#Electric Tube Expansion System Machine

Explore tagged Tumblr posts

Text

Electric Tube Cleaner | Subzero Solutions

Subzero Solutions provides quality tools and service to the heat exchangers, boiler manufacturing, and re-tubing industry. We are Manufacturer of tube cleaning machine in india. Our Electric Tube Cleaner represents our most commonly used package for cleaning chiller tubes. Subzero Solutions offers a wide range of tube cleaning brush to match your specific tube cleaning need. There are various types of brushes. nylon brush, brass brush, stainless steel brush. We Subzero manufactures pneumatic tube cleaner which is shock resistance- especially for distillery plant & where electric equipment is hazardous. machine speed/torque can be controlled as per the application. For more details visit our site.

#Electric Tube Cleaner#Pneumatic Tube Cleaner#Manufacturer of Tube Cleaning Machine In India#Electric Tube Expansion System Machine

0 notes

Text

Copper Alloys Market Disruption: How New Tech Is Changing Everything

Rising Demand and Transformative Growth in the Global Copper Alloys Market

The global copper alloys market is experiencing an era of substantial expansion, projected to grow at a CAGR of 11.2% between 2024 and 2031. As the demand for high-performance, corrosion-resistant, and electrically conductive materials surges across sectors—particularly in electronics, construction, automotive, marine, aerospace, and renewable energy—copper alloys have emerged as indispensable components of modern industrial ecosystems.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40473-global-copper-alloys-market

Copper Alloys Market Dynamics Driving Growth:

Surging Electrical and Electronics Applications

The electronics and electrical segment remains the largest end-user of copper alloys, leveraging their exceptional conductivity, durability, and thermal management properties. Copper alloy wires, connectors, and terminals are vital in:

Smart grids and renewable energy systems

High-performance computing devices

Consumer electronics and telecom infrastructure

As the global transition to electric vehicles (EVs) and green power accelerates, the demand for copper alloys in EV batteries, charging systems, and powertrain architectures is poised for exponential growth.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40473-global-copper-alloys-market

Infrastructure Modernization and Construction Boom

Modern construction projects emphasize aesthetic appeal, longevity, and sustainability. Copper alloys—used in roofing, cladding, plumbing, and ornamental components—are at the core of smart infrastructure development across North America, Europe, and Asia-Pacific. Their low maintenance costs and resistance to weathering make them ideal for both residential and commercial applications.

Automotive and Marine Sector Momentum

In automotive manufacturing, copper alloys serve in radiators, bushings, connectors, and sensor housings, enhancing both performance and safety. Meanwhile, marine applications increasingly depend on copper-nickel and aluminum bronze for their superior seawater corrosion resistance, significantly reducing maintenance in ships, offshore structures, and desalination plants.

Strategic Copper Alloys Market Segmentation

By Alloy Type

Brass (Copper + Zinc)

Preferred for its machinability, strength, and aesthetic finish, brass finds extensive use in:

Plumbing fixtures

Musical instruments

Decorative hardware

Bronze (Copper + Tin)

A legacy alloy with exceptional wear resistance and strength, bronze is key to:

Sculptures

Bearings

Marine components

Copper-Nickel Alloys (Cu-Ni)

Known for superior corrosion resistance, especially in saltwater, Cu-Ni alloys are indispensable in:

Shipbuilding

Coinage

Heat exchangers

Nickel-Silver

This silver-like alloy offers high strength and visual appeal in:

Cutlery

Jewelry

Optical frames

Phosphor Bronze

Valued for elasticity and fatigue resistance, it's used in:

Electrical contacts

Fasteners

Precision springs

Aluminum Bronze

With superior tensile strength and oxidation resistance, it serves in:

Oil & gas valves

Aerospace fasteners

High-load bushings

Beryllium Copper (BeCu)

A high-performance alloy offering spark resistance and thermal stability for:

Explosive environments

Instrumentation tools

Aerospace connectors

By Product Form

Sheets & Plates: Construction and machinery

Bars & Rods: Automotive and electrical applications

Wires: Critical in power transmission and electronics

Tubes & Pipes: Plumbing, HVAC, industrial systems

Strips & Foils: Electrical connectors, precision electronics

Fittings: Used extensively in HVAC, plumbing, and electrical systems

Regional Copper Alloys Market Analysis

Asia-Pacific

China, India, Japan, and South Korea lead in both consumption and production.

Infrastructure growth, EV proliferation, and industrialization are major growth catalysts.

Dominant manufacturing hub for electronics and heavy machinery.

North America

The United States remains a technological innovator, particularly in aerospace, defense, and healthcare.

Emphasis on sustainable infrastructure and electric mobility is boosting demand.

Europe

Nations like Germany, France, and the UK drive demand through green energy adoption and precision engineering.

Strong focus on recyclability and eco-friendly materials.

Middle East and Africa

Rising construction activity and energy sector investments, especially in UAE and Saudi Arabia.

Marine and oilfield applications fueling growth in copper-nickel alloys.

South America

Brazil is a dominant player with strong construction and mining sectors.

Expanding urbanization fosters copper alloy usage in utilities and infrastructure.

Competitive Landscape

The copper alloys market is moderately consolidated with a blend of global giants and regional specialists. Key players are driving innovation through advanced metallurgy, sustainability initiatives, and expansion into high-growth regions.

Major Companies Include:

KME Germany GmbH

Wieland

Aurubis AG

Mueller Industries

Poongsan Corporation

NGK Insulators, Ltd.

Mitsubishi Materials Corporation

Hitachi High-Tech Analytical Science

Cadi Company, Inc.

Hussey Copper

Chase Brass and Copper Company, LLC

Metalminotti

Shri Manak Copper

Aviva Metals

Diehl Stiftung & Co. KG

Their strategies revolve around:

Geographic Expansion

Sustainable Recycling Techniques

Strategic Mergers and Acquisitions

R&D in High-Performance Alloys

Future Copper Alloys Market Outlook (2024–2031)

The trajectory of the copper alloy market is unequivocally upward. With clean energy adoption, urbanization, and industrial automation on the rise, demand for durable, conductive, and recyclable materials will only intensify. Copper alloys are perfectly positioned to meet these multi-industry needs, underscoring their role in the future of sustainable industrial materials.

Key Copper Alloys Market Growth Forecasts:

Widening use in EVs and renewable energy infrastructure

Surge in demand from healthcare and defense sectors

Expanded R&D investments in next-generation alloys

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40473-global-copper-alloys-market

Conclusion

The global copper alloys market is undergoing transformative growth, anchored in its unmatched versatility and performance across critical sectors. As industrial demands evolve toward sustainability, precision, and efficiency, copper alloys will remain central to powering tomorrow's innovations.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Enhancing Innovation with TipTop Composites: Your Trusted Carbon Fiber Supplies Partner

carbon fiber stands out as a true game-changer. Known for its exceptional strength-to-weight ratio, high stiffness, and resistance to corrosion, carbon fiber has become a staple in industries ranging from aerospace and automotive to sports equipment and construction. At the forefront of this revolution is TipTop Composites, a company dedicated to delivering high-quality carbon fiber supplies that meet the needs of both industrial giants and individual innovators.

