#ElectricalInfrastructure

Explore tagged Tumblr posts

Text

Why Armored Cables Are Essential for Industrial Operations in Harsh Environments

Trusted Brands, Guaranteed Performance

At MTK Supply International Corp, we supply a wide variety of electrical and telecommunication products, including armored cables, from globally recognised brands like Belden, Nexans, Southwire, 3M, Panduit, Leviton, and Hubbell. These names are trusted in industrial settings across the world, and we’re proud to connect your projects with the best the market has to offer.

Read More:-Why Armored Cables Are Essential for Industrial Operations in Harsh Environments

#ArmoredCablesUSA#CableInstallation#ElectricalSafety#HomeWiring#ElectricalContractor#QualityCables#USAElectrical#CableManagement#ArmoredCableInstallation#DurableWiring#ConstructionLife#BuildingSafety#ElectricalInfrastructure#WiringSolutions#CableProtection#USAIndustry#SafeWiring#PowerYourProjects#ElectricalInnovation

0 notes

Text

MV Cables Reliable Medium Voltage Solutions for Industrial Applications

MV cables are multi-layered and designed to provide many layers of protection from wear and tear from mechanical abuse, moisture, chemicals, abrasives, high temperatures, and many other grueling items, maximizing the life of the cable while keeping it operational. MV cables allow power to be distributed over large distances with very low energy loss, keeping industrial operations operating efficiently and financially successful.

MV cables are utilized in power stations, substations, manufacturing facilities, mines, or heavy industrial sites. MV Cables allows clients to maintain operations with safety, efficiency, and without interruptions, thus increasing their performance under pressure. MV cables are essential in allowing industrial businesses to ensure maximum productivity with minimal downtime, especially in this age of competition.

#MVCables#ElectricalSafety#PowerDistribution#IndustrialCables#Electronics#CableManagement#ElectricalEngineering#HighVoltage#Cables#PowerSupply#EnergySolutions#CircuitSafety#MVTransmission#CableInstallation#RenewableEnergy#TechInnovation#ElectricalInfrastructure#EnergyEfficiency#WiringSolutions

0 notes

Text

Padmavahini Distribution Transformers: Reliable and Efficient Power Delivery Solutions

What is a Distribution Transformer? A distribution transformer is a step-down transformer designed to reduce high-voltage electricity from the transmission lines to a lower voltage suitable for residential, commercial, and industrial use. These transformers are typically small in size and filled with insulating oil. Padmavahini offers various types of distribution transformers, including single-phase, multi-phase, pad-mounted, pole-mounted, and underground transformers.

Purpose: The primary purpose of Padmavahini's distribution transformers is to:

Efficiently transmit and distribute electrical power from the primary distribution circuit to end-users.

Provide voltage levels suitable for residential, commercial, and light industrial applications.

Ensure reliable power supply with minimal energy losses.

Facilitate easy on-site maintenance and repair.

Key Features:

High Mechanical Strength: Designed to withstand mechanical stresses during operation.

Short Circuit Resilience: Strong ability to endure short circuit conditions without damage.

Low Partial Discharge: Minimizes energy loss and prolongs transformer life.

Good Thermal Stability: Maintains performance under varying temperature conditions.

Energy Conservation: Efficient design reduces energy losses during transmission.

Benefits:

Cost Efficiency: Optimized design leads to reduced operational costs.

Versatility: Available in various types to suit different applications and environments.

Reliable Power Distribution: Ensures consistent power supply to end-users.

Ease of Maintenance: Structured for straightforward on-site maintenance and repair.

Conclusion: Padmavahini's distribution transformers are engineered to meet the diverse needs of modern power distribution networks. With a focus on efficiency, reliability, and compliance with international standards, these transformers provide dependable solutions for delivering electricity to homes, businesses, and industries.

#DistributionTransformer#PadmavahiniTransformers#PowerDistribution#EnergyEfficiency#ReliablePower#ElectricalInfrastructure#MadeInIndia#IndustrialPower

0 notes

Text

The Future of Electrical Power Distribution: Trends and the Evolving Role of Switchgear

The electrical power distribution landscape is undergoing a profound transformation, driven by technological advancements, environmental concerns, and evolving energy demands. As we move towards a more electrified and interconnected world, understanding the future of electrical power distribution — its emerging trends and the significant challenges it faces — is crucial for stakeholders across the energy sector. At the heart of this evolution lies switchgear, the critical equipment responsible for controlling, protecting, and isolating electrical circuits. This article delves into the key forces shaping the future of how electricity is generated, transmitted, and ultimately consumed, emphasizing the pivotal role of advanced switchgear products in this dynamic environment.

Key Trends Shaping the Future of Electrical Power Distribution and Switchgear:

Several powerful trends are converging to redefine the future of electrical power distribution, directly impacting the requirements and capabilities of switchgear:

· Decentralization and Distributed Generation (DG): The traditional model of centralized power plants is giving way to distributed generation sources like solar PV, wind turbines, microgrids, and energy storage. This shift necessitates switchgear capable of managing bidirectional power flow, seamlessly integrating these diverse sources, and providing advanced protection for localized networks.

· The Rise of Renewable Energy Integration and Advanced Switchgear: The urgent drive towards decarbonization demands the integration of intermittent renewable energy sources. Switchgear with smart grid capabilities, including sophisticated protection relays, fault ride-through functionalities, and advanced control systems, is essential to ensure grid stability and reliability when dealing with fluctuating renewable generation.

· Smart Grids and Intelligent Switchgear: The realization of smart grids relies heavily on digital technologies and intelligent devices. Smart switchgear is a cornerstone of this evolution, offering features like remote monitoring, automated fault detection and restoration, load management capabilities, and seamless communication with grid management systems.

