#FlowMeasurement

Explore tagged Tumblr posts

Text

Ultrasonic Flowmeters Market Driving Forces, Growth Opportunities, and Technology Advancements Insights for 2024 and Beyond

The Ultrasonic Flowmeters Market is gaining significant traction across industries due to its precision, reliability, and versatility in measuring fluid flow. Ultrasonic flowmeters utilize sound waves to measure the velocity of liquids and gases, making them ideal for industries such as oil & gas, water & wastewater, pharmaceuticals, chemicals, and HVAC. This article explores the key drivers accelerating the growth of the Ultrasonic Flowmeters Market, highlighting why it has become an indispensable technology for diverse applications.

Growing Focus on Energy Efficiency and Sustainability

Energy efficiency has become a priority across industries as global climate change intensifies. Ultrasonic flowmeters play a pivotal role in this trend by providing highly accurate and non-invasive flow measurement, allowing industries to optimize fluid dynamics and reduce waste. The shift towards sustainability has increased the demand for precision measurement devices, making ultrasonic flowmeters a crucial tool for achieving energy conservation objectives.

Expanding Water and Wastewater Management Needs

With rising global water scarcity and increasing environmental regulations, efficient water and wastewater management has emerged as a pressing concern. Ultrasonic flowmeters, with their ability to operate reliably in harsh environments and measure flow in large pipelines, have become essential for water treatment plants, distribution networks, and waste management facilities. The growing investment in water infrastructure and aging pipelines across many nations is a strong driver for ultrasonic flowmeter market growth.

Growing Oil and Gas Industry

The oil and gas sector remains one of the largest end-users of ultrasonic flowmeters due to their ability to measure flow accurately in both upstream and downstream applications. As exploration and production activities rise, the demand for robust, maintenance-free flow measurement solutions has increased sharply. Ultrasonic flowmeters offer high reliability and low maintenance compared to traditional mechanical meters, making them ideal for harsh environments common in oil and gas installations.

Advancements in Sensor Technology

Innovations in sensor design and electronics have significantly enhanced the performance of ultrasonic flowmeters. Modern flowmeters now feature multi-path measurement, higher precision, and advanced data processing capabilities, making them ideal for critical process industries. These advances have increased the range of flow applications and expanded their adoption across industries seeking precise and reliable flow measurement solutions.

Favorable Regulations and Standards

Government regulations focusing on environmental monitoring, water quality, and energy efficiency have fueled the adoption of ultrasonic flowmeters across industries. Regulations such as the EPA’s Clean Water Act and EU’s environmental directives have compelled industries to invest in accurate flow measurement technologies, making ultrasonic flowmeters a preferred choice.

Advantages over Mechanical and Differential Pressure Flowmeters

Compared to traditional mechanical or differential pressure flowmeters, ultrasonic flowmeters have no moving parts, making them highly resistant to wear and tear. They also reduce maintenance costs and minimize downtime. The ability to measure flow from the outside of the pipe allows for quick installation and ease of use, making ultrasonic flowmeters ideal for industries that require precision and reliability.

Increasing Adoption of Smart Technologies

The trend towards smart factories and digitalization has further boosted the demand for ultrasonic flowmeters. The integration of IoT, remote monitoring, and advanced analytics allows industries to gain real-time insights and optimize fluid flow across complex infrastructure. This digital shift is expected to drive growth in ultrasonic flowmeter adoption in the years to come.

Growing Pharmaceutical and Food & Beverage Sectors

As pharmaceutical and food & beverage industries continue to evolve, the requirement for precision fluid measurement has surged. Ultrasonic flowmeters, thanks to their hygienic design and high accuracy, have become a preferred choice for applications where contamination must be avoided, making them an ideal solution for these highly regulated industries.