The Rising Demand for Carbon Fiber Products

The adoption of carbon fiber materials is on a steep rise due to their ability to outperform traditional materials like steel and aluminum in various applications. Whether it's in the form of a carbon fiber pipe, carbon fiber tube, or sheets and laminates, these composites offer incredible design flexibility and structural performance. With sustainability and energy efficiency becoming crucial design parameters, carbon fiber provides a reliable solution that reduces weight without compromising strength or durability.

TipTop Composites: Excellence in Carbon Fiber Supply

TipTop Composites has carved a niche for itself by consistently delivering premium carbon fiber supplies to meet the complex requirements of high-performance applications. With a commitment to quality, precision, and customer satisfaction, TipTop has become a trusted name among engineers, designers, and manufacturers seeking the very best in composite materials.

What sets TipTop Composites apart is their comprehensive product range and a deep understanding of the unique characteristics of carbon fiber. Whether a project requires lightweight structural components or high-temperature-resistant materials, TipTop Composites provides tailored solutions using a variety of weaves, finishes, and resins to meet specific application demands.

Product Range: Precision Meets Performance

TipTop Composites offers an expansive selection of carbon fiber products, including:

Carbon Fiber Pipe: Designed for superior strength and minimal weight, carbon fiber pipes are commonly used in structural applications, exhaust systems, and support frameworks. These pipes offer resistance to fatigue and chemical damage, making them ideal for long-term use in demanding environments.

Carbon Fiber Tube: Available in both standard and custom diameters, carbon fiber tubes from TipTop Composites are favored in aerospace, robotics, and sports gear manufacturing. These tubes boast high stiffness, low weight, and excellent dimensional stability, making them ideal for load-bearing applications.

Carbon Fiber Tubing: A versatile product category, carbon fiber tubing is used across numerous sectors for its ease of machining, aesthetic appeal, and unmatched performance. From drone arms to camera rigs and automotive roll cages, carbon fiber tubing enhances both functionality and design.

Each of these product lines is manufactured with meticulous attention to detail, ensuring consistency, strength, and longevity.

Applications Across Industries

The superior properties of carbon fiber materials supplied by TipTop Composites make them suitable for a wide range of applications:

Aerospace: Carbon fiber’s low weight and high tensile strength make it indispensable in the aerospace sector. Components such as wing spars, control rods, and fuselage sections benefit significantly from TipTop’s quality supplies.

Automotive: With electric vehicles (EVs) and performance cars prioritizing weight reduction for better efficiency, TipTop’s carbon fiber tubing and pipes are ideal for body panels, chassis components, and aerodynamic elements.

Sports and Recreation: From bicycles to hockey sticks, the sports industry thrives on lightweight, durable materials. TipTop’s carbon fiber products enhance performance and user comfort in recreational gear.

Medical Devices: The non-magnetic and biocompatible nature of carbon fiber makes it suitable for imaging equipment, prosthetics, and surgical instruments.

Industrial Automation and Robotics: Carbon fiber tubes and pipes are used to reduce inertia in robotic arms and improve speed and precision in automated systems.

Commitment to Customization and Innovation

Understanding that no two projects are the same, TipTop Composites offers extensive customization options. Customers can specify dimensions, wall thicknesses, resin systems, and weave patterns to meet their exact needs. The company’s team of experienced engineers works closely with clients to develop prototypes, optimize designs, and deliver high-performance solutions that align perfectly with project goals.

Innovation is a cornerstone of TipTop’s operations. The company continues to invest in research and development to improve manufacturing processes, explore new resin systems, and create composite materials with even better performance characteristics. Their ability to adapt to the latest technological advancements ensures that clients always receive state-of-the-art products.

Quality You Can Rely On

TipTop Composites prides itself on stringent quality control measures at every stage of production. From raw material inspection to final product testing, the company ensures that all carbon fiber supplies meet international standards for strength, safety, and durability.

Their manufacturing facilities are equipped with cutting-edge technology, and all products undergo rigorous testing for mechanical properties, thermal stability, and environmental resistance. This dedication to quality ensures that clients receive materials that perform reliably even under the most challenging conditions.

Sustainability and Future Outlook

As industries shift toward greener, more sustainable practices, carbon fiber plays a critical role in reducing material waste and improving energy efficiency. TipTop Composites is committed to sustainable manufacturing, minimizing environmental impact through efficient resource use, waste reduction, and the incorporation of eco-friendly materials where possible.

Looking ahead, TipTop is poised to lead the next wave of innovation in composite materials. With growing applications in renewable energy, urban transportation, and infrastructure, the demand for carbon fiber tubing, pipes, and other composite elements will only continue to grow. TipTop Composites remains dedicated to supplying the cutting-edge materials that will shape the future of engineering and design.

Conclusion

Whether you are building the next-generation electric vehicle, designing a lightweight drone, or constructing high-performance sports equipment, TipTop Composites offers the carbon fiber solutions you need. With an extensive product lineup that includes carbon fiber pipe, carbon fiber tube, and carbon fiber tubing, backed by a commitment to quality and innovation, TipTop is the partner of choice for all your advanced material needs.

0 notes

Text

An Overview of Advanced Ceramics

Advanced ceramics can be divided into structural ceramics, tool ceramics, and functional ceramics according to their different uses.

Structural Ceramics

The main materials of structural ceramics are alumina (Al2O3), silicon nitride (Si3N4), silicon carbide (SiC), and hexagon boron nitride ceramics (BN).

Alumina (Al2O3)

The main composition is Al2O3, and the general content is more than 45%. Alumina ceramics have various excellent properties such as high-temperature resistance, corrosion resistance and high strength, which is 2~3 ordinary ceramics. However, alumina ceramics have the disadvantage of being brittle and unable to accept sudden changes in ambient temperature. Alumina ceramics are widely used as the crucible, engine spark plug, high-temperature refractory, thermocouple sleeve, sealing ring and so on.

Silicon nitride (Si3N4) ceramics

Si3N4 is the main component of silicon nitride ceramics, which is a kind of high-temperature ceramics with high strength, high hardness, abrasion resistance, corrosion resistance, and self-lubrication. The linear expansion coefficient of silicon nitride is the smallest among all kinds of ceramics, and it has excellent electrical insulation and radiation resistance. It has excellent corrosion resistance, and it can withstand the corrosion of various acids except the hydrofluoric acid, as well as alkali, corrosion of various metals. Silicon nitride ceramics can be used as high-temperature bearings, sealing rings used in corrosive media, thermocouple sleeves, and metal cutting tools.

Silicon carbide ceramics (SiC)

Silicon carbide ceramics are mainly composed of SiC, which is a kind of high-temperature ceramic with high strength and high hardness. When used in the high temperature of 1200 ℃ ~ 1400 ℃, silicon carbide ceramics can still maintain a high bending strength. In addition, silicon carbide ceramics also have good thermal conductivity, oxidation resistance, electrical conductivity, and high impact toughness. It is a good high-temperature structural material and can be used for rocket tail nozzle, thermocouple sleeve, furnace tube, and other high-temperature components.

