#Fully Automatic Composting Machine

Explore tagged Tumblr posts

Text

Composter Machines Like Oxygen For Waste Management

Introduction:

Waste management is a critical concern in our modern world, with overflowing landfills and environmental degradation posing serious threats. One promising solution that has emerged to tackle this issue is the use of organic waste composters. These devices act as the oxygen for waste management systems, enabling the efficient decomposition of organic waste into nutrient-rich compost. In this blog, we'll explore why organic waste composters are crucial for sustainable waste management.

1. Diminish Landfill Waste:

The traditional method of disposing of organic waste in landfills not only consumes valuable land but also generates harmful greenhouse gases like methane. Organic waste composters, on the other hand, provide a sustainable alternative. They divert organic waste away from landfills, reducing the volume of waste sent to these overflowing sites and mitigating the environmental impact.

2. Creates High-Quality Compost:

An Organic waste composter is designed to create the optimal conditions for the decomposition of organic materials. Through controlled temperature, moisture, and aeration, these systems break down organic matter efficiently. The end result is nutrient-rich compost, a valuable resource that can be used to improve soil quality and promote sustainable agriculture.

3. Decreasing Greenhouse Gas Emissions:

When organic waste decomposes anaerobically in landfills, it releases methane, a potent greenhouse gas that contributes to climate change. Organic waste composters foster aerobic decomposition, which significantly reduces methane emissions. By utilizing composters, we can mitigate the negative impact of organic waste on our climate.

4. Supporting Sustainable Agriculture:

The compost produced by organic waste converters is a natural fertilizer rich in essential nutrients for plant growth. When used in agriculture, it enhances soil fertility, increases water retention, and reduces the need for chemical fertilizers. This not only benefits crop yields but also promotes sustainable farming practices.

5. Encouraging Waste Reduction at the Source:

Organic waste converters can be implemented at various scales, from households to large-scale facilities. By having a composter at home, individuals can take responsibility for their organic waste and reduce the overall waste they send to landfills. This fosters a culture of waste reduction at the source.

6. Promoting Circular Economy:

The use of organic waste composters aligns with the principles of a circular economy, where resources are reused and recycled. Composting organic waste creates a closed-loop system, where the nutrients from food scraps and yard waste are returned to the soil to support future growth.

Key Features:

An Organic waste converter is a specialized piece of equipment designed to efficiently convert organic waste materials, such as food scraps and agricultural residues, into nutrient-rich compost.

These machines come in various sizes and capacities, but they typically share several key features:

1. In-Vessel Composting: OWC composting machines are designed to facilitate in-vessel composting, where organic waste is contained within a sealed unit or chamber. This controlled environment allows for better regulation of temperature, moisture, and aeration, optimizing the composting process.

2. Automatic Operation: Many OWC machines are automated, reducing the need for manual labor. They often feature programmable controls that manage the composting process, including mixing, turning, and monitoring temperature and humidity levels.

3. Mixing and Aeration: Efficient composting requires the periodic turning and mixing of organic materials to ensure even decomposition and proper aeration. OWC machines incorporate mechanisms like agitators, augers, or rotating drums to achieve this mixing and aeration.

4. Temperature Control: Composting generates heat as microorganisms break down organic matter. OWC machine has temperature control systems to maintain the ideal temperature range for microbial activity, typically between 130°F to 160°F (54°C to 71°C).

5. Odor Control: Managing odors is crucial, especially for large-scale composting operations. OWC machines often employ odor control mechanisms such as biofilters, negative air pressure systems, or activated carbon filters to prevent unpleasant odors from escaping.

6. Moisture Management: Proper moisture content is essential for effective composting. OWC machines may include sensors and systems to monitor and regulate moisture levels within the composting chamber, ensuring the right balance between wet and dry materials.

7. Closed System: OWC machines are typically designed as closed systems to contain composting materials and prevent pests and rodents from accessing the organic waste. This closed design also helps reduce the risk of contamination and the escape of pathogens.

8. Remote Monitoring and Control: Many modern OWCs offer remote monitoring and control capabilities through digital interfaces. This allows operators to track the composting process, adjust settings, and receive alerts or notifications as needed.

9. Modular Design: Some OWCs have modular components that can be customized or expanded based on the specific needs and capacity requirements of the facility. This modular design allows for scalability and flexibility.

10. Efficiency and Speed: OWC machines are designed to accelerate the composting process, often producing finished compost in a matter of weeks rather than months. This efficiency reduces the footprint of the composting facility and saves time and resources.

11. Safety Features: Safety is a paramount concern, especially in larger composting operations. OWC machines incorporate safety features such as emergency shutdown systems, protective barriers, and safety interlocks to ensure the well-being of operators and maintenance personnel.

12. Energy Efficiency: Some OWC composting machine is designed to be energy-efficient, incorporating features like insulated chambers, energy recovery systems, or low-energy components to reduce operational costs and environmental impact.

These features make OWC machines effective tools for managing organic waste efficiently and sustainably, allowing for the conversion of organic waste into valuable compost while minimizing environmental impacts and odors. The specific features and capacity of an OWC machine can vary depending on its intended use and the scale of the composting operation.

Conclusion:

Organic waste composters play a crucial role in revolutionizing waste management. They act as the oxygen that breathes life into sustainable practices, reducing landfill waste, curbing greenhouse gas emissions, and enriching soil for agriculture. As we strive for a more environmentally conscious and sustainable future, embracing these composters is not just an option but a necessity. By making organic waste composting a part of our daily lives, we contribute to a healthier planet and a more sustainable future for generations to come.

#organic waste composter#organic waste converter#owc machine#waste converter machine#food waste composter#food waste converter#fully automatic composting machine#waste management#fully automatic composter

0 notes

Video

youtube

Organic Waste Composter Machine for hotels, canteens, mess, temples, ind...

