#Fully Automatic Composting Machine in India

Explore tagged Tumblr posts

Video

youtube

Organic Waste Composter Machine for hotels, canteens, mess, temples, ind...

#organic waste composter#owc waste management#waste management#organic waste composter machine#organic waste converter#owc machine manufacturer#Natural Composter#Owc Machine manufacturers#Composter manufacturers#Fully Automatic Composting Machine#composting for waste disposal#organic waste for composting#food waste converter machine#OWC Machine Price#semi automatic organic waste composter#Fully Automatic Composting Machine in India

1 note

·

View note

Text

Revolutionizing Waste Management: The Power of Fully Automatic Composting Machines

Introduction:

In the quest for sustainable waste management solutions, fully automatic composting machine has emerged as a cutting-edge technology that promises to transform organic waste disposal. With their advanced features and efficiency, these machines are revolutionizing the way we handle organic waste. In this blog, we will explore the significance of fully automatic composting machines, their benefits, and their impact on waste management in India.

Understanding Fully Automatic Composting Machines:

Fully automatic composting machine, also known as fully automatic organic waste converter, is state-of-the-art devices designed to process organic waste into nutrient-rich compost through an automated and controlled process. These machines efficiently accelerate the composting process, making it hassle-free and more accessible for individuals, businesses, and communities.

The Need for Fully Automatic Composters in India:

As India grapples with increasing urbanization and a growing population, the amount of organic waste being generated is rising exponentially. Traditional waste management methods struggle to keep up, leading to overflowing landfills and environmental degradation. Fully automatic composting machines offer a sustainable and eco-friendly solution to manage organic waste, reducing the burden on landfills and curbing greenhouse gas emissions.

Advantages of Fully Automatic Composting Machines:

Time and Labor-Saving: Fully automatic composter requires minimal human intervention, saving time and effort in waste management.

High Efficiency: These machines accelerate the composting process, converting organic waste into compost within a short period.

Odor Control: Advanced technology in fully automatic composters ensures odor control, making them suitable for both residential and commercial settings.

Resourceful Compost: The compost produced by these machines is a valuable resource for agriculture, horticulture, and landscaping, improving soil fertility and plant growth.

Fully Automatic Composting Machines in India:

The demand for Fully Automatic Composting Machine in India has driven the growth of the fully automatic composting machine market. Numerous manufacturers are now offering state-of-the-art machines tailored to India's diverse waste management needs. These machines cater to both small-scale and large-scale composting operations, making them accessible to households, restaurants, hotels, educational institutions, and industries.

Sustainability and Waste Reduction:

Fully automatic composting machines are a critical component of sustainable waste management practices in India. By diverting organic waste from landfills and converting it into valuable compost, these machines play a vital role in reducing environmental pollution and conserving natural resources.

Conclusion:

Fully automatic composting machines have emerged as game-changers in waste management, offering an efficient and eco-friendly solution for handling organic waste. Their automated features, high efficiency, and resourceful compost production make them indispensable tools in the pursuit of sustainability. As India strives to build a cleaner and greener future, fully automatic composting machines pave the way for a more responsible approach to waste disposal, ensuring a healthier environment for generations to come.

#Fully Automatic Composting Machine#Fully Automatic Composter#Fully Automatic Composting Machine in India#Fully automatic organic waste converter

1 note

·

View note

Text

Paper Cup Making Machines: Powering the Green Packaging Revolution in 2025

In a world shifting rapidly toward sustainability, paper cups are no longer just a convenience—they’re a statement. As single-use plastic bans tighten across India and the globe, eco-friendly alternatives like paper cups are leading the charge in foodservice, hospitality, and retail.

\But behind every biodegradable cup is a powerful piece of machinery: the Paper Cup Making Machine.

In 2025, the market is not only growing—it’s transforming. From automation to smart diagnostics and ultra-fast output, paper cup machines have become smarter, faster, and greener. For manufacturers, entrepreneurs, and packaging businesses, investing in the right paper cup making machine is now more than a necessity—it’s a competitive edge.