Hexagonal boron nitride (h-BN)

The main composition of hexagonal boron nitride ceramics is BN, and the crystal structure is hexagonal crystal system. The structure and performance of hexagonal boron nitride ceramics are similar to graphite, so it is known as “White Graphite “. Hexagonal boron nitride ceramics are of low hardness and can be machined with self-lubricating properties, and they can also be made into self-lubricating high-temperature bearings and glass-forming molds.

Tool Ceramics

The main materials of tool ceramics are cemented carbide, natural diamond (diamond), cubic boron nitride (CBN), etc.

Cemented carbide

Carbides are mainly composed of carbides and binders. Carbides mainly include WC, TiC, TaC, NBC, VC, etc., and binders are mainly cobalt (Co). Compared with the tool steel, cemented carbide has a high hardness (87 ~ 91 HRA), good red hardness (1000 ℃) and excellent wear resistance. When used as a cutter, its cutting speed is 4~7 times higher than that of HSS, and its service life is 5~8 times higher. However, its disadvantages are high hardness, brittle, and difficult to be machined, so it is often made into a blade and welded on the tool rod for use. Carbide is mainly used for machining tools; Various dies, including drawing die, drawing die, cold heading die; Mining tools, geology, and petroleum use a variety of drill bits, etc.

Natural diamond (diamond)

Natural diamond (diamond) is a precious ornament, while synthetic diamond is widely used in the industry. Diamond is the hardest material in nature and has a very high elastic modulus, and the thermal conductivity of diamond is the highest among known materials. Besides, diamond has good insulation, which can be used as the drill bit, cutter, grinding tool, drawing die, dressing tool. However, the thermal stability of the diamond tool is poor, and the affinity with iron group elements is large, so it cannot be used for processing iron, nickel-based alloy, but mainly for processing non-iron metal and non-metal, widely used in ceramics, glass, stone, concrete, gem, agate and other processing.

Tool Ceramics

• Cubic boron nitride (CBN)

Cubic boron nitride (CBN) has a cubic crystal structure, and its hardness is second only to diamond. The thermal and chemical stability of cubic boron nitride is better than that of diamond, and it can be used for cutting hardened steel, wear-resisting cast iron, thermal spraying material, nickel, and other difficult materials.

• Other tool ceramics

Other tool ceramics are alumina, zirconia, silicon nitride, and other ceramics, but they are not as good as the above three tool ceramics from the comprehensive performance and engineering applications.

Functional Ceramics

Functional ceramics usually have special physical properties and cover many fields, and the characteristics and applications of common functional ceramics are as follows.

• Dielectric ceramics

Performance: Insulation, thermoelectric, piezoelectric, strong dielectric

Material composition: Al2O3, Mg2SiO4, BaTiO3, PbTiO3, LiNbO3

Application: Integrated circuit substrates, thermistors, oscillators, capacitors

• Optical ceramic

Performance: Fluorescence, luminescence, infrared transmittance, high transparency, the electrochromic effect

Material composition: Al2O3CrNd glass, CaAs, CdTe, SiO2, WO3

Application: Laser, infrared window, optical fiber, display

Functional Ceramics

• Magnetic Ceramics

Performance: Soft magnetism and hard magnetism

Material composition: ZnFe2O, SrO, y-Fe2O3

Application: Magnetic tape, all kinds of the high-frequency magnetic core, electro-acoustic devices, instruments and control devices of the magnetic core

• Semiconductive ceramics

Performance: Photoelectric effect, resistance temperature change effect, thermionic emission effect

Material composition: CdS, Ca2Sx, VO2, NiO, LaB6, BaO

Application: Solar cells, temperature sensors, the hot cathode

Development of advanced ceramics

Advanced ceramic is a significant piece of new material, broadly utilized in correspondence, hardware, flying, aviation, military, and other fields, and has significant applications in data and correspondence innovation.

Most utilitarian pottery are broadly utilized in the gadgets business, which is frequently alluded to as electronic artistic materials. For instance, clay protection materials utilized in chip producing, fired substrate materials, earthenware bundling materials, and capacitor ceramics, piezoelectric ceramics, ferrite attractive materials utilized in electronic gadgets fabricating.

As of now, progressed pottery has framed a high-tech industry. Overall deals of high-tech earthenware production surpass the US $30 billion and are developing at a yearly pace of over l0%, with the United States and Japan driving the field. Progressed earthenware materials assume an undeniably significant part in industry, conventional industry change, and public guard and military industry because of their great high-temperature mechanical properties and their special composite impacts of light, sound, power, attraction, warmth, or capacity.

0 notes

Text

Quartz Glass: The Invisible Backbone of Modern Technology

Quartz glass, also known as fused silica, is a high-performance material that combines optical clarity with extreme durability. Composed of nearly pure silicon dioxide (SiO₂), this glassy substance is prized for its ability to withstand harsh environments while maintaining exceptional transparency across a broad spectrum of light. From deep-space telescopes to semiconductor labs, quartz glass plays a pivotal role in pushing the boundaries of science and industry.

Unique Material Properties Unlike ordinary soda-lime glass, quartz glass lacks additives like sodium or calcium, giving it unparalleled purity. This results in three standout characteristics:

Thermal Resilience: With a melting point of 1,650°C (3,002°F) and a low thermal expansion coefficient, quartz glass resists thermal shock, enduring rapid temperature swings without cracking.

Optical Transparency: It transmits light from the ultraviolet (180 nm) to infrared (3,500 nm) range, outperforming most glasses. This makes it indispensable for UV lamps, laser optics, and astronomical instruments.

Chemical Inertness: Resistant to acids, solvents, and high-purity processes, it remains stable even in corrosive environments.

Manufacturing Techniques Quartz glass is produced by melting natural quartz crystals or synthetic silica sand in high-temperature furnaces (above 2,000°C/3,632°F). Two primary methods are used:

Electric Fusion: Raw materials are melted in vacuum or inert gas environments to minimize impurities.

Flame Hydrolysis: Vaporized silicon compounds are burned in a hydrogen-oxygen flame, depositing layers of pure SiO₂ to form transparent glass. Post-production, the material is often annealed to relieve internal stresses and machined into custom shapes for specialized applications.

Versatile Applications

Optics and Photonics: Quartz glass lenses, windows, and prisms are critical in lasers, telescopes, and UV lithography systems used in microchip production.

Semiconductor Industry: As crucibles, wafer carriers, and reactor tubes, its purity prevents contamination during silicon wafer processing.

Lighting: High-intensity discharge lamps, UV sterilization bulbs, and halogen lamps rely on quartz glass envelopes to contain gases and transmit light efficiently.

Fiber Optics: Ultra-pure quartz forms the core of optical fibers, enabling high-speed data transmission over long distances.

Extreme Environments: It serves as viewing windows in industrial furnaces, spacecraft heat shields, and sensors for deep-sea exploration.

Challenges and Innovations While quartz glass is remarkably durable, its brittleness and high production costs drive ongoing research. Scientists are developing doped variants—such as titanium-doped quartz for improved UV resistance—and exploring additive manufacturing to create complex geometries. Sustainability efforts also focus on recycling industrial quartz waste.

Conclusion Quartz glass is a testament to how a single material can revolutionize multiple fields. Its unique blend of optical, thermal, and chemical properties makes it irreplaceable in cutting-edge technologies. As industries demand materials capable of withstanding higher temperatures, harsher chemicals, and more precise optical requirements, quartz glass will remain at the forefront of innovation, silently enabling advancements from nanoscale electronics to explorations of the cosmos.