#organic waste composter#owc waste management#waste management#organic waste composter machine#organic waste converter#owc machine manufacturer#Natural Composter#Owc Machine manufacturers#Composter manufacturers#Fully Automatic Composting Machine#composting for waste disposal#organic waste for composting#food waste converter machine#OWC Machine Price#semi automatic organic waste composter#Fully Automatic Composting Machine in India

1 note

·

View note

Text

Why Investing in a Paper Bag Machine is a Smart Move in 2025

As the world moves toward sustainability and eco-conscious living, businesses across the globe are rapidly shifting from plastic to paper packaging. One of the most significant outcomes of this transition is the growing demand for paper bags — and with that, a rising interest in high-performance paper bag making machines.

At Prakash Machineries , we specialize in manufacturing fully automatic paper bag machines that are helping businesses make the smart switch. Here’s why investing in a paper bag machine is not only good for the planet but also great for your business.

🌿 1. Environmentally Friendly Solution

Plastic bags have become one of the biggest environmental threats in recent decades. They take hundreds of years to decompose and often pollute landfills, rivers, and oceans. In contrast, paper bags are 100% biodegradable, recyclable, and compostable. Paper bag machines enable businesses to produce eco-friendly packaging on a large scale — reducing carbon footprint and aligning with global sustainability goals.

⚙️ 2. High-Speed, Automated Production

Modern paper bag machines, like those offered by Prakash, are equipped with fully automatic systems that can produce a wide range of paper bags with minimal manual labor. Whether it’s grocery bags, shopping bags, or food delivery pouches, these machines can handle various sizes and specifications with precision and efficiency.

With outputs ranging from 100 to 400 bags per minute, these machines significantly boost productivity and help meet large-scale commercial demands.

💼 3. Business Opportunity & Market Demand

The ban on single-use plastics in many states and countries has opened up a huge market for paper bag manufacturers. From retail stores and supermarkets to restaurants and e-commerce companies — the demand is only increasing.

Starting a paper bag manufacturing unit is now seen as a profitable and future-ready business, especially with support from government initiatives promoting sustainable alternatives.

🧠 4. Easy to Operate and Maintain

Our paper bag machines are designed to be user-friendly, even for first-time entrepreneurs. With touchscreen controls, automatic counting systems, and durable build quality, they require minimal maintenance and training. Plus, our dedicated service team ensures smooth installation and after-sales support.

🏷️ 5. Customization & Branding Benefits

Paper bags are not just about functionality; they are also a powerful branding tool. Our machines allow for in-line printing and handle attachments, giving businesses the freedom to create custom, brand-enhancing packaging.

🔧 Why Choose Prakash Machineries ?

With decades of engineering experience, Prakash Machineries is a trusted name in the packaging machinery industry. Our paper bag making machines are built for performance, reliability, and long-term ROI.

We help entrepreneurs, SMEs, and large enterprises shift toward sustainable packaging with confidence and efficiency.

📞 Get in Touch

If you're ready to start or scale your paper bag manufacturing business, we’re here to help. Visit www.prakashoffset.com to explore our range of machines or request a free quote.

Join the green revolution — with Prakash.

2 notes

·

View notes

Text

Paper Cup Making Machines: Powering the Green Packaging Revolution in 2025

In a world shifting rapidly toward sustainability, paper cups are no longer just a convenience—they’re a statement. As single-use plastic bans tighten across India and the globe, eco-friendly alternatives like paper cups are leading the charge in foodservice, hospitality, and retail.

\But behind every biodegradable cup is a powerful piece of machinery: the Paper Cup Making Machine.

In 2025, the market is not only growing—it’s transforming. From automation to smart diagnostics and ultra-fast output, paper cup machines have become smarter, faster, and greener. For manufacturers, entrepreneurs, and packaging businesses, investing in the right paper cup making machine is now more than a necessity—it’s a competitive edge.

Why Paper Cups Are More Relevant Than Ever

The demand for paper cups is being driven by multiple converging trends:

Ban on Single-Use Plastics in India and other countries

The rise of eco-conscious consumers demanding sustainable alternatives

Growth in takeaway food, cafés, and cloud kitchens

Government support for MSMEs and sustainable packaging ventures

This surge has created a booming opportunity for paper cup manufacturers, especially those using high-efficiency, modern equipment.

What’s Trending in the Paper Cup Machine Industry in 2025?

1. Fully Automatic Machines

Today’s top manufacturers offer machines that can produce up to 100 cups per minute, with minimal manual intervention. These machines:

Reduce labor costs

Improve consistency and hygiene

Enable round-the-clock production

2. Smart Touch Control Panels

Modern machines now feature digital touchscreens with programmable settings. Operators can adjust cup size, material thickness, speed, and more—all with a few taps.

3. Eco-Friendly Configurations

Machines are now being optimized to work with coated paper, biodegradable sheets, and PLA (cornstarch-based) films, supporting global eco-packaging norms.

4. Multi-Size Compatibility

The best manufacturers now design machines that can switch between 45ml to 350ml cups, perfect for businesses serving both tea stalls and large food courts.

5. Minimal Maintenance Design

With precision-engineered parts and self-lubrication systems, paper cup machines now require less frequent servicing, reducing downtime and increasing ROI.

What to Look for in a Paper Cup Making Machine Manufacturer

Choosing the right machine supplier is crucial if you’re planning to enter the paper cup manufacturing business or upgrade your setup. Here’s what to consider:

Machine Output Speed – Does it match your production goals?

Cup Size Range – Can it handle small to large cup sizes?

Automation Level – Manual, semi-automatic, or fully automatic?

After-Sales Support – Do they offer installation, training, and maintenance services?

Warranty & Parts Availability – Long-term reliability is key.

Certifications & Quality Standards – Ensure ISO, CE, or BIS compliance.

Business Opportunity: Why Now Is the Time to Invest

Whether you are a startup in packaging, an MSME looking to expand, or a distributor of eco-friendly products, now is the best time to step into paper cup manufacturing.

