#Precision-engineered cylinder blocks

Explore tagged Tumblr posts

Text

Manufacturer of Premium Cylinder Blocks for Superior Engine Performance: Dasset Engineering

In the competitive world of automotive engineering, the importance of high-quality components cannot be overstated. Among these, cylinder blocks play a crucial role in determining the performance and longevity of an engine. At Dasset Engineering, we specialize in manufacturing premium cylinder blocks that deliver superior engine performance. This blog delves into the significance of cylinder blocks, the attributes of our premium products, and why Dasset Engineering stands out in this industry.

The Importance of Cylinder Blocks

The cylinder block is the backbone of any internal combustion engine. It houses the cylinders, coolant passages, and oil galleries, providing structural integrity and maintaining optimal engine temperature. The performance, efficiency, and durability of an engine largely depend on the quality of the cylinder block. Poorly manufactured blocks can lead to overheating, oil leaks, and ultimately, engine failure.

Attributes of Premium Cylinder Blocks

At Dasset Engineering, we understand that premium cylinder blocks are not just about high-grade materials but also about precision engineering and meticulous craftsmanship. Here are some key attributes that define our premium cylinder blocks:

High-Quality Materials

We use the finest materials, such as cast iron and aluminum alloys, to manufacture our cylinder blocks. These materials offer excellent durability, heat resistance, and strength, ensuring that the engine performs optimally under various conditions.

Precision Engineering

Our cylinder blocks are engineered with precision to meet exact specifications. Advanced machining techniques ensure that each block has the correct dimensions, smooth surfaces, and precise alignment of the cylinders. This precision is crucial for achieving optimal engine performance and efficiency.

Superior Cooling and Lubrication

Efficient cooling and lubrication are vital for engine performance and longevity. Our cylinder blocks feature optimized coolant passages and oil galleries that ensure efficient heat dissipation and lubrication. This reduces the risk of overheating and wear, thereby extending the engine's lifespan.

Rigorous Testing

Every cylinder block manufactured by Dasset Engineering undergoes rigorous testing to ensure it meets the highest standards of quality and performance. We conduct various tests, including pressure testing, thermal cycling, and dimensional inspections, to verify the integrity and reliability of our products.

Why Choose Dasset Engineering?

Dasset Engineering has established itself as a leading manufacturer of premium cylinder blocks, and here's why:

Expertise and Experience

With years of experience in the industry, we possess the technical expertise and knowledge required to produce top-tier cylinder blocks. Our team of skilled engineers and technicians is dedicated to delivering products that exceed customer expectations.

State-of-the-Art Facilities

We operate state-of-the-art manufacturing facilities equipped with the latest machinery and technology. This allows us to maintain strict quality control and produce cylinder blocks that meet the most demanding specifications.

Commitment to Quality

Quality is at the core of everything we do. From sourcing the best materials to implementing stringent quality control measures, we are committed to delivering cylinder blocks that offer unmatched performance and reliability.

Customer-Centric Approach

At Dasset Engineering, we believe in building long-term relationships with our customers. We work closely with them to understand their specific needs and provide customized solutions that cater to their requirements.

Conclusion

The cylinder block is a critical component that significantly impacts an engine's performance, efficiency, and durability. At Dasset Engineering, we take pride in manufacturing premium cylinder blocks that set the benchmark for quality and performance. By choosing our products, you are investing in superior engine performance, reliability, and longevity. Trust Dasset Engineering to be your partner in achieving excellence in automotive engineering.

#High-quality cylinder blocks for engines#Premium engine cylinder block manufacturer#Superior engine performance cylinder blocks#Precision-engineered cylinder blocks#Best materials for cylinder blocks#Advanced machining cylinder blocks#Cylinder blocks with optimized cooling#Durable cylinder blocks for automotive engines#Reliable cylinder blocks for high-performance engines#Custom cylinder block manufacturing#Top-rated cylinder block manufacturers#Cylinder blocks with efficient lubrication#Engine cylinder block quality testing#Benefits of premium cylinder blocks#Engine longevity with high-quality cylinder blocks#Cylinder block structural integrity for engines#Leading cylinder block manufacturers in the industry#State-of-the-art cylinder block production facilities#Expert cylinder block engineering services#Long-lasting cylinder blocks for vehicles

0 notes

Text

Go further, faster, and more comfortably. A new Gran Turismo that brings you the ultimate driving pleasure.

GT 4DOOR SEDAN

released

LEGACY

2000/1800

Refined driving that responds faithfully to your will. Stable driving as if on rails. Deep driving that envelops all passengers in a sense of trust. The Legacy is a sedan that thoroughly pursues the ultimate appeal of a car: driving. The new generation BOXER is the crystallization of Subaru's horizontally opposed engine technology. A suspension that harmonizes handling stability and ride comfort at a high level. Equipped with the engine and mechanisms of the 100,000 km world speed record car, the 200 horsepower GT model has also been released, further refining its driving performance. A car becomes even more of a car. What the Legacy has been refining is driving.

PHOTO TOP: 4WD 4-door sedan GT Indigo Blue Metallic

PHOTO BOTTOM LEFT: R.S. Everything is for the ultimate joy of control. Handling sedan, Legacy RS 4WD 4-door Sedan RS Black Mica

PHOTO BOTTOM RIGHT: Touring Wagon

Performance and ample utility worthy of its name. Legacy Touring Wagon

GT TOURING WAGON released

PHOTO: 4WD Touring Wagon GT Indigo Blue Metallic

It was selected as a Good Design in '89.

Legacy Touring Wagon VZ (Ministry of International Trade and Industry Selection

All vehicles are equipped with the new generation BOXER. The Legacy has Subaru's will to drive.

BOXER Three power units full of driving pleasure.

New generation horizontally opposed engine = BOXER.

All vehicles are equipped with the new generation BOXER, which is a further development of Subaru's traditional horizontally opposed engine and pursues the potential suitable for a driver's sedan. The 2.0-liter 4-cam 16-valve EJ20 has high performance across the entire range, the 1.8-liter 16-valve EJ18 is a highly complete and well-balanced base engine, and the EJ20 Turbo is a high-performance unit equipped with a water-cooled intercooler and turbo. In particular, the EJ20 Turbo comes in two versions, the 200ps (GT) which provides ample, flat torque and linear response from low to mid-range to high revolutions, and the 220ps (RS) which pursues top-end power at high revolutions, in line with the driving concept. All of them are equipped with a 5-bearing crankshaft, a flywheel housing cylinder block, and a comprehensive electronically controlled injection system. It makes the most of the natural qualities of the BOXER, such as its high engine rigidity and vibration and rotation characteristics, to deliver precise response and an exhilarating power feel.

The technology focuses on depth rather than freshness. This driving experience embodies Subaru's philosophy.

All-range electronically controlled 4-speed fully automatic E-4AT

This is the latest automatic transmission that gives drivers a lot of freedom. Automatic control of power/normal gear shift modes provides smooth and agile acceleration. Seven select positions and a manual switch provide versatility. Highly easy to drive and precise driving according to driving conditions are possible.

For more reliable operation of AT vehicles ●Key interlock ●Shift lock ●Reverse alarm

●AT select indicator is adopted.

Electronically controlled active torque split 4WD

This is Subaru's world-renowned original 4WD high-speed easy-drive system. The computer accurately judges the driving conditions and road surface conditions, and instantly and continuously controls the torque distribution between the front and rear wheels. It always maximizes the potential of the 4WD, creating a stable and refined driving experience. In addition, manual transmission vehicles are equipped with a center differential full-time 4WD with a viscous LSD.

It fits your hand, your body, and your movements. This space is designed with a passion for running.

