#DFMA

Explore tagged Tumblr posts

Text

MMC Consultancy London: Driving Modern Construction with Innovation and Expertise:-

As construction evolves, partnering with a trusted MMC consultancy London is essential for delivering efficient, sustainable, and future-ready buildings. Modern Methods of Construction (MMC) involve off-site fabrication, modular design, and advanced technologies that reduce costs, speed up delivery, and improve quality. An experienced MMC consultancy in London helps developers, architects, and contractors adopt these approaches effectively—ensuring compliance with local regulations, smart integration of DfMA principles, and optimised project outcomes. Whether for residential, commercial, or public-sector developments, MMC experts bring innovation and precision to every stage of the build, reshaping how London builds for the future.

0 notes

Text

youtube

Design for Manufacturing and Assembly (DFMA) is revolutionizing product design by simplifying manufacturing and assembly processes to save costs, improve quality, and reduce time-to-market. In this video, we break down the core principles of DFMA—Design for Manufacturing (DFM) and Design for Assembly (DFA)—and explore how they can transform product development.

We also dive into a real-world case study of a leading power tool manufacturer that implemented DFMA principles to cut manufacturing costs by 20%, improve product quality, and speed up production. Learn how reducing parts, simplifying assembly, and standardizing components can drive innovation and efficiency.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fAf4z4

#DFMA#CostOptimization#QualityImprovement#Manufacturing#SmartDesign#DesignEngineering#EfficiencyInManufacturing#SkillLync#Youtube

0 notes

Text

Optimización de Procesos: La Metodología DFMA para Manufactura y Ensamble

La metodología DFMA (Diseño para la Manufactura y Ensamble) integra el Diseño para la Manufactura (DFM) y el Diseño para el Ensamble (DFA) para optimizar la producción. Cada una de estas metodologias DFM y DFA, tienen un objetivo específico que contribuye a la eficiencia en el desarrollo de productos. Diseño para la Manufactura (DFM) El DFM se centra en optimizar el diseño de un producto para…

0 notes

Text

Boost Your Building Efficiency with Modular and Prefabricated Construction

In today's fast-paced world, efficiency is key to success. Whether you're a builder, architect, or property owner, you're likely always looking for ways to streamline your processes and reduce costs. One innovative approach that can help you achieve these goals is modular and prefabricated construction. In this blog, we'll explore the benefits of this method and how it can revolutionize your building projects.

What is Modular and Prefabricated Construction?

Modular and prefabricated construction involves building structures in a factory, rather than on-site. This approach consists of assembling the building components in a controlled environment, which can significantly reduce construction time and costs. The finished modules are then transported to the site and assembled, often in days or weeks.

Benefits of Modular and Prefabricated Construction

Faster Construction Time: Modular and prefabricated construction can reduce construction time by up to 50%. This is because the building components are manufactured in a factory, eliminating the need for on-site assembly and reducing the risk of delays due to weather or labor shortages.

Cost Savings: Prefabricated construction can save money by reducing labor costs, minimizing waste, and improving quality control. The factory environment also allows for more precise construction, which can reduce the need for costly rework.

Improved Quality Control: Modular and prefabricated construction takes place in a controlled factory environment, which ensures that every component meets strict quality standards. This reduces the risk of defects and ensures that your building is built to last.

Related blog: Ramp Up Your Construction With The Modular/Prefab Or DFMA

Increased Sustainability: Prefabricated construction can be more sustainable than traditional on-site construction. The factory environment allows for more efficient use of materials, and the reduced need for on-site labor and equipment can minimize waste and environmental impact.

Enhanced Safety: Modular and prefabricated construction takes place in a controlled environment, which reduces the risk of accidents and injuries. The factory environment also allows for more precise construction, which can reduce the risk of defects and ensure that your building is safe and secure.

Flexibility and Customization: Prefabricated construction can be customized to meet your specific needs. The modules can be designed and built to fit your unique requirements, ensuring that your building is tailored to your particular needs.

Reduced Disruption: Modular and prefabricated construction can minimize disruption to your daily operations. The modules are built in a factory, so there is no need for on-site construction, reducing the risk of disruption and ensuring that your business can continue to operate as usual.

Improved Energy Efficiency: Prefabricated construction can be designed to be more energy-efficient. The modules can be built with energy-efficient materials and systems, reducing energy consumption and costs.

