#automation processes

Explore tagged Tumblr posts

Text

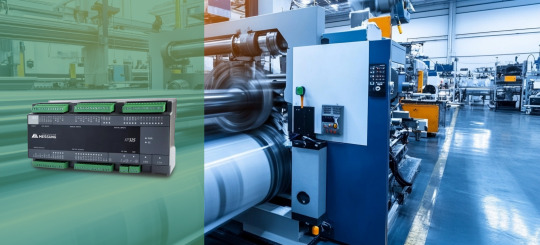

Enhancing Textile Machinery Efficiency with Messung's NX-ERA Xpress PLC

The textile industry, being a part of global manufacturing, has witnessed a massive transformation in recent years due to accelerated technological advancements. From yarn making to dyeing yarns with complex patterns, each process of textile production has been streamlined for higher productivity, accuracy, and efficiency. The need for high-quality products and shorter production cycles has generated fertile ground for automation, especially with the use of Programmable Logic Controllers (PLCs)in textile manufacturing.

This is where we at Messung Industrial Automation come in the picture with our cutting-edge automation solutions. With our strong heritage of delivering strong and scalable automation solutions, we have been the industry leader in industrial automation. Our innovative and compact PLC, NX-ERA Xpress has been crafted to specifically address the specific requirements of industries such as textile manufacturingwith the ideal combination of performance, flexibility, and energy efficiency. In this blog, let’s explore the revolutionary potential of NX-ERA Xpress PLCand its impact on textile machinery, with an emphasis on how it improves operational efficiency, cuts costs, and accelerates the journey towards Industry 4.0.

The Role of PLCs in Modern Textile Manufacturing

Programmable Logic Controllers (PLCs) form the foundation of automation in textile manufacturing, especially in the "cotton to yarn" and "yarn to fabric" segments where their role is most critical. These rugged, industrial-grade controllers ensure precision, speed, and efficiency by managing machinery and processes in real time. From ginning and bale plucking to spinning, carding, drawframe, combing, ring frame machines, and autoconers, PLCs are deeply embedded in every stage of the cotton-to-yarn journey.

In the yarn-to-fabric sector, PLCs continue to play a significant role in the operation of warping machines, twisting machines, and various types of looms such as shuttle, airjet, and rapier looms. They are equally vital in fabric processing lines, managing singeing, bleaching, dyeing, and a wide range of finishing machines designed to enhance textile properties like softness, wrinkle resistance, or water repellency. Printing lines, including rotary and flat bed printing machines, also rely heavily on PLC-controlled automation.

Across these applications, PLCs are integrated with Human Machine Interfaces (HMI), Variable Frequency Drives (VFDs), and in high-speed machines like spinning lines, Servo amplifiers and Servo motors are used for superior speed and torque control.

While the garment sector (fabric to garment) does involve automation, Messung’s core expertise and solutions, including the NX-ERA Xpress PLC and NX-ERA Jet PLC, are primarily focused on the earlier and more automation-intensive stages of textile manufacturing.

Benefits of Implementing PLCs on Textile Machinery

Increased Efficiency: PLCs allow streamline operations by automating processes that were previously manual, significantly reducing downtime and increasing throughput

Improved Accuracy: The high-level precision control afforded by PLCs ensures each activity in the fabric process, whether spinning or weaving, is undertaken with perfection.

Real-Time Monitoring: PLC-based systems make equipment monitoring in real-time a certainty, where defects are flagged off early and avoid costly downtime along with plant operation performance improvements.

As the textile industry advances, compact PLCs are not an indulgence but a must-have. Automation is the key to staying competitive, and industrial automation PLC systems like the NX-ERA Xpress are at the forefront of this revolution.

Learning More About NX-ERA Xpress PLC

The NX-ERA Xpress PLC is our response to the increasing needs of the textile industry. By harnessing the capability of Programmable Logic Control Systems and the flexibility of contemporary communication protocols, the NX-ERA Xpress provides a powerful and scalable solution for numerous industrial automation applications.

