#Engine cylinder block quality testing

Explore tagged Tumblr posts

Text

Manufacturer of Premium Cylinder Blocks for Superior Engine Performance: Dasset Engineering

In the competitive world of automotive engineering, the importance of high-quality components cannot be overstated. Among these, cylinder blocks play a crucial role in determining the performance and longevity of an engine. At Dasset Engineering, we specialize in manufacturing premium cylinder blocks that deliver superior engine performance. This blog delves into the significance of cylinder blocks, the attributes of our premium products, and why Dasset Engineering stands out in this industry.

The Importance of Cylinder Blocks

The cylinder block is the backbone of any internal combustion engine. It houses the cylinders, coolant passages, and oil galleries, providing structural integrity and maintaining optimal engine temperature. The performance, efficiency, and durability of an engine largely depend on the quality of the cylinder block. Poorly manufactured blocks can lead to overheating, oil leaks, and ultimately, engine failure.

Attributes of Premium Cylinder Blocks

At Dasset Engineering, we understand that premium cylinder blocks are not just about high-grade materials but also about precision engineering and meticulous craftsmanship. Here are some key attributes that define our premium cylinder blocks:

High-Quality Materials

We use the finest materials, such as cast iron and aluminum alloys, to manufacture our cylinder blocks. These materials offer excellent durability, heat resistance, and strength, ensuring that the engine performs optimally under various conditions.

Precision Engineering

Our cylinder blocks are engineered with precision to meet exact specifications. Advanced machining techniques ensure that each block has the correct dimensions, smooth surfaces, and precise alignment of the cylinders. This precision is crucial for achieving optimal engine performance and efficiency.

Superior Cooling and Lubrication

Efficient cooling and lubrication are vital for engine performance and longevity. Our cylinder blocks feature optimized coolant passages and oil galleries that ensure efficient heat dissipation and lubrication. This reduces the risk of overheating and wear, thereby extending the engine's lifespan.

Rigorous Testing

Every cylinder block manufactured by Dasset Engineering undergoes rigorous testing to ensure it meets the highest standards of quality and performance. We conduct various tests, including pressure testing, thermal cycling, and dimensional inspections, to verify the integrity and reliability of our products.

Why Choose Dasset Engineering?

Dasset Engineering has established itself as a leading manufacturer of premium cylinder blocks, and here's why:

Expertise and Experience

With years of experience in the industry, we possess the technical expertise and knowledge required to produce top-tier cylinder blocks. Our team of skilled engineers and technicians is dedicated to delivering products that exceed customer expectations.

State-of-the-Art Facilities

We operate state-of-the-art manufacturing facilities equipped with the latest machinery and technology. This allows us to maintain strict quality control and produce cylinder blocks that meet the most demanding specifications.

Commitment to Quality

Quality is at the core of everything we do. From sourcing the best materials to implementing stringent quality control measures, we are committed to delivering cylinder blocks that offer unmatched performance and reliability.

Customer-Centric Approach

At Dasset Engineering, we believe in building long-term relationships with our customers. We work closely with them to understand their specific needs and provide customized solutions that cater to their requirements.

Conclusion

The cylinder block is a critical component that significantly impacts an engine's performance, efficiency, and durability. At Dasset Engineering, we take pride in manufacturing premium cylinder blocks that set the benchmark for quality and performance. By choosing our products, you are investing in superior engine performance, reliability, and longevity. Trust Dasset Engineering to be your partner in achieving excellence in automotive engineering.

#High-quality cylinder blocks for engines#Premium engine cylinder block manufacturer#Superior engine performance cylinder blocks#Precision-engineered cylinder blocks#Best materials for cylinder blocks#Advanced machining cylinder blocks#Cylinder blocks with optimized cooling#Durable cylinder blocks for automotive engines#Reliable cylinder blocks for high-performance engines#Custom cylinder block manufacturing#Top-rated cylinder block manufacturers#Cylinder blocks with efficient lubrication#Engine cylinder block quality testing#Benefits of premium cylinder blocks#Engine longevity with high-quality cylinder blocks#Cylinder block structural integrity for engines#Leading cylinder block manufacturers in the industry#State-of-the-art cylinder block production facilities#Expert cylinder block engineering services#Long-lasting cylinder blocks for vehicles

0 notes

Text

What Kind of Rebuilt Engine Does the Buick Encore Have?

The Buick Encore is a popular compact SUV known for its fuel efficiency and comfortable ride. If your Encore’s engine needs replacing, a rebuilt engine can be a cost-effective and reliable solution. This guide answers common questions about rebuilt engines for the Buick Encore, helping you make informed decisions for your car’s future.

The 2016 Buick Encore Sport Touring was the first model to offer a 1.4-litre Ecotec turbocharged engine with 153 horsepower. This engine became the standard option for higher trim levels in subsequent years. Therefore, any 2016 or later Encore, depending on the trim level, could potentially benefit from a 153 HP rebuilt engine.

Where is the 2016 Buick Encore Rebuilt Engine made?

Used engines can come from various sources. Here’s what to consider:

Original Engine Manufacturer (OEM): In some cases, rebuilt engines might use parts sourced directly from the original engine manufacturer (General Motors in this case).

Aftermarket Rebuilders: Many reputable companies specialize in rebuilding engines using high-quality aftermarket parts that meet or exceed OEM specifications.

What Kind of Rebuilt Engine Does the Buick Encore Have?

Rebuilt engines typically involve taking a used engine block and meticulously restoring it to its original specifications. This process often includes:

Disassembly and Cleaning: The engine is disassembled, and all parts are thoroughly cleaned and inspected.

Replacing Worn Parts: Worn components like pistons, rings, bearings, and gaskets are replaced with high-quality new parts.

Machining and Rebuilding: Essential engine components like the cylinder head or crankshaft might be reconditioned or replaced to ensure proper functionality.

Testing and Quality Control: The rebuilt engine undergoes rigorous testing to ensure it meets performance and reliability standards.

Why Choose USA Auto Parts to Buy a Buick Encore Rebuilt Engine?

If you need a rebuilt engine for your Buick Encore, USA Auto Parts offers several advantages:

Wide Selection: We have a vast nationwide network of suppliers, increasing your chances of finding the perfect rebuilt engine for your specific Buick Encore year and model.

Quality Assurance: All our rebuilt engines undergo a thorough inspection process by experienced mechanics, ensuring they meet our high standards.

Competitive Prices: We offer competitive pricing on rebuilt engines, helping you find a cost-effective solution for your repair needs.

Warranty Options: We provide warranty options on rebuilt engines, giving you peace of mind on your purchase.

Fast and Reliable Shipping: We understand the urgency of getting your car back on the road. We offer fast and reliable shipping options throughout the USA.

Expert Advice: Our knowledgeable customer service team can answer your questions and help you choose the best rebuilt engine for your needs.

#usedengines#engine#enginerepair#usedenginesforsale#autoengine#ConnectWithUs#powerengines#Transmission#repairengines#trendingpost#like#comment#share#usa#usatoday#EngineReplacement#engineswap#engineoil

2 notes

·

View notes

Text

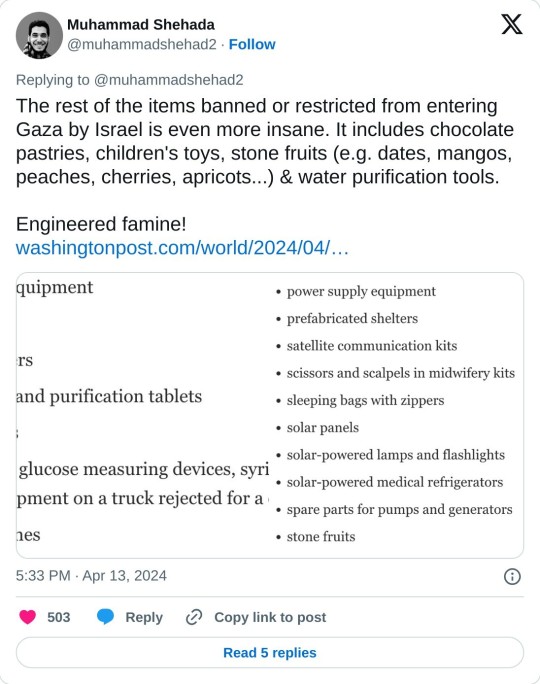

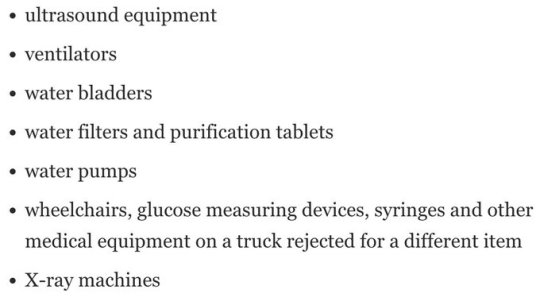

[ID: a Twitter thread by Muhammad Shehada @/muhammadshehad2 reading:

Famished Gazans have been eating animal feed to survive. So Israel decided to ban animal feed as well! The depravity is unfathomable...

