Don't wanna be here? Send us removal request.

Text

Roll-Wrapped Carbon Fiber Tube Manufacturer

TipTop Composites is a trusted roll-wrapped carbon fiber tube manufacturer, delivering high-strength, lightweight solutions for aerospace, automotive, industrial, and sporting applications. With precision engineering and premium materials, they produce durable, custom carbon fiber tubes that meet the demands of performance-driven industries worldwide.

#carbon fiber auto accessories#carbon intake pipe#telescoping carbon fiber pole#aerial photography pole

0 notes

Text

Carbon Fiber BMW Parts - TipTop Composites

TipTop Composites offers high-performance carbon fiber BMW parts designed for strength, style, and lightweight efficiency. Precision-engineered for various BMW models, our parts enhance aerodynamics and durability while delivering a sleek, modern look. Trust TipTop for quality carbon fiber upgrades that redefine your BMW’s performance.

#carbon fiber idler roller#camera pole for roof inspection#10m camera pole#telescoping carbon fiber pole

0 notes

Text

Lightweight Strength Redefined by TipTop Composites

TipTop Composites’ tapered carbon tubes is an original product, with the highest strength-to-propagation ratio available. These tubes are for those industries where a smooth transition is required, has the combination of excellent rigidity and corrosion resistant properties to prevent intergranular corrosion. Whether you’re crafting drones, sports equipment, or prototypes, TipTop tapered carbon tubes is built to perform again and again — giving you that competitive edge in any application. For more information, visit the website.

0 notes

Text

Elevate Your Sports Footage with Precision and Stability

TipTop Composites' tripod for sports video delivers unmatched performance on the field. Lightweight yet robust, this carbon fiber tripod ensures steady, elevated shots for clear, comprehensive game footage. Designed for outdoor sports recording, it's your essential tool for high-angle sports videography. To know more about premium tripod for sports video, visit the website.

0 notes

Text

High-Performance Carbon Intake Pipe by TipTop Composites

Boost your engine with TipTop Composites' carbon intake pipe--light, strong, and designed to flow. Great for cars racing and high performance, it provides better airflow with a cool carbon fibre look. Transform your air intake system with advanced composite technology. Visit the website and learn more about the carbon intake pipe.

0 notes

Text

Lightweight Carbon Fiber Extension Pole

TipTop Composites' carbon fiber extension pole offers unmatched durability and ultra-lightweight performance. Designed for professionals, it reduces fatigue while extending your reach with precision. Perfect for high-access tasks, it's your reliable partner in tough environments where strength, stability, and control matter most. To learn more, visit the website.

0 notes

Text

TipTop Composites - Aerial Photography Pole Lightweight Precision

Capture stunning aerial shots with TipTop Composites’ Aerial Photography Pole. Crafted from high-strength carbon fiber, this lightweight, durable pole extends for versatile angles while ensuring stability. Perfect for photographers seeking precision and portability, it elevates your photography game with unmatched quality and innovative design.

0 notes

Text

Upgrade Your Ride with TipTop's Carbon Intake Solutions

TipTop Composites offers premium carbon intake pipes crafted for superior airflow and reduced engine strain. Combining innovation with top-tier materials, their products provide power gains, improved throttle response, and long-lasting performance — ideal for drivers who demand both function and style.

0 notes

Text

Enhancing Innovation with TipTop Composites: Your Trusted Carbon Fiber Supplies Partner

carbon fiber stands out as a true game-changer. Known for its exceptional strength-to-weight ratio, high stiffness, and resistance to corrosion, carbon fiber has become a staple in industries ranging from aerospace and automotive to sports equipment and construction. At the forefront of this revolution is TipTop Composites, a company dedicated to delivering high-quality carbon fiber supplies that meet the needs of both industrial giants and individual innovators.