Conclusion

The Ultrasonic Flowmeters Market is on a robust growth trajectory, driven by increasing demand for precision measurement across a range of industries. Factors such as rising water and wastewater management needs, advances in sensor technology, favorable regulations, and the trend towards digitalization are propelling its adoption. As industries evolve, ultrasonic flowmeters will remain at the heart of flow measurement, ensuring efficiency, reliability, and sustainability for the future.

0 notes

Text

TVSPL High Pressure Diffuser

For Total Air Particulate of Compressed Air/Gas we can use it in conjunction with a 1CFM, 28.3LPM, 50LPM, 75LPM, or 100 LPM Optical Particle Counters of all makes.

TECHNICAL SPECIFICATIONS

Material of Construction: SS 316 (Stainless Steel)

Output Flow/Use: 1 CFM, 28.3 LPM, 50 LPM, 75 LPM, or 100 LPM

Requirements Suitable For: All Makes Optical/Laser Particle Counters

Inlet Pressure Required: 25 to 125 PSI (approx for HPD)

HPD Dimensions (Approx): 140mm x 32mm QD

HPD for 1 CFM/28.3 LPM OPC: Model No. TVS HPD SS6 001 (TVSPL High Pressure Diffuser)

HPD for 50 LPM OPC: Model No. TVS HPD SS6 050

HPD for 75 LPM/100 LPM OPC: Model No. TVS HPD SS6 100

HPD for 28.3/50/100 LPM OPC: Model No. TVS HPD SS6 002*

Visit www.twchnovale.in for more info.

#CompressedAir#ParticleCounting#OpticalParticleCounter#CleanroomMonitoring#AirQuality#HighPressureDiffuser#SS316#ContaminationControl#IndustrialEquipment#FlowMeasurement#LaserParticleCounter#AirMonitoring#PharmaManufacturing#CleanAirSolutions#EnvironmentalMonitoring

0 notes

Text

High-Precision Elliptical Gear Flowmeter | Tianchang Qiyu Instrument

Shop high-accuracy elliptical gear flowmeters from Tianchang Qiyu Instrument—ideal for precise liquid flow measurement in industrial applications. Reliable, durable, and efficient.

#EllipticalGearFlowmeter#FlowMeasurement#IndustrialInstruments#TianchangQiyu#PrecisionFlowmeter#FluidMeasurement#GearFlowmeter#EngineeringSolutions

0 notes

Text

Industrial Water Flow Meter by Lakewood Instruments for Measure Flow Rate

Industrial water meters are used for precise measurement of water flow in enclosed pipe systems. It measure the volume of water used by industrial or commercial units. It is essential equipment for measuring the flow rate of water in various industrial piping system.

0 notes

Text

ISM Series Flow Meter: Precision Flow Measurement Solutions

The ISM Series Flow Meter offers exceptional accuracy and reliability for monitoring and controlling fluid flow in diverse applications. Designed with advanced technology, it ensures precise measurements, durability, and easy integration into industrial systems. Ideal for optimizing efficiency in processes requiring accurate flow data.

0 notes

Text

🌊 Discover Precision in Flow Measurement with Yokogawa Flowmeters! 🌊

Looking for top-notch flow measurement solutions? Look no further than Yokogawa Flowmeters! 💡

👉 Why choose Yokogawa? 1️⃣ Accuracy: Our flowmeters provide unparalleled precision, ensuring you get reliable data every time. 2️⃣ Durability: Built to last, Yokogawa Flowmeters are designed for long-term performance in various industries. 3️⃣ Innovation: Stay ahead with cutting-edge technology and advanced features. 4️⃣ Customization: Tailored solutions to meet your specific needs.

