#HVAC Compressor system

Explore tagged Tumblr posts

Text

No one knows when their compressor will fail, but it is important to prevent it from happening in the first place. Following some simple rules can reduce the chances of your compressor failure.

0 notes

Text

"AC Maintenance Tips for Homes and Businesses in Saudi Arabia’s Harsh Climate"

Air conditioning systems are vital for both homes and businesses in Saudi Arabia, where temperatures often soar to extreme levels. Ensuring that your AC unit functions at its best is essential not only for comfort but also for maintaining efficiency and reducing energy costs. Proper maintenance can prevent unexpected breakdowns during the hottest months, while also prolonging the lifespan of your system.

To maintain an efficient and reliable cooling system, many property owners opt for professional AC maintenance services to ensure their air conditioning units stay in top condition. Regular maintenance services can help identify potential issues before they escalate, avoiding costly repairs or the need for a full replacement.

1. Regular Filter Cleaning and Replacement

One of the simplest yet most effective maintenance tasks for any air conditioning system is regular filter cleaning or replacement. In Saudi Arabia’s dusty environment, filters can quickly become clogged with dust and debris, making the system work harder and reducing efficiency. Dirty filters restrict airflow, which not only increases energy usage but also decreases the unit's ability to cool properly. For both homes and businesses, it is recommended to clean or replace filters every one to three months, depending on the frequency of use.

2. Inspect and Clean Condenser Coils

The outdoor unit of your air conditioning system contains condenser coils that are responsible for releasing the heat absorbed from the indoor air. These coils are exposed to the elements, and in a harsh climate like Saudi Arabia, dust, dirt, and debris can easily accumulate. When the coils are dirty, the system's ability to dissipate heat is compromised, leading to reduced cooling performance and higher energy consumption. Regular cleaning of the condenser coils helps ensure optimal performance and efficiency.

3. Check Refrigerant Levels

For your AC system to cool effectively, it needs the correct amount of refrigerant. Low refrigerant levels can lead to inadequate cooling, causing the system to run longer and work harder. Over time, this can increase wear and tear on the unit and even lead to system failure. It’s important to have a professional check refrigerant levels during routine maintenance and top off as necessary to keep your system running smoothly.

4. Inspect Ductwork for Leaks

Leaky ductwork can significantly affect the efficiency of your air conditioning system, as cool air escapes before it reaches its intended destination. For businesses and larger properties, this can result in uneven cooling, higher energy bills, and an overworked AC unit. Regularly inspecting ductwork for leaks or gaps and sealing them as needed will help ensure that your air conditioning system is delivering cooled air efficiently.

5. Schedule Professional Maintenance

In Saudi Arabia’s extreme climate, scheduling professional AC maintenance at least twice a year is highly recommended. Professional technicians have the knowledge and tools to thoroughly inspect your system, clean essential components, and identify potential problems before they escalate. Businesses, in particular, can benefit from having a comprehensive maintenance plan to avoid costly downtime due to AC failure.

Whether you own a small home or manage a large commercial facility, regular AC rental service and maintenance are crucial for ensuring the longevity and efficiency of your cooling systems.

6. Optimize Thermostat Settings

Maintaining an optimal temperature setting on your thermostat can greatly impact energy usage and overall system performance. In Saudi Arabia, where temperatures can reach extreme highs, setting your thermostat just a few degrees higher can significantly reduce the strain on your AC unit. Additionally, programmable thermostats allow you to set different temperatures based on your schedule, which can help save energy when cooling is not needed.

7. Keep the Area Around the Outdoor Unit Clear

The outdoor unit of your air conditioner needs adequate airflow to function properly. Debris such as leaves, dirt, and plants can obstruct the airflow, causing the unit to work harder and reducing its efficiency. Regularly check and clear any debris from around the outdoor unit, and make sure that there is at least two feet of clearance on all sides to promote optimal airflow.

8. Ensure Proper Ventilation

Ventilation plays a crucial role in the effectiveness of your AC system, particularly in business settings where large numbers of people and equipment generate heat. Poor ventilation can increase humidity levels, making it harder for your air conditioner to cool the space. Make sure that vents and return air registers are not blocked by furniture or other obstructions, and consider using ceiling fans to help distribute cool air more evenly throughout the space.