The Rising Demand for Carbon Fiber Products

The adoption of carbon fiber materials is on a steep rise due to their ability to outperform traditional materials like steel and aluminum in various applications. Whether it's in the form of a carbon fiber pipe, carbon fiber tube, or sheets and laminates, these composites offer incredible design flexibility and structural performance. With sustainability and energy efficiency becoming crucial design parameters, carbon fiber provides a reliable solution that reduces weight without compromising strength or durability.

TipTop Composites: Excellence in Carbon Fiber Supply

TipTop Composites has carved a niche for itself by consistently delivering premium carbon fiber supplies to meet the complex requirements of high-performance applications. With a commitment to quality, precision, and customer satisfaction, TipTop has become a trusted name among engineers, designers, and manufacturers seeking the very best in composite materials.

What sets TipTop Composites apart is their comprehensive product range and a deep understanding of the unique characteristics of carbon fiber. Whether a project requires lightweight structural components or high-temperature-resistant materials, TipTop Composites provides tailored solutions using a variety of weaves, finishes, and resins to meet specific application demands.

Product Range: Precision Meets Performance

TipTop Composites offers an expansive selection of carbon fiber products, including:

Carbon Fiber Pipe: Designed for superior strength and minimal weight, carbon fiber pipes are commonly used in structural applications, exhaust systems, and support frameworks. These pipes offer resistance to fatigue and chemical damage, making them ideal for long-term use in demanding environments.

Carbon Fiber Tube: Available in both standard and custom diameters, carbon fiber tubes from TipTop Composites are favored in aerospace, robotics, and sports gear manufacturing. These tubes boast high stiffness, low weight, and excellent dimensional stability, making them ideal for load-bearing applications.

Carbon Fiber Tubing: A versatile product category, carbon fiber tubing is used across numerous sectors for its ease of machining, aesthetic appeal, and unmatched performance. From drone arms to camera rigs and automotive roll cages, carbon fiber tubing enhances both functionality and design.

Each of these product lines is manufactured with meticulous attention to detail, ensuring consistency, strength, and longevity.

Applications Across Industries

The superior properties of carbon fiber materials supplied by TipTop Composites make them suitable for a wide range of applications:

Aerospace: Carbon fiber’s low weight and high tensile strength make it indispensable in the aerospace sector. Components such as wing spars, control rods, and fuselage sections benefit significantly from TipTop’s quality supplies.

Automotive: With electric vehicles (EVs) and performance cars prioritizing weight reduction for better efficiency, TipTop’s carbon fiber tubing and pipes are ideal for body panels, chassis components, and aerodynamic elements.

Sports and Recreation: From bicycles to hockey sticks, the sports industry thrives on lightweight, durable materials. TipTop’s carbon fiber products enhance performance and user comfort in recreational gear.

Medical Devices: The non-magnetic and biocompatible nature of carbon fiber makes it suitable for imaging equipment, prosthetics, and surgical instruments.

Industrial Automation and Robotics: Carbon fiber tubes and pipes are used to reduce inertia in robotic arms and improve speed and precision in automated systems.

Commitment to Customization and Innovation

Understanding that no two projects are the same, TipTop Composites offers extensive customization options. Customers can specify dimensions, wall thicknesses, resin systems, and weave patterns to meet their exact needs. The company’s team of experienced engineers works closely with clients to develop prototypes, optimize designs, and deliver high-performance solutions that align perfectly with project goals.

Innovation is a cornerstone of TipTop’s operations. The company continues to invest in research and development to improve manufacturing processes, explore new resin systems, and create composite materials with even better performance characteristics. Their ability to adapt to the latest technological advancements ensures that clients always receive state-of-the-art products.

Quality You Can Rely On

TipTop Composites prides itself on stringent quality control measures at every stage of production. From raw material inspection to final product testing, the company ensures that all carbon fiber supplies meet international standards for strength, safety, and durability.

Their manufacturing facilities are equipped with cutting-edge technology, and all products undergo rigorous testing for mechanical properties, thermal stability, and environmental resistance. This dedication to quality ensures that clients receive materials that perform reliably even under the most challenging conditions.

