#CrackScan

Explore tagged Tumblr posts

Text

How to Effectively Conduct Tank Crack Scanning for Beverage Storage Tanks

Beverage storage tanks are vital to ensuring the quality and safety of products. Over time, these tanks can develop cracks that compromise their structural integrity, potentially leading to contamination and other serious issues. To maintain the highest standards in beverage production, it is crucial to conduct regular crack scanning and inspections of storage tanks. Here's how to effectively carry out tank crack scanning to ensure your tanks are in optimal condition.

Step 1: Thorough Visual Inspection

Begin by performing a thorough visual examination of the tank. While visual inspections can reveal surface-level damage, they might not detect deeper cracks that could compromise the vessel's integrity. Therefore, this initial step is just a starting point for a more detailed investigation. Complement this with advanced vessel crack test inspection services to identify hard-to-see defects.

Step 2: Utilize Advanced Crack Scanning Technology

To ensure no potential issues are missed, utilize specialized crack scanning technology. This involves using high-tech equipment designed to detect micro-cracks that are invisible to the naked eye. Advanced scanning methods are highly effective in spotting even the smallest fractures, which could lead to leaks or contamination.

Step 3: Conduct Regular Tank Inspection Services

Routine tank inspection services should be conducted to prevent minor cracks from developing into larger, more dangerous issues. Regular inspections are crucial for maintaining the structural integrity of the tank, ensuring that it is fit for storing beverages safely. Inspections should be scheduled annually or more frequently, depending on usage and tank conditions.

Step 4: Address Pathogen Detection

Cracks in beverage storage tanks create an ideal environment for bacteria and other pathogens to thrive. It is essential to integrate pathogen detection measures during the crack scanning process. Detecting pathogens early ensures your storage tanks maintain the necessary hygiene standards and protect the quality of your beverages.

By following these steps, you can effectively safeguard your beverage storage tanks, ensuring long-term performance and product safety.

Bioscan LTD offers expert vessel crack test inspection services and tank inspection services to keep your tanks safe and efficient.

#CrackScan#CrackScanning#TankInspectionServices#VesselCrackTestInspection#BeverageStorageTanks#PathogenDetection#TankSafety#StructuralIntegrity#IndustrialTankMaintenance#BeverageProductionSafety

1 note

·

View note

Text

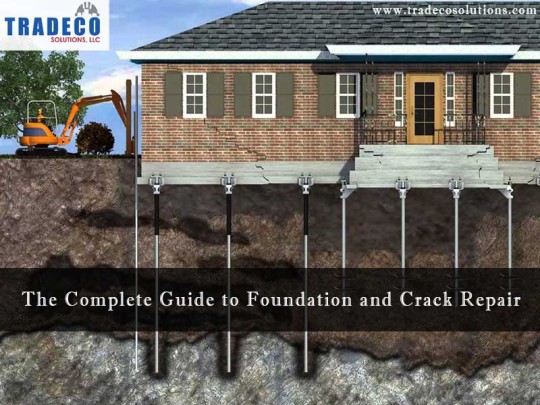

The Complete Guide To Foundation And Crack Repair

Most of us yearn to have a nice, well-maintained home since this is where we will be spending a lot of time. Home is also one of the biggest investments we will be making during our entire life span. Foundation problems or repairs can cause serious damage and threaten that investment if left unattended. Basement repairs or threats such as crackscan arise due to various reasons namely excessive water, poor construction and bad soil which can lower the home’s value over time. Regardless of the type of problem, you should ensure that repairs happen at the right time so that you can protect the property from foundation failure.

Residential foundation repair services

If you are facing problems such as cracked ceilings, bowing walls or slanting floors, it is time you consulted an expert from Residential Foundation Repair Company in Jackson. The staffthere can offer the best solution for your home repair problems after providing you a free inspection of your property. They use only genuine products for foundation and crack repair so that you can rest easy in the future.

Concrete crack repair

Concrete crack repair is not an easy job that you can take up yourself. By availing the services of professionals Concrete Crack Repair Contractors in Jackson & Dallas you can rest assured of a long term solution. Whether you are experiencing problems with your foundation, basement or any other area, you can contact these trained staff who can give instant solutions at a nominal cost. These contractors are not only insured and trained but can also be relied upon to use products with warranty. You can be assured of the best experience possible when you hire reputable contractors from a reliable company in Jackson and Dallas.

