#Hydraulic Universal Testing Machine

Explore tagged Tumblr posts

Text

To perform tension, compression, bending, and shearing tests on metal and non-metal materials, a hydraulic universal testing machine with an underside-type oil cylinder and four columns is employed. Applications include metallurgy, building, light industry, aircraft, aviation, materials, universities, and scientific research facilities.

#hydraulic universal testing machine#hydraulic universal testing machine price#hydraulic universal testing machine suppliers#hydraulic universal testing machine manufacturer#hydraulic universal testing machine in India#hydraulic testing machine#hydraulic testing machine price#hydraulic testing machine suppliers#hydraulic testing machine in India

0 notes

Text

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine is a digital display unit offers 200 KN test force. Features hydraulic loading with 2 to 100% FS of force measuring range. Designed with 2 columns and leading screws, has oil cylinder underneath work bench for stable performance. Equipped with hand panel for beam movement, metal cover and advance protection system for a reliable performance. With real time display of operating parameters and test curve, it also allows the result printing in excel or word format.

0 notes

Text

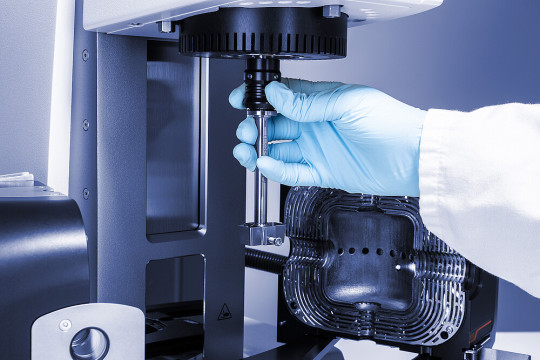

Computerized Universal Testing Machine Front Open with Hydraulic Grip

Computerized universal testing machine with a front-open design and hydraulic grip is a versatile testing instrument used for evaluating the mechanical properties of various materials. This type of machine offers a front-opening configuration, allowing easy sample loading and positioning, while hydraulic grips provide secure and reliable clamping of the test specimens. Consider the maximum load capacity of the testing machine, which determines the range of materials and specimen sizes it can handle. Machines typically have load capacities ranging from a few kilonewtons to several hundred kilonewtons or more, depending on the application requirements.

Universal Testing Machines supplied completed with UTM Software. It has a wide range of applications. A number of materials and metals in different forms and shapes can be tested for a variety of tests like tension, Compression, Transverse, Bend, Shear, Brinell Hardness, etc. Special attachments are also available for testing of flat belts, chain links, wire ropes etc.

Universal Testing Machines have a wide range of applications and number of materials, metals in different form and shapes can be tested for variety of tests like Tension, Compression, Transverse, Bend, Shear, Brinell Hardness etc. Special attachments are also available for testing of Flat Belts, Chain Links, Wire Ropes etc.

Hydraulic grips provide a reliable clamping mechanism for securing the test specimen during testing. The hydraulic system allows for controlled and consistent gripping force application, ensuring accurate and repeatable results.

testing machine, universal testing machine, computerized universal testing machine, universal testing machine with hydraulic, computerized universal testing machine with hydraulic, universal testing machine with front open, universal testing machine with hydraulic front open

#manufacture#industrial equipment#metallurgical#manufacturer#testing#metallographicequipments#testing machine#universal testing machine#front open universal testing machine#hydraulic universal testing machine#computerized universal testing machine#universal testing machine with hydraulic#universal testing machine with front open

1 note

·

View note

Text

From Humidity Chambers to Testing Machines - India’s Expert Equipment Manufacturer

Kant Plastology has established itself as a leader in the field of manufacturing high-quality testing and processing equipment. With a strong focus on innovation and precision, we are dedicated to delivering solutions that meet the diverse needs of industrial, research, and development sectors across India and beyond. Our products are engineered with cutting-edge technology to ensure superior performance and reliability, making us a trusted partner for businesses and institutions.

We take pride in offering a comprehensive range of machinery that caters to different industries, including materials testing, manufacturing, and quality control. Our commitment to customer satisfaction drives us to continuously innovate and create products that help our clients achieve accurate and repeatable results. With strict quality control and advanced manufacturing practices, Kant Plastology ensures that every machine leaving our facility meets the highest industry standards.

Reliable Manufacturing Equipment for Industrial, Research, and Quality Control Needs

One of our standout products is the universal tensile testing machine, designed to deliver precision in evaluating material strength, elasticity, and tensile properties. This machine is vital for industries requiring consistent quality assurance in their production processes. Additionally, as a leading hydraulic press machine manufacturer in India, we offer robust solutions tailored for applications requiring high-pressure operations, ensuring efficiency and durability in every project.

Kant Plastology is also renowned as a humidity chamber manufacturerin India, providing equipment that offers controlled environments for testing materials under various temperature and humidity conditions. Furthermore, as a trusted tensile testing machine manufacturer, we focus on creating customizable solutions that cater to the specific testing needs of our clients.

At Kant Plastology, we believe in building relationships based on trust, quality, and exceptional service. Our goal is to empower businesses with reliable machinery that enhances their operational efficiency and supports their growth. Partner with us today and experience the expertise and dedication that set Kant Plastology apart in the industry.