Sustainability and Future Outlook

As industries shift toward greener, more sustainable practices, carbon fiber plays a critical role in reducing material waste and improving energy efficiency. TipTop Composites is committed to sustainable manufacturing, minimizing environmental impact through efficient resource use, waste reduction, and the incorporation of eco-friendly materials where possible.

Looking ahead, TipTop is poised to lead the next wave of innovation in composite materials. With growing applications in renewable energy, urban transportation, and infrastructure, the demand for carbon fiber tubing, pipes, and other composite elements will only continue to grow. TipTop Composites remains dedicated to supplying the cutting-edge materials that will shape the future of engineering and design.

Conclusion

Whether you are building the next-generation electric vehicle, designing a lightweight drone, or constructing high-performance sports equipment, TipTop Composites offers the carbon fiber solutions you need. With an extensive product lineup that includes carbon fiber pipe, carbon fiber tube, and carbon fiber tubing, backed by a commitment to quality and innovation, TipTop is the partner of choice for all your advanced material needs.

0 notes

Text

Innovative Carbon Fiber Tubes by Tiptop Composites

Tiptop Composites stands out among carbon fiber tube manufacturers, offering tailored, corrosion-resistant tubes. Utilizing cutting-edge processes and premium materials, they cater to diverse applications, from drones to sports equipment, blending strength, versatility, and lightweight design for superior results.

0 notes

Text

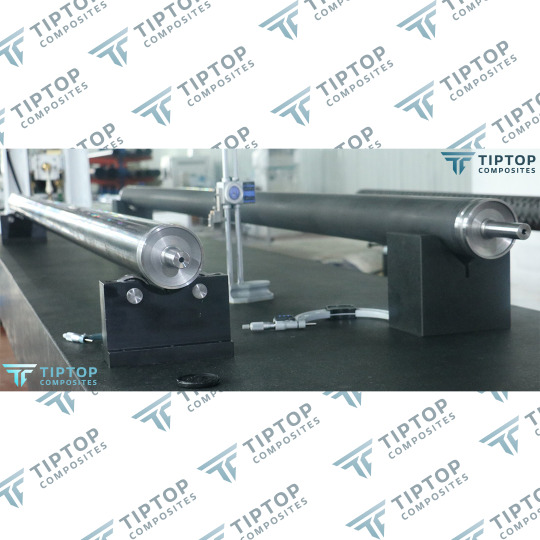

Revolutionizing Industrial Performance with TipTop Composites’ Advanced Composite Rollers

In the ever-evolving landscape of industrial engineering, where efficiency, durability, and precision are paramount, material innovation is often the key to performance breakthroughs. One such innovation making waves across multiple industries is the composite roller — a vital component that is lighter, stronger, and more durable than traditional metal alternatives. Leading the charge in this domain is TipTop Composites, a trusted manufacturer known for producing high-performance composite rollers that exceed modern engineering expectations.

Understanding the Role of Composite Rollers

Rollers are essential mechanical components used in a wide array of industrial applications, from conveyor systems and web handling equipment to textile machines and paper mills. Traditionally made of steel or aluminum, rollers have long been used to guide, support, or press moving materials during processing.

However, these metal rollers come with limitations — they are heavy, prone to corrosion, and can suffer from fatigue over time, especially in high-speed or high-load environments. Enter composite rollers, engineered from advanced materials such as carbon fiber, fiberglass, and epoxy resins, offering a lightweight yet incredibly strong alternative.

Composite rollers significantly reduce inertia, minimize energy consumption, and offer resistance to wear, corrosion, and chemicals, all while maintaining excellent dimensional stability. TipTop Composites has taken these advantages to the next level, producing rollers that are not only technically superior but also tailored to the exact needs of modern industries.

TipTop Composites: Engineering Excellence

TipTop Composites is a recognized name in the world of advanced composites. With a firm focus on quality, innovation, and client-centered solutions, the company has developed a portfolio of industry-leading composite products, including an impressive range of composite rollers.

