#Drawframe

Explore tagged Tumblr posts

Text

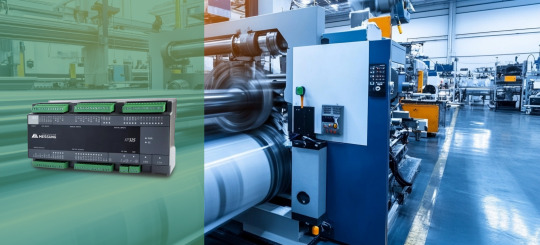

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

Importance of Spinning Machines & Components | A.T.E. India

A spinning machine is a machine that makes a fiber-forming polymer solution or melts from filaments. A.T.E. offers a variety of spinning machines. It provides parts for textile spinning machinery, assisting in meeting the demands of the textile industry.

A.T.E. provides the newest technology systems for blowrooms, cards, drawframes, combers, twisting machines, and humidification systems, as well as a variety of accessories and spinning machinery components. The company has a strong manufacturing base and technology agreements with important global players.

0 notes

Photo

Best Textile Spinning Machines & Components | A.T.E. India

Find various spinning machines from A.T.E. that offer textile spinning machinery components for blow rooms, cards, draw frames, combers, ring spinning systems and helps to meet the needs of textile industries.

With a robust manufacturing base, and technology partnerships with key world leaders, A.T.E. offers the latest technology systems for blowrooms, cards, drawframes, combers, twisting machines, humidification systems, as well as a range of accessories and spinning machinery components.

0 notes

Text

List of Waste in Spinning Mill (Blowroom, Carding, Drawframe, Combing, Simplex and Ring Frame)

List of Waste in Spinning Mill (Blowroom, Carding, Drawframe, Combing, Simplex and Ring Frame) #spinningwaste #blowrromwaste #cardingwaste #combingwaste #ringframewaste #drawframewaste

What is Waste / Wastage? Waste is type of material which has not in use, discarded some waste are useful some are not useful. The action or process of losing or destroying something by using it carelessly or extravagantly. Waste includes all items that people no longer have any use for, which they either intend to get rid of or have already discarded. Some waste are usable which are used for the…

View On WordPress

0 notes

Text

Computer Graphics, Lab Assignment 6 solved

Computer Graphics, Lab Assignment 6 solved

1. Write your own myLookAt() and myFrustum() functions (of the following form) that behaves exactly same as gluLookAt() and glFrustum(). A. B. Set the window title to your student ID and the window size to (480,480). C. Code skeletonD. Find code for drawFrame(), drawCubeArray() from 6-Viewing & Projection2 & mesh slides. E. DO NOT use gluLookAt() inside myLookAt() and glFrustum() inside…

View On WordPress

0 notes

Text

Explore Blow Room Machine at A.T.E. India

A.T.E. provides latest technology blow room machinery. With a robust manufacturing base, and technology partnerships with key world leaders, A.T.E. offers the latest technology systems for blowrooms, cards, drawframes, combers, twisting machines, humidification systems, as well as a range of accessories and spinning machinery components.

0 notes

Text

The Best Carding Machines Available in India Today

Carding machines are the mainstay of any spinning mill as they are used to -

eliminate impurities

mix the raw material more thoroughly

reduce the blend down to the size of a fibre web and then break it down into rovings that meet the number, which can be fed into spinning machines.

However, before we get to carding machine, we need to know how they operate. The carding process is a mechanical procedure that separates fibres and cleanses them to form a continuous web or sliver for further processing. This is accomplished by moving fibres through alternating surfaces covered by "card clothing", a solid, flexible material surrounded by metal pins. It breaks down blocks and unorganised clumps of fibres and aligns them so that they can be in a parallel line with one another.

Let us look at some of the best carding machines available in the Indian market by A.T.E. group, one of the top textile machine manufacturers.

1. Card T.C. 15:

Truetzschler T.C. 15 offers a competitive edge due to its high productivity, quality and low operating costs. It's flexible and allows for fast lot, flats and carding changes.

The compact T.C. 15 is similar to other Truetzschler cards and features the longest carding section in the market - ensuring high product quality.