Why Paper Cups Are More Relevant Than Ever

The demand for paper cups is being driven by multiple converging trends:

Ban on Single-Use Plastics in India and other countries

The rise of eco-conscious consumers demanding sustainable alternatives

Growth in takeaway food, cafés, and cloud kitchens

Government support for MSMEs and sustainable packaging ventures

This surge has created a booming opportunity for paper cup manufacturers, especially those using high-efficiency, modern equipment.

What’s Trending in the Paper Cup Machine Industry in 2025?

1. Fully Automatic Machines

Today’s top manufacturers offer machines that can produce up to 100 cups per minute, with minimal manual intervention. These machines:

Reduce labor costs

Improve consistency and hygiene

Enable round-the-clock production

2. Smart Touch Control Panels

Modern machines now feature digital touchscreens with programmable settings. Operators can adjust cup size, material thickness, speed, and more—all with a few taps.

3. Eco-Friendly Configurations

Machines are now being optimized to work with coated paper, biodegradable sheets, and PLA (cornstarch-based) films, supporting global eco-packaging norms.

4. Multi-Size Compatibility

The best manufacturers now design machines that can switch between 45ml to 350ml cups, perfect for businesses serving both tea stalls and large food courts.

5. Minimal Maintenance Design

With precision-engineered parts and self-lubrication systems, paper cup machines now require less frequent servicing, reducing downtime and increasing ROI.

What to Look for in a Paper Cup Making Machine Manufacturer

Choosing the right machine supplier is crucial if you’re planning to enter the paper cup manufacturing business or upgrade your setup. Here’s what to consider:

Machine Output Speed – Does it match your production goals?

Cup Size Range – Can it handle small to large cup sizes?

Automation Level – Manual, semi-automatic, or fully automatic?

After-Sales Support – Do they offer installation, training, and maintenance services?

Warranty & Parts Availability – Long-term reliability is key.

Certifications & Quality Standards – Ensure ISO, CE, or BIS compliance.

Business Opportunity: Why Now Is the Time to Invest

Whether you are a startup in packaging, an MSME looking to expand, or a distributor of eco-friendly products, now is the best time to step into paper cup manufacturing.

Here’s why:

Demand is skyrocketing due to the environmental push

Government subsidies and Make in India initiatives are encouraging local production

High profit margins with low-cost raw materials (paper rolls)

Quick ROI with machines delivering 24/7 output and low maintenance

The Manufacturer’s Perspective

If you’re a paper cup making machine manufacturer, this is your moment to shine.

The market is looking for:

High-speed, reliable, and low-energy consumption machines

Local technical support and spare part availability

Custom solutions for startups, large-scale factories, and exporters

Machines capable of handling eco-coated and compostable paper

A strong online presence, certifications, customer testimonials, and product videos can set your brand apart in a competitive market.

Conclusion

As the world moves toward greener alternatives, the paper cup industry is no longer a side hustle—it’s a sunrise sector. From small kiosks to national brands, everyone is shifting to paper-based packaging. And at the center of this movement lies smart, efficient, and sustainable paper cup making machines.

Whether you’re a business owner, eco-entrepreneur, or manufacturer, this is your opportunity to build a profitable, future-ready brand—with sustainability as your foundation.

FAQs on Paper Cup Making Machines

Q1. What is the production capacity of a paper cup making machine?Modern machines can produce between 45 to 120 cups per minute, depending on automation and size range.

Q2. Can I start a paper cup business from home or a small unit?Yes. Many startups begin with a semi-automatic or compact machine in small spaces. As demand grows, you can scale up.

Q3. What kind of paper is used in these machines?PE-coated or PLA-coated food-grade paper rolls are used for paper cup production.

Q4. How much does a paper cup making machine cost in India?Prices can range from ₹5 lakhs to ₹25 lakhs, depending on speed, size range, automation, and brand.

Q5. Do manufacturers offer training and installation support? Reputed manufacturers provide on-site installation, operator training, and after-sales support across India and abroad. Paper Cup making Machine Manufacturer

0 notes

Text

Why Biodegradable Disposable Plate Making Machine is Booming in India?