Here’s why:

Demand is skyrocketing due to the environmental push

Government subsidies and Make in India initiatives are encouraging local production

High profit margins with low-cost raw materials (paper rolls)

Quick ROI with machines delivering 24/7 output and low maintenance

The Manufacturer’s Perspective

If you’re a paper cup making machine manufacturer, this is your moment to shine.

The market is looking for:

High-speed, reliable, and low-energy consumption machines

Local technical support and spare part availability

Custom solutions for startups, large-scale factories, and exporters

Machines capable of handling eco-coated and compostable paper

A strong online presence, certifications, customer testimonials, and product videos can set your brand apart in a competitive market.

Conclusion

As the world moves toward greener alternatives, the paper cup industry is no longer a side hustle—it’s a sunrise sector. From small kiosks to national brands, everyone is shifting to paper-based packaging. And at the center of this movement lies smart, efficient, and sustainable paper cup making machines.

Whether you’re a business owner, eco-entrepreneur, or manufacturer, this is your opportunity to build a profitable, future-ready brand—with sustainability as your foundation.

FAQs on Paper Cup Making Machines

Q1. What is the production capacity of a paper cup making machine?Modern machines can produce between 45 to 120 cups per minute, depending on automation and size range.

Q2. Can I start a paper cup business from home or a small unit?Yes. Many startups begin with a semi-automatic or compact machine in small spaces. As demand grows, you can scale up.

Q3. What kind of paper is used in these machines?PE-coated or PLA-coated food-grade paper rolls are used for paper cup production.

Q4. How much does a paper cup making machine cost in India?Prices can range from ₹5 lakhs to ₹25 lakhs, depending on speed, size range, automation, and brand.

Q5. Do manufacturers offer training and installation support? Reputed manufacturers provide on-site installation, operator training, and after-sales support across India and abroad. Paper Cup making Machine Manufacturer

0 notes

Text

How to choose the right bio-organic fertilizer production line based on farm size?

When turning livestock manure into a resource, picking the right bio-organic fertilizer production line needs to perfectly match the farm’s scale. Farms with different herd sizes have very different manure handling needs, budgets, and ways of operating.

1.Small Farms

Recommended Setup: Simple trough fermentation line (Investment: ¥150,000 – ¥250,000)

Capacity: 3-5 tons/day

Key Equipment: Small windrow compost turning machine (1.5m wide), combined crusher and screener, manual packaging station.

Benefits: Needs only about 300 sqm of space, can flexibly handle mixtures like pig or chicken manure.

2.Medium Farms

Recommended Setup: Semi-automatic fermentation line (Investment: ¥500,000 – ¥800,000)

Capacity: 10-20 tons/day

Upgrades: Intelligent turner (with temperature sensors), automatic batching system, disc granulator set, mobile packaging machine.

Cost-Effectiveness: Processing cost per ton is 40% lower than small lines. Can also handle manure from nearby farms.

3.Large Farming Groups

Recommended Setup: Smart factory-style production line (Investment: ¥2 million+)

Capacity: 50-100 tons/day

Advanced Features: Fully enclosed fermentation workshop (with bio-deodorization), computer-controlled turner, extrusion granulator + coating machine, automated palletizing and storage system.

Always choose a production line with slightly more capacity than your current manure output, leaving about 20% room for growth. Getting the right equipment can turn manure handling from a cost center into a profit center.

0 notes

Text

The structural advantages of the large wheel compost turning machine

The large wheel compost turning machine has significant structural advantages in organic fertilizer production. These advantages make it perform well in dealing with organic waste such as livestock and poultry manure, sludge and garbage, sugar factory filter mud, dregs, cake meal and straw sawdust. The following are its main structural advantages:

1. High turning depth and large span: The turning depth of the large disc turning machine can reach 1.5 to 3 meters, capable of handling deeper fermentation materials and suitable for large-span fermentation tanks.

2. Energy-saving and high-efficiency transmission mechanism: It adopts a unique energy-saving and high-efficiency transmission structure, significantly reducing energy consumption compared to traditional turning and throwing equipment under the same operation volume. Equipped with a hydraulic lifting system, it enables the turntable to rise and fall automatically, ensuring that the equipment can move without obstacles.

3. No blind spot turning: The symmetrical design of the wheel disc, in combination with the displacement of the variable-speed transfer trolley, ensures no blind spot turning and guarantees the uniformity of the fermentation materials.

4. High degree of automation: Equipped with a fully automated electrical control system, the organic fertilizer equipment does not require human operation during operation, improving production efficiency and operational safety.

5. Durable and robust: Made of high-quality materials and advanced manufacturing techniques, the equipment is highly durable, reducing maintenance costs.

6. Strong applicability: It is suitable for the fermentation and turning of various organic wastes and is widely used in organic fertilizer plants, compound fertilizer plants, sludge and garbage plants, horticultural farms, and button mushroom cultivation plants, etc.

7. Flexible customization: It can be customized according to the width and length of the fermentation tank to meet the needs of different users.

Through these structural advantages, the large wheel turning machine can not only enhance the efficiency and quality of organic fertilizer production, but also reduce production costs and minimize environmental pollution. It is an indispensable high-efficiency equipment in organic fertilizer production.

0 notes

Text

Best Organic Waste Compost Machine for Homes, Hotels, and Societies

Waste management is currently ranked as a highly significant issue of the 21st century. Urbanization and consumption rates go higher with the generation of organic wastes-from veg peels and food leftovers to garden clippings and biodegradable packaging wastes. Hence, the very problem creates an opportunity-that of Composting. One of the efficient ways to handle biodegradable waste is by installing an Organic Waste Compost Machine.

Choosing the right model is crucial. Refer to our Commercial Organic Waste Compost Machine: A Complete Buying Guide before making your decision.

Knowing about the Organic Waste Compost Machine

An Organic Waste Compost Machine is a fully automatic machine that converts organic waste into compost within a time frame of 24 to 48 hours (about 4 days). The machine maintains an ideal aerobic environment for the microbes to decompose the waste, thus protecting the manual composting method, which is time-consuming and messy.

