#ESD power circuit

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--esd-protection/usblc6-2sc6-stmicroelectronics-5742044

What is ESD protection, ESD protection arrays, ESD power circuit, ESD circuit

USBLC6 Series 2 Line 6 V Uni / Bi-Directional ESD Protection - SOT-23-6

#ESD Protection & Diode Arrays#USBLC6-2SC6#STMicroelectronics#circuit#ESD power clamp#Diode Array device#ESD protection arrays#ESD power circuit#ESD Clamp Circuit#ESD protection equipment#ESD Ultra-Low Power Applications

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--esd-protection/0603esda2-tr2-eaton-3147847

Circuit Protection Devices, ESD Protection equipment, Solid state relays

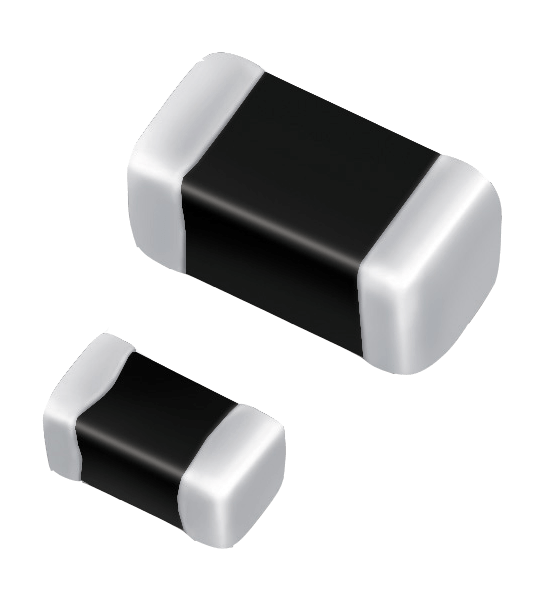

MLP Series 60 V 0.1 pF Bi-Directional 0603 Surface Mount ESD Suppressor

#Eaton#0603ESDA2-TR2#Circuit Protection Devices#ESD Protection & Diode Arrays#Power relay#Circuit Devices#equipment#Solid state relays#Bi-Directional#ESD protections circuit#ESD protection arrays#Electrostatic discharge protection

1 note

·

View note

Text

https://www.futureelectronics.com/p/semiconductors--Led-lighting-components--led-driver-modules-rev--constant-current-acdc-led-drivers/esd-240s660dt-inventronics-2179709

Led power supply, LED driver chip, LED Lighting, Replacement led Driver

277 - 480Vac, 240W, 462 - 6600mA, 19-52V, [0-10V, PWM...], IP67 LED Driver

#Inventronics#ESD-240S660DT#Constant Current AC/DC LED Drivers#power supply#chip#LED Lighting#Replacement led Driver#Unregulated DC voltage#Replacement led#led power supply#fixtures#Modules#Led driver circuit#voltage driven devices

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--esd-protection/smda05-tbt-semtech-3008745

Circuit Protection, ESD Protection & Diode Arrays, SMDA05.TBT, Semtech

SMDA Series 11 V 400 pF Uni-Directional Surface Mount TVS Diode Array - SOIC-8

#Circuit Protection#ESD Protection & Diode Arrays#SMDA05.TBT#Semtech#equipment#array#Uni-Directional Surface Mount#Circuit Protection Devices#Discharge tubes#power supply#components#Diode Array devices

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--esd-protection/usblc6-2sc6-stmicroelectronics-7967441

What is ESD protection, Diode Array devices, esd protection circuit

USBLC6 Series 2 Line 6 V Uni / - SOT-23-6

#STMicroelectronics#USBLC6-2SC6#ESD Protection & Diode Arrays#Solid state relays#Protection equipment#Diode Array devices#esd protection circuit#Bi-Directional ESD Protection#Circuit Protection Devices#Power relay

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--circuit-protection--esd-protection/bat54swfilm-stmicroelectronics-4009193

STMicroelectronics, BAT54SWFILM, ESD Protection & Diode Arrays

BAT54 Series 300 mA 0.9 V Small Signal Schottky Rectifier

#STMicroelectronics#BAT54SWFILM#ESD Protection & Diode Arrays#Circuit Protection Devices#ESD protection diode circuit#power clam#ESD circuits#esd clamp circuit#diodes#High-voltage ESD entering#ESD protection arrays#esd power clamp

1 note

·

View note

Text

BAT54 Series: The Tiny Star Guarding Our Tech Planets

A Meeting in the Circuit Desert

When I first wandered into the desert of old circuit boards and forgotten gadgets, I thought all diodes were like the ones I’d seen—loud, flashy, and eager to shout about their power. But then I spotted it: a small, unassuming shape, half-buried in sand, smaller than a Tic Tac.

“You’re… very small,” I said, kneeling. “And you’re a child who talks to diodes,” it replied, its surface glinting faintly. “But some stars are brightest when they’re tiny. Ask the fox.”

