#MarineEngineering

Explore tagged Tumblr posts

Text

In 2025, India’s maritime industry is booming, with a growing number of global and domestic players entering the ship management space. If you’re searching for Top 10 ship management companies in India, this guide delivers the most trusted names renowned for technical, crew, and commercial management. These companies combine international excellence with local expertise, making them the top choice for owners and charterers alike.

#ShipManagement#MaritimeIndustry#ShippingCompany#IndianShipping#ShipManagementIndia#MarineServices#ShipOperations#VesselManagement#MarineEngineering

2 notes

·

View notes

Text

youtube

#merchant navy#MerchantNavyAdmission#TopMaritimeColleges#MaritimeEducationIndia#StudyMaritimeAbroad#MerchantNavyCareer#NovikontasMaritimeCollege#STCWTraining#IMOApprovedCourses#EMSA#MaritimePlacement#PaidMaritimeInternship#EuropeanCoC#ShipNavigation#MarineEngineering#Plus2CareerOptions#GlobalMaritimeJobs#CareerAfter12th#StudyAbroad#HighPayingJobs#AdventureCareer#SeafarerLife#BiosEducation#NavyJobs#Shiplife#MarineCourses#MerchantNavyIndia#MaritimeCareer#IMUCET#IMUCET2025

2 notes

·

View notes

Text

Understanding the Genius Behind Underwater Construction😮😆

#desiviralrecap#UnderwaterConstruction#EngineeringMarvels#ConstructionInnovation#MarineEngineering#BuildingUnderwater#EngineeringGenius#DeepSeaConstruction#OceanEngineering#InnovativeDesign#FutureOfConstruction#CivilEngineering#EngineeringLife#ConstructionTrends#TechInConstruction#SmartInfrastructure#MarineTechnology#UnderwaterWorld#EngineeringExcellence

1 note

·

View note

Text

Welcome, DPSW LLC!

The leading engineering powerhouse catering to Construction, Process, Oilfield, and Marine industries. Specializing in Air Pollution solutions, they are locally manufacture top-notch equipment like Fans, and offer Heavy Fabrication services for Storage Tanks, Towers, Cyclones, and Piling equipment.

DPSW LLC dedicated Air Pollution division provides consultancy, designs, and fabricates Industrial Fans, Ducts, Painting Booths, Dust Collectors, and more. With turnkey projects in Industrial Exhaust, Fume Extraction, and Ventilation, DPSW LLC ensures top-tier quality with in-house Balancing facilities.

Explore DPSW LLC's catalog now - https://www.tradersfind.com/seller/dpsw-llc

#engineeringservices#airqualitycontrol#pollutioncontrolequipment#industrialfabrication#environmentalsolutions#industrialengineering#localmanufacturing#turnkeysolutions#engineeringconsultancy#industrialdesign#airqualitymanagement#industrialfans#fabricationservices#heavyequipment#pilingequipment#airpollutionsolution#industrialexhaust#fumeextractionsystem#ventilationsystem#industrialducting#pollutioncontroltechnology#balancingservices#marineengineering#oilfieldservices#constructionindustry#processindustries#DPSWLLC

3 notes

·

View notes

Text

Structural Composites Market: Transforming Aerospace, Automotive & Energy Sectors

The structural composites market has witnessed significant growth in recent years, driven by advancements in material science and increasing demand across multiple industries, including aerospace, automotive, construction, and wind energy. Structural composites, often referred to as composite materials, are made by combining two or more materials that are superior in performance than individual components. These materials are lightweight, durable, corrosion-resistant, and provide enhanced mechanical strength, making them ideal for a wide range of applications.

Get a Free Sample Report - https://www.skyquestt.com/sample-request/structural-composites-market

The global structural composites market is expected to continue its growth trajectory, driven by technological innovations, increased awareness of environmental sustainability, and the rising demand for lightweight, high-performance materials. By 2032, the market is poised to expand significantly, with substantial contributions from key sectors, including aerospace and defense, automotive, and wind energy.

Market Size and Forecast

The global structural composites market was valued at USD 50.43 billion in 2024 and is projected to reach USD 94.81 billion by 2032, growing at a compound annual growth rate (CAGR) of 7.54% during the forecast period from 2025 to 2032.