Benefits:

Best quality because of the longest carding section in the market

Flat guiding special toothed belts - quick and easy flat replacement without tools

Reduced maintenance

Lowest operating costs

2. T.C. 12

In 2016, Truetzschler T.C. 10 carding machines were launched. There are currently several thousand of these cards in India. The T.C. 10, with its unique value-adding features, has won the hearts of the spinners of the country in just five years.

The T.C. 12 is the successor of the T.C. 10, and it enables spinners to improve their quality, productivity and efficiency. Carding machines need to be taken care of to deliver exceptional quality and high productivity. Setting up and maintaining them is crucial, and the T.C. 12 allows for less operator interference and maximises availability.

Benefit:

Productivity and high quality through a high precision carding gap device (PFS40)

High reliability and low maintenance at high speeds

Simple and intuitive operation using state-of-the-art SmartTouch

Save up to 2% on good fibres when you use W.C.T.

Maximum capacity with T-MOVE 2. Up to 15% more content thanks to the new filling function, T-MOVE 2

3. T.C. 19i

The T.C. 19i is the most advanced carding machine in the textile industry. The T.C. 19i has three main components:

Gap Optimisation T-GO: Optimises carding gaps under changing production conditions and responds automatically to changes in material properties, production levels, cylinder speeds and other environmental influences like room and ambient temperature.

WASTE CONTROL - Ensures efficient use of raw materials with minimal waste.

NOPECONTROL: Continuous monitoring of the nep levels throughout the card sliver.

The T.C. 19i comes with T-CON 3 technology, protecting against possible hazards as this machine will shut down if any part touches the cylinder clothing.

Benefits:

As simple as using a smartphone

Simple quality control

Remote display with T-LED allows operators to see the machine's operating status from a distance.

Final Words

The textile industry is one of the most labour-intensive industries, and it accounts for a significant share of the country’s exports. To meet the ever-growing demand for textiles, it is essential to have efficient carding machines.

One of the major textile machine manufacturers in the Indian market is the A.T.E. group. A.T.E. offers the newest technology systems for blow rooms, cards, drawframes, combers, etc., thanks to a strong manufacturing base and technology agreements with important world leaders.

0 notes

Text

Worried About Wood – Eco Friendly Framing

When it comes to looking after the future of our planet, it is everyone’s responsibility. The effects of global warming have been increasing exponentially, and that’s a big worry. From the overuse of plastics to the way we dispose of our waste, the most miniscule of actions can have a big effect on the future.

Although we can never fully reverse the damage we’ve caused, through educating and implementing changes we can change the outcome. The use of recyclable materials has been on the rise with more and more companies looking to reduce their carbon footprint.

This doesn’t stop shy of the art industry.

Aluminium

At Drawframes we look to use the least harmful products in our frames and canvases. We’d expect that your framed photo’s have a much higher shelf life than a can of cola, of course. But, looking to the future, we’d like to have as minimal an impact as possible.

Our aluminium frames are 100% recyclable. Aluminium has such a great recycling rate that 75% of all the aluminium ever mined, in the history of the metal, is still in use today. The methods used to extract bauxite ore from the ground are that industrious and time consuming, that it’s actually cheaper to recycle than produce new.

Not just a small fraction either. Recycling aluminium sees a reduction rate of 90% in the time, energy and money it takes to produce new metal. That’s what gives an empty drink cans a recyclable value.

Wood

Our parent company, Drawdeck plant a tree for every print they sell. Offsetting our imprint on the planet and remaining as carbon neutral as possible is the goal. Recycling old materials to create your own picture frame is another way you can help to do your bit for the environment.

Using reclaimed wood and just a few tools you can always knock up your own frame to add a little extra bit of satisfaction to your wall. With just clamps, a mitre saw, some wood glue and a stapler, you can make frames to fit from wood you’ve found. To read more about custom framing, check our blog here.

Shelf Life

Magical moments or pieces of art are not usually something easily thrown away. They move home with you, are passed forward if replaced and rarely condemned to the rubbish bin. If you do remove or replace and works from your walls, ask first if they could be repurposed or appreciated by someone else. Reducing waste should be everyone’s goal.

For more on our framing services, click here.