1. What Is a BAT54? (Not a Villain, Just a Guardian)

This wasn’t just silicon and metal—it was a BAT54 series diode, a Schottky hero in an SOT-23 suit. Let me decode its story:

Variants: BAT54, BAT54A, BAT54C, BAT54S. Each is like a different flower on a single planet—same roots, unique blooms.

Specs:

Voltage: 30-40V reverse—laughs at your Wi-Fi rage, steadier than a baobab’s trunk.

Speed: 5-15ns switching—faster than the fox darting across the desert.

Low Drop: 0.3-0.8V forward voltage—sips power like a hummingbird, not a thirsty camel.

Size: Smaller than a Tic Tac, tougher than Monday mornings.

Fun Fact: Engineers call it the “Tech Cockroach.” It survives toddler tantrums, Martian dust, and even your “quick fix” with a butter knife. Volcanoes? It shrugs.

“Why so tough?” I asked. “Because the universe needs guardians,” it said. “Even small ones.”

2. Tiny, But Mightier Than Most

On its home planet (Earth), the BAT54 isn’t just a diode—it’s a secret. While flashy chips flex AI muscles, this $0.05 star does the real work:

Speed: 5ns (Usain Bolt mode) vs. generic diodes’ 100ns (sloth energy). It’s the fox to their tortoise.

Efficiency: 0.3V voltage drop (sipping power) vs. 0.7V (guzzling like a cactus in rain).

Price: $0.05 (change from a latte) vs. $0.02 (penny-pincher bait). Worth every cent.

“Why not be bigger?” I asked. “Big things break,” it said. “Tiny things fit. In smartwatches. In pacemakers. In Mars rovers.”

3. The Guardian of a Thousand Planets

From your wrist to the stars, the BAT54 guards:

Consumer Tech (Your Daily Planet): Powers smartwatches that outlast your gym motivation. Survives TV remote juice spills (because couch potatoes are ruthless). It’s the invisible hand keeping your world ticking.

Industrial & Medical (The Healer’s Planet): In pacemakers, it keeps hearts steady as a Pensieve. In factory robots, it works 24/7 without complaining—no unionizing, just loyalty.

Space & Automotive (The Cosmic Planet): In satellites, it laughs at cosmic radiation (SD cards cry). In EVs, it stops Teslas from becoming fire memes. Even Elon needs its magic.

Retro Gaming (The Nostalgia Planet): Saves your God of War progress in PSP mods. RIP UMD discs, but the BAT54? It remembers.

“Do you get lonely?” I asked. “No,” it said. “I’m everywhere. In your watch, in your car, in the stars. Loneliness is for roses that forget they’re loved.”

4. The Secret Sauce: Clamping & Protecting

The BAT54S (two diodes in one) is the fox of the bunch—clever, quick, and a master of boundaries.

Voltage Clamping: Limits spikes to 0.7V—no “fried microcontroller” surprises. It’s like a fence around a garden, keeping storms out.

Reverse Polarity Protection: Stops your DIY project from becoming a smoke machine. Think of it as a Protego shield for circuits.

Pro Tip: Use it for ESD protection. Static shock isn’t a personality trait—it’s just bad manners.

5. How to Find Your BAT54 (Avoid the Baobab Sellers)

In 2025, choose wisely—no dodgy baobab sellers:

Legit Sources: Digi-Key, Ersa Electronics, or eBay sellers with 4.9 stars (the ones who water their roses).

Price Alert: Generic diodes cost $0.02, but they’re like unwatered cacti—prickly and short-lived. BAT54? $0.05, but it’s a star, not a pebble.

Roast Alert: Generic Diode: “I’m cheaper!” BAT54: “I’m in space. You’re in a gas station flashlight. Bye.” 🚀

The Secret of the Tiny Star

The BAT54 isn’t flashy. It doesn’t need a name in lights or a viral meme. It’s the kind of friend you remember when your TV remote works, or your pacemaker ticks, or a Mars rover sends back photos.

“What makes you special?” I asked, as I left. It didn’t answer. It just sat there, quiet as the desert, as the stars, as time itself.

And I realized—some stars don’t need to be big. They just need to shine.

Written by a wanderer who once mistook a BAT54 for a Tic Tac. (Spoiler: It didn’t taste good. But it powered a toy robot. Close enough.)

🌵 You become responsible, forever, for the stars you once overlooked.

1 note

·

View note

Text

Before Learning This Trick, I Burned 3 MOSFETs

It's not voltage. It's not current. It's heat—the silent killer.

Three MOSFETs gone in two weeks. I thought I had the specs nailed: Rdson looked low, Vds was comfortably within range, and the datasheet said the part could handle 30A. So what went wrong?

As I painfully learned, the answer lies in what datasheets don't always highlight upfront: thermal dynamics under switching conditions.

🔍 The Hidden Enemies: Switching Losses + Thermal Bottlenecks

In switch-mode power designs—whether DC-DC converters, ESCs, or battery chargers—it's not just about Rdson.

Here's what gets overlooked:

Qg (Gate Charge): High gate charge leads to longer switching transitions → more heat.