From Oil & Gas to Chemicals, Water Treatment to Food & Beverage, Yokogawa has you covered. 🏭🥤💧

Join the flow measurement revolution today! 🚀

To know more visit our website : https://centumcontrols.com/flow-measuring-instruments/

YokogawaFlowmeters

0 notes

Text

#MagneticFlowMeter#FlowMeasurement#GlobalMarket#MarketAnalysis#TypeOfFlowMeters#EndUserIndustries#WaterWastewater#OilGasIndustry#ChemicalIndustry#PowerGeneration#PulpPaper#FoodBeverages#IndustrialMeasurement#IndustryForecast#TechnologyTrends#FluidMeasurement#MagneticFlowSensors#IndustrialAutomation#EnergySector#ProcessControl#EnvironmentalMonitoring#Fluid Dynamics#OilandGasMarket#WaterManagement#ManufacturingIndustry#Innovation#Sustainability#EmergingMarkets#EconomicAnalysis

1 note

·

View note

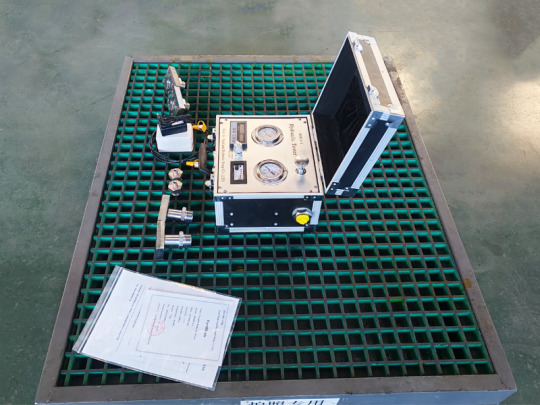

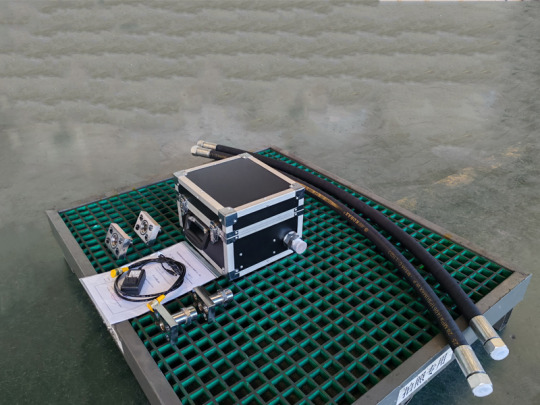

Photo

Factory direct sale! The MYHT-1-5 hydraulic flow meter offers accurate flow measurement up to 500L/min. Compact, portable, and ideal for testing pumps, motors, and systems. Contact us now! #MYHT15 #HydraulicFlowMeter #FlowMeasurement #500Lmin #HydraulicTester #HighlandHydraulic

0 notes

Text

Flow Computers Market 2025-2033: Navigating the Future of Industrial Automation

Flow Computer Market centers around advanced devices designed to measure and calculate the flow of liquids and gases with unparalleled accuracy. These computers, integrated with sensors and transmitters, play a pivotal role in sectors like oil and gas, chemicals, and water management. By leveraging digitalization and real-time monitoring capabilities, flow computers enhance operational efficiency, streamline process optimization, and ensure adherence to regulatory standards.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS25215 &utm_source=SnehaPatil&utm_medium=Article

The market is segmented by type, including ultrasonic, turbine, and Coriolis flow computers, and by application, with dominance in oil and gas, water management, and chemical industries. The oil and gas sector leads, commanding 45% of the market, due to its critical reliance on precise measurement in exploration and production. Following closely, the water and wastewater segment accounts for 30%, reflecting global efforts in sustainable resource management. North America spearheads regional growth, supported by technological advancements and key industry players, while Europe ranks second, driven by energy-efficient systems and stringent regulations.

Key trends include the rise of IoT-enabled solutions and cloud-based technologies, offering enhanced data acquisition and remote monitoring capabilities. The integration of wireless communication further amplifies process efficiency. These advancements align with global shifts toward automation and smart infrastructure.

Drivers of market growth include increasing demand for real-time data, stricter environmental compliance standards, and a focus on process optimization across industries. Leaders like Emerson Electric, ABB, and Schneider Electric are at the forefront, investing in R&D to expand their offerings. While challenges such as high initial costs and regulatory hurdles persist, the market is projected to grow at a robust CAGR of 10% by 2033, presenting abundant opportunities in energy-efficient and digitalized solutions.