Attached is a screenshot from a Washington Post article reading:

Here is a list of items the United Nations and other aid agencies say Israeli authorities have blocked from entering Gaza at least once since Oct. 7:

anesthetics

animal feed

cardiac catheters

chemical water quality testing kits

chocolate croissants

crutches

field hospital boxes

flak jackets and helmets for aid workers

fittings for water pipeline repair

generators for hospitals

green tents and sleeping bags

maternity kits

medical thread in reproductive health kits

medical scissors in children’s aid kits

microbiological water-testing kits

mobile desalination units with solar system and generators

The Twitter thread continues:

The rest of the items banned or restricted from entering Gaza by Israel is even more insane. It includes chocolate pastries, children's toys, stone fruits (e.g. dates, mangos, peaches, cherries, apricots...) & water purification tools. Engineered famine!

The attached screenshots continue the list:

nail clippers in hygiene kits

obstetric clamps

oxygen concentrators

oxygen cylinders

power supply equipment

prefabricated shelters

satellite communication kits

scissors and scalpels in midwifery kits

sleeping bags with zippers

solar panels

solar-powered lamps and flashlights

solar-powered medical refrigerators

spare parts for pumps and generators

stone fruits

surgical tools for doctors

tap-stand kits for water distribution

tent poles

toys in wooden boxes

ultrasound equipment

ventilators

water bladders

water filters and purification tablets

water pumps

wheelchairs, glucose measuring devices, syringes and other medical equipment on a truck rejected for a different item

X-ray machines

End ID.]

Transcriber's note: A non-paywalled copy of the source article is available here (link).

[SOURCE]

Maternity kits, medical threads and scissors, water testing kits, anesthetics, mobile desalination units, etc do you see the pattern? Israel is not only starving the people of Gaza but it also wants to ensure the spread of disease through contaminated water and surgical tools, as well as ensuring injured Palestinians suffer through horrendous pain.

It's beyond sickening.

34K notes

·

View notes

Text

Performance Starts Here – Mini Cooper Automotive Parts & Tuning Gear

Performance tuning requires precision, dedication, and parts that are built to last. Whether you're rebuilding an engine from scratch or upgrading for competitive driving, having the right components makes all the difference. From forged pistons to high-performance headers, the focus should always be on quality, reliability, and long-term performance. Enthusiasts and professionals alike seek trusted brands and proven engineering to push their builds further, on and off the track.

Engineered for performance and built with precision, every part is designed to elevate your driving experience. At MINI Cooper S Engine Parts, you’ll discover a curated collection of race-tested rebuild kits, high-performance internals, and upgrade components tailored for MINI models across every generation. Whether you're enhancing a supercharged R53 or a modern turbocharged B-series, this platform delivers complete solutions engineered for power and reliability. B

Engine Rebuild Kits – Complete Packages

Rebuilding an engine is a detailed process that demands quality components and expert precision. Whether you’re refreshing a worn-out block or preparing for a performance upgrade, the right rebuild kit ensures reliability and longevity. These packages typically include everything needed to restore engine integrity—from gaskets and seals to timing chains and pistons—making the job more streamlined for both DIY builders and professionals.

For enthusiasts focused on Mini Cooper Engine Tuning, these complete rebuild kits offer both reliability and performance flexibility. Designed to support everything from daily driving to high-boost setups, they include durable parts optimized for horsepower gains and long-term use.

Full gasket sets for head and block sealing

OEM-quality or upgraded piston ring kits

High-performance main and rod bearings

Timing chain kits with tensioners and guides

Optional forged pistons and head stud upgrades

Components tailored for boosted or naturally aspirated builds

Why Choose Mini Cooper Automotive?

Choosing the right performance parts supplier goes beyond just finding what fits. It’s about trust, expertise, and proven results on and off the track. Backed by years of racing experience, a strong support team, and a passion for engineering excellence, this platform delivers more than just products—it offers peace of mind.

From weekend projects to full-scale builds, customers benefit from hands-on guidance and tested solutions. For those serious about Mini Cooper Automotive, this is the go-to destination for reliable, race-proven upgrades. Every component is selected with performance and durability in mind, helping drivers get the most from their engines without compromising on quality.

Expert-built kits based on real motorsport experience

Internal engine parts rated for high horsepower applications

Cylinder heads and stud kits designed for boosted setups

High-flow exhaust components for increased power and torque

Conclusion

Unlock the full potential of your build with performance parts engineered for precision, power, and durability. Whether you’re upgrading for reliability, track performance, or daily driving excellence, using the right components from a trusted source ensures long-term results and peace of mind.Have questions or need help choosing the right parts? Contact us today for expert guidance and personalized recommendations. Every engine deserves attention to detail, especially when it's part of a brand built for spirited performance and handling.

0 notes

Text

Remanufactured Cylinder Heads: Reliable Engine Performance with ADV Auto Pro

When your engine shows signs of wear, a complete replacement can be costly and unnecessary. One of the most practical and budget-friendly options for restoring engine performance is choosing remanufactured cylinder heads. At ADV Auto Pro, we specialize in high-quality cylinder head remanufacturing for all vehicle types and models. Our process ensures durability, reliability, and a perfect fit, whether you're running a gasoline, diesel, marine, motorcycle, or heavy-duty diesel engine.

In this article, we’ll cover everything you need to know about remanufactured and rebuilt cylinder heads, why ADV Auto Pro is your trusted cylinder head supplier, and how our commitment to quality sets us apart in the engine parts industry.

What is a Remanufactured Cylinder Head?

A remanufactured cylinder head is a used head that has been completely disassembled, cleaned, inspected, and restored to meet original manufacturer specifications. Unlike basic repairs, remanufacturing includes replacing worn parts, correcting surface damage, and ensuring that the head is pressure-tested and ready for installation.

At ADV Auto Pro, we use advanced equipment and strict quality control procedures to ensure every remanufactured cylinder head meets or exceeds OEM standards. This level of care results in a product that performs just like a new head, but at a fraction of the cost.

Why Choose ADV Auto Pro for Cylinder Head Remanufacturing?

ADV Auto Pro is a leader in cylinder head remanufacturing. With years of experience and a reputation for excellence, we serve both individual customers and businesses with precision-machined, high-performance heads.

Each remanufactured cylinder head goes through a detailed quality assurance process, including:

Complete disassembly and inspection

Cleaning and resurfacing

Pressure testing using Sunnen equipment

Replacement of worn or damaged components

Final inspection to ensure a perfect seal and performance

Our strict standards make us one of the most reliable cylinder head remanufacturers in the industry.

Who We Serve

We provide rebuilt cylinder heads for a wide range of applications:

Gasoline engines for commercial and personal vehicles

Diesel engines for both industrial and commercial use

Heavy-duty diesel trucks and equipment

Marine engine cylinder heads

Motorcycle engines

High-performance and customized heads

Whether you manage a fleet, repair vehicles professionally, or simply want the best for your car, ADV Auto Pro has you covered.

Rebuilt Cylinder Heads Near Me – Nationwide Shipping

Many customers search for rebuilt cylinder heads near me, not realizing that ADV Auto Pro ships across the United States. Our streamlined process allows you to place an order, receive your remanufactured head quickly, and return the core using the same box and a prepaid FedEx label.