Several factors contribute to the market's growth, including the increasing demand for lightweight materials, the rising need for energy-efficient solutions, and advancements in composite manufacturing technologies. Composites are particularly attractive for industries where strength-to-weight ratios are critical, such as in aerospace and automotive applications.

Key Market Segments

1. By Resin Type:

- Epoxy Resin: Epoxy resins are the most widely used in structural composites due to their superior mechanical properties, resistance to moisture, and excellent bonding capabilities.

- Polyester Resin: Used predominantly in automotive and construction applications, polyester resins are a more cost-effective option.

- Vinyl Ester Resin: Offering a balance between performance and cost, vinyl ester resins are used in applications like marine and automotive industries.

2. By Fiber Type:

- Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber composites are extensively used in aerospace, automotive, and sports equipment.

- Glass Fiber: Glass fibers are the most commonly used fibers in structural composites. They are cost-effective and widely used in construction, marine, and transportation sectors.

- Aramid Fiber: Aramid fiber composites offer high impact resistance and are used in applications that require ballistic protection, such as in defense and automotive sectors.

3. By Application:

- Aerospace & Defense: The aerospace industry remains a dominant sector for structural composites due to the material’s lightweight and high-strength properties. Aircraft manufacturers are increasingly adopting composites to reduce fuel consumption and improve efficiency.

- Automotive: Lightweight composite materials are essential for the automotive sector to improve fuel efficiency and reduce carbon emissions. With growing demands for electric vehicles (EVs), the automotive industry is turning to composites for body parts, interiors, and under-the-hood components.

- Wind Energy: Wind turbine blades are commonly made from composite materials, as they provide the necessary durability and strength while reducing the overall weight of the turbines.

- Construction: Structural composites are finding increasing applications in the construction sector, particularly in bridges, beams, and support structures, where strength and corrosion resistance are paramount.

- Marine: Composites are used in boat and ship construction due to their resistance to corrosion, weight reduction, and durability.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/structural-composites-market

Regional Market Analysis

1. North America: North America is one of the largest markets for structural composites, driven by the aerospace and automotive industries in the U.S. and Canada. The region is home to major aerospace manufacturers such as Boeing and Lockheed Martin, which are heavily investing in composite materials for aircraft manufacturing. Additionally, the push for fuel-efficient vehicles in the automotive sector continues to bolster the demand for lightweight materials.

2. Europe: Europe is another key market for structural composites, with strong demand coming from the automotive and wind energy sectors. The region's commitment to reducing carbon emissions and improving energy efficiency is a key driver of market growth. Leading countries like Germany, France, and the U.K. have seen significant investment in renewable energy infrastructure, including wind farms that rely on composite materials for turbine blades.

3. Asia-Pacific: The Asia-Pacific region is expected to experience the fastest growth in the structural composites market. The expanding automotive and construction industries in countries like China, Japan, and India are major factors contributing to the region's rapid market expansion. Moreover, the increasing investments in renewable energy and the aerospace sector in countries like China are fueling demand for structural composites.

4. Latin America and Middle East & Africa: The Latin American market for structural composites is gradually growing due to the construction and automotive sectors' increasing adoption of lightweight materials. Similarly, the Middle East and Africa region is showing promising growth, particularly in the aerospace and defense sectors, where composites are used for aircraft components.

Key Market Drivers

1. Increasing Demand for Lightweight Materials: One of the primary drivers of the structural composites market is the increasing demand for lightweight materials. Industries such as aerospace, automotive, and wind energy are seeking to reduce the weight of their products to improve fuel efficiency, reduce carbon emissions, and increase overall performance.

2. Advancements in Composite Manufacturing: Technological advancements in composite manufacturing techniques, such as automated fiber placement (AFP) and resin transfer molding (RTM), are making it easier and more cost-effective to produce high-quality composites. These advancements have made composites more accessible to a wide range of industries.

3. Environmental Sustainability: The growing emphasis on sustainability and environmental responsibility is driving the adoption of composite materials. Composites can help reduce fuel consumption and energy use in transportation, which aligns with global sustainability goals. Additionally, the longer lifespan and recyclability of certain composite materials make them attractive for companies seeking to minimize their environmental impact.

4. Growth in Aerospace and Automotive Sectors: The aerospace and automotive industries continue to be significant consumers of structural composites, with major companies like Boeing, Airbus, and Tesla adopting advanced composites in their products. The shift toward electric vehicles (EVs) is expected to further boost the demand for lightweight composite materials.