Features of NX-ERA Xpress PLC:

High-Density Digital and Analog I/O: The NX-ERA Xpress PLC features a high-density I/O design that is capable of processing vast amounts of data input and output at one time. This is important for the textile industry, where real-time data from many machines need to be processed efficiently in order to optimize performance.

Programming through Codesys® (IEC 61131 Standard): Among the most impressive aspects of the NX-ERA Xpress PLC is its support for Codesys®, an open-source programming platform. This standardization enables seamless integration with industrial equipment across the board, which makes it an attractive option for PLC manufacturing companies.

Integrated Communication Protocols: With inbuilt compatibility for communication protocols such as Ethernet TCP/IP, Modbus, and CANopen, the NX-ERA Xpress PLC facilitates smooth connectivity among various machines and devices on the shop floor. This connectivity is vital for ensuring smooth operation throughout the complete manufacturing process.

Industry 4.0 Readiness: NX-ERA Xpress PLC comes with OPC-UA and MQTT readiness, making it Industry 4.0-ready. These are technologies that support data exchange over different platforms, and they simplify the integration of machines by manufacturers into a smart factory environment.

Integrated HTML Web Server for Remote Monitoring: Remote monitoring has never been simpler. The integrated HTML web server enables operators to monitor and control the PLC remotely, offering flexibility and real-time visibility into machine performance.

The high-performance features and compact PLC design of NX-ERA Xpress PLC make it perfect for the textile industry. Whether you're automating cotton spinning, weaving, or dyeing, the NX-ERA Xpress provides all the power you need to optimize your operations.

Advantages of NX-ERA Xpress in Textile Applications

The textile industry requires solutions that are capable of providing not just high performance but also cost-effectiveness and sustainability. Our NX-ERA Xpress PLC provides a number of benefits for applications in textile machinery, such as:

Energy Efficiency

In the textile industry, energy consumption is a major operational expense. The NX-ERA Xpress PLC is built to maximize control and minimize power consumption, especially in power-hungry processes such as spinning. Through automation processes and optimizing machine efficiency, the PLC ensures textile plants make substantial savings on energy.

High-Speed Processing

Textile production processes often involve rapid and adaptive control systems that are necessary for handling high-speed manufacturing lines. The processing of high speeds facilitated by the NX-ERA Xpress PLC helps data move faster to provide instant adjustment capabilities, ensuring minimum lags in manufacturing processes.

Precision Control

The clothing industry is based on the effective control of variables like thread tension, fabric alignment, and dying processes. NX-ERA Xpress PLC ensures accurate control in order to match every parameter in the manufacturing process to the prescribed specifications. The result is repetitive product quality, and less it is defective.

Scalability

As textile factories develop and expand, scalable automation systems become increasingly relevant. NX-ERA Xpress PLC uses a modular construction that means that automation systems can be expanded as they are required by manufacturers, presenting a great solution for expanding businesses in the textile industry in the long term.

Cost-Effectiveness

Automation must not be expensive. The NX-ERA Xpress PLC is an affordable solution for textile producers that offers high-end features without an exorbitant price tag. It is meant to offer high-performance at an affordable rate, so any textile firm can use it.

Textile Machinery Applications: PLC Precision for a Modern Mill

As textile factories embrace digital transformation, the NX-ERA Xpress PLC emerges as a compact yet powerful solution tailored for automation-ready textile machinery. With its robust control features and Industry 4.0 connectivity, the NX-ERA Xpress brings intelligence and agility to a wide range of textile processes.

Let’s explore key use cases across the textile value chain:

Yarn Steaming Machine:

Steaming is a critical stage in yarn preparation where temperature, pressure, and timing must work in harmony. The NX-ERA Xpress PLC ensures:

Precise control of temperature and steam pressure for consistent yarn conditioning

Regulation of steaming duration to match different yarn types and production speeds

Automation of loading and unloading mechanisms, reducing manual intervention and boosting throughput

With its real-time responsiveness and compact design, the NX-ERA Xpress PLC enhances efficiency, consistency, and reliability in yarn steaming operations.