The interior of the Legacy is designed around the theme of driving pleasure, just like the mechanism. The interior is wrapped in a sense of security and has a rich texture, reflecting Subaru's commitment to driving. In addition, the GT (AT model) is available with a manufacturer-installed option of genuine leather seats with a soft texture that become more comfortable the more you use them.

PHOTO:GT (AT)

Matured legs. New strut suspension.

In pursuit of a deep ride that resonates pleasantly with the driver's sensibilities in any situation and becomes more appealing the more you ride, we thoroughly pursued the fundamentals of the suspension.

The roll center is set low to obtain a good feeling of control and grip of the tires. The system has been thoroughly refined to ensure ample wheel stroke and reduce friction. You can enjoy a relaxed, solid ride and handling that is faithful to your will.

PHOTO: 4WD 4-door sedan GT Indigo Blue Metallic

A steering system with a firm steering feel.

The steering system also has sufficient rigidity and is more responsive, and also features light power steering.

Reliable 4-wheel disc brakes & 4-channel ABS

The Legacy's stopping ability has also been thoroughly improved. Large-capacity brakes and boosters are used on all vehicles, and EJ20-equipped vehicles are equipped with 4-wheel disc brakes. The 4-wheel anti-lock brakes (ABS) are also the most advanced system currently available, with a 4-sensor 4-channel control method developed.

(ABS is a manufacturer option, and the settings vary depending on the type, so please refer to the catalog for details.)

A quality-feeling ride and highly rigid body.

The Legacy's powerful driving feel is due to its incredibly strong body, which boasts overwhelming rigidity. In addition to thoroughly strengthening the basic structure, large stiffening materials are used in various parts to increase overall rigidity.

PHOTO: 4WD 4DR Sedan GT (genuine leather seats are a manufacturer's option for AT vehicles). Sunroof and sunroof options are not available.

9 notes

·

View notes

Text

Car Parts and Key Components: Proper Uses that Every Beginner Driver Should Know

Transporting your car can be daunting task, but it doesn’t have to be. A well-planned auto transport process making sure your car's safety from start to finish. With a reliable car carrier service like San Jose auto transport, rest assured your car will be delivered to your doorstep on-time.

This guide will provide you necessary information and useful tips about choosing a reliable auto transport service, common car parts, and basic function of your vehicle for safe driving journey.

Car Parts and It's Basic Function

This guide will shed you light with the common car parts and its basic functions for maintaining your car for efficient running condition. From the engine to the brakes, each part plays an important role. Get ready to gain confidence in your driving journey.

The engine generates power, while the transmission transfers that power to the wheels.

Brakes are important for stopping, so understanding how they work will guarantee safety and quickly respond to any unforeseen situations.

The battery powers electrical systems and starts the engine.

Familiarity with fluid levels, such as oil and coolant, prevent overheating and engine damage.

Learning about tire pressure helps maintain traction and safety on the road.

Proper knowledge of these common car parts are important for responsible car owner and safe driving practices.

Today's vehicles are complex machines with many interconnected systems and components. Vehicle owners who understand these simple parts can maintain their cars better and talk effectively with mechanics.

Car Cooling Systems:

Engine and Power-train components

Cooling and exhaust systems

Starting and charging systems

Fuel delivery mechanisms

Braking and steering assemblies

Suspension components

Heating and air conditioning

The engine acts as the vehicle's heart and converts fuel into mechanical energy through controlled combustion. Multiple precision components like the engine block, cylinder heads, camshafts, and crankshaft work together harmoniously.

Supporting systems are equally crucial. The cooling system regulates optimal operating temperatures, and the exhaust system handles waste gasses. The battery and alternator power the starting and charging system, which supplies electrical energy to run the engine and vehicle accessories.

This knowledge helps new car owners during routine maintenance and unexpected problems.

Car owners who understand simple car parts can:

Identify potential problems early

Schedule appropriate maintenance

Make informed repair decisions

Communicate clearly with service professionals

Maintain vehicle value through proper care

The drive-train moves power from the engine to the wheels. The braking system creates friction to stop safely. These systems collaborate with steering and suspension components to provide safe, comfortable transportation.

Important Functions of Car Engine

Your car's internal combustion engine transforms chemical energy into mechanical power through a precise sequence of events.

A well-maintained engine runs smoothly and improves your vehicle's performance and longer engine life.

Regular Engine Maintenance Schedule:

Check spark plugs every 30,000 miles

Monitor fluid levels monthly

Inspect air filters regularly for debris

Clean battery connections at the first sign of corrosion

Your engine's combustion chamber acts as a powerhouse that combines fuel and air to generate energy. The spark plug ignites the compressed fuel-air mixture and creates a controlled explosion that moves the pistons. A timing belt keeps all components in perfect sync during this sequence.

Power flows from the combustion chamber through several key steps:

Piston movement converts explosive force to linear motion

Crankshaft changes linear motion to rotational force

Flywheel smooths the power delivery

Transmission system directs power to wheels

A network of components prevents your engine from overheating. The radiator and water pump work together to circulate coolant through passages around the cylinders. Regular inspection of this temperature management system helps avoid repairs that can get pricey.

Your engine needs proper fluid levels to perform at its best:

Engine oil (check monthly)

Coolant

Brake fluid

Power steering fluid

Spark plugs play a vital role in the combustion process. Engine problems develop rapidly if they malfunction. You should inspect them regularly and replace them according to manufacturer specifications.

Understanding basic car parts and key components is important for any beginner driver in San Jose. This knowledge helps you maintain your vehicle and recognize issues early on. Remember the importance of the engine, brakes, and tires, as these are important parts of your vehicle for safe driving.

With this guide, you now have the tools to feel more confident behind the wheel. Always keep learning and be familiarized with every parts of your vehicle.

For more tips on finding a trusted service like auto transport company California, keep exploring our blog.

youtube

#safe car shipping#auto transport tips#car carrier service#Lucky Star Auto Transport#reliable service#Youtube

10 notes

·

View notes

Text

#Engine #Components⚙️ #Power⚡️starts here From Cylinder #heads to engine #blocks #GoyalInc🗜️#Aluminum🔧#DieCast #parts are #built for #performance & #Precision #Lighter engines better #fuel⛽️#Economy & longer #life-its all begin with right components http://incgoyal.com https://x.com/goyal_inc https://www.youtube.com/@GoyalInc https://www.instagram.com/goyalinc https://in.pinterest.com/goyalinc https://www.facebook.com/incgoyal https://www.threads.net/@goyalinc #DigitalMarketing #Engineering📐 #PrecisionMachining #CNC #tools🛠️ #Casting #Precisionmachinedparts #MachinedParts⚙️ #MachinedComponents #Manufacturing #hpdc

2 notes

·

View notes

Text

Essential Guide to Mk5 GTI Timing Belt and Water Pump Replacement

When it comes to maintaining your Volkswagen Mk5 GTI, one of the most critical aspects of engine care is the timing belt and water pump. These two components play a vital role in ensuring the engine runs smoothly, efficiently, and without catastrophic failure. At Kiwi Car Parts, we understand the importance of quality replacement parts and timely maintenance. In this guide, we’ll walk you through everything you need to know about the Mk5 GTI Timing Belt and water pump, when to replace them, common issues, and why it’s best to get both replaced together.

Understanding the Mk5 GTI Timing Belt

The timing belt is essentially the heartbeat of your Mk5 GTI’s engine. It synchronizes the camshaft and crankshaft rotations so that the engine's valves open and close at the proper time during each cylinder’s intake and exhaust strokes. In simpler terms, it ensures your engine components work together perfectly.