Conclusion

Maintaining your air conditioning system is essential in Saudi Arabia’s harsh climate, where efficient cooling is a necessity rather than a luxury. By following these AC maintenance tips, you can ensure that your system operates efficiently, keeps energy costs under control, and provides reliable cooling when you need it most.

Investing in regular AC maintenance service is key to extending the life of your system and avoiding the discomfort and expense of unexpected breakdowns. Whether for a home or business, proper maintenance is a proactive step toward achieving consistent and cost-effective cooling year-round.

#Commercial chiller maintenance#HVAC maintenance#Chiller efficiency#AC maintenance service#Chiller rental service#Cooling solutions Saudi Arabia#Energy-efficient cooling#Chiller system repair#Chiller optimization#Facility management#Preventive maintenance#Refrigerant monitoring#Compressor maintenance#Saudi Arabia HVAC services#Cooling equipment upkeep#HVAC Maintenance#Chiller Maintenance#Commercial Cooling Solutions#Energy Efficiency#Saudi Arabia Climate Control#Building Management Systems#Facility Management#AC Maintenance Services#Chiller Rental Services#Sustainable Cooling Solutions#Industrial Cooling Systems#Preventive Maintenance Tips

3 notes

·

View notes

Text

How to Find and Fix AC Refrigerant Leaks the Right Way

When your air conditioning system starts blowing warm air or struggles to maintain consistent temperatures, a refrigerant leak may be to blame. As a common yet critical issue in air conditioning repair, refrigerant leaks can compromise system performance, energy efficiency, and even your indoor air quality. Fixing them the right way requires proper diagnosis, skilled repair, and in many cases, professional help.

Why Refrigerant Leaks Matter

Refrigerant is the chemical that allows your AC system to cool the air. It cycles through the evaporator and condenser coils, absorbing heat from inside and releasing it outside. When a leak occurs, the system loses this vital substance, leading to:

Reduced cooling power

Higher energy bills

Overheating compressors

Frozen evaporator coils

If left unchecked, a refrigerant leak can cause serious damage to the compressor, leading to a costly air conditioning repair or full system replacement.

Step 1: Spot the Symptoms Early

Recognizing the early warning signs can help you act before a small leak becomes a major headache. Look out for:

Hissing or bubbling noises (indicative of gas escaping)

Ice buildup on the refrigerant lines or evaporator coil

Warm air blowing through vents

Unusually long cooling cycles

Unexplained spikes in utility bills

These red flags signal it’s time to schedule an inspection.

Step 2: Detect the Leak

Finding the source of the leak is the most important part of any air conditioning repair involving refrigerant. HVAC professionals use several techniques to locate leaks:

Electronic Leak Detectors: Devices that sense the presence of escaping refrigerant.

UV Dye Testing: A dye is added to the system and leaks are detected using UV light.

Soap Bubble Method: Bubbles form at leak sites when a soapy solution is applied.

Accurate detection ensures the problem is fixed at the source, not just masked.

Step 3: Decide on a Repair Strategy

Once located, the leak must be sealed or the damaged component replaced. Common leak points include:

Schrader valves

Copper tubing connections

Evaporator or condenser coils

Capillary tubes

Minor issues like valve leaks may only need tightening or replacement. Larger problems, such as corroded coils, often require part replacement—a more involved and costly repair.

Step 4: Recharge the System

After the leak is sealed, the next step is to recharge the air conditioning system with the correct type and amount of refrigerant. This ensures proper pressure levels and optimal performance. Refrigerants like R-410A or R-22 (phasing out) require EPA-certified handling.

Failing to recharge properly can result in:

Inconsistent cooling

Compressor damage

Continued inefficiency

That’s why recharging is a critical part of professional air conditioning repair.

Step 5: Prevent Future Leaks

Preventive maintenance is key to keeping your system leak-free. Tips include:

Schedule annual HVAC tune-ups

Change air filters regularly

Ensure proper airflow around the outdoor unit

Avoid bending or damaging copper lines during cleaning

Proactive care reduces wear and tear, helping you avoid recurring leaks and costly repairs.