What sets TipTop apart is its ability to combine material science expertise with state-of-the-art manufacturing techniques. The result is a line of composite rollers that meet — and often exceed — the demanding requirements of high-performance industries such as packaging, converting, textiles, aerospace, printing, and more.

Key Benefits of TipTop’s Composite Rollers

TipTop Composites’ composite rollers are engineered for optimal performance in high-speed and high-precision environments. Here are the core advantages that make them a superior choice:

1. Lightweight Construction

Composite rollers weigh significantly less than metal rollers, reducing the overall load on machinery. This leads to lower energy requirements, faster acceleration/deceleration, and reduced mechanical wear — critical benefits in high-throughput environments.

2. Corrosion and Chemical Resistance

Unlike metal rollers, composite rollers do not rust or degrade when exposed to moisture or corrosive chemicals. This makes them ideal for use in paper mills, food processing plants, and chemical manufacturing, where exposure to harsh substances is common.

3. High Stiffness and Strength

Despite being lightweight, TipTop’s composite rollers offer high tensile strength and stiffness, maintaining their structural integrity even under substantial loads. This ensures consistent performance over time, even in dynamic or vibration-heavy systems.

4. Low Thermal Expansion

Composite materials exhibit minimal thermal expansion, which helps maintain alignment and precision in temperature-variable environments — a key factor in printing, laminating, and web handling systems.

5. Vibration Damping

Composite rollers naturally dampen vibrations and absorb shocks better than metal, helping reduce noise and improve the smoothness of operation, which is especially important in high-speed industrial machines.

6. Custom Design Options

TipTop Composites offers fully customized composite rollers tailored to specific applications. From core materials to outer coatings, dimensions, surface finishes, and bearing configurations, every element can be specified to meet exact operational needs.

Application Versatility Across Industries

The adaptability of TipTop’s composite rollers makes them suitable for a vast range of industrial uses:

Packaging and Converting: Used for guiding, laminating, or applying tension to materials like plastic films and foils.

Printing: Ensures consistent roller pressure and alignment, improving print accuracy and reducing machine maintenance.

Paper and Pulp: Offers corrosion resistance and longevity in wet, high-humidity environments.

Textile Processing: Maintains consistent fabric tension and alignment at high speeds.

Food Processing: Compliant with hygienic standards and resistant to harsh cleaning agents.

Quality Control and Manufacturing Precision

At TipTop Composites, quality isn’t just a promise — it’s a process. The company maintains rigorous quality control protocols throughout manufacturing. From raw material inspection to final dimensional checks and dynamic balancing, every composite roller is engineered to meet strict industry standards.

Advanced production techniques such as filament winding, resin infusion, and precision CNC machining ensure each roller is built to exacting tolerances. The company also employs non-destructive testing methods to guarantee structural integrity and long-term performance.

Sustainability and Operational Efficiency

TipTop’s composite rollers contribute to more sustainable industrial practices by reducing energy consumption and increasing equipment life spans. Their lightweight nature lowers the operational load on motors and drive systems, leading to lower power usage and reduced carbon emissions.

Additionally, the durability and resistance of composite rollers mean less frequent replacement, lowering material waste and total cost of ownership.

Future-Ready Innovation

As industries continue to evolve toward automation, digitization, and sustainability, the demand for high-performance materials like composites will only increase. TipTop Composites is well-positioned to support this transition. By investing in R&D and staying ahead of trends in material science, the company continues to expand its capabilities and product offerings.

TipTop is actively exploring next-generation composite formulations, smart roller technologies with embedded sensors, and advanced coatings that further enhance performance and durability.

Conclusion

For industries that rely on precision, durability, and efficiency, TipTop Composites’ composite rollers offer a transformative solution. With benefits that far exceed traditional metal alternatives, these rollers help improve machine performance, reduce maintenance costs, and support more sustainable operations.

Whether you're managing a high-speed packaging line or a precision printing system, TipTop Composites delivers the high-quality, high-performance rollers your operations need to stay competitive. When excellence matters, trust TipTop to roll you into the future.