1 note

·

View note

Text

Anesthesia Equipment Market: Market Growth and Market Dynamics 2024-2032

The Anesthesia Equipment Market is projected to grow from USD 7.9 billion in 2023 to USD 14.28 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.8% during the forecast period of 2024-2032. The increasing prevalence of chronic diseases, rising demand for minimally invasive surgeries, and advancements in anesthesia technology are key drivers of this market expansion.

Get Free Sample Report @ https://www.snsinsider.com/sample-request/3436

Regional Analysis

North America: Dominates the market due to advanced healthcare infrastructure and a rising number of surgical procedures.

Europe: Exhibits significant growth driven by technological advancements and an aging population.

Asia-Pacific: Anticipated to experience the fastest growth, attributed to increasing healthcare investments and a growing prevalence of chronic diseases.

Market Segmentation

By Type:

Anesthesia Devices

Anesthesia Workstations

Anesthesia Delivery Machines

Anesthesia Ventilators

Anesthesia Monitors

Other Devices

Anesthesia Disposables

Anesthesia Circuits (Breathing Circuits)

Anesthesia Masks

Endotracheal Tubes (ETTs)

Laryngeal Mask Airways (LMAs)

Other Accessories

By Application:

Orthopedics

Neurology

Respiratory Care

Urology

Cardiology

Others

By End User:

Hospitals

Clinics

Ambulatory Surgical Centers

Other End Users

Key Players

The major players are GE Healthcare, Spacelabs Healthcare, Septodont Inc, Draegerwerk AG & Co. KGaA, Beijing Aeonmed Co., Ltd., HEYER Medical AG, ORICARE, Inc,Philips Healthcare, Becton Dickinson and Company, Getinge AB, 3M, General Electric, SunMed, Teleflex Incorporated, Ambu A/S and others.

Key Market Highlights

Increasing global elderly population is leading to a higher incidence of age-related diseases requiring surgical interventions.

Technological advancements and the introduction of innovative anesthesia workstations are enhancing market growth.

Challenges include unfavorable reimbursement scenarios and budget constraints in hospitals, particularly in developing regions.

Future Market Prospects

The anesthesia equipment market is poised for substantial growth, fueled by ongoing technological innovations and the rising demand for surgical procedures globally. Manufacturers are focusing on developing advanced, user-friendly, and cost-effective anesthesia devices to cater to the evolving needs of healthcare providers. Additionally, the increasing adoption of anesthesia information management systems (AIMS) is expected to further drive market expansion.

Conclusion

The anesthesia equipment market is on a robust growth trajectory, driven by demographic shifts, technological advancements, and increasing surgical procedures worldwide. Despite challenges such as reimbursement issues and budgetary constraints, the market presents significant opportunities for innovation and expansion, particularly in emerging economies.

Contact Us: Jagney Dave - Vice President of Client Engagement Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Other Related Reports:

Fertility Services Market

Medical Power Supply Market

Post Traumatic Stress Disorder Treatment Market

MRI Guided Neurosurgical Ablation Market

#Anesthesia Equipment Market#Anesthesia Equipment Market Share#Anesthesia Equipment Market Trends#Anesthesia Equipment Market Size#Anesthesia Equipment Market Growth

0 notes

Text

High-density tungsten alloy information summary

Tungsten heavy alloy is based on tungsten, with a small amount of Ni, Co, Mo and other elements added to it. It is a typical two-phase alloy and is also called "high-density alloy". According to different product uses and working environment requirements, the tungsten content of high-density tungsten alloy products is usually distributed in 79%W~97%W, and the density range is 15.00g/cm~18.50g/cm. At the same time, some rare metal elements (Co, Mo, Cr, etc.) can be added to improve some product properties, such as: hardness, ultimate tensile strength, yield strength, elongation, etc.

The most commonly used are: W-Ni-Cu and W-Ni-Fe two series. This material has remarkable characteristics in physical properties such as density, strength, hardness, ductility, conductivity/thermal properties, etc., so it is widely used in defense industry, aerospace industry, medical industry, electrical industry and other industries

Performance

High-density tungsten alloy is a kind of alloy with tungsten as the matrix (W content 85-99%) and added with elements such as Ni, Cu, Co, Mo, Cr, etc.

According to the composition characteristics and uses of the alloy, it is divided into main series such as W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag, etc. Its density is as high as 16.5-19.0g/cm3, and it is called high-density alloy by the world.

It also has a series of excellent properties, high specific gravity: generally 16.5-18.75g/cm3, high strength: tensile strength is 700-1000Mpa, strong radiation absorption ability: 30-40% higher than lead, high thermal conductivity: 5 times that of mold steel; small thermal expansion coefficient: only 1/2-1/3 of iron or steel, good electrical conductivity; good weldability and processability. In view of the above excellent functions of high specific gravity alloy, it is widely used in aerospace, aviation, military, oil drilling, electrical instruments, medicine and other industries.

Process flow

1. Mixing: tungsten powder, nickel powder, iron powder (if the product has magnetic requirements, copper powder can be added instead of iron powder and mixed evenly)

2. Mixing → vacuum drying → pressing and molding → pre-burning and degreasing → processing and molding → vacuum sintering → quality inspection → rough product → subsequent processing (oil immersion, machining, heat treatment, electroplating, rolling, forging, etc.) → fine grinding product → product delivery

Main products

1. Tungsten alloy fishing sinker series: bullet type, teardrop type, round tube type, semi-teardrop type, cylindrical hole type.

2. Tungsten beads, tungsten ball series: φ1.5mm -φ10mm accuracy ±0.01mm, used for fish sinker counterweights, submunitions, medical instrument counterweights, shotgun pellets; φ0.1mm-φ10mm accuracy ±0.1mm, used for oil drilling balance, shotgun pellets.

3. High-density tungsten-based alloy counterweight series: Mechanical counterweights; Flyweights; Oil drilling counterweights; Darts; Golf counterweights; Racing counterweights; Mobile phone and game console vibrators; Aerospace gyroscopes; Clock pendulums; Balanced counterweights; Anti-vibration knife bars.

4. Medical tungsten alloy radiation shielding material series:

(1) Tungsten alloy grating blades;

(2) Tungsten alloy protective tanks - used for medical radioactive shielding walls; Shielded needle tubes - used for medical radioactive liquid shielding; Tungsten alloy storage - used for cans, boxes and other containers for storing radioactive materials.

(3) Collimators - used for tungsten alloy series detection container systems in medical linear accelerators and nuclear technology applications; Co60 and other radiation shielding.

5. Electrical materials series: Electrodes for EDM and resistance welding; High-density electrical contacts, contacts in air circuit breakers.

6. Military series: armor-piercing projectiles; cluster bullets, balls, rods, square pellets, cylinders, other tungsten alloy electric upsetting blocks, tungsten alloys in nuclear technology applications.