When to Call a Professional

Although detecting a refrigerant leak might seem like a DIY task, repairs should always be handled by a licensed HVAC technician. Reasons include:

EPA Regulations: Only certified pros can handle refrigerants legally.

Safety: Mishandling refrigerant poses health and fire risks.

Proper Tools: Leak detection and system recharging require specialized equipment.

Trusting a certified expert ensures your air conditioning repair is done correctly, safely, and in compliance with regulations.

#air conditioning repair#refrigerant leak#HVAC technician#AC troubleshooting#AC maintenance#compressor damage#refrigerant recharge#evaporator coil issues#energy efficiency#home cooling system#HVAC safety#AC not cooling#EPA certified repair#AC system diagnostics#DIY HVAC repair

0 notes

Text

Kulthorn Aza0413Yk1-Compressor Mbp Lst 1/6Hp 115V | PartsHnC

The Kulthorn AZA0413YK1 Compressor Mbp Lst 1/6Hp 115V is a high-performance component intended for HVAC (Heating, Ventilation, and Air Conditioning) applications. With a power output of 1/6 horsepower and 115-volt operation, this compressor is appropriate for a wide range of household and commercial uses. With this compressor, appropriate temperature levels are maintained by effectively controlling the flow of refrigerant inside the system through the use of cutting-edge technology.

For an efficient and reliable HVAC system, the Kulthorn Compressor is a great choice for optimal system performance.

#Kulthorn#Aza0413Yk1#Compressor#Kulthornparts#PartsHnC#PartsHnCBuzz#HVACParts#FurnaceParts#AirConditionerParts#For an efficient and reliable HVAC system

0 notes

Text

/PRNewswire/ -- The global AC Motors Market is anticipated to grow from estimated USD 4.60 billion in 2024 to USD 6.60 billion by 2029, at a CAGR of 7.5% during the forecast period. Industrial growth, rapid urbanization, and increased usage in HVAC systems, water treatment, and manufacturing activities are driving the demand for AC motors. The industries located in China, India, and Japan require AC motors for efficient operation, power pumps, fans, and compressors.

#ac motor#ac motors#ac motors market#motor#motors#electric motors#electric motor#energy#energia#power generation#utilities#power#utility#HVAC#hvac system#pumps#compressor#smart grid#water treatment#water treatment systems#water treatment plant#manufacturing#industrial automation

0 notes

Text

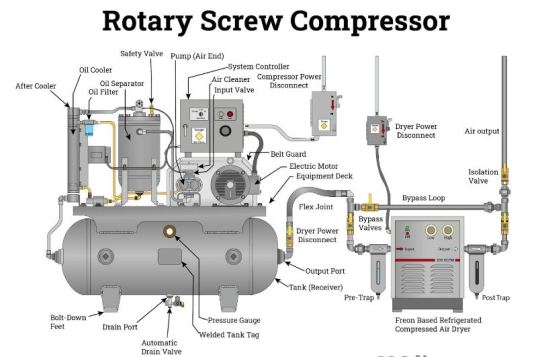

Why Rotary Screw Compressor is the AC/DCs of the Industry?

Rotary Screw Compressor, the not-so-glamorous but incredibly important world of industrial machinery. Specifically, we’re talking about air compressors – those workhorses that keep the factory floors humming and construction sites bustling. But hold on, because just like your grandpa’s record player might seem like a relic compared to today’s streaming services, there’s a new sheriff in town when…

View On WordPress

0 notes

Text

Moonlight Mechanical A/C Service

Address

14500 Blanco Rd Apt #916, San Antonio, TX 78216

Phone

210-903-8107

Email

Website

Welcome to Moonlight Mechanical A/C Service, your local solution for professional AC repair in San Antonio, Texas! We're more than just a service; we're your trusted partners in ensuring you and your family stay comfortable throughout the year. We are your go-to team for prompt, reliable, and expert AC repair in San Antonio, dedicated to making your space comfortable and cool, especially during those scorching summer months. Don't sweat the Texas heat anymore! Call or schedule an appointment with our experienced technicians and let us bring the chill back into your life!