Modern organic waste composting machine offer a clean, odorless, and space-saving solution for the disposal of biodegradable waste, unlike conventional pits or bins. Be it a housing society, school, hotel, hospital, or factory, these machines drastically reduce the daily waste output while churning out compost that is full of nutrients for use.

Key Features and Benefits

1. Efficient Waste Reduction

It can reduce the volume of organic waste by up to 80% and thereby reduce the load on municipal waste systems.

2. Environmentally Friendly

The use of an organic waste composter reduces methane gas emissions into the atmosphere from landfilling activity and also prevents the leachate from permeating the groundwater.

3. Faster Process of Composting

Although composting takes several weeks or months through the old-fashioned methods of composting, the composting machine can make ready compost in just 1 to 2 days.

4. Odorless

Advanced composting machines are designed with air filters and deodorization systems and are, therefore, suitable for indoor installation.

5. Reduces Operational Costs

Waste disposal costs are considerable for commercial kitchens, food processing units, and hotels. An onsite composting unit reduces these costs while generating a valuable product.

6. Promotes Sustainability

The compost can be used for landscaping, gardening, or sold to farmers who use it in sustainable agricultural production.

To explore how the hospitality industry is transforming waste into a resource, read our blog on How Does an Organic Waste Composter Benefit Hotels and Restaurants?.

Ideal Users of Organic Waste Composting Machines

Hotels & Restaurants: To manage leftover food waste fairly and to maintain hygiene in the kitchen.

Residential Societies: To lessen the household waste footprint and to inculcate the concept of green living.

Educational Institutions: To set an example in eco-consciousness and sustainability.

Hospitals: For the management of cafeteria and garden waste which is biodegradable.

Agricultural Farms: Recycling plant waste and making compost on-site.

How to Choose the Right Organic Waste Composter

The following are some of the things to bear in mind when purchasing an organic waste composting machine:

Capacity Needs: Machines vary in their capacity from about 25 kg/day to 500 kg/day or more.

Automation Level: Do you want a semi-automatic system or a fully automatic one?

Power & Energy Consumption: Consider the energy-efficient ones; they are not bad for your pocket in the long run.

Warranty & Support: Makes sure that the vendor has some after-sales services and maintenance that he can depend on.

Conclusion

With sustainability slowly seeping in as a core topic for business, institutions, and the community, it becomes a must to implement smart case waste-management tools. The Organic Waste Compost Machine is not just an appliance but a higher evolution of the workplace toward cleaner surroundings, less landfill dependency, and greener ecosystems.

So, if you are planning to go in for a green solution for waste management at your premises, you should consider going for the robust and reliable organic waste-composting machines of EnvCure Technocrat LLP with the capacity to satisfy any requirements. They are performance-based and durable systems that meet environmental standards and thus make a good partner towards a greener future.

0 notes

Text

The usage features of the large wheel compost turning machine

The large wheel compost turning machine is a highly efficient equipment suitable for large-scale organic fertilizer production and has the following significant usage features:

1. High turning depth and large span: The turning depth of the large disc turning machine can reach 1.5 to 3 meters, capable of handling deeper fermentation materials. Its maximum turning width can reach 30 meters, making it suitable for large-span fermentation tanks.

2. High efficiency and energy saving, low energy consumption: It adopts a unique energy-saving and high-efficiency transmission mechanism, which significantly reduces energy consumption compared with traditional turning and throwing equipment under the same operation volume. Through the high-speed rotating wheel and blades, the turning, stirring and mixing of materials can be completed quickly, improving the fermentation efficiency.

3. No blind spot flipping: The symmetrical design of the wheel disc, in combination with the displacement of the variable-speed transfer trolley, can achieve no blind spot flipping, ensuring uniform flipping of materials.

4. High degree of automation: Equipped with a fully automated electrical control system, the organic fertilizer equipment can operate automatically without human intervention during operation. Easy operation: Users only need to press the start button, and the device will automatically complete the flipping and throwing operation.

5. Structural and performance advantages: Novel design, simple structure, sturdy and durable, suitable for the fermentation and turning of various organic wastes. High-quality materials and advanced manufacturing processes are adopted to ensure the long-term stable operation of the equipment.

6. Wide range of application: It is suitable for the fermentation and turning of various organic wastes such as livestock and poultry manure, sludge, garbage, sugar factory filter mud, residue, cake meal and straw sawdust.

The large wheel turning machine, with its features of high efficiency, energy conservation, high degree of automation and no blind spots in turning, has become an indispensable equipment in organic fertilizer production. It can significantly improve production efficiency and product quality, while reducing production costs.

0 notes

Text

Building an organic fertilizer production line in a chicken farm

Establishing an organic fertilizer production line at a chicken farm not only helps manage chicken waste effectively but also transforms it into a valuable resource, creating additional income.

1. Site Planning and Selection

First, designate a suitable area near the chicken coops for the production line to simplify manure transportation. Ensure the location is well-ventilated to minimize odors affecting both the farm and nearby areas. Leave enough space for equipment, raw material storage, and finished products.

2. Raw Material Handling System

Chicken manure is the primary raw material. Set up an efficient collection system, such as conveyor belts, to quickly transport manure from coops to the processing area. Install a manure separator to split solids from liquids. The solid part moves to the next production stage, while the liquid can be treated for irrigation or other uses.

3. Fermentation System

Fermentation is crucial. Build fermentation tanks or pits, and mix the manure with microbial agents like Bacillus subtilis. Use temperature and humidity sensors to monitor conditions. Turn the mixture regularly with a compost turning machine to ensure even fermentation. Maintain temperatures between 50-65°C for 10-15 days until the manure fully decomposes.

4. Processing System

After fermentation, further process the organic fertilizer. Crush the material into fine particles using a grinder, then shape it into uniform granules with equipment like a disc granulator or double roller press granulator. Adjust the size and shape based on market needs.