0 notes

Text

Boron nitride tube - refractory insulation for high-temperature vacuum furnace

Boron nitride tube is a material with good high-temperature insulation performance, mainly used in high-temperature, high-pressure, and industrial applications requiring excellent electrical insulation performance. In high-temperature vacuum furnaces with carbon materials, as heating elements and carbon felt and graphite felt as insulation materials, the insulation performance between the heating electrode and the insulation structure is the key to whether the equipment can be used normally. At temperatures exceeding 1600℃, only boron nitride ceramics can be competent for a long time.

The main features and application areas of boron nitride ceramic tubes are as follows:

High-temperature stability

Boron nitride ceramics can maintain their structure and performance unchanged at extremely high temperatures (up to 900℃ in air and up to 2100℃ in inert gas) and are suitable for applications in high-temperature environments. Therefore, it is suitable for high-temperature components in the aerospace field, such as engine components and thermal protection systems, where the material needs to withstand extreme temperatures and mechanical stress. It can also be used in high-temperature industrial equipment, such as heat treatment furnaces, kilns, and reactors, and boron nitride tube are used as structural and insulating components.

Excellent electrical insulation

Boron nitride provides excellent electrical insulation, with a room temperature resistivity of up to 10^16 Ω.cm, ensuring safety in electrical applications. Boron nitride sleeves are used to handle and position sensitive silicon wafers during semiconductor manufacturing, especially in heat treatment and wafer manufacturing, to provide necessary structural support and thermal management. They can also be used as insulators and thermal interface materials at high temperatures to protect sensitive electronic components from overheating.

Excellent thermal conductivity

High thermal conductivity (50-70 W/(m·K)) is suitable for a thermal management system to optimize the device’s thermal performance.

Low thermal expansion coefficient

The low thermal expansion coefficient (1-1.2 x 10^-6/K) maintains dimensional stability in thermal cycling applications and reduces thermal stress.

Chemical inertness

Highly resistant to most chemicals and corrosive environments, ensuring performance is not affected in harsh environments.

Self-lubricating properties

With a certain degree of lubricity, it is suitable for use in mechanical applications requiring a low coefficient of friction.

Machinability

Boron nitride ceramics have excellent machinability and can be processed into complex shapes with minimum tolerances according to customer requirements.

Edgetech provides the Boron nitride ceramic tubes, which have become indispensable in semiconductor aerospace, and high-temperature industrial applications due to their high-temperature stability, excellent electrical insulation, and good thermal management capabilities. Its design and material machinability make it particularly important in modern technology applications requiring high reliability and precise control. It provides customers with key support and guarantees to help customers achieve improved production efficiency and optimized product performance.

0 notes

Text

Laser Welding Industry Poised for Strong Growth, Reaching USD 5.4 Billion by 2032

The demand for laser welding is projected to reach USD 2,758.3 million in 2022 and is expected to grow at a CAGR of 6.9%, reaching USD 5,387.0 million by 2032.

The Laser Welding Market is expected to witness significant growth during the forecast period, driven by the shift towards renewable energy and its increasing use in the electronics and automotive sectors. Currently, Laser beam Welding equipment accounts for around 20% of automotive welding operations, a figure expected to rise as improvements in productivity, quality, and weld strength continue. The broad range of applications, from engine components to wind turbines, further supports market growth.

The rise of additive manufacturing is transforming production by allowing for complex designs, optimizing material use, and minimizing waste. Manufacturers are adopting this technology to streamline production, reduce costs, and accelerate design iterations, signaling a major shift in the manufacturing landscape.

However, the capital-intensive and technically complex nature of Laser beam Welding equipment poses challenges, as users may opt for cheaper alternatives. Competition from other welding methods, such as electron beam welding, oxy-fuel welding, and resistance welding, also limits the market expansion of laser welding.

North America currently leads the market, driven by the demand for high productivity in welding operations. Europe offers significant growth opportunities due to its strong automotive industry and technological advancements.

The Asia Pacific region is poised for growth, fueled by industrialization, expanding manufacturing facilities, and increasing adoption of laser welding across various industries. The Middle East and Africa are also contributing, with rising demand for fabricated metal parts in heavy machinery and increasing automation supporting market growth.

Key Takeaways from the Laser Welding Market Research Study:

North America has the leading market share in the laser welding industry.

From 2022 to 2032, the North American laser welding business is expected to grow to a 27% share.

In 2022, Europe's laser welding industry was predicted to have a sizable share of 30%.

In 2022, the Asia Pacific laser welding business is projected to have a 24.6% market share.

In 2022, the Middle East and Africa laser welding industry is anticipated to have a 13.3% market share.

Top 14 Companies in Laser Welding Market and Their Marketing Strategies:

ROFIN-SINAR Laser GmbH

The Emerson Electric Company

O.R. Laser Technologies GmbH

TRUMPF GmbH + Co. KG

Panasonic Corporation

Colfax Corporation

CMF Groupe

Control Laser Corporation

Wuhan Farley Laserlab Cutting Welding System Engineering Co., Ltd.

ALPHA LASER GmbH

Bielomatik Leuze GmbH + Co. KG

LaserStar Technologies Corporation

Sahajanand Laser Technology Ltd.

Others

Laser Welding Market Segmentation:

By Product Type:

Carbon Dioxide Laser (CO2) Welding Machine

Fibre

Solid-State

Others

By End-Use Industry

Energy Industry

Transportation Industry

Aerospace Industry

Communications Industry

Metal Fabrication Industry

Automotive Industry

Electronics Industry

Others

By Application

Spot and Seam Welding

Laser Deposit Welding

Scanner Welding

Tube Welding

Profile Welding

By Region

North America

Latin America

Europe

Asia Pacific

Middle East & Africa

Report Preview: https://www.futuremarketinsights.com/reports/laser-beam-welding-equipment-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Contact Us:

Future Market Insights Inc. Christiana Corporate, 200 Continental Drive, Suite 401, Newark, Delaware - 19713, USA T: +1-347-918-3531 For Sales Enquiries: [email protected] Website: https://www.futuremarketinsights.com LinkedIn| Twitter| Blogs | YouTube

0 notes

Text

The Role of Condenser Expansion Machines

The Role of Condenser Expansion Machines in Modern HVAC Systems

In the realm of modern HVAC (Heating, Ventilation, and Air Conditioning) systems, the condenser expansion machine plays a pivotal role. These machines are essential for ensuring the efficiency and longevity of HVAC systems, which are critical for maintaining comfortable and healthy indoor environments in both residential and commercial buildings.Get more news about Condenser Expansion Machine,you can vist our website!

Introduction to Condenser Expansion Machines Condenser expansion machines are specialized tools used to expand and secure tubes within condensers, heat exchangers, and evaporators. These machines ensure a tight fit between the tubes and the tube sheets, which is crucial for the efficient transfer of heat. The process involves expanding the tubes to create a leak-proof seal, preventing any loss of refrigerant or coolant.