#tensile testing machine manufacturer#humidity chamber manufacturerin India#hydraulic press machine manufacturer#universal tensile testing machine

0 notes

Note

Is there something that says the animatronics are real in universe that I missed/forgot??

Yup! They are real.

The main plot of FNAF AR is that Fazbear Entertainment partnered with a company called "DLZ Shipping Solutions" to mass produce animatronic models, using recycled parts and chips from old animatronics as a reference. Those new models are then delivered to people who sign up to the Fazbear Funtime Rental Service, also known simply as the Fazbear Funtime Service. During the project, some vintage hardware caused a virus to appear in the system and make the animatronics go haywire.

This is all spelled out in the E-Mails you can receive. There's way too many to describe in detail, you can find them easily in the Freddy Fazbear's Pizza Wiki if you're curious. I'll leave here some of the more notably quotes, showing how DLZ Shipping Solutions designed these new animatronic models (most of these are about Mangle because it just has the most detailed explanation lol):

As a callback to the classics, for a limited time only we are adding to the Eternal Package a recreation of the vintage "Mangle" animatronic!

I've been looking over those reports on the motility tests for the new model and I gotta say I'm a little disturbed. The original was purportedly able to move along the ceiling, and from what I'm seeing here, we're having issues getting our rebuilds to even move on level ground properly.

There's a huge difference between a new model based on the same bipedal chassis and one based on a... A spider? A tripod? The locomotion is completely different, which means the power needs are different, the hydraulic calibrations have to be completely redone, and the CPU has to be switched out for a newer one with a faster baud rate. And then on top of all that, we have to put together this "Controlled Disassembly" feature?

I warned management that reproducing the more exotic endoskeletons would be a problem, and they decided to go ahead and put them on the schedule anyways. They're just going to have to live with the limitations of, you know, basic physics.

Toy Freddy is not safe to go out to the public. The interference happening with the upgraded facial recognition suite risks rendering all the safety functions on the users' handsets useless.

What do your people think, a computer controlled animatronic can somehow get into the holiday spirit and reprogram itself? It's just a machine controlled by a circuit board. It has to do what we tell it to and nothing more.

TL;DR

So, as you can tell from most of that, the animatronics in AR have to obey the laws of physics, have real endoskeletons that people have to put together, require hydraulic calibrations and real CPUs, and can be unsafe to the public. There's also an email mentioning how Springtrap smells but I don't have it on hand and I've already been writing this for way too long so Imma just leave that one for you to look for.

If we wanna include the scrapped emails, then there's also one talking about Bonnie EATING A STRAY CAT. Like, Bonnie, the robot, devouring a kitten whole. Again, I don't have it on hand so you're gonna have to find that yourself. Just thought it was worth mentioning.

I

I completely forgot about that last email you mentioned that was some wild whiplash LMAO

Thanks for the clarification though!! Guess my only question now is how Fazbear Entertainment keeps the cost of this kind of service manageable,,, They can create and ship hundreds of Springtraps to people houses, but having more than one Glamrock Freddy shell in case of emergency? Nahhhhhhhh who needs that

#Chip Chatter#I swear I never hear anyone talking about AR other than the occasional mention of the animatronics in it being real#I forgot there even *were* non-scrapped emails lmao#also by this logic- what the hell is the dark circus DLC#did they just send the player character to another fucking dimension?#hit them over the head and throw them in some weird ass house with the circus animatronics?#That's one way to keep someone quiet ig#I mean that's kinda what they did in TFTPP Help Wanted iirc- so that's not exactly out of character 4 Fazbear Entertainment

7 notes

·

View notes

Text

INDECO Hydraulic Breakers: A Tool Built for Every Job

In the world of construction, mining, and infrastructure development, having the right tools can make all the difference. Whether you're drilling through rock, breaking up concrete, or working on roadways, you need equipment that’s powerful, reliable, and efficient.

That’s exactly what INDECO delivers.

For over 25 years, INDECO has been building hydraulic breakers that professionals trust. From small projects to massive industrial operations, their tools are made to tackle tough tasks with ease. And as they proudly say — “A Tool for Every Job.”

What Makes INDECO Stand Out?

When you’re out on the job, you don’t have time for breakdowns or inefficiency. That’s why INDECO focuses on features that make a real difference in the field:

✅ Fuel Saving Design

Fuel costs can eat into your bottom line fast. INDECO breakers are built to run efficiently, helping you save fuel without sacrificing performance.

✅ Low Operating Pressure

Lower pressure means less strain on your equipment and more life out of your machines. These breakers are gentle on your carrier while still delivering heavy-duty impact.

✅ Simple and Strong

INDECO believes in keeping things simple — and strong. Their tools are designed for easy use and quick maintenance. Less downtime, more productivity.

✅ Built-In Power Greasing

Forget about stopping to lubricate your breaker. INDECO’s automatic greasing system keeps everything running smoothly, which is especially helpful during long hours in mining or roadwork.

✅ Industry-Leading Warranty

You want peace of mind with your purchase — and INDECO offers it. Their strong warranty support shows they stand by their products 100%.