Taking into consideration the pollution because of single use plastic, the recognition of using biodegradable plates has risen. Individuals are choosing environmentally friendly products over plastic. This has resulted in the increased need for biodegradable plates, creating a brand new possibility for service and the need for biodegradable plate making machines in India.

Made from natural resources, biodegradable plates break down in the environment quickly, which reduces the burden of injury to nature, garbage dumps, and marine life. The expanding necessity for biodegradable plates has motivated the development of modern technologies in India and worldwide. Specifically in the production field in India, the development of biodegradable plates goes to its height. Suppliers are presenting sustainable biodegradable plates making machines in India.

In this blog site, we will certainly explore the procedure of how biodegradable plates are made, the biodegradable plate making machines in India, and the supplier of the biodegradable plate making machines in India.

Biodegradable Plate Making in India

Biodegradable plate making machines are the heart of the environmentally friendly tableware industry. Referred to as the creating machines, they are particularly developed to generate molded fiber items from natural basic materials.

The biodegradable disposable machines in India are of many types. These are semi-automatic, robot, totally automatic, and hydraulic presses. Each kind is tailored for different production demands. These machines can shape and mold the raw product into different plate layouts and sizes.

The portions of eco friendly disposable plate making machine in India contain the forming section where the mold is presented into the mold and mildew, the mold made according to the numerous requirements, and the hot press area where the molded items are warmed to give them up.

Among the innovative technologies in biodegradable plate making machines in India is an automatic creating machine. Agarwal Machineries a leading name in the market, makes premier developing machines and is the leader of fully automatic machines in India.

Production of Biodegradable Plate Utilizing Sugarcane Bagasse

Among the most appropriate and used basic materials for making eco-friendly tableware items in India is sugarcane bagasse. The biodegradable plates produced by using sugarcane bagasse as raw material are compostable and can break down in nature quickly.

The production of biodegradable plates includes a pulping procedure where the raw product or the sheets made from the raw material are processed in the pulper to create a slurry. This slurry proceeded further to the refiner to obtain the fiber as per the demand.

The pulp is then approved to the evolving machines. The creating equipment has a developing terminal where the pulp is poured into the mold to obtain the wanted shape of home plates or tableware. The plates from the mold are then gotten rid of after drying and shifted to a heat terminal to obtain the finishing. Home plates are trimmed to obtain the great side, and the biodegradable plates await product packaging and send off.

This method not only makes use of agricultural waste efficiently but also generates biodegradable products that decay naturally, adding to a cleaner and greener atmosphere. The use of bagasse tableware making machine in this production procedure emphasizes the dedication to sustainability and the effective use of sources.

If you want to begin the biodegradable plate making plant, then learn more concerning the detailed info regarding how to begin a sugarcane bagasse plate making plant here.

Suppliers of Biodegradable Plate Making Machines in India

India is home to a number of reliable producers of biodegradable plate making machines, with us sticking out as a popular leader in the field. We provides state-of-the-art remedies for the manufacturing of molded fiber products, consisting of biodegradable plates. Their machines are renowned for their integrity, performance, and advanced modern technology, making them a recommended choice for producers intending to create premium eco-friendly tableware.

The innovation of biodegradable plate making machines in India is exceptional. With a variety of semi-automatic, robotic, and totally automatic forming machines, we provide a full option to set the biodegradable plate making mills in India and worldwide.

To get a complete therapy for your demand concerning your brand new biodegradable plate making machine, you can contact us today.

Conclusion

The change towards biodegradable plates is a crucial action in resolving the international plastic pollution situation. With the improvement of biodegradable plate making machines, particularly in India, the manufacturing of lasting eating ware has become extra accessible and reliable. Businesses like Agarwal Machineries are leading the way, supplying innovative solutions that change farming byproducts into environment-friendly items. As we continue to seek options for single-use plastics, the duty of biodegradable plates and their production procedures will most certainly come to be much more considerable in our efforts to protect the planet.