Category: HVAC Contractor Service or Product: AC Repair, Heating Repair

Bus. hrs/day Mon - Thurs: 8 AM–7 PM, Fri: 8 AM–3 PM, Sat - Sun: Closed

No. of employees 5-9

Social Media profiles urls

Google Maps

Youtube

Pinterest

Reddit

#AC Repair#Heating Repair#HVAC in San Antonio#Air conditioning repair#AC troubleshooting#Cooling system maintenance#Emergency AC service#AC compressor repair#HVAC technician#Central air repair#AC unit diagnostics#Freon leak repair#Condenser coil cleaning#Heating system repair#Furnace maintenance

1 note

·

View note

Text

How a Broken Compressor Can Impact Your Cooling Comfort

A well-functioning air conditioning system is essential for maintaining a comfortable indoor environment, especially during hot summer months. The compressor plays a crucial role in the cooling process, and when it malfunctions, it can significantly impact your overall comfort. In this article, we will delve into the various ways a broken compressor can affect your cooling comfort and explore potential solutions.

The Role of the Compressor:

The compressor is the heart of your air conditioning unit, responsible for pressurizing and circulating refrigerant to absorb and release heat. When the compressor is in optimal condition, it ensures efficient cooling throughout your space. However, if it breaks down, the entire cooling process is compromised.

Reduced Cooling Capacity:

One of the most noticeable effects of a malfunctioning compressor is a decrease in cooling capacity. Your AC unit may struggle to reach the desired temperature, resulting in an uncomfortable indoor environment. This reduction in cooling efficiency often leads to increased energy consumption as the system works harder to compensate.

Uneven Temperature Distribution:

A broken compressor can also cause uneven temperature distribution within your home. Certain areas may be cooler than others, creating discomfort and frustration. This inconsistency can be attributed to the compressor's inability to maintain a consistent flow of refrigerant, hindering the even distribution of cool air.

Increased Energy Bills:

As the compressor works harder to compensate for its malfunction, your energy bills are likely to spike. The system's inefficiency can lead to increased energy consumption, causing a financial strain. Addressing compressor issues promptly can help prevent unnecessary energy expenses and keep your cooling costs in check.

Strain on Other Components:

A malfunctioning compressor can place added stress on other components of your air conditioning system. Over time, this strain may lead to further breakdowns, potentially resulting in costly repairs or even the need for a complete system replacement. Regular maintenance and timely repairs are crucial to preventing such cascading issues.

Unusual Noises:

A broken compressor often produces unusual noises, such as banging, clanking, or hissing sounds. These noises can be indicative of internal damage or refrigerant leaks. If you notice any unusual sounds coming from your AC unit, it's essential to seek professional assistance promptly to diagnose and address the issue.

Environmental Impact:

Beyond affecting your comfort, a malfunctioning compressor can have environmental consequences. Refrigerant leaks, a common issue associated with compressor failure, contribute to greenhouse gas emissions, harming the environment. Regular maintenance and prompt repairs are crucial for minimizing the environmental impact of your air conditioning system.

FAQs:

1: What are the signs of a failing compressor?

Answer: Signs of a failing compressor include reduced cooling capacity, uneven temperature distribution, unusual noises, and increased energy bills. If you experience any of these issues, it's advisable to consult with a professional HVAC technician for a thorough diagnosis.

2: Can a broken compressor be repaired, or is replacement necessary?

Answer: In some cases, a broken compressor can be repaired, especially if the issue is identified early. However, if the damage is extensive, a replacement may be more cost-effective. It's crucial to consult with a qualified HVAC technician to determine the most suitable course of action based on the specific circumstances.

By addressing compressor issues promptly and scheduling regular maintenance, you can ensure your air conditioning system operates efficiently, providing optimal cooling comfort while minimizing energy consumption and environmental impact.

