#CustomFasteners

Explore tagged Tumblr posts

Text

Hex Flange Bolts Manufacturer, Supplier & Exporter

Introduction

Ananka Group is a leading global manufacturer, supplier, and exporter of industrial fasteners, known for delivering precision-engineered solutions to a wide range of sectors including oil & gas, petrochemical, aerospace, marine, construction, and heavy engineering.

With a state-of-the-art manufacturing facility based in Vasai, Maharashtra (India) and fully operational offices in the USA and UK, Ananka Group is strategically positioned to serve clients worldwide with superior quality, timely delivery, and technical support.

We specialize in standard and non-standard fasteners, made from high-performance materials such as stainless steel, duplex, and super duplex, Inconel, Monel, Hastelloy, Titanium, and other specialty alloys. Our commitment to ISO-certified quality management, innovation in design, and customization capabilities makes us a preferred partner for mission-critical applications.

Key Strengths:

In-house design, prototyping, and rapid manufacturing

Wide range of coating and plating solutions

Custom fastener solutions in both metric and imperial sizes

Global exports with full compliance to ASTM, DIN, ISO, and BS standards

A dedicated R&D division focused on aerospace and API-certified components

Hex flange bolts are among the most versatile and widely used fasteners in the industrial world, known for their built-in washer-like flange that distributes load efficiently and eliminates the need for a separate washer. As a trusted manufacturer and supplier of hex flange bolts, we deliver high-performance, corrosion-resistant, and precision-engineered fasteners tailored to suit diverse applications across global industries.

What Are Hex Flange Bolts?

Hex flange bolts are hexagonal head bolts with an integrated flange at the base of the head. This flange acts as a washer, spreading the clamping load over a larger surface area. It reduces the risk of damage to the fastening material and enhances bolt retention, especially in high-vibration environments.

These bolts are frequently used in the automotive, aerospace, oil & gas, heavy machinery, and construction sectors for their strength and reliability.

Design & Prototyping

Whether you need a bolt designed for extreme environments or specialized machinery, our engineering team can prototype the fastener to your exact specifications, including:

Flange diameter customization

Thread pitch variation (coarse/fine)

Head height and drive type

Unique surface treatments or alloy choices

Our focus is on innovative fastening solutions to meet modern engineering demands.

Rapid Manufacturing Capabilities

Thanks to our state-of-the-art CNC machines, forging units, and automated plating lines, we support rapid manufacturing of hex flange bolts, from small-batch custom orders to bulk production runs.

We maintain large inventories of standard sizes and provide just-in-time delivery across various industries and countries. Our agile manufacturing approach ensures minimal lead times and consistent quality.

Custom Coating & Plating Options

Corrosion resistance and environmental compatibility are crucial for bolt longevity.

Zinc and yellow zinc plating

PTFE (Teflon) coating

Hot-dip galvanizing

Black oxide finish

Dacromet and Geomet coatings

Nickel, chrome, and copper plating

These coatings enhance performance in aggressive conditions like marine, chemical, offshore, and automotive applications.

Product Types Offered

High-Performance Hex Flange Bolts

Designed for critical applications like aerospace, nuclear, and motorsports, where reliability and durability are essential.

Custom Fastener Solutions

Our team creates bespoke fasteners that align with your blueprints or technical requirements, including unique dimensions, threading, and materials.

Precision-Engineered Fasteners

Manufactured to tight tolerances, ensuring optimal performance in applications that demand high accuracy.

Specialty Alloy Hex Flange Bolts

Manufactured from premium materials like Inconel, Monel, Hastelloy, Titanium, Duplex, Super Duplex, and others, engineered to perform reliably in the most demanding and corrosive environments.

Corrosion-Resistant Fasteners

Manufactured using stainless steel grades like SS 304, SS 316, and SS 316L or coated with advanced finishes to withstand harsh conditions.

Non-Standard Hex Flange Bolts

Custom dimensions, threading types, and geometries that don't conform to conventional fastener norms.

Metric & Imperial Sizes

Available in a wide range of thread sizes and lengths in both metric (M6 to M80) and imperial (¼” to 3”) standards.

Applications of Hex Flange Bolts

Automotive Industry: Engine components, transmissions, and chassis

Construction: Steel frameworks, bridges, and heavy structures

Oil & Gas: Offshore rigs, refineries, and chemical plants

Aerospace: Airframe structures and engine assemblies

Heavy Equipment: Cranes, bulldozers, and mining machinery

Railways: Track assemblies and locomotive parts

Why Choose Us?

As an ISO-certified manufacturer, supplier, and exporter of hex flange bolts, we ensure:

Superior material selection & quality control

Compliance with international standards: DIN, ASTM, ISO, BS, JIS

Bulk availability and global shipping

In-house R&D for developing advanced fastening systems

Offices & supply chains in India, USA, UK, Europe, and the Middle East

Conclusion

Whether you require standard, non-standard, or custom-engineered hex flange bolts, we have the manufacturing expertise, design capability, and international reach to deliver what you need fast and reliably. With a focus on quality, innovation, and performance, we are your ideal partner for all your fastener requirements.

FAQs

What materials are hex flange bolts made from?

They are typically manufactured from stainless steel, alloy steel, titanium, and specialty alloys like Inconel and Monel.