Made for Every Kind of Tough Job

It doesn’t matter if you’re digging tunnels, crushing rock, or resurfacing roads — INDECO tools are up for the challenge. They’re the perfect match for professionals working with:

Rock Tools

Tunneling Tools

Mining Tools

Road Milling Tools

These aren’t just words. INDECO has spent decades understanding what real users need. Their breakers are field-tested, operator-approved, and built to last.

Why Pros Trust INDECO

INDECO’s tools are more than just machines — they’re partners on the job site. Their signature yellow breakers stand tall with strength, visibility, and style.

What makes them even better is their adaptability. Whether you're using a standard excavator or a specialized carrier, INDECO breakers work seamlessly with most machines. That means no complicated setup — just plug in and get to work.

Need proof? Thousands of contractors, mining crews, and road builders across the globe rely on INDECO every day.

Got Questions? We've Got Answers.

❓ Q1: Who uses INDECO hydraulic breakers? A: They're used by contractors, engineers, and operators in mining, tunneling, demolition, and roadwork. If you're using Rock Tools or Mining Tools, these breakers are built for you.

❓ Q2: Are INDECO tools compatible with my excavator? A: Most likely, yes! INDECO breakers are designed to fit a wide range of equipment thanks to their low-pressure requirements and universal mounts.

❓ Q3: How do I keep my breaker in good shape? A: Use the built-in power greasing system and stick to a regular check-up schedule. Also, pair it with original Tunneling Tools or Road Milling Tools for the best results.

Work Smarter. Work Stronger. Work with INDECO.

You don’t just need tools — you need tools that work with you. INDECO understands what it means to put in a hard day’s work. That’s why they’ve created hydraulic breakers that are easy to use, tough enough for extreme conditions, and designed to last.

Whether you're resurfacing highways or drilling deep into bedrock, INDECO gives you the confidence to handle whatever the job throws at you. And with strong service support, a trusted reputation, and cutting-edge design, you’ll know you’re in good hands.

0 notes

Text

What Makes ICCL Female Fittings Ideal for High-Pressure Global Projects?

In the realm of high-pressure systems, there's simply no room for error. Whether we're talking about an oil pipeline in the Middle East, a hydraulic power unit in Europe, or a chemical processing facility in Asia, every single connection has to endure extreme conditions—pressure, temperature, corrosion, and the test of time. That’s precisely why ICCL Female Fittings have become the trusted choice for engineers and project managers around the globe who are tackling critical infrastructure projects across various sectors.

So, what sets ICCL Female Fittings apart in high-pressure applications worldwide? Let’s dive into the features that have earned them a solid reputation across borders.

1. Designed for Extreme Pressure Environments

ICCL Female Fittings are crafted specifically for high-pressure systems where performance is non-negotiable. They are:

Rated to handle high PSI loads in both fluid and gas applications

Engineered to provide leak-proof sealing even with dynamic pressure fluctuations

Compatible with systems like hydraulic machinery, oil & gas pipelines, refineries, and power plants

Each fitting goes through rigorous hydrostatic and pneumatic testing, guaranteeing flawless performance even under the most demanding working pressures. For global projects where failure is simply not an option, ICCL delivers complete peace of mind.

2. Precision Machined Threads for a Secure Fit

One of the most crucial elements of female fittings is their threading. ICCL employs CNC precision machining to ensure:

Perfectly aligned internal threads that fit male connectors from various standards (BSP, NPT, SAE, etc.)

Smooth engagement that prevents cross-threading or loosening

Reliable sealing through multiple connection cycles

This level of precision guarantees a tight, vibration-resistant seal, which is especially vital in high-pressure or high-vibration environments.

3. Material Strength That Endures Global Conditions

From the icy climates of Northern Europe to the blistering deserts of the Middle East, ICCL Female Fittings are constructed from top-quality materials designed for every environment:

Stainless Steel 304/316 – Outstanding corrosion resistance

Brass and Carbon Steel – Perfect for everyday use and hydraulic applications

Special Alloys – Designed to withstand aggressive chemicals or saltwater exposure

Every fitting is carefully chosen and crafted with material integrity at the forefront — minimizing the chances of deformation, leaks, or corrosion over time.

4. Trusted Compliance with Global Standards

At ICCL, we recognize that international projects demand adherence to global standards. That’s why all our female fittings are produced in accordance with key international guidelines:

ISO, DIN, ASTM, SAE, and JIS standards

Materials that comply with RoHS and REACH

Pressure testing and certification available upon request

This commitment makes ICCL fittings universally compatible, ensuring seamless integration into international supply chains and systems.

5. Wide Range of Sizes and Configurations

From standard female connectors to elbows, tees, reducers, and cross fittings — ICCL boasts a diverse product lineup. This versatility empowers engineers and designers to:

Align fittings with specific layouts and unique piping requirements

Reduce the need for adaptors or compromises

Save time and cut down on potential leak points in high-pressure designs

With options for custom sizes and threading, ICCL also caters to clients dealing with non-standard or legacy systems.

6. Proven Performance in Real-World Projects

ICCL Female Fittings aren’t just lab-tested — they’re actively used in real-world projects around the globe, including:

Oil & Gas rigs and refineries

Utilities in high-rise buildings

Water and wastewater treatment facilities

Chemical processing industries

Power plants and renewable energy projects

Their impressive track record of high performance and low failure rates has established ICCL as a trusted supplier in over 30 countries.