0 notes

Text

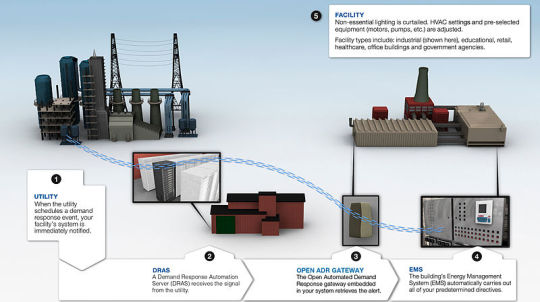

A Comprehensive Guide to HVAC System Diagrams

When understanding the functionality and design of HVAC (Heating, Ventilation, and Air Conditioning) systems, a comprehensive understanding of HVAC system diagrams is essential. By familiarizing yourself with these diagrams, you can grasp the inner workings of HVAC systems, diagnose issues, and effectively communicate with professionals in the field. Whether you are a homeowner, a technician, or simply interested in HVAC systems, this guide will introduce you to the basics of HVAC system diagrams.

Image Source: https://upload.wikimedia.org/

Types of HVAC System Diagrams

Block Diagrams

Block diagrams provide a simplified representation of the overall HVAC system. They illustrate the major components and their connections without going into intricate details. Block diagrams are useful for giving an overview of system functionality.

Pictorial Diagrams

Pictorial diagrams use illustrations of the physical components of an HVAC system. This type of diagram is valuable for understanding the physical layout and positioning of the parts involved.

Schematic Diagrams

Schematic diagrams offer a more detailed representation of an HVAC system. They use symbols and lines to depict the electrical connections and flow of refrigerants, air, and other elements. Schematic diagrams are helpful for troubleshooting and identifying potential issues within the system.

Key Components in HVAC System Diagrams

Air Handling Unit (AHU)

The AHU is responsible for the supply and circulation of conditioned air. It typically consists of a fan, filters, heating and cooling coils, and dampers. The AHU connects to the ductwork, allowing air distribution throughout the building.

Heat Exchangers

Heat exchangers are essential components for heat transfer in HVAC systems. They include the evaporator coil (responsible for cooling the air) and the condenser coil (responsible for heating the air). In some systems, there may also be a heat recovery ventilator, which exchanges heat between the incoming and outgoing air streams.

Thermostat

The thermostat serves as the control center of an HVAC system. It allows the user to set the desired temperature and activates the appropriate heating or cooling components to maintain the preferred climate.

Ductwork

Ductwork is the network of tubes that distributes conditioned air throughout a building. Diagrams will show the layout of the ducts, including the size, shape, and direction of airflow.

Compressor

The compressor handles the circulation of refrigerant within the HVAC system. It pressurizes the refrigerant, causing it to release or absorb heat depending on the system's mode of operation.

Fans and Blowers

Fans and blowers are responsible for moving air through the system. They might be present in the AHU and individual units such as air conditioners or furnaces.

Benefits of Understanding HVAC System Diagrams

Troubleshooting

By analyzing a system diagram, you can identify potential issues or malfunctions. This knowledge will enable you to communicate effectively with HVAC professionals, saving time and ensuring accurate repairs.

Upgrades and Modifications

Understanding HVAC system diagrams will allow you to comprehend the impact of potential upgrades or modifications. You can assess whether an addition or alteration aligns with the existing system's capabilities and requirements.

Energy Efficiency

HVAC system diagrams can help you understand your system's operation and identify opportunities for increased energy efficiency. You can implement changes to decrease energy consumption and lower utility costs by pinpointing areas where energy is wasted.

Conclusion

Becoming familiar with HVAC system diagrams is a valuable skill for homeowners, technicians, and anyone interested in understanding the inner workings of HVAC systems. By studying these diagrams, you can comprehensively understand the major components, their connections, and system functionality. Whether you aim to troubleshoot issues, make informed decisions regarding upgrades, or increase energy efficiency, HVAC system diagrams provide a roadmap to successfully navigate the world of heating, ventilation, and air conditioning.

#HVAC#diagrams#hvac systems#home & lifestyle#hvac services#hvac repair#hvac installation#hvac contractor#acrepair#hvac design#compressor#ductwork#thermostat#Air Handling Unit#hvac solutions#HVAC System Diagrams

0 notes

Text

Co to chłodzenie procesowe i dlaczego jest tak ważne?💨❄️

Chłodzenie procesowe, mające na celu utrzymanie stałej i niezmiennej temperatury, ale także przepływu i ciśnienia medium chłodzącego. Stabilność tych parametrów przekłada się następująco na wydajną, bezpieczną i bezawaryjną pracę Twojego systemu w każdych warunkach.📈🛡️