Take Action Now: Secure Your Structural Composites Market Today - https://www.skyquestt.com/buy-now/structural-composites-market

Challenges

Despite the significant growth prospects, the structural composites market faces several challenges, including:

- High Production Costs: The cost of producing composite materials, especially carbon fiber, remains high, which can limit their widespread adoption in cost-sensitive industries.

- Complex Manufacturing Processes: The manufacturing of structural composites requires specialized equipment and expertise, which can make it difficult for small and medium-sized enterprises to enter the market.

- Recycling Issues: While certain composites are recyclable, the recycling of composite materials remains a challenge, particularly for thermoset composites.

Top Players in Structural Composites Market

Owens Corning (USA)

Toray Industries, Inc. (Japan)

Teijin Limited (Japan)

Mitsubishi Chemical Holdings Corporation (Japan)

Hexcel Corporation (USA)

SGL Carbon (Germany)

Huntsman International LLC. (USA)

Solvay (Belgium)

Gurit Holding AG (Switzerland)

BASF SE (Germany)

3M (USA)

Hexion Inc. (USA)

Johns Manville (USA)

Saint-Gobain (France)

Kordsa (Turkey)

Lanxess AG (Germany)

China Jushi Co., Ltd. (China)

Avient Corporation (USA)

Borealis AG (Austria)

Celanese Corporation (USA)

Read Structural Composites Market Report Today - https://www.skyquestt.com/report/structural-composites-market

The global structural composites market is poised for significant growth through 2032, driven by increasing demand for lightweight, high-performance materials across industries such as aerospace, automotive, and wind energy. The continued advancement in manufacturing technologies and a growing focus on sustainability will play key roles in shaping the market's future. However, challenges related to production costs, manufacturing complexity, and recycling must be addressed to unlock the full potential of structural composites in the coming years. With ongoing research and development, the market is expected to witness the emergence of innovative solutions that will further expand the scope of composites in various industries.

#StructuralComposites#CompositeMaterials#MaterialsScience#AdvancedMaterials#CompositesMarket#SmartMaterials#GlobalMarketTrends#EngineeringMaterials#HighPerformanceMaterials#LightweightMaterials#AerospaceEngineering#AutomotiveInnovation#WindEnergy#SustainableConstruction#GreenEnergy#MarineEngineering#ElectricVehicles#EVMaterials#DefenseTechnology#InfrastructureInnovation

0 notes

Text

#BathymetricSurvey#GoaPorts#MarineSurvey#CoastalMapping#UnderwaterTopography#HydrographicSurvey#MarineConservation#SustainableDevelopment#ClimateAdaptation#EcoFriendlyInitiative#PortDevelopment#MaritimeSafety#NavigationSafety#MarineEngineering#CoastalEngineering

0 notes

Text

Built for durability and system efficiency, the Bypass Arrangement Swing Check Valve by Prime Valves offers smart pressure equalization and prevents reverse flow with minimal maintenance. Ideal for marine systems, power plants, chemical and water treatment applications. Small design, big protection. https://www.primevalvesindia.com/products/swing-check-valve

#primevalveindia#SwingCheckValve#BackflowPrevention#IndustrialValveSolutions#PrimeValves#MarineEngineering#ChemicalProcessSafety#SmartFlowControl

0 notes

Text

Duplex and Super Duplex Subsea Bolts: High-Performance Fasteners for Extreme Environments

Equipment used in these environments must withstand intense pressure, corrosive saltwater exposure, and extreme temperature variations. In such extreme situations, Duplex and Super Duplex Subsea Bolts play a critical role in ensuring structural integrity and long-term performance of underwater infrastructure.

In this blog, we will explore what makes these fasteners ideal for subsea applications, their unique material properties, key applications, and how they contribute to the safety and longevity of marine structures.

What Are Duplex and Super Duplex Subsea Bolts?

Duplex stainless steel bolts are crafted from a class of stainless steels that feature a dual-phase microstructure, composed of both austenite and ferrite. This combination results in higher strength and excellent corrosion resistance compared to standard stainless steel.

Super Duplex stainless steel bolts take these advantages further by offering even higher levels of strength and corrosion resistance. These bolts are specifically engineered for environments with extreme chemical exposure, such as deep-sea installations, oil rigs, and underwater pipelines.