Heat Setting and Space Dyeing Machine Integration:

In advanced textile finishing, seamless integration between heat setting and dyeing is essential. NX-ERA Xpress PLC brings synchronization and control to:

Temperature management for precise heat setting, improving dimensional stability and dye fixation

Control of dye application in the space dyeing process, enabling unique patterns with consistent results

Coordination of material flow between machines, ensuring smooth transitions and avoiding process bottlenecks

The result is an integrated, high-performance workflow for specialty dyeing applications, digitally governed for optimal output and reduced waste.

Integration with Messung's Automation Ecosystem

One of the major strengths of the NX-ERA Xpress PLC is that it can integrate smoothly with all our other products, like the XM-PRO remote I/O modules. This makes it possible to have a unified automation solution that simplifies the control and monitoring of your entire textile plant.

With a single provider for all automation needs, textile manufacturers can enjoy streamlined operations, reduced complexity, and improved support. The synergy between the NX-ERA Xpress PLC and our other products ensures that your factory is fully equipped to tackle the challenges of modern textile manufacturing.

Conclusion

In summary, our NX-ERA Xpress PLC is a game-changer in the textile sector, providing powerful, scalable, and affordable automation. With its high-performance capabilities, energy efficiency, and accurate control, the NX-ERA Xpress PLC is ideally positioned to address the changing needs of textile producers.

With the NX-ERA Xpress PLC, you can elevate your textile manufacturing process to the next level. Whether you want to optimize spinning, weaving, or dyeing processes, Messung's automation solutions provide the reliability and performance that you require to remain ahead in a competitive market.

So, why wait? Consult Messung today for a customized automation solutionthat suits your textile manufacturing needs. It’s time to embrace the future of textile production with the NX-ERA Xpress PLC - where automation meets innovation

#textile manufacturers#Programmable Logic Controllers (PLCs)#textile manufacturinG#cutting-edge automation solutions#compact PLC#NX-ERA Xpress PLC#textile machinery#Industry 4.0#spinning#carding#drawframe#combing#ring frame machines#autoconers#singeing#bleaching#dyeing#PLC-controlled automation.#NX-ERA Jet PLC#industrial automation#PLC systems#IEC 61131 Standard#Ethernet TCP/IP#Modbus#CANopen#cotton spinning#automation processes#remote I/O modules#automation needs#customized automation solution

0 notes

Text

my baby :(

#btw the hands are connected to nothing on purpose!!#I feel like the killjoy capture & re-education process is very automated and they have hundreds of holding cells with hundreds of#mechanical hands#I don’t know#I have a lot of lore set up for red 40’s time being brainwashed….#it will all be revealed drawing by drawing#restraints whump#medical whump#whumpblr#whump community#whump art#knife tw#danger days#ddttlotfk#ttlotfk#killjoy oc#knife whump#tortured for information

118 notes

·

View notes

Text

its two months till june but wk has me by the throat i had no choice im sorry. this is like the best person-shaped thing i’ve drawn ever i don’t know how i feel

114 notes

·

View notes

Text

my side quest is complete. I wrote these letters for the template with a marker so they're extra round and cute btw.

#val art#oh no I'm automating part of my art making process with a computer instead of putting my innate human soul into each mark sorry

31 notes

·

View notes

Text

why is mattel so allergic to giving their dolls curly natural hair

#like. i know irl black women can do whatever they want with their hair#black hair is super versatile and that's legitimately amazing#and i know giving hundreds of thousands of dolls tiny little braids would be very expensive to manufacture#even if the process is totally automated#but. would it kill them to give their dolls tighter curls??#or not just slap a few braids on top of straight hair and go 'eh good enough'#like. there are SO many natural hairstyles they could do that don't involve microbraiding doll hair#half up half down. fauxhawks. bantu knots. pineapple updos. tree braids. afros. afro puffs. thick twists. french braids#goddess braids. undercut fades. pixie cuts. literally just ponytails#like! there are so many options! and it feels like they keep hitting the mark#monster high

74 notes

·

View notes

Text

JobsHorn, a fast-growing local talent hiring platform in the USA. We’re inviting businesses to join our platform and start hiring smarter.

