#Compressor Market

Explore tagged Tumblr posts

Text

Compressor Market Growth, Trends, and Opportunities by 2034

Compressor Market Overview The global compressor market is evolving at a significant pace, driven by increasing industrialization, the expansion of manufacturing industries, and the rising demand for energy-efficient systems. Compressors are vital across a wide range of applications, from powering industrial equipment to facilitating critical processes in oil and gas exploration. As of 2024, the…

0 notes

Text

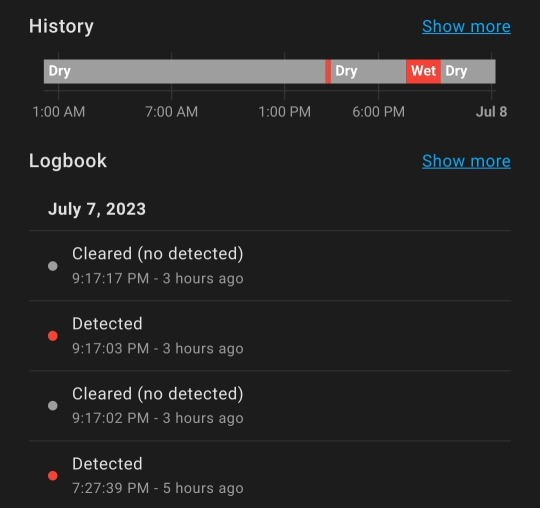

Installed a sensor on my girl so i know when

#Funy jokey#I've become addicted to cheap zigbee switches and sensors#I set this up so the air conditioner in our bedroom will stop running when the bucket is almost full theres something wrong with me#It works too and i love it :')#Next up is a small switched pump that will pump the water out for a set amount of time#Directly to the balcony plants#Our windowsill is too high up to run the condensed water out with gravity sadly so some kind of reservoir with sensor and pump has to do#Also planning a dedicated channel for outside air directly to the compressor with some kind of blowback valve#I hate mobile acs for how they are designed but there are no good high capacity mobile acs on the market yet#This should mitigate most of the issues though#The main issue is the lack of separation of compression and expansion stages which is why you should use outside air for the former#AND i have an hourly energy price contract which means i should switch the ac on/of on a set of preset conditions#I love tinkering and this is both pretty cheap and actually rewarding us with much better sleep during heat waves & less fuss#Also electricity savings#I put a bunch of stuff on this kind of sensing/logic already and its so nice to see your expenses go down with little to no impact#I feel like such a dad even though i dont have any kids#All of this is completely local and relatively cheap to set up but you have to like tinkering a little#Hmu if you want some advice i can point you away from large cloud based nonsense & help with initial startup#The two investments are a raspberry pi and a zigbee dongle#Possibly also a p1 reader or similar if you want data directly from your utilities#And after that most investments should be 10 dollars max per sensor or switch and most of the ali ones will work#And even have fancy features like somewhat accurately displaying power usage and current#Sorry for extremely rambly long tags i just get excited sometimes

2 notes

·

View notes

Text

Centrifugal Compressor Market Expansion Plans and Forecast 2034

The centrifugal compressor market is undergoing a transformation driven by rapid industrialization, rising energy demand, and the growing adoption of clean energy solutions. These powerful, high-efficiency compressors are becoming integral to several industries including oil & gas, power generation, HVAC, petrochemicals, and manufacturing. According to recent market research, the global centrifugal compressor industry was valued at US$ 3.5 Bn in 2023, and it is projected to expand at a CAGR of 4.6% from 2024 to 2034, reaching approximately US$ 5.7 Bn by the end of 2034.

Expanding Application Spectrum Boosting Market Demand

Centrifugal compressors are widely favored for their capability to deliver high-pressure ratios in a compact design. Industries such as oil & gas and chemicals extensively use these machines for gas transportation, refrigeration, and processing applications. Additionally, increasing focus on energy efficiency and lower emissions is prompting businesses to replace conventional compressors with modern, oil-free centrifugal variants.

In power plants, especially those utilizing combined cycle gas turbines, centrifugal compressors play a crucial role in enhancing system output and efficiency. In the HVAC sector, large commercial buildings and data centers are increasingly relying on centrifugal chillers powered by these compressors, thereby further widening the market’s growth potential.