· Electrification of Everything and Increased Demand on Switchgear: The growing trend of electrification in transportation, heating, and industry will significantly increase electricity demand. Switchgear will need to handle higher current ratings, provide robust and reliable connections for increased loads, and ensure the safety and efficiency of these electrified systems.

· Advanced Metering Infrastructure (AMI) and Data-Driven Switchgear: The data generated by AMI systems provides valuable insights into grid performance. Future switchgear can leverage this data for predictive maintenance, optimized operation, and enhanced diagnostics, contributing to a more efficient and reliable distribution network.

· Energy Storage Systems (ESS) and Switchgear Integration: Battery storage is crucial for grid stability and renewable energy integration. Switchgear plays a vital role in safely and efficiently connecting and managing the charging and discharging cycles of ESS at various scales.

· Cybersecurity for Critical Switchgear Infrastructure: With increasing digitalization, protecting switchgear and its control systems from cyber threats is paramount. Future switchgear must incorporate robust cybersecurity measures to ensure grid resilience and prevent disruptions.

Key Challenges in the Future of Electrical Power Distribution and Implications for Switchgear:

Addressing the following challenges will drive innovation and development in the switchgear products industry:

· Grid Modernization Costs and Investment in Advanced Switchgear: Upgrading the existing infrastructure with modern switchgear and smart grid technologies requires significant investment. Justifying these costs and finding effective funding mechanisms are key challenges.

· Integrating Distributed Generation and Ensuring Switchgear Compatibility: Connecting numerous DG sources requires switchgear that can manage bidirectional power flow, ensure protection coordination, and maintain power quality.

· Securing Digitalized Switchgear Against Cyber Threats: Implementing robust cybersecurity measures in switchgear and control systems is essential to protect the grid from malicious attacks.

· Adapting Regulatory Frameworks for New Switchgear Technologies: Regulations need to evolve to facilitate the adoption of advanced switchgear and smart grid technologies.

· Developing a Skilled Workforce for Installation and Maintenance of Modern Switchgear: The installation, commissioning, and maintenance of advanced switchgear require a skilled workforce with specialized knowledge.

· Replacing Aging Switchgear Infrastructure with Modern and Sustainable Solutions: The need to replace aging switchgear presents an opportunity to adopt more efficient, reliable, and environmentally friendly technologies.

The Evolving Role of Switchgear Products:

Switchgear is no longer just a means of switching circuits, it is becoming an intelligent and integrated component of the smart grid. The future demands switchgear products that are:

· Smarter: Equipped with advanced sensors, communication protocols, and digital control platforms.

· More Flexible: Capable of handling bidirectional power flow and seamlessly integrating diverse energy resources.

· More Reliable: Designed with advanced diagnostics, predictive maintenance capabilities, and enhanced fault management.

· More Secure: Incorporating robust cybersecurity features to protect critical infrastructure.

· More Sustainable: Utilizing environmentally friendly insulating mediums and materials.

Conclusion:

The future of electrical power distribution presents both exciting opportunities and significant challenges for the switchgear products industry. The trends of decentralization, renewable energy integration, smart grids, and electrification are driving the need for innovative and advanced switchgear solutions. Companies like Blitz Bahrain, specializing in providing high-quality switchgear products, are at the forefront of enabling this transformation. By understanding these evolving trends and addressing the associated challenges, Blitz Bahrain is committed to developing and supplying the cutting-edge switchgear necessary to build a safer, more reliable, and sustainable energy future for their customers.

#Switchgear#ElectricalPowerDistribution#FutureGrid#SmartGrid#RenewableEnergy#DistributedGeneration#GridModernization#PowerSystems#EnergyStorage#Cybersecurity#ElectricalInfrastructure#EnergyTransition#FutureofEnergy#ElectricalEngineering#PowerGrid#BlitzBahrain#electrical engineers#electrical supplies#electrical equipment#bahrain25

0 notes

Text

Experience the future of overhead transmission with our All Aluminium Alloy Conductor (AAAC). Designed for superior strength, conductivity, and resistance to corrosion, AAAC is the smart, sustainable solution for modern power distribution networks. Lighter than ACSR and more durable than AAC — it’s performance redefined by Capital Cables.

For more details, visit- https://www.capitalcables.co.in/wires-cables/aaac-cable-conductor

#capitalcables#CableConductor#aluminiumalloyconductor#alloyconductor#IndustrialInfrastructure#commercialinfrastructure#ElectricalInfrastructure#AAAC#overheadtransmission#wirecables

0 notes

Text

Trusted Transmission Cable, Electrical Companies in India, and Switches Company in India – HPL India

HPL India stands out as a leading name when it comes to transmission cable solutions, trusted by industries nationwide. Recognized among the top electrical companies in India, HPL delivers superior quality products that meet global standards. As a reliable switches company in India, HPL offers a wide range of durable and innovative switches for residential and commercial spaces. Whether you need efficient transmission cable systems or are searching for one of the most dependable electrical companies in India, HPL India remains your go-to switches company in India for trusted electrical solutions.

Visit for more info: HPL Electric & Power Limited

Address: 1/20, Asaf Ali Road, New Delhi - 110002

Email: [email protected]

Phone: +91-11-2323441

#TransmissionCable#ElectricalCompaniesInIndia#SwitchesCompanyInIndia#PowerTransmission#ElectricalSolutions#CableManufacturers#Switchgear#ElectricalInfrastructure#SmartSwitches#IndiaManufacturing#HPLIndia

0 notes

Text

High-Quality Power Transformers: The Backbone of Energy Efficiency

In the short-paced global of these days, with energy usage at an all-time excessive, industries and groups are usually searching out method to maximize electricity intake on the same time as minimizing charges. At the middle of this power revolution is a silent hero—fantastic energy transformers. These vital portions of device are critical to developing power common performance, reliability, and sustainability feasible in power distribution systems.