Increased Property Value: Modular and prefabricated construction can increase the value of your property. The high-quality, precision-built modules can enhance the aesthetic appeal of your building, making it more attractive to potential buyers or renters.

Government Incentives: Many governments offer incentives for using prefabricated construction methods. These incentives can include tax breaks, grants, and other financial benefits that can help offset the costs of using this approach.

Conclusion

Modular and prefabricated construction is a game-changer for builders, architects, and property owners. By reducing construction time, costs, and environmental impact, this approach can help you achieve your goals more efficiently. With its numerous benefits, including faster construction time, cost savings, improved quality control, and increased sustainability, prefabricated construction is an innovative solution that can revolutionize your building projects.

0 notes

Text

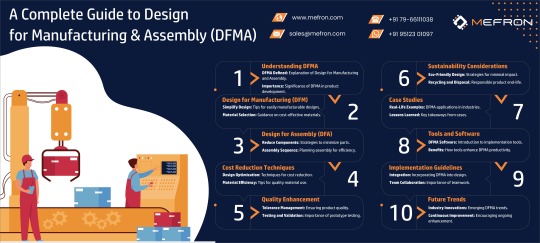

Unlock the secrets of Design for Manufacturing and Assembly (DFMA) with our comprehensive guide. Streamline product design and manufacturing for efficiency.

#design for manufacturing and assembly#design for manufacturing#design for assembly#DFMA#electronic manufacturing#EMS Industry

0 notes

Text

The Future of Construction with Modular/Prefab and DFMA

In our latest blog post, we delve into the dynamic realm of construction, exploring the transformative potential of Modular/Prefab construction and Design for Manufacture and Assembly (DFMA). Witness a paradigm shift in the construction landscape as we unravel the advantages of these cutting-edge methodologies. From accelerated project timelines and heightened sustainability to precision engineering and cost-efficiency, discover how modular solutions and DFMA can redefine the way you build. Ready to usher in a new era of construction excellence? Immerse yourself in the future of building practices by reading our blog. 🌐🏡🔨

0 notes

Text

Facade Platform Design to Reduce Carbon

Platform Design, better known in the construction industry as ‘A Platform approach to Design for Manufacture and Assembly’ or ‘P-DfMA’. It is a specific subset of DfMA, which is the general term for using prefabrication and automation applied project by project basis. P-DfMA is a solution that is designed to be used more programmatically across a range of projects or assets. So, what is ‘P-DfMA’ and how does it help to reduce construction costs and reduce carbon? In this short article, we aim to explain the basis of this innovative approach to construction and suggest how it could revolutionise our future construction requirements.

Initiated by the UK Government in 2017 in their drive to cut costs for new buildings, such as schools, hospitals, offices and social housing, the construction approach takes its lead from the automotive and aerospace sectors. Defining the construction product requirements, such as internal spaces, storey height, access requirements, to name but a very few of these parameters, the aim is to standardise these requirements and begin to create a ‘list of standard parts’ that creates those spaces. Doors are a very good example of this approach, available in a range of materials, sizes and hardware options, once adopted as a standard product across many projects, costs can be significantly reduced. Including offsite construction to this, whether delivering the product to the site as a kit or in a pre-constructed form, not only lowers costs but also minimises on-site labour, expedites construction on site, and reduces site defects. The same approach can be used in facades and fenestration products.

To be fair, aluminium fenestration has seen much of its construction being undertaken off-site for many years, but much more can be done. Window construction can easily follow what has been done with door sets by adopting standard sizes and hardware options. Windows can be supplied to the site already glazed and installed within panel construction. Curtain wall requirements adopt an off-site unitised construction approach which we know already reduces time on site by approximately 50% whilst further improving quality.

A review of five recent projects supplied by Aluprof UK shows the supply of special lengths alone has reduced material supply by an average of 27.5%. Not only does this save on costs but has a significant impact on carbon reduction. But this can go even further. Using a standard product size, profiles can be designed that work nearer to their safety limits over a given size or length which can further optimise aluminium content. Adopting a specification of a low-carbon content, usually high in recycled aluminium with low-carbon prime aluminium, further reduces carbon content of these assemblies.

It is not just about cost and carbon saving, it is about getting better buildings. From the government’s own analysis under their current construction framework, for every £1 spent just 51% is retained in residual asset value. Reducing time to install on site, reducing wastage, reducing deliveries to site by adopting off-site construction, reducing ‘on site design’, all of which reduce overall site time and programme and all have a big impact on carbon reduction as well. Using a standard kit of parts reduces the need for bespoke designs which can go hand in hard to improve overall quality.