Tj (max): Even if your MOSFET technically handles 30A, reliability plummets once junction temp creeps above 125–150°C.

PCB Layout: Without good thermal vias or pad design, heat can't escape.

Yes, all these reach their limits long before you hit maximum current ratings.

I remember the third failure vividly—debugging a 400W solar inverter prototype. The scope showed a steady 15A, well below 30A, but the heatsink was scalding to touch. Prying open the enclosure revealed charred solder joints on the MOSFET pins—a classic sign of thermal runaway.

🛠 The Fix: What to Check Before Power-Up

This is my survival checklist now:

✅ Low Qg: Reduces high-frequency switching losses. Above 100kHz, every 10nC increase in Qg adds roughly 2μJ of per-cycle loss.

✅ Package Thermal Resistance (RθJA): Critically important in TO252, DFN types.

✅ Reverse Recovery Charge (Qrr): Impacts diode switching behavior.

✅ Beyond Max Current—check thermal derating curves @100°C ambient.

💡 Scenario-Specific Solutions

Industrial Control Power (200-500W):

Prioritize low Qg in TO252 packages. Pair with 4-layer PCBs and at least 8x 0.3mm thermal vias under the pad.

Motor Drive Circuits:

Focus on Qrr specs—opt for fast-recovery MOSFETs. Shorten power loop lengths in layout to reduce stray inductance.

Portable Device Power:

Seek DFN packages with RθJA <40°C/W. Consider local potting for enhanced heat dissipation when needed.

What I Use Now (And Why)

After research, I switched to VBsemi's VBE16R07S, an N-channel MOSFET in TO252 package:

Voltage: 600V (covers most industrial bus voltages)

Qg: A low 18nC (typ) cuts switching losses by 40% vs my previous part at 50kHz.

Rth(j-a): 75°C/W—excellent for TO252, keeping junction temps under 100°C with proper PCB design.

Built for rugged operation in 200–400W converters, with built-in ESD protection for safer debugging.

No burnout since the switch—just stable performance. Last week's 48-hour full-load test maxed out at 92°C junction temp, well below the 125°C threshold.

👉 Check the VBE16R07S Datasheet Here

📩 Join the Discussion:

Ever had a MOSFET fail mysteriously? What application were you working on? What troubleshooting steps did you take? Share your story below. For more practical design insights, subscribe to my weekly updates. Or join our tech chat group to discuss MOSFET selection and application tips with fellow engineers.

#semiconductor#youtube#mosfet#electronics#technology#circuit#electronic#munich#mosfets#popular science animation

0 notes

Text

Soldering Station – Why Is It Essential in Modern Electronics?

Introduction to Soldering Stations

Soldering stations play a crucial role in modern electronics work, offering enhanced control and precision during soldering tasks. Unlike basic soldering irons, these stations combine variable temperature control with versatile tools, making them ideal for hobbyists, technicians, and engineers alike. Whether you're working on microcontrollers, sensors, or connectors, having a high-quality soldering station ensures consistent performance and safety. As the demand for compact and complex circuits grows, so does the importance of reliable soldering solutions.

What Makes a Soldering Station Different?

Soldering stations are more advanced than traditional soldering irons. They consist of a control unit and a detachable soldering iron. The control unit allows for better thermal regulation and safety features, making them suitable for sensitive components like LEDs, capacitors, and microprocessors. Moreover, some stations are compatible with hot air guns and desoldering tools, offering a full-service solution for electronics repair and development.

Types of Soldering Stations

Analog Soldering Stations

Offer manual temperature control via a dial

Simple and affordable, suitable for basic electronics

Ideal for working with fuses, cables, and switches

Digital Soldering Stations

Provide precise temperature settings using digital displays

Great for delicate work involving sensors and microcontrollers

Often include safety features like automatic shut-off

Hot Air Rework Stations

Used for surface-mount devices and rework tasks

Include nozzles for controlled air flow

Useful for tasks involving thermal pads and oils

Soldering and Desoldering Stations

Combine soldering and removal features

Essential for reworking connectors and contactors

Reduce time spent on complex circuit boards

Key Features of a Good Soldering Station

Temperature Control

Precise thermal adjustment prevents damage to sensitive components

Required when soldering microcontrollers, laptops, and electronics

Interchangeable Tips

Compatible with various tip shapes for different jobs

Useful when working with capacitors, fuses, or grips

Ergonomic Design

Comfortable grips reduce hand fatigue during long sessions

Enhances control while handling small connectors or controllers

Safety Measures

Built-in grounding and static protection

Ensures safe usage around delicate electronics and switches

Accessories and Add-ons

Comes with stands, sponge holders, and cleaning kits

Supports maintenance while working with oils or thermal compounds

Benefits of Using a Soldering Station

Improved Soldering Quality

Controlled heat leads to cleaner joints

Reduces the risk of cold solder joints in microprocessors and LEDs

Time Efficiency

Quick heat-up and stable performance save time

Ideal for repetitive tasks involving controllers and cables

Versatility in Application

Suitable for various materials and sizes

Works well across a range of tasks, including repairing laptops and fuses

Enhanced Safety

Auto shut-off and ESD-safe designs protect both user and equipment

Provides extra assurance when handling sensors and capacitors

Common Applications of Soldering Stations

Electronics Repair

Fixing printed circuit boards (PCBs)