New home buyers will normally hesitate to buy a house that has visible cracks or repairs on its structure. Hence it is up to each and every house owner to keep the house in proper condition by undertaking repairs as and when needed so that the value of the home remains intact. Our contractors at Jackson and Dallas give a quote only after a thorough inspection of the property to see what kind of foundation repairs are actually needed for the property. With efficient management and years of experience, we are your one stop solution for all your foundation and crack repair needs. To know more, contact us at http://www.tradecosolutions.com/ today!

1 note

·

View note

Text

Where Can I Find the Best Foundation Crack Repair Companies in Chicago?

Foundation Crack Repair Companies

The concrete foundation of your home creates the basement area that you live in. The most common cause of basement water seepage in poured concrete foundations is a vertical crack. While repairing cracks from the exterior was the original remedy, the most robust and cost effective repair method today is filling and sealing the crack from the inside, commonly referred to as foundation crack injection.

Specially formulated Epoxy materials and engineered injection techniques bond cracked surfaces from the inside out, which completely closes the crack, and permanently stops any leak. We are so confident in our technology and expertise that we back our services with a 10 Year Warranty plan. There are many causes of a concrete foundation crack, most notably settling and drying out of the concrete.

This foundation wall crack repair is a low cost process that is quick, very effective, and extremely clean. We will repair your leaking cracked concrete wall by injecting a urethane compound into the problem area. The Urethane expands inside the foundation crack to form a closed cell foam. This closed cell foam fills the leaking basement crack from top to bottom and front to back.

Truths Everybody Should Know About Foundation Crack Repair Companies

The concrete foundation of your home creates the basement area that you live in. When this foundation cracks, water can leak into the basement. Water in the basement causes mold, mildew and unpleasant odors There are many causes of a concrete foundation crack. You should know that most of the cracks can be repaired from the inside.

This basement crack repair is a low cost process that is quick and very clean. We will repair your leaking cracked concrete wall by injecting a liquid polyurethane into it. This liquid polyurethane expands inside the foundation crack on contact with water to form a closed cell foam. This closed cell foam fills the leaking basement crack from top to bottom and front to back.

Foundation Crack Repair Companies? It’s Easy If You Do It Right

Foundation wall crackscan be repaired from the interior or exterior. If the basement is unfinished (no drywall or paneling) and the crack is exposed on the interior, we’ll typically recommend our Epoxy / Urethane Injection Process. This is a two step process which involves sealing the crack on its inside face with an epoxy paste and injecting a urethane resin which fills the entire crack to the outside soil.

This involves coring a small hole in the earth at the crack location and filling the hole with a granular clay to form an impermeable water barrier. Both foundation crack repair processes are minimally invasive and time proven to be equally effective. They also come with a transferable lifetime warranty to the homeowner.

Certain crack pattern formations and those wider than 1/8″, however, can be a sign of a structural problem that should be further evaluated. Ready to get started?

youtube

Power Up Your Foundation Crack Repair Companies

The national average foundation repair cost is around $350 – $1,350. Repairing the foundation of a house can cost as little as $350 for a single crack to $1,350 for multiple cracks. However, the total cost can be as high as $10,000 or more if you’re also dealing with major structural problems.

Your home is a safe and cozy place, so spotting a cracked wall, sloping floor, or other sign of a foundation problem is undoubtedly stressful. Not only can it be a sign of a bigger (and costly) problem, but foundation and structural damage can impact the resale value of your house.

Do you think you might have a foundation issue? It’s important to act quickly because letting a foundation problem slide can lead to water damage, foundation instability, insect problems, and even more expensive repairs. Before you Average cost of foundation repairFoundation repair cost factorsThe most common types of foundationsFoundation repair and home insuranceHow long foundation repair lastsHow to find a contractor for foundation repairThe national average cost to repair cracks in a foundation is $350 to $1,350.

Power Up Your Foundation Crack Repair Companies

Major structural issues can cost as much as $10,000 to $15,000 to fix — which is why it’s important to catch and repair damage early. A foundation repair contractor typically charges based on equipment, materials and labor needed to repair the foundation. The labor often is charged at an hourly rate.