Are hex flange bolts reusable?

Yes, if not overtightened or damaged, they can be reused. However, it depends on the application and environmental conditions.

Do I need a washer with a hex flange bolt?

No, the integrated flange serves the same purpose as a washer, distributing the load and preventing loosening.

#HexFlangeBolts#FlangeBolt#CustomFasteners#CorrosionResistantBolts#SpecialtyAlloyFasteners#NonStandardFasteners#CustomBoltSolutions#RapidManufacturing#CoatedFasteners#AnankaGroup#HexBoltsSupplier#FastenersExporter#BoltsAndNuts#FlangeBoltSupplier#Anankafasteners#Blog#Articles#tumblr#ananka#tumblr blog

0 notes

Text

Welcome to Dalloyed – Global Leaders in Fastener Solutions

Dalloyed is a trusted name in the world of industrial fasteners, recognized as a leading manufacturer, global supplier, reliable stockist, and premier exporter based in India. With years of industry expertise and a commitment to excellence, we deliver high-quality fasteners that meet the rigorous demands of diverse industries across the globe.

We specialize in a wide range of standard and custom fasteners, including:

Bolts

Nuts

Screws

Washers

Stud Bolts

Coated Fasteners

Our extensive product portfolio ensures we can cater to your specific requirements with precision and reliability.

At Dalloyed, we manufacture fasteners using premium-grade materials to ensure strength, durability, and performance in every application. Our material range includes:

Stainless Steel (SS) Fasteners

SMO 254 Fasteners

Duplex and Super Duplex Fasteners

Monel Fasteners

Inconel Fasteners

Incoloy Fasteners

Hastelloy Fasteners

We are proud to serve clients across industries worldwide, delivering excellence from India to every corner of the globe. Whether you need bulk industrial supply or custom-engineered components, Dalloyed is your one-stop destination for reliable and high-performance fastening solutions.

#Fasteners#IndustrialFasteners#CustomFasteners#HardwareSolutions#EngineeringSupplies#MechanicalComponents#IndustrialSolutions#ManufacturerInIndia#GlobalSupplier#WorldwideExporters#IndianExporter#MadeInIndia#ExportQuality#StockistFromIndia#Bolts#Nuts#Screws#Washers#StudBolts#CoatedFasteners#StainlessSteelFasteners#SMO254Fasteners#DuplexFasteners#MonelFasteners#InconelFasteners#IncoloyFasteners#HastelloyFasteners

1 note

·

View note

Text

How does Royal Hardware support the construction industry's demand for specialized fasteners in Karachi?

Royal Hardware plays a pivotal role in supporting Karachi's construction industry by providing a comprehensive range of specialized fasteners tailored to meet diverse project requirements. Established in 2016 and located on Serai Road, Karachi, the company has become a trusted name in the fastener supply sector.

Key Contributions:

Extensive Product Range: Royal Hardware offers a wide array of fasteners, including bolts, nuts, washers, socket screws, grub screws, studs, anchor bolts, and circlips. These are available in high tensile and stainless steel materials, ensuring durability and strength for various construction applications.

Custom Solutions: Understanding the unique needs of the construction industry, they provide custom-made bolts such as engineering stud bolts with left-hand threads and fine or extra-fine threading, catering to specific project requirements.

Industry Experience: As a third-generation fastener supplier, Royal Hardware brings a wealth of experience and expertise, ensuring that clients receive knowledgeable support and high-quality products.

Quality Assurance: The company emphasizes providing quality materials, with a focus on accuracy in grades and measurements, ensuring reliability and safety in construction projects.

For more information or to explore their product offerings, visit their official website: https://royalhardware.com.pk/.

#RoyalHardware#Fasteners#ConstructionSupplies#KarachiConstruction#SpecializedFasteners#BoltsAndNuts#EngineeringSolutions#StainlessSteelFasteners#HighTensileFasteners#HardwareSupplier#KarachiBusiness#PakistanConstruction#IndustrialFasteners#CustomFasteners#ReliableHardware

0 notes

Text

High Quality Hex Bolts Manufacturers in India | SS International

Sachiya Steel International is a leading Hex Bolts Manufacturer in India, supplying high-quality hex head bolts in various sizes and materials. Our precision-engineered hex bolts ensure durability and strength, meeting international standards. We offer stainless steel, carbon steel, and alloy steel hex bolts for industrial and commercial applications. With a strong commitment to quality and timely delivery, we serve diverse industries across India and worldwide.

Visit Sachiyasteel.com today to explore high-quality hex bolts engineered for strength, precision, and superior industrial performance.

#HexBolts#BoltsManufacturers#HexBoltIndia#Fasteners#IndustrialBolts#SteelBolts#BoltsAndNuts#HardwareSupplies#SachiyaSteel#FastenerManufacturers#EngineeringSupplies#ConstructionMaterials#HeavyDutyBolts#CustomFasteners#IndustrialSupplies

0 notes

Text

Custom Hex Washers: When and Why You Should Consider Them for Your Projects

Hex washers are essential components in a variety of industrial and construction applications. While standard washers may work for many tasks, there are times when custom hex washers are the best solution. These washers provide precise fit and enhanced durability for projects requiring specific sizes, materials, and conditions. Let’s explore when and why you should consider using custom hex washers.

