements. This blog will provide you with effective maintenance tips to ensure that your compressed air hose remains in top shape for as long as possible, minimizing downtime and maximizing performance.

1. Regular Inspection for Wear and Tear

The first step to maintaining your compressed air hose is conducting regular inspections. Look out for any visible signs of wear and tear, such as cracks, kinks, bulges, or other deformations. Over time, hoses can become brittle or develop weak spots, which can lead to air leaks or sudden failures. Inspecting your hose regularly allows you to spot potential problems early and replace damaged sections before they become dangerous.

2. Store Properly When Not in Use

How you store your compressed air hose is just as important as how you use it. Ensure that the hose is stored in a cool, dry area away from direct sunlight, extreme temperatures, or any sharp objects that could cause damage. Coiling the hose correctly, without kinking or twisting, can help to prevent damage to the inner lining. Using a reel can make it easier to store the hose neatly and reduce wear over time.

3. Avoid Excessive Bending and Kinking

Compressed air hoses are vulnerable to damage from excessive bending and kinking. When using your hose, be mindful of the way you lay it out to avoid tight bends, especially near the fittings. Repeated kinking in the same spot can weaken the hose and eventually lead to leaks or breaks. To prevent kinking, always uncoil the hose fully before use and avoid sharp turns.

4. Keep the Hose Clean

Keeping your compressed air hose clean is crucial for its longevity. Dirt, oil, and debris can accumulate on the hose and cause wear, especially if the hose is dragged across dirty surfaces. Wipe down the hose after use to remove any grime, and make sure the connectors are clean before attaching the hose to tools or compressors. This simple habit will help extend the life of your hose and keep it functioning efficiently.

5. Use the Right Hose for the Job

Using the correct type of hose for your specific application is key to prolonging its lifespan. Compressed air hoses come in different materials, pressure ratings, and diameters, each suited to specific uses. Make sure that your hose is rated for the maximum pressure of your compressor and that the material is appropriate for the environment. For example, if you are working in a harsh environment, a heavy-duty reinforced hose may be necessary.

6. Monitor and Control Air Pressure

One of the most common reasons for hose failure is exceeding the recommended pressure rating. Always monitor the air pressure using a gauge and ensure it stays within the safe limits specified for your hose. Over-pressurizing a hose can cause it to expand and weaken, which significantly reduces its lifespan. Use a pressure regulator to maintain the correct pressure and avoid damaging your equipment.

7. Protect Against Environmental Damage

Exposure to sunlight, extreme temperatures, and chemicals can degrade your compressed air hose over time. UV radiation from the sun can cause the hose material to crack, while extreme cold can make it brittle. If your work requires outdoor use, consider using a UV-resistant hose or applying a protective cover. Additionally, if you work with chemicals, make sure your hose is rated to resist any substances it may come into contact with.

8. Check Fittings and Connections

The connections and fittings are critical points that often suffer from wear and tear. Ensure that the fittings are secure and check for any signs of leaks. Loose or worn fittings can lead to air leaks, reducing the efficiency of your tools and increasing energy costs. Replacing worn fittings promptly can prevent more significant damage to your hose.

9. Drain Moisture Regularly

Compressed air systems often produce moisture, which can accumulate inside the hose. This moisture can lead to internal corrosion and weaken the hose material. To prevent this, drain any moisture from the compressor and the hose regularly. Using an air dryer or a moisture separator can also help to reduce the amount of moisture that enters the hose, thereby extending its life.

10. Avoid Dragging the Hose

Dragging your hose across rough surfaces can cause abrasion and damage to the outer layer. Instead of pulling the hose along the ground, try to lift it or use hose reels to move it smoothly. Abrasions weaken the hose and make it more susceptible to leaks and failures. Using hose protectors in high-wear areas can also help minimize damage from friction.

11. Replace Damaged Hoses Immediately

If your hose shows signs of significant damage—such as deep cuts, severe kinking, or leaks—it is essential to replace it immediately. Continuing to use a damaged hose can be dangerous, leading to sudden failure or injury. Replacing the hose when needed ensures the safety of your equipment and personnel and prevents costly downtime.

12. Use Hose Reels for Easy Handling

Hose reels are a great way to store and handle your compressed air hose effectively. They help prevent kinks, make it easier to wind and unwind the hose, and keep it off the ground, reducing the chances of tripping or abrasion. Investing in a good-quality hose reel can significantly improve the lifespan of your hose.

Conclusion

Proper maintenance of your compressed air hose can save you time, money, and hassle in the long run. By following these practical tips—such as regular inspections, proper storage, and mindful use—you can extend the life of your hose and ensure that your tools operate efficiently. Remember, a well-maintained hose not only improves performance but also keeps your workspace safe.

At Hose Shop, we provide high-quality compressed air hoses and accessories to suit your needs. Whether you need advice on selecting the right hose or are looking for top-notch products, we are here to help. Visit Hose Shop today to explore our range of compressed air hoses and accessories.