0 notes

Text

Bound Weapon

A magic spell book that can generate an ethereal bow or ethereal sword. Made by Laz2727

Demo: https://gfycat.com/EnormousAdmirableAmericanriverotter

/spawnitem rarestaff 1 '{"shortdescription":"Bound Weapon","description":"Primary: Bound Bow\nSecondary: Bound Blade","level":6,"elementalType":"fire","tooltipKind":"base","rarity":"Legendary","category":"Spell","animationCustom":{"transformationGroups":{"weapon":{},"muzzle":{},"swoosh":{}},"animatedParts":{"stateTypes":{"swoosh":{"default":"idle","states":{"idle":{},"fire":{"frames":3,"cycle":0.1,"mode":"transition","transition":"idle"},"fire2":{"frames":3,"cycle":0.1,"mode":"transition","transition":"idle"},"fire3":{"frames":3,"cycle":0.1,"mode":"transition","transition":"idle"}}},"bow":{"default":"idle","states":{"idle":{},"draw":{"frames":5,"cycle":0.1,"mode":"end"},"fire":{"frames":5,"cycle":0.1,"mode":"end"}}}},"parts":{"swoosh":{"properties":{"zLevel":-1,"centered":true,"offset":[-0.25,2.5],"transformationGroups":["swoosh"],"rotationCenter":[0,0]},"partStates":{"swoosh":{"idle":{"properties":{"image":""}},"fire":{"properties":{"image":"/items/active/weapons/melee/broadsword/swoosh/physicalswoosh.png:<frame>?setcolor=77FFFF?multiply=FFFFFF77","offset":[0,2.5],"damageArea":[[-5,2],[-2.5,3],[1,3],[4,1.75],[5,-0.25],[5,-2.25],[4,-3.25],[0,-2.5]]}},"fire2":{"properties":{"image":"/items/active/weapons/melee/broadsword/swoosh2/physicalswoosh.png:<frame>?setcolor=77FFFF?multiply=FFFFFF77","offset":[5,1],"damageArea":[[-4,1],[2.5,1],[2.5,-2],[-4,-2]]}},"fire3":{"properties":{"image":"/items/active/weapons/melee/broadsword/swoosh3/physicalswoosh.png:<frame>?setcolor=77FFFF?multiply=FFFFFF77","offset":[3.5,0],"damageArea":[[-4.75,1.5],[3,1],[3,-1],[-4.75,-1.5]]}}}}},"bow":{"properties":{"centered":true,"offset":[0.375,0],"image":"<partImage>:<drawFrame>?setcolor=77FFFF?multiply=FFFFFF77","transformationGroups":["weapon"]},"partStates":{"bow":{"idle":{"properties":{"image":""}},"draw":{"properties":{"image":"<partImage>:<drawFrame>?setcolor=77FFFF?multiply=FFFFFF77"}},"fire":{"properties":{"image":"<partImage>:<drawFrame>?setcolor=77FFFF?multiply=FFFFFF77"}}}}},"stone":{"properties":{"zLevel":3,"centered":true,"image":"","offset":[0,0],"focalPoint":[0,0],"transformationGroups":["weapon"]}},"handle":{"properties":{"zLevel":1,"centered":true,"image":"","offset":[0,0],"transformationGroups":["weapon"]}},"crown":{"properties":{"zLevel":2,"centered":true,"image":"","offset":[0,0],"transformationGroups":["weapon"]}}}},"particleEmitters":{"fireswoosh":{"active":false,"transformationGroups":["swoosh"],"emissionRate":50,"offsetRegion":[0.75,0,4.25,5],"particles":[{"particle":"fireswoosh1"},{"particle":"fireswoosh2"},{"particle":"fireswoosh3"}]},"bow":{"active":true,"offsetRegion":[-0.5,-1,0.25,1],"emissionRate":4,"particles":[{"particle":"energyblade"}],"transformationGroups":["weapon"]}},"sounds":{"draw":["/sfx/gun/bow_draw1.ogg"],"release":["/sfx/melee/laser_weapon_swing2.ogg"],"perfectRelease":["/sfx/melee/laser_weapon_swing1.ogg"]}},"animationParts":{"bow":"/items/active/weapons/bow/bow/bowfull.png"},"inventoryIcon":[{"image":"/codex/avian/aviancover1.png?replace;ccae7c=cb13ff;a47844=9b1dcf;754c23=580682;","position":[0,0]}],"scripts":["/items/active/weapons/melee/meleeweapon.lua"],"primaryAbilityType":"bowshot","primaryAbility":{"drawSpeedMultiplier":"constant","projectileType":"energyarrow","powerProjectileType":"chargedenergyarrow","projectileParameters":{"power":6.5},"stances":{"idle":{"armRotation":-30,"weaponRotation":0,"allowRotate":true,"allowFlip":true,"twoHanded":false,"animationStates":{"bow":"idle"}},"draw":{"armRotation":0,"weaponRotation":0,"allowRotate":true,"allowFlip":true,"twoHanded":true,"animationStates":{"bow":"draw"}},"fire":{"duration":0.2,"armRotation":0,"weaponRotation":0,"allowRotate":false,"allowFlip":true,"twoHanded":true,"frontArmFrame":"idle.3","animationStates":{"bow":"fire"}}}},"altAbilityType":"broadswordcombo","altAbility":{"fireTime":1,"baseDps":10.5,"allowHold":false,"stances":{"idle":{"armRotation":0,"weaponRotation":0,"twoHanded":false,"allowRotate":true,"allowFlip":true}}}}'