Importance in HVAC Systems Efficiency Enhancement: One of the primary benefits of using condenser expansion machines is the enhancement of system efficiency. By ensuring a tight seal, these machines prevent leaks that can lead to a loss of refrigerant. This not only improves the efficiency of the HVAC system but also reduces energy consumption and operational costs. Longevity and Durability: Properly expanded tubes are less likely to suffer from wear and tear. This increases the longevity of the HVAC system components, reducing the need for frequent maintenance and replacements. The durability of the system is significantly enhanced, leading to long-term cost savings. Environmental Impact: Efficient HVAC systems have a lower environmental impact. By preventing refrigerant leaks, condenser expansion machines help in reducing the release of harmful substances into the atmosphere. This is particularly important in the context of global efforts to combat climate change and reduce greenhouse gas emissions. Types of Condenser Expansion Machines There are various types of condenser expansion machines available, each designed for specific applications and requirements:

Hydraulic Expansion Machines: These machines use hydraulic pressure to expand the tubes. They are known for their precision and are commonly used in large-scale industrial applications. Pneumatic Expansion Machines: Utilizing compressed air, these machines are suitable for applications where hydraulic machines might be too cumbersome. They are often used in smaller HVAC systems and for on-site repairs. Electric Expansion Machines: These machines are powered by electricity and are known for their ease of use and portability. They are ideal for a wide range of applications, from small residential systems to larger commercial installations. Innovations and Future Trends The field of condenser expansion machines is continually evolving, with new innovations aimed at improving efficiency and ease of use. Some of the latest trends include:

Automation: Automated expansion machines are becoming increasingly popular. These machines can perform the expansion process with minimal human intervention, reducing the risk of errors and increasing productivity. Digital Controls: Modern machines are equipped with digital controls that allow for precise adjustments and monitoring. This ensures optimal performance and can help in diagnosing issues before they become major problems. Sustainability: There is a growing focus on developing machines that are more environmentally friendly. This includes the use of sustainable materials and the development of machines that consume less energy. Conclusion Condenser expansion machines are a critical component in the maintenance and operation of modern HVAC systems. They play a vital role in enhancing efficiency, ensuring durability, and reducing environmental impact. As technology continues to advance, these machines will become even more integral to the HVAC industry, driving innovations that will lead to more efficient and sustainable systems.

0 notes

Text

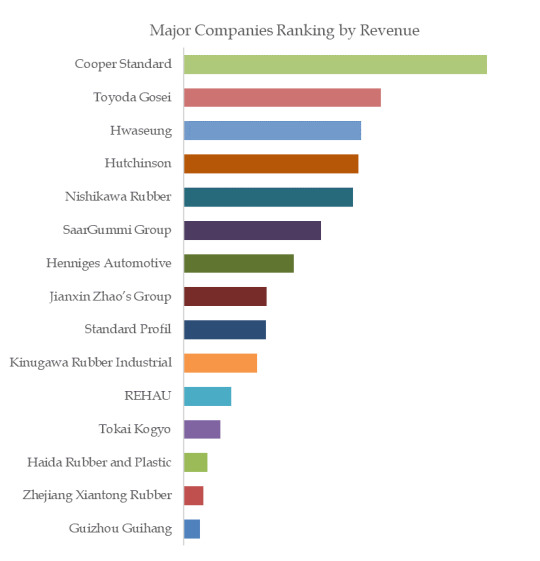

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

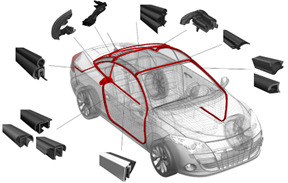

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Video

youtube

Automatic counting packaging machine for hardware plastic components wit...

Automatic counting packaging machine for hardware plastic components with six vibration bowl Bestar automatic counting packaging machine is widely used, the special shape of the parts can also be customized according to customer requirements. The machine uses microcomputer control, automatic packaging process.

Application: Can be widely used in electrical appliances, hardware screws, screw parts, hardware parts, furniture hardware, furniture accessories, furniture accessory, furniture spare part, furniture screw, screw fitting, nuts, nut, fastener, wire nails, nails, hardware, hardware fittings, bolts, expansion tubes, gaskets, copper parts, pipe joints, pipe joints and fitting, copper pipe joints for furniture, metal pipe joints, plastic pipe joints, rubber gaskets and mineral & aramid flat simple gaskets, etc.

FEATURES: 1. Machine can automatically counting exactly quantity, then filling, cutting, sealing, making bags. 2. Machine with counting system, vibration bowls & counting bowls could be customized from 1 to 48 bowls. 3. Each machine is customized: efficient, flexible, reliable, low maintenance, productive, safe, pneumatic system, reliable working, convenient maintenance. 4. Mitsubishi PLC control, bag length can be set and cut on one step, saving time and film. 5. High sensitivity photoelectric, numerical input of cutting sealing position for extra accuracy. 6. Four temperature independent PID control, more suitable for packing different materials 7. Positioned stop function, without sticking knife or wasting film 8. All control is realized through software, easy for function adjusting and technical upgrade 9. Touch screen easy and quick setting and operation.

MACHINE PARAMETERS: Type: BSTV320C Packing speed: 8-30bags/min Bag length: max180mm Bag Width: 30-150mm Max film width: 320mm Sealing type: 3 sides,4 sides or back sealing Packing film material: OPP/CPP, OPP/CE, PET/AL/PE, paper/PE, PET/AC/PE, etc hot sealable film material (customized to PE film if need) Power: 220V, 50Hz, 2.0KVA Net weight:280KG

#youtube#packing machine#packaging machine#counting packing machine#packaging solution#packing idea#automatic packaging machine#automation#hardware packaging#bestar packaging#bestar rachel

0 notes

Text

Enhancing Industrial Efficiency: Welding Components on Nikit Engineers’ Mini Profile Welder

n the realm of industrial automation, precision and efficiency are paramount. Nikit Engineers Welding Automation and Robotics Solutions India have been at the forefront of revolutionizing industrial processes with their cutting-edge technologies. Among their impressive array of offerings, the Mini Profile Welder stands out as a versatile solution for welding various industrial components with utmost precision. Let’s delve into the diverse components welded on this remarkable machine and explore how they contribute to enhancing industrial efficiency.

Stellite Welding

Stellite, known for its exceptional wear resistance and durability, is a vital component in many industrial applications, particularly in high-temperature and corrosive environments. Welding Stellite requires precision and expertise to ensure a strong bond without compromising its properties. The Mini Profile Welder, equipped with advanced welding capabilities, ensures seamless welding of Stellite components, guaranteeing optimal performance and longevity in industrial settings.

youtube

Bellow with Flange

Bellow assemblies find widespread use in various industries for their ability to absorb thermal expansion, vibration, and misalignment. Welding bellows with flanges demands meticulous attention to detail to maintain structural integrity and sealing effectiveness. With its precise control and customizable welding parameters, the Mini Profile Welder ensures flawless welding of bellows with flanges, meeting the stringent quality standards required in industrial applications.

youtube

Spin Tube

Spin tubes play a crucial role in diverse industrial machinery, facilitating smooth rotational motion and power transmission. Welding spin tubes demands high precision to achieve uniformity and strength along the weld joints. The Mini Profile Welder’s advanced welding technology, coupled with its automated processes, enables consistent and reliable welding of spin tubes, contributing to the seamless operation of industrial equipment.

youtube

Copper Busbar

Copper busbars are essential components in electrical power distribution systems, requiring robust welding techniques to ensure efficient current flow and conductivity. Welding copper demands specialized expertise due to its high thermal conductivity and susceptibility to oxidation. The Mini Profile Welder’s advanced welding capabilities, including precise heat control and shielding gas management, facilitate accurate and reliable welding of copper busbars, ensuring optimal electrical performance in industrial applications.

