#ConveyorSystem

Explore tagged Tumblr posts

Text

Our Full Automatic Conveyor Filling Machine ensures high efficiency in packaging processes. It is designed to handle liquid filling with precision and speed.

Наша автоматическая машина для розлива с конвейером обеспечивает высокую эффективность упаковочных процессов. Она разработана для точного и быстрого розлива жидкостей.

Tam Otomatik Konveyör Dolum Makinemiz, ambalajlama süreçlerinde yüksek verimlilik sağlar. Sıvı dolum işlemlerini hassasiyet ve hızla gerçekleştirmek üzere tasarlanmıştır.

www.pdmmakina.com www.pdmmakina.com.tr www.pdmmachinery.ru

#FillingMachine#AutomaticFilling#ConveyorSystem#PackagingInnovation#FoodPackaging#IndustrialMachinery#AutomationSolutions#РозливМашина#Автоматиче��кийРозлив#КонвейернаяСистема#УпаковочныеРешения#ПищеваяУпаковка#ПромышленноеОборудование#Автоматизация#DolumMakinesi#OtomatikDolum#KonveyörSistemi#AmbalajlamaÇözümleri#GıdaDolumu#SanayiMakinesi#OtomasyonÇözümleri

1 note

·

View note

Video

youtube

How to Install Slide Rubber Lagging - Complete Tutorial@DCCD_Group

#youtube#conveyorsystem#rubberlagging#installationtips#industrialmaintenance#conveyormaintenance#installationguide#dccd

0 notes

Text

#seimtisu#itohdenki#conveyorsystem#materialhandling#dcpowermoller#dcroller#mdr#authorizeddistributor#supplier#logistics#warehousing#materialhandlingequipment#powermoller#distributors#Manufacturers#india#japan

0 notes

Text

Explore the essential details and top-notch qualities of Rough Top Belts! 🛠️🔍 From surface texture to construction materials and pattern types, uncover the advantages of these versatile solutions. Discover why they're not just effective but also the most cost-effective option! 💼🔝

Read more: https://lakhotiaindia.in/

Contact us: +919025194360

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#automation#industry#materialhandling#belts#manufacturing#conveyorrollers

0 notes

Text

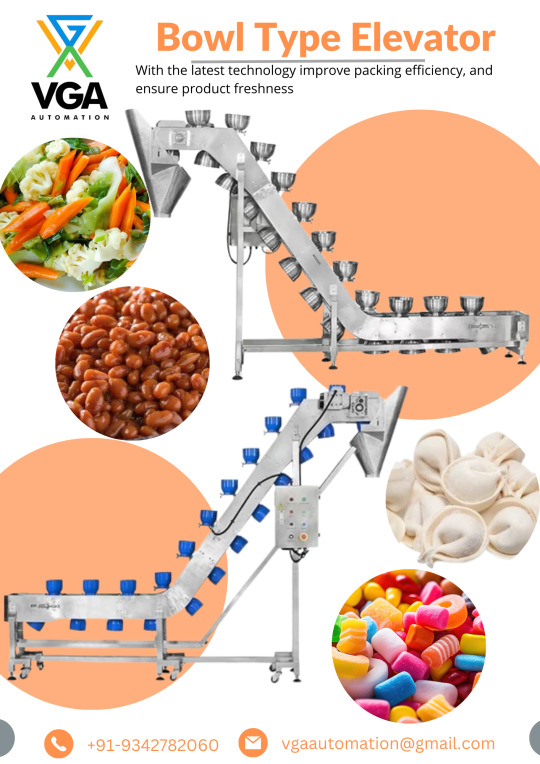

Bowl Type Elevator – VGA Automation

VGA Automation Bowl Type Elevator uses a chain drive system, with bowls attached to the chain, allowing discrete or pre-weighed materials to be transported in separate containers without mixing. This design also accommodates heating or cooling during transport, ideal for packing. It can be integrated with a packing machine or used with manual packing, making it suitable for frozen foods or high-temperature materials like frozen meat, frozen dumplings, seeds, hardware, crops, pharmaceuticals, and chemical products.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationbowlelevator#BucketElevator#ZTypeElevator#MaterialHandlingconveyor#ConveyorSystem#IndustrialAutomation#BulkMaterialHandling#FoodProcessing#ProcessingEquipment#vgapackingmachine#Manufacturing#packingmachine#VerticalConveyors#cookedfoodHandling#PharmaceuticalMachiner#PackagingEquipment#ProductionLine#GrainHandling#IndustrialConveyor

1 note

·

View note

Text

DKT Engineering

Our PVC & PU Conveyor Belt Product line covers genral and food grade bekts that are used in nearly every industry abd come in a variety of sizes and varieties

#conveyor#conveyorbelt#conveyors#conveyorsystems#rubberbelt#belt#engineering#conveyorsystem#konvey#automation#industry#materialhandling#belts#manufacturing#conveyorrollers#quarry#industrial#beltconveyor#quarrylife#bearing#conveyorbelts#pvcbelt#beltsplicer#vulcanising#r#enduroply#qpiltd#fabrication#quality#conveyoridlers

0 notes

Text

Customized Gearbox Solutions | SMD Gearbox

SMD Gearbox is dedicated to providing tailor-made solutions for your power transmission challenges, emphasizing our commitment to quality, innovation, and customer satisfaction. As your perfect partner for developing custom right-angle, parallel output gearboxes or any other type, we set ourselves apart.