We do not charge upfront for cores. As long as the complete core is returned within 21 days of purchase, there are no additional fees. This makes it easy and affordable for anyone, anywhere in the U.S., to access high-quality rebuilt heads without hassle.

Full Engine Part Solutions from Trusted Cylinder Head Suppliers

As one of the most trusted cylinder head suppliers in the country, ADV Auto Pro also offers a wide range of additional engine parts, including:

Gasket sets and head bolt kits

Engine blocks

Crankshafts and camshafts

Rebuilt long blocks

Accessories and auto parts for engine performance

We work with industry-leading gasket manufacturers like Victor Reinz, and offer different material types such as graphite and MLS (multi-layered steel) to ensure a proper seal based on your vehicle’s requirements.

With each cylinder head purchase, you can add a discounted head gasket set to your order, making ADV Auto Pro your one-stop solution for all engine rebuild needs.

Quality Control That Sets Us Apart

Our customers choose ADV Auto Pro not just for our wide selection, but for our unmatched attention to detail. After a cylinder head is cleaned, it is sent for pressure testing using advanced Sunnen machines that detect even hairline cracks not visible to the naked eye. If any flaw is found, that head is removed from production. This process ensures that every remanufactured or rebuilt head we sell is ready to install and built to last.

Additionally, each head is backed by a 3-year unlimited mileage warranty, giving our customers peace of mind and added value. Please note that high-performance heads are not included in the warranty. Proper installation is essential, including using the recommended head gasket and ensuring all related engine components—like the radiator, water pump, and hoses—are in good working condition.

Every head includes heat tabs, which serve as a clear indicator if overheating occurs. Removal or melting of the tab voids the warranty, as it indicates improper use or engine failure unrelated to the head itself.

Easy Returns and Customer Support

We understand that sometimes things change. That’s why we offer a 15-day return window on unused items. Returned parts must be in original packaging and not installed or filled with oil or coolant. A 20 percent restocking fee and round-trip shipping charges apply. To make a return, contact us for proper authorization before sending the product back. Refunds are processed using the original method of payment.

We do not issue refunds to alternative payment methods and deduct costs for open gasket sets or bolt kits.

Why Our Customers Keep Coming Back

ADV Auto Pro has built a reputation for quality, reliability, and customer support. We make the ordering and return process easy, and we focus on delivering performance-tested, long-lasting engine parts at competitive prices.

Whether you're in need of a standard replacement or a performance upgrade, we’re here to help with top-tier products and expert advice.

Contact Us Today

If you are looking for dependable remanufactured cylinder heads, rebuilt cylinder heads, or a trusted cylinder head remanufacturer, ADV Auto Pro is your best choice. We combine advanced engineering, strict quality control, and outstanding service to deliver the performance you need.

0 notes

Text

How Does Engine Mileage Impact the Quality of a Reconditioned Jaguar Engine?

The quality of a reconditioned Jaguar engine is influenced by many factors, with engine mileage being one of the most crucial. As vehicles age and accumulate miles, their engines undergo wear and tear that can significantly affect performance, reliability, and longevity. When considering a reconditioned engine, especially for a luxury brand like Jaguar, the original mileage of the engine becomes a vital element in determining its potential after reconditioning. We explores how engine mileage impacts the quality of a reconditioned Jaguar engines, examining both the challenges and solutions offered by professional reconditioning processes.

What Is Engine Mileage and Why It Matters for Jaguar Engines

Engine mileage refers to the total number of miles a vehicle’s engine has operated. For Jaguar engines, known for their performance and engineering finesse, higher mileage often equates to more internal wear. Components such as pistons, valves, bearings, and cylinder heads degrade over time, especially if regular maintenance has not been followed. In high-performance engines like those found in Jaguars, this degradation can lead to decreased power output, poor fuel efficiency, and more frequent breakdowns. Thus, mileage is often used as a benchmark to estimate engine condition before reconditioning begins.

Effects of High Mileage on Jaguar Engine Components

A high-mileage Jaguar engine might exhibit worn-out cylinder walls, reduced compression, carbon buildup, and increased oil consumption. The timing chain or belt could also be stretched or degraded, and bearings may be worn. These factors impact engine performance and reliability. During the reconditioning process, such components must be thoroughly inspected and either replaced or refurbished to restore the engine to optimal working condition. The more mileage the engine has seen, the more parts may need replacement, thereby influencing both cost and turnaround time of the reconditioning job.

How Low Mileage Benefits the Reconditioning Process

Low mileage engines generally require fewer part replacements and show less overall wear, making them ideal candidates for reconditioning. For reconditioned Jaguar engines, a low mileage base means that the core components such as the engine block and crankshaft are likely still in relatively good condition. This reduces the need for excessive machining or replacements, which can help preserve the engine’s original specifications. In most cases, reconditioning a low-mileage Jaguar engine results in better overall reliability, longer lifespan, and cost efficiency compared to high-mileage options.

Key Steps in Reconditioning a Jaguar Engine with High Mileage

Reconditioning a high-mileage Jaguar engine involves a meticulous multi-step process. It starts with complete disassembly, followed by a thorough cleaning to remove oil sludge and carbon buildup. Each component is then inspected for wear. Critical parts such as pistons, rings, bearings, gaskets, and timing systems are usually replaced. The cylinder head and engine block are machined to restore factory specifications. After reassembly, the engine undergoes bench testing to ensure it performs like new. Although high mileage adds complexity, expert technicians can restore these engines to exceptional working condition.

Assessing Engine Mileage During Jaguar Engine Reconditioning

Before a Jaguar engine is reconditioned, professionals conduct a full assessment of its mileage and overall condition. This helps determine the viability of the engine core and whether it is suitable for reconditioning or should be replaced. Engine mileage data is reviewed in conjunction with maintenance history and physical inspection findings. Factors like oil change frequency, coolant quality, and driving habits are considered. An engine with 100,000 miles but excellent maintenance history may be in better shape than a 60,000-mile engine with poor care.

The Role of Advanced Diagnostics in Evaluating Mileage Impact

Advanced diagnostic tools allow engine reconditioners to measure wear and damage directly related to mileage. For instance, compression tests, bore measurements, and endoscopic inspections can reveal internal wear patterns. For Jaguar engines, which are built to high tolerances, even minor wear can significantly affect performance. These diagnostics provide vital data that guide the reconditioning process, ensuring that parts beyond their wear limits are replaced. This data-driven approach ensures consistent results and high-quality reconditioned engines, even when starting with a high-mileage core.

Comparing Reconditioned Engines from High vs. Low Mileage Donors

When comparing reconditioned Jaguar engines sourced from high versus low mileage donors, the difference often lies in component longevity post-reconditioning. While both can perform equally well when rebuilt correctly, low-mileage engines may require fewer parts to be replaced and retain more original components. This can lead to marginally better long-term reliability and potentially lower costs. However, a well-reconditioned high-mileage engine that has been rebuilt with quality components and precision engineering can perform on par with its low-mileage counterpart, showcasing the importance of craftsmanship.

Tips for Buyers: Choosing the Right Reconditioned Jaguar Engine

Buyers looking for a reconditioned Jaguar engine should inquire about the original mileage of the engine, the reconditioning procedures used, and whether the parts replaced were OEM (Original Equipment Manufacturer) or aftermarket. Warranty coverage, service history, and testing certifications are also important. It’s advisable to work with reputable reconditioning specialists who provide detailed reports and offer installation services. Buyers should prioritize engines that have undergone complete overhauls, as mileage becomes less of a concern when the reconditioning process is comprehensive and professionally handled. Read the full article

#ReconditionedJaguarEngine#ReconditionedJaguarEngineforsale#ReconditionedJaguarEngines#supplyandfitReconditionedJaguarEngine

0 notes

Text

Reliable SG Castings Manufacturers in India for Heavy-Duty Applications

In the world of heavy-duty engineering, durability, precision, and strength are non-negotiable. Whether it's in the automotive sector, power generation, agriculture, railways, or construction machinery, the quality of cast components directly impacts the performance and longevity of equipment. Among various casting materials, Spheroidal Graphite (SG) Iron also known as ductile iron stands out for its superior mechanical properties. As demand grows, reliable SG castings manufacturers in India have become crucial partners in delivering high-performance components built to endure the toughest conditions.