It is also an iterative process, what is learnt on one project leads to a fine tuning of the ‘kit of parts’ which in turn leads to even better future construction and a continuation in the reduction of carbon. As a result, the P-DfMA approach increases productivity, while reducing carbon, construction time and cost.

In a world first, a major project completed under the P-DfMA is The Forge, located just south of the Thames in the city of London. The building is also the first to adopt the UK’s Green Building Council’s definition of a net-zero carbon building in both construction and operation.

With regard to the development of the facade, Aluprof were invited to take an early design role in developing a unitised facade system that meets the P-DfMA specification pioneered by architects and engineers Bryden Wood. Construction was led by Sir Robert McAlpine and Mace, working together in an innovative joint venture partnership.

Jaimie Johnston of Bryden Wood comments, “The collaboration with Aluprof was fantastic. It was great to have a partner with such a depth of manufacturing experience who really understood and amplified the benefits of a platform approach. We hope that others will learn and build on the success that was achieved at The Forge and we’ll start to see platforms adopted at scale.”

Padraig Delaney, London Regional Manager for Digital Construction at Sir Robert McAlpine, in his role working with the construction team, sees The Forge as a model for how future projects should be delivered: “The innovation-led approach taken by Landsec has allowed us to push the boundaries with our use of technology. The more data we have, the better our decision making. It is also important we have the right tools to help us get the most from the data. By driving these digital solutions, as we have done at The Forge, we’re transforming the way we will deliver future projects, identifying the value to each stakeholder and ultimately providing the best value for our clients.”

Tom Cherowbrier, Aluprof’s Major Projects Manager comments: “The bespoke system from Aluprof is finished in three shades of bronze anodising which will offer a sustainable finish and an aesthetic appearance for many decades to come. The new system was designed with a standard +/-15mm stack joint for to accommodate the building movement, as well as an impressive non-standard stack joint for the 7th floor which had to accommodate a +20/-30mm movement. The project also has a range of external feature fins with concealed fixing to provide the building with sight-lines of 120mm and 170mm that project 125mm or 225mm from glazing line.”

The unitised curtain wall system, designed in close collaboration with Bryden Wood, allowed Aluprof to develop a highly-efficient facade unit. The full-size mock-up unit was rigorously tested in Aluprof’s own Research and Innovation Centre in Ogrodzona where it passed air leakage, impact, wind resistance, and water penetration tests. These units were transported in purpose designed, reusable stillages which were then lifted to the floor plates using a combination of large material hoists and tower cranes for installation by specialist installers NACWL. A key feature of the stillage design was to protect the units from any stress and impact during transportation and lift. The new bespoke system was named MB-SE120 with a Uw value of <1.3 W(m2K).

Aluprof are proud to be one of Europe's largest aluminium systems companies. Specification support is available through the company’s website at aluprof.co.uk, directly from their UK head office in Altrincham or from their London office at the Building Design Centre by phoning +44 (0) 161 941 4005.

0 notes

Text

Oh, that's actually a case of both.

(Assuming we're talking about the same Vomit Prison here). Getting your local population to vomit upon prisoners is generally frowned upon in the laws of war [citation needed] and the vomit prison requires the building of a nausea-inducing greenhouse above the prison pit.

Proably the most fucked-up thing I reguarly do in Dwarf Fortress is not war criming but building lots of stuff aboveground like it's minecraft

#dwarf fortress#fortress mode#Routpainted#unfortunately with the death of flash much of dfma is unviewable at the moment#vomit prison#vomit mention

79 notes

·

View notes

Text

Leng Aik Engineering Launches Advanced DfMA Factory For Prefab MEP Systems

Developed with the support of Building and Construction Authority (“BCA”) and A*STAR Singapore Institute of Manufacturing Technology (“A*STAR SIMTech”), the factory utilises automation, robotics and AR technologies to improve quality control, efficiency, safety and accuracy. SINGAPORE – Media OutReach Newswire – 27 March 2025 – Leng Aik Engineering Pte Ltd (“LAE”), a wholly owned subsidiary of…

0 notes

Text

Design Completely, Deliver Perfectly Podium empowers you to design efficiently, price accurately, and build sustainably. Deliver build-ready designs in minutes, not months. Design with the end in mind Your first draft is not just a concept. It’s realistically buildable from the start, seamlessly integrating DfMA principles through Podium. Cost & Time Savings with Data-Driven Precision Podium’s…

0 notes

Text

Sharad Chauhan Designer – Innovating Excellence in Design

Sharad Chauhan is a visionary designer known for crafting innovative, functional, and aesthetically superior designs. With expertise in Industrial Design, Product Design, and Design Services, he transforms creative concepts into reality, ensuring every design is a perfect blend of form, function, and cutting-edge technology. His deep understanding of Design for Manufacturing and Assembly (DFMA) allows him to develop products that are not only visually appealing but also optimized for cost-effective production and seamless assembly.