What Are Custom Hex Washers?

Custom hex washers are washers with a six-sided (hexagonal) shape, designed to meet specific requirements. They can be made from materials like stainless steel, brass, or carbon steel, and are customized to fit unique bolt sizes, load capacities, and environmental conditions. These washers are used to distribute load evenly, prevent surface damage, and ensure a secure, durable fit.

Unlike standard washers, custom hex washers are tailored to provide the precise fit and strength required for demanding applications.

When Should You Consider Custom Hex Washers?

There are several situations where custom hex washers are necessary:

Non-standard Bolt Sizes: If you’re working with bolts or nuts that don't fit typical washers, custom washers provide the perfect match.

Harsh Conditions: For projects exposed to high temperatures, chemicals, or corrosion, stainless steel washers or brass shim sheets offer better durability than standard washers.

Tight Tolerances: In applications where precision is critical (e.g., aerospace or medical equipment), custom washers ensure a perfect fit.

Heavy Loads or Vibrations: Custom washers help with better load distribution and prevent damage or failure in high-stress environments, such as machined washers in heavy machinery.

Unique Shapes or Sizes: If you need a washer with a specific thickness or shape, custom hex washers can be made to suit these unique requirements.

Key Benefits of Custom Hex Washers

Custom hex washers offer several advantages that make them ideal for various applications:

Improved Load Distribution: They evenly distribute pressure across the fastened joint, reducing surface damage and wear. This is essential for foundation bolts or U bolts in construction.

Enhanced Durability: Custom washers made from materials like brass shim sheets or stainless steel can withstand extreme environmental conditions, ensuring long-term performance.

Better Fit: Custom washers are made to match the exact dimensions of your bolts or nuts, ensuring a secure and stable fit.

Increased Safety: By preventing loosening or movement, custom washers help maintain the integrity of the assembly. Wedge lock washers and spring lock washers can add extra security in high-vibration applications.

Longer Lifespan: With the right custom washer, the life of your project increases because it reduces wear and tear on the materials being fastened.

Applications of Custom Hex Washers

Custom hex washers are used across various industries:

Construction: In heavy-duty applications like foundation bolts, U bolts, and anchor bolts, custom washers ensure structural stability and strength.

Automotive and Aerospace: For critical parts like engines and suspension components, custom hex washers provide precision and durability.

HVAC Systems: Used in ducts and piping, custom washers help prevent leaks and vibrations. Sealing washers are often used in these systems for extra protection.

Machinery and Equipment: In machinery, custom washers reduce vibrations and wear. Machined washers or tab washers can help secure equipment during operation.

Electronics: Custom washers are important for securing electrical components, preventing shorts, and ensuring system reliability.

How to Choose the Right Custom Hex Washer for Your Project

Selecting the right custom hex washer requires careful consideration of the following factors:

Material: Choose a material based on environmental conditions. Stainless steel washers are ideal for corrosion resistance, while brass offers excellent wear resistance.

Size and Dimensions: Measure the bolt and nut sizes to ensure the washer fits perfectly. An incorrect size can compromise the load distribution and stability.

Thickness: The washer’s thickness affects its load-bearing capacity. Ensure you select the right thickness for your specific requirements.

Special Features: For high-vibration or heavy-load applications, consider washers like wedge lock washers or spring lock washers to prevent loosening.

Custom hex washers are an essential component for projects requiring precision, durability, and efficiency. Whether you're working on construction, machinery, or aerospace, choosing the right custom washer can significantly improve your project’s performance and longevity. Make sure to partner with trusted shim washer manufacturers or washer manufacturers who can provide high-quality custom solutions tailored to your needs.

#CustomWashers#HexWashers#ProjectTips#HardwareSolutions#CustomFasteners#EngineeringEssentials#ProjectEfficiency#WasherDesign#FastenerInnovation#CustomHardware#DIYProjects#ConstructionTips

0 notes

Text

#HeavyHexNuts#IndustrialFasteners#ConstructionMaterials#QualityFasteners#StructuralIntegrity#BoltAndNutSuppliers#ProjectSafety#ManufacturingEssentials#CustomFasteners

0 notes

Text

THREADED RODS | DIC | Dedicated Impex Co

DIC Fasteners is a Brand of Dedicated Impex Co. DIC is a leading Exporter of Threaded Rods in India.

#threadedrods#threadedrodsexporters#customthreadedrods#stainlesssteelthreadedrods#topthreadedrodsexportersinindia#threadedrodssuppliers#dic#customfasteners#dicfastener#fastenerssuppliers#threadedrodsexportersinusa#threadedrodsexporter#rodsexporter#rods#threadedbar#studrod#threadrods#dedicatedimpexcompany#business#exporters#industrial#worldwideexporters#worldwideshipping