Replacing components like resistors, LEDs, and microcontrollers

Prototype Development

Essential during the design phase of controllers and sensors

Enables easy updates and modifications

Educational Use

Used in training and academic labs

Helps students understand the practical use of tools and electronics

Industrial Maintenance

Maintaining automation systems involving contactors and switches

Supports professional-grade repairs with thermal efficiency

Choosing the Right Soldering Station

Power Rating

Higher wattage (70W–100W) suits industrial tasks

Lower wattage is fine for DIY electronics and light use

Temperature Range

Choose models with a wide range (200°C–480°C)

Important when soldering diverse components like cables and thermal pads

Brand Reliability

Look for trusted brands with a strong reputation in tools and electronics

Ensures quality results and long-term use

Budget Considerations

Analog models are cost-effective for basic needs

Digital or hybrid models offer more precision at a higher cost

Maintenance Tips for Soldering Stations

Tip Cleaning

Use brass wool or wet sponges for regular cleaning

Prevents oxidation and ensures heat transfer

Proper Storage

Always place the iron in the stand when not in use

Avoid leaving it powered on unattended

Tip Replacement

Change worn-out tips to maintain quality

Ensure compatibility with controllers and contactors

Calibration

Periodically check temperature accuracy

Crucial for delicate components like microprocessors and capacitors

Final Thoughts

A soldering station is more than just a tool—it's a gateway to precision, control, and creativity in electronics. From professional technicians to DIY hobbyists, this essential device enhances the quality and reliability of your work. With adjustable thermal settings, ergonomic tools, and safety features, soldering stations simplify complex tasks involving connectors, fuses, sensors, and more.

0 notes

Text

Antistatic Foam Is Essential For Circuit Board Protection

Antistatic Foam is a fabric designed to prevent the buildup of static power. Commonly utilized in packaging and protective programs, it allows shield touchy electronic additives from electrostatic discharge (ESD). The foam is usually made from polyurethane or polyethylene, providing both cushioning and static protection in transit or storage.

0 notes

Text

Robots' Body --- Why Does the Mechanical Arm "Malfunction"? The Invisible Pit of Electromagnetic Interference, and Leiditech's Solution to Fix It!

High-speed robotic operations generate heat that risks controller crashes. Leiditech’s solution integrates:

l Intelligent temperature-controlled fan drives with real-time speed adjustment, reducing noise by 30% and energy consumption by 20%.

Flickering LEDs cause operational errors. Leiditech’s design ensures:

l A low-power drive circuit paired with the SM5819WS diode to stabilize display signals and reduce power waste.

Delayed or muffled alarms waste critical response time. Leiditech’s solution delivers:

l An optimized PWM-driven circuit with the SM5819WS diode, enabling 0.1-second alarm response.

Industrial EMI often causes RS485 packet loss. Leiditech’s dual-protection design includes:

l The PCI0420T-142-N common-mode choke to suppress differential-mode noise.

Gigabit Ethernet stability is critical for robotic control. Leiditech’s solution features:

l The 3R090–5S gas discharge tube (≤2pF capacitance) for surge protection, ensuring gigabit compatibility.

Static discharge during UART hot-plugging risks MCU failure. Leiditech’s protection includes:

l 3.3V lines: ESDA33CP30 (22kV contact/25kV air discharge, 12pF capacitance).

Core Value: Precision Engineering

With 15 years of industrial EMC expertise, Leiditech optimizes component selection and circuit design to minimize faults, extend service life, and boost operational efficiency. From thermal management to communication, every module is engineered for rugged EMI resilience.

Leiditech Electronics is committed to becoming a leading brand in electromagnetic compatibility (EMC) solutions and component supply. We offer a wide range of products, including ESD, TVS, TSS, GDT, MOV, MOSFET, Zener diodes, and inductors. With an experienced R&D team, we provide personalized customization services to deliver the highest quality EMC solutions tailored to our customers’ needs.

#Leiditech #RoboticAutomation #EMCsolutions #IndustrialElectronics #ESDProtection #FactoryAutomation #MechanicalArm #EngineeringInnovation #RS485 #EthernetStability #ElectromagneticInterference #SmartManufacturing #TechBlog #IndustrialSolutions

0 notes

Text

Common Electrical Issues in Commercial Marinas and How to Avoid Them

Marinas are complex environments where water, electricity, and changing weather converge. That makes them uniquely vulnerable to electrical issues that, if ignored, can lead to fires, equipment failures, or even fatal accidents such as electric shock drowning (ESD). Preventing these problems starts with understanding the most common risks and having a trusted partner in marina electrical services.