However, unlike chains, timing belts are made of rubber and wear out over time. If the timing belt breaks while the engine is running, it can lead to catastrophic damage—bent valves, damaged pistons, and a costly repair bill. That’s why regular inspection and timely replacement are crucial.

When Should You Replace the Mk5 GTI Timing Belt?

For the VW Mk5 GTI, it’s generally recommended to replace the timing belt every 60,000 to 100,000 miles, depending on your driving habits and the specific engine model (e.g., 2.0 TFSI). However, if you notice signs like ticking noises from the engine, misfires, or oil leaking from the front of the motor, it could indicate timing belt wear.

At Kiwi Car Parts, we provide high-quality, OEM-compatible Mk5 GTI timing belts that ensure durability and reliability.

The Role of the Mk5 GTI Water Pump

While the timing belt keeps your engine’s internals in sync, the water pump handles engine cooling. It circulates coolant through the engine block, radiator, and hoses to keep the operating temperature within safe limits. Without a functioning water pump, your engine can overheat in minutes, leading to serious damage.

In the Mk5 GTI, the water pump is typically driven by the timing belt. That means if one component fails, the other could be compromised as well. For this reason, mechanics often recommend replacing the water pump during timing belt service, even if it hasn’t failed yet.

Why Replace Both at the Same Time?

If you’re thinking about servicing your Mk5 GTI timing belt, it’s highly recommended to replace the water pump at the same time—and vice versa. Here's why:

Labor overlap: Both parts are located in the same area of the engine, meaning much of the labor involved overlaps. Doing both together saves you from paying twice for labor.

Preventative maintenance: Even if the water pump looks fine, it could fail before the next timing belt change. Replacing it early avoids future breakdowns.

Complete reliability: Installing both components ensures your engine runs smoothly and is protected from avoidable mechanical failures.

At Kiwi Car Parts, we offer complete Mk5 GTI timing belt and water pump kits, ensuring you get everything you need in one go—belt, pump, pulleys, tensioners, and seals.

Signs You Need to Replace the Water Pump

Here are some symptoms indicating your Mk5 GTI Water Pump might be on the way out:

Coolant leak from the front of the engine

Overheating or fluctuating engine temperatures

Steam from under the hood

A high-pitched whining sound

Engine warning lights, especially related to coolant temperature

If you notice any of these signs, it’s time to inspect both the water pump and the timing belt.

Choosing the Right Parts for Your Mk5 GTI

Not all replacement parts are made equal. At Kiwi Car Parts, we stock only the best:

OEM-quality Mk5 GTI timing belts made from high-strength rubber and reinforced with durable materials

Precision-engineered Mk5 GTI water pumps for optimal flow and cooling efficiency

Complete kits with tensioners, idler pulleys, and all necessary hardware for a smooth installation

We also offer expert advice and support to help you choose the right parts for your engine variant.

DIY or Mechanic: What’s the Best Approach?

Replacing a timing belt and water pump isn’t a job for the average DIY mechanic unless you have experience with engine disassembly. It requires special tools, attention to timing marks, and knowledge of engine assembly. Mistakes can be costly.

That said, if you're mechanically inclined and have a proper service manual, you can use a complete kit from Kiwi Car Parts to tackle the job yourself. Otherwise, we recommend working with a certified mechanic for peace of mind.

Final Thoughts

The Mk5 GTI is a performance icon loved by enthusiasts for its balance of power and practicality. To keep it running like new, don’t overlook essential maintenance like the timing belt and water pump replacement. Whether you're planning a replacement or just doing research, Kiwi Car Parts is your trusted partner for reliable, high-quality parts.

Visit Kiwi Car Parts to explore our full range of Mk5 GTI timing belt kits and water pumps, and keep your GTI running strong for years to come.

0 notes

Text

Boosting Manufacturing Precision with BTA Machines and Hob Sharpeners

In today’s fast-evolving industrial landscape, precision and performance are more critical than ever. From aerospace to automotive, industries are pushing boundaries and demanding tighter tolerances, faster cycles, and greater consistency. That’s where advanced machining solutions like BTA machines, hob sharpeners, and deep hole drilling systems step in, offering game-changing capabilities that traditional methods simply can't match.

Understanding the Role of BTA Machines in Modern Manufacturing

Ever wondered how manufacturers create long, precise holes in solid metal blocks? The answer lies in BTA machines—powerful tools designed for deep hole drilling operations. BTA (Boring and Trepanning Association) drilling is a highly specialized method that delivers unmatched accuracy when it comes to deep, straight bores.

BTA machines are commonly used in industries such as:

Oil and gas, for creating holes in drill collars and hydraulic cylinders

Aerospace, for precise internal cavities

Heavy machinery, for engine blocks and spindles

Why choose BTA machines? These machines are known for their excellent chip removal systems, coolant-fed drilling, and capacity to handle large workpieces with ease. They not only improve productivity but also enhance the overall quality of machining by minimizing tool wear and maintaining bore consistency.

Hob Sharpeners: Essential for Gear Cutting Excellence

In gear manufacturing, the hob is a cutting tool used to shape gear teeth with high accuracy. But like any tool, hobs wear out over time. That’s where a hob sharpener becomes essential.

A high-quality hob sharpener restores the original profile of a worn hob, ensuring it can continue to produce precise gears. Here’s why investing in a reliable hob sharpener matters:

Extended Tool Life – Regular sharpening prevents premature disposal of expensive hobs.

Consistent Output Quality – Sharp hobs ensure uniform gear tooth profiles.

Reduced Downtime – A well-maintained hob results in fewer reworks and tool changes.

With gear tolerances getting tighter, having a dependable hob sharpening machine in your toolkit is non-negotiable for any serious gear manufacturer.

Deep Hole Drilling: Where Precision Meets Depth

Deep hole drilling refers to the process of drilling holes where the depth is ten times or more the diameter. While it sounds straightforward, it poses several technical challenges, such as chip evacuation, cooling, and tool deflection.

Thanks to innovations in BTA machines, gun drills, and other specialized tooling, manufacturers can now achieve deeper and more precise holes than ever before. Deep hole drilling plays a pivotal role in:

Hydraulics – For making accurate channels in cylinders and pistons.

Defense and aerospace – Where internal pathways are crucial for performance.

Medical devices – Precision bores in surgical tools and implants.

These machines are not just about drilling holes—they're about engineering excellence.

WIDMA: Pioneering Precision with Cutting-Edge Solutions

When it comes to trusted solutions in deep hole drilling and precision machining, Widma stands out as a leading name. A division of Kennametal India, Widma brings decades of experience, engineering excellence, and a customer-centric approach to the table.

Whether you're looking for a robust BTA machine, a precision hob sharpener, or high-performance deep hole drilling systems, Widma offers machines that are tailor-made for your industry needs.

Why Widma?

Advanced CNC-based machinery designed for performance and longevity

Proven track record in the automotive, aerospace, and general engineering sectors

In-house R&D and manufacturing facility that ensures quality control at every stage

Global recognition for precision, innovation, and reliability

Final Thoughts

Precision isn’t just a goal—it’s the standard in modern manufacturing. Solutions like BTA machines, hob sharpeners, and deep hole drilling technology are critical for companies aiming to stay competitive and efficient. And if you're looking to invest in world-class machining capabilities, Widma is the name you can trust for superior quality, innovation, and support.

Let precision lead the way—with Widma.

0 notes

Text

Industrial Foundry

In today’s world of advanced machinery, massive infrastructure, and high-performance vehicles, there is one silent contributor that powers it all — the industrial foundry. Foundries are the starting point for most heavy-duty components, where molten metal is cast into precise shapes to serve vital mechanical functions. Without industrial foundries, the global manufacturing ecosystem would quite literally grind to a halt.