Why Do High-Quality Power Transformers Matter? A high-quality power transformers for energy efficiency is greater than an electrical tool—it's far the link that ensures clean strength switch from power plant life to households, workplaces, and industries. Yet, no longer all transformers are of the equal desired.

Poor-exquisite or vintage transformers can motive excessive strength losses, overheating, or perhaps tool breakdown. In evaluation, great power transformers are designed with notably-contemporary materials and pretty-modern-day generation to optimize normal widespread basic overall performance and decrease strength wastage.

The Function of Power Transformers in Energy Efficiency Energy fundamental general overall performance isn't a high priced but a want. High-brilliant transformers are engineered to:

� Minimize Energy Losses: New transformers are constructed with better middle substances, optimized windings, and superior insulation structures to lessen electricity dissipation.

� Improve System Reliability: High-wonderful transformers offer better durability, minimizing the opportunities of outages and high-priced protection.

� Facilitate Renewable Energy Integration: As the globe is transitioning inside the course of renewable electricity belongings, extremely good transformers play a essential characteristic in dealing with numerous hundreds from sun and wind electricity systems.

� Reduced Operational Expenses: Through minimizing wastage of energy, terrific transformers make certain maximum essential charge economic monetary savings inside the path of their operational length.

What Is a High-Quality Transformer?

When deciding on a power transformer, companies have to look for the number one tendencies that replicate pinnacle-notch excellent:

� Low Loss Cores – High-latest common standard overall performance center materials like amorphous metallic lessen center losses and increase performance.

� Efficient Windings – Optimized copper or aluminum windings offer hundreds an lousy lot less resistance and warmth generation.

� Advanced Cooling Systems – Effective cooling structures keep away from overheating and boom transformer existence.

� Stringent Manufacturing Standards – Adherence to worldwide necessities like IEC, IEEE, and NEMA gives reliability and safety.

Investing in a Sustainable Future An energy of will to amazing power transformers is a power of will to sustainability. Upgrading to energy-green transformers permits businesses to lower their carbon footprint even as growing a contribution to global power conservation responsibilities.

At Pavika Power Equipment, we're dedicated to offering incredible electricity transformers that set the same vintage for power desired overall performance. Our products are crafted with the modern-day-day-day technology to allow groups to maximize energy consumption, restriction costs, and create a greener destiny.

Ready to make the switch to remarkable electricity transformers? Let's power a greater green international—collectively! Visit www.pavikapowerequipment.in today.

#HighQualityPowerTransformers#EnergyEfficiency#PowerTransformers#EnergyInnovation#SustainableEnergy#RenewableEnergy#ElectricalEngineering#EnergySolutions#EfficiencyInPower#GreenTechnology#EnergySaving#PowerQuality#Transformers#ElectricalInfrastructure#SmartGrids#IndustrialEnergy#EnergyManagement#Electrics#SustainablePower

0 notes

Text

Arteche Relays for Error-Free Operation: Protecting Power Transformers and Circuit Breakers

In the high-stakes world of power systems, ensuring the safety and reliability of critical equipment is paramount. Power transformers and circuit breakers form the backbone of electrical infrastructure, handling massive loads and enabling smooth power distribution. However, these vital components are susceptible to faults, overloading, and other hazards. Arteche relays, particularly their trip and lockout relays, have become a trusted solution to safeguard such equipment, offering reliability, speed, and durability in demanding environments.

The Role of Relays in Power Systems

Relays serve as protective devices in electrical circuits, detecting anomalies such as overcurrent, short circuits, and other fault conditions. When an issue is detected, relays promptly isolate the affected section to prevent further damage. This protective mechanism is critical for power transformers and circuit breakers, as failures in these systems can lead to costly repairs, extended downtime, and potential safety hazards.

Arteche, a globally recognized leader in relay manufacturing, has been at the forefront of developing high-performance relays for over 60 years. Their trip and lockout relays are specifically designed to meet the rigorous demands of modern power systems, ensuring error-free operation and long-term reliability.

Arteche’s Trip and Lockout Relays: Key Features

Arteche’s trip and lockout relays are purpose-built for high-voltage environments, such as substations, power generation plants, and industrial facilities. Here are some standout features that make these relays indispensable:

High-Speed Operation

Arteche relays boast a rapid response time, typically between 3 and 20 milliseconds, depending on the model. This swift action minimizes the risk of cascading failures and ensures that faults are isolated before they can escalate.

Latching Mechanism

The latching design of Arteche’s lockout relays (LOR - ANSI 86) ensures that once a trip occurs, the relay remains in a locked position until it is manually or electrically reset. This feature prevents inadvertent re-energization of faulty equipment, enhancing overall safety.

High Breaking Capacity

Arteche relays are engineered to handle high fault currents without compromising performance. Their robust construction guarantees reliable operation even under extreme fault conditions.

Compliance with International Standards

Arteche relays meet stringent standards such as IEC 61000, IEC 60947, IEC 60255, and ANSI C37.90. This compliance ensures compatibility and reliability across diverse power systems worldwide.

Wide Voltage Range

Arteche offers relays with a broad spectrum of auxiliary voltage options, making them suitable for various applications and environments.

Durability in Harsh Environments

Designed to withstand seismic conditions, vibrations, and extreme temperatures, Arteche relays are ideal for deployment in demanding operational environments.

Protecting Power Transformers

Power transformers are crucial for voltage regulation and power transmission in electrical grids. They operate under high stress and are prone to issues like overheating, oil leaks, and insulation failures. Arteche relays provide several layers of protection for transformers:

Fault Isolation: Arteche’s trip relays rapidly disconnect transformers from the grid in case of overcurrent or short circuits, preventing further damage.

Preventing Re-Energization: The lockout feature ensures that a transformer cannot be re-energized until the fault is rectified and the relay is manually reset. This eliminates the risk of additional damage from unresolved issues.