Doradztwo w sprawie chłodzenia procesów technologicznych z zakresu temperatury od -32 oC, aż do +60 oC. Indywidualne rozwiązania dla Twojej Firmy, Gwarancja satysfakcji.👌🔝

Chcesz wiedzieć więcej na temat chłodzenia procesowego w przemyśle? Przeczytaj Nasz artykuł❗

#chillertech wiktor aptacy#chillertech#klimatyzacja#hvac#chłodnictwo#systemy hvac#biznes#polska#poland#industrial air compressors#cooling system#cooling#refrigeration#refrigeration system#business

0 notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

Green energy law to crack down on HVAC units in new year

The new year will ring in new “green” requirements from the Environmental Protection Agency for heating and air conditioning units that threaten to raise prices and, for the first time, require flammable refrigerants in residential and commercial HVAC units.

The rule has triggered special training requirements for technicians and fire departments as they grapple with the possibility of HVAC systems catching fire, although testing shows the risk is low under most circumstances.

“It’s certainly a unique challenge. We’re trying to balance environmental considerations with fire safety in this particular instance,” said Robin Zevotek, an engineer at the National Fire Protection Association.

The NFPA offers a training course to help the fire service handle the “unique challenges presented by these new refrigerants.” Under certain circumstances, they could catch fire faster than the nonflammable refrigerants the EPA is phasing out.

As of Wednesday, manufacturers will no longer be allowed to build heating, ventilation and air conditioning units that use a nonflammable refrigerant known as R-410A, a hydrofluorocarbon that the EPA says is a greenhouse gas that contributes to climate change if it leaks from equipment into the atmosphere.

Instead, manufacturers must build systems that can accommodate hydrofluoroolefins, a class of slightly flammable unsaturated organic compounds considered less of a danger to the climate than hydrofluorocarbons, which the Biden administration has sought to essentially ban by 2036.

HVAC companies say consumers purchasing equipment that meets the EPA requirements will face price increases.

Some companies anticipate up to 30% price increases in HVAC systems because of the cost of new equipment, added training and more extended installation and servicing times. Companies have also warned that the refrigerant cost is likely to be higher.

The systems will require special leak detection sensors, for example, that can shut down the HVAC compressors and turn on a fan motor to dilute the refrigerant leakage with the air to reduce flammability.

6 notes

·

View notes

Text

Beat the Heat and Chill Out: Affordable Cooling Solutions for Every Home

Introduction

As summer time tactics, the need for triumphant cooling suggestions becomes a growing number of big. With growing temperatures, ensuring your own home stays a comfy haven may well be challenging. Fortunately, there are quite a few low-budget cooling air conditioning installation Redeemed HVAC - HVAC Services Springfield ideas handy that cater to each and every dwelling’s wants. This finished consultant will discover a large number of options, from basic HVAC strategies to ingenious cooling technology. Whether you're looking HVAC installation, air conditioning repair, or actually purchasing for vigour-valuable HVAC systems, we’ll cover it all.

Beat the Heat and Chill Out: Affordable Cooling Solutions for Every Home Understanding Your Cooling Needs What Are Your Specific Requirements?

Before diving into explicit suggestions, it's critical to evaluate your unusual cooling necessities. Do you stay in a small residence or a sprawling family dwelling? Is your neighborhood prone to severe warmness waves, or do you revel in gentle summers? Understanding those points will let you make suggested alternatives approximately which cooling techniques will work easiest for you.

The Importance of Energy Efficiency

Energy-competent HVAC methods no longer handiest in the reduction of your carbon footprint however also prevent check on power debts. Look for instruments with top SEER (Seasonal Energy Efficiency Ratio) ratings whilst in view that air-con install.

Types of Cooling Solutions Available Central Air Systems

Central air con procedures are superb for larger homes. They distribute cool air with the aid of ducts in each room, making them effectual and high quality. However, installing expenditures is also higher than other features.

Advantages:

Even temperature distribution

Quiet operation

Improved indoor air quality

Disadvantages:

Higher prematurely costs

Requires ductwork

Split System HVAC

Split technique HVAC gadgets consist of an out of doors compressor and an indoor unit. They be offering flexibility on account that they can cool multiple rooms independently.