7. Corrosion Resistance for Long-Term Reliability

Corrosion can be a silent threat in high-pressure systems. ICCL Female Fittings provide:

Anti-corrosive finishes (Electroplated, Passivated, or PTFE-coated)

Stainless steel options ideal for marine and coastal environments

Chemical-resistant choices for handling harsh industrial fluids

These features are designed to enhance the longevity of the entire system while also cutting down on the total cost of ownership by minimizing maintenance and replacement needs.

8. Easy Installation with Universal Compatibility

High-pressure projects often come with tight deadlines, multilingual teams, and a variety of tools. That’s where ICCL Female Fittings shine, offering:

A tool-friendly design for quick and easy installation

Standardized dimensions and threads for consistency

Error-proof connections that significantly lower the risk of leaks

This user-friendly approach makes them perfect for international contractors racing against the clock.

9. Support and Logistics That Scale Globally

ICCL provides timely global shipping, comprehensive documentation support, and expert technical guidance, making them a go-to partner for EPC contractors, OEMs, and distributors around the world. Their dedicated team ensures you receive the right fittings, in the right sizes, along with the necessary documentation—no matter where your project is located.

Final Thoughts: Designed to Perform. Built to Last. Trusted Worldwide.

ICCL Female Fittings combine engineering excellence, global compatibility, and reliability under pressure. They are the product of decades of expertise, cutting-edge manufacturing, and a steadfast commitment to quality.

If your project requires fittings that can withstand high pressures, corrosive environments, and tight tolerances—and you can’t afford even a moment of failure—then ICCL is the solution you need.

0 notes

Text

Everything You Need to Know About Graduate Marine Engineering (GME) Course

If you're a mechanical engineering graduate aspiring to pursue a career in the maritime industry, then the GME course for merchant navy is your gateway to an exciting and rewarding profession at sea. This one-year postgraduate program is designed specifically for mechanical engineers who want to become certified marine engineers and join the merchant navy.

What Is the GME Course?

The Graduate Marine Engineering (GME) course is a pre-sea training program approved by the Directorate General of Shipping (DGS), Government of India. It is a 12-month residential course that trains mechanical engineering graduates to work as marine engineers onboard merchant navy vessels. Upon successful completion, candidates can join a ship as a trainee marine engineer and begin their journey toward becoming a licensed officer.

Why Choose the Merchant Navy After Mechanical Engineering?

Opting for the merchant navy after mechanical engineering is a popular and lucrative choice. Mechanical engineers already possess a strong foundation in subjects like thermodynamics, fluid mechanics, and machine design—all of which are crucial in marine engineering. The GME course builds on this foundation with maritime-specific training, enabling a smooth transition into shipboard roles.

Key Advantages:

High salary packages in USD for international voyages

Tax-free income in many countries

Opportunities to travel around the world

Fast-track promotions based on performance and experience

Eligibility Criteria

To apply for the GME course, candidates must meet the following criteria:

A B.E./B.Tech degree in Mechanical Engineering or Naval Architecture from a recognized university

Minimum 50% marks in final year and 50% in English in 10+2 or graduation

Age should not exceed 28 years at the time of course commencement

Medically fit as per DG Shipping norms

Syllabus and Training Modules

The GME course curriculum includes both theoretical and practical training aligned with International Maritime Organization (IMO) standards. Key topics covered include

Marine engines and auxiliaries

Naval architecture and ship construction

Marine electrical systems

Marine hydraulics and pneumatics

Fire prevention and firefighting

Personal safety and social responsibility (PSSR)

Engine room simulator training

Hands-on training in ship-like environments, workshops, and engine room simulators helps bridge the gap between academic knowledge and onboard requirements.

Admission Process

Admission to the GME course for merchant navy typically involves

Filling out online or offline applications through recognized institutes

Passing an entrance test (if applicable)

Clearing a personal interview and medical examination

Final selection based on merit and seat availability

Top institutions offering GME courses include:

IMS Goa

Anglo-Eastern Maritime Academy

Great Eastern Institute of Maritime Studies (GEIMS)

Samundra Institute of Maritime Studies

HIMT College

Placement and Career Growth

Once the GME course is completed, candidates receive a Certificate of Competency (CoC) as a Trainee Marine Engineer. You can then join merchant navy ships and gain sea-time experience. After completing required sea time (usually 6 months), you can appear for the MEO Class IV exams conducted by the Maritime Authorities. With this license, you can become a 4th Engineer and climb up the ranks to Chief Engineer over time.

Reputed shipping companies like Maersk, NYK Line, MSC, and Anglo-Eastern frequently hire GME graduates from top institutes.

Conclusion

The merchant navy after mechanical engineering is a highly attractive career option for those who seek adventure, excellent pay, and professional growth. The GME course for merchant navy serves as the essential bridge between your engineering degree and a successful maritime career. With proper training, certifications, and dedication, you can set sail toward a bright future in the global shipping industry.