Monitoring Critical Parameters: Arteche relays integrate seamlessly with monitoring systems, enabling real-time tracking of key transformer parameters like temperature, gas pressure, and oil levels. This proactive approach enhances reliability and reduces maintenance costs.

Enhancing Circuit Breaker Reliability

Circuit breakers play a pivotal role in interrupting fault currents and protecting electrical circuits. Arteche relays enhance their operation in several ways:

Precise Command and Control: Arteche’s high-speed relays ensure that circuit breakers receive accurate and timely trip commands, minimizing response times during fault conditions.

Long Wiring Support: The high-burden configuration of Arteche relays prevents false trips caused by transient signals or long wiring distances. This feature is particularly beneficial in large substations where relay-to-breaker connections can span significant distances.

Durability and Longevity: Arteche’s relays are built to last, ensuring consistent performance over decades of operation. Their robust design minimizes the risk of relay failure, which could otherwise compromise circuit breaker functionality.

Meeting the Demands of High-Voltage Substations

High-voltage substations are complex environments where reliability and safety are non-negotiable. Arteche’s relays are specifically designed to address the challenges of such settings:

Handling High Fault Currents: Arteche relays are equipped to manage the high fault currents typical of HV substations, ensuring seamless operation during fault conditions.

Seismic and Vibration Resistance: Arteche relays are tested to withstand seismic activity and mechanical vibrations, making them suitable for installations in earthquake-prone regions.

Error-Free Operation Under Transients: Arteche’s compliance with ESI 48-4 standards ensures that their relays operate reliably even under transient conditions, minimizing the risk of nuisance trips.

Arteche’s Legacy of Excellence

With over six decades of experience, Arteche has earned a reputation for producing high-quality electromechanical relays. Millions of their relays are in service worldwide, safeguarding critical power equipment in diverse applications. Here are some reasons why Arteche continues to lead the industry:

Uncompromising Quality: Arteche’s relays undergo rigorous testing to ensure they meet the highest standards of performance and reliability.

Innovative Designs: Arteche’s commitment to innovation is evident in features like high-speed operation, latching mechanisms, and high-burden configurations.

Global Reach: Arteche’s relays are trusted by utilities, industrial plants, and power generation facilities across the globe, thanks to their adaptability and compliance with international standards.

Case Studies: Arteche Relays in Action

Substation Safety in Europe: A high-voltage substation in Europe implemented Arteche trip and lockout relays to enhance equipment safety. The relays’ rapid response and high-breaking capacity significantly reduced downtime during fault incidents, saving the utility millions in repair costs.

Transformer Protection in Asia: A power generation company in Asia relied on Arteche relays to protect its fleet of transformers. The relays’ real-time monitoring capabilities helped identify potential issues before they escalated, improving overall system reliability.

Industrial Facility in North America: An industrial plant in North America integrated Arteche relays into its control systems to ensure seamless operation of circuit breakers. The relays’ durability and precision were key factors in minimizing production losses due to electrical faults.

Conclusion

Arteche relays are a cornerstone of modern power systems, offering unmatched reliability, speed, and durability. Their ability to protect vital equipment like power transformers and circuit breakers ensures that electrical grids and industrial facilities operate smoothly and safely. Whether it’s preventing the re-energization of faulty equipment, handling high fault currents, or enduring harsh environmental conditions, Arteche’s trip and lockout relays consistently deliver error-free performance.

For power systems where safety and reliability are paramount, Arteche relays provide the peace of mind that comes with over 60 years of engineering excellence. As the demands on power infrastructure continue to grow, Arteche remains a trusted partner in safeguarding the critical components that keep the lights on and the world running.

At Digital & Smart Grid Enterprises, we pride ourselves on delivering cutting-edge solutions, including reliable Arteche relays, to ensure the safety and operational efficiency of your power systems. Our expertise spans comprehensive testing, commissioning, and monitoring services tailored to safeguard your critical power equipment, such as power transformers and circuit breakers.Contact us today at +917021624024 or email [email protected] to learn more about how we can support your power system's reliability and safety. Click here to explore our Relay Protection and Maintenance Services.

#PowerSystemSafety#ElectricalInfrastructure#ArtecheRelays#TransformerProtection#CircuitBreakerReliability#HighVoltageSolutions#RelayProtection#EnergyEfficiency#ElectricalSafety#SubstationAutomation#IndustrialPowerSolutions#FaultDetection#GridReliability#ElectricalEngineering#SmartGridSolutions

0 notes

Text

Saudi Arabia Electric Motor Market size by value at USD 2.7 billion in 2024. During the forecast period between 2025 and 2031, BlueWeave expects Saudi Arabia Electric Motor Market size to boom at a robust CAGR of 7.3% reaching a value of USD 4.4 billion by 2031. The growth of Electric Motor Market in Saudi Arabia is propelled by the rapid urbanization. Increasing disposable incomes are fostering a heightened demand for household appliances, such as washing machines, dishwashers, and microwaves. The Kingdom's tropical climate necessitates the widespread usage of air conditioning, which further spurs a demand for electric motors. Additionally, the gradual displacement of gas turbines by electric motors within industrial settings serves as another key growth driver for the market. The government’s supportive initiatives that promote industrial growth, combined with substantial investments in infrastructure development, are projected to further propel the market expansion. A growing emphasis on environmental sustainability, along with the expanding electric vehicle (EV) sector, is expected to boost the growth of Saudi Arabia Electric Motor Market in the coming years.