🎯 Register your business today and get 5,000 job postings absolutely FREE! Use the referral link below to sign up:

👉Recruiters Register: https://jobshorn.com/employer/register?refcode=2023DhKVu916MS2 🔐 Promo Code: JHVINAY2025

Whether you’re scaling fast or planning ahead, JobsHorn helps you find the right local talent quickly and easily. Share this with your network—let’s grow together!

#fast job posting#quick job posting#instant job posting#hire fast#quick recruitment#speedy hiring#job ads#quick hire#post jobs online#hire in minutes#fast hiring process#easy job posting#job post automation#instant hiring#quick job ads#rapid recruitment#job posting tips#recruit faster#fast job board#one-click job posting#real-time hiring#turbocharged recruitment#express hiring#seamless job posting#simple hiring process#hire employees fast#immediate job posting#fastest way to hire#job posting platform#quick vacancy posting

9 notes

·

View notes

Text

#0049 - Venomoth

#venomoth#pokemon#gif#the backface has a toon shader in-game that I'm not sure how to properly render in blender so this is the closest approximation i could get#on the bright side this got me to write some automation scripts for the gif making process!

39 notes

·

View notes

Text

I think if OllieDinahBabs was ever canon they'd divorce once a week and go to the next permutation of possible marriages between the three of them.

#dc#comics#barbara gordon#dinah lance#oliver queen#dinahbabs#DinahOllie#olliebabs#OllieDinahBabs#Barbara has the whole process automated they get sll the paperwork sebt to theur emsil abd new marrige certificates every week#charlie uses them to fold paper airplanes

13 notes

·

View notes

Text

collecting valuable personal data from applicants is not enough. no. they also want you to train their shitty chatbots for free

#there is no universe in which this is not a scam#if this was about automating the hiring process#theyd have you take an aptitude test#or submit work samples#or a test project#if this was about 'getting to know you' theyd have you speak to a real person#but this? this is them using you as their personal lab monkey#&#i hate the future

7 notes

·

View notes

Text

I understand that a lot of things are called AI, and none of them are actually "artificial intelligence", but I do want to point out that a lot of the "AI = complex scientific models that have been used for years" is genuinely the exact same thing as "Ai = generative tools"

The ai that gets applauded on here because it can detect sickle cell disease is constructed on the same basic principles as the ais that everyone on here hates, like chatgpt and dall-e

#I'd wager that some things falling into the 'things that automate tedious processes' example are also constructed the same way#but im not positive#i am fairly positive that there are nearly zero games that use the same structure to handle npc behavior though#that seems way too complex for how npcs work in the vast majority of games and would probably backfire more often than be useful

19 notes

·

View notes

Text

there are potential spreadsheets everywhere for those with the eyes to see

#relevant to nothing I just looooove data and automation and processing and dashboards :)#lee speaks#adding your smile to my spreadsheet. extracting this beautiful sunny day using an api. etc etc

3 notes

·

View notes

Text

Gentle reminder that there's a person behind this blog and a little patience + compassion goes a long way. If you're concerned about something, please give me a little while to respond before messaging multiple times. I've got 40+ people to coordinate contact with for this year, but I promise I will get back to you if given more than a couple of hours.

#log#sorry if this post reads as prickly. just got some stuff that warranted a reminder that this is not an automated process and i am just a guy#and a guy who would appreciate some grace and maybe a please once in a while#thanks

18 notes

·

View notes

Text

Ok so why have I been backing up my blog for what? Four days? With no end in sight? No progress bar? No nothing? No updates? My laptop is gonna kill itself at this point. Why on earth does it take that long and it's still not done??

#it is an automated process#i know that much#no one needs to overlook it#its not a staffing problem#it just.. takes forever?

4 notes

·

View notes

Text

unfair when I think automating a process should be very easy but it turns out to be very not

#mine#I spent two precious hours trying to dynamically produce a pivot table#a task that takes six clicks to fully format manually#I gave up on the second half of the process#which was the part I was actually hoping to automate#fuck excel and fuck VBA

9 notes

·

View notes

Text

the LAST place i wanna be is at this fuck ass job omg

#yap.package#RELEASEEEE MEEEE#SO much work came in to process over the weekend because everything is automated#i just wanna go HOME oh my god

6 notes

·

View notes