Advantages:

Space-saving design

youtube

Energy-efficient

No ductwork required

Disadvantages:

Can be greater high-priced than window units

Requires official installation

Ductless Mini-Split Systems

Ductless mini-splits are absolute best for residences with out present ductwork. These techniques permit you to cool designated parts efficiently.

youtube

Advantages:

Easy installation

Zoning capabilities

Increases assets value

Disadvantages:

Initial funding could be high

youtube

Aesthetic concerns with wall-fastened units

Choosing the Right HVAC Contractor Finding the Best HVAC Contractors Near You

When it comes to setting up or servicing your heating and cooling methods, settling on the good contractors is very important. Look for lic

2 notes

·

View notes

Text

The Importance of AC Repair and Tune-Up in New York City

As summer temperatures soar in New York City, air conditioning becomes more than a luxury — it’s a necessity. With high humidity levels and concrete buildings trapping heat, a properly functioning AC system can make all the difference between comfort and discomfort. That’s why timely AC repair and tune-up in New York City is essential for both residential and commercial property owners.

Why AC Tune-Ups Matter

Many homeowners overlook regular tune-ups until the system stops working. However, annual maintenance ensures your unit operates efficiently, reduces energy consumption, and extends its lifespan. A professional tune-up involves cleaning coils, checking refrigerant levels, inspecting electrical components, and ensuring your thermostat is working correctly. This proactive approach helps prevent small issues from turning into major repairs.

In a fast-paced city like New York, the last thing you want is a broken air conditioner during a heatwave. With a proper AC tune-up in New York City, you can avoid unexpected breakdowns, improve air quality, and lower your monthly utility bills.

When to Call for AC Repair in NYC

If your AC unit is blowing warm air, making strange noises, or leaking water, it’s time to schedule a repair. Delaying service can worsen the problem and increase costs. Qualified HVAC professionals in New York City can quickly diagnose and fix issues ranging from faulty compressors to clogged filters.

Some of the most common signs that indicate the need for AC repair in New York City include:

Uneven cooling or hot spots in rooms

Higher-than-usual energy bills

Frequent cycling on and off

Unpleasant odors coming from the vents

Addressing these symptoms early ensures that your AC continues to perform when you need it most.

Choosing the Right Service Provider

Given the dense population and unique challenges of New York City’s infrastructure, it’s important to choose an HVAC company experienced in urban environments. Look for licensed professionals who offer emergency services, transparent pricing, and excellent customer reviews. Reliable companies also provide bundled services for AC repair and tune-up in New York City, saving you time and money in the long run.

2 notes

·

View notes

Text

Top 5 Benefits of Using Rubber Gaskets in Industrial Settings

In the demanding world of industrial manufacturing, efficiency and reliability are non-negotiable. From high-pressure pipelines to sanitary processing systems, one seemingly small component plays a critical role in keeping operations running smoothly: the rubber gasket. At California Rubber, we specialize in precision-engineered rubber gaskets designed for performance, durability, and safety across a wide range of applications.

Rubber gaskets offer significant advantages over metal or fiber alternatives in terms of flexibility, resilience, and resistance to extreme conditions. In this blog, we explore the top five benefits of using rubber gaskets in industrial environments.

1. Superior Sealing Capability

The primary function of any gasket is to create a leak-proof seal between two surfaces, and rubber gaskets excel at this. Thanks to their inherent flexibility and compressibility, rubber gaskets can conform to surface irregularities, ensuring a tight seal even in imperfect or worn flange connections.

This superior sealing capability is particularly vital in high-pressure systems or where liquids and gases must be contained with absolute precision. Components like Sanitary Gaskets used in food and beverage manufacturing rely on high-grade rubber to maintain hygiene and prevent leaks under demanding conditions.

Rubber materials such as EPDM, NBR, and silicone are also excellent at maintaining seal integrity across a wide range of temperatures and pressures, making them ideal for dynamic and static applications alike.

2. Chemical and Temperature Resistance

Industrial environments often expose components to aggressive chemicals and extreme temperatures. Rubber gaskets are available in a variety of formulations that offer excellent resistance to these challenges.