0 notes

Link

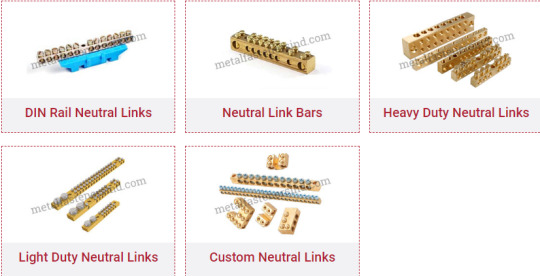

#NeutralLinks#MetalFasteners#Fasteners#German#StandardFasteners#CustomFasteners#IndustrialFasteners#brass#Copper#DINRail#Heavy-dutyLinks#Light-dutyLinks#NeutralLinkBars#brassfittings#PrecisionBrassCoponents#CommonFasteners#SpecialFasteners#Manufacturer#Exporter#Berlin#Screws#Bolts#Nuts#Washers#Rivets#Belgium#France#Luxembourg#Netherlands#Switzerland

1 note

·

View note

Link

#MetalTurnedParts#Brassfitting#brasserie#Copper#PrecisionBrassComponents#MachineParts#CommonParts#SpecialFasteners#CustomFasteners#TurnedParts#ElectricFitting#PipeFitting#PneumaticFitting#GardenFitting#ThreadedFitting#GasFitting#AutomotiveFitting#IrrigationFitting#StandardTurnedParts#German#Berlin#Belgium#Luxebourg#Netherlands#Switzerland#France#Poland#Austria#Manufacturer#Exporter

1 note

·

View note

Link

#brass#brasscomponents#bearings#brassbearings#aerospacebearings#brassaerospacebearings#aerospacefasteners#fasteners#brassfasteners#manufacturer#customfasteners

0 notes

Photo

#customsized #hexagon #socketheadcapscrews in #nickelalloy #monelk500 & #hastelloyc22 #machined from #barstock with #metric #rolledthreads #manufactured with #precision by #Boltport in #mumbai #india #fasteners #fastenersaresexy #bolting #customfasteners #customscrew #custom #manufacturingservices #packedanddelivered (at Mumbai, Maharashtra)

#customsized#hexagon#socketheadcapscrews#nickelalloy#monelk500#hastelloyc22#machined#barstock#metric#rolledthreads#manufactured#precision#boltport#mumbai#india#fasteners#fastenersaresexy#bolting#customfasteners#customscrew#custom#manufacturingservices#packedanddelivered

0 notes

Text

304 Stainless Steel Machine Screws for Marine Equipment

Introduction

In maritime engineering and marine fabrication, selecting the appropriate fastening components is paramount to ensuring structural integrity, corrosion resistance, and long-term performance. Among the vast array of fastening solutions available, 304 stainless steel machine screws stand out as a versatile and cost-effective choice. Their widespread use in marine environments stems from their reliable mechanical properties, resistance to environmental degradation, and adaptability across various marine assemblies.

This article explores the metallurgical characteristics, performance attributes, and application suitability of 304 stainless steel machine screws in marine-grade equipment.

What Are 304 Stainless Steel Machine Screws?

Machine screws are precision-threaded fasteners engineered to engage with pre-tapped holes or mating nuts. They are utilized in applications demanding controlled torque and uniform clamping pressure, particularly in metal-to-metal assemblies. When fabricated from 304 stainless steel, these screws exhibit an optimal combination of corrosion resistance and tensile strength, making them suitable for semi-corrosive marine environments, especially in topside or splash zone installations.

Material Profile: Composition & Properties of 304 Stainless Steel

304 stainless steel is a member of the austenitic AISI 300-series and is chiefly alloyed with the following elements:

Iron (Fe) – Base metal

Chromium (Cr) – approximately 18%, which promotes passivation and enhances corrosion resistance.

Nickel (Ni) – ~8% (for ductility and enhanced corrosion resistance)

Key Metallurgical and Mechanical Properties:

Corrosion Resistance: Exhibits excellent resistance to atmospheric and mildly saline conditions due to the formation of a stable chromium oxide (Cr₂O₃) passive layer.

Mechanical Strength: Ultimate tensile strength typically ranges between 515–750 MPa, providing robust fastening under mechanical loading.

Ductility and Toughness: High elongation at break (≥40%), enabling resistance to shock and vibration.

Non-Magnetic Behavior: Non-ferromagnetic in the annealed state; however, slight magnetism may develop post-cold-working.

Thermal Stability: Performs well up to moderately elevated temperatures (~870°C intermittent service), making it ideal for engine and electrical enclosures.

Why Choose 304 Stainless Steel Screws for Marine Applications?

Although 304 SS does not match the chloride pitting resistance of 316 SS (which includes 2–3% Molybdenum), it is widely specified in non-submerged or intermittently wet marine environments due to its:

Advantages:

Cost Efficiency: Lower alloying content makes it more economical than molybdenum-bearing grades like 316 or duplex stainless steels.

Extensive Availability: Compliant with global standards such as ASTM A193, DIN, and ISO, and offered in a wide range of head types, thread configurations, and dimensional specifications.

Adequate Marine Corrosion Resistance: Suitable for above-deck hardware, coastal installations, and indoor marine compartments.

Fabrication Versatility: Compatible with welding, machining, and forming processes without loss of corrosion resistance.

Marine Applications of 304 Stainless Steel Machine Screws

304 SS machine screws are integrated across numerous marine subsystems and hardware components:

1. Deck and Superstructure Hardware

Used to fasten cleats, railings, winch plates, and deck-mounted brackets.