Industries That Depend on Foundries

Industrial foundries are critical suppliers to many major sectors, including:

Automotive – Engine blocks, gearbox housings, brake drums, wheel hubs

Agriculture – Tractor parts, hydraulic components, plough bodies

Construction – Structural castings, pump housings, fittings

Power & Energy – Turbine components, generator housings

Mining & Heavy Equipment – Wear-resistant parts, housings, plates

Hydraulics & General Engineering – Valves, manifolds, cylinders, and more

Every gear that turns in a machine or component that supports a heavy load often starts its life in an industrial foundry.

Key Processes in an Industrial Foundry

Modern foundries follow a systematic, high-precision casting process that ensures both strength and consistency:

Pattern Making A model of the component is made from wood, metal, or resin to create the mold cavity.

Molding Sand or no-bake molding processes are used to create the negative shape of the casting.

Melting Raw materials are melted in induction furnaces or cupola furnaces, achieving high temperatures for uniform metal flow.

Pouring The molten metal is poured into the mold cavity with strict temperature control.

Cooling & Solidification The metal is left to cool and harden into the desired form.

Fettling The casting is cleaned, trimmed, and sandblasted to remove rough edges or excess material.

Inspection & Testing Each casting is tested for dimensional accuracy, strength, hardness, and chemical composition to meet industry standards.

Machining (if required) Complex parts are further machined to meet precision tolerances using CNC, VMC, and turning centers.

0 notes

Text

Lifting Tools | Lifting Tools Manufacturers, Suppliers in Pune

In the fast-moving world of industrial and construction work the success of your undertaking may well depend on the reliability and efficacy of lifting equipment. Applied Engineering appreciates the importance of hoisting heavy loads safely. As a top lifting tool manufacturer and supplier in Pune, we have been investigating the best way to provide reliable, heavy-duty lifting solutions that meet the needs of your project. Our lifting tools are designed for accuracy, certified for maximum load capacity and optimized to meet heavy lifting challenges in the manufacturing, construction, logistics and infrastructure sectors.

Why Lifting Tools from Applied Engineering?

Being one of the leading Lifting Tool Suppliers in Pune, we have been trusted for the following:

High Strength: All our tools are manufactured from high-grade steel and alloys to withstand high-stress work situations.

Safety: In addition to using the safest materials and methods, each tool is tested to the highest safety requirements and conforms to internationally recognized quality standards.

Full Range of Products: We can provide a complete range of manual chain blocks, hydraulic jacks, hoists, lifting slings, and clamps.

Expert Advice: We advise, based on your required lift height, lift weight, and the environment in which it will be used.

Rapid delivery throughout India: We can provide you with tools when needed, from Pune to pan-India, so that your operations do not cease to operate due to unavailable lifting tools.

Types of lifting Tools We Supply:

At Applied Engineering we can supply:

Chain Blocks and Lever Hoists; For safe, load lifting applications, with manual lifting in confined space situations.

Hydraulic Jacks and Cylinders; For total precision lifting and do so with heavy-duty capacity.

Wire Rope Slings and Chain Slings; With various weight and load configurations.

Lifting Clamps and Eye Bolts; For easy and safe material handling and vertical/horizontal lifting.

Crane Accessories; All hooks, shackles and swivels designed to carry high-tension loads safely and efficiently.

Versatility Across All Industries:

The lifting tools we manufacturer have applications in:

🏭 Manufacturing Plants – For assembly, maintenance, and heavy component

🧱 Construction Sites – Lifting steel beams, concrete blocks, and machinery

🚛 Warehousing & Logistics – Material movement to reduce manual movement

⚙️ Automotive and Engineering Workshops – Equipment installation and maintenance

Trusted by Leading Brands

Applied Engineering is the largest Lifting Tools Manufacturer in Pune, with years of experience and a customer-first approach. Our focus on quality, innovation, and service, has supported businesses in improving operational efficiencies and increasing safety.

0 notes

Text

Engineering Precision at Scale: Exploring the Rise of Large Bore Milling in Chicago’s Industrial Epicentre

Large boring mill machining in Chicago has been widely adopted, as the Chicagoland region is home to a high concentration of manufacturing businesses (approximately 12,000) — from oil and gas and food processing to heavy industries and aerospace. Let’s understand what large-bore milling is and why it matters so much for Chicago’s manufacturing units.

Understanding Large Bore Milling

These are types of precision machining that can drill, cut, or even broaden holes in metal parts using highly advanced CNC boring mills. Therefore, whether one requires drilling into large machine components, such as engine blocks or turbines, to create or repair large, precisely shaped holes, large-bore milling machining is the ideal solution for achieving accuracy at scale.

Why large bore milling in Chicago matters for industries

Chicago’s Manufacturing History- Chicago has long been a manufacturing hub and continues to build its future through a wide and multifaceted manufacturing framework. As manufacturers depend on heavy machinery, the demand for large precision-machined components is increasing. This increases the need for large-bore milling machining services.

Budget-friendly refurbishment of old plant equipment- Manufacturers in Chicago use outdated equipment that requires regular maintenance. Large boring mill machining in Chicago helps them rebuild and upgrade those parts. It saves both time and resources.

Oversized Component Machining- The region is an epicenter for large-scale manufacturing industries. It requires machining services that deliver fine precision that improves machine performance and lifespan. Chicago’s local manufacturers look to produce complex and large machine components without sacrificing the finer details, and leveraging large-bore milling machining helps them achieve their goals.

Quick response time - Nearby support for machining services reduces waiting time, offers quicker repairs, and lowers the cost. This is a crucial gain for industries that rely on large machinery.

Real-World Application of Large-Bore Milling- The industrial base of Chicago supports numerous industries that require large-bore machining. Its oil and gas sector uses large-bore milling to re-bore hydraulic cylinders that match the original component. Likewise, industries in the construction sector use it to refurbish large equipment. It is also used in reconditioning turbines in power plants.

Marvel Machining Company: Experts You Can Count On

Established in 1987, this machining and part-rebuilding company has helped Chicago's industrial sector by offering reliable, high-precision solutions for heavy equipment and critical components. The company’s pro machinists use some of the most technologically advanced CNC boring and milling machining equipment to deliver precision repair, rebuilds, and large-scale machining solutions to businesses. It uses the skills of local expert machinists with digital quality systems to rejuvenate aging machinery—keeping companies productive and resilient.

The Road Ahead

The city’s manufacturing base is all set to expand in sectors such as automotive, aerospace, and other heavy industries, and so will the demand for high-quality large-bore milling. Service providers like Marvel Machining are all set to lead this transformational journey.

0 notes

Text

The Enduring Power of Sand Casting in Modern Manufacturing

In the age of high-tech manufacturing and rapid prototyping, one might assume that traditional metal casting methods have become obsolete. Yet, sand casting—one of the oldest known metals forming techniques- continues to play a critical role in modern industry. Its ability to create complex shapes, accommodate a wide range of metals, and offer cost-effective production makes it a cornerstone of manufacturing around the world.

Whether it’s for the automotive, aerospace, energy, or heavy equipment sector, sand casting remains a dependable solution for producing durable metal parts with precision. This blog explores what makes sand casting so valuable, its key advantages, the process involved, and what to look for in a reliable sand casting company.

What is Sand Casting?

Sand casting, also known as sand molded casting, is a metal casting process that uses sand as the mold material. It involves creating a cavity in sand, pouring molten metal into it, and allowing the metal to cool and solidify. Once the metal has hardened, the sand mold is broken apart, revealing the final cast product.

The method can be used for both ferrous and non-ferrous metals, including aluminum, iron, steel, bronze, and more. Sand casting is ideal for both low-volume and high-volume production runs and can create large and complex components with minimal waste.