What Are SG Castings and Why Are They Important?

SG castings are made from spheroidal graphite iron, which is known for its remarkable ductility, impact resistance, and tensile strength. Unlike grey iron, which has flake-shaped graphite, SG iron has graphite in spherical nodules. This microstructure offers enhanced toughness and elasticity, making it ideal for components subjected to high stress or shock loads.

These properties make SG castings the material of choice for:

Engine blocks and crankshafts

Gear housings and differential cases

Hydraulic cylinder components

Axle shafts and steering knuckles

Pump and valve bodies

In industries where operational efficiency and safety are paramount, the reliability of the components is as essential as the machinery itself.

The Role of SG Castings Manufacturers in India

India has emerged as a global hub for metallurgy and precision castings. SG castings manufacturers in India are known for blending traditional foundry expertise with modern metallurgical technologies to meet international standards. These manufacturers invest in high-end infrastructure, automated molding lines, advanced testing equipment, and quality control processes to ensure consistent, defect-free outputs.

Key qualities that make Indian manufacturers reliable include:

Use of high-purity raw materials and controlled metallurgical compositions

In-house testing for hardness, tensile strength, microstructure, and dimensional accuracy

Adherence to global quality standards such as ASTM, IS, and EN

Scalable production capacity for bulk industrial orders

Flexibility to deliver custom-cast solutions based on application-specific requirements

SG Castings for Heavy-Duty Applications

Heavy-duty industries demand materials that can withstand extreme pressures, temperatures, and operational wear. SG castings are uniquely suited for such applications due to their superior mechanical performance. When sourced from a trusted manufacturer, SG iron components provide the dual benefit of structural integrity and cost efficiency, especially over long service lifespans.

Applications in sectors like mining, oil and gas, infrastructure, marine, and transportation heavily rely on these durable components for safety and uninterrupted operation.

Why Reliability Matters in SG Casting Manufacturing

Reliability in SG casting doesn’t just mean strong products it also refers to timely delivery, consistent quality, and technical support. Working with a reliable manufacturer ensures:

Fewer production downtimes due to component failure

Improved equipment efficiency and lower maintenance costs

Long-term partnerships that streamline procurement and logistics

Customization capabilities to match unique project requirements

Choosing a dependable SG castings partner is, therefore, a strategic decision that contributes directly to your project’s success and operational continuity.

Ready to strengthen your supply chain with durable SG castings? Get in touch with us today to discuss your project requirements and receive a customized solution with https://www.bharatengg.in/

0 notes

Text

What’s Included in a ‘Supply and Fit’ Package for Ford Ranger Reconditioned Engines?

The term "supply and fit" is frequently mentioned in the world of automotive repairs, especially when dealing with reconditioned engines. For Ford Ranger owners, a supply and fit package represents a complete engine replacement solution. This includes both the engine itself and professional installation services, ensuring your vehicle gets back on the road in optimal condition. Reconditioned engines are becoming increasingly popular due to their cost-effectiveness and reliability. Instead of purchasing a brand-new engine or risking a used one with unknown history, a reconditioned engine offers a balance between performance and affordability. Ford Rangers are renowned for their rugged utility, and when an engine failure occurs, a timely and effective replacement is crucial. A supply and fit package removes much of the stress from this process, as everything from selecting the right engine to the final installation is handled professionally. This guide will walk you through all the elements included in such a package, what you should expect in terms of quality and service, and why reconditioned engines are a smart choice. The information also applies broadly to other vehicles, including popular models like the Range Rover engine setups, where reconditioning and professional fitting are equally critical.

Reconditioned Engine Supply: The Core of the Package

At the heart of any supply and fit package is the engine itself. In the case of a Ford Ranger, a reconditioned engine means that a previously used engine has been thoroughly overhauled to restore it to optimal working condition. Reconditioning typically involves replacing worn-out parts such as pistons, bearings, timing chains, gaskets, and seals. The cylinder head may be skimmed, valves reseated, and the engine block inspected for cracks or warping. The result is an engine that performs nearly as well as a brand-new unit, but at a significantly reduced cost. Suppliers who offer reconditioned engines for the Ford Ranger usually provide units that have been tested and meet strict quality control standards. It’s essential that the reconditioned engine not only fits the specific Ford Ranger model but also complies with manufacturer specifications. Some suppliers may offer additional choices between standard, high-performance, or eco-tuned versions, depending on your driving needs. This stage of the supply and fit package ensures that you receive a high-quality engine that has been revitalized and inspected, ready to provide years of dependable service—similar to what's offered in premium Range Rover engine reconditioning services.

Professional Installation: Ensuring Proper Engine Fitment

Once a reconditioned engine is selected, the next critical step in the supply and fit package is professional installation. This process must be executed by skilled technicians familiar with the specific model of the Ford Ranger. The installation involves removing the faulty engine, preparing the engine bay, and securely fitting the reconditioned engine. This isn't just about bolting the engine into place—it also includes aligning it with the transmission, exhaust, electrical systems, and fuel lines. A successful installation ensures that all sensors, mounts, and connections are intact and functioning. Furthermore, it involves recalibrating the vehicle’s ECU (Engine Control Unit) to ensure seamless operation with the reconditioned engine. Technicians also check the cooling system and verify that oil and fuel delivery systems are properly connected and functioning. Professional installation gives peace of mind and is a crucial reason why supply and fit packages are preferred over DIY engine replacements. This level of expertise is also essential in luxury vehicles like those with a Range Rover engine, where precision and attention to detail directly affect performance and longevity.

Diagnostic and Compatibility Checks Before Fitting

Before installing the reconditioned engine, comprehensive diagnostic checks are conducted to ensure compatibility and avoid post-installation issues. These diagnostics typically include engine code scans, emissions testing, compression tests, and oil pressure evaluations. This ensures that both the vehicle’s systems and the reconditioned engine are functioning optimally before integration. Compatibility checks are especially important when dealing with different engine variants, as even slight differences in ECU software, mounts, or sensors can lead to poor performance or warning lights on the dashboard. The process may also involve checking for updated firmware or software patches required for newer engine variants or reconditioned upgrades. This step is vital not just for Ford Rangers but also mirrors the approach taken in premium vehicle maintenance, such as with a Range Rover engine. Ensuring that all systems communicate correctly prevents future breakdowns and avoids voiding warranties due to misaligned engine components. The result is a seamless, error-free installation process where the reconditioned engine functions just like a new one, with all systems correctly synced and validated.

Ancillary Parts Replacement and Upgrades

A good supply and fit package for reconditioned engines doesn’t just stop at engine installation. It often includes replacement of ancillary components that work in tandem with the engine. These may include new timing belts or chains, water pumps, thermostats, spark plugs, fuel injectors, and gaskets. Some packages also provide an upgraded turbocharger or improved cooling components if required. Replacing these components ensures that your newly installed engine operates without being hindered by old or worn-out parts. Imagine installing a reconditioned engine only for it to be compromised by a failing water pump or degraded spark plug—this undermines the investment and leads to further costs down the line. This level of attention to detail is common in high-end vehicles as well, such as when upgrading or reconditioning a Range Rover engine. Reliable suppliers aim to minimize future breakdowns and optimize vehicle longevity by addressing all parts critical to engine performance. As a result, your Ford Ranger comes out of the garage not just with a reconditioned heart, but with all its supporting systems fresh and robust.

Fluid Replacements and System Flushing

A vital component of any engine installation is the flushing of old fluids and the replenishment of new, high-quality fluids. Supply and fit packages typically include complete oil changes, coolant replacements, brake fluid checks, and sometimes power steering and transmission fluid top-ups. Flushing the cooling and lubrication systems is critical to prevent contamination of the new engine. During the reinstallation of a reconditioned engine, residual sludge or debris from the previous unit can significantly reduce performance or cause damage. Hence, professional installers take the time to flush all relevant systems. In many cases, they also install new filters—oil filters, fuel filters, and air filters—to ensure maximum purity and performance. This meticulous approach enhances the longevity of the reconditioned engine and keeps it running smoothly for the long haul. Whether it's a robust Ford Ranger or a luxury Range Rover engine, clean fluids and flushed systems are crucial for peak performance and durability. It’s a simple yet often overlooked step that makes a world of difference in the final result of an engine replacement service.