#graduate marine engineering course#engine room simulator course#best marine engg colleges in india#govt marine engineering colleges in india#gme course for merchant navy

0 notes

Text

Common Tests Conducted in Geo Textiles Testing Labs Explained

In modern civil engineering and construction projects, geo textiles are indispensable materials used for soil stabilization, erosion control, filtration, drainage, and reinforcement. Given their critical role in ensuring structural integrity and environmental protection, geo textiles must meet strict quality and performance standards before deployment. This is where geo textiles testing becomes essential.

Testing labs worldwide conduct a variety of tests on geo textiles to verify their mechanical, hydraulic, and environmental properties. These tests help engineers, manufacturers, and contractors ensure the geo textile materials they use will perform reliably under the demanding conditions of construction sites.

In this blog, we explain the most common tests conducted in geo textiles testing labs, what each test measures, and why it’s important for overall material performance.

What Are Geo Textiles?

Geo textiles are permeable fabrics made from synthetic or natural fibers designed to interact with soil and rock. They serve multiple functions such as separation, filtration, drainage, reinforcement, and protection in civil engineering applications including roads, embankments, retaining walls, landfills, and erosion control.

Why Testing Geo Textiles Matters

Geo textiles must withstand mechanical stresses, harsh environmental exposure, and chemical interaction with soils or water. Improperly tested or substandard geo textiles can lead to project failures such as soil erosion, structural collapse, or waterlogging. Therefore, testing labs evaluate geo textiles through standardized methods to certify their quality and performance.

Common Tests Conducted in Geo Textiles Testing Labs

1. Tensile Strength Test

Purpose: Measures the maximum force a geo textile can endure when stretched before breaking.

Why It Matters: Tensile strength indicates the material’s ability to withstand soil pressure and mechanical loads during installation and service.

How It’s Done: Using a universal testing machine, a specimen of the geo textile is pulled until it breaks, recording the force and elongation.

2. Elongation Test

Purpose: Measures how much a geo textile stretches under tensile load before failure.

Why It Matters: Elongation affects the fabric’s ability to deform without breaking, important for applications requiring flexibility.

Method: Often conducted alongside tensile tests, elongation is expressed as a percentage increase from the original length.

3. Tear Resistance Test

Purpose: Assesses the material’s ability to resist propagation of tears once initiated.

Why It Matters: Geo textiles can be exposed to sharp objects or rough handling; tear resistance ensures durability during installation and use.

Procedure: A pre-cut specimen is subjected to controlled tearing force, usually via trapezoid or tongue tear methods.

4. Puncture Resistance Test

Purpose: Evaluates resistance to penetration by sharp or pointed objects.

Why It Matters: Geo textiles often lie beneath rocks or debris; puncture resistance ensures they remain intact under such conditions.

How It Works: A standardized probe is pushed through the fabric, and the force required is measured.

5. Water Permeability Test

Purpose: Measures the flow rate of water through the geo textile.

Why It Matters: Important for filtration and drainage functions — the fabric must allow water to pass while retaining soil particles.

Method: Water is passed through the fabric under a set hydraulic head or pressure, and flow rate is recorded.

6. Apparent Opening Size (AOS) Test

Purpose: Determines the effective pore size of the geo textile.

Why It Matters: AOS dictates which size soil particles the fabric will retain, crucial for preventing soil migration and erosion.

Procedure: Testing involves passing a range of sieve sizes through the fabric and measuring retention.

7. UV Resistance Test

Purpose: Assesses how well the geo textile withstands degradation from ultraviolet radiation.

Why It Matters: Exposure to sunlight during storage and installation can weaken synthetic fibers; UV resistance ensures longevity.

Test Method: Samples are exposed to artificial UV light for a set duration, then tested for changes in tensile strength and elongation.

8. Chemical Resistance Test

Purpose: Evaluates the geo textile’s ability to resist deterioration from chemicals commonly found in soils and water (e.g., acids, alkalis, oils).

Why It Matters: Ensures fabric integrity in chemically aggressive environments like landfills or industrial sites.

How It’s Performed: Samples are immersed in chemical solutions for specified periods, then retested for mechanical properties.

9. Water Absorption Test

Purpose: Measures how much water the geo textile absorbs when submerged.

Why It Matters: High absorption may affect the fabric’s weight, flexibility, and hydraulic performance.

Procedure: The dry weight is compared to the weight after soaking in water for a specific time.

10. Thickness and Mass per Unit Area Test

Purpose: Measures the fabric thickness and weight per square meter.

Why It Matters: These physical properties influence performance characteristics like strength, permeability, and durability.

Method: Thickness is measured using mechanical or digital gauges; mass is calculated from weighed fabric samples.

How These Tests Support Construction Projects

Quality Assurance: Confirm geo textiles meet design specifications and international standards (ASTM, ISO, AASHTO).

Safety: Prevent material failure that could jeopardize structural integrity or cause environmental damage.

Regulatory Compliance: Many construction projects require certified test reports to meet local and international regulations.

Material Selection: Helps engineers choose the right geo textile for specific soil, load, and environmental conditions.

Cost Efficiency: Ensures durability and reduces maintenance or replacement costs.