When you need a dependable and efficient gearbox designed to your precise needs, look no further. Our team of skilled engineers and designers is resolute in delivering exceptional solutions crafted to suit your distinct requirements.

To learn more please visit https://www.smdgearbox.com/right-angle-gearbox

#gearboxmanufacturer#automatedguidedvehicle#spm#asrsshuttles#conveyorsystem#parallelgearbox#motioncontrolsolution#servogearbox#customizedsoulutions#smdgearbox

0 notes

Text

Reach New Heights: Elevate Your Factory's Potential with Our Conveyor Belts

Are you looking to revolutionize your factory's productivity and efficiency? Look no further! At ConveyorsJoint, we bring you state-of-the-art Conveyor Belts that will take your factory operations to new heights!

Unleash Unmatched Performance:

Factory Conveyor Belt meticulously engineered with cutting-edge technology to handle heavy loads, streamline material handling, and maintain seamless operations. No matter the industry or application, our belts ensure smooth transportation of goods with minimal downtime.

Tailored Solutions for Your Factory:

We understand that every factory is unique. That's why we offer customizable conveyor solutions to perfectly fit your requirements. Our team of experts will work closely with you to design and implement a conveyor system that maximizes your factory's potential.

Superior Quality, Unbeatable Durability:

Quality is our top priority. Our Conveyor Belts are crafted using premium-grade materials, making them incredibly robust and long-lasting. You can trust our belts to withstand the toughest of conditions, reducing maintenance costs and boosting your factory's overall performance.

Global Reach, Local Support:

With a wide network of satisfied clients across the globe, Conveyors Joint is your reliable partner in elevating factory efficiency. Wherever your factory is located, our dedicated support team is always ready to assist you with prompt service and expert advice.

Sustainable Solutions:

At Conveyors Joint, we believe in sustainable manufacturing practices. Our Conveyor Belts are designed with energy efficiency in mind, reducing your factory's carbon footprint while enhancing productivity.

#FactoryConveyorBelts#ConveyorBeltSolutions#ManufacturingAutomation#IndustrialProductivity#EfficientFactoryOperations#ConveyorSystem#MaterialHandling

0 notes

Video

youtube

Conveyor Belt Test Run | Stainless Steel Incline Belt Conveyor

0 notes

Text

Top Quality Conveyor System - Swisser Instruments

We supply a optimum quality Conveyor System that is one of the best mechanical handling apparatuses that is used in many industries. We are one of the ideal Conveyor System Manufacturers and Suppliers in India.

0 notes

Text

#ChainConveyorforSale#ChainConveyorforPaperMakingLine

Leizhan company provides conveying equipment for paper mills. If you are interested in it, please leave your email or contact me for price or more details!

#Email: [email protected]

#WhatsApp: +8615824887816

1 note

·

View note

Text

#seimtisu#itohdenki#conveyorsystem#materialhandling#dcpowermoller#dcroller#mdr#authorizeddistributor#supplier#logistics#warehousing#materialhandlingequipment#powermoller#distributors#Manufacturers#india#japan

0 notes

Text

Composite Roller Market Trends Highlight Sustainability Needs in Material Handling and Conveyor Applications

The composite roller market has emerged as a dynamic and rapidly expanding segment within the broader industrial components industry. As global manufacturing, mining, and logistics sectors strive for higher efficiency, safety, and sustainability, composite rollers have gained significant traction due to their lightweight construction, corrosion resistance, and enhanced durability compared to traditional steel or aluminum rollers.

Composite rollers are primarily used in conveyor systems across various industries such as mining, pulp & paper, food processing, packaging, logistics, and automotive. Their composition typically includes reinforced materials like fiberglass or carbon fiber embedded in a resin matrix, offering exceptional strength-to-weight ratios and longer service life under harsh working conditions.

Market Drivers and Opportunities

Several key factors are driving the growth of the composite roller market:

Industrial Automation and Efficiency Demands: The global push toward smart manufacturing and automation has increased the demand for conveyor systems that offer reduced downtime and improved energy efficiency. Composite rollers, being lighter, reduce power consumption and minimize strain on conveyor systems.

Rise in Mining and Bulk Material Handling: In mining, durability and resistance to extreme conditions are crucial. Composite rollers are ideal for dusty, corrosive, and high-load environments, making them an attractive choice for mining operations worldwide.

Environmental and Regulatory Pressures: Many industries are under pressure to adopt eco-friendly and sustainable materials. Composite rollers, due to their corrosion resistance and minimal maintenance requirements, support green manufacturing initiatives by reducing replacement frequency and waste generation.