#FlowComputerMarket #Digitalization #IoTSolutions #IndustrialAutomation #OilAndGas #WaterManagement #ProcessOptimization #RealTimeData #EnergyEfficiency #SmartInfrastructure #PrecisionEngineering #FlowMeasurement #TechInnovation #SustainableSolutions #FutureReadyTech

0 notes

Text

0 notes

Text

Steam Flow Measurement

The Orifice plate flow meter is a type of differential pressure flow meter used to measure the flow of clean liquid, gas, and steam services. It is mainly known for its robust design and durability. The orifice meter is also approved by many organizations for custody transfer for fluid flow. Commonly orifice meters are used to measure the flow of steam at the outlet of a boiler. The orifice meter for steam also refers to IBR approved steam flow meter.

0 notes

Text

Ultrasonic Flowmeters Market: Drivers Fuel Growth Across Industrial and Utility Sectors Worldwide

The Ultrasonic Flowmeters Market has witnessed notable growth in recent years, driven by various factors reshaping fluid measurement technologies across industries. These flowmeters, known for their accuracy, low maintenance, and non-intrusive nature, are gaining traction across oil & gas, water and wastewater, power generation, and chemical processing sectors. In this article, we delve into the key drivers propelling the global ultrasonic flowmeters market and explore the conditions fostering their rapid adoption.

Industrial Automation and Digitalization as Key Drivers

One of the primary drivers of the ultrasonic flowmeters market is the global wave of industrial automation and digital transformation. As industries evolve toward Industry 4.0, the demand for real-time, precise, and reliable measurement systems increases. Ultrasonic flowmeters offer the ability to transmit flow data directly to supervisory control and data acquisition (SCADA) systems, enabling continuous monitoring and analytics.

This advantage becomes essential in applications where flow accuracy directly impacts production efficiency, product quality, and energy management. The seamless integration of these devices with industrial IoT platforms further accelerates their adoption.

Environmental Regulations and Water Management Needs

Another major driver for ultrasonic flowmeters is the rising emphasis on sustainable resource management. Governments worldwide are enforcing stricter environmental regulations and promoting efficient water usage to combat climate change and pollution. As a result, industries and municipalities are investing in advanced flow measurement technologies to monitor water usage, detect leaks, and reduce wastage.

Ultrasonic flowmeters, particularly clamp-on models, are ideal for water and wastewater applications. Their ability to measure flow without pipe penetration or process interruption makes them suitable for retrofitting existing infrastructure—an attractive feature for utilities and municipalities under pressure to modernize systems without halting operations.

Growing Demand in Oil & Gas and Power Generation

The oil & gas sector remains a critical segment for ultrasonic flowmeters due to their ability to handle high-pressure and high-temperature conditions. Transit-time and Doppler-based ultrasonic meters provide accurate readings for both custody transfer and allocation measurement. This reliability is vital in environments where even minor inaccuracies can lead to significant financial discrepancies.

Additionally, the power generation industry increasingly uses ultrasonic flowmeters for steam and condensate measurements. With the global shift toward clean energy and the growth of combined heat and power (CHP) plants, the demand for precise flow measurement systems has expanded.

Technological Advancements in Meter Design

Continuous advancements in ultrasonic technology have also emerged as powerful drivers. Innovations in transducer materials, signal processing algorithms, and measurement electronics have enhanced the performance of modern flowmeters. These improvements have expanded their application range to include challenging fluids, such as slurries or fluids with low flow rates.

Battery-powered and wireless ultrasonic flowmeters are also entering the market, catering to remote or hazardous environments where wired systems are impractical. These advances reduce installation costs and simplify maintenance, further encouraging market adoption.