Testing and Quality Assurance After Installation

Once the reconditioned engine is installed and all components are replaced or upgraded, the vehicle undergoes a series of post-installation tests. These quality assurance checks validate the success of the installation and assess the performance of the engine under real-world conditions. Technicians may conduct road tests to evaluate responsiveness, check for unusual sounds, and monitor fluid levels. Engine diagnostics are run again to ensure no fault codes appear and that emissions are within acceptable limits. They also verify cooling efficiency, oil pressure stability, and ECU synchronization. Quality assurance is crucial to ensure that the reconditioned engine is ready for long-term use. A thorough test drive is part of this process, simulating various driving conditions—city, highway, and off-road if applicable. Whether you're driving a hard-working Ford Ranger or a luxurious Range Rover engine-equipped vehicle, these tests provide final confirmation that the supply and fit package has been executed to the highest standard. Any anomalies are addressed before the vehicle is handed back to the customer.

Warranty Coverage and Aftercare Support

One of the biggest advantages of choosing a supply and fit package for a reconditioned engine is the comprehensive warranty that often accompanies it. These warranties can range from 6 months to 24 months, depending on the supplier, and may include mileage limits. The warranty generally covers both parts and labor, giving customers peace of mind. In addition to warranty protection, many reputable suppliers offer aftercare services such as periodic check-ups, diagnostics, and support for any issues that may arise post-installation. This is particularly helpful during the engine's break-in period, where early diagnostics can catch potential issues before they escalate. This level of service reflects what one might expect from high-end brands like Range Rover engine reconditioning and servicing. It’s a sign of confidence in the quality of the reconditioned engine and the professionalism of the fitting service. Customers are advised to read the fine print of the warranty to understand inclusions, exclusions, and maintenance requirements to keep the warranty valid.

Customer Consultation and Vehicle Handover

The final stage in a supply and fit package is customer consultation and handover. This includes a full explanation of the work done, the parts replaced, warranty details, and recommended maintenance practices moving forward. It also includes documentation of diagnostic results, test drives, and fluid changes. Customers are encouraged to ask questions about the new engine’s capabilities, maintenance intervals, and performance expectations. A reputable service provider ensures that you drive away with full confidence and a complete understanding of your vehicle’s condition. A well-documented handover process not only shows transparency but also builds trust between the customer and service provider. This is a standard practice with premium reconditioned engine services, including those for Range Rover engines, where transparency and detailed reports are expected. This final step rounds off the professional experience and ensures that the investment in a reconditioned engine truly pays off with years of reliable performance. Read the full article

#FordRanger#FordRangerEngine#FordRangerEnginesupplyandfit#FordRangerengines#FordRangerEnginesforsale#FordRangerReconditionedEngines#replacementFordRangerEngine

0 notes

Text

A28V130 Hydraulic Pump Parts Quality Check! 🔥

Testing the strength of our A28V130 Hydraulic Pump Cylinder Block and Distribution Plate!

Watch this: It takes serious effort to pull that distribution plate off the cylinder block – that's proof of an incredibly tight seal and precision engineering! Then listen to that crisp sound when we tap it – the sign of premium, durable material built to last.

Invest in quality parts for your excavator. Get the performance and reliability you need.

DM us for details or a quote! www.bsdhydro.com

#A28V130 #HydraulicPump #ExcavatorParts #HeavyEquipment #ConstructionMachinery #QualityParts #Supplier #Export #Durable #Reliable #Precision #Hydraulics #Construction #Machinery #BORSINDAHYDRAULIC

0 notes

Text

Understanding Your BMW M Series Engine Needs

The BMW M Series is synonymous with performance, precision engineering, and high-powered driving experiences. Whether you're piloting an M3, M4, or the more aggressive M8, your BMW engine is the heart of its performance. Over time, however, even the most robust engines experience wear and tear. Owners often face a tough decision when engine issues arise: should you recondition your existing engine or opt for a complete engine replacement? Understanding this choice is critical not just for your vehicle’s performance, but also for long-term reliability and financial investment. We explores both options reconditioning your existing BMW engine or replacing it with a new or used one and helps you decide which path suits your situation best. We will also cover the pros and cons of each approach while integrating critical considerations like cost, performance, and reliability. Whether you're a seasoned BMW enthusiast or a first-time BMW M Series owner, this guide will provide clear insights and help you make an informed decision regarding your high-performance machine.

Assessing the Current Condition of Your BMW M Series Engine

Before making any decisions, a detailed assessment of your BMW M Series engines is crucial. The M Series engines, such as the S55, S63, or even the newer S58, are engineered for extreme performance, meaning they undergo more stress than standard engines. Symptoms such as knocking sounds, oil leaks, power loss, overheating, or excessive smoke may signal internal damage. A professional diagnostic can pinpoint whether your engine suffers from issues like worn pistons, damaged cylinder heads, or a faulty turbocharger. Additionally, consider the vehicle’s mileage. Engines with over 100,000 miles that haven’t received timely maintenance are more likely to suffer from internal damage. Determining the extent of the damage is essential in evaluating whether reconditioning is feasible or if a replacement is the more viable solution. A compression test, oil analysis, and ECU diagnostics can provide valuable data on the engine's condition. Understanding these details will inform your next steps and prevent unnecessary costs or future failures.

The Benefits of Reconditioning Your Existing BMW Engine

Reconditioning your BMW M Series engine means restoring it to near-new condition. This process involves dismantling the engine, cleaning components, replacing worn-out parts (like piston rings, bearings, gaskets), and reassembling it to factory specifications. One major benefit of reconditioned engines is retaining your original engine block, which preserves the vehicle’s matching numbers important for resale value and authenticity. Moreover, reconditioning is often more cost-effective than a full replacement, especially for high-performance engines like those in the M Series. Since you're refurbishing the existing engine, there are fewer compatibility concerns with the car’s ECU and wiring harness. Furthermore, reputable reconditioning services provide warranties, offering peace of mind. With skilled technicians and quality parts, your reconditioned engine can deliver performance comparable to a new one. Overall, reconditioning offers a balance of cost, originality, and performance, making it a highly attractive option for many BMW M Series owners.

When Is Engine Replacement the Better Option for Your BMW?

Despite the advantages of reconditioning, there are situations where engine replacement is the better choice. If your BMW engine has suffered catastrophic damage like a cracked engine block or complete seizure reconditioning may not be feasible. Additionally, if the vehicle has experienced repeated mechanical failures, a replacement engine could ensure longer-term reliability. BMW engine replacements often come in two forms: new engines (OEM) or used/reconditioned units. New engines provide factory-fresh performance but are typically the most expensive option. Used or reconditioned engines sourced from low-mileage donors can be a cost-effective alternative. Engine replacement is also ideal when time is a factor; sourcing a ready-to-install unit can be quicker than reconditioning your original engine. This path may also introduce newer generation engines or slight performance upgrades, depending on compatibility. However, ensure that the replacement engine is fully compatible with your vehicle’s model, ECU, and transmission system to avoid integration issues.

Cost Comparison: Reconditioned Engines vs Full Engine Replacement

One of the most critical factors in deciding between reconditioning and replacement is cost. Reconditioning your BMW engine generally ranges from £2,000 to £5,000, depending on the extent of the rebuild and labor involved. This price includes part replacements, machining work, and professional assembly. In contrast, a new OEM BMW M Series engine can cost between £6,000 and £12,000, excluding labor charges for installation. Used or reconditioned replacement engines are more affordable, typically ranging from £3,500 to £7,000, but prices vary depending on mileage, model year, and supplier reliability. It’s also important to consider long-term costs. A well-reconditioned engine with a warranty might offer better value over time than a cheap used engine with unknown history. Additionally, labor costs for removal and installation are generally similar in both cases. Therefore, reconditioning can often provide the best balance between performance restoration and financial prudence.