Request Sample Copy - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=58767

0 notes

Text

Japan Turbo Compressor Market Set to Accelerate Towards 2037

The Japan Turbo Compressor Market, valued at USD 303.4 million in 2024, is projected to reach USD 599.6 million by 2037. This significant growth reflects a compound annual growth rate (CAGR) of 5.3% over the forecast period of 2025–2037. This trajectory underscores the increasing relevance of turbo compressors in industrial operations and clean energy applications not only within Japan but also influencing global market dynamics due to Japan’s position as a technological leader in industrial machinery.

Japan Turbo Compressor Industry Demand

The Japan Turbo Compressor Market comprises high-performance, dynamic compressors that operate primarily on the principle of radial or axial airflow to compress gases. These machines are predominantly used in industries requiring continuous, high-efficiency compression such as oil & gas, steel production, LNG terminals, and the rapidly growing hydrogen and ammonia-based power generation sectors.

Demand is fueled by several critical factors:

Cost-Effectiveness: Turbo compressors offer a low cost-per-unit compression output over their lifespan.

Operational Efficiency: They are valued for ease of integration into existing systems, reduced maintenance downtime, and energy efficiency.

Long Shelf Life: Due to durable build materials and high-precision engineering, turbo compressors exhibit long operational lifespans, making them attractive investments for industries seeking long-term reliability.

With Japan transitioning toward cleaner energy systems and industrial decarbonization, the turbo compressor market is poised to support these initiatives with sustainable and robust solutions.

Request Sample@ https://www.researchnester.com/sample-request-7681

Japan Turbo Compressor Market: Growth Drivers & Key Restraint

Growth Drivers:

Technological Advancements in Energy and Industrial Systems: Continuous innovations in turbo machinery, including the adoption of digital twin technologies, IoT-enabled diagnostics, and high-efficiency impeller design, are enhancing the performance of turbo compressors, making them a staple in both legacy and greenfield infrastructure.

Industrial Decarbonization and Energy Transition: Japan’s roadmap for achieving carbon neutrality by 2050 has increased the deployment of turbo compressors in hydrogen and ammonia power generation, carbon capture and storage (CCS), and other renewable energy applications.

Outsourcing and Cross-Border Infrastructure Projects: The expansion of Japanese OEMs into other Asian and European markets has led to increased outsourcing of turbo compressor solutions from Japan, bolstering domestic production and innovation.

Key Market Restraint:

High Initial Capital Investment: Despite long-term cost benefits, the upfront costs associated with installing advanced turbo compressors remain a barrier for small and mid-size enterprises (SMEs), particularly those operating in less capital-intensive sectors.

Japan Turbo Compressor Market: Segment Analysis

By Type:

Centrifugal Turbo Compressor: These dominate the market due to their adaptability in mid-to-large scale industrial applications. Their compact design, low maintenance, and higher operational efficiency drive their widespread adoption, especially in LNG and air compression systems.

Axial Turbo Compressor: Typically utilized in large-scale, high-flow applications such as power generation and petrochemical processing. Their performance at constant pressure and ability to handle massive airflow volumes make them essential in sectors like steel manufacturing and refinery operations.

By Stage:

Single-Stage Compressors: Primarily used in applications requiring lower compression ratios. These are favored for their simplicity and lower operational costs, often deployed in smaller industrial setups or pre-compression systems.

Multi-Stage Compressors: Key in heavy-duty industrial operations where higher pressure ratios and continuous flow are required. Industries such as oil & gas and hydrogen energy sectors rely heavily on multi-stage variants for enhanced energy efficiency and pressure control.

By Application:

Oil & Gas: This sector remains a foundational pillar for turbo compressor demand, with compressors deployed in gas lift, re-injection, and pipeline transport applications.

Steel Plant: Compressors are integral to blast furnace operations, oxygen enrichment, and pneumatic controls within steel manufacturing processes.

LNG Terminal: Turbo compressors are vital for gas liquefaction, storage, and transport, providing stable flow and energy savings.

Hydrogen & Ammonia Fuel Power Generation: A rapidly growing segment due to Japan’s green energy initiatives. Compressors ensure the efficient handling and compression of clean fuels.