Chemical Composition

Typical Duplex (e.g., UNS S31803 / 2205):

Chromium: 21–23%

Nickel: 4.5–6.5%

Molybdenum: 2.5–3.5%

Nitrogen: 0.14–0.2%

Balance: Iron

Typical Super Duplex (e.g., UNS S32750 / 2507):

Chromium: 24–26%

Nickel: 6–8%

Molybdenum: 3–5%

Nitrogen: 0.24–0.32%

Balance: Iron

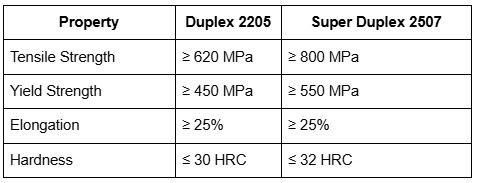

Mechanical Properties

These properties ensure the bolts can withstand high-stress environments, particularly in subsea applications where pressure and corrosion are constant threats.

Corrosion Resistance

Subsea bolts must resist:

Pitting and crevice corrosion caused by stagnant seawater

General corrosion due to long-term exposure to seawater and harsh chemicals

With elevated levels of molybdenum and nitrogen, Super Duplex bolts provide exceptional corrosion resistance, making them perfectly suited for highly aggressive subsea environments.

Uses of Duplex and Super Duplex Subsea Bolts

Subsea Oil and Gas InstallationsRiser systems, manifolds, BOPs (Blowout Preventers), and wellhead systems Underwater PipelinesFor flanged joints, pipe supports, and brackets in offshore pipelines Offshore Wind TurbinesBolt connections exposed to splash and tidal zones Underwater InfrastructureBridges, tunnels, and seabed constructions requiring corrosion-resistant fasteners

Benefits of Using Duplex and Super Duplex Subsea Bolts

Enhanced Mechanical Strength: Provides significantly higher yield and tensile strength than conventional stainless steel fasteners

Outstanding Corrosion Resistance: Perfect for chloride-heavy environments such as seawater

Excellent Fatigue Resistance: Designed to endure high pressures and repeated stress cycles

Cost Efficiency: Extended service life minimizes maintenance and replacement costs

Wide Temperature Range: Maintains reliable performance under varying temperature extremes

Standards and Specifications

ASTM A182 / A479 – For forged or rolled duplex/super duplex materials

ASTM A276 – For stainless steel bars used in bolts

NORSOK M-630 – For materials used in oil & gas subsea systems

Why Choose Duplex or Super Duplex for Subsea Fasteners?

When choosing fasteners for subsea installations, material performance over time is crucial. Duplex and Super Duplex bolts offer a superior blend of strength and corrosion resistance, outperforming most traditional alloy fasteners in demanding environments. While initial costs may be higher than regular carbon steel fasteners, their long-term benefits less maintenance, fewer replacements, and improved safety, far outweigh the investment.

Conclusion

In subsea engineering, the reliability of every component counts. Duplex and Super Duplex Subsea Bolts are high-strength, with superior corrosion resistance and long life, making them the first choice for offshore oil rigs, pipelines, naval systems, and underwater structures.

For any organization working in subsea environments, investing in the right fasteners is not just a technical decision; it's a strategic one. Choose duplex and super duplex bolts for safer, stronger, and longer-lasting underwater infrastructure.

FAQs

Q1. Difference between Duplex and Super Duplex bolts?

Duplex bolts deliver excellent strength and corrosion resistance, whereas Super Duplex bolts enhance these properties further with superior mechanical strength and exceptional durability in extremely corrosive environments.

Q2. Can Super Duplex bolts be used in sour gas environments?

Yes. Super Duplex bolts like UNS S32750 meet NACE MR0175 standards and are suitable for sour service environments.

Q3. Can I use duplex bolts in submerged saltwater applications?

Yes. Duplex bolts are well-suited for continuous exposure to saltwater but Super Duplex is recommended for the most aggressive conditions.

Q4. Do duplex and super duplex bolts require special coatings?

Often, they don’t need additional coatings due to their inherent corrosion resistance, but some applications may use passivation or other surface treatments for added protection.