At Weisman Electric Co., we work with commercial marina owners across Maryland to inspect, repair, and modernize their waterfront electrical systems. We commonly encounter:

Corroded or deteriorated wiring exposed to salt and moisture

Improperly grounded equipment or pedestals

Overloaded shore power systems

Inconsistent voltage delivery

These problems are code violations, and they’re serious safety risks. Our team provides thorough system audits and commercial electric repair services tailored to the demanding needs of marina operations. We install weather-resistant materials, GFCI-protected circuits, proper grounding systems, and energy-efficient lighting.

Regular electrical maintenance helps prevent costly liability issues and downtime. If your marina hasn’t had an inspection in over a year, you may be operating with outdated or unsafe infrastructure. We’re here to help you fix that before problems arise.Curious about how to protect your marina and its visitors? Check out our full blog here

0 notes

Text

KT148A Voice Chip - Core Solution for Smart Voice Interaction in Electronic Pill Boxes

I. Core Chip Features: Voice Capabilities Tailored for Electronic Pill Boxes

As a 32-bit DSP voice chip, KT148A, with its SOP8 compact package (4.7mm×5.1mm) and cost-effectiveness, is an ideal choice for voice interaction in electronic pill boxes. Its core parameters are fully adapted to medical device requirements:

Storage and Battery Life Balance: Built-in 420KByte storage supports up to 420 seconds of voice content (at 8KHz sampling rate), capable of storing multi-language medication reminders (e.g., "Time to take medicine", "Insufficient medicine"); standby current is as low as 25uA, and ultra-low voltage mode (triggered by F0 command) consumes only 1.7uA, enabling over 6 months of battery life with a button cell.

Hardware Driving Capability: 16-bit PWM output directly drives an 8Ω/0.5W speaker without an external power amplifier; operating voltage ranges from 2.0V to 5.5V, compatible with lithium batteries (3.3V-4.2V) and dry cell power supplies.

Industrial-grade Reliability: Operating temperature -40℃~85℃, with 4kV ESD contact discharge resistance, meeting the stability requirements of medical devices.

II. Key Applications in Electronic Pill Boxes

Precise Medication Reminders Through the one-wire communication protocol (6ms low-level start signal + 8-bit data transmission), KT148A can receive MCU trigger commands and play voice prompts at preset times. It supports "interrupt playback" - if the user does not respond promptly, the F2 command can realize cyclic reminders until confirmation.

Real-time Operation Feedback Combined with the pill box's lid sensor and margin detection circuit, KT148A can output scenario-based voice in real-time:

Flexible Voice Customization Users can update voice content independently via PC tools: convert WAV files to F1A format, connect to the chip's PB1/RX pin via a USB-TTL module (CH340G), and complete programming in download mode (Pin5 grounded during power-up) without professional equipment. Supports 224 voice addresses, expandable to more via F4 command (e.g., multi-language versions).

III. Advantages in Development and Mass Production

Minimal Circuit Design: The reference circuit only requires an external 105 filter capacitor (VDDIO pin) and 1K current-limiting resistor (communication pin), reducing PCB area requirements.

Quick Debugging Support: Provides logic analyzer waveform examples (e.g., 0x01 command waveform) and MCU reference code (one-wire sending function) to shorten development cycles.

Mass Production Guarantee: Supports batch pre-programming of voice content, and provides test boards (with 8Ω speakers) for functional verification before delivery, with a defect rate below 0.1%.

1 note

·

View note

Text

Multilayer Varistor Market Gains Traction with Surge in Portable Devices

The global Multilayer Varistor (MLV) Market is on a robust growth trajectory, with a market value of US$ 0.5 Bn in 2024 projected to reach US$ 1.1 Bn by the end of 2035, expanding at a steady CAGR of 6.9% from 2025 to 2035. As modern electronic systems become increasingly sophisticated, the role of protective components like multilayer varistors has become crucial in ensuring device safety, longevity, and compliance with electromagnetic compatibility (EMC) regulations.

The multilayer varistor market is poised for significant expansion due to multiple converging trends—widespread adoption of electric vehicles (EVs), the proliferation of smart grids, increased penetration of Internet of Things (IoT) devices, and accelerating 5G deployment. Multilayer varistors, being compact, efficient, and capable of protecting delicate circuitry from voltage surges, are indispensable in these high-tech environments.

Asia-Pacific, particularly East Asia, remains the manufacturing and innovation hub for MLVs, thanks to a strong industrial base in China, Taiwan, and Japan. However, markets in Europe and North America are also gaining traction, driven by stringent EMC standards and rapid expansion of EV and renewable energy infrastructure.

Market Overview

Multilayer varistors are vital electroceramic components made from alternating layers of metal oxide and ceramic materials, primarily zinc oxide. These layers provide non-linear voltage-current characteristics, enabling them to absorb excessive transient voltages. The result is superior protection for sensitive electronic devices against electrostatic discharge (ESD), electrical overstress (EOS), and lightning-induced surges.

Their compact design, low leakage current, and high surge energy absorption make them ideal for consumer electronics, automotive systems, medical devices, industrial machinery, and telecommunication infrastructure.