youtube

Castor Wheel Brackets

Castor wheel brackets play a critical role in facilitating mobility and maneuverability in various industrial setups. Welding these brackets demands structural integrity and stability to withstand dynamic loads and harsh operating conditions. The Mini Profile Welder’s precision welding technology ensures strong and durable welds on castor wheel brackets, providing reliable support for equipment mobility in industrial environments.

youtube

Bellow Nut Assembly

Bellow nut assemblies are integral components in mechanical systems, providing adjustable support and sealing capabilities. Welding bellow nut assemblies requires precision to maintain dimensional accuracy and thread integrity. With its advanced welding features and customizable parameters, the Mini Profile Welder enables seamless welding of bellow nut assemblies, ensuring optimal functionality and performance in industrial applications.

youtube

In conclusion, the Mini Profile Welder by Nikit Engineers Welding Automation and Robotics Solutions India offers a comprehensive solution for welding a diverse range of industrial components with precision and efficiency. By seamlessly welding components such as Stellite, bellows, spin tubes, copper busbars, castor wheel brackets, and bellow nut assemblies, this innovative machine enhances industrial productivity and reliability, setting new standards in welding automation technology. With its advanced features and robust performance, the Mini Profile Welder continues to revolutionize industrial welding processes, driving progress and innovation across various sectors.

Why Choose Nikit Engineers for Mini Profile Welding Automation?

Tailored Solutions: At Nikit Engineers, we understand that every welding project is unique. Our automation solutions are customized to suit the specific needs and intricacies of profile welding applications. From simple profiles to complex geometries, our systems adapt to the nuances of each project.

Expertise that Matters: Backed by years of experience, our team of engineers is well-versed in the intricacies of profile welding. We provide comprehensive support from the initial consultation to the implementation phase, ensuring a seamless transition to automated welding processes.

Robust Training Programs: Transitioning to automation can be daunting, but not with Nikit Engineers. We offer robust training programs to empower your workforce with the skills needed to operate and maintain our automated welding systems. Our goal is to make the adoption of automation a smooth and positive experience for your team.

Experience the Future with Nikit Engineers: Free Weld Trial Services

Embark on the journey of enhanced efficiency and precision with Nikit Engineers. To showcase the transformative power of our automation solutions, we are proud to offer Free Weld Trial Services. Experience firsthand how our profile welding automation systems can elevate your welding processes.

Book Free Weld Trial Services

At Nikit Engineers, we believe that the future of welding lies in automation. Our commitment to excellence, precision, and efficiency sets us apart as leaders in the field. Elevate your profile welding processes with Nikit Engineers Welding Automation and Robotic Solutions – where innovation meets craftsmanship.

Contact us today to schedule your Free Weld Trial Services and unlock the potential of automation in profile welding.

Nikit Engineers’ Robotic Welding Automation Solutions proudly declare that all our products are #MADEININDIA

Check out our other industrial ventures www.thewelder.in and www.civilautomation.com

Don’t forget to subscribe to our YouTube Channel for the latest videos and updates – www.youtube.com/@Nikitengineers

#robotics solutions#welding automation#orbital welding#circular welding#Stainless Steel Welding#Profile Wedling#Youtube

0 notes

Text

Tube and Pipe Bending Machines

The United Arab Emirates (UAE) has experienced unprecedented growth in various industries, including construction, oil and gas, and manufacturing. Among the key players contributing to this economic surge are tube and pipe bending machines, essential tools that have undergone significant evolution over the years. This article explores the journey of tube and pipe bending machines in the UAE, their role in shaping the industrial landscape, and the technological advancements driving this sector forward.

Historical Perspective:

The UAE's industrial development traces back to the early days of oil discovery in the region. The need for efficient methods to handle and transport oil and gas prompted the establishment of advanced manufacturing processes. Tube and pipe bending machines emerged as crucial tools in fabricating pipelines, oil rigs, and various infrastructure components.

Initially, manual bending techniques were prevalent, requiring skilled artisans to shape tubes and pipes according to project specifications. However, as industrial demands grew, the need for automation became apparent.

Automation Revolution:

The late 20th century witnessed a revolution in manufacturing processes globally, and the UAE was quick to adopt advanced technologies. CNC (Computer Numerical Control) tube and pipe bending machines emerged as game-changers, offering precise, efficient, and repeatable bending processes. This automation not only improved accuracy but also increased production speed, a critical factor in meeting the demands of the burgeoning construction and oil industries.

Key Technological Advancements:

CNC Technology: Computer-controlled bending machines allowed for highly accurate and complex bending operations. This technology became a cornerstone in enhancing efficiency and reducing waste in material usage.

3D Bending: With the advent of 3D bending machines, manufacturers gained the capability to create intricate and multi-dimensional bends. This was particularly beneficial in projects where unconventional pipe configurations were required.

Hydraulic and Electric Benders: The shift from traditional hydraulic benders to electric benders marked another milestone. Electric benders are known for their energy efficiency, reduced maintenance, and quieter operation, contributing to a more sustainable and cost-effective industrial landscape.

Current Landscape:

In the present day, the UAE boasts a sophisticated tube and pipe bending machinery sector, with local manufacturers and international suppliers catering to diverse industries. The machines available are equipped with state-of-the-art features, including advanced control systems, real-time monitoring, and predictive maintenance capabilities.

The demand for tube and pipe bending machines in the UAE remains robust, fueled by ongoing infrastructure projects, oil and gas exploration, and the rapid expansion of manufacturing capabilities. Moreover, the emphasis on sustainability has led to the adoption of eco-friendly technologies within the sector.

Conclusion:

The evolution of tube and pipe-bending machines in the UAE reflects the nation's commitment to technological advancement and industrial excellence. From manual craftsmanship to CNC precision, these machines have played a pivotal role in shaping the infrastructure that defines the UAE today. As the country continues to embrace innovation, the tube and pipe-bending machinery sector is poised to contribute significantly to its future industrial landscape.

0 notes

Text

Supplier of SS Fasteners in Bihar

Supplier of SS Fasteners in Bihar: Meghmani Metal: We Are a Well-Known Manufacturer and Supplier of All Ferrous And Non-Ferrous Metal Products, Such As Stainless Steel Pipes, Stainless Steel Tubes, Steel Flanges, Steel Butt Welding, Steel Pipe Fittings, Steel Rods, Wires, Colls, Flats, Structural, and so on. Meghmani Metal is one of the leading manufacturers and Suppliers of SS Fasteners in Bihar. Our Stainless Steel Fasteners division is specialized in the manufacturing of Austenitic grade fasteners. Applications of SS Fasteners: Construction: Building facades, bridges, railings, structural components, and electrical installations. Automotive industry: Engine components, exhaust systems, body panels, and interior trim. Marine industry: Boats, yachts, offshore platforms, and marine equipment. Chemical industry: Pipes, tanks, reactors, and processing equipment. Food processing: Machinery, conveyor systems, and equipment components. Medical equipment: Surgical instruments, prosthetics, and dental implants. Electronics: Circuit boards, electrical enclosures, and heat sinks. Household appliances: Washing machines, refrigerators, and kitchen equipment. Common Types of SS Fasteners: Nuts and bolts: The most common type, available in various sizes, threads, and head styles. Screws: Wood screws, machine screws, self-tapping screws, set screws, and socket head screws. Washers: Flat washers, lock washers, fender washers, and spring washers. Rivets: Blind rivets, solid rivets, and pop rivets. Anchors: Expansion anchors, wedge anchors, and chemical anchors. Dowel pins: Used for alignment and positioning of components. Clips and clamps: Used for securing cables, hoses, and other components. We Provide Supplier of SS Fasteners in Bihar Including Patna, Gaya, Bhagalpur, Muzaffarpur, Purnia, Darbhanga, Ara (Arrah), Begusarai, Katihar, Chapra, Munger (Monghyr), Saharsa, Bettiah, Hajipur, Sasaram, Dehri, Siwan, Motihari Etc. Read the full article