4 notes

·

View notes

Photo

Its been forever since i made a happy/sad post for you last. But hear it goes Dad, time has flown your baby has grown into a man. I landed a job i thought i would dread, it turns out you would be more proud of me than i ever thought. I may have to look up words on google still to make sure im spelling right. It sucks but its true. I graduated highschool, got my electrical certificate. I dropped out mainly because of bills, but also because it was not for me. I know that possibly disappointed you. But a year ago in 18 days i started a job. I thought i would suck at it. But i do not. I have went from cleaning crew, to mechanic, back to cleaning/mechanic, then phase 2, then back to cleaning crew, now i am in training for assitant supervisor under carding,blowing,drawframe. You would have been the first person i called, actually no i would have driven to your house that day to tell you. Its been hard over the years, i still listen to your old voicemails. I wear your clothes to work somedays so you are there with me. I understand you are in my heart, but somedays its not good enough. I hope you are proud, its been a rough road. But it does not stop here. April 1st is open enrollement for insurance, so i will be able to get my shoulder and knee checked out. Also i wish you could meet my fiancé she is amazing you would like her. But most of all i wish you could see your oldest my brother, he has been through hell and back. But he has the cutest son ever, you would be proud of him. We all love you Dad you are missed. But until next time give grandmaw, grandad, lucky, and rocky love for me. #cloudsforjamie #ripdad #4yearsand5months #ihopeyouareproud

0 notes

Text

Explore Efficient and Effective Textile Spinning Machines from A.T.E India

A.T.E India is a global leader in offering innovative and sustainable solutions of world-class standards. Its core technologies and strategic partnerships have revolutionized various textile processes.

Spinning in textile manufacturing is indispensable in textile engineering. They are used to convert raw fibre into yarn and are well-equipped to twist and wind. High-end textile spinning machines can produce yarn of various qualities and specifications.

Here is an overview of the significance of A.T.E Group's textile spinning machines that offer world-class textile engineering solutions.

Efficiency and Significance of Textile Spinning Machines by A.T.E Group

Textile spinning machines are used for converting raw materials into yarn and the right quality impacts the quality and consistency of the yarn produced.

A.T.E India, a leader in providing world-class textile engineering solutions, recognizes the critical role of spinning in textile manufacturing and offers cutting-edge technologies, innovative solutions, and expert engineering.

A.T.E India's textile spinning machines ensure superior yarn production with maximized effectiveness and sustainability. Textile manufacturers can collaborate with A.T.E Group, and make the most of such advanced spinning machine solutions.

Let us now understand the key specifications and features of A.T.E Group's textile spinning machines.

Features, Specifications, and Benefits of A.T.E Group's Textile Spinning Machines

A.T.E India offers the latest technology systems for blowrooms, cards, drawframes, combers, twisting machines, and humidification systems, as well as a range of accessories and spinning machinery components.