A crack can be a sign of a bigger foundation problem. For example, if the crack in your foundation is caused by a leak, the crack will need to be repaired and the leak will need to be sealed off and waterproofed. A sinking or shifting foundation may need to be repaired by underpinning or house leveling.

House leveling may require slabjacking or mudjacking, in which grout gets pumped into holes in the foundation. Here are some common types of foundation repairs and average costs: Repair Type Average Cost Cracks $350-$1,350 Leaks $500-$3,500 Underpinning $9,500-$15,000 Mudjacking $2,700 for an average home basement Stabilizing $5,000-$10,000 You may also need an inspection by a structural engineerto determine the cause of the problem and the repair needed at a cost of $200 to $400 for a typical home.

Important Strategies To Foundation Crack Repair Companies

A foundation “transfers the load of a structure to the earth and resists loads imposed by the earth,” according to the International Association of Certified Home Inspectors. Here’s what you should know about common types of foundations: Basement: common in the East and Midwest, a basement is a living space that is part of the home and needs to be kept dry.

Slab-on-grade: the most popular type of foundation in the Southeast, a slab-on-grade foundation has a concrete floor that supports the building. Pile: used in coastal flood zones, a pile foundation has long posts pushed deep into the ground to provide stability and prevent shifting. The most common materials used to make foundations are concrete blocks and other masonry products and cast-in-place concrete.

Homeowners insurance generally does not cover foundation repair unless the damage was caused by a covered disaster. For example, if a tornado made your basement walls buckle, your home insurance policy should cover the work. Home insurance will not cover repairs for foundation damage caused by wear and tear, tree roots, construction defects, or soil settling.

Foundation Crack Repair Companies – How to Do It Right

A foundation that has been fixed may need additional repairs in the future. For example, if you repaired one side of your foundation, the other side may need a similar repair at some point. Reputable foundation repair companies offer warranties for their work. Homeowners should carefully read warranties to know exactly what is covered under the warranty and how long the warranty lasts.

Read customer reviews: Check feedback from other homeowners who have had work done to thoroughly vet a foundation repair contractor. Get a free quote: Obtain a written estimate that lists the problems, needed repairs, and cost of the proposed repairs before you commit. A good foundation keeps a home sound, sturdy and dry.

Solutions for every problem. If your foundation is cracked, buckling, or has other damage, our experts can restore your home to safe, functional condition. Foundation problems can affect your home’s safety, appearance, and value. In order to effectively repair your foundation, you must properly diagnose the problem. Complete Foundation Repair Pros has been providing expert foundation repair services to this area since 1975, and we have the experience to provide you with a quality solution.

And How To Avoid Problems with Foundation Crack Repair Companies

Complete Foundation Repair Pros, we install exclusive foundation products that come with a warranty and are installed by our team of trained contractors. If you’re ready to find a solution to your foundation issues, give us a call or click below to schedule a professional inspection with one of our foundation repair experts.

https://chicago.smartfoundationrepair.net/blog/foundation-crack-repair-companies/

0 notes

Text

Time to Become Part of the Steamroller

Bridge inspectors should be asked to hand over inspections to technology and get retrained to analyze data obtained through technology and advise on repair decisions

In any industry, people will either be part of the problem or part of the solution.

The lines appear to be drawn clearly enough in the bridge inspection, concrete inspection services industry.

Primarily, the reasons why problems assail the bridges of the world today, are self-explanatory. The ever-increasing daily loads on bridges and extreme weather conditions that seem to be the norm than the exception, exacerbate deterioration of bridges. In the US, in particular, most bridges were built in the 1950s, and are now old and crumbling. Many of the bridges are in dire need of repair. Some require outright replacement. Recent history records horrific bridge collapses, destroying lives and property of unimaginable proportions. The latest bridge collapse occurred recently in Genoa, Italy.

In every bridge collapse, subsequent investigations concluded that the problems on the bridges were not properly understood or addressed by those responsible for repairs.

It is also self-explanatory that a prerequisite to successful resolution of a problem, is insightful knowledge of the problem, and therein lies the biggest stumbling block in the bridge inspection industry.

In this age of technology, America still persists in using manual inspection of bridges. To make matters worse, federal and state guidelines for manual inspection of bridges are about fifty years old, with significantly subjective inspection methods. So, antiquated methods which ought to have been grandfathered years ago, are still pervasively used, and new technology is blatantly sidelined and ignored.