CO₂ & Air Storage Power Generation: Turbo compressors play a central role in compressed air energy storage (CAES) systems and carbon capture solutions.

Others: Includes chemicals, pharmaceuticals, and manufacturing sectors that rely on reliable compressed air or gas systems.

By Capacity:

Medium-Capacity Turbo Compressor (500 - 5000 m³/hour): These units are common in small to mid-sized industrial setups, valued for their balance between cost and performance.

Large-Capacity Turbo Compressor (Above 5000 m³/hour): Employed in heavy industries and power plants, these are chosen for their high throughput and energy-efficient operations.

By Power Output:

150 kW – 300 kW: Suited for utility and mid-range industrial applications. Demand is consistent in ancillary systems and mobile compressor units.

300 kW – 2 MW: Core segment for most industrial operations. High flexibility and adaptability to different use cases make this the most versatile power range.

Above 2 MW: Reserved for mega projects, large-scale refineries, and energy generation facilities. This segment benefits from government-backed infrastructure and energy transition projects.

Japan Turbo Compressor Market: Regional Insights

North America:

The market in North America is largely driven by shale gas extraction, refinery operations, and infrastructure retrofitting for clean energy transitions. Stringent emission norms and energy-efficiency mandates fuel the replacement of older compressor systems with high-performance turbo compressors. Investment in hydrogen hubs and carbon capture technologies further accelerates market uptake.

Europe:

Europe demonstrates strong growth due to aggressive decarbonization policies, including EU’s Green Deal and industrial transformation strategies. The region’s established chemical and manufacturing base continues to adopt turbo compressors for their efficiency and sustainability benefits. Key growth areas include Germany, France, and Nordic countries investing in hydrogen and CCS infrastructure.

Asia-Pacific (APAC):

Led by Japan, APAC is witnessing expansive growth due to industrialization, urbanization, and increased demand for clean and efficient energy systems. Japan’s strategic position as a technology exporter and its role in regional supply chains amplify its influence across Southeast Asia. Turbo compressors are increasingly deployed in integrated gasification, smart factories, and renewable energy systems throughout the region.

Top Players in the Japan Turbo Compressor Market

The Japan Turbo Compressor Market is characterized by the presence of established domestic players with strong global footprints. Key manufacturers include IHI Corporation, a pioneer in aerospace and industrial machinery; Mitsubishi Heavy Industries Compressor Corporation (MCO), known for high-efficiency industrial solutions; Hitachi Industrial Products, Ltd., delivering innovation in energy-efficient systems; Kobe Steel, Ltd. (Kobelco), offering reliable steel plant compressor technologies; Ebara Corporation, a leading player in pumps and compressors with robust R&D; and Turbo Systems United Co., Ltd. (TSU), which specializes in customized compressor engineering and global OEM partnerships.

Access Detailed Report@ https://www.researchnester.com/reports/japan-turbo-compressor-market/7681

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Vietnam Air Compressor Market Size, Share, Trends, 2025-2033

The Vietnam air compressor market is projected to exhibit a compound annual growth rate (CAGR) of 2.82% during 2025–2033. The market growth is being driven by the increasing application of air compressors in the manufacturing of pharmaceutical products and the government's sustained investments in infrastructure development projects aimed at enhancing trade efficiency and transportation networks.

visit us: https://www.imarcgroup.com/vietnam-air-compressor-market

0 notes

Link

#market research future#screw compressor market trends#screw compressor technology#screw compressor services#screw compressor application

0 notes

Text

Liquid Ring Compressors Market Analysis: Key Players and Competitive Landscape

Rising Demand for Efficient and Reliable Vacuum Solutions Fuels Growth in the Liquid Ring Compressors Market.

The Liquid Ring Compressors Market size was valued at USD 1.22 Billion in 2023 and is expected to reach USD 2.0 Billion by 2032 and grow at a CAGR of 5.6% over the forecast period 2024-2032.

The Liquid Ring Compressors Market is experiencing significant growth due to its increasing adoption in chemical processing, oil & gas, pharmaceuticals, food & beverage, and wastewater treatment industries. Liquid ring compressors are widely used for handling wet, corrosive, and gas-laden processes due to their high efficiency, reliability, and minimal maintenance requirements. The rising focus on energy-efficient and environmentally friendly compression solutions is further driving market expansion.