The Sand Casting Process: Step-by-Step

1. Pattern Creation

The process begins with making a pattern of the object to be cast. This pattern is typically made from wood, plastic, or metal and is a replica of the final product.

2. Mold Preparation

The pattern is placed in a molding box and packed with special sand mixed with binders to retain shape. The sand is compacted tightly around the pattern to form the mold cavity.

3. Core Insertion (if needed)

For hollow components, a core is placed inside the mold cavity. Cores are typically made of sand and shaped to match the internal geometry of the final product.

4. Melting and Pouring

The chosen metal is melted in a furnace and poured into the sand mold. This step requires precision in temperature and timing to avoid defects.

5. Cooling and Solidification

Once poured, the metal is allowed to cool and solidify inside the mold. Cooling time depends on the size and complexity of the component.

6. Shakeout and Cleaning

After cooling, the sand mold is broken apart to extract the metal casting. The casting is then cleaned to remove excess material, sand, or oxidation.

7. Inspection and Finishing

The final product undergo inspection for quality and may receive additional machining or surface treatment depending on the application.

Key Advantages of Sand Casting

1. Cost-Effective for Complex Shapes

Sand casting allows for the creation of intricate designs at a lower cost compared to machining or other casting processes. It's especially beneficial for large parts that would be expensive to fabricate using alternative methods.

2. Wide Range of Metal Compatibility

This method supports a diverse array of metals and alloys, making it suitable for a variety of industries with specific material requirements.

3. Low Tooling Costs

Unlike die casting or investment casting, sand casting does not require expensive molds or dies, significantly reducing the upfront tooling investment.

4. Scalability

Sand casting can handle both small and large production runs efficiently, providing flexibility for manufacturers of all sizes.

5. Recyclable Materials

The sand used in molds can often be recycled and reused in future castings, contributing to eco-friendly manufacturing.

Applications Across Industries

Thanks to its versatility and reliability, sand casting is used in a variety of industries:

Automotive: Engine blocks, cylinder heads, brake discs

Aerospace: Structural components, brackets, housings

Energy: Turbine parts, gearboxes, electrical fittings

Agriculture: Machinery parts, frames, mounts

Marine: Propellers, pump housings, valve bodies

Construction: Heavy equipment components, anchors, bases

These industries rely on the durability and strength that sand casting offers, ensuring performance in high-stress environments.

Choosing the Right Sand Casting Company

When looking for a sand casting partner, it's crucial to evaluate more than just cost. A reliable foundry will offer:

1. Engineering Expertise

Look for companies that provide design consultation and pattern-making support. Their knowledge can help you optimize part design for casting success.

2. Material Versatility

Ensure the foundry can handle the specific metal or alloy required for your application. Not all foundries are equipped to cast all types of metals.

3. Quality Control Standards

Top-tier foundries follow rigorous quality control protocols, including dimensional checks, chemical composition testing, and non-destructive evaluation (NDE).

4. Production Capacity

Whether you need one-off prototypes or large-volume production, your partner should be able to scale to your needs.

5. Finishing Capabilities

Post-casting processes like machining, painting, and heat treatment should be available for end-to-end service.

6. Sustainability Practices

Modern manufacturers should prioritize environmental responsibility. Sand reclamation, waste management, and energy-efficient processes are all indicators of a future-ready company.

One such trusted name in the industry is Taural India, which delivers precision-engineered sand casting solutions with a commitment to quality and innovation.

Challenges in Sand Casting (and How Experts Overcome Them)

While sand casting is highly effective, it comes with challenges that only experienced foundries can manage well:

Porosity and Shrinkage Defects

These are common but preventable with proper gating design and temperature control.

Surface Finish Quality

Although sand casting typically produces a rougher finish than die casting, expert finishing techniques can significantly improve appearance and tolerances.

Dimensional Inaccuracy

Compensation for shrinkage and mold distortion must be calculated accurately. Advanced pattern making and simulation software help mitigate this risk.

Core Placement Issues

Skilled core setting is vital for maintaining structural integrity and dimensional accuracy in hollow parts.

The right foundry will have the tools, experience, and processes to navigate these complexities successfully.

The Future of Sand Casting

Technology continues to evolve even in traditional manufacturing. The sand casting industry is seeing significant upgrades, such as:

3D-Printed Patterns and Cores

This allows for faster prototyping and increased design flexibility.

Casting Simulation Software

Helps identify defects before pouring, saving time and resources.

Automation in Molding and Handling

Reduces human error, improves consistency, and boosts production rates.

Sustainability Efforts

Foundries are adopting green practices, including the use of renewable energy, recyclable sand, and cleaner melting technologies.

Conclusion

Sand casting has stood the test of time, and for good reason. Its adaptability, cost-efficiency, and broad application potential make it an essential part of the global manufacturing ecosystem. Whether you're building industrial machinery, automotive parts, or aerospace components, sand casting provides the durability and customization required for success.

With experienced companies like Taural India leading the way, businesses can count on precision, reliability, and quality in every cast component. As innovation continues to enhance traditional practices, sand casting is poised to remain a vital and forward-looking manufacturing method.

0 notes

Text

Performance Starts Here – Mini Cooper Automotive Parts & Tuning Gear

Performance tuning requires precision, dedication, and parts that are built to last. Whether you're rebuilding an engine from scratch or upgrading for competitive driving, having the right components makes all the difference. From forged pistons to high-performance headers, the focus should always be on quality, reliability, and long-term performance. Enthusiasts and professionals alike seek trusted brands and proven engineering to push their builds further, on and off the track.

Engineered for performance and built with precision, every part is designed to elevate your driving experience. At MINI Cooper S Engine Parts, you’ll discover a curated collection of race-tested rebuild kits, high-performance internals, and upgrade components tailored for MINI models across every generation. Whether you're enhancing a supercharged R53 or a modern turbocharged B-series, this platform delivers complete solutions engineered for power and reliability.

Engine Rebuild Kits – Complete Packages

Rebuilding an engine is a detailed process that demands quality components and expert precision. Whether you’re refreshing a worn-out block or preparing for a performance upgrade, the right rebuild kit ensures reliability and longevity. These packages typically include everything needed to restore engine integrity—from gaskets and seals to timing chains and pistons, making the job more streamlined for both DIY builders and professionals.

For enthusiasts focused on Mini Cooper Engine Tuning, these complete rebuild kits offer both reliability and performance flexibility. Designed to support everything from daily driving to high-boost setups, they include durable parts optimized for horsepower gains and long-term use.

Full gasket sets for head and block sealing

OEM-quality or upgraded piston ring kits

High-performance main and rod bearings

Timing chain kits with tensioners and guides

Optional forged pistons and head stud upgrades

Components tailored for boosted or naturally aspirated builds

Why Choose Mini Cooper Automotive?

Choosing the right performance parts supplier goes beyond just finding what fits. It’s about trust, expertise, and proven results on and off the track. Backed by years of racing experience, a strong support team, and a passion for engineering excellence, this platform delivers more than just products—it offers peace of mind.

From weekend projects to full-scale builds, customers benefit from hands-on guidance and tested solutions. For those serious about Mini Cooper Automotive, this is the go-to destination for reliable, race-proven upgrades. Every component is selected with performance and durability in mind, helping drivers get the most from their engines without compromising on quality.

Expert-built kits based on real motorsport experience

Internal engine parts rated for high horsepower applications

Cylinder heads and stud kits are designed for boosted setups

High-flow exhaust components for increased power and torque

Conclusion

Unlock the full potential of your build with performance parts engineered for precision, power, and durability. Whether you’re upgrading for reliability, track performance, or daily driving excellence, using the right components from a trusted source ensures long-term results and peace of mind.Have questions or need help choosing the right parts? Contact us today for expert guidance and personalized recommendations. Every engine deserves attention to detail, especially when it's part of a brand built for spirited performance and handling.