Effective Blowrooms

The blow room serves to prepare raw fibres for further processing and extracts the best qualities from each fibre. Key inclusions in the blow room lineup include:

T-BLEND modular tuft blending system. TRUETZSCHLER CL-X for removing coarse contaminants from cotton. BO-P | PORTAL BALE OPENER, which offers larger working widths, requires less space and delivers superior blending performance. BLENDOMAT series comprises the BO-A for flexible automatic bale plucking. BO-E, a robust bale opener with a penetration inversion mechanism for effective cotton opening. The PRE-CLEANER CL-P provides unique beating pre-cleaning for all types of cotton. MULTIMIXER MPM and UNIVERSAL MIXER MX-U 6/10 ensure maximum homogeneity and blending. For efficient cleaning, our CLEANOMAT CL-C1 and CL-C3 offer energy-efficient solutions with minimal fibre loss. HEAVY PART SEPARATOR SP-H is used for effective heavy part separation. The T-SCAN TS-T5 represents the latest generation foreign parts separator. DUSTEX DX stands as a unique de-dusting machine for efficient micro-dust removal.

Carding Process and Drawframe of A.T.E Group's Textile Spinning Machines

The carding process further prepares fibres for spinning in textiles by aligning them into a continuous web. A

TE offers a range of high-productivity carding machines designed to provide precision control for enhanced cleaning efficiency and superior fibre preparation.

CARD TC 15, d for its flexibility, high production output, and low operating costs. The TC 12 offers reduced operator interference and maximized availability. TC 19I stands as the first intelligent card, integrating advanced technology for optimized performance. TD 10 incorporates the latest digital levelling technology, resulting in improved silver quality. TD 9T boasts a unique feature where one side of the draw-frame stops if a fault occurs.

Combing Process

This process refines fibres to achieve superior yarn quality. A.T.E India offers exceptional combers that prevent quality variations and enhance overall performance.

The TRUETZSCHLER COMBER TCO 21 stands out as a pinnacle of excellence, delivering top-notch combing performance backed by reliable Truetzschler technology. You can trust A.T.E India's high-tech combers to elevate your textile manufacturing processes to new heights.

Humidification and Air Control

It is imperative to maintain optimal humidity and air quality to ensure maximum efficiency and quality of textile production processes. A.T.E India offers a comprehensive range of solutions under the Total Air Control (TAC) system tailored for traditional textiles.

The inclusion of innovative technologies such as the Luwa Precision Air Conditioning system ensures precise control over temperature and humidity levels. With features like the DIGI5 CONTROL system for intelligent monitoring and Luwa Cleaner Circulaire for microdust removal, A.T.E India's solutions offer the perfect air control technology.

Assembly Winders

A.T.E India offers a range of assembly winders built on the innovative modular winding machine platform from SSM Schärer Schweiter Mettler AG.

The SSM XENO series, comprising the YD, FD, and BD models, represents a versatile solution. The SSM DURO-TD stands out as a modular assembly winding platform specifically designed for processing coarse technical yarns with efficiency and precision. The SSM NEO-FD precision assembly winder delivers unparalleled performance and reliability in winding operations.

Spinning Accessories

A.T.E India offers a comprehensive range of spinning accessories that enhance the performance and efficiency of spinning in textile manufacturing. These accessories include:

High-precision spinning machinery components sourced from trusted brands like TeraSpin and Truetzschler card clothing. A.T.E India provides upgrades and conversions for blow room and carding components. High-tech card clothing from Trützschler and award-winning compact systems from Dechang.

Testing Equipment

A.T.E India offers top-of-the-line fibre and yarn testing equipment manufactured by MAG Solvics Private Limited, India. Our range of fibre testing instruments includes:

Tools for assessing length, strength, maturity, fineness, moisture content, colour, and gravimetric trash. Measure yarn strength, elongation, evenness, imperfections (IPI), and hairiness. With MAG Solvics' cutting-edge technology, textile manufacturers can ensure the quality and consistency of their fibres and yarns Conclusion

A.T.E India's textile spinning machines stand as the cornerstone of textile engineering and facilitate the conversion of raw fibres into yarn with precision and efficiency.

Conclusion:

A.T.E India offers world-class textile engineering solutions and plays a crucial role in advancing the capabilities of spinning machines. A.T.E India works on innovation and excellence and empowers the textile industry with superior spinning machine solutions.