Key Players

Nash

Gardner Denver

Fusheng

Secop

Nanjing Huade Vacuum Pump Factory

DUNN SYSTEM

ANHUI JIAXIN VACUUM PUMP

Pfeiffer Vacuum

Busch Vacuum Pumps and Systems

Shandong Weifang Huaxin

Future Scope

The Liquid Ring Compressors Market is expected to witness steady growth, driven by increasing industrial applications and stringent environmental regulations. The demand for oil-free and low-maintenance compression solutions is rising, particularly in chemical, pharmaceutical, and food processing industries, where contamination-free operation is critical. Additionally, the expansion of wastewater treatment plants and the adoption of sustainable gas recovery systems are propelling the market forward. Manufacturers are focusing on enhancing energy efficiency and integrating smart monitoring technologies to meet industry demands.

Emerging Trends

The industry is shifting towards eco-friendly and energy-efficient liquid ring compressors, aligning with global sustainability goals. The integration of Internet of Things (IoT) and predictive maintenance technologies is gaining traction, enabling real-time monitoring and operational efficiency improvements. Additionally, rising investments in biogas and renewable energy projects are creating new opportunities for vacuum and gas compression solutions. Manufacturers are also focusing on compact and lightweight designs to improve operational flexibility in space-constrained industrial setups.

Key Points

Growing adoption of liquid ring compressors in chemical, oil & gas, and food industries.

Rising demand for oil-free, low-maintenance, and energy-efficient compression solutions.

Expansion of wastewater treatment facilities driving market growth.

Integration of IoT-based smart monitoring for improved efficiency and predictive maintenance.

Increasing applications in biogas and renewable energy projects.

Conclusion

The Liquid Ring Compressors Market is on an upward trajectory, fueled by industrial advancements, regulatory compliance, and the shift toward energy-efficient solutions. As industries prioritize sustainability, reliability, and cost-effectiveness, liquid ring compressors will continue to be a preferred choice across multiple sectors. With ongoing technological innovations and increasing adoption of smart monitoring systems, the market is set to expand, offering enhanced performance and operational efficiency for industries worldwide.

Read Full Report: https://www.snsinsider.com/reports/liquid-ring-compressors-market-2019

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Liquid Ring Compressors Market#Liquid Ring Compressors Market Size#Liquid Ring Compressors Market Share#Liquid Ring Compressors Market Report#Liquid Ring Compressors Market Forecast

0 notes

Text

Gas Jet Compressor Market Surges with Growing Demand for Energy Efficiency and Industrial Applications

The gas jet compressor market is experiencing significant growth, driven by various factors that contribute to its increasing adoption across multiple industries. As industrial operations continue to emphasize energy efficiency and sustainable processes, gas jet compressors are gaining traction as a reliable and effective solution for compressing gases without moving parts, resulting in reduced maintenance and operational costs.

Rising Demand in the Oil and Gas Industry

One of the primary drivers of the gas jet compressor market is the increasing demand from the oil and gas sector. Gas jet compressors are widely used in refineries, natural gas processing plants, and petrochemical facilities for tasks like vapor recovery, flare gas recovery, and gas recompression. As the global energy demand rises, oil and gas companies are investing in advanced compression technologies to optimize production processes and reduce emissions.

Emphasis on Energy Efficiency and Cost Reduction

Energy efficiency has become a key focus across industries, contributing to the growing preference for gas jet compressors. Unlike conventional compressors, gas jet compressors operate without mechanical components, leading to lower maintenance costs and improved reliability. Companies are increasingly adopting these systems to achieve operational efficiency and reduce energy consumption, ultimately driving market growth.

Growing Applications in Chemical and Petrochemical Industries

The chemical and petrochemical industries also play a significant role in driving the gas jet compressor market. These industries rely heavily on compressed gases for various processes, including distillation, heat exchange, and gas mixing. Gas jet compressors offer a reliable and cost-effective solution for maintaining desired pressure levels, ensuring seamless operations in manufacturing plants.