5. Drying and Packing

Freshly granulated fertilizer has high moisture content. Use a drum fertilizer dryer to reduce it to acceptable levels. Finally, pack the finished product automatically, labeling details like nutrient content and suitable crops.

With these steps, a functional organic fertilizer production line can be built right on the chicken farm, turning waste into profit while promoting eco-friendly practices.

#organic fertilizer production line#compost turning machine#disc granulator#double roller press granulator

0 notes

Text

Composters Machines - A True Friend Of Our Society

Introduction:

In an age where environmental awareness is growing, composting has emerged as a vital practice for individuals and communities alike. Composting is not just a sustainable way to manage organic waste; it's also a significant step toward reducing our carbon footprint. Composting machines have quickly become a true friend of our society, offering a convenient and efficient solution to address environmental concerns.

The Growing Issue of Organic Waste:

As our populations grow and urbanization accelerates, the amount of organic waste generated by households, businesses, and industries has skyrocketed. Organic waste includes food scraps, yard trimmings, and other biodegradable materials that, when disposed of improperly, contribute to landfill overflow and greenhouse gas emissions. The need for sustainable and responsible waste management practices has never been more pressing.

Enter the Organic Waste Composter:

The Organic waste composter is a specially designed machine that facilitates the decomposition of organic waste into nutrient-rich compost.

These composters offer numerous advantages, making them a valuable friend to our society:

1. Reduced Landfill Waste: One of the primary benefits of organic waste composters is their ability to divert organic waste from landfills. By doing so, they help reduce landfill overflow and the associated environmental problems.

2. Sustainable Soil Enrichment: Compost produced by these machines is a valuable resource for enhancing soil quality. It provides essential nutrients, improves soil structure, and enhances water retention, ultimately promoting healthier plant growth and sustainable agriculture.

3. Mitigation of Greenhouse Gas Emissions: Composting organic waste aerobically (with oxygen) produces significantly fewer greenhouse gases, particularly methane, compared to landfill decomposition. This makes composting a vital tool in our fight against climate change.

4. Resource Recovery: Organic waste converters recover valuable resources from waste, reducing the need for chemical fertilizers and promoting a closed-loop, sustainable approach to agriculture and gardening.

5. Odor Control: Many composters are designed with odor control mechanisms, ensuring that the composting process remains odor-free and convenient.

6. Ease of Use: The organic waste converter is user-friendly, requiring minimal effort and expertise to operate. They often feature automated mixing and aeration systems, making composting accessible to everyone.

7. Community and Household Solutions: These composters come in various sizes, from small-scale options for households to larger units suitable for community gardens and businesses.

Working Principles:

The working principle of an OWC composting machine involves creating controlled conditions that facilitate the decomposition of organic materials into nutrient-rich compost. Here's a step-by-step explanation of how organic waste composters operate:

1. Input: Organic waste, including food scraps, yard trimmings, and other biodegradable materials, is collected and placed into the composter's chamber or bin. It's crucial to ensure that the waste is free of non-organic materials like plastics, metals, and glass, as these can interfere with the composting process.

2. Aeration: To initiate decomposition, OWC composting machines provide adequate aeration. This is typically achieved through the following methods:

Mechanical Aeration: Some composters are equipped with automated systems that turn or mix the composting materials periodically. This helps introduce oxygen into the pile, promoting aerobic decomposition, which is less odorous and more efficient than anaerobic decomposition.

Ventilation: Composters may have ventilation systems that allow a controlled flow of air into the composting chamber, ensuring that the microorganisms responsible for decomposition have access to oxygen.

3. Temperature Control: Compost microorganisms thrive within a specific temperature range. To facilitate efficient decomposition, organic waste composters often incorporate temperature control mechanisms. These may include electric heaters or insulation to maintain the ideal temperature range, typically between 110°F to 160°F (43°C to 71°C).

4. Moisture Management: Maintaining the right moisture level is crucial for composting. Composters may include moisture sensors or irrigation systems to ensure that the compost pile remains adequately moist. The moisture content is typically maintained at around 50-60%.

5. Microbial Activity: The heart of the composting process lies in microbial activity. Naturally occurring bacteria, fungi, and other microorganisms break down the organic materials into simpler compounds. This microbial activity generates heat, which is essential for accelerating the decomposition process.

6. Odor Control: To address concerns about odor, organic waste composters often include odor control mechanisms. These may involve carbon filters or other technologies that capture and neutralize odorous compounds.

7. Monitoring and Control: Many modern Waste Converter machines come equipped with sensors and automated control systems. These sensors monitor temperature, moisture, and sometimes even pH levels in the compost pile. The control system can adjust aeration, heating, and other parameters to optimize the composting process.

8. Output: Over time, the organic waste undergoes a transformation into compost. The composting duration can vary depending on factors like temperature, aeration, and the type of organic materials used. Typically, composting with a composter is faster than traditional open-air composting, often taking several weeks to a few months.

9. Harvesting: Once the composting process is complete, the finished compost is ready for use. It is typically removed from the composter and can be used to enrich soil in gardens, farms, or landscaping.

In summary, the working principle of a Waste Converter Machine involves creating an optimized environment that encourages the natural decomposition of organic materials by microorganisms. This controlled process efficiently converts organic waste into nutrient-rich compost while minimizing odors and environmental impacts associated with traditional waste disposal methods.

Conclusion:

The OWC machine is indeed a true friend of our society, providing a sustainable solution to manage organic waste effectively. By reducing landfill waste, mitigating greenhouse gas emissions, and enriching soil with nutrient-rich compost, these machines play a crucial role in building a more sustainable and environmentally responsible future.

As we collectively strive to address the challenges of waste management and climate change, the OWC machine stands as a testament to our commitment to a greener, cleaner, and more sustainable planet. Embrace this technology and take a significant step towards becoming a better friend to our society and the environment.