2. Marine Engine and Machinery Assemblies

Ideal for fastening control housings, engine shrouds, pump casings, and protective equipment covers.

3. Electrical and Navigation Panels

Ensures conductive-free fastening in switchboards, marine lighting systems, and navigation control units.

4. Marina and Dock Fixtures

Suitable for weather-exposed components like dock brackets, signage plates, and structural guards.

5. Yacht and Boat Interiors

Commonly used in cabinetry, seat frame assemblies, and stainless fixtures for corrosion-free aesthetics.

Limitations in Saltwater Environments

While 304 SS offers reliable performance in aerial and splash zones, it lacks the pitting and crevice corrosion resistance required for continuous saltwater immersion or high-chloride concentrations.

For submerged applications or chemical exposure zones, opt for:

316 Stainless Steel (A4)

Duplex Stainless Steel (e.g., UNS S31803/S32205)

Super Duplex (UNS S32750/S32760)

Maintenance Recommendations for Marine Durability

Even corrosion-resistant materials benefit from basic care in marine environments:

Routine Cleaning: Rinse with fresh water post-exposure to salt spray to remove chloride residues.

Insulate from Carbon Steel: Prevents galvanic coupling that accelerates corrosion.

Apply Anti-Seize Lubricants: Especially in high-humidity zones to prevent thread galling and facilitate removal.

Periodic Inspection: Check for discoloration or early signs of corrosion and replace if necessary.

Conclusion

304 stainless steel machine screws provide an optimal balance of performance, availability, and cost for a broad spectrum of marine-grade assemblies, particularly those not subject to full immersion or harsh saline exposure. When used with appropriate design practices and maintenance schedules, they serve as reliable fasteners for both recreational and commercial maritime applications.

Whether you're engineering a yacht interior, outfitting a coastal dock, or installing deck-mounted hardware, 304 stainless steel screws remain a proven and trusted solution.

Frequently Asked Questions (FAQ)

1. Are 304 stainless steel screws appropriate for continuous submersion in marine environments?

Not recommended. While 304 SS is corrosion-resistant, continuous immersion in seawater may cause localized corrosion. 316 SS or duplex grades should be used instead.

2. Is 304 stainless steel magnetic?

In its annealed form, it is non-magnetic. However, cold working processes like forming or machining can impart slight magnetic properties.

3. How can corrosion be mitigated on 304 SS screws in marine use?

Rinse with fresh water after saltwater exposure

Avoid contact with dissimilar metals

Use protective coatings or anti-seize compounds

4. What head types and threads are available in 304 SS machine screws?

Available in multiple configurations such as:

Head Types: Pan, Flat, Round, Hex, Truss

Threads: UNC, UNF, Metric Coarse/Fine

Standards: ASTM, ISO, DIN

5. Where to source marine-grade 304 SS machine screws?

You can purchase them from specialized marine hardware suppliers, industrial fastener distributors, or directly from manufacturers like Ananka Fasteners, who offer high-quality stainless steel fasteners tailored for marine and industrial use.

#FlangeHeadBolt#HexFlangeBolt#FlangeBolts#CustomFasteners#AnankaFasteners#AerospaceFasteners#APIFasteners#CustomCoating#RapidManufacturing#MadeInIndia#USAFastenerSupplier#UKFastenerSupplier#GlobalFastenerManufacturer#AnankaGroup#Anankafasteners#ananka#manufacturer#fasteners#Tumblr#blog tumblr#supplier

0 notes

Text

HomeGuy3: #customfastener Screws Vs. Nails: Which is the Better Fastener? https://t.co/Yfsybj35Uy

HomeGuy3: #customfastener Screws Vs. Nails: Which is the Better Fastener? https://t.co/Yfsybj35Uy

— Grand Rapids Roofing (@grandrapidssrvs) February 11, 2017

from Twitter https://twitter.com/grandrapidssrvs

0 notes

Text

Washer Manufacturer | F436 Fasteners: Complete Guide for Manufacturers, Suppliers, and Buyers

In the world of fastening solutions, washers play a crucial role in ensuring the stability, longevity, and integrity of assemblies. These small but essential components distribute load, prevent loosening, and protect surfaces from damage. From industrial machinery to household appliances, washers are indispensable.

Introduction to Washers

Washers are thin plates (typically disk-shaped) with a hole in the middle that is used to distribute the load of a threaded fastener, such as a bolt or nut. They serve multiple functions:

Load Distribution: Preventing localized stress on surfaces.

Vibration Absorption: Minimizing loosening due to vibrations.

Sealing: Preventing leakage in fluid systems.

Spacing: Adjusting the gap between components.

Depending on the application, washers can be made from various materials, including mild steel (MS), stainless steel (SS), brass, copper, and high-nickel alloys.

Introduction to F436 Washer

F436 fasteners primarily consist of hardened steel washers manufactured in accordance with the ASTM F436 specification. These fasteners are designed to be used with structural bolts, nuts, and assemblies, particularly in high-strength structural connections. The ASTM F436 standard ensures the washers are capable of handling the heavy loads and environmental conditions encountered in structural steel construction, bridges, towers, buildings, and other critical infrastructure.

The unique properties of F436 fasteners, especially washers, include excellent hardness, strength, and resistance to deformation under load, making them an essential component in high-strength bolted connections.