Market Drivers

1. Boom in Consumer Electronics

The rising global appetite for AI-powered electronics—including smartphones, smart TVs, and wearables—has created unprecedented demand for compact, high-performance protection components. India, for example, is poised to hit US$ 300 Bn in electronics output by 2025–26, according to the Ministry of Electronics and Information Technology (MeitY). Taiwan, another major player, reported a 11.2% rise in export orders for electronics in October 2024, touching US$ 55.4 Bn.

These trends underscore the critical need for MLVs in protecting AI-enabled, high-frequency electronic circuits from transient electrical threats, ensuring consistent performance and durability.

2. Telecommunications Infrastructure Expansion

Next-gen telecom technologies like 5G require precision-engineered electronics capable of high data throughput. MLVs are essential here, safeguarding base stations, networking hardware, and power distribution units. Government investments in digital infrastructure globally are reinforcing this demand:

India announced a ₹26,316 crore investment for expanding 4G connectivity to 6,279 rural villages.

Australia committed US$ 3.8 Bn to upgrade the NBN, including laying 23,000 km of fiber-optic cable.

As digital connectivity deepens across the globe, MLVs will continue to be integrated into critical telecommunication equipment.

Segmental Analysis: Voltage Range

The "Up to 30 V" segment led the market in 2024, commanding a 32.8% share, driven by demand for low-voltage protection in:

Smartphones and tablets

Smart home devices and wearables

Compact industrial electronics

Electric and hybrid vehicles

As miniaturization, power efficiency, and high-speed performance become top design priorities, MLVs in the sub-30V range offer ideal protective solutions.

Regional Outlook

East Asia: Global Powerhouse

East Asia, led by China, Japan, and South Korea, accounted for 38.0% of the global market share in 2024. This leadership stems from:

Advanced R&D capabilities

Abundant raw material supply

Highly automated and cost-effective manufacturing

Strategic public-private partnerships

The region’s dominance is further reinforced by rising adoption of MLVs in automotive electronics, consumer gadgets, and industrial automation systems. Ongoing innovation in miniaturization and multilayer stacking techniques gives East Asia a clear technological edge.

Europe and North America: Rising to the Occasion

Both regions are expected to witness steady growth due to:

Stricter EMC regulations

Strong presence of premium electronics brands

Increasing investments in EVs, aerospace, and industrial automation

Adoption of renewable energy and grid modernization programs

Key Players & Industry Developments

The MLV market is characterized by intense competition, technological innovation, and strategic partnerships. Leading manufacturers include:

Bourns, Inc.

KOA Speer Electronics Ltd.

Panasonic Corporation

TDK Corporation

KYOCERA AVX Components

Littelfuse, Inc.

Vishay Intertechnology, Inc.

AEM Components, Inc.

Walsin Technology Corp.

MARUWA Co., Ltd.

Recent Developments:

KOA Speer Electronics (July 2024) launched the NV73S series, a metal oxide varistor capable of handling up to 6,000 A surge current, five times the capacity of its predecessor. The product addresses ESD, EMI, and motor surge protection in compact form factors.

Bourns, Inc. (January 2024) introduced the BVR Series of low-voltage MLVs, designed for superior transient absorption and optimized power dissipation. These are tailored for low-voltage AI and IoT devices.

These product introductions reflect a broader trend of innovation in materials, form factor optimization, and performance enhancement.

Challenges and Opportunities

Challenges:

Raw Material Price Volatility: The fluctuating prices of ceramics and metal oxides impact cost predictability for manufacturers.

Alternative Technologies: Competing solutions like transient voltage suppression (TVS) diodes pose a challenge in specific applications.

Opportunities:

Renewable Energy Sector: MLVs can play a pivotal role in surge protection for solar inverters, wind turbines, and smart grids.

Healthcare Devices: The demand for safe, compact surge protection in diagnostic and monitoring devices opens new frontiers.

Automotive Electrification: EVs and ADAS (advanced driver-assistance systems) require robust, miniaturized protection against electrical surges.

Conclusion

The multilayer varistor market is entering a phase of dynamic growth, fueled by an electrified, connected, and miniaturized world. With East Asia leading manufacturing, and strong momentum building in Europe and North America, the global MLV landscape is evolving rapidly.

Ongoing investments in telecommunications, consumer electronics, electric mobility, and industrial automation are ensuring that multilayer varistors will remain central to the safe and efficient functioning of advanced electronic systems. For stakeholders, including component manufacturers, OEMs, and investors, the market offers lucrative opportunities driven by relentless innovation and expanding application diversity.

As we move toward 2035, MLVs are set to remain the frontline defense in an increasingly electrified and data-driven ecosystem.

0 notes

Text

Multi Purpose Diodes for ESD Protection Market: Share, Size, Trends, 2025–2032

Multi Purpose Diodes for ESD Protection Market, Global Outlook and Forecast 2025-2032

Multi Purpose Diodes for ESD Protection Market was valued at US$ 1.24 billion in 2024 and is projected to reach US$ 1.87 billion by 2032, at a CAGR of 5.43% during the forecast period 2025-2032

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=88022

MARKET INSIGHTS

The global Multi Purpose Diodes for ESD Protection Market was valued at US$ 1.24 billion in 2024 and is projected to reach US$ 1.87 billion by 2032, at a CAGR of 5.43% during the forecast period 2025-2032.