The US Department of Transportation (USDOT) in a multitude of states, and Asset Managers in large companies that win inspection contracts, have stock excuses for not using technology.

“The inspection protocols are pretty much defined by FHWA (Federal Highway Administration), and we have to adhere to their standards.”

“FHWA regulations require hands-on inspections.”

“We cannot change criteria because we are stuck with the FHWA requirements.”

“Hands-on inspections mean you must be within arm’s reach of the object you are looking at. A lot of things we do, like sounding, taking a big hammer and beating on something and listening to the frequency - you can’t do that with a drone.”

“We are not allowed to do inspections without being physically present.”

“We are only interested is using technology when it is appropriate.”

“Technology hasn’t been around for long.”

These statements, if nothing else, indicate it is about time bridge inspections are taken off the hands of asset managers and handed over to companies that have developed sophisticated technology to handle in-depth and accurate inspections.

Small companies like Florida-based Infrastructure Preservation Corporation (IPC), have a range of modern technologies utilizing customized robotics and drones for convenient and speedy inspections, with the ability to provide accurate and quantitative data that records anomalies, raising red flags even before a problem has materialized.

Archaic visual inspection or “sounding” with a hammer to listen to changes in tone are flawed and subjective in the extreme, and conclusions will differ according to the experience and perspective of different inspectors. When an inspector sees a crack on a bridge, it is probably too late for repairs.

In contrast, after six years of R&D, IPC has added TendonScan to its service range, able to scan the inside of the tendon and locate vulnerability to corrosion by analyzing air, water and bleeding grout within the tendon. Using the latest Non-Destructive Evaluation (NDE) and Non-Destructive Testing (NDT) technologies, the TendonScan is able to track the size and shape of the developing abnormality, and guide timely and necessary repairs with razor-sharp accuracy.

IPC’s solutions also include CableScan to handle bridge cable stay inspections, PoleScan for high mast light pole inspections and CrackScan for concrete and steel crack assessments.

These robotic systems can identify deterioration in concrete and other structural material at the initial stages, andare geared to galvanize repairs and maintenance before deterioration spreads and compromises the safety of bridges.While averting a disaster, such swift proactive measures can save millions of taxpayer dollars.

Also, Unmanned Aerial Systems (UAS) in drones can easily access all areas of a bridge,unlike the outdated manual inspection methods that require lane closures, night inspections to allow uninterrupted traffic flow and expensive equipment to access the under bridge.

Thus, it is as clear as day that the existing system of manual inspections must change immediately and give way to the age of technology. Obstinately clinging to antiquated methods will only compromise the safety of bridges and gobble up many millions of precious dollars in unnecessary repairs and replacements. The naked eye and even a trained ear are no match for the incredible performance and information that technology can provide.

Furthermore, history records how manually conducted in-depth Inspections have missed detecting vital deficiencies that led to major tragedies.The collapse of Interstate 35W Bridge over Mississippi River during rush hour on August 1, 2007, which killed 13 people, injured 145 and destroyed 111 vehicles, was later attributed to a serious flaw in the original bridge design. Manual inspections never caught this because focusing on design aspects are outside the scope of manual inspections. The bridge was weakest at the point it should have been the strongest, and everyone was blissfully unaware of a disaster waiting to happen.

President of IPC, Doug Thaler says, “Technology today allows us to develop very sophisticated condition assessments. We just need state and federal governments to evaluate and adopt them.”

This brings the conversation to how experienced bridge inspectors can use their years of experience and analytical skills to read the information provided by technology and assess the condition of the bridge while identifying existing issues and problems in the making. This means that bridge inspectors need to be retrained to take on these new responsibilities, and make informed repair decisions based on information provided by technology.

Says Thaler,”“A human inspector cannot compete with technology.In one instance, for example, the regular manual inspection on cable stays on bridges was for eighty-four cables. The inspectors found one problem on one stay. IPC did a quality control inspection on just nine of those stays and found twelve issues. Some of them were actually issues that were caused by the inspectors or the painters. A painter’s bucket had hit a cable in an earlier time and scraped off the coating, creating rust and pitting which resulted incorrosion of the steel.”

As much as old habits are hard to overcome, survival and progress require embracing change. American author Stewart Brand said, “Once a new technology rolls over you, if you're not part of the steamroller, you're part of the road.”