Contact Details:

Website: https://hoseshop.net

Phone: 01423 712038

Email: [email protected]

#CompressedAirHose#HoseMaintenance#AirHoseCare#IndustrialTools#HoseShop#AirTools#CompressedAir#HoseStorage

1 note

·

View note

Text

Compressed Air Collector NCAC-200

Labnics Compressed Air Collector ensures precise microorganism detection, adhering to GMP standards. It measures particles ≥ 0.3 µm at a flow rate of 100 L/min, supporting both 50 L/min and 100 L/min. Adjustable cavity pressure enhances sampling accuracy.

0 notes

Text

Waiting for an upgrade.

#dronification#gay gear#rubberman#gas mask#rubberdrone#gay rubber#transformation#gay men#compressedair#scubadiving#scifiart#scuba gear#gay biker#gay leather

275 notes

·

View notes

Text

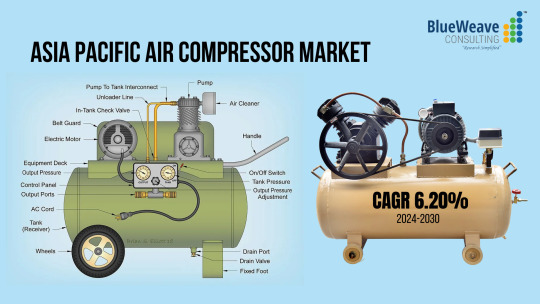

Asia Pacific Air Compressor Market size by value at USD 9.39 billion in 2023.During the forecast period between 2024 and 2030, BlueWeave expects Asia Pacific Air Compressor Market size to expand at a CAGR of 6.20% reaching a value of USD 15.02 billion by 2030. Asia Pacific Air Compressor Market is driven by the growing demand from industries such as manufacturing, oil & gas, and construction. Rapid industrialization in countries like China and India boosts market growth, along with the expansion of the automotive and electronics sectors. Increasing investment in infrastructure projects and advancements in energy-efficient compressor technologies also contribute to market expansion. Moreover, the rising use of air compressors in HVAC systems and food & beverage processing further fuels demand in the region.

Sample Request @ https://www.blueweaveconsulting.com/report/asia-pacific-air-compressor-market/report-sample

Opportunity – Industrialization and Infrastructure Development

Asia Pacific Air Compressor Market is driven by rapid industrialization and infrastructure development across the region. Expanding sectors like construction, manufacturing, and automotive are boosting demand for air compressors to support production and operational needs. Additionally, major infrastructure projects, such as smart cities and transportation networks, are fueling the use of air compressors in various applications, including pneumatic tools and HVAC systems. The region's evolving industrial landscape ensures steady growth for air compressor technologies in the coming years.

#Blueweave#Consulting#marketreserch#marketforecast#IndustrialAutomation#CompressedAir#EnergyEfficiency#AsiaPacificMarket#MarketForecast#GrowthOpportunities

0 notes

Text

Improve Airflow with EXAIR’s Super Air Amplifiers

EXAIR’s Super Air Amplifiers use a small amount of compressed air to generate high volume, high velocity flows. Efficient and quiet, they move smoke, fumes, and light materials, or cool, clean, and dry parts. Ideal for dust collection and ventilation.

0 notes

Text

Aerol Multipurpose Dust Remover Spray

Keep Your Tech Spotless with Aerol Dust Remover Spray! Discover the ultimate solution for maintaining a dust-free environment with Aerol Dust Remover Spray. Perfect for cleaning electronics, keyboards, and hard-to-reach areas, this powerful spray quickly blasts away dust and debris, ensuring your devices operate efficiently and look pristine. KEY FEATURES

Releases a dry, high pressure burst of gas for the safe removal of dust, grime and lint from all delicate precision equipment and electronics.

Noncorrosive and leaves no residue or condensation. Ideal for servicing when compressed air is not available.

Removing dust and contaminants from circuit boards, precision electronic equipment, keyboard, computers, printers, camera, mobile phones etc.

Cleaning of smoke detector sensors, panel boards, textile machinery etc.

Some other popular applications are dust removal from delicate instruments, air removal from clippers, dirt removal from jewellery.

Compressed Air Technology: Powerful compressed air spray for effective and precise dust removal.

Multipurpose Cleaning: Versatile solution suitable for cleaning TVs, laptops, printers, keyboards, circuit boards, and machinery.

Aerol, dust remover, electronics cleaner, keyboard cleaning, compressed air spray

Website URL: https://aerolgroup.com/ Amazon Buy URL - https://www.amazon.in/Aerol%C2%AE-Multipurpose-Remover-250gm-450ml/dp/B08LNJ5RXN?ref_=ast_sto_dp

0 notes

Text

The Elephant Air Compressor 50L, 2 HP, AC 50 C is a high-performance air compressor designed for both industrial and DIY applications. It features a durable 50-liter air tank for extended use and clearly labeled indicators for monitoring pressure and performance.

#ElephantAirCompressor#AirCompressor#IndustrialTools#PowerTools#CompressedAir#HeavyDutyCompressor#EfficientTools#DIYTools#WorkshopTools#ElephantTools#ReliablePerformance#HighPowerCompressor#ToolExperts

0 notes