What are ASTM F436 Washers?

ASTM F436 is a standard that defines the chemical, mechanical, and dimensional specifications for hardened steel washers designed for use with:

ASTM A325 (now ASTM F3125) structural bolts

ASTM A490 (now ASTM F3125) structural bolts

Other high-strength bolted assemblies

They are typically flat washers that help distribute the load evenly and protect the mating surfaces from damage due to tightening torque and dynamic loads.

Types of F436 Fasteners

While ASTM F436 specifically covers washers, many people often refer to "F436 fasteners" to describe the broader assembly they're part of. Below are common F436 fastener components:

1. F436 Hardened Washers

F436 Type 1: Hardened washers manufactured from standard carbon steel, providing high strength and durability.

F436 Type 3: Hardened washers produced from weathering steel, offering superior corrosion resistance, ideal for outdoor and exposed applications.

Coated F436 Washers: Including zinc-plated, hot-dip galvanized, mechanical galvanized, and others for corrosion protection.

2. F436 Assembly Components

Though technically not part of ASTM F436, these are typically used with F436 washers:

Structural Bolts (ASTM F3125 A325 or A490)

Heavy Hex Nuts (ASTM A563)

Tension Control Bolts

Anchor Bolts

Applications of F436 Fasteners

F436 washers and associated fasteners are widely used in industries that demand strong, durable, and reliable connections, such as:

Structural Steel Construction

Bridges

Transmission Towers

Wind Turbines

Cranes

Offshore Platforms

Skyscrapers

Infrastructure Projects

Their high hardness prevents embedding and deformation when high-strength bolts are tightened to the required pretension levels.

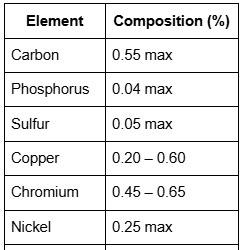

ASTM F436 Material Specifications

Chemical Composition (Type 1 - Carbon Steel)

Chemical Composition (Type 3 - Weathering Steel)

Mechanical Properties

This high hardness ensures the washers will not deform under high clamping forces.

Coating Options for F436 Washers

To improve corrosion resistance, particularly in outdoor or marine conditions, ASTM F436 washers can be supplied with a variety of protective coatings:

Hot-Dip Galvanizing (HDG)

Mechanical Galvanizing

Zinc Electroplating

Geomet® or Delta Protekt® coatings

Phosphate and Oil Coating

Note: Coating thickness and method must meet the requirements to ensure proper fit and function in bolted assemblies.

Advantages of F436 Fasteners

High Hardness: Resists embedment and helps maintain preload during tightening and operation.

Excellent Load Distribution: Protects mating surfaces during tightening.

Durability: Withstands severe loading and vibration conditions.

Corrosion Resistance: Especially for Type 3 and coated variants.

Compliance with International Standards: Ensures global application across industries.

ASTM F436 vs. Other Washer Standards

Why Choose Ananka Fasteners for F436 Fasteners?

As a leading manufacturer, stockist, and exporter of high-strength structural fasteners, Ananka Fasteners offers:

In-House Production: Equipped with state-of-the-art CNC machines and advanced forging capabilities.

Quality Control: ISO-certified manufacturing processes with rigorous quality checks at every stage.

Customized Solutions: Fully customized washer manufacturing as per client drawings and specifications.

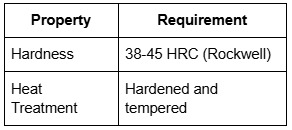

Sizes and Dimensions Chart (Sample)

Inspection and Testing for F436 Fasteners

To ensure quality and compliance, F436 washers undergo rigorous testing:

Hardness Testing (Rockwell HRC)

Dimensional Inspection

Coating Thickness Testing

Chemical Analysis (Spectrometer)

Heat Treatment Verification

Visual Inspection

Frequently Asked Questions (FAQ)

Q1. Can F436 washers be reused?Generally not recommended in structural applications as hardness may be affected after the first installation.

Q2. Are F436 washers compatible with galvanized bolts?Yes. F436 washers are often hot-dip galvanized to match the coating of structural bolts.

Q3. Where are ASTM F436 fasteners commonly used?Bridges, buildings, steel structures, towers, heavy industrial equipment.

Q4. Do you offer third-party inspection (TPI)?Yes. Ananka Fasteners offers TPI services from agencies like BV, SGS, TUV, Lloyd’s, etc.

Conclusion

ASTM F436 fasteners, especially washers, play a crucial role in ensuring the integrity, safety, and long-term durability of structural connections. Their high hardness, precise dimensions, and corrosion-resistant options make them indispensable for structural steel projects worldwide.

Whether you're a contractor, procurement manager, or project engineer, choosing the right F436 fastener supplier ensures your project meets all safety and performance standards. Ananka Fasteners is fully equipped to fulfill all your F436 fastener needs, offering exceptional quality and worldwide export services.