EPDM is commonly used for steam and water applications due to its excellent heat and weather resistance.

Nitrile rubber offers superb resistance to oils, fuels, and other hydrocarbons.

Silicone rubber is ideal for high-temperature sealing up to 230°C (446°F).

This adaptability ensures long-term performance without degradation, reducing the frequency of replacements. It’s particularly valuable in environments such as Cannabis Extraction Parts, where chemical exposure is frequent and operational safety is a top concern.

3. Durability and Longevity

Rubber gaskets are known for their excellent wear and fatigue resistance. When properly installed and maintained, they can provide years of reliable service, even in environments with high levels of vibration, pressure fluctuations, or abrasive materials.

This durability not only lowers the total cost of ownership but also contributes to reduced downtime and maintenance cycles. In sectors like brewing, where production schedules are tight and efficiency is key, using high-performance components such as Brewing Gaskets can significantly improve system reliability.

The use of advanced manufacturing techniques like compression molding and injection molding ensures that rubber gaskets meet precise dimensional tolerances for consistent performance.

4. Noise and Vibration Dampening

In addition to sealing, rubber gaskets offer excellent vibration isolation and noise reduction. Their elastic nature absorbs mechanical energy, dampening vibration between metal parts and reducing wear and fatigue on adjacent components.

This feature is particularly useful in dynamic systems such as pumps, compressors, and HVAC systems. Components like aodd pump parts often integrate rubber seals and diaphragms to ensure quieter operation and longer mechanical life.

By minimizing mechanical noise and vibration, rubber gaskets also contribute to safer and more comfortable working environments in industrial facilities.

5. Versatility Across Applications

Rubber gaskets are incredibly versatile, available in a wide variety of shapes, sizes, and materials to suit almost any industrial requirement. Whether you need a standard flange gasket or a custom-molded seal for a unique configuration, rubber provides a flexible solution.

Their usage spans industries including:

Food and beverage processing

Pharmaceuticals and biotechnology

Oil and gas

Automotive and aerospace

Water treatment and chemical processing

Rubber gaskets can also be tailored to meet regulatory and compliance standards such as FDA, NSF, and USP Class VI, depending on the application.

From standard sealing tasks to highly specialized roles, rubber gaskets can be engineered to solve complex challenges efficiently and economically.

Maintenance Tips for Longer Gasket Life

To get the most out of rubber gaskets, consider these simple but effective maintenance tips:

Perform regular visual inspections for signs of wear, cracking, or hardening.

Ensure proper torque is applied during installation to avoid over-compression.

Store spare gaskets in a cool, dry place away from sunlight and ozone sources.

Replace gaskets at the first sign of leakage to prevent downstream damage.

Proactive care will maximize the life span of your gaskets and ensure uninterrupted system performance.

Why Rubber Gaskets Are a Smart Investment

Rubber gaskets are not only a practical solution for sealing and insulation but also a strategic choice for improving operational efficiency. With the right material and design, they reduce maintenance needs, enhance equipment life, and support safe, clean processing environments.

For manufacturers in regulated industries, choosing the correct gasket material is also key to maintaining product quality and compliance. Investing in high-performance rubber gaskets is ultimately an investment in your operation’s reliability and success.

Conclusion

Rubber gaskets offer a powerful combination of sealing performance, chemical resistance, durability, and versatility that make them indispensable in modern industrial settings. At California Rubber, we understand the critical role gaskets play in your operations, and we offer expertly engineered solutions to meet the most demanding requirements.

Whether you're upgrading aodd pump parts, installing FDA-compliant seals in food processing systems, or customizing Brewing Gaskets for specialized production needs, we provide the quality and expertise you can rely on. Reach out today to learn how our custom rubber gasket solutions can optimize your systems and extend the life of your equipment.

2 notes

·

View notes

Text

What is Vapor Compression Cycle and How It Works?

On a scorching summer day, there’s nothing quite like the sweet relief of a cool blast of air conditioning. But have you ever wondered how that magic happens? Ever wondered how your fridge magically pulls coolness out of thin air? It’s not sorcery, folks, but a clever dance of physics called the vapor compression cycle. Today, we’re diving into the world of vapor compression cycles, the hidden…

View On WordPress

0 notes