#DuplexBolts#SuperDuplexBolts#SubseaFasteners#MarineBolts#CorrosionResistantBolts#OffshoreBolts#DuplexStainlessSteel#SuperDuplexStainlessSteel#OilAndGasFasteners#HighStrengthBolts#AnankaFasteners#FastenersManufacturer#IndustrialFasteners#MarineEngineering#DuplexFasteners#SuperDuplexFasteners#Ananka#tumblr blog#tumblr

1 note

·

View note

Text

Cambridge University Riviera Racing: Prototyping, Testing, Goals

✍ Article: https://3dwithus.com/cambridge-university-riviera-racing-prototyping-testing-goals

🎥 Short: https://www.youtube.com/shorts/ktiiCHKNjlA?feature=share

0 notes

Text

#bioseducation#marineengineering#merchantnavyindia#easa#maritime#education#merchant navy#mbbs abroad#shipnavigation#merchantnavycareer

0 notes

Text

Crane is being used to lift the Ship😲😆

#desiviralrecap#ShipLifting#HeavyMachinery#EngineeringMarvel#CraneOperation#IndustrialWork#ConstructionLife#WorkInProgress#EngineeringInAction#MaritimeIndustry#OceanEngineering#ViralVideo#AmazingScenes#DailyInspiration#TechInMotion#EpicMoments#EngineeringGoals#BehindTheScenes#InnovationInAction#PowerOfMachines#MarineEngineering#PortOperations

1 note

·

View note

Link

#biomimeticdesign#cutting-edgeyachttechnology#futureofluxuryyachts#high-endyachtaccommodations#luxurycruiseyachts#luxuryyachtamenities#luxuryyachtdesign#luxuryyachtsustainability#marineengineering#ModernYachtDesign#REIyacht#REIyachtfeatures#superluxuryyacht#superyachtfeatures#sustainableluxuryyacht#sustainablepropulsionsystems#Vikengroupyacht#yachtdesigninspiration#yachtexploration#yachtinnovation

0 notes

Text

How to Become a Marine Engineer: The Complete Guide for Aspiring Experts

If you're passionate about working at sea, maintaining the heart of a ship, and building a rewarding career in one of the most dynamic engineering fields, then marine engineering could be your perfect path. This comprehensive guide will walk you through every step of becoming a successful marine engineer—from education and certifications to choosing the right training institute like the School of Marine Education (SME).

What Does a Marine Engineer Do?

A Marine Engineer is responsible for the design, maintenance, and operation of a ship’s engines, machinery, and onboard systems. These professionals ensure vessels run smoothly, safely, and efficiently on global waters. They play a critical role in the marine industry and are in constant demand across commercial fleets, naval forces, and offshore projects.

Step-by-Step Guide to Becoming a Marine Engineer

1. Meet the Educational Requirements

To begin your journey, a strong foundation in science and mathematics is essential. Here’s what you need:

A Bachelor’s degree in Marine Engineering, Mechanical Engineering, or an equivalent discipline.

Completion of specialized maritime training courses.

Certification from recognized maritime authorities.

2. Enroll in a Reputable Maritime Training Institute

Choosing the right institute is crucial. The School of Marine Education (SME) stands out as a leading choice. In collaboration with South Shields Marine School (UK), SME provides globally accredited courses and career-building opportunities designed to meet the latest industry standards.

3. Obtain Required Certifications & Licenses

Certifications are essential for marine engineers to work onboard. SME prepares you for all major certifications, including:

Officer of the Watch (OOW) – Entry-level certification for engine room duties.

Engine Officer of the Watch – Allows operation of ship engines.

Second Engineer – Mid-level certification assisting with engine operations.

Chief Engineer – The highest certification, overseeing all ship machinery.

With SME’s structured training and mentorship, obtaining these certifications becomes a streamlined process.

4. Gain Hands-On Experience

Marine engineering is a practical profession. SME integrates hands-on learning through ship visits, simulation training, and onboard operations. Their short-term technical courses and internships equip students with real-world experience in:

Ship engine room management

Onboard technical systems

Safety procedures and maintenance protocols

5. Explore Career Growth Opportunities

Once employed, there are vast opportunities for advancement in the marine industry. You can progress from:

Officer of the Watch → Second Engineer → Chief Engineer, and eventually to senior roles like Chief Mate or Master Mariner.

SME provides career mentoring, helping you plan and achieve each stage of your professional growth.