Multi Purpose Diodes for ESD Protection are semiconductor devices designed to safeguard electronic circuits from electrostatic discharge (ESD) and transient voltage events. These diodes function as voltage clamps, diverting excess current away from sensitive components to prevent damage. The product range includes TVS diodes, switching diodes, rectifier diodes, and specialized variants catering to different voltage thresholds and response times. These components are critical for modern electronics where miniaturization increases ESD sensitivity.

The market growth is driven by increasing adoption in consumer electronics, automotive applications, and industrial automation systems. Rising demand for compact circuit protection solutions in 5G infrastructure and IoT devices further accelerates adoption. Key industry players like Infineon, Nexperia, and STMicroelectronics are expanding their portfolios with advanced low-capacitance diodes optimized for high-speed data lines. The U.S. accounts for approximately 28% of global demand, while China’s market is growing at 9.2% CAGR through 2031, fueled by local semiconductor manufacturing expansion.

List of Key Multi-Purpose Diodes for ESD Protection Companies

Infineon Technologies AG (Germany)

Nexperia BV (Netherlands)

SEMTECH Corporation (U.S.)

Vishay Intertechnology (U.S.)

Littelfuse, Inc. (U.S.)

BrightKing (China)

Amazing Microelectronic Corp (Taiwan)

STMicroelectronics (Switzerland)

ON Semiconductor (U.S.)

OmniVision Technologies (U.S.)

WAYON (China)

Prisemi (China)

Bourns, Inc. (U.S.)

LAN technology (China)

ANOVA (China)

MDE Semiconductor (U.S.)

TOSHIBA Electronic Devices (Japan)

UN Semiconductor (China)

PROTEK Devices (U.S.)

INPAQ Technology (China)

EIC Semiconductor (U.S.)

Segment Analysis:

By Type

TVS Diodes Segment Dominates the Market Due to High Demand for Robust ESD Protection

The market is segmented based on type into:

TVS Diodes

Subtypes: Uni-directional, Bi-directional, and others

Switching Diode

Rectifier Diode

Others

By Application

Automotive Segment Leads Due to Growing Adoption of Advanced Electronics in Vehicles

The market is segmented based on application into:

Automobile

Industrial

Power Supply

Military/Aerospace

Telecommunications

Others

Regional Analysis: Multi-Purpose Diodes for ESD Protection Market

North America The North American market for multi-purpose diodes for ESD protection is driven by high demand from the telecommunications, automotive, and aerospace sectors. With stringent safety and reliability standards, particularly in the U.S., industries prioritize high-performance ESD protection solutions. The rapid expansion of 5G infrastructure and electric vehicle (EV) adoption further fuels demand. Leading semiconductor manufacturers like Littelfuse and ON Semiconductor dominate the market, supported by technological innovation and regulatory compliance. However, supply chain disruptions and semiconductor shortages have recently impacted production timelines, increasing lead times for critical components.

Europe Europe’s market is shaped by strong industrial and automotive sectors, with Germany and the U.K. as key contributors. The European Union’s emphasis on environmental sustainability and advanced manufacturing drives adoption of diodes with low power consumption and high efficiency. Companies like Infineon and STMicroelectronics lead in innovation, particularly in automotive and IoT applications. However, the market faces challenges due to regulatory complexities and the need for RoHS-compliant components. The rise in renewable energy projects also creates opportunities for ESD protection diodes in power supply systems, boosting regional demand.

Asia-Pacific Asia-Pacific is the largest and fastest-growing market, led by China, Japan, and South Korea, owing to massive electronics manufacturing and industrial automation investments. The region benefits from cost-effective production capabilities and a robust semiconductor supply chain. TVS diodes are particularly in demand due to their widespread use in consumer electronics, including smartphones and wearables. However, competition is fierce, with local players like WAYON and BrightKing challenging global leaders. While affordability drives sales, quality concerns and intellectual property issues remain challenges for market expansion.

South America The market in South America is developing, with Brazil and Argentina as primary growth drivers. The increasing adoption of telecommunications infrastructure and industrial automation is boosting demand for ESD protection diodes. However, economic instability and limited local semiconductor manufacturing restrict market growth, making the region heavily reliant on imports. Despite these challenges, the renewable energy sector offers potential opportunities as governments invest in wind and solar power projects, requiring reliable power protection solutions.

Middle East & Africa This region exhibits gradual growth, supported by telecommunications expansion and increasing industrial investments in the UAE, Saudi Arabia, and South Africa. The demand for ESD protection diodes is rising in power supply and military/aerospace applications. However, the market remains constrained by limited local production, supply chain inefficiencies, and price sensitivity. Long-term growth potential exists if regional governments prioritize infrastructure development and regulatory frameworks to attract international semiconductor suppliers.