International Standards Guiding Geo Textile Testing

Common test methods used in labs generally follow established standards such as:

ASTM (American Society for Testing and Materials) – widely used for tensile strength, permeability, UV resistance, etc.

ISO (International Organization for Standardization) – harmonizes test methods globally for consistent results.

AASHTO (American Association of State Highway and Transportation Officials) – essential for highway and transportation projects.

Choosing a Reliable Geo Textiles Testing Lab

When selecting a testing lab for geo textiles, consider:

Accreditation: ISO/IEC 17025 accreditation ensures lab competence and quality management.

Comprehensive Testing: Ability to perform all relevant mechanical, hydraulic, chemical, and environmental tests.

Experienced Staff: Skilled technicians and engineers for accurate testing and interpretation.

Clear Reporting: Detailed test reports with interpretations for easy decision-making.

Fast Turnaround: Timely results to keep projects on schedule.

Conclusion

Geo textiles are vital components in infrastructure projects, offering solutions to complex geotechnical challenges. However, their effectiveness depends heavily on rigorous testing that ensures durability, strength, permeability, and environmental resistance.

Geo textiles testing labs conduct a suite of standardized tests—ranging from tensile strength and tear resistance to UV and chemical resistance—that collectively guarantee material quality and suitability. Understanding these common tests helps manufacturers improve products, engineers select the right materials, and contractors ensure project success.

0 notes

Text

SSC JE 2025: Complete Guide with Syllabus for Civil and Electrical Engineering

The Staff Selection Commission (SSC) conducts junior engineer (JE) exam every year for recruitment of engineers to different departments under India's government. The SSC JE 2025 exam is expected to follow a similar pattern as previous years, but with updated courses and guidelines. This article provides detailed information on SSC JE 2025, including the SSC JE 2025 course, qualification and specific details for civil engineering and electrical engineering branches.

What is SSC JE 2025?

SSC JE 2025 is a competitive examination conducted by the Staff Selection Commission to recruit Junior Engineers in government departments like CPWD, MES, BRO, and others. The exam is open for candidates with diplomas or degrees in Civil, Mechanical, or Electrical Engineering.

This is a golden opportunity for aspiring engineers to secure a stable job in the central government with good pay, job security, and career growth.

SSC JE 2025 Eligibility Criteria

Before applying, candidates must ensure they meet the basic eligibility:

Nationality: Must be a citizen of India.

Age Limit: Varies by department, typically between 18 to 32 years. Relaxations apply for reserved categories.

Educational Qualification: Diploma or degree in Civil, Mechanical, or Electrical Engineering from a recognized university.

SSC JE 2025 Exam Pattern

The SSC JE exam is conducted in two phases:

Paper 1 (Objective Type)

General Intelligence and Reasoning – 50 marks

General Awareness – 50 marks

Part A (Civil) or Part B (Electrical/Mechanical) – 100 marks Total: 200 marks | Duration: 2 hours

Paper 2 (Descriptive Type)

Subject-specific (Civil/Electrical/Mechanical) – 300 marks Duration: 2 hours

SSC JE 2025 Syllabus Overview

The SSC JE 2025 syllabus is divided into common subjects and branch-specific subjects. While Paper 1 tests general reasoning and awareness, Paper 2 focuses purely on technical knowledge.

Let’s look at the detailed syllabus for Civil and Electrical Engineering.

SSC JE 2025 Civil Engineering Syllabus

Paper 1 – General Sections : SSC JE 2025 Civil Engineering Syllabus

General Intelligence & Reasoning

Analogies, similarities, differences

Space visualization

Problem-solving, analysis, judgment

Arithmetical reasoning, syllogisms

General Awareness

Current events

India and its neighboring countries

History, culture, geography, economic scene

Scientific Research and Indian Constitution

Paper 1 – Civil Engineering

Building Materials

Estimating, Costing, and Valuation

Surveying

Soil Mechanics

Hydraulics

Irrigation Engineering

Transportation Engineering

Environmental Engineering

Paper 2 – Civil Engineering (Descriptive)

RCC Design

Steel Design

Theory of Structures

Concrete Technology

Water Supply and Sanitation

Highway Engineering

Construction Management

CPM and PERT

Fluid Mechanics

Building Planning and Drawing

SSC JE 2025 Electrical Engineering Syllabus

Paper 1 – General Sections

(Same as above for General Intelligence & Reasoning and General Awareness)

Paper 1 – Electrical Engineering

Basic Concepts of Electrical Engineering

Circuit Law (Ohm’s Law, Kirchhoff’s Law)

Magnetic Circuit

AC Fundamentals

Measurement and Measuring Instruments

Electrical Machines

Fractional Kilowatt Motors and Single Phase Induction Motors

Generation, Transmission, and Distribution

Estimation and Costing

Utilization of Electrical Energy

Basic Electronics

Paper 2 – Electrical Engineering (Descriptive)

Detailed theory of Electrical Machines (DC, AC)

Power Systems and Protection

Transmission Lines and Cables

Control Systems

Electrical Measurements

Power Electronics and Drives

Microprocessors and Digital Electronics

Energy Efficiency and Renewable Sources

Circuit Analysis using Theorems

Tips to Prepare for SSC JE 2025

Understand the Syllabus: Go through the SSC JE 2025 syllabus carefully and mark high-weightage topics.