#Ara(Arrah)#Begusarai#Bettiah#Bhagalpur#Bihar#Chapra#Darbhanga#Dehri#Gaya#Hajipur#India#Katihar#Motihari#Munger(Monghyr)#Muzaffarpur#Patna#Purnia#Saharsa#Sasaram#Siwan#SSFasteners#Stockiest#supplier

0 notes

Text

Hydraulic Power Market to Witness a Pronounce Growth During 2021 To 2031

The hydraulic power market size was valued at $13.7 billion in 2021, and the hydraulic power market is estimated to reach $24.1 billion by 2031, growing at a CAGR of 5.8% from 2022 to 2031. Hydraulic power is a vital part of a hydraulic system as it can generate a significant quantum of power to initiate almost any type of hydraulic ram. They draw power using Pascal’s law, i.e., through ratios of area and pressure. The hydraulic power industry includes applications such as machine tools, aerospace test equipment, automation systems, meat processing machinery, mobile equipment, rolling mill machinery, and material handling equipment. Also, they are applied in agricultural equipment, paper mill machinery, oil exploration, oil spill clean-up equipment, industrial process, marine equipment, construction equipment, and theatrical & production equipment.

Get a PDF brochure for Industrial Insights and Business Intelligence @ https://www.alliedmarketresearch.com/request-sample/17642

The rise in construction and increase in production capacities of oil fields coupled with a surge in stress on the agricultural sector is projected to drive the demand for hydraulic equipment. It has witnessed considerable growth in the past decades since its implementation in hydraulic machinery. The rise in demand for these machinery and rapid industrialization across the globe are the factors expected to foster the growth of the hydraulic power market. However, an increase in demand for alternative power systems such as electromechanical and electric drives with efficient clean, and shorter lead times are some of the factors hampering the hydraulic power market growth.

Hydraulic power consists of various components, such as a hydraulic motor and pump, reservoir/accumulators, and other accessories, such as filters, valves, tubes, regulators, and instruments used to monitor the performance of a hydraulic system. In 2021, there was a rapid increase in construction across the United States and Canada. The residential sector was a key driver of the increasing demand for more housing units needing hydraulic power. For instance, construction spending in the United States registered significant growth in 2021 compared to 2020. As of 2021, the average construction spending in the private sector was around USD 1230 billion and over USD 346 billion in the public sector, thus creating significant market demand for hydraulic power. Also, construction projects in Europe like Crossrail1, Crossrail2, Heathrow airport expansion, Hinkley Point C nuclear plant (UK), and Fehmarn Fixed Belt link (Denmark) are likely to increase the need for hydraulic power during the forecast period. In January 2020, there were nearly 343 pre-construction coal-powered thermal power plants worldwide. The pre-construction plants are estimated to have a capacity of around 299 GW, which may drive the hydraulic power market considerably.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/17642

The hydraulic power market forecast is segmented on the basis of operating pressure, component, application, end-user, and region. On the basis of operating pressure of hydraulic power, the market is segmented into 0-750 PSI, 750-2000 PSI, 2000-3000 PSI, and more than 3000 PSI. On the basis of components, it is classified into power components, control components, and auxiliary components. On the basis of application, the market is divided into cutting, grinding, milling, multi-tooling, forming, rubber & plastic, handling, simulation & testing, and others. On the basis of end-use, it is segmented into mobile, industrial, and others. Region-wise, the market is studied across North America, Europe, Asia-Pacific, and LAMEA. Presently, North America accounts for the largest share of the market, followed by Asia-Pacific and Europe.

The major companies profiled in this report include Bosch Rexroth AG, Brevini Fluid Power S.p.A, Nachi-Fujikoshi Corporation, Parker Hannifin Corporation, Weber Hydraulik GmbH, Hydac International GmbH, Hydro-Tek Co Ltd., Bailey International LLC, Eaton Corporation, Energy Manufacturing Company Inc., Hydromega, Branch Hydraulic Systems Ltd., Related Fluid Power Ltd., HCS Control Systems Ltd., Danfoss, Siemens AG, and Daikin Industries. The rapid development of industrialization, modernization, and investment in the development of the tourism industry has led to a surge in the construction and other sectors; which in turn has fueled the demand for hydraulic power. Additional growth strategies such as expansion of production capacities, acquisition, partnership, and research & innovation in the application of hydraulic equipment in various sectors will provide a suitable platform for the development of hydraulic power market trends.

Key findings of the study

- Japan contributes around 3.9% of the total hydraulic power market share and would exhibit a CAGR of 5.7% during 2022-2031. - South Korea contributes around 2.51% of the total market share and would exhibit a CAGR of 7.0% during 2022-2031 - As per global hydraulic power market analysis, by operating pressure, the 2000-3000 PSI segment accounted for the largest share of 46.2% in 2021. - By component, auxiliary component was the leading segment in 2021 comprising 47.6% of market share in 2021. - By application, the cutting segment occupied a market share of 27.5% and is the leading segment in 2021. - By end use, the mobile segment was the highest revenue contributor in 2021 contributing a market share of 45.2% in 2021. - By region, North America was the leading segment in 2021expected to possess a CAGR of 5.2% during 2022-2031

Procure Complete Report @ https://www.alliedmarketresearch.com/checkout-final/4aa14177033cb7c00eaeb000b829e56b

COVID-19 analysis:

COVID-19 has severely impacted the global economy with devastating effects on global trade, which has simultaneously affected households, businesses, financial institutions, industrial establishments, and infrastructure companies. The novel coronavirus has affected several economies and caused lockdowns in many countries which has limited the growth of the market. The shutdown of industrial manufacturers led to a decline in the demand for solar-related equipment in most countries across the world led to a decline in the demand in the hydraulic power market. The decrease in the utilization of power in industrial facilities across the globe during the outbreak has had a negative impact on the development of the market.

After the global vaccination, the government of various countries has taken initiatives to increase the investment in the energy and transportation infrastructure. Furthermore, India's policies to make the country a world-class manufacturing hub have led to investment in the construction of airports, sea ports, and large-scale manufacturing facilities. The presence of the above-mentioned activities and changes in policies due to the outbreak of the pandemic has had a positive impact on the development of the market during the forecast period.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domains.

David Correa Allied Analytics LLP 1 800-792-5285

0 notes