Expertise in Industrial Design

Industrial design is at the heart of Sharad Chauhan’s creative journey. His designs redefine user experience by incorporating ergonomic solutions, sustainable materials, and innovative technology. By focusing on user needs, market trends, and production feasibility, he delivers solutions that enhance efficiency and elevate industries. Whether it's consumer electronics, automotive components, or medical devices, his industrial design expertise ensures that every product stands out in the competitive market.

Innovative Product Design Solutions

As an expert in Product Design, Sharad Chauhan takes ideas from the sketchpad to the marketplace. His approach combines market research, user insights, and technological advancements to create highly functional and visually striking products. Whether designing household appliances, smart gadgets, or industrial tools, he ensures that each product aligns with user expectations while being cost-effective and scalable for mass production.

Comprehensive Design Services

From conceptualization to prototyping, Sharad Chauhan provides comprehensive design services that cater to startups, established brands, and manufacturers. His expertise spans across:

UI/UX Design – Creating seamless digital experiences through intuitive user interfaces.

Prototyping & Testing – Ensuring functionality, durability, and efficiency before mass production.

Material & Manufacturing Optimization – Selecting the right materials for durability and cost-effectiveness.

Branding & Aesthetics – Crafting visually compelling designs that enhance brand identity.

Design for Manufacturing & Assembly (DFMA)

A key strength of Sharad Chauhan is his expertise in Design for Manufacturing and Assembly (DFMA). His design philosophy ensures that products are easy to manufacture, assemble, and scale without compromising quality. By reducing material waste, simplifying production processes, and enhancing durability, his designs optimize costs while maintaining superior quality.

Product Design in Delhi – A Hub of Innovation

Based in Delhi, Sharad Chauhan’s design studio is at the forefront of innovation, serving businesses across India and beyond. The capital city’s dynamic ecosystem fuels his creativity, allowing him to collaborate with top manufacturers, tech startups, and industry leaders to develop groundbreaking designs that set new industry benchmarks.

Why Choose Sharad Chauhan?

Expertise in Industrial Design, Product Design, and DFMA

A track record of successful projects across multiple industries

A user-centric approach ensuring innovative and functional designs

Strong collaboration with manufacturers for seamless production

Commitment to sustainability and cost-effective design solutions

Let’s Create Something Extraordinary!

Whether you're looking for industrial design, product innovation, or complete design services, Sharad Chauhan is the designer you need to turn ideas into reality. Elevate your brand with world-class design solutions that blend technology, creativity, and functionality.

1 note

·

View note

Text

Estudio de las Concreciones formales en DFMA

La Metodología de Diseño para la fabricación y el ensamblaje (DFMA, por sus siglas en inglés) es un enfoque utilizado en la ingeniería de diseño para optimizar la eficiencia y la calidad de los productos. Una de las áreas clave de estudio dentro de esta metodología son las concreciones formales. Las concreciones formales son elementos físicos o componentes que se agregan a un producto o sistema…

View On WordPress

0 notes

Text

Revolutionize Your Projects: Modular, Prefab, and DFMA in Construction

Explore how Modular, Prefabricated (Prefab) construction, and Design for Manufacture and Assembly (DFMA) techniques are revolutionizing the construction industry. These innovative methods streamline building processes, reduce costs, and accelerate project timelines. Modular and Prefab construction involves creating building components off-site in controlled environments, ensuring higher quality and minimizing on-site labor. DFMA enhances these benefits by optimizing designs for ease of manufacturing and assembly, further improving efficiency and reducing waste. Embrace these cutting-edge approaches to achieve faster, more cost-effective, and sustainable construction projects.

0 notes

Text

Design for Manufacturing and Assembly (DFMA) is a critical skill for any product designer. Our expertise is optimising product design for manufacturing and assembly.

0 notes