Advancements in Compressor Technology

Continuous advancements in gas jet compressor technology are further boosting market expansion. Innovations in materials, design, and control systems have enhanced the performance and efficiency of compressors. Additionally, the integration of digital monitoring systems allows real-time tracking of operations, facilitating predictive maintenance and minimizing downtime. Companies are increasingly adopting these technological advancements to streamline their processes and improve overall productivity.

Focus on Environmental Sustainability

Environmental concerns and stricter regulations regarding emissions are encouraging industries to implement cleaner and more efficient solutions. Gas jet compressors contribute to sustainable operations by supporting processes such as gas recovery and emission reduction. By minimizing gas flaring and capturing excess gases, these compressors help companies achieve their sustainability goals while complying with environmental standards.

Growing Investments in Natural Gas Infrastructure

The expansion of natural gas infrastructure worldwide is also propelling the gas jet compressor market. With the increasing adoption of natural gas as a cleaner alternative to traditional fossil fuels, governments and private sector companies are investing in pipelines, storage facilities, and gas processing plants. Gas jet compressors play a crucial role in ensuring efficient transportation and utilization of natural gas, further driving market growth.

Regional Market Expansion and Industrialization

Rapid industrialization and urbanization in emerging economies are creating lucrative opportunities for the gas jet compressor market. Countries in regions like Asia-Pacific, the Middle East, and Latin America are witnessing increased investments in oil and gas exploration, chemical production, and infrastructure development. As industries expand, the demand for reliable and efficient gas compression solutions is expected to rise significantly.

Conclusion

The gas jet compressor market is poised for continued growth, driven by factors such as increasing energy demand, technological advancements, and the focus on sustainability. With industries seeking efficient and cost-effective compression solutions, gas jet compressors are emerging as a preferred choice across various applications. As market players continue to innovate and expand their offerings, the market is expected to witness robust growth in the coming years.

0 notes

Text

/PRNewswire/ -- The global Screw Compressor Market is anticipated to grow from estimated USD 12.74 billion in 2025 to USD 16.30 billion by 2030, at a CAGR of 5.0% during the forecast period. The market is growing due to Industrialization, demand for energy-efficient solutions, and growth in the manufacturing, oil and gas, and construction industries. Strict emission regulations and the necessity for low-maintenance, high-performance compressors propel adoption. Automation and smart monitoring advancements also stimulate growth in the market.

#screw compressor#screw compressor market#energia#energy#utilities#power generation#compressor#compressors#manufacturing#oil and gas#construction#industrial#industrialization

0 notes

Text

Automotive Electric HVAC Compressor Market: Growth, Opportunities, and Challenges

The global automotive electric HVAC compressor market size is expected to reach USD 53.11 billion by 2030, registering a CAGR of 23.3% from 2025 to 2030, according to a new report by Grand View Research, Inc. An electric compressor offers several benefits over a conventional compressor, such as lower energy consumption, compact size, controlled revolution speed, and noise-free operations. Also, unlike a conventional compressor, which is belt-driven, an electric compressor is independent of the vehicle engine. An electric compressor draws power from a separate electric motor, which is powered using an inverter. Such an arrangement ensures that the cooling operation of the vehicle continues even when the vehicle is turned off. The electric compressor also requires lesser power to drive as a result of this arrangement, thereby leaving the vehicle performance unaffected and ensuring cleaner operations due to low oil carryover.

The function of an electric compressor in an electric vehicle is much significant than that of a conventional compressor in an ICE vehicle. In an electric vehicle, the compressor is responsible for the cooling of the entire cabin as well as the battery pack. Electric compressor protects the battery from overheating and subsequently the vehicle from breaking down. Hence, an electric HVAC compressor serves as an essential component for the overall functioning of an electric vehicle. Rising fuel prices coupled with the growing awareness about environmental protection have been driving the adoption of electric vehicles and subsequently the demand for electric HVAC compressors.

However, the high initial costs and maintenance costs associated with electric HVAC compressors are expected to restrain the growth of the market. The installation of electric HVAC compressors involves heavy-duty electric wiring, which increases the overall cost of the system. Repairs and maintenance of electric compressors is also a complex task requiring a high level of expertise, thereby adding to the overall cost. Moreover, the demand for electric compressors relies entirely on the demand for electric vehicles. However, the sales of electric vehicles are already facing a double whammy of the higher price and range anxiety associated with electric vehicles. Nevertheless, advances in technology, the subsequent launch of new products, and the continued installation of electric chargers and charging stations are expected to encourage consumers to opt for electric vehicles, thereby driving the demand for electric HVAC compressors over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Automotive Electric HVAC Compressor Market

Automotive Electric HVAC Compressor Market Report Highlights

• The 20-40 CC segment dominated the market with a share of 54.7% in 2024, owing to the increasing demand for efficient cooling systems in passenger and light commercial vehicles, which require compact and effective solutions to manage cabin temperatures.