#organic waste composter#organic waste converter#owc machine#waste converter machine#food waste composter#food waste converter#fully automatic composting machine#waste management#fully automatic composter

0 notes

Text

Why Biodegradable Disposable Plate Making Machine is Booming in India?

Taking into consideration the pollution because of single use plastic, the recognition of using biodegradable plates has risen. Individuals are choosing environmentally friendly products over plastic. This has resulted in the increased need for biodegradable plates, creating a brand new possibility for service and the need for biodegradable plate making machines in India.

Made from natural resources, biodegradable plates break down in the environment quickly, which reduces the burden of injury to nature, garbage dumps, and marine life. The expanding necessity for biodegradable plates has motivated the development of modern technologies in India and worldwide. Specifically in the production field in India, the development of biodegradable plates goes to its height. Suppliers are presenting sustainable biodegradable plates making machines in India.

In this blog site, we will certainly explore the procedure of how biodegradable plates are made, the biodegradable plate making machines in India, and the supplier of the biodegradable plate making machines in India.

Biodegradable Plate Making in India

Biodegradable plate making machines are the heart of the environmentally friendly tableware industry. Referred to as the creating machines, they are particularly developed to generate molded fiber items from natural basic materials.

The biodegradable disposable machines in India are of many types. These are semi-automatic, robot, totally automatic, and hydraulic presses. Each kind is tailored for different production demands. These machines can shape and mold the raw product into different plate layouts and sizes.

The portions of eco friendly disposable plate making machine in India contain the forming section where the mold is presented into the mold and mildew, the mold made according to the numerous requirements, and the hot press area where the molded items are warmed to give them up.

Among the innovative technologies in biodegradable plate making machines in India is an automatic creating machine. Agarwal Machineries a leading name in the market, makes premier developing machines and is the leader of fully automatic machines in India.

Production of Biodegradable Plate Utilizing Sugarcane Bagasse

Among the most appropriate and used basic materials for making eco-friendly tableware items in India is sugarcane bagasse. The biodegradable plates produced by using sugarcane bagasse as raw material are compostable and can break down in nature quickly.

The production of biodegradable plates includes a pulping procedure where the raw product or the sheets made from the raw material are processed in the pulper to create a slurry. This slurry proceeded further to the refiner to obtain the fiber as per the demand.

The pulp is then approved to the evolving machines. The creating equipment has a developing terminal where the pulp is poured into the mold to obtain the wanted shape of home plates or tableware. The plates from the mold are then gotten rid of after drying and shifted to a heat terminal to obtain the finishing. Home plates are trimmed to obtain the great side, and the biodegradable plates await product packaging and send off.

This method not only makes use of agricultural waste efficiently but also generates biodegradable products that decay naturally, adding to a cleaner and greener atmosphere. The use of bagasse tableware making machine in this production procedure emphasizes the dedication to sustainability and the effective use of sources.

If you want to begin the biodegradable plate making plant, then learn more concerning the detailed info regarding how to begin a sugarcane bagasse plate making plant here.

Suppliers of Biodegradable Plate Making Machines in India

India is home to a number of reliable producers of biodegradable plate making machines, with us sticking out as a popular leader in the field. We provides state-of-the-art remedies for the manufacturing of molded fiber products, consisting of biodegradable plates. Their machines are renowned for their integrity, performance, and advanced modern technology, making them a recommended choice for producers intending to create premium eco-friendly tableware.

The innovation of biodegradable plate making machines in India is exceptional. With a variety of semi-automatic, robotic, and totally automatic forming machines, we provide a full option to set the biodegradable plate making mills in India and worldwide.

To get a complete therapy for your demand concerning your brand new biodegradable plate making machine, you can contact us today.

Conclusion

The change towards biodegradable plates is a crucial action in resolving the international plastic pollution situation. With the improvement of biodegradable plate making machines, particularly in India, the manufacturing of lasting eating ware has become extra accessible and reliable. Businesses like Agarwal Machineries are leading the way, supplying innovative solutions that change farming byproducts into environment-friendly items. As we continue to seek options for single-use plastics, the duty of biodegradable plates and their production procedures will most certainly come to be much more considerable in our efforts to protect the planet.

0 notes

Text

What Kind of Paper Can Be Used in Fully Automatic Machines?

With the global rise in demand for eco-friendly and sustainable packaging, paper bags have become a crucial part of retail, food, grocery, and e-commerce industries. Businesses are investing in fully automatic paper bag-making machines to produce high volumes of paper bags with speed and precision.

But an equally important factor in efficient production is the type of paper used in these machines. Choosing the right kind of paper ensures smooth operation, strong bag quality, and cost-effective output.

So, what kinds of paper are compatible with fully automatic paper bag machines? In this article, we’ll explore the best paper types for different bag applications—and how to make the right choice for your production line.

🧾 Why Paper Selection Matters

The paper you choose directly impacts

Machine speed and performance

Strength and durability of the bag

Print quality (if using inline printing)

Cost of production

Environmental friendliness

At Prakash Machineries Pvt. Ltd., our fully automatic machines are designed to handle a wide range of paper types to support various industries—from pharma to fashion.

✅ Compatible Paper Types for Fully Automatic Bag Machines

1. Brown Kraft Paper

Kraft paper is the most widely used material in paper bag manufacturing. It is strong, biodegradable, and cost-effective.

Key Features:

Natural brown color

High tensile strength

Tear-resistant

Recyclable and compostable

Ideal For:

Grocery bags

Retail shopping bags

Food packaging

Agricultural products

GSM Range:

40 to 120 GSM, depending on bag size and weight capacity

Most fully automatic machines—like those from Prakash Machineries Pvt. Ltd.—are optimized to handle Kraft paper without modification.

2. White Kraft Paper

White Kraft paper offers the same durability as brown Kraft but with a clean, polished appearance—ideal for branding and printing.