Why Choose the School of Marine Education (SME)?

1. Wide Range of Courses

SME offers a full suite of marine engineering certifications and training options, including:

Engine Officer of the Watch

Second Engineer

Chief Engineer

Officer of the Watch

Chief Mate

Master Mariner

2. Global Recognition and UK Training Opportunities

SME’s collaboration with South Shields Marine School allows students to train in the UK and benefit from world-class facilities, enhancing their global career prospects.

3. Personalized Career Support

More than just training, SME offers:

Custom career plans

One-on-one guidance

Certification and document support

Interview preparation and industry counseling

4. End-to-End Student Assistance

Studying abroad can be overwhelming, but SME supports you throughout the process:

Notice of Eligibility (NOE) application assistance

UK Visa and immigration guidance

Loan and financial counseling

Help with UK accommodation arrangements

5. Skill-Enhancing Short Courses

To stay current with industry advancements, SME also provides short, upskilling courses tailored for working professionals looking to boost their knowledge and certifications.

Why Marine Engineering is a Promising Career Choice

High Demand & Job Security: With global trade depending on maritime transport, marine engineers are always in demand.

Excellent Salary & Perks: Attractive salary packages with travel benefits.

Global Travel: A career that takes you across international waters and cultures.

Rapid Career Progression: Clear, structured paths for promotion and leadership.

Take the First Step Towards a Rewarding Career

Becoming a marine engineer involves dedication, the right education, practical training, and strategic career planning. The School of Marine Education (SME), in partnership with South Shields Marine School, equips you with everything you need to thrive in this industry.

Start your marine engineering journey with SME today and set sail towards an exciting global career.For more information, visit SME’s official website or contact their admissions team

0 notes

Text

"Subsea Thermal Insulation Materials: Essential Solutions for Deepwater Oil and Gas Operations"

Subsea thermal insulation materials are critical for maintaining the integrity and efficiency of offshore oil and gas pipelines. These materials help reduce heat loss from the fluid within pipelines, ensuring that the transported substances—such as oil or gas—maintain their optimal temperature throughout long subsea distances. In the harsh conditions of the deep sea, proper insulation is essential for preventing hydrate formation and ensuring the safety of the operation.

The most common subsea thermal insulation materials include polyurethane foam, glass wool, and microporous insulation. Each material has unique properties, such as flexibility, thermal stability, and durability, to withstand extreme temperatures and pressure levels found at great ocean depths. These materials not only protect the pipeline but also extend its lifespan, reducing the risk of corrosion and mechanical damage.

With the growth of deepwater exploration and subsea production, the demand for advanced thermal insulation is increasing. As the industry shifts toward more sustainable practices, there is a growing focus on environmentally friendly insulation materials that provide both high performance and minimal ecological impact. Innovations in this field are enhancing the energy efficiency of subsea operations, aligning with global goals to reduce carbon emissions and increase sustainability in offshore energy production.

#SubseaThermalInsulation#OffshoreEnergy#DeepwaterOperations#PipelineTechnology#EnergyEfficiency#SustainableInsulation#SubseaTechnology#OffshoreOilGas#MarineEngineering#EcoFriendlyMaterials

0 notes

Text

⚓ What is Marine Engineering? Explore the field that focuses on the design, construction, operation, and maintenance of ships, submarines, and offshore structures.

#MarineEngineering#NavalArchitecture#OceanEngineering#ShipDesign#OffshoreEngineering#MarineTechnology#EngineeringWorld#STEMCareers#EngineeringLife#FutureOfEngineering#InnovationInEngineering#EngineersHeaven

1 note

·

View note

Text

Top Marine Services & Shipbuilding Companies in UAE You Should Know

The UAE has become a regional hub for world-class marine services and shipbuilding companies. With advanced ports, world-class infrastructure, and a strong maritime tradition, the demand for high-quality ship manufacturing companies in UAE continues to rise.

One of the top shipbuilding companies in the region is VU Marine, known for delivering reliable and cost-effective marine solutions. From ship design and engineering to vessel maintenance and support, they cover the full spectrum of marine services in UAE.

Whether you’re a shipping company, yacht owner, or looking for reliable ship maintenance, it's important to choose a partner that delivers quality and professionalism.

If you're searching for marine services in UAE, make sure to visit: 👉 VU Marine

0 notes