Growth in E-commerce and Logistics: The exponential rise in e-commerce has fueled the development of large-scale distribution centers that rely heavily on high-speed conveyor systems. Composite rollers help maintain smooth operations while reducing maintenance costs and energy consumption.

Technological Advancements: Innovations in composite material science have resulted in rollers that are more impact-resistant, quieter in operation, and capable of withstanding higher loads. The integration of sensors and IoT capabilities for real-time condition monitoring is also emerging as a trend in smart conveyor systems.

Regional Insights

North America holds a significant share due to established mining and manufacturing infrastructure, coupled with strong demand for advanced automation.

Europe emphasizes sustainability and efficient logistics, driving adoption in industries like packaging, food & beverage, and warehousing.

Asia-Pacific, led by China, India, and Southeast Asian countries, is witnessing the fastest growth. Expanding industrial bases, rising investments in infrastructure, and increasing mining activities contribute to this surge.

Middle East and Africa are also seeing growth due to ongoing mining projects and improvements in industrial logistics.

Competitive Landscape

The composite roller market is moderately fragmented, with key players focusing on technological innovations and strategic partnerships to gain a competitive edge. Companies such as Lorbrand Composites, Sandvik AB, NEPEAN Conveyors, and CPS Conveyors are leading manufacturers offering specialized solutions tailored to various industrial needs.

Product differentiation is mainly based on factors like load capacity, lifespan, weight, noise reduction, and resistance to environmental stress. Additionally, manufacturers are investing in R&D to develop smart rollers integrated with sensors for predictive maintenance and performance monitoring.

Challenges in the Market

Despite its many advantages, the composite roller market faces certain challenges:

High Initial Cost: Composite rollers can be more expensive than traditional metal rollers, which may discourage smaller enterprises from adopting them, despite long-term cost savings.

Limited Awareness and Availability: In some regions, lack of awareness about the benefits and limited supplier presence pose obstacles to market penetration.

Customization Needs: Different industries require specific designs and load-bearing capacities, which may increase production complexity and lead times.

Future Outlook

The composite roller market is expected to continue its upward trajectory in the coming years. As industries worldwide focus more on sustainability, operational efficiency, and automation, the demand for high-performance conveyor components like composite rollers will only grow stronger.

With continued advancements in materials engineering, the development of more cost-effective manufacturing techniques, and the rising adoption of Industry 4.0 practices, the composite roller market is well-positioned for substantial global expansion. Companies that can offer innovative, durable, and intelligent roller solutions will be the key drivers of this transformation.

0 notes

Text

Z Type Bucket Elevator - VGA Automation

VGA Automation Z-type bucket elevator is a type of conveyor system used to transport bulk materials vertically, horizontally, or in a Z-shaped pattern. It's particularly useful for materials that need to be moved with minimal spillage or breakage, such as grains, snacks, seeds or delicate items.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationBucketElevator#BucketElevator#ZTypeElevator#MaterialHandlingconveyor#ConveyorSystem#IndustrialAutomation#BulkMaterialHandling#FoodProcessing#ProcessingEquipment#vgapackingmachine#Manufacturing#packingmachine#VerticalConveyors#AgriculturalEquipment#PharmaceuticalMachiner#ConveyorTechnology#ProductionLine#GrainHandling#IndustrialConveyor

1 note

·

View note

Text

PU Conveyor Belt

DKT Engineering Enterprises has been in the business of manufacturing top-quality PU conveyor belts since 2010. Our offered range of products finds its wide applications in various areas such as Food processing, Medicine, Electrics, Printing, Packaging, Textile industries, and many more. The unique features of the PU Conveyor Belt are low maintenance, durability, and affordability. For more, you can visit our Website

#puconveyorbelt#manufacturer#conveyor#quality#production#manufacturing#supplier#conveyorsystem#dktee#navimumbai#worldwidesupplier#exporters#suppliers#industrialbelts#manufacturers#industrial#dktengineeringenterprises#india#mumbai

0 notes

Text

Advanced Engineering That Delivers Packaging Perfection – Fair Pack Machineries Pvt. Ltd.

Discover how Fair Pack Machineries Pvt. Ltd. is revolutionizing the packaging industry with over 25 years of engineering excellence. This infographic highlights their wide range of innovative solutions including packing systems, filling systems, and conveyors tailored for granules, powders, liquids, pastes, and solids. With both fully automatic and semi-automatic machines, Fair Pack caters to diverse packaging needs—from gusset and spouted pouches to zipper and 4-side sealed formats. Backed by global standards, eco-friendly designs, and a dedicated R&D team, Fair Pack stands out as a trusted leader in packaging machinery since 1998.

For more, visit us at - www.fairpack.in

#PackagingSolutions#PackingMachines#FillingMachines#ConveyorSystems#FairPack#IndustrialMachinery#SustainablePackaging#AutomaticPacking#MadeInIndia#PackagingInnovation

0 notes