Sample Request: https://www.blueweaveconsulting.com/report/saudi-arabia-electric-motor-market/report-sample

Opportunity - Rising Demand for Electric Vehicles (EVs)

The rising demand for electric vehicles (EVs) is expected to provide significant growth opportunities for companies in Saudi Arabia Electric Motor Market over the forecast period. With a vision to transition 30% of Riyadh’s vehicles to electric vehicles by 2030, the Kingdom is advancing its EV infrastructure and production capabilities through government-led initiatives and substantial investments. Key developments include the establishment of more than 5,000 charging points across 1,000 stations by 2030, spearheaded by the Electric Vehicle Infrastructure Company (EVIQ). Prominent manufacturers like Lucid Motors and Ceer are bolstering local production. Lucid aims to produce more than 150,000 EVs annually at its complete manufacturing facility in King Abdullah Economic City (KAEC) and Ceer building a state-of-the-art EV manufacturing complex. The surge in EV production directly addresses the increasing demand for high-performance electric motors, which enhance vehicle efficiency, reduce emissions, and support sustainability goals. Moreover, the integration of renewable energy sources into EV infrastructure aligns with Saudi Arabia’s Vision 2030 objectives, emphasizing economic diversification and carbon neutrality. As global and local players collaborate to drive innovation in EV manufacturing, Saudi Arabia’s electric motor market is poised for rapid expansion, supported by the Kingdom’s commitment to sustainable mobility and technological advancement.

#BlueWeave#Consulting#Marketforecast#Marketresearch#ElectricalGrowth#ElectricalInfrastructure#SaudiArabiaElectric#ElectricMotorMarketTrends#IndustrialDevelopment

0 notes

Text

Ring Main Unit Market-Industry Forecast, 2024–2030

Ring Main Unit Market Overview:

Ring Main Unit Market size is estimated to reach $5.2 billion by 2030, growing at a CAGR of 8.0% during the forecast period 2024–2030.

Request Sample Report :

The two major trends in the Ring Main Unit Market are the adoption of eco-friendly technologies and the integration of smart systems. Increasingly, ecofriendly advancements like Siemens’ F-gas free RMUs with climate neutral Clean Air insulation are coming to the fore. These solutions eliminate SF6 gases and reduce the carbon footprint of power distribution systems by an order of magnitude, while maintaining high efficiency and safety. Moreover, smart technologies are integrated into RMUs to make them intelligent solutions. A key enabler provided by digitalization is the remote monitoring, automated control and IoT connectivity of features as seen in ABB’s SafeLink RMUS. These capabilities improve operational efficiency, support predictive maintenance, and integrate easily with the modern decentralized grids. These trends, together, guarantee that RMUs satisfy increasing requirements for sustainability, reliability, and sophisticated functionality in power distribution.

Inquiry Before Buying :

COVID-19 / Ukraine Crisis — Impact Analysis:

COVID 19 pandemic heavily impacted Ring Main Unit (RMU) market by creating delays in manufacturing, supply chain issues and project delays. Reduced availability of the workforce and the slow pace of production of RMU components in the regions with strong dependence on imports due to lockdowns and restrictions. Key sectors such as industrial and commercial projects continued to demand less due to persisting economic uncertainties.

Russia Ukraine war also added to the RMU market by aggravating the supply chain problems and intensifying the energy security issues. This conflict disrupted global trade in all critical raw materials for RMU costs, such as copper and steel, and this state of inflation. At the same time, energy supply disruptions in Europe triggered investments in reliable and decentralized power systems.

Key Takeaways:

APAC Dominates the Market

APAC is the dominant region in the Ring Main Unit market driven by industrialization, growing demand for power and infrastructure development. Countries like China, India and Japan are heavily investing in expanding their power distribution networks to support growing electricity demand. According to the Central Electricity Authority, Government of India, India generated 1,949 TWh of electricity in FY 2023–24, with 1,734 TWh coming from utilities, and achieved a per capita electricity generation of 1,395 kWh, reflecting substantial energy demands. Additionally, the region’s focus on renewable energy integration with extensive wind and solar projects increases the deployment of RMUs for efficient power distribution. There is a need for reliable electrical systems, further fueling RMU demand. Moreover, APAC’s strong manufacturing base reduces production costs for RMUs, making them more accessible to local utilities and industries.

Gas Insulated Represent the Largest Segment

The Ring Main Units (RMUs) market is dominated by Gas-insulated RMUs which are characterized by a compact design, high efficiency, and ability to support reliable electricity distribution in urban areas with limited space. This trend is further underscored by the expansion efforts of Siemens India, which were announced on May 2024. Siemens will invest $3.95 million to enhance its gas insulated switchgear (GIS) production capacity by 23% which includes 22,000 feeders for its Ring Main Unit. The expansion will be phased over three years from 2024–25 and will be funded from internal accruals. Such investments demonstrate the increasing need for gas insulated RMUs, which are essential to modern power systems for switching, transformation, measuring and distributing electrical energy in a reliable and efficient way. Thus, gas insulated RMUs are a preferred choice to address the rising energy needs globally due to their scalability and performance.

Schedule A Call :

Industrial is the Largest Segment

The industrial sector is the largest application area for RMUs owing to its high demand for reliable and uninterrupted power supply. Industries such as manufacturing, mining, oil & gas and petrochemicals operate in environments where power outages can result in significant financial losses and operational downtime. RMUs are preferred in these settings due to their compact design, durability and enhanced safety features. Additionally, industries often require medium-voltage distribution systems where RMUs provide an ideal solution for efficient load management and fault isolation. The growing trend of automation and electrification in industrial operations further boosts the demand for advanced RMUs with smart monitoring and control capabilities. According to Aktif Elektroteknik, RMUs are essential components in power distribution particularly valuable in industrial applications and humid environments. These medium-voltage switchgear systems, compact yet powerful, ensure steady electricity flow and can quickly switch between power sources during repairs or emergencies, minimizing downtime. Their versatility, low maintenance, and adaptability for indoor and outdoor installations make them indispensable for industrial use. With advancements in smart grid technology and renewable energy integration, RMUs continue to evolve, offering enhanced capabilities to support modern industrial operations. This makes them a cornerstone for ensuring operational continuity and energy efficiency in industries worldwide.