Performance and Reliability: Which Option Ensures a Longer Engine Life?

When done correctly, both reconditioned engines and replacement engines can offer excellent performance and reliability. A professionally reconditioned BMW engine is essentially restored to OEM standards, with all critical components either replaced or refurbished. This ensures dependable performance, especially if genuine BMW parts are used. Many reconditioned engines come with warranties ranging from 6 months to 2 years, showcasing confidence in their longevity. On the other hand, a brand-new engine offers unmatched reliability, but at a premium cost. A used engine may present unknown risks unless it has been inspected and reconditioned before sale. Additionally, reconditioned engines retain ECU compatibility and factory performance tuning, which is crucial for the precise engineering of BMW M Series models. In terms of longevity, both options can exceed 100,000 miles with proper care. Ultimately, performance and reliability are closely tied to the quality of the parts used and the expertise of the service provider.

Availability and Compatibility of BMW M Series Engine

The availability of replacement engines depends on your specific M Series model and production year. Popular models like the BMW M3 (F80) or M5 (F10/F90) may have more engines available in the used and reconditioned market. However, rarer models or limited editions may require special orders or longer lead times for both reconditioning and replacements. Compatibility is a key issue with replacements ensuring the new engine integrates seamlessly with the transmission, ECU, cooling system, and emissions equipment is vital. In some cases, coding and reprogramming are needed for the vehicle’s electronics to recognize the new engine. Reconditioning avoids many of these compatibility issues, as you're rebuilding the existing unit already tailored to your vehicle. Regardless of your choice, sourcing engines from trusted suppliers or BMW specialists is essential. They can offer insights on compatibility, provide verified mileage reports, and ensure the integrity of the engine you're installing.

Warranty and Support: Protecting Your Investment

Investing in either a reconditioned engine or a replacement requires reliable warranty coverage to safeguard your finances. Reputable reconditioning workshops typically offer warranties ranging from 12 to 24 months, depending on the parts and labor involved. These warranties often cover major components and may include support services like diagnostics and free adjustments during the warranty period. On the other hand, OEM new engines from BMW dealers come with a manufacturer’s warranty, often extending up to 2 years. Used or non-OEM replacement engines may have limited or no warranty at all unless purchased from certified reconditioners. Always inquire about what the warranty covers does it include parts, labor, or both? Is roadside assistance available if a failure occurs? Support services like installation assistance, ECU reprogramming, and post-installation checks are also worth considering. A comprehensive warranty adds peace of mind, especially when dealing with high-performance BMW engines that require precision and care. Read the full article

#BMWMSeriesEngine#BMWMSeriesEngineforsale#BMWMSeriesEnginesupplyandfit#BMWMSeriesEngines#BMWMSeriesEnginesForSale#reconditionedBMWMSeriesEngines

0 notes

Text

Why Choosing the Right Cylinder Head Matters for Detroit Motor Parts Performance

When it comes to maintaining or upgrading heavy-duty engines, especially for those relying on Detroit Motor Parts, one component often overlooked—but critical—is the cylinder head. The cylinder head plays a pivotal role in the engine’s performance, affecting everything from fuel efficiency to horsepower output and overall engine lifespan. For diesel engines operating under intense workloads, the importance of a high-quality cylinder head cannot be overstated.

If you're sourcing parts for your engine rebuild or repair, especially Detroit diesel engines, using a reliable supplier like shop.nadieselparts.com ensures you're getting top-quality components built to withstand the pressures of heavy-duty applications. Whether you're dealing with a classic Series 60 or a modern DD15, the cylinder head is a key area where quality should never be compromised.

A cylinder head is more than just a metal block with valves—it’s the upper sealing component of the combustion chamber. In diesel engines, which operate at high compression ratios, the cylinder head must endure extreme stress and temperature variations. A poorly manufactured or worn-out cylinder head can lead to major issues such as compression loss, coolant leaks, or even catastrophic engine failure. That’s why technicians and fleet managers prioritize quality when choosing replacements.

Detroit Motor Parts are engineered to meet the exacting standards required by OEM specifications. That means precise casting, machining, and testing processes that ensure each cylinder head meets the rigorous demands of modern diesel engines. However, not all aftermarket parts providers are created equal. While some offer low-cost alternatives, they may not match OEM standards in metallurgy or design, potentially leading to premature wear or mechanical failure.

This is where shop.nadieselparts.com shines. With a wide inventory of diesel engine components, including cylinder heads for Detroit applications, they cater to customers who understand that cutting corners on critical parts can cost more in the long run. By partnering with trusted manufacturers and maintaining strict quality control, they help ensure that every part sold performs reliably in real-world conditions.

One of the advantages of purchasing from a specialized online diesel parts store is the access to expertise. Unlike generic auto parts platforms, shop.nadieselparts.com is staffed by diesel professionals who understand the nuances of Detroit engines and their components. Whether you're working on a two-stroke 8V92 or a four-stroke DD13, having expert guidance makes a difference. You not only get the correct part but also recommendations on installation best practices, compatible upgrades, and maintenance schedules.

For fleet operators, downtime is a major cost factor. That’s why selecting a trusted source for Detroit Motor Parts and critical components like the cylinder head is crucial. A well-built, properly installed cylinder head helps keep vehicles on the road longer, reducing unexpected breakdowns and improving operational efficiency. It also contributes to lower emissions, better fuel economy, and higher compression stability, all of which are essential for compliance and performance in today’s trucking and logistics environments.

It's also worth noting that today’s diesel engines are becoming increasingly complex. Cylinder heads now often incorporate integrated exhaust gas recirculation (EGR) ports, variable valve timing components, and improved coolant flow channels. Selecting a part that’s fully compatible with your engine model and year is essential. That’s another reason to rely on a dedicated diesel parts supplier with in-depth product knowledge.

In conclusion, the cylinder head may not be the most visible part of your engine, but its role is absolutely vital. Whether you’re maintaining a single truck or an entire fleet of Detroit-powered equipment, investing in high-quality components and sourcing them from reputable suppliers like shop.nadieselparts.com is a smart move. With performance, durability, and reliability on the line, there's simply no room for compromise.

For more info:-

Facebook

0 notes

Text

Your Trusted Exporter for Honda Spare Parts – Smart Parts Exports

When it comes to two-wheelers, no other name sells like Honda. Of scooters, the Honda Activa, Dio, and the motorcycles Shine, SP125, Unicorn and Hornet. Honda is known for its reliability, fuel efficiency and smooth performance. Even machines as good as these still require repair and maintenance, and parts do wear out over time. To have the vehicle’s safety preserved, outside equipment like Honda OEM parts is needed.

Smart Parts exports ships all over the globe, and takes pride in saying that we export genuine Honda spare parts from the heart of India. Retailers, workshop proprietors and even parts dealers, with us get the utmost Honda two-wheeler spare parts in no time.

Why Genuine Honda Parts Matter

The scooter spare parts, like the Dio and Activa, already have duplicates manufactured, and more are being made. For security and defiance against forgeries, Honda parts are secure, allowing the bike itself to outlast competitors:

✅ Perfect Fit & Compatibility: Each genuine part is manufactured to match the precise specifications of Honda vehicles.

✅ OEM Quality Assurance: Original Honda parts go through strict quality checks and durability testing.

✅ Improved Safety: Sub-standard parts can lead to serious mechanical failures. Genuine ones preserve the structural integrity of the bike.

✅ Longer Service Life: Authentic parts last significantly longer, reducing the frequency of replacements.

✅ Warranty Compliance: Using non-OEM parts may void your bike’s warranty. Stick with real Honda spare parts to protect your investment.

When your business relies on delivering quality, genuine Honda two wheeler spare parts are the best choice every time.

Our Range of Honda Two Wheeler Spare Parts

Smart Parts Exports takes pride in providing an extensive range for every Honda spare part, alongside your favorite models so easily accessible are the scooters and motorcycles.