Follow a Study Schedule: Make a realistic timetable covering theory, practice, and revision.

Solve Previous Year Papers: Analyze past questions to understand the pattern and difficulty level.

Mock Tests: Attempt regular mock tests to improve time management and accuracy.

Use Standard Books: Refer to trusted authors and publications. For Civil, books by EA Publication.

Why SSC JE is a Good Career Option?

Government Job Security: Permanent position under central government departments.

Attractive Pay Scale: Basic pay of Level 6 (Rs. 35,400 – Rs. 1,12,400) plus allowances.

Work-Life Balance: Regular working hours with job satisfaction.

Promotions & Growth: Opportunity to rise to senior technical roles.

Conclusion

The SSC JE 2025 exam offers a prestigious and safe career path for civilian and electric engineers. With the right preparation strategy, SSC JE 2025 Understanding the course and continuous practice, candidates can clean the exam with flying colors.

Be sure to stay up to date with official information from the SSC website and start your preparations to stay ahead of competition quickly. Whether you target the SSC JE 2025 Civil Engineering Plan or SSC JE 2025 Electrical Syllabus, structured preparation is the key to success.

FAQs

Q1. What is the age limit for SSC JE 2025?

The general age limit is 18 to 32 years. However, it may vary depending on the department and category of the candidate. Age relaxation is applicable as per government rules.

Q2. Can diploma holders apply for SSC JE 2025?

Yes, candidates with a diploma in Civil, Electrical, or Mechanical Engineering from a recognized institute can apply.

Q3. Is there any interview in SSC JE 2025?

No, there is no interview. Selection is based on the marks obtained in Paper 1 and Paper 2.

Q4. How many attempts are allowed for SSC JE?

There is no limit on the number of attempts, but candidates must fulfill the age and eligibility criteria.

Q5. Is the SSC JE 2025 syllabus the same for all branches?

No. While the general subjects are the same in Paper 1, the technical syllabus differs for Civil, Mechanical, and Electrical Engineering.

#SSC JE 2025#SSC JE 2025 Syllabus#SSC JE 2025 Civil Engineering Syllabus#SSC JE 2025 Electrical Engineering Syllabus

0 notes

Text

Hydraulic Universal Testing Machines for Quality Control

Discover top-quality hydraulic universal testing machines, designed for precision material testing. Our machines are ideal for testing a variety of materials like metals, plastics, and composites. Enhance your testing process with reliable equipment built for the toughest applications.

Follow us for more updates and product insights.

0 notes

Text

The Function of a Compression Testing Machine

Considering checking things prior to purchasing is one of the ways of behaving that grew consequently in us. From vegetables to the test drive of vehicles, there are various models where we judge things in different boundaries prior to getting them. Then, at that point, what befalls us when we buy a property or construct a house for us? Isn’t it important to check the nature of the unrefined substance utilized? Indeed! It is fundamental. Furthermore, consequently to check the nature of the material, a Compression Testing Machine is utilized

#Compression Testing Machine#hydraulic machines#cement testing equipment#hydraulic machine#servo hydraulic universal testing machine#universal testing machine

0 notes

Text

Hydraulic Universal Testing Machine

Hydraulic Universal Testing Machine LB-10HUT is a digital display unit offers 200 KN test force. Features hydraulic loading with 2 to 100% FS of force measuring range. Designed with 2 columns and leading screws, has oil cylinder underneath work bench for stable performance. Equipped with hand panel for beam movement, metal cover and advance protection system for a reliable performance. With real time display of operating parameters and test curve, it also allows the result printing in excel or word format

0 notes

Text

Why Smart Parts Exports is Your Trusted Source for Mahindra Genuine Parts

In today’s fast-paced and highly aggressive automotive production, maintaining the staging, well-being, and longevity of your vehicle is more important than ever. The footing of that reliability goes about using the right spare parts. For Mahindra vehicle owners, this measure fix on Mahindra Genuine Parts—components specifically designed and manufactured to meet the original engineering degree of your vehicle. These parts guarantee seamless rapport, superior durability, and optimal performance under all driving conditions.

At Smart Parts Exports, we understand how testing genuine parts are to safeguard your Mahendra running smoothly. That’s why we are committed to provide only 100% authentic Mahindra spare parts to purchasers in all directions the world. With our global reach, substantial statement, and deep manufacturing expertise, we have one of the most trusted handles in the business. Whether you're carrying a personal vehicle or managing an entire fleet, count on us for quality, reliability, and complete customer satisfaction.

The Importance of Using Mahindra Genuine Parts

Mahindra is a brand known for constructing bumpy, strongly made, and high-performance vehicles suitable for both urban and off-road use. From SUVs and private enterprise vehicles to tractors, Mahindra's portfolio is multiple and widely used across continents. Anyway, keeping up the showing of these vehicles depends significantly on the use of Mahindra genuine spare parts.

Genuine parts are developed alongside Mahindra vehicles to ensure perfect agreement and seamless meshing. These parts undergo studious quality checks, ensuring they meet the high standards set by the manufacturer. In contrast, feigned or non-genuine parts may compromise machine recital, fuel efficiency, and even safety.