Infrastructure Development in Emerging Economies

Emerging markets across Asia-Pacific, Latin America, and the Middle East are witnessing rapid infrastructure development. These projects often include water supply networks, energy distribution systems, and manufacturing facilities—all of which require reliable flow measurement solutions. The scalability and cost-effectiveness of ultrasonic flowmeters make them ideal for such applications.

Countries like China and India, in particular, are investing heavily in smart city projects and industrial corridors. The need for effective water management and energy efficiency in these initiatives is fueling demand for advanced flowmeters.

Cost-Efficiency and Maintenance Benefits

Unlike mechanical flowmeters, ultrasonic flowmeters have no moving parts. This results in minimal wear and tear, reducing long-term maintenance costs and extending service life. Their non-invasive installation also minimizes downtime and eliminates the need for pipe modifications. These features translate into significant operational savings, making ultrasonic flowmeters a cost-effective solution over the product lifecycle—another strong driver of their growing popularity.

Conclusion

The global Ultrasonic Flowmeters Market continues to thrive, supported by key drivers such as industrial automation, environmental regulations, expanding applications in oil & gas and power generation, and technological innovation. As industries worldwide strive for greater efficiency and sustainability, the adoption of advanced flow measurement solutions is set to accelerate. The versatility, reliability, and cost-effectiveness of ultrasonic flowmeters position them as critical components in modern process control and infrastructure systems.

0 notes

Text

Horizontal detachable photoelectric direct-reading water meter Size: DN40-200 Application: Horizontal detachable photoelectric direct-reading water meter series is suitable for measuring water in factories, mines, water supply lines, etc.

#watermeter#smartwatermeter#smartmeter#intelligentwatermeter#digitalwatermeter#remotewatermeter#mechanicalwatermeter#ultrasonicwatermeter#ultrasonicflowmeter#waterflowmeter#plasticwatermeter#bulkwatermeter#flowmeasurement#turbineflowmeter#largediameterwatermeter#watermachine#removablewatermeter#woltmanwatermeter#digitalflow#flowmeter#digitalflowmeters

0 notes

Photo

#vortex #vortexflowmeter #flowmeter #rosemount #hart #stainlesssteel #oilandgas #iran #flowmeasurement #fieldinstruments #instrumentation #ورتکس #فلومترورتکس #رزمونت #اندازه_گیری_فلو #نفت_گاز_پتروشیمی #ابزاردقیق #فیلداینسترومنتس #ابزار_دقیق #گازوئیل #هارت #استنلس_استیل #صنعت (at Tehran, Iran) https://www.instagram.com/p/CAVz138D-7m/?igshid=qx8t6k8ippvg

#vortex#vortexflowmeter#flowmeter#rosemount#hart#stainlesssteel#oilandgas#iran#flowmeasurement#fieldinstruments#instrumentation#ورتکس#فلومترورتکس#رزمونت#اندازه_گیری_فلو#نفت_گاز_پتروشیمی#ابزاردقیق#فیلداینسترومنتس#ابزار_دقیق#گازوئیل#هارت#استنلس_استیل#صنعت

0 notes

Text

To all plant managers out there.

When you are trying to improve your cost control practices within your company, it’s important to make a detailed and correct cost accounting of gas usage. To ensure gas leaks are prevented, they must be monitored efficiently and with the proper measurement of flow.

You can use Manas's #ThermalMassFlowmeters to ensure the reliability of your gas/air flow measurement.

See our flow metering solutions to help with daily challenges in your plant.

#manasmicro#flowmeters#FlowMeasurement#ThermalMassFlowMeter#gasflowmeter#massflowmeter#airflowmeter#compressedairflowmeter#manufacturers#suppliers#exporters#reliable#accurate#flowmetering

0 notes

Text

Precision Gas Flow Management with GFC Gas Mass Flow Controllers

Achieve accurate and reliable control of gas flow with GFC Gas Mass Flow Controllers. These advanced instruments ensure precise flow measurements and seamless process integration for various industrial applications. Designed for efficiency and accuracy, they are ideal for controlling gas flow rates in diverse environments.

0 notes