Here’s what we supply:

Category

Examples

Engine Parts

Piston kits, crankshafts, cylinder blocks

Electrical Parts

Coils, switches, CDI units, starter motors

Body Parts

Mudguards, panels, side covers, seats

Suspension & Brake

Front forks, shock absorbers, brake pads

Transmission

Clutch plates, gear sets, chain kits

Air & Fuel System

Carburettors, filters, fuel pumps

Whether you're ordering in bulk or need parts for specific Honda models, you’ll find a complete range of Honda bike spare parts in our catalog.

Why Choose Smart Parts Exports for Honda Spare Parts

With over 80 countries, we are a trusted name in the automotive parts export industry, having delivered genuine Honda spare parts internationally. Here’s why clients from Asia, Africa, the Middle East, and South America trust us:

🌍 Worldwide Shipping

We handle all export formalities and ensure timely door-to-door delivery of your Honda parts, no matter where you're located.

🧾 Accurate Invoicing

We supply commercial invoices, packing lists, and HS codes to support smooth customs clearance.

💬 Expert Support

Our team has years of experience in identifying the right Honda two wheeler spare parts based on model, part number, or visual description.

🔒 100% Genuine Parts

We only deal in OEM Honda bike spare parts—no duplicates, no second-hand items, no compromises.

📦 Custom Packaging

Your orders are securely packed with labeling for easy identification and inventory management.

How to Order Honda Bike Spare Parts in 3 Easy Steps

Share Your Parts List: Send us the part numbers or names via email or WhatsApp.

Receive Quotation: Our team will respond with availability, pricing, and lead times.

Confirm & Dispatch: Once payment is confirmed, we’ll dispatch the parts to your destination via your preferred shipping method.

We also assist with part identification if you're not sure which Honda parts match a particular model. Just share photos, the chassis number, or a model name—we’ll take care of the rest.

Serving a Wide Range of Customers

Our clients include:

🛠 Two-wheeler Workshops: We supply genuine Honda spare parts in bulk for routine repairs.

🏪 Retail Shops & Distributors: We help parts shops stock fast-moving Honda bike spare parts at competitive prices.

🏍 Fleet Owners: We provide ongoing support for companies managing large fleets of Honda two-wheelers.

🌐 Online Sellers: Many eCommerce businesses rely on Smart Parts Exports for their backend Honda parts supply.

Whatever your business model, we ensure you receive the right Honda two wheeler spare parts every time—backed by professional service.

Models We Cover

We export Honda parts for a wide range of models, including:

Honda Activa (3G, 4G, 5G, 6G, 125)

Honda Dio

Honda Shine & Shine SP

Honda Unicorn 150 / 160

Honda Hornet 160R / X-Blade

Honda Livo

Honda Dream Yuga / Dream Neo

Honda CB200X / CB350

If it's a Honda two-wheeler, we can get you the exact parts you need—genuine and fast.

Final Thoughts

Smart Parts Exports fulfills their promise as a global exporter of Honda spare parts, fulfilling the commitment of quality, reliability, and customer satisfaction. Our promise is simple; you can count on us. Order from us and we provide you with genuine Honda two wheeler spare parts at the best prices. We offer full export support and are available for communication.

For an honest, reliable, and trustworthy partner for Honda bike spare parts, you need not look further.

0 notes

Text

Will 3D Printing Change the Way We Rebuild Used Engines?

The used engine market has long relied on traditional tools and processes — from dismantling parts by hand to machining replacements in industrial workshops. But now, an exciting technological wave is pushing its way into the garage: 3D printing.

Could it redefine how we rebuild used engines? The answer is closer than you think.

🔧 What’s Involved in Rebuilding a Used Engine?

A typical engine rebuild includes:

Disassembling and cleaning engine components

Replacing worn-out parts (bearings, seals, pistons, gaskets)

Machining the block and cylinder heads

Testing and reassembling the unit

This process is labour-intensive, expensive, and often delayed by the availability of compatible parts — especially for older models.

🖨️ Enter 3D Printing: The Game Changer

3D printing, or additive manufacturing, creates objects layer by layer from digital models. While it’s been used in aerospace and medical industries for years, it's now being explored in automotive repairs, particularly for:

Hard-to-find engine parts

Custom components

Lightweight replacements

Rapid prototyping for rebuild testing

This means mechanics may no longer need to hunt down rare parts — they can print what they need.

🔍 Real Examples of 3D Printing in Engine Repair

Ford and Volkswagen already use 3D printing to prototype engine parts.

Mechanics in the US and Germany are printing intake manifolds, cylinder head covers, and brackets.

Classic car restorers now print obsolete components that haven’t been manufactured in decades.

For used engine rebuilds, this means reviving units that would otherwise be scrapped due to part shortages.

⚙️ Benefits of 3D Printing for Rebuilt Engines

✅ Speed: Print parts on-demand, reducing wait times

✅ Cost-effective: Avoid high tooling and moulding costs

✅ Customisation: Modify designs to suit specific rebuild needs

✅ Sustainability: Less material waste and energy use compared to machining

✅ Local production: Reduces shipping and logistics costs

🧪 What About Strength and Safety?

Early 3D-printed parts were made from plastic — not great for engines. But today’s printers can use metal powders, ceramics, and high-grade composites.

Modern 3D-printed engine parts can match or even outperform OEM components, depending on the design and materials used.

Of course, safety and reliability testing is still critical, especially for high-stress parts like pistons or crankshafts. But the tech is improving rapidly.

🏗️ Challenges That Still Exist

🕒 Print speed: Large parts still take hours or days

💸 Equipment cost: Industrial metal printers are expensive

📜 Certification: Regulatory standards for printed auto parts are still evolving

👨🔧 Skill gap: Not every workshop is trained to use 3D printing yet

Despite these hurdles, more workshops are integrating 3D printing into their rebuild and testing processes.

🚗 The Future: Rebuilding Smarter, Not Harder

Imagine this future scenario:

A customer needs a used engine for their 2005 vehicle

Your auto shop finds a suitable core engine

You diagnose a failed valve component

Instead of waiting 3 weeks for an OEM part, you print it in-house within 48 hours

The engine is rebuilt, tested, and installed in record time

This isn’t science fiction. It’s the next evolution in used engine repairs.

🔁 All Good Parts: Ready for What’s Next

At All Good Parts, we stay ahead of the curve. While we currently source and test quality used engines the traditional way, we’re closely watching the 3D printing space — and preparing for a future where rebuilding gets faster, greener, and smarter.

Final Thoughts

3D printing won’t replace traditional engine rebuilding overnight. But it will complement it, offering mechanics and car owners a new level of flexibility and efficiency. Whether you're restoring a vintage engine or rebuilding a daily driver, printed parts may soon become a key piece of the puzzle.

🔧 The future of used engines is being built — one printed layer at a time.

0 notes

Text

Performance Starts Here – Mini Cooper Automotive Parts & Tuning Gear

Performance tuning requires precision, dedication, and parts that are built to last. Whether you're rebuilding an engine from scratch or upgrading for competitive driving, having the right components makes all the difference. From forged pistons to high-performance headers, the focus should always be on quality, reliability, and long-term performance. Enthusiasts and professionals alike seek trusted brands and proven engineering to push their builds further, on and off the track.

Engineered for performance and built with precision, every part is designed to elevate your driving experience. At MINI Cooper S Engine Parts, you’ll discover a curated collection of race-tested rebuild kits, high-performance internals, and upgrade components tailored for MINI models across every generation. Whether you're enhancing a supercharged R53 or a modern turbocharged B-series, this platform delivers complete solutions engineered for power and reliability.

Engine Rebuild Kits – Complete Packages

Rebuilding an engine is a detailed process that demands quality components and expert precision. Whether you’re refreshing a worn-out block or preparing for a performance upgrade, the right rebuild kit ensures reliability and longevity. These packages typically include everything needed to restore engine integrity—from gaskets and seals to timing chains and pistons—making the job more streamlined for both DIY builders and professionals.

For enthusiasts focused on Mini Cooper Engine Tuning, these complete rebuild kits offer both reliability and performance flexibility. Designed to support everything from daily driving to high-boost setups, they include durable parts optimized for horsepower gains and long-term use.