0 notes

Text

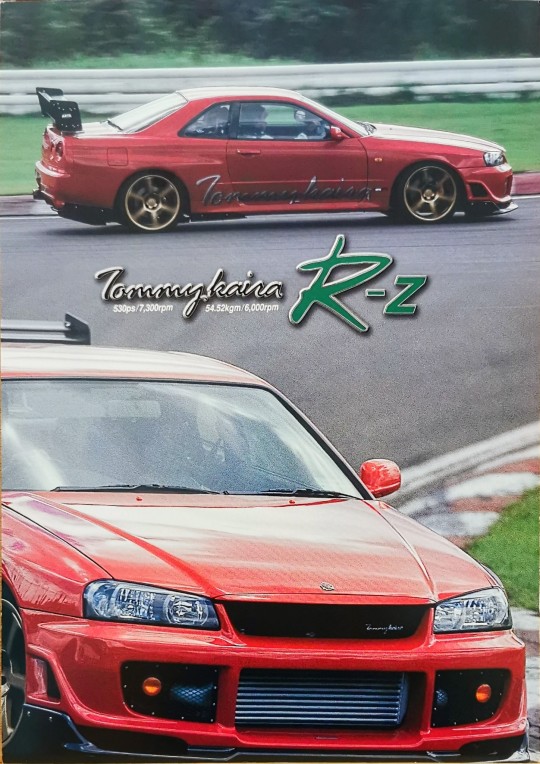

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

19 notes

·

View notes

Text

Cylinder Head Function: What It Does & Why It's Crucial for Engine Performance

https://autorepairlebanontn.com/?p=4012 Cylinder Head Function: What It Does & Why It's Crucial for Engine Performance Ever wondered what makes your car engine run smoothly? The cylinder head is one of those critical components that many drivers overlook until something goes wrong. It’s the metal component that sits atop your engine block, sealing the combustion chambers and playing a crucial role in your vehicle’s performance. We’ve found that understanding your cylinder head’s function can save you thousands in unnecessary repairs. This vital engine part houses the valves, spark plugs, and fuel injectors while managing airflow and maintaining proper compression. Without a properly functioning cylinder head, your engine simply wouldn’t operate efficiently—or at all. Table of Contents Toggle The Core Function of a Cylinder Head in an EngineAnatomy of a Cylinder Head: Key ComponentsValves and Valve SeatsIntake and Exhaust PortsCombustion ChambersHow a Cylinder Head Works in the Combustion ProcessControlling Air-Fuel Mixture FlowManaging Exhaust Gas ReleaseDifferent Types of Cylinder HeadsOverhead Valve DesignsOverhead Camshaft ConfigurationsCommon Cylinder Head Problems and SymptomsCracked Cylinder Head Warning SignsGasket Failure IssuesMaintaining Your Cylinder Head for Engine LongevityConclusionFrequently Asked QuestionsWhat is a cylinder head and why is it important?How does a cylinder head affect engine performance?What are the main components of a cylinder head?What’s the difference between OHV and OHC cylinder heads?How can I tell if my cylinder head is failing?What causes cylinder head damage?How expensive is it to replace a cylinder head?How can I maintain my engine’s cylinder head?Can a cracked cylinder head be repaired?How does the cylinder head affect fuel efficiency? The Core Function of a Cylinder Head in an Engine The cylinder head forms the upper section of the engine block and serves as a critical sealing component for the combustion chamber. Located atop the engine block, it creates an airtight seal that contains the immense pressure generated during combustion. This containment is essential for converting fuel energy into mechanical power effectively. Cylinder heads manage the flow of gases in and out of the combustion chamber through precisely engineered passages. Air and fuel mixtures enter through intake ports, while exhaust gases exit through exhaust ports, creating a continuous cycle that powers the engine. These flow paths are carefully designed to optimize engine performance based on exact vehicle requirements. Beyond sealing and directing gas flow, cylinder heads house several crucial engine components. Valves, valve springs, spark plugs, and fuel injectors all reside within the cylinder head assembly. The integration of these components in a single unit allows for efficient operation and simplified engine design. Temperature regulation represents another vital function of cylinder heads. Most modern cylinder heads incorporate water jackets—channels that allow coolant to circulate around the combustion chamber. This cooling system prevents overheating by transferring heat away from the combustion chambers, maintaining optimal operating temperatures even under demanding conditions. Cylinder heads contribute significantly to an engine’s compression ratio by defining the volume of the combustion chamber. The exact design and shape of the combustion chamber in the cylinder head affect how efficiently the air-fuel mixture burns, directly impacting engine power, fuel economy, and emissions performance. Anatomy of a Cylinder Head: Key Components The cylinder head’s complex structure contains several critical components that work together to enable proper engine function. Understanding these elements helps explain how this crucial part facilitates the engine’s operation and performance. Valves and Valve Seats Valves control the flow of gases into and out of the combustion chamber, serving as gatekeepers for the engine’s breathing process. Intake valves open to allow the air-fuel mixture to enter the cylinder, while exhaust valves release spent gases after combustion occurs. These valves rest on precisely machined surfaces called valve seats when closed, creating an airtight seal that prevents pressure loss during compression and combustion cycles. The valve assembly includes springs and lifters that ensure proper valve timing and operation throughout various engine speeds. Intake and Exhaust Ports Intake ports channel the air-fuel mixture from the intake manifold directly to the combustion chamber through carefully designed passages in the cylinder head. These pathways are engineered with exact shapes and dimensions to optimize airflow velocity and volume, improving the engine’s breathing capability. Exhaust ports, located on the opposite side, form passages that direct combustion byproducts away from the cylinder and into the exhaust system. The design of these ports significantly impacts engine performance, with larger or more efficiently shaped ports typically allowing better gas flow for increased power output. Combustion Chambers Combustion chambers form the space where the controlled explosion of fuel and air generates power to drive the vehicle. The chamber’s shape, size, and design directly influence how efficiently fuel burns and how effectively the energy transfers to the pistons. Modern combustion chamber designs focus on promoting complete fuel burning while minimizing knocking and pre-ignition issues. The chamber walls must withstand extreme heat and pressure variations that occur with each combustion cycle. Engine manufacturers create various combustion chamber configurations—such as hemispherical, pentroof, or wedge designs—each offering different performance characteristics for exact applications. How a Cylinder Head Works in the Combustion Process The cylinder head serves as the mechanical control center of an internal combustion engine. It sits atop the engine block, forming the roof of the combustion chamber and integrating multiple critical systems necessary for the engine’s operation. Controlling Air-Fuel Mixture Flow Cylinder heads contain strategically designed passages and ports that optimize the air-fuel mixture’s journey into the combustion chamber. These pathways aren’t merely hollow tunnels but precisely engineered channels that enhance flow dynamics, ensuring the proper mixture reaches each cylinder at the ideal moment. Intake valves housed within the cylinder head regulate the entry timing of this mixture, opening and closing at exact intervals determined by the camshaft rotation. The mechanical components in the cylinder head, including valve springs and lifters, work in concert to maintain this precise timing sequence across all engine speeds and loads. Performance engines often feature cylinder heads with larger or redesigned intake ports to maximize airflow capacity, directly impacting the engine’s power output and efficiency. Managing Exhaust Gas Release Cylinder heads control the evacuation of exhaust gases through dedicated valves and ports that activate after the combustion process completes. The exhaust valves open at predetermined timing intervals, allowing spent gases to exit the combustion chamber and flow through exhaust ports toward the exhaust manifold. Efficient exhaust gas flow represents a critical function of well-designed cylinder heads, as any restriction in this system can reduce engine performance and increase harmful emissions. The size, shape, and surface finish of exhaust ports significantly influence the engine’s breathing capability, with smoother, more direct pathways promoting better scavenging of exhaust gases. Modern cylinder heads incorporate advanced port designs that balance flow velocity with volume capacity to optimize exhaust gas release across the engine’s operating range. Different Types of Cylinder Heads Cylinder heads come in various designs to accommodate different engine configurations and performance requirements. Each type offers exact advantages in terms of efficiency, power output, and manufacturing complexity. Overhead Valve Designs Overhead valve (OHV) designs represent a traditional cylinder head configuration where the valves are positioned above the combustion chamber. In these systems, the camshaft remains in the engine block rather than in the cylinder head itself. Operation occurs through a series of mechanical components including lifters, pushrods, and rocker arms that transfer motion from the camshaft to the valves. OHV designs offer several practical advantages, including reduced manufacturing costs and a more compact overall engine height. This configuration creates an engine that’s less expensive to produce while maintaining decent reliability for everyday driving applications. Though simpler than other designs, OHV setups typically can’t match the efficiency and high-RPM performance of overhead camshaft configurations due to the increased reciprocating mass and indirect valve actuation. Overhead Camshaft Configurations Overhead camshaft (OHC) configurations position the camshaft directly within the cylinder head, providing more direct control over valve operation. This arrangement reduces the number of moving parts in the valvetrain and allows for more precise valve timing and lift. OHC designs fall into two primary categories: Single Overhead Camshaft (SOHC) and Dual Overhead Camshaft (DOHC). SOHC engines use one camshaft to operate both intake and exhaust valves, striking a balance between performance and complexity. DOHC systems employ separate camshafts for intake and exhaust valves, enabling even greater precision in valve control and timing. The direct actuation of valves in OHC designs