#WasherManufacturer#Fasteners#SpringWasher#PlainWasher#FlatWasher#CountersunkWasher#StainlessSteelWashers#MildSteelWashers#IndustrialFasteners#GlobalSupplier#FastenerIndustry#MadeInIndia#ExportQuality#OilAndGas#MarineIndustry#CustomFasteners#Ananka#AnankaFasteners#manufacturer#tumblr#tumblr blog#blogs

0 notes

Text

Complete Fasteners Product List — Types & Applications

Fasteners are the mechanical backbone of countless structures and systems, ranging from industrial machines to home appliances. They serve as crucial elements engineered to firmly join two or more components in an assembly. At Ananka Fasteners, we specialize in manufacturing, supplying, and exporting a wide array of high-performance fasteners to meet diverse industrial requirements across the globe.

Below is a detailed list of fastener products we offer:

1. Coated Fasteners

Coated fasteners are surface-treated fasteners designed to resist corrosion, enhance durability, and improve performance under extreme conditions.

Types of Coatings:

Zinc Coating (Electroplated, Hot Dip Galvanized)

PTFE Coating (Xylan, Teflon)

Cadmium & Nickel Coating

Black Oxide Coating

Applications:

Marine structures

Offshore platforms

Petrochemical industries

Construction projects are exposed to weathering

2. SMO 254 Fasteners

SMO 254 is a high-alloy austenitic stainless steel known for excellent corrosion resistance and strength, especially in chloride-bearing environments.

Available Fastener Types:

SMO 254 Bolts

SMO 254 Nuts

SMO 254 Washers

SMO 254 Screws

Applications:

Desalination plants

Pulp and paper industries

Seawater cooling systems

Chemical processing industries

3. Bolt Fasteners

Bolts are externally threaded fasteners designed to be used with nuts or threaded holes to securely join multiple components.

Common Bolt Types:

Hex Bolts

Heavy Hex Bolts

U Bolts

Eye Bolts

Carriage Bolts

Flange Bolts

Applications:

Structural steel fabrication

Equipment and machinery

Automotive and heavy-duty applications

Aerospace and defense

4. Screw Fasteners

Screws are threaded fasteners that create their mating thread during installation, often used without a nut.

Popular Screw Types:

Wood Screws

Machine Screws

Self-Tapping Screws

Socket Head Cap Screws

Sheet Metal Screws

Applications:

Electronics and electrical panels

Wood and furniture work

HVAC and appliance assembly

Construction and industrial machinery

5. Washers Fasteners

Washers are disk-shaped components used under nuts or bolt heads to distribute loads and prevent loosening.

Types of Washers:

Plain Washers

Spring Washers

Lock Washers

Conical and Dome Washers

Applications:

Vibration-prone assemblies

Automotive and aerospace

Electrical and electronics

Construction and pipelines

6. Stud Bolts Fasteners

Stud bolts are fully threaded rods paired with nuts on both ends, specifically designed for use in high-pressure and high-temperature applications.

Types of Stud Bolts:

Full Threaded Studs

Tap-End Studs

Double-End Studs

Continuous Thread Studs

Applications:

Flanged pipe connections

Oil & gas industry

Chemical and petrochemical equipment

Pressure vessels and reactors

7. Custom Fasteners

Custom fasteners are specially manufactured to meet unique project requirements based on dimensions, material, and finish.

Options Available:

Unique threading and shapes

Non-standard lengths or heads

Special alloys (Titanium, Inconel, Monel, etc.)

OEM & drawing-based production

8. Nuts Fasteners

Nuts are internally threaded fasteners paired with bolts or screws to secure components.

Common Nut Types:

Hex Nuts

Lock Nuts

Wing Nuts

Cap Nuts

Flange Nuts

Square Nuts

Applications:

General engineering

Automobile assembly

Power generation equipment

Home improvement and furniture

Why Choose Ananka Group?

Wide Material Range – From carbon steel to exotic alloys like Inconel, Monel, Hastelloy, and SMO 254

Worldwide Presence – Catering to industries throughout the USA, Europe, the Middle East, and Asia

Custom Solutions – Precision manufacturing based on client drawings or specifications

Compliance – All fasteners are manufactured to ASTM, DIN, ISO, and other global standards

Conclusion

Whether you're building infrastructure, assembling machinery, or fabricating precision equipment, choosing the right fastener is critical. The extensive range of fasteners we offer at Ananka Fasteners ensures reliable performance, safety, and longevity in every application. From coated fasteners for enhanced corrosion resistance to custom-engineered solutions for niche applications, our products meet the highest quality standards.

Frequently Asked Questions (FAQ)

Q1. What material types do you provide for these fasteners?We offer fasteners in stainless steel, carbon steel, alloy steel, brass, copper, Inconel, Monel, Hastelloy, SMO 254, titanium, and more.

Q2. Do you provide testing certificates?Yes, we provide Mill Test Certificates (MTC), third-party inspection reports, and compliance certificates as required.

Q3. Can fasteners be customized? Absolutely. We specialize in custom fastener production based on your drawing, specifications, and application.

Q4. What industries do you serve?We serve industries such as oil & gas, petrochemical, marine, construction, automotive, aerospace, and power generation.

Q5. Do you export globally?Yes, Ananka Group exports fasteners globally, with a strong presence in the USA, UK, Germany, UAE, Singapore, and more.