Demand for Uninterrupted Electricity in Critical Applications to Drive the Market

The demand for uninterrupted electricity in critical applications, such as medical facilities, data centers and manufacturing, is a significant driver for RMU installations. The rapid growth in global electricity demand is projected to increase by around 4% in 2024, up from 2.5% in 2023, which compounds this need, according to the IEA’s Electricity Mid-Year Update. This is the highest annual growth rate since 2007, except for exceptional rebounds following crises. As global electricity consumption grows, with a further 4% growth expected in 2025, consistent power supply is critical to the functioning of critical sectors. They expect renewables to expand rapidly, accounting for 30% of global electricity supply in 2023 and 35 percent in 2025. Though, strong electricity demand, in economies like India with 8% growth and China with over 6% growth TO ensures stable CO₂ emissions from coal reliance. This robust demand demonstrates the need for reliable RMU systems to maintain uninterrupted power to the energy intensive infrastructure of modern economies.

Buy Now :

Lack of Skilled Professionals to Hamper the Market

There is a shortage of skilled workers required for installation, operation and maintenance. RMUs involve sophisticated technologies including advanced circuit breakers, insulation systems and digital monitoring tools which demand expertise for effective handling. In developing countries, where power infrastructure development is accelerating, the gap between workforce capabilities and technological advancements is particularly pronounced. This skill deficit leads to delays in project implementation, suboptimal system performance and increased operational risks. According to TeamLease, this problem is very significant in the renewable energy sector, where there is a skill gap of nearly 1.2 million workers. Moreover, TeamLease Services states, the industry will need 1.7 million trained workers by 2027, which is when demand for skilled professionals is expected to rise by 26%. This is a similar challenge occurring in other power sector infrastructure sectors, including RMUs, where the shortage of skilled professionals not only slows down growth, but also raises concerns about the quality and reliability of systems deployed around the world.

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Ring Main Unit Market. The top 10 companies in this industry are listed below:

Siemens AG

Schneider Electric SE

Eaton Corporation Plc

ABB Ltd.

GE Vernova

Toshiba Corporation

CG Power and Industrial Solutions

CHINT Group

LS Electric Co., Ltd

Lucy Electric

For more Automation and Instrumentation Market reports, please click here

#RingMainUnit#ElectricalInfrastructure#PowerDistribution#SmartGrid#ElectricalEngineering#EnergySolutions#PowerGeneration

0 notes

Text

Exporter of LV Panels in Nigeria

Sempra Electric Pvt. Ltd. is a Manufacturer and Exporter of LV Panels in Nigeria. Sempra Electric Pvt. Ltd., established in 1996, ensures that all our products meet international quality standards at every stage of the manufacturing process. We offer a wide range of products, including diesel generators, LV panels, HV panels, transformers, UPS & battery banks, voltage stabilizers. LV Panels play a crucial role in controlling the flow of electricity from the main power source. To various circuits and equipment within buildings, industrial plants, and other facilities. Our LV Panels often include components such as circuit breakers, fuses, meters, switches, and control systems. They are essential for protecting electrical systems from overloads, short circuits, and other electrical faults. LV panels feature components like circuit breakers, fuses, meters, and switches to distribute electricity safely and efficiently at low voltage levels, safeguarding against overloads and faults in electrical systems. We use our LV panels in buildings, industrial plants, and facilities to distribute electricity safely and efficiently. They control power flow to equipment, lighting, and other electrical loads while protecting against faults. Sempra Electric Pvt. Ltd. is a Manufacturer and Exporter of LV Panels in Nigeria and locations like Lagos, Kano, Ibadan, Benin City, Port Harcourt, Jos, Ilorin, Abuja, Kaduna, Enugu, Zaria, Warri, Maiduguri, Aba, Bauchi, Akure, Abeokuta. If you have any questions or require further information, please feel free to contact us. Read the full article

#Aba#Abeokuta#Abuja#Akure#andvoltagestabilizers#BatteryBanks#Bauchi#BeninCity#circuitbreakers#CircuitProtection#components#ControlSystems#DieselGenerators#Efficiency#ElectricalDistribution#ElectricalInfrastructure#ElectricalLoads#Enugu#EquipmentProtection#Exporter#ExporterofLVPanels#ExporterofLVPanelsinNigeria#fuses#HVPanels#Ibadan#Ilorin#industrialplants#Jos#Kaduna#Kano

0 notes

Text

North America Cable Management Market

📡 𝐂𝐥𝐞𝐚𝐧 𝐈𝐧𝐬𝐭𝐚𝐥𝐥𝐬 | 🔌 𝐌𝐚𝐱𝐢𝐦𝐮𝐦 𝐏𝐞𝐫𝐟𝐨𝐫𝐦𝐚𝐧𝐜𝐞 | 🔒 𝐒𝐞𝐜𝐮𝐫𝐞 𝐒𝐲𝐬𝐭𝐞𝐦𝐬

North America Cable Management Market size is estimated to reach $5927.8 million by 2030, growing at a CAGR of 8.6% during the forecast period 2024-2030.

🔑 𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬

𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧 𝐨𝐟 𝐒𝐦𝐚𝐫𝐭 𝐚𝐧𝐝 𝐂𝐨𝐧𝐧𝐞𝐜𝐭𝐞𝐝 𝐒𝐲𝐬𝐭𝐞𝐦𝐬

The demand for intelligent cable management solutions is on the rise. These systems utilize Internet of Things (IoT) technology to offer real-time monitoring, predictive maintenance, and enhanced airflow management.

𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐚𝐧𝐝 𝐄𝐜𝐨-𝐟𝐫𝐢𝐞𝐧𝐝𝐥𝐲 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬

There's a growing emphasis on environmentally responsible cable management solutions. Approximately 60% of new cable management systems are now made from recycled materials.