permits higher engine speeds and improved volumetric efficiency compared to OHV configurations. Modern performance engines predominantly use DOHC arrangements to maximize power output and efficiency, especially in applications where high-RPM operation is desirable. Common Cylinder Head Problems and Symptoms Cylinder head failures represent some of the most serious engine issues vehicle owners encounter. These problems often manifest through exact symptoms that signal potential damage requiring immediate attention. Cracked Cylinder Head Warning Signs Cracked cylinder heads typically result from engine overheating, warping, or physical damage to the component. When a crack develops, several telltale symptoms appear: coolant leaking into the combustion chamber or oil system, white smoke billowing from the exhaust pipe, and persistent engine overheating even though proper coolant levels. Performance issues become noticeable through power loss during acceleration or rough idling. The most definitive evidence often appears as contamination—oil and coolant mixing together, visible as a milky substance in either the oil or coolant reservoirs. Gasket Failure Issues Head gasket failures stem from worn-out materials, improper installation during previous repairs, or repeated engine overheating cycles. Identifying gasket problems involves looking for visible coolant or oil leaks around the cylinder head sealing surfaces. Bubbles appearing in the coolant reservoir while the engine runs indicate air entering the cooling system through gasket breaches. White smoke emissions from the exhaust pipe signal coolant burning in the combustion chamber due to gasket failure. Engine performance suffers significantly as compression loss occurs between cylinders, resulting in rough running, misfires, and decreased power output. Other common cylinder head issues include warping from excessive heat exposure, which prevents proper sealing against the engine block. Corrosion can develop on cylinder head surfaces over time, particularly in cooling system passages, leading to restricted coolant flow and subsequent overheating. Valve-related problems within the cylinder head assembly—such as burned valves, worn valve guides, or broken valve springs—create additional performance issues that compromise engine efficiency and reliability. Maintaining Your Cylinder Head for Engine Longevity Regular inspection forms the foundation of proper cylinder head maintenance. Checking for signs of wear including cracks, warping, and head gasket leaks prevents minor issues from becoming major repairs. Physical damage often appears as hairline fractures or visible deformation that compromises the seal between the cylinder head and engine block. Coolant system maintenance ensures your engine operates at optimal temperatures. Flush and replace coolant according to manufacturer recommendations to prevent buildup of sediment and corrosion that can damage water jackets within the cylinder head. Proper coolant levels and quality directly protect against overheating, which is the leading cause of cylinder head failure. Lubrication plays a critical role in cylinder head longevity. Consistent oil changes using the correct grade and type of oil keep moving components functioning smoothly. Engine oil not only lubricates valves and other cylinder head components but also helps transfer heat away from critical areas, reducing thermal stress. Valve maintenance requires periodic inspection and adjustment. Intake and exhaust valves undergo tremendous stress during normal operation, making regular maintenance essential for proper sealing and optimal engine performance. Carbon buildup on valves restricts airflow and reduces efficiency, particularly in direct injection engines. Temperature management through proper driving habits extends cylinder head life. Allowing your engine to reach operating temperature before demanding high performance prevents thermal shock to cylinder head components. Similarly, cool-down periods after high-load driving give the cylinder head time to dissipate heat evenly. Conclusion The cylinder head truly stands as the unsung hero of your engine’s performance and longevity. Acting as both gatekeeper and command center it orchestrates the complex dance of air fuel and exhaust while housing critical components that keep your vehicle running smoothly. Regular maintenance of your cylinder head isn’t just recommended—it’s essential for preventing costly repairs and ensuring optimal engine efficiency. By understanding its functions and recognizing warning signs of potential issues you’ll be better equipped to protect this vital component. Remember that proper driving habits along with routine inspections can significantly extend your engine’s life. Your cylinder head may be just one part of a complex system but it’s undeniably at the heart of your vehicle’s performance and reliability. Frequently Asked Questions What is a cylinder head and why is it important? A cylinder head is the upper section of an engine block that seals the combustion chambers and houses vital components like valves, spark plugs, and fuel injectors. It’s crucial because it manages airflow and compression, directly affecting engine performance and efficiency. A properly functioning cylinder head ensures optimal power output and fuel economy, while a damaged one can lead to severe engine problems and costly repairs. How does a cylinder head affect engine performance? The cylinder head directly impacts engine performance by controlling airflow into and out of combustion chambers through precisely engineered passages. It affects the engine’s compression ratio, which determines power output and fuel efficiency. The design of intake and exhaust ports influences how effectively air enters and exits the engine. Additionally, well-designed combustion chambers optimize the fuel-air mixture for better combustion and energy transfer. What are the main components of a cylinder head? The main components include valves (intake and exhaust) that control gas flow, valve seats that provide sealing surfaces, valve springs that return valves to closed positions, intake and exhaust ports that channel gases, combustion chambers where fuel-air mixture ignites, spark plug holes, and water jackets for cooling. Some cylinder heads also contain camshafts, rocker arms, and fuel injectors depending on the engine design. What’s the difference between OHV and OHC cylinder heads? Overhead Valve (OHV) designs position valves above the combustion chamber but place the camshaft in the engine block, offering lower manufacturing costs and compact engine height. Overhead Camshaft (OHC) designs locate the camshaft directly in the cylinder head for more precise valve control and higher engine speeds. OHC comes in two variations: Single (SOHC) with one camshaft and Dual (DOHC) with separate camshafts for intake and exhaust valves. How can I tell if my cylinder head is failing? Signs of cylinder head failure include white smoke from the exhaust (indicating coolant burning), coolant leaks, engine overheating, decreased performance, unusual engine noise, and contaminated oil (milky appearance). You might also notice bubbling in the radiator or overflow tank, sweet-smelling exhaust, or poor fuel economy. If you experience multiple symptoms, have your vehicle inspected immediately to prevent catastrophic engine damage. What causes cylinder head damage? The most common causes include engine overheating due to cooling system failures, physical damage from foreign objects, pre-ignition or detonation (engine knock), manufacturing defects, improper maintenance, freeze damage from inadequate antifreeze protection, and age-related fatigue. Overheating is particularly damaging as it can cause warping or cracking. Regular maintenance and prompt attention to warning signs can help prevent most cylinder head problems. How expensive is it to replace a cylinder head? Cylinder head replacement costs typically range from $500 to $1,000 for parts alone, depending on vehicle make and model. Labor adds another $500 to $1,500, as the job requires significant disassembly. Total costs can reach $2,000-$3,000 for passenger vehicles and much more for luxury or performance engines. Some situations might require replacing the entire engine if damage is extensive. How can I maintain my engine’s cylinder head? Maintain your cylinder head by following regular service intervals for coolant changes to prevent overheating, changing oil on schedule to ensure proper lubrication, avoiding engine overheating by monitoring temperature gauges, addressing small problems before they become serious, using quality fuel to prevent detonation, and warming up your engine properly in cold weather. Have valve adjustments performed as recommended in your vehicle’s service manual. Can a cracked cylinder head be repaired? Yes, cracked cylinder heads can sometimes be repaired through welding, metal stitching, or other specialized repair techniques performed by professional machine shops. The success of repairs depends on the crack’s location, size, and severity. Minor cracks in non-critical areas have higher repair success rates. However, extensive cracks or those in high-stress areas often necessitate replacement rather than repair. Always consult with a professional to evaluate repair viability. How does the cylinder head affect fuel efficiency? The cylinder head significantly impacts fuel efficiency through its combustion chamber design, which influences how completely fuel burns. Port designs affect airflow efficiency, while valve timing and lift control the precise amount of air-fuel mixture entering the chamber. The compression ratio, partially determined by the cylinder head, directly affects fuel consumption. Modern heads with features like variable valve timing can optimize efficiency across different engine speeds and loads. https://autorepairlebanontn.com/?p=4012 Absolute Auto Repair