0 notes

Text

High-Performance Composite Rollers by TipTop Composites

TipTop Composites’ composite rollers offer exceptional strength, lightweight performance, and corrosion resistance. Designed for industrial applications, these rollers enhance efficiency and durability. Upgrade your machinery with high-performance composite rollers that deliver reliability and longevity in demanding environments.

0 notes

Text

Enhance Performance with Carbon Fiber Motorcycle Parts by TipTop Composites

TipTop Composites offers premium carbon fiber motorcycle parts designed for strength, lightweight efficiency, and durability. Upgrade your ride with high-performance components that enhance speed, aerodynamics, and style. Experience superior quality and precision engineering for an unbeatable riding experience.

0 notes

Text

Precision-Engineered Tapered Carbon Tubes by TipTop Composites

TipTop Composites’ tapered carbon tubes offer exceptional strength, lightweight performance, and aerodynamic efficiency. Ideal for aerospace, robotics, and sporting applications, these tubes provide seamless load distribution, enhanced durability, and superior stiffness, making them the perfect choice for high-performance engineering and structural advancements.

0 notes

Text

Elevating Safety: How TipTop Composites' Pole Inspection Camera Revolutionizes Utility Maintenance

In today’s world of expanding infrastructure and aging utility systems, ensuring safety while maintaining operational efficiency has never been more critical. Whether it’s electric utility lines, telecom poles, street lighting, or railway infrastructure, regular inspections are a must to prevent hazards, minimize downtime, and maintain public safety. However, traditional inspection methods can be time-consuming, labor-intensive, and hazardous for workers.

Enter TipTop Composites’ Pole Inspection Camera—a game-changing innovation that is redefining the standards of utility maintenance. Built with cutting-edge technology and precision engineering, this pole inspection system allows utility companies and field technicians to inspect tall, hard-to-reach structures without ever having to leave the ground.

The Challenge of Utility Pole Inspections

Utility poles are typically located in difficult or dangerous environments—on roadsides, in remote locations, or in areas with high voltage exposure. Inspecting them has traditionally involved climbing, bucket trucks, or drones, each of which comes with its own set of risks and logistical challenges.

Climbing poles requires skilled technicians and involves significant fall risk, not to mention the fatigue and physical strain it places on workers. Bucket trucks, while safer, are expensive to operate and can’t always access poles due to terrain or space restrictions. Drones provide an aerial view but are often limited by flight time, weather conditions, and regulatory constraints.

These issues are compounded when inspections need to be done quickly—after a storm, for instance—or over a large number of poles in a short time frame. That’s where TipTop Composites steps in with a practical, efficient, and safety-oriented alternative.

A Smarter, Safer Solution

The TipTop Composites Pole Inspection Camera is a lightweight, extendable, and highly maneuverable camera system mounted on a composite pole. Designed specifically for high-reach inspections, it offers technicians a way to view, record, and assess pole-top hardware, connections, and structural integrity from the ground.

Made from advanced composite materials, the inspection pole is durable yet lightweight, making it easy to carry and deploy by a single technician. The high-definition camera at the tip provides crystal-clear images and video, even at full extension, ensuring no detail is missed. With real-time viewing capabilities and options for wireless data transfer, inspection teams can make immediate decisions based on accurate visual information.

Key Features and Benefits

Here’s a closer look at the features that make the TipTop Composites Pole Inspection Camera a standout solution in the utility maintenance sector:

1. Extended Reach with Stability

The composite pole can be extended up to 40 feet or more, allowing for safe ground-level inspection of even the tallest poles. Unlike traditional telescopic systems, the high-rigidity design minimizes wobble and flex, offering stability even when fully extended.

2. High-Resolution Imaging

Equipped with a powerful camera system, the device delivers sharp, high-resolution images and video. Whether capturing corrosion on hardware, damaged insulators, or loose wiring, the imaging quality ensures nothing goes unnoticed.