0 notes

Text

Organic Waste Composter Machine Manufacturer In India

Are you searching for a fully automatic Organic Waste Composter machine manufacturer in India? Green Aqua Technologies is the perfect choice for you. We are top rated manufacturer and supplier of organic waste composter machines in India, specializing in innovative solutions that convert organic waste into nutrient-rich compost. An organic waste converter is a machine that efficiently transforms kitchen scraps, garden waste, and food processing by-products into high-quality compost. Excel’s OWC not only simplifies the composting process but also promotes sustainable waste management by preventing waste buildup in landfills. Website: https://www.greenaquatechnologies.com/organic-waste-composter/

0 notes

Text

Mushroom Machinery Manufacturing Pvt. Ltd. is a leading & Mushroom Machines Manufacturer & Supplier in India. We are the manufacturer of all types of Mushroom Farming Machinery for Button Mushroom, Mushroom growing unit machinery, Oyster Mushroom and Milky Mushroom. Our machinery are fully automatic, Semi-automatic as well as computerized to maintained favorable environmental condition within Mushroom growing rooms and composting unit to produce best quality of Mushrooms throughout the year. Contact us 8171599292.

0 notes

Text

#Waste Management Services#Waste management services in bangalore#Waste management companies in bangalore#Home biogas manufacturers in india#biogas plant manufacturers in bangalore

1 note

·

View note

Text

Organic Waste Converter Machine Market to Observe Strong Growth to Generate Massive Revenue in Coming Years

Global Organic Waste Converter Machine Market Report from AMA Research highlights deep analysis on market characteristics, sizing, estimates and growth by segmentation, regional breakdowns & country along with competitive landscape, players market shares, and strategies that are key in the market. The exploration provides a 360° view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improved profitability. In addition, the study helps venture or private players in understanding the companies in more detail to make better informed decisions. Major Players in This Report Include:

BioHiTech Global (United States)

Emerson Electric Co. (United States)

KCS Engineering (India)

Oklin International (Hong Kong)

Enic Co Limited (South Korea)

Hungry Giant Recycling (United States)

Weimar Enterprise Sdn Bhd (Malaysia)

IMC WasteStation (United Kingdom)

Excel Industry Co. LLC (United Arab Emirates)

Mentari Alam Eko (M) Sdn Bhd (Malaysia)

Nachiket Engineering Pvt. Ltd. (India)

Greenviron India (India)

Ecoman Envio Solutions Pvt. Ltd. (India)

Earth Care Equipments Private Limited (India)

Organic Waste Compost Machine (India)

Taizhou Dengshang Mechanical & Electrical Co., Ltd (China)

Organic waste is nothing but unwanted material created from day to day activities. It is generated from the room, house, office, canteens, etc. Disposal of waste in the open may have hazardous impacts on the environment. Waste cannot be left as it is and therefore it is quite obvious that it is needed to be disposed in the most sustainable, economical, and eco-friendly manner. To segregate the waste the organic waste converter machines are used. These machines use the composition process to convert the organic waste into culture media that can be further used as compost in gardens. As per a survey of the Food and Agriculture Organization (FAO) of the United Nations, approximately 1.3 billion tons of food is wasted on an annual basis. Hence to recycling massive quantities of food the demand for organic waste converter machine is expected to boost in upcoming years. Market Drivers Ease to Covert Large Quantity of Solid Waste into To Fertilizer

Increasing Amount Daily Waste in Industries

Demand for Fully Automatic Organic Waste Converter Machine

Market Trend Trend for Eco-friendly Organic Waste Recycling

Opportunities Less Processing Time Compared to Manual Waste Converting Process

Need Less Manpower and Maintenance

Challenges Availability of Counterfeit Products

The Organic Waste Converter Machine market study is being classified 21529 Presented By

AMA Research & Media LLP

0 notes

Link

#owc machine#OWC manufacturer#OWC machine manufacturers#OWC Machine Organic waste converter#Organic waste composting machine#Organic waste converter machine#organic waste composter machine#Semi Automatic Organic Waste Converter#Semi-Automatic Organic Waste Converter#Semi Automatic Organic Waste composter#Fully Automatic Composter#fully automatic composting machine price#Fully Automatic Organic Waste Converter#Fully Automatic Organic Waste Composter#semi automatic composter manufacturers in india