#Fasteners#IndustrialFasteners#BoltManufacturer#StudBolts#CustomFasteners#WasherManufacturer#QualityMatters#TrustedSupplier#ExportQuality#ManufacturingExcellence#EngineeringSolutions#IndustrialSupply#Ananka#AnankaFasteners#manufacturer#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Exotic Fasteners Manufacturer & Supplier in the USA – Ananka Group LLC

Introduction

In today's demanding industrial environments, standard fasteners often fail to meet expectations. This is where exotic fasteners come into play. Known for their superior strength, resistance to extreme temperatures, and exceptional corrosion resistance, exotic fasteners are essential in sectors such as aerospace, petrochemicals, marine, and nuclear energy.

Ananka Group LLC is a trusted manufacturer and supplier of exotic fasteners in the USA, providing premium-quality fasteners designed to perform under the harshest conditions. With extensive stock and international supply strength, we support customers across major U.S. We offer many more Grades, just share your requirements.

What Are Exotic Fasteners?

Exotic fasteners are made from special alloys and metals not typically used in standard fasteners. These materials offer unique mechanical and chemical properties suited for high-performance and corrosive environments.

Key Characteristics of Exotic Fasteners:

High corrosion resistance

Strength at extreme temperatures

Excellent fatigue resistance

Non-magnetic or low magnetic permeability (in some alloys)

Longevity in aggressive media (saltwater, acids, chemicals)

Types of Exotic Fasteners We Supply

Ananka Group LLC specializes in the manufacturing and stocking of a comprehensive range of exotic fasteners, including:

Inconel Fasteners

Grades: Inconel 600, 625, 718

Applications: Jet engines, gas turbines, subsea equipment

Monel Fasteners

Grades: Monel 400, K500

Applications: Marine engineering, chemical processing, pumps, and valves

Hastelloy Fasteners

Grades: Hastelloy C22, C276

Applications: Chemical reactors, flue gas scrubbers, waste treatment

Titanium Fasteners

Grades: Titanium Grade 2, Grade 5

Applications: Aerospace, medical implants, offshore structures

Duplex & Super Duplex Fasteners

Grades Offered: UNS S31803 (Duplex 2205) and UNS S32750 (Super Duplex)

Typical Uses: Designed for harsh environments in desalination facilities, offshore oil & gas platforms, and industrial paper production

SMO 254 Fasteners

Highly resistant to pitting and crevice corrosion

Applications: Chloride-rich environments, marine processing units

Common Types of Fasteners Offered

Hex Bolts, Socket Head Cap Screws

Nuts (Heavy Hex Nuts, Nylock Nuts)

Washers (Flat Washers, Spring Washers)

Stud Bolts, Threaded Rods

Machine Screws, Self-Tapping Screws

Anchor Fasteners, U-Bolts, J-Bolts

All fasteners can be customized with metric and imperial sizes and supplied with various coatings and finishes.

Industries We Serve in the USA

We cater to the demanding needs of major industries with our specialized exotic fasteners, including:

Aerospace & Defense

Oil & Gas

Chemical Processing

Marine & Shipbuilding

Pharmaceutical

Nuclear Power

Water Treatment

Mining and Metallurgy

Why Choose Ananka Group LLC?

Certified Quality

All our exotic fasteners conform to international standards like ASTM, ASME, DIN, and ISO. We maintain full traceability and offer Mill Test Certificates (MTC) with every shipment.

Custom Manufacturing

We manufacture fasteners as per client specifications, including size, grade, thread type, and coating.

Fast Delivery Across the USA

Whether you are in Texas, California, New York, Florida, Auburn, or any other U.S. state, we ensure timely delivery through efficient logistics.

Competitive Pricing

Thanks to bulk production and global sourcing, we offer competitive pricing without compromising quality.

Packaging & Documentation

Secure packaging (wooden crates, bubble wraps, HDPE bags)

Product tagging and marking

Complete paperwork (Test Certificates, Country of Origin, Compliance Sheets)

Contact Ananka Group LLC

If you are looking for high-quality exotic fasteners in the USA, connect with Ananka Group LLC today!

Conclusion

Exotic fasteners are crucial for industries that demand strength, durability, and resistance beyond the ordinary. Ananka Group LLC offers an extensive range of top-quality exotic alloy fasteners, expertly manufactured and shipped across the United States. Backed by years of experience and adherence to international quality standards, we ensure that your fastening needs are met with precision and reliability. We offer many more grades, just share your requirement

FAQs

Q1. What are exotic fasteners used for?Exotic fasteners are used in environments with extreme temperatures, pressures, or corrosive substances - commonly found in aerospace, chemical processing, and offshore drilling.

Q2. Do you provide certification with your fasteners?Absolutely. We provide all necessary certifications, including ASTM/ASME specs, MTCs, and compliance documents.

Q3. Which exotic alloy offers the best performance in marine environments?Monel and SMO 254 are excellent for marine applications due to their superior resistance to saltwater corrosion.

#ExoticFasteners#FastenersUSA#IndustrialFasteners#CorrosionResistantFasteners#AlloyFasteners#CustomFasteners#AnankaGroup#GlobalSupplier#FastenerManufacturer#USAIndustries#OilAndGasIndustry#MarineEngineering#AerospaceComponents#anankafasteners#ananka#manufacturer#fasteners#supplier#tumblr blog#tumblr

0 notes