• The passenger vehicles segment dominated the market with the largest revenue share in 2024. This dominance can be attributed to consumers' growing preference for personal vehicles that offer enhanced comfort and energy efficiency.

• The automotive scroll compressor is a vital component within the automotive electric HVAC compressor market, notable for its efficiency, compact design, and superior performance.

• The BEV segment is expected to grow at the highest CAGR over the forecast period, driven by increasing environmental awareness and advancements in battery technology.

• Asia Pacific automotive electric HVAC compressor market dominated the global market with a revenue share of 66.3% in 2024. This is primarily driven by the rapid adoption of Electric Vehicles (EVs) and robust government support for sustainable transportation initiatives.

Automotive Electric HVAC Compressor Market Segmentation

Grand View Research has segmented the global automotive electric HVAC compressor market on the basis of on cooling capacity, product, vehicle, drivetrain, and region:

Automotive Electric HVAC Compressor Cooling Capacity Outlook (Revenue, USD Million, 2018 - 2030)

• Less than 20 CC

• 20-40 CC

• 40-60 CC

• More than 60 CC

Automotive Electric HVAC Compressor Product Outlook (Revenue, USD Million, 2018 - 2030)

• Scroll

Automotive Electric HVAC Compressor Vehicle Outlook (Revenue, USD Million, 2018 - 2030)

• Passenger Vehicles

• LCV

• HCV

• Buses and Coaches

Automotive Electric HVAC Compressor Drivetrain Outlook (Revenue, USD Million, 2018 - 2030)

• PHEV

• BEV

• HEV

Automotive Electric HVAC Compressor Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

• Europe

o Germany

o UK

o France

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

• Middle East and Africa (MEA)

o UAE

o Saudi Arabia

o South Africa

List of Key Players in the Automotive Electric HVAC Compressor Market

• Brose Fahrzeugteile SE & Co. KG

• BorgWarner, Inc

• Denso Corporation

• Hanon Systems

• MAHLE GmbH

• Sanden Corporation

• Toyota Industries Corporation

• Valeo

• Highly Marelli

• Robert Bosch GmbH

Order a free sample PDF of the Automotive Electric HVAC Compressor Market Intelligence Study, published by Grand View Research.

#Automotive Electric HVAC Compressor Market#Automotive Electric HVAC Compressor Market Analysis#Automotive Electric HVAC Compressor Market Report#Automotive Electric HVAC Compressor Market Size#Automotive Electric HVAC Compressor Market Share

0 notes

Text

0 notes

Text

Health Insurance Market Growth, Trends, and Regional Insights (2024-2034)

Hydrogen Compressor Market Size and Growth Factors The global hydrogen compressor market size was valued at approximately USD 2 billion in 2024 and is projected to expand by USD 3.96 billion by 2034, with a compound annual growth rate (CAGR) of 7.14% during the forecast period from 2025 to 2034. The market’s growth is primarily driven by the increasing demand for hydrogen as an alternative fuel,…

View On WordPress

0 notes

Text

What is a Piston Air Compressor? A Complete Guide

The Blog As the business started upgrading and technology became advanced, air compressors became an important tool for a range of businesses. An air compressor is a tool that converts power into potential energy stored in pressurized air. This process is done by using a gasoline engine, diesel, or electric motor. An air compressor is being used for a variety of applications and it is classified according to the pressure it delivers. There are multiple types of air compressor available in the market as per the preference and requirements of the market and in this blog, we will discuss about the most important air compressor i.e. Piston Air Compressor. A piston air compressor, also known as reciprocating compressor, is the most common and the oldest type of industrial compressor. This compressor was invented in the 18th century and has been used since then. Unlike traditional piston air compressors, modern ones relatively work on versatility and durability.

0 notes