Key Features:

Smooth, white surface

Excellent printability

Suitable for colored logos and designs

Ideal For:

Boutique and clothing store bags

Premium grocery chains

Branded takeout packaging

GSM Range:

50 to 120 GSM

It is especially popular with businesses looking to enhance the visual appeal of their packaging while staying eco-friendly.

3. Recycled Paper

Environmentally conscious brands often prefer 100% recycled paper, which is made from post-consumer waste.

Key Features:

Eco-friendly and sustainable

May have a slightly rough texture

Supports green business goals

Ideal For:

Organic product packaging

Small grocery shops

NGO or government distribution programs

GSM Range:

40 to 100 GSM

Our machines at Prakash Machineries Pvt. Ltd. are capable of processing recycled paper rolls smoothly, provided they meet basic uniformity standards.

4. Newsprint Paper

Newsprint is a low-cost option for businesses that need lightweight, disposable bags for small goods or internal packaging.

Key Features:

Economical

Thin and lightweight

Not suitable for heavy loads

Ideal For:

Bakeries

Fruit & vegetable vendors

Bookstores and stationery shops

GSM Range:

28 to 60 GSM

While not as durable as kraft, it can be used in fast-moving consumer environments where disposability is key.

5. Art Paper or Coated Paper

Art paper, also known as gloss or matte-coated paper, is ideal for luxury paper bags with high-resolution printing and a premium finish.

Key Features:

Coated surface for vibrant printing

Can be laminated for water resistance

Visually attractive

Ideal For:

Gift bags

High-end retail

Event and promotional packaging

GSM Range:

100 to 180 GSM

Note: Machines must be compatible with coated surfaces, especially for folding and gluing functions. At Prakash Machineries Pvt. Ltd., we offer custom models suited for handling laminated and art paper.

6. Bleached Paper Board (for Heavy-Duty Bags)

Bleached board is used for strong, durable bags meant to carry heavy items. It combines strength with a polished look.

Key Features:

High stiffness

Suitable for reinforced handle bags

Good for branding

Ideal For:

Electronics packaging

Branded garment bags

Wine or liquor bags

GSM Range:

150 to 250 GSM

This type may require a more powerful machine configuration to ensure smooth feeding and folding.

🔧 Paper Quality Requirements

To ensure the best performance from your machine, the selected paper should have:

Uniform thickness (GSM)

Proper tension and winding on rolls

Clean edges to avoid tearing during feeding

Compatible coating (if applicable) for folding and pasting

All paper types should be tested with the machine prior to bulk production. At Prakash Machineries Pvt. Ltd., we offer full assistance in trial runs and sample testing to help you choose the right paper stock.

🏭 Benefits of Using Versatile Paper Bag Machines

Investing in a machine that supports multiple paper types means

Greater flexibility in serving different industries

Ability to switch between product lines with minimal downtime

Opportunities to expand into premium or eco-niche markets

Lower production costs with access to multiple paper suppliers

Our fully automatic paper bag machines are built for multi-material compatibility, fast size changes, and high-volume production.

Why Choose Prakash Machineries Pvt. Ltd.?

At Prakash Machineries Pvt. Ltd., we design and manufacture paper bag machines that are

Compatible with kraft, art paper, recycled paper, and coated paper

Built with precision controls for smooth feeding and folding

Equipped with PLC systems for automated adjustments

Energy-efficient and built to last

Supported by a team of engineers and trainers to guide your production journey

Final Thoughts

Choosing the right paper is just as important as selecting the right machine. Whether you want to make budget-friendly grocery bags or premium printed shopping bags, your fully automatic paper bag machine must handle a wide range of paper types efficiently.

At Prakash Machineries Pvt. Ltd., our machines are designed for maximum paper flexibility, high-speed production, and minimal waste, ensuring your packaging business can meet changing market demands with confidence.

Interested in finding the right machine for your paper type? Contact Prakash Machineries Pvt. Ltd. today to get expert advice and a free consultation.

#paper bag manufacturer#manufacturer#v bottom#flexo#square bottom#machines#paper#paper bag#dan and phil#baking#cake#chris sturniolo#alien stage#bagas#critical role#cooking#delicious#breakfast#chocolate

0 notes

Text

Briefly describe the process of organic fertilizer production line

Organic fertilizer production is to harmlessly treat and recycle organic raw materials such as agricultural waste and livestock and poultry manure, and finally produce fertilizers rich in organic matter and nutrients. The process of organic fertilizer production includes composting fermentation of organic matter and post-fermentation treatment.

The first step is composting fermentation. The organic waste should be mixed evenly in a certain proportion, then placed in a fermentation tank, and then fermentation agents should be added. During the fermentation process, environmental factors should be strictly controlled, and the compost should be regularly turned and oxygenated by a Compost Turning Machine The high temperature stage lasts for several weeks to allow microorganisms to fully decompose organic matter.

Then there is post-fermentation processing. The fermented organic fertilizer includes two types: powdered organic fertilizer production line and granular organic fertilizer production line.

1. The processing technology of powdered organic fertilizer production line is relatively simple, which is divided into three stages: crushing, screening and packing. Crushing: Crushing large or agglomerated fermented materials to produce uniform powdered organic fertilizer. Screening: Screen out organic fertilizer that meet the requirements to ensure product quality. Packing: Final packing of the screened organic fertilizer for easy storage and transportation.