0 notes

Video

tumblr

Waste Water Treatment Plant

#Kelvin Coconut shredder machine#Fully Automatic Composter#Semi-Automatic Organic Waste Converter#RO Plant Company#Commercial RO Plant Manufacturers in Delhi#Rain Water Harvesting Plant Manufacturer#zld plant manufacturers in india#ZERO LIQUID DISCHARGE PLANT Manufacturer#CETP Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in Delhi#Sewage Treatment Plant in India#Extension Work of STP Plant

0 notes

Text

25/day organic waste convert into compost daily. Buy machine @ 9812241001 ✅ OWC Machine Post Caption (Professional + Engaging) ♻️ हर दिन निकलने वाले कचरे को अब बनाएँ सोना! Kelvin Water Technologies की OWC Machine (Organic Waste Composter) के साथ करें Food Waste को High-Quality Compost में बदलने का काम — वो भी बिना गंध, बिना झंझट!

🌱 Features: ✅ 100% Eco-friendly ✅ Fully/Semi Automatic Options ✅ Compact Design for Societies, Hotels, Institutions ✅ Govt Norms Approved ✅ PAN India Delivery & Support

🌍 Zero Waste Society की ओर एक कदम 📞 Call now for demo & pricing: +91-9812241001 🌐 Visit: www.kelvinindia.in

KelvinWaterTech #OWCMachine #WasteToCompost #OrganicWasteComposter #SwachhBharat #SmartWasteManagement #CompostKarBharatSavdhan #GoGreenWithKelvin #EcoIndia

0 notes

Text

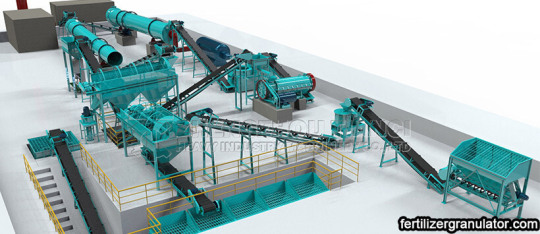

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Video

youtube

Mushroom growing unit machinery Mushroom Machinery Manufacturing Pvt. Ltd. is a leading & Mushroom Machines Manufacturer & Supplier in India. Our machinery are fully automatic, Semi-automatic as well as computerized to maintained favorable environmental condition within Mushroom growing rooms and composting unit to produce best quality of Mushrooms throughout the year. Contact us 8171599292.

1 note

·

View note

Text

Mushroom Equipment Our machinery are fully automatic, Semi-automatic as well as computerized to maintained favorable environmental condition within Mushroom growing rooms and composting unit to produce best quality of Mushrooms throughout the year. capacity of Mushroom dryer is available Post Harvesting Equipment MushroomMachines.com. Contact us 8171599292.

#MushroomEquipment#ShedConstruction#MushroomShedConstruction#CompostTurner#MushroomMachines#MushroomMachinery

1 note

·

View note

Text

youtube

Mushroom Machinery Manufacturing Pvt. Ltd. is a leading & Mushroom Machines Manufacturer & Supplier in India. We are the manufacturer of all types of Mushroom Farming Machinery for Button Mushroom, Mushroom growing unit machinery, Oyster Mushroom and Milky Mushroom. Our machinery are fully automatic, Semi-automatic as well as computerized to maintained favorable environmental condition within Mushroom growing rooms and composting unit to produce best quality of Mushrooms throughout the year. Contact us 8171599292.

1 note

·

View note

Text

Organic Waste Composter Machine Manufacturer In India

Are you searching for a fully automatic Organic Waste Composter machine manufacturer in India? Green Aqua Technologies is the perfect choice for you. We are top rated manufacturer and supplier of organic waste composter machines in India, specializing in innovative solutions that convert organic waste into nutrient-rich compost. An organic waste converter is a machine that efficiently transforms kitchen scraps, garden waste, and food processing by-products into high-quality compost. Excel’s OWC not only simplifies the composting process but also promotes sustainable waste management by preventing waste buildup in landfills. Website: https://www.greenaquatechnologies.com/organic-waste-composter/

0 notes