0 notes

Text

Choosing the Right Multi Layer Steel Gaskets for Your N14 Cummins Engine

When it comes to maintaining or rebuilding an N14 Cummins Engine, choosing the right Multi Layer Steel Gaskets can make all the difference in performance and longevity. Many truck owners and heavy equipment operators understand that the N14 Cummins Engine is known for its reliability, but even the best engines need quality parts to run efficiently. Multi Layer Steel Gaskets are especially important for ensuring a tight seal that withstands the high pressures and temperatures inside the engine.

Unlike older gasket types, Multi Layer Steel Gaskets are designed to cope with the demands of modern diesel engines. For the N14 Cummins Engine, these gaskets play a crucial role in maintaining compression and preventing leaks that could lead to costly repairs down the road. Whether you are performing routine maintenance or a complete overhaul, using premium Multi Layer Steel Gaskets will help you avoid the risk of engine failure due to poor sealing.

Another benefit of Multi Layer Steel Gaskets is their durability compared to composite or copper alternatives. The layers of steel, often treated with special coatings, expand and contract with the engine’s thermal cycles, providing a consistent seal. This is vital for an N14 Cummins Engine, which is often pushed to its limits in demanding applications like long-haul trucking, construction, or agriculture.

Many mechanics recommend Multi Layer Steel Gaskets because they can handle higher cylinder pressures. For an N14 Cummins Engine, which produces substantial power and torque, this resilience is critical. Poor-quality gaskets can fail under extreme conditions, causing coolant leaks, oil leaks, or loss of compression. Choosing the right gasket reduces downtime and helps keep your engine operating at peak performance for longer periods between major services.

When sourcing Multi Layer Steel Gaskets for your N14 Cummins Engine, you should always look for suppliers that offer trusted brands and proven quality. One such trusted place is shop.nadieselparts.com, which provides a range of high-performance diesel engine parts to meet the specific needs of Cummins owners. By choosing reliable parts, you can extend the service life of your engine and minimize unexpected breakdowns that cost time and money.

Replacing head gaskets on an N14 Cummins Engine is a job that demands precision and the right tools. Even the best Multi Layer Steel Gaskets will not perform well if they are installed incorrectly. Surfaces must be clean and flat, torque specifications must be followed precisely, and all head bolts should be replaced or properly inspected for wear. Many experienced diesel mechanics stress that rushing this process can result in a failed seal, requiring the job to be done all over again.

If you’re tackling this project yourself, be sure to follow the service manual for your specific N14 Cummins Engine model. Take the time to check for any warping on the cylinder head or engine block surface. Even a slight imperfection can prevent Multi Layer Steel Gaskets from sealing correctly. It’s also wise to check your coolant and oil passages for any blockages before reassembly, as these can cause overheating or contamination that shortens the life of the new gasket.

Regular inspection and maintenance are key to getting the most out of your Multi Layer Steel Gaskets and the N14 Cummins Engine itself. Keep an eye out for signs of a failing head gasket, such as white smoke from the exhaust, coolant loss without a visible leak, or oil that appears milky due to coolant mixing. Early detection can prevent more serious damage to the cylinder head or engine block.

Truck owners who depend on the N14 Cummins Engine know how crucial it is to invest in the right parts the first time. Multi Layer Steel Gaskets are a small but vital part of the overall reliability of your engine. By choosing high-quality components and installing them with care, you protect your investment and keep your equipment running strong for years to come.

If you’re in the market for premium Multi Layer Steel Gaskets and other diesel parts, consider checking out shop.nadieselparts.com for trusted options. A well-maintained N14 Cummins Engine is a powerhouse that can deliver thousands of reliable miles when supported by the right parts and maintenance routine.

Taking the time to understand your engine’s needs and selecting quality Multi Layer Steel Gaskets will give you peace of mind on the road or on the job site. Proper care today means fewer headaches tomorrow, letting you focus on the work that matters most.

Facebook

0 notes

Text

Top Automobile Engine Rebuilding Machines Provider

Vermaent – Leading Automobile Engine Rebuilding Machines Provider

Engine rebuilding requires precision, durability, and expert engineering. At Vermaent, we proudly stand as a trusted Automobile Engine Rebuilding Machines Provider, offering a complete range of machines that redefine the standards of accuracy and performance in automotive repair.

With a focus on innovation and reliability, our machines help professionals restore engines to optimal condition—whether it’s for personal vehicles, commercial fleets, or industrial power units.

Why Engine Rebuilding Machines Are Vital

Over time, all engines face wear due to heat, friction, and high-pressure operations. Instead of replacing an entire engine, rebuilding key components can:

Restore engine efficiency

Improve fuel economy

Extend vehicle lifespan

Save costs for both mechanics and customers

Reduce environmental impact by reusing critical parts

To rebuild engines accurately and safely, workshops require high-grade machines that perform consistently—and that’s exactly what Vermaent delivers.

Our Range of Automobile Engine Rebuilding Machines

As a dedicated Automobile Engine Rebuilding Machines Provider, Vermaent supplies a full suite of tools to cover every stage of the engine restoration process. Our offerings include:

Cylinder Boring Machines Accurately rebore worn-out engine cylinders to factory specs with minimal effort.

Honing Machines Refine cylinder surfaces for better piston-ring sealing and oil retention.

Crankshaft Grinding Machines Smooth out journal surfaces and maintain crankshaft alignment.

Valve Seat & Guide Machines Precision grinding and cutting tools for improved airflow and engine combustion.

Head and Block Resurfacing Machines Restore flatness and sealing capability to ensure engine head and block fit perfectly.

Connecting Rod Reconditioning Tools Maintain roundness and alignment of bearing bores.