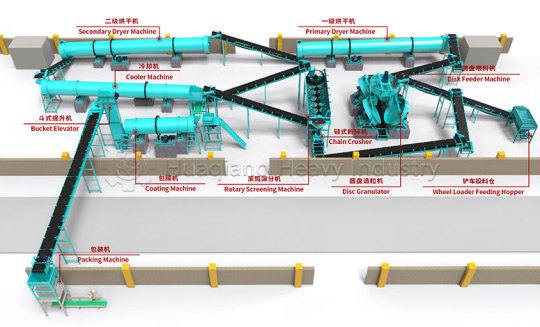

2. The production line of granular organic fertilizer is relatively more complicated, with the following steps: Ingredient mixing: Add humic acid or other elements of fertilizer to the fermented organic fertilizer, and then mix them evenly through a mixer to facilitate subsequent processing. Granulation: Use Granulators (such as Disc Granulator)to make the organic fertilizer into uniform granules. This is not only conducive to storage and transportation, but also improves the convenience of fertilization. Drying and cooling: Reduce the moisture content of organic fertilizer to prevent mold and deterioration, and increase the hardness of fertilizer particles. Screening: Use a Drum Screener Machine to screen out broken particles and select particles of appropriate size for subsequent processing. Coating: Use a Coating Machine to coat the fertilizer particles to prevent the particles from sticking. Packing: Packing is the last step. Generally, an automatic packing machine is used. Our Granular Fertilizer Packing Machine is controlled by a computer to ensure the accuracy of fertilizer packing.

This completes the entire production process of organic fertilizer from raw materials to finished products. This production method achieves efficient transformation of waste and provides high-quality organic fertilizer for agricultural production.

0 notes

Text

The advantages of the windrow compost turning machine over other equipment

Compared with other types of pile turners, windrow compost turning machines have many significant advantages, the following is the specific analysis:

1. Efficient stacking capacity: The caterpillar stacking machine can turn materials quickly and evenly, improve fermentation and composting efficiency, and shorten the processing cycle. The height of the tipping shaft can be automatically lifted and lowered, and can choose forced tipping or high-speed tipping according to the size of the material moisture.

2. Strong adaptability: The crawler type stacking machine uses tracks to walk, has strong off-road ability and stability, and can work on uneven ground. This design allows it to easily traverse a variety of complex terrain, ensuring comprehensive and thorough waste disposal.

3. Low energy consumption and high output: the crawler-type stacking machine has the obvious advantages of less investment, low energy consumption, fast fertilizer formation and large output. Its fully hydraulic operating system reduces mechanical wear, reduces failure rates and further reduces energy consumption.

4. Durability and reliability: The crawler pile tiller adopts the frame multi-column automobile type overall structure, which has longer service life and is not easy to deform. The hydraulic lifting design of the tipping shaft can be used to turn the pile at high and low speeds according to the water content of the material, further reducing the production of odor and dust.

5. Intelligent control: The crawler stacking machine is equipped with an intelligent control system, which can monitor the working status in real time and automatically adjust it to improve work efficiency.

To sum up, the crawler stacker has significant advantages in efficient stacker, adaptability, operational flexibility and so on, and is an ideal choice of organic fertilizer equipment.

0 notes

Text

What is the current situation of fermentation compost turning machine

The current situation of fermentation compost turning machine can be analyzed from the following aspects:

1. Promotion of environmental protection policies: With the increasingly strict environmental protection policies, more and more farms and organic fertilizer production enterprises have begun to pay attention to the treatment and resource utilization of waste. As a kind of efficient organic fertilizer equipment, the market demand continues to grow.

2. Agricultural sustainable development: The importance of organic fertilizer in the sustainable development of agriculture is becoming increasingly prominent, and more and more farmers and agricultural enterprises have begun to use organic fertilizer, which has promoted the market demand for fermentation turning machines.

3. Increased degree of automation: The degree of automation of modern fermentation pile turning machine continues to improve, reducing manual intervention and improving production efficiency. For example, the large wheel compost turning machine is equipped with a fully automated electrical control system, which can achieve manual or automatic control functions.

4. Energy saving and environmental protection: The new fermentation pile turning machine has excellent performance in energy saving and environmental protection.

5. Future development trend Intelligent and automation: The future fermentation pile turning machine will be more intelligent and automated, reduce manual intervention, improve production efficiency.

6. Energy saving and environmental protection: The equipment will pay more attention to energy saving and environmental protection, using clean energy and efficient energy-saving technology to reduce the impact on the environment.

In summary, the status quo of the use of fermentation stacking machine in organic fertilizer equipment is generally good, the market demand is growing, the technological progress is significant, and the application field is wide. In the future, with the further development of technology and the continuous expansion of the market, fermentation stacking machine is expected to play a greater role in the organic fertilizer industry.

#fermentation compost turning machine#organic fertilizer equipment#large wheel compost turning machine

0 notes

Text

Selecting equipment for a granular organic fertilizer production line is a complex process that requires comprehensive consideration of multiple factors to ensure the smooth operation of the production line and the quality and stability of the product. The following are the main factors to consider: 1. Production capacity Annual or daily output: First of all, it is necessary to clarify the production capacity of the production line, such as how many tons of granular organic fertilizer can be produced annually or how many tons of granular organic fertilizer can be produced per day. This directly determines the scale and quantity of equipment required. Production efficiency: The production efficiency of the equipment is also an important consideration. It determines how much fertilizer can be produced per unit time, thus affecting the overall production capacity of the production line.

2. Product type Granular shape: Determine what shape of granular organic fertilizer is produced, such as standard spherical, cylindrical, oblate, etc. Different shapes may require different types of granulators. Fertilizer type: Is it pure organic fertilizer, organic-inorganic compound fertilizer, biological organic fertilizer or compound microbial fertilizer? Different types of fertilizers also have different requirements for equipment. 3. Equipment selection Granulator: Select a suitable granulator according to the shape of the particles and production requirements, such as disc granulator, drum granulator, wet granulator, flat die granulator, ring film granulator, etc. Fermentation equipment: Select suitable fermentation equipment, such as trough compost turner, chain plate compost turner or self-propelled compost turner, etc., to ensure that the raw materials are fully fermented and mature. Pulverizer: Select a pulverizer suitable for processing fermented materials to crush them into fine powder for subsequent granulation. Drying and cooling equipment: Configure dryers and coolers to remove excess moisture from the particles and reduce the temperature. Screening equipment: Use a sieving machine to grade and screen the particles to ensure the uniformity and quality of the product. Packaging equipment: Select a fully automatic packaging machine to quantitatively weigh and package the finished products.

0 notes