MARKET DYNAMICS

As telecommunications companies prepare for 6G deployment, the need for ESD protection capable of handling frequencies above 100GHz is creating significant opportunities. Early development cycles show that 6G components will require protection diodes with capacitance below 0.1pF while maintaining robust clamping performance. Several leading manufacturers have already announced development programs targeting these specifications, with prototype availability expected within the next two years. This technological evolution represents a potential market expansion worth $800M annually by 2028.

The AI revolution in semiconductor design is enabling more sophisticated ESD protection strategies. Machine learning algorithms are being used to optimize diode performance for specific application scenarios, creating opportunities for customized solutions. In automotive applications, intelligent ESD protection systems that adapt to changing environmental conditions are gaining traction, with adoption rates growing 40% year-over-year in advanced driver assistance systems. This trend is expected to accelerate as autonomous vehicle development progresses.

The semiconductor industry’s ongoing supply chain challenges are particularly acute for specialized components like multi-purpose diodes. Lead times for certain diode variants have extended beyond 52 weeks, forcing OEMs to redesign circuits or accept performance compromises. The situation is exacerbated by the concentration of specialty wafer production in limited geographic regions. While the industry is working to diversify manufacturing bases, establishing new capacity for specialized semiconductor processes remains a multi-year endeavor.

Modern electronic designs require ESD protection that doesn’t compromise signal integrity or power efficiency. Balancing these competing requirements has become increasingly difficult as data rates climb into the multi-gigabit range. A recent industry survey revealed that 68% of design engineers cite ESD protection integration as a significant challenge in high-speed interface design. This complexity is driving demand for application-specific diode arrays and integrated protection solutions, though these often carry higher price tags that impact project budgets.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=88022

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Multi Purpose Diodes for ESD Protection Market?

Which key companies operate in this market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:

https://semiconductorblogs21.blogspot.com/2025/07/global-market-for-gas-scrubbers-for.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/transistor-outline-to-package-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/force-sensing-capacitor-market-size.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/video-adapter-market-opportunities.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/storage-adapters-market-segmentation.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/emi-suppression-filters-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/07/cpu-embedded-wireless-lan-market-demand_8.html

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Mastering Disassembly and Assembly Techniques in Mobile Repairing

In the world of smartphones, breakdowns and damages are common. A skilled mobile technician must know how to properly disassemble and assemble a mobile phone without causing damage to internal components. At our Mobile Repairing Institute, we place strong emphasis on mastering these essential techniques as part of our mobile repairing training course.

Why Are Disassembly and Assembly Skills Important?

Every mobile phone consists of delicate components like the motherboard, screen, battery, cameras, speakers, and connectors. Improper handling during disassembly can damage these parts, making the repair more difficult or even impossible. Assembly is just as critical — poor reassembly can lead to loose connections, dust accumulation, and even device failure.

🔧 Essential Tools for Disassembly and Assembly

In our practical classes at the mobile repairing institute, students are trained to use:

Precision screwdrivers

Plastic pry tools and spudgers

Anti-static tweezers

Suction cups

Magnetic project mats

ESD protection gear

Understanding each tool's role helps prevent damage during mobile repair.

🔍 Step-by-Step Disassembly Process

Here’s a simplified version of how we teach mobile disassembly in our classes:

Power Off the Device Always begin by turning off the phone to avoid short circuits.

Remove SIM and SD Card Trays Eject these before opening the case to avoid breaking internal connections.

Unscrew the Back Panel Using appropriate screwdrivers, remove all visible screws while keeping track of each.

Open the Housing Safely Use pry tools to gently lift the back cover. Never forcefully pull or twist.

Disconnect Battery First Always disconnect the battery before touching any other internal components.

Disconnect Cables and Modules Carefully detach display, charging port, and other connectors using tweezers or spudgers.

Remove Components Sequentially We teach students to remove and label parts in the correct order to ensure easy reassembly.

🛠️ Assembly Tips for Mobile Technicians

Once repairs or inspections are done, reassembly begins. Our mobile repairing training program teaches students:

Double-check connections before screwing anything back

Clean internal parts using isopropyl alcohol and a brush

Ensure camera lenses and sensors are dust-free

Apply the right amount of pressure while placing back the screen

Test the device before completely closing the housing

📚 Learn From Experts at Our Mobile Repairing Institute

At our Mobile Repairing Institute in Kochi, students receive hands-on experience under expert guidance. Whether you're a beginner or looking to upgrade your skills, our course offers:

Real device training (Android & iPhone)

Latest disassembly techniques (including Edge Display and Foldables)

Practical sessions for troubleshooting

Industry-recognized certifications

🚀 Start Your Mobile Repairing Career Today

Disassembly and assembly techniques are just the beginning. Our mobile repairing training prepares students for careers in service centers, retail shops, or their own repair businesses.

👉 Ready to master the art of mobile repairing? Join our expert-led training program today. 🔗 Visit: https://nexgeninstitute.in

0 notes