0 notes

Link

IPC’s concrete and bridge #concretecrackinspections crack inspection system allows for the mapping of the length, width and position of cracks on concrete structures. X, Y and Z axis. By monitoring the progression of the cracks in concrete, we can see the progression of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

0 notes

Link

IPC’s concrete and bridge #suspensionbridgeinspection crack inspection system allows for the mapping of the length, width and position of cracks on concrete structures. X, Y and Z axis.

By monitoring the progression of the cracks in concrete, we can see the progression of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or concrete structure. Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.

0 notes

Link

monitoring the progression of the cracks in concrete, we can see the progression #wedgingofbridges of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or concrete structure. #suspensionbridgeinspection Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.#miningshaftinspection #robottoreplacewedgingforbridgeinspections

0 notes

Text

The ROI of Regular Industrial Tank Crack Scanning

Industrial tanks are the workhorses of countless industries, storing and processing everything from chemicals to food products. However, even the most robust tanks can develop cracks over time due to wear and tear, pressure fluctuations, or external factors. Left undetected, these cracks can lead to catastrophic failures with severe consequences, including:

Product contamination: Leaking tanks can compromise product quality and safety.

Environmental damage: Spills from cracked tanks can pollute the environment.

Workplace injuries: Tank failures can pose serious safety risks to workers.

Production downtime: Repairs and replacements for cracked tanks can significantly disrupt operations.

Fortunately, regular crack scanning can significantly reduce these risks. Bioscan LTD, a leader in non-destructive testing (NDT) services, offers a comprehensive approach to vessel crack test inspection services, helping you identify cracks early on and maximize the return on investment (ROI) of your industrial tanks.

How Crack Scanning Delivers ROI:

Prevents Catastrophic Failures: Early detection of cracks allows for timely repairs, preventing costly and disruptive tank failures.

Extends Tank Lifespan: By identifying and addressing minor cracks before they become major problems, crack scanning can significantly extend the lifespan of your tanks, saving you money on replacements.

Reduces Maintenance Costs: Regular crack scanning allows for preventative maintenance, avoiding the need for extensive repairs or emergency replacements down the line.

Minimizes Downtime: Early detection and repair of cracks prevent unexpected tank failures that can halt production for extended periods.

Enhances Safety: A proactive approach to tank maintenance through crack scanning creates a safer work environment for your employees.

Ensures Regulatory Compliance: Many industries have regulations regarding tank inspections. Regular crack scanning helps you demonstrate compliance with these regulations.

Bioscan LTD: Your Partner in Crack Scanning Solutions

Bioscan LTD utilizes a variety of advanced NDT techniques, including ultrasonic testing and magnetic particle inspection, to perform comprehensive tank inspection services. Our experienced inspectors can identify even the most minute cracks, ensuring the integrity of your tanks and maximizing their ROI.

Investing in regular crack scanning is not an expense, it's an investment in the safety, efficiency, and profitability of your operations. Contact Bioscan LTD today to discuss your specific needs and discover how our crack scanning expertise can contribute to your success.

#CrackScan#CrackScanning#VesselCrackTest#TankInspection#IndustrialTankInspection#PreventativeMaintenance#StructuralIntegrity#IndustrialSafety#AssetManagement#MaintenanceStrategy#EquipmentHealth#TankCrackDetection#InspectionServices#OperationalEfficiency#CostSavings

1 note

·

View note

Text

What are the Methods of Detecting Cracks in Industrial Tanks?

Industrial tanks are crucial components in various industries, from petrochemical to food processing. Ensuring their structural integrity is vital to prevent leaks, contamination, and potentially catastrophic failures. Effective crack detection methods are essential to maintain safety and efficiency. Here's a look at some of the most reliable techniques used by leading tank inspection companies.

1. Visual Inspection The most straightforward method, visual inspection, involves trained technicians examining the tank's surface for visible signs of cracks or damage. While this method can identify obvious defects, it often misses subsurface cracks and requires supplemental methods for comprehensive assessment.

2. Ultrasonic Testing (UT) Ultrasonic testing is a highly effective crack test inspection method that uses high-frequency sound waves to detect flaws. A transducer sends sound waves into the tank material; reflections from cracks are analyzed to determine their size and location. This method is widely used for its accuracy and ability to detect subsurface cracks.