𝐌𝐨𝐝𝐮𝐥𝐚𝐫 𝐚𝐧𝐝 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐛𝐥𝐞 𝐃𝐞𝐬𝐢𝐠𝐧𝐬

The market is witnessing a shift towards modular and customizable cable management systems. This trend allows businesses to tailor solutions to their specific needs, facilitating seamless integration into existing infrastructures and improving scalability .

🔗 𝐆𝐞𝐭 𝐑𝐎𝐈-𝐟𝐨𝐜𝐮𝐬𝐞𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐟𝐨𝐫 𝟐𝟎𝟐𝟓-𝟐𝟎𝟑𝟏 → 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐍𝐨𝐰

🚀 𝐊𝐞𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬

𝐄𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧 𝐨𝐟 𝐃𝐚𝐭𝐚 𝐂𝐞𝐧𝐭𝐞𝐫𝐬 𝐚𝐧𝐝 𝟓𝐆 𝐍𝐞𝐭𝐰𝐨𝐫𝐤𝐬

The rapid growth of data centers and the rollout of 5G networks are significant drivers. These developments necessitate efficient cable management solutions to handle high-density cabling and ensure optimal performance in critical applications .

𝐆𝐫𝐨𝐰𝐭𝐡 𝐢𝐧 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐈𝐨𝐓

The increasing adoption of automation and IoT technologies across various sectors is propelling the demand for advanced cable management systems.

𝐈𝐧𝐟𝐫𝐚𝐬𝐭𝐫𝐮𝐜𝐭𝐮𝐫𝐞 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭 𝐚𝐧𝐝 𝐒𝐦𝐚𝐫𝐭 𝐂𝐢𝐭𝐢𝐞𝐬

Ongoing infrastructure projects, including the development of smart cities, are driving the need for integrated cable management solutions.

𝐓𝐨𝐩 𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬:

Legrand, North America, Schneider Electric Industrial Services, Eaton, Panduit., HellermannTyton North America, ABB E-mobility., Atkore, Hubbell Incorporated, TE Connectivity., Southwire Company, LLC, GENERAL CABLES / PDIC, Leviton, Siemon, Chatsworth Products.,

#CableManagement #WireManagement #StructuredCabling #DataCenterSolutions #ElectricalInfrastructure #CableTrays #ConduitSystems #IndustrialCabling #NorthAmericaMarket #USInfrastructure #CanadaConstruction #NAIndustrialGrowth

0 notes

Text

IEC Standard for Underground Cable Laying

The IEC standard for underground cable laying is essential for safe, reliable, and efficient installation of electrical systems. Underground cables are widely used in modern cities, industries, and infrastructure projects. Proper installation helps prevent faults, reduces maintenance costs, and enhances safety. The International Electrotechnical Commission (IEC) provides globally accepted guidelines for these practices.

IEC Standard for Underground Cable Laying The main goal of the IEC standard for underground cable laying is to ensure cables are installed properly without mechanical damage, overheating, or interference. It covers various aspects including trench dimensions, cable protection, spacing, backfilling materials, and installation techniques. Following the right standards is important not just for operational efficiency but also for compliance with legal and insurance requirements. Engineers and technicians must understand these details thoroughly.

Importance of Following IEC Standard for Underground Cable Laying

Compliance with the IEC standard for underground cable laying is critical for several reasons. It ensures electrical safety, mechanical protection, and environmental security. It reduces chances of cable failure due to moisture, temperature changes, chemical attacks, or physical damages. When installation is done poorly, it often leads to frequent cable faults, fire hazards, and costly repairs. Thus, strict adherence to the standards protects the investment made in infrastructure projects. Proper underground cable laying also supports standard earthing systems, reducing touch and step potentials which enhances personal and equipment safety.

Main IEC Standards Referenced for Underground Cable Laying

The IEC standard for underground cable laying is not a single document but refers to several standards collectively. Some important ones include: IEC StandardTitlePurposeIEC 60364-5-52Electrical installations of buildings – Selection and erection of electrical equipment – Wiring systemsLaying procedures and mechanical protectionIEC 60287Electric cables – Calculation of the current ratingDetermining cable size considering thermal conditionsIEC 60502-1Power cables with extruded insulation and their accessories for rated voltages from 1 kV to 30 kVCable construction and installation guidelinesIEC 60079-14Electrical installations in explosive gas atmospheres – Design, selection and erectionSpecial guidelines for hazardous areas These standards work together to ensure successful cable installations. They are also linked with other topics like IEC Standard for Hazardous Area Classification where explosive environments require special attention.IECStandard, #UndergroundCableLaying, #ElectricalEngineering, #CableLaying, #IECStandards, #CableInstallation, #UndergroundCabling, #ElectricalInfrastructure, #CableManagement, #PowerDistribution, #ElectricalSafety, #PowerCables, #InfrastructureDevelopment, #EnergyDistribution, #SmartGrid Read the full article

#CableInstallation#CableManagement#ElectricalCabling#ElectricalEngineering#ElectricalStandards#IECStandard#Infrastructure#PowerCables#powerdistribution#UndergroundCableLaying

0 notes

Text

Padmavahini Power Transformers: High-Capacity Solutions for Efficient Energy Transmission

What is a Power Transformer? A power transformer is a static electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. Designed for high-voltage applications exceeding 33 kV, these transformers are pivotal in transmitting electricity over long distances with minimal losses. They are integral components in power generation and distribution networks, facilitating voltage regulation between generators and distribution systems.

Purpose: Padmavahini's power transformers are engineered to:

Transmit electrical energy efficiently over long distances.

Step up or step down voltage levels to meet specific application requirements.

Reduce power losses during transmission, enhancing overall system efficiency.

Operate reliably under continuous full-load conditions, ensuring uninterrupted power supply.

Key Features:

High Capacity HandlingCapable of supporting loads up to 25 MVA, making it suitable for heavy-duty industrial and utility applications.