Full gasket sets for head and block sealing

OEM-quality or upgraded piston ring kits

High-performance main and rod bearings

Timing chain kits with tensioners and guides

Optional forged pistons and head stud upgrades

Components tailored for boosted or naturally aspirated builds

Why Choose Mini Cooper Automotive?

Choosing the right performance parts supplier goes beyond just finding what fits. It’s about trust, expertise, and proven results on and off the track. Backed by years of racing experience, a strong support team, and a passion for engineering excellence, this platform delivers more than just products—it offers peace of mind.

From weekend projects to full-scale builds, customers benefit from hands-on guidance and tested solutions. For those serious about Mini Cooper Automotive, this is the go-to destination for reliable, race-proven upgrades. Every component is selected with performance and durability in mind, helping drivers get the most from their engines without compromising on quality.

Expert-built kits based on real motorsport experience

Internal engine parts rated for high horsepower applications

Cylinder heads and stud kits are designed for boosted setups

High-flow exhaust components for increased power and torque

Conclusion

Unlock the full potential of your build with performance parts engineered for precision, power, and durability. Whether you’re upgrading for reliability, track performance, or daily driving excellence, using the right components from a trusted source ensures long-term results and peace of mind. Have questions or need help choosing the right parts? Contact us today for expert guidance and personalized recommendations. Every engine deserves attention to detail, especially when it's part of a brand built for spirited performance and handling.

0 notes

Text

Buy Used Chevy Auto Parts for Trucks

Want to purchase used Chevy auto parts for trucks or cars? Don’t worry! You are at the right place. We offer premium-quality used Chevy parts at affordable prices. Meanwhile, we provide a wide range of used auto parts for various Chevy models. You can contact our professionals to purchase used Chevy parts, and they will be delivered to your doorstep within a few days.

Where to Buy Used Chevy Auto Parts for Trucks?

However, there are various options available for purchasing used Chevy auto parts in the United States. To make it simple, call our agents to get your Chevy truck parts within three days to your home.

Auto Salvage Yards

They are commonly referred to as junkyards or scrap yards.

Chevy Silverado salvage yards offer high-quality auto parts, ensuring complete customer satisfaction.

Online Websites

Our website offers different types of used car parts for sale.

Our services and reviews are available on our website. Thus, we also offer a return policy.

Specialized Retailers

You can also shop at specialized retailers, which focus on used or refurbished auto parts. Meanwhile, our retailers offer premium-quality used auto parts for sale. So, grab the offer soon.

What are the Different Chevy Trucks Auto Parts?

If you need car parts, contact our agents for the best-quality used auto parts in the United States.

Engine: The engine comprises the block, cylinder head, pistons, and crankshaft components. We offer a wide range of elements at affordable rates.

Transmission: This helps transfer the power from the engine to the wheels. The driver controls it and automatically shifts gears based on speed and torque.

Brake System: The brake system has pads and rotors that helps in generating friction to slow or stop the vehicle. The brake calipers house the pads and squeeze them against the rotors.

Suspension: The correct suspension cushions road impacts, allowing for a smooth ride. The control arms help connect the wheels to the truck’s frame.

Cooling and Heating System: The radiator helps dissipate heat from the engine coolant, and the thermostat regulates the engine's temperature through controlling the flow of coolant through it.

Tires and Wheels: Tires provide grip and traction for various road conditions, while rims support the tires and connect to the axles, which transfer power from the engine to the wheels.

Factors to Check While Buying Used Chevy Auto Parts

While buying Chevy aftermarket parts, there are several factors that you must follow and check. You can check our website to purchase used auto parts for sale and of premium quality.

Inspect Your Truck Requirements

Before purchasing, you must know your vehicle’s model and specifications. This will ensure that the part used is compatible with your car and will benefit it.

Select a Reputed Seller

You must buy aftermarket auto parts from a reputed seller to ensure quality and get a warranty. We provide different parts for each model at the best prices.

Verify Product Authenticity

While buying used parts, you must check if the product is authentic and reliable. You might purchase a cheap product to save money, yet the product must be worthy.

Compare Rates

When buying used Chevy auto parts, check rates from different websites and retailers. After comparing the prices and ensuring the quality, you can buy the used auto parts.

Check the Customer Reviews

When you order online car parts, you can check for the customer reviews of those who have bought from that website. However, if you purchase from our website, you can buy aftermarket body parts of the best quality.

Bottomline

While buying from carpartzone.com, you get tested and cheaper auto parts in comparison to brand-new parts. Many older vehicle parts are only available through used options. We provide all types of aftermarket auto parts, meeting safety and functionality standards, giving you peace of mind with every purchase.

Frequently Asked Questions

Are Used auto parts be durable?

You can purhcase used car parts that are cost-efficient and of premium quality within your budget. Our website offers used car parts for sale, and you can check out the offer soon.

What is the cost of a used bumper?

If you want to buy a used bumper for your Chevy truck, you can check our website, which offers all models and bumpers. Depending on your requirements and conditions, the cost varies.

How to buy used car parts online?

However, there are different ways to obtain used auto parts across the states. You can check various websites, auto salvage yards, or specialized manufacturers.

Can I install the Chevy truck parts on my own?

If you know the way to install car parts, you can try. But usually, it is not advised to install the auto parts on your own, as it can be dangerous if not installed correctly. You can call our professionals for assistance regarding your car and its parts.

0 notes

Text

How to Build a Library of Modular 3D Props for Game Environments

In the rapidly growing world of 3D modeling games, developers constantly seek ways to streamline their workflow, save time, and maintain consistency in visuals. One of the most efficient ways to do this is by building a library of modular 3D props for use in 3D game environments. Whether you're an indie developer or part of a large game studio, modularity in 3D game assets enhances creativity and speeds up level design without compromising quality.

In this guide, we'll walk you through creating your reusable library of modular props — from planning and asset creation to integration in 3D game environments.

Why Modular Props Matter in 3D Modeling Games

Think of them like LEGO blocks for game designers — from crates and barrels to walls and fences, each piece can be mixed and matched to build a wide range of environments.

Using modular assets in 3D environment modeling offers several advantages:

Efficiency: No need to model every prop from scratch.

Consistency: Ensures visual coherence across levels.

Optimization: Fewer unique assets reduce memory usage.

Scalability: Makes it easier to scale game worlds or create downloadable content (DLC).

Step 1: Define Your Game's Environment Style

Before diving into the modeling process, it's essential to determine the aesthetic and genre of your game. Are you building a sci-fi world, a medieval fantasy realm, or a modern urban setting?

Your game’s environment style will dictate the look and feel of your 3D game assets, as well as the technical requirements for poly count, texture resolution, and shading techniques. For example:

Sci-Fi: Emphasize clean panels, vents, and glowing elements.

Fantasy: Focus on organic curves and hand-crafted textures.

Urban: Utilize realistic props 3D model references like benches, traffic lights, and car 3D models.

Step 2: Plan Your Modular Kit

A good modular kit should cover all the basic building blocks required to create a complete 3D game environment.

Walls, floors, and ceilings

Doors and windows

Furniture

Structural elements (beams, stairs)

Decorative props (props 3D model like crates, barrels, posters)

Vehicles (3D vehicle modeling assets like cars, trucks, or drones)

Each asset should adhere to a unified grid system, such as 1x1 meter units, to ensure seamless snapping during level design. Don’t forget to establish naming conventions and folder structures for easy management.

Step 3: Master Hard Surface Modeling Techniques

Most modular props fall under the category of Hard Surface Modeling, which focuses on mechanical and man-made objects with clean lines and defined edges. This technique is especially useful for assets like walls, pipes, machinery, and 3D vehicle models.

Key tips for 3D hard surface modeling:

Start with primitives: Use boxes, cylinders, and planes to block out basic shapes.

Use Boolean operations wisely: They’re great for cutting holes or adding detail, but may require cleanup.

Step 4: Create and Optimize Props

Once the base models are ready, move on to texturing and optimization. For performance, make sure your textures follow the power-of-two rule (e.g., 512x512, 1024x1024).

Optimize your props 3D model by:

Reducing poly count without sacrificing silhouette

Combining meshes where possible

Removing hidden faces