3. Magnetic Particle Testing (MPT) Magnetic particle testing is another popular crack testing inspection technique. It involves magnetizing the tank's surface and applying ferrous particles. These particles gather around cracks, making them visible under ultraviolet light. MPT is particularly effective for detecting surface and slightly subsurface cracks in ferromagnetic materials.

4. Dye Penetrant Testing (DPT) Dye penetrant testing is a simple yet effective crack scan method. A dye solution is applied to the tank's surface and allowed to seep into any cracks. After a set period, excess dye is removed, and a developer is applied to draw out the dye from cracks, making them visible. This method is ideal for detecting fine surface cracks.

5. Radiographic Testing (RT) Radiographic testing uses X-rays or gamma rays to capture images of the tank's interior. This crack scanning technique is highly effective for detecting internal flaws that are not visible on the surface. It provides detailed images that help in assessing the severity of the cracks.

Each of these methods offers unique advantages, and often, a combination of techniques is used to ensure thorough crack detection. For industries relying on the integrity of their tanks, partnering with a specialized tank inspection company like Bioscan LTD ensures the highest standards of safety and reliability. Bioscan LTD offers comprehensive vessel crack test inspection services, utilizing state-of-the-art technology to keep your operations running smoothly.

Visit Bioscan LTD to learn more about their crack detection and inspection services.

#CrackDetection#CrackTestingInspection#CrackTestInspection#CrackScan#CrackScanning#TankInspection#IndustrialTankSafety#UltrasonicTesting#MagneticParticleTesting#DyePenetrantTesting#RadiographicTesting#TankInspectionCompany#VesselCrackTestInspectionServices#IndustrialSafety#StructuralIntegrity#NondestructiveTesting#BioscanLTD#InspectionServices#IndustrialMaintenance

1 note

·

View note

Link

IPC’s concrete and bridge crack suspensioncableinspection inspection system allows for the mapping of the length, width and position of cracks on concrete structures. X, Y and Z axis.

By monitoring the progression of the cracks in concrete, we can see the progression of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or concrete structure. Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.

0 notes

Link

IPC’s concrete and bridge crack inspection system allows for the mapping of the length, width and position of cracks on concrete structures. X, Y and Z axis.

By monitoring the #suspensionbridgeinspection progression of the cracks in concrete, we can see the progression of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or concrete structure. Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.

0 notes

Link

monitoring the progression of the cracks in concrete, we can see the progression #infrastructureinspectionservices of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or #groundpenetratingradarservicesconcrete structure. Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.#posttensionedbridgeconstruction

0 notes

Link

American writer and Professor of Biochemistry, Isaac Asimov, speaking at the Newark College of Engineering in New Jersey, once said, "I discovered, to my amazement that all through history #ConcreteCrackinspections there had been resistance. #posttensionedbridgeconstruction .. and bitter, exaggerated, last-stitch resistance... to every significant technological change that had taken place on earth. Usually the resistance came from those groups who stood to lose influence, status, money... as a result of the change."

Professor Asimov's comments are astute in observing bridge inspections in the US. One could even say truer words were never spoken. As the world's only super power, the #groundpenetratingradarservices US is expected to set standards for the rest of the world to follow. So it seems incredulous, even shocking, to observe antiquated methodology still used extensively in inspecting the country's vital bridges. Why? And, even as technology advances, bridges are still being inspected manually.

#infrastructureinspectionservices

0 notes

Link

IPC’s concrete and bridge crack #concretecrackinspections inspection system allows for the mapping of the length, width and position of cracks on concrete structures. X, Y and Z axis. By monitoring the progression of the cracks in concrete, we can see the progression of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, saving money and helping to protect the public safety.

0 notes

Link

monitoring the progression of the cracks in concrete, we can see the progression #ConcreteCrackinspections of deterioration in concrete and address areas of concern early. Making repairs to these areas of concern will result in prolonging the assets life, #bridgemaintenanceservices saving money and helping to protect the public safety.

IPC’s condition assessment reports offer a complete mapping of a concrete bridge, bridge deck or concrete structure. Year over year comparisons of bridge crack progression give a detailed 2D and 3D mapping of those cracks and progression over time to help manage repairs.#suspensioncableinspection #bridgemaintenanceservices

0 notes