3. Real-Time Monitoring

Technicians can view the live feed via a mobile device or tablet, allowing for immediate analysis and decision-making. This real-time visibility means less guesswork and faster response times for urgent maintenance needs.

4. Portability and Ease of Use

The lightweight composite construction makes the camera pole easy to transport and operate. One person can carry it to the inspection site, set it up, and begin inspections within minutes—no additional crew or heavy equipment required.

5. Cost-Efficient Operations

By removing the need for bucket trucks or drone pilots, this solution drastically reduces operational costs. It also increases the number of poles that can be inspected in a day, enhancing productivity.

6. Enhanced Worker Safety

Perhaps the most significant benefit is safety. By keeping inspectors on the ground, the system virtually eliminates the risks associated with climbing or working at heights. This translates to fewer injuries, less downtime, and improved compliance with safety regulations.

Applications Across Industries

Though designed with utility pole inspections in mind, the versatility of TipTop Composites’ camera system lends itself to multiple use cases across various industries:

Electric Utilities: Inspect transformers, crossarms, and conductors for damage or wear.

Telecommunications: Monitor antenna mounts, junction boxes, and cable integrity.

Transportation: Assess overpasses, traffic light supports, and railway signal structures.

Municipal Services: Evaluate street lighting, signage poles, and urban infrastructure without disrupting traffic.

By serving multiple verticals, the pole inspection camera helps organizations centralize their inspection protocols with one streamlined solution.

Data-Driven Maintenance

Another major advantage of the TipTop Composites system is how it supports predictive and preventive maintenance strategies. With high-quality visual data collected regularly, utility companies can spot trends, track degradation over time, and address issues before they escalate into costly failures.

Captured footage can be stored, cataloged, and analyzed using asset management software, enabling long-term monitoring and more informed decision-making. This approach not only enhances equipment lifespan but also aligns with modern asset management standards such as ISO 55000.

Supporting a Greener Future

Environmental impact is another area where this technology makes a difference. Unlike drones, which require battery recharging or fuel for transport vehicles, and bucket trucks that rely on diesel, the TipTop pole system is human-powered and eco-friendly. By reducing the need for large machinery and vehicle emissions, it supports greener, more sustainable field operations.

The Future of Utility Inspections

As infrastructure networks grow in complexity, the need for reliable, efficient, and safe inspection tools will only increase. Innovations like the TipTop Composites Pole Inspection Camera are not just enhancing how inspections are carried out—they are setting new standards for what’s possible in field safety and maintenance efficiency.

By allowing teams to do more with less risk, TipTop Composites is helping organizations modernize their operations and build a safer, more resilient utility network.

Conclusion

Utility inspections don’t have to be high-risk or high-cost. With the right tools, organizations can protect their workforce, optimize maintenance workflows, and extend the life of critical infrastructure. The TipTop Composites Pole Inspection Camera is proof that innovation doesn’t always need to be complex—it just needs to be smart, safe, and designed with real-world challenges in mind.

Whether you’re managing power lines, telecommunications equipment, or municipal lighting, the future of inspections is already here—and it’s looking up.

#carbon fiber rectangular tube#carbon fiber drone parts#kevlar tubing#ducati carbon fiber#telescopic pole

0 notes

Text

Carbon Fiber Square Tubes: Strength & Precision from TipTop Composites

Discover high-performance carbon fiber square tubes from TipTop Composites, engineered for superior strength, lightweight durability, and precision. Ideal for aerospace, robotics, and structural applications, our composite tubes offer excellent rigidity and corrosion resistance. Explore our premium carbon fiber solutions today!

0 notes

Text

Precision and Durability: TipTop Composites’ Sports Video Tripod

Designed for fast-paced sports recording, TipTop Composites' tripod for sports video offers exceptional stability and lightweight portability. Its rugged carbon fiber construction ensures vibration-free shooting while providing smooth, effortless adjustments. Ideal for stadiums, outdoor fields, and sports enthusiasts, this tripod guarantees crystal-clear video footage every time.

0 notes