0 notes

Text

PROCESS PARAMETERS IN DRAW FRAME

INTRODUCTION:

Draw frame is a very critical machine in the spinning process. Its influence on quality, especially on evenness is very big. If draw frame is not set properly, it will also result in drop in yarn strength and yarn elongation at break. The faults in the sliver that come out of draw frame can not be corrected. It will pass into the yarn. The factors that affect the yarn quality are the total draft no of draw frame passages break draft no of doublings grams/meter of sliver fed to the draw frame fibre length fibre fineness delivery speed type of drafting type of autoleveller settings The total draft depends upon material processed short fibre content fibre length following are some facts derived from trials wider back roller setting will result in lower yarn strength wider back roller setting will affect yarn evenness wider back roller setting will increase imperfections higher back top roller loading will reduce yarn strength higher back top roller loading will reduce end breakage rate wider front roller setting will improve yarn strength Higher draft in draw frame will reduce sliver uniformity, but will improve fibre parallelization. Sometimes the improvement in fibre parallelization will overcome the detrimental effects of sliver irregularity.

Most of the improvement in fibre parallelization and reduction in hooks takes place at first draw frame passage than at second passage. Better fibre parallelization generally results in more uniform yarns and a lower end breakage rate in spinning. Higher the weight of sliver fed to draw frame, lower the yarn strength, yarn evenness, and it leads to higher imperfections in the yarn and more end breakages in ring spinning Irregularities arise owing to the instability of the acceleration point over time. The aprons and rollers are used in the drafting zone to keep the fibre at the back roller velocity until the leading end is firmly gripped by the front roller, but individual fibre control is not achieved. Drafting wave is caused primarily not by mechanical defects as such but by the uncontrolled fibre movement of a periodic type resulting from the defects. As the fibre-accelerating point moves towards the front rollers, the draft increases (and vice versa), so that a periodic variation in linear density inevitably results.

With variable fibre-length distribution (with more short fibre content), the drafting irregularity will be high. More the number of doublings lower the irregularity caused due to random variations. Doublings does not normally eliminate periodic faults. But it reduces the effects of random pulses. Doubling does not have any effect on Index of Irregularity also, since both the irregularities are reduced by square root of the number of doublings. Fibre hooks influences the effective fibre length or fibre extent. This will affect the drafting performance. For carded material normally a draft 7.5 in both breaker and finisher draw frame is recommended. Seven of a draft can be tried in breaker, since it is a carded material. For combed material, if single passage is used, it is better to employ draft of 7.5 to 8. If combers with four doublings are used, it is better to use two draw frame passages after combing. This will reduce long thick places in the yarn.

In case of two draw frame passage, first draw frame passage will reduce the periodic variation due to piecing. Therefore the life of servomotor and servo amplifier will be more, if two draw frame passage is used. Quality of sliver will also be good, because of less and stable feed variation. For synthetic fibres (44 mm to 51 mm), 8 of a total draft can be employed both in breaker and finisher passage. The number of doublings depends upon the feeding hank and the total draft employed. Most of the modern draw frames are capable of drafting the material without any problem, even if the sliver fed is around 36 to 40 grams per meter. Especially for synthetic fibres with very high drafting resistance, it is better to feed less than 38 grams per meter to the draw frame. Break draft setting for 3/3, or 4/3, drafting system is as follows for cotton, longest fibre + (8 to 12 mm) for synthetic fibre, fibre length + (20 to 30% of fibre length) Break draft for cotton processing is normally 1.16 to 1.26. For synthetics it is around 1.42 to 1.6 to meet the present quality requirements, finisher draw frame should be an autoleveller draw frame. Since the draw frame delivery speed is very high the top roller shore hardness should be around 80 degrees. It should not be less than that. It is advisable to buff the rubber cots once in 30 days (minimum) to maintain consistent yarn quality. Coiler size should be selected depending upon the material processed. For synthetic fibres, bigger coiler tubes are used. This will help to avoid coiler choking and kinks in the slivers due to coiling in the can. Speed of the coiler will also affect the coiling. Speed of the coiler should be selected properly.