Wide Voltage RangePrimary voltage up to 132 kV, ideal for transmission and substation-level operations.

Customizable DesignBuilt to client specifications in terms of voltage, capacity, and cooling requirements.

Efficient Cooling SystemsAvailable with ONAN (Oil Natural Air Natural) and ONAF (Oil Natural Air Forced) cooling options for effective heat dissipation.

Robust Phase ConfigurationSupplied as Three-Phase units, ensuring balanced power distribution across loads.

Tap Changer OptionsEquipped with Off-Circuit Tap Changer or On-Load Tap Changer (OLTC) for remote, auto, or parallel operations.

Vector Group FlexibilityOffered with standard vector groups like Dyn11, Ynd11, Ddo, etc., to meet various system connection needs.

High-Quality Insulation & Core MaterialConstructed using top-grade insulating materials and CRGO steel cores to minimize core losses and ensure operational longevity.

International Standard ComplianceDesigned and tested in accordance with IEC 60076 and IS 2026 standards for safety, quality, and performance.

Corrosion-Resistant ConstructionBuilt with weather-resistant finishes for outdoor installations, ensuring longevity even in harsh environmental conditions.

Benefits:

Low Maintenance: Robust design minimizes the need for frequent servicing.

High Mechanical and Tensile Strength: Ensures durability and longevity under demanding conditions.

Energy Efficiency: Optimized to reduce power consumption and operational costs.

Corrosion Resistance: Constructed with materials that withstand harsh environmental conditions.

Versatility: Suitable for various applications, including power plants, aerospace, and industrial facilities.

Conclusion: Padmavahini's power transformers are designed to meet the rigorous demands of modern electrical infrastructure. With a focus on efficiency, durability, and compliance with international standards, these transformers provide reliable solutions for high-voltage power transmission across diverse industries

Company Details:

📍 Company Name: Padmavahini Transformers 🌐 Website: Padmavahini Transformers 📞 Contact No: +91 99430 49222 📧 Email: [email protected] 📍 Address: S. F. No. 353/1, Door No. 7/140, Ruby Matriculation School Road, Keeranatham, Saravanampatti, Coimbatore, Tamil Nadu - 641035, India

🔗 Follow Us on Social Media: 📘 Facebook 📸 Instagram

#PadmavahiniTransformers#PowerTransformer#HighVoltageSolutions#EnergyEfficiency#ElectricalInfrastructure#MadeInIndia#IEC60076#IS2026#IndustrialPower#ReliableEnergy

0 notes

Text

Screw Wire Connectors Market: Climbing to $7.9 Billion by 2033 🔩📈

Screw Wire Connectors Market is a vital industry focused on manufacturing and distributing devices designed to securely join electrical wires. These connectors are indispensable for ensuring safe, reliable, and efficient electrical connections across residential, commercial, and industrial applications. Featuring diverse types like twist-on, push-in, and waterproof connectors, the market is driven by advancements in electrical infrastructure, smart home technologies, and demand for easy-to-install wiring solutions.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS26919 &utm_source=SnehaPatil&utm_medium=Article

In 2023, the market achieved a volume of 320 million units and is projected to reach 480 million units by 2033. The residential segment leads with a 45% market share, fueled by rising home renovations and smart home installations. The commercial sector follows with a 35% share, bolstered by the growing demand for energy-efficient systems, while industrial applications hold 20%, driven by automation and modernization initiatives.

North America dominates the market, benefiting from mature electrical infrastructure and technological innovations. Europe is the second-largest region, supported by stringent safety regulations and a focus on energy efficiency. Within countries, the United States leads due to investments in smart grid technologies, while Germany excels in sustainable energy solutions. Emerging markets in Asia-Pacific and Latin America present lucrative growth opportunities, spurred by rapid urbanization and infrastructure development.

Key players like 3M, ABB, and Eaton Corporation are shaping the market through innovation and strategic investments. Technological advancements, such as the integration of IoT and AI into electrical systems, are unlocking new growth avenues. Despite challenges like regulatory compliance and fluctuating raw material prices, the market is expected to grow annually by 10%, with a forecasted 15% rise in R&D investment by 2033.

#ElectricalInnovation #ScrewWireConnectors #EnergyEfficiency #SmartHomes #IndustrialAutomation #ElectricalSafety #ConnectivitySolutions #IoTIntegration #SustainableEnergy #Urbanization #TechAdvancements #GlobalMarkets #ElectricalInfrastructure #FutureTech #SmartGrid

0 notes

Text

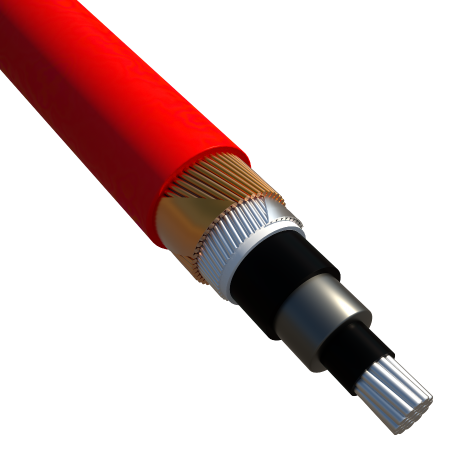

Engineered to perform under pressure, our 11kV Aluminium Single Core Power & Control Cable is designed for durability, reliability, and maximum efficiency in high-voltage applications. Whether you're powering infrastructure, industry, or innovation — trust Capital Cables to deliver the strength you need.

For more details, visit- https://www.capitalcables.co.in/wires-cables/power-control-cables/11kv-aluminium-single-core

#capitalcables#PowerAndControlCables#11kVAluminiumCable#HighVoltageApplications#ElectricalInfrastructure#DurableCables#ReliableCables#PowerSolutions#IndustrialCabling

0 notes