In draw frames like RSB D-30(RIETER), any coiler speed can be selected through the variator type pulley. Since, the option is open; there is also more probability for making mistakes. One should take enough care to set the coiler speed properly. Whenever coiler speed is adjusted, the diameter of the coil is also changed. Hence it is necessary to check the gap between the slivers and can. If it is more than 5 mm, then turn table position (can driving unit) should be altered so that the gap between coil outer and can inner is around 5 mm. Pressure bar depth plays a major role in case of carded mixing and OE mixings. If it is open, U% will be affected very badly. It should always be combined with front roller setting. If the pressure bar depth is high, Creel height should be fixed as low as possible (especially for combed material). Top roller condition should be checked properly. While processing 100% polyester fibres, fibre scum should be removed by a wet cloth from the top roller at least once in a shift. Sliver funnel size should be selected properly. Very wide funnel will affect the U%. But very small funnel will end up in more sliver breaks at the front. If the department humidity variation is very big, then corresponding correction to be made for checking the wrapping of sliver (sliver weight). Otherwise, there will be unwanted changes in the draw frame which will affect the count C.V.% of yarn. Most of the Autoleveller draw frames are working on the principle of OPEN LOOP control system. Sliver monitor should be set properly. Whenever there is a problem in sliver weight, this will stop the machine. Sometimes sliver monitor may malfunction. If it is found malfunctioning, it should be calibrated immediately. AUTOLEVELLING: Most of the modern autolevllers are open loop autolevllers. This system is effective on short, medium and to some extent long tem variations. Mechanical draft should be selected properly in autoleveller draw frames. To decide about the mechanical draft, draw frame should be run with autoleveller switched off. If the sliver weight is correct, then the mechanical draft selected is correct. Otherwise, the gears should be changed so that the sliver is weight is as per the requirement without autolevllers. Intensity of leveling and timing of correction are two important parameters in autolevllers. Intensity of leveling indicates the amount of correction. i.e. If 12% variation is fed to the draw frame the draft should vary 12% , so that the sliver weight is constant. Timing of correction indicates that if a thick place is sensed at scanning roller, the correction should take place exactly when this thick place reaches the correction point(leveling point) Higher the feed variation, higher the correction length. e.g. if feed variation is 1 %, and if the correction length is 8 mm, if feed variation is 5% the correction length will be between 10 to 40 mm depending upon the speed and type of the autoleveller. Higher the speed, higher the correction length Whenever the back roller setting, guide rails setting, delivery speed, break draft etc are changed, the timing of correction should also be changed. U% of sliver will be high, if timing of correction is set wrongly if intensity of leveling selected is wrong, then 1 meter C.V % of sliver will be high.

Most of the modern autolevllers can correct 25% feed variation. It is a general practice to feed 12% variation both in plus and minus side to check A%. This is called as Sliver test. The A% should not be more than 0.75%. A% is calculated as follows If no of sliver fed to draw frame is N, Check the output sliver weight with "N", "N+1", "N-1" slivers. then A% = ((gms/mt(N-1) - gms/mt(N))/ gms/mt(N) ) x 100 A% = ((gms/mt(N+1) - gms/mt(N))/ gms/mt(N)) x 100 Life of servo motor and servo amplifier will be good, if it is used for carded material feed variation is less motor is checked for carbon brush damages, bearing damages etc periodically if the delivery speed is less

0 notes

Text

Jute Draw Frame | Functions of Jute Drawing | Types of Jute Draw Frame

0 notes

Text

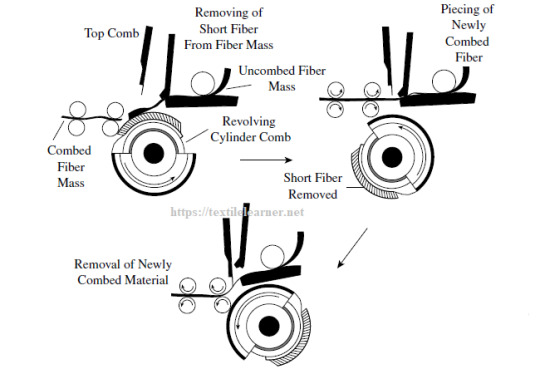

Combing Cycle of Comber Machine in Cotton Spinning

Combing Cycle of Comber Machine in Cotton Spinning #combing #combingcycle #combingoperation #combingprocess #comber

Combing: Combing allows the production of very fine, high-quality spun yarns. Combing is an intermittent operation carried out between carding and drawframe. The combing process is normally used to produce smoother, finer, stronger and more uniform yarns. The carded materials (sliver) contain certain amount of short fibers, neps, fine kitty and leaf particles. Short fibers are a hindrance to…

View On WordPress

0 notes