Why Choose Smart Parts Exports?

Smart Parts Exports has positioned itself as a global leader in automotive spare parts distribution. With a solid reputation for delivering Mahindra spare parts across continents, we stand out for several reasons:

Authenticity Guaranteed Every part you order from Smart Parts Exports is 100% genuine. We source all our Mahindra genuine parts directly from authorized distributors or the manufacturer, eliminating the risk of forged or substandard elements.

Wide Range of Parts Whether you're looking for engine components, suspension parts, brake systems, electricals, or body parts, our catalog covers an extensive range of Mahindra parts for both old and new vehicle models.

Global Reach From India to Africa, the Middle East to Latin America, Smart Parts Exports hand over high-quality Mahindra spare parts to purchasers across the universe. Our logical logistics and shipping network ensure timely deliveries no matter where you are located.

Competitive Pricing While genuine parts can often be big-budget, we work hard to offer the best practicable charge to our purchaser without compromising on quality. Our direct partnerships and large volumes allow us to keep costs low and pass on the decrease.

Exceptional Customer Support Our team is a collection of automotive experts who can help you identify the perfect Mahindra genuine spare parts for your vehicle. Whether you're a garage owner, fleet operative, or an individual Mahindra owner, we offer personalized support every step of the way.

Applications of Mahindra Parts

Mahindra vehicles are used in a variety of supplication, counting transportation, agriculture, and logistics. Each application puts unique stress on disparate vehicle arrangement. For example, tractors may have experience on their hydraulic and engine components, while commercial vehicles might stand in need of frequent replacements of brake pads or clutch kits.

Using Mahindra genuine parts ensures that the replacing integrant can hold out against the pressure of the job. Whether it's a Bolero, Scorpio, XUV500, or a Mahindra tractor, Smart Parts Exports has the right parts to keep your vehicle running like new.

A Long-Term Investment in Performance and Safety

Choosing Mahindra genuine spare parts is not just about protecting your vehicle on the road today—it’s about safeguarding your financing for years to come. Genuine parts extend the life of your vehicle, improve fuel efficiency, and make compact the probability of future breakdowns.In addition, using verified parts helps keep up the resale value of your Mahindra vehicle, which can be significantly impacted by the use of substitute or unsuited parts.

Conclusion

When it comes to sourcing Mahindra spare parts, there’s no free space for settlement. At Smart Parts Exports, we combine reliability, authenticity, and affordability to deliver the distinctly best in Mahindra parts to buyers around the world. Whether you’re managing a fleet, running a workshop, or revenue care of your personal Mahindra vehicle, trust us to provide the right solutions with the right parts—every time.

Choose Smart Parts Exports for all your Mahindra genuine parts needs and experience the difference that quality makes.

0 notes

Text

#frontopenwithhydraulicgripscomputerizeduniversaltesting machine#manufacturer#supplier#fmi#finemanufacturing

0 notes

Text

How to Maintain and Calibrate a Universal Testing Machine for Accurate Results

A Universal Testing Machine (UTM) is a crucial piece of equipment used in various industries, including manufacturing, construction, and research, to test the mechanical properties of materials. Whether performing tensile, compression, flexural, or shear tests, the accuracy of a UTM is essential for ensuring reliable data and compliance with industry standards.

To maintain consistent and accurate results, regular maintenance and calibration are necessary. This article explores the best practices for maintaining and calibrating a Universal Testing Machine, ensuring optimal performance and longevity.

Why Maintenance and Calibration Are Essential

Over time, UTMs can experience wear and tear, affecting their precision, load accuracy, and test repeatability. Factors such as environmental conditions, improper handling, and mechanical stress can lead to inaccurate measurements.

Regular maintenance and calibration ensure:

Accurate test results for quality control and research.

Compliance with industry standards such as ASTM, ISO, and EN.

Prolonged lifespan of the UTM, reducing long-term operational costs.

Safety for operators, preventing sudden failures during testing.

Routine Maintenance of a Universal Testing Machine

Proper maintenance of a UTM involves regular inspections, cleaning, lubrication, and software updates. Below are key steps to keep your machine in excellent working condition.

1. Regular Visual Inspection

Perform a visual check before and after each testing session. Look for:

Loose bolts, screws, and connections that may affect stability.

Cracks or deformations in grips, load cells, and fixtures.

Unusual noises during operation, which may indicate mechanical wear.

Hydraulic leaks in systems using hydraulic power.

2. Cleaning and Lubrication

Wipe down machine surfaces after each use to prevent dust buildup.

Clean lead screws and ball screws using lint-free cloths and manufacturer-approved solvents.

Apply lubricants to moving parts (as recommended by the manufacturer) to prevent friction-related wear.

3. Checking Load Cells and Sensors

The load cell is the heart of a UTM, converting force into measurable data. To ensure accuracy:

Avoid exceeding load limits, which can damage the load cell.

Store load cells in a stable, temperature-controlled environment.

Check for sensor drift or deviations in readings over time.

4. Software Updates and Functionality Checks

Keep testing software up to date to benefit from improvements and bug fixes.

Verify that data acquisition systems are properly connected and recording values accurately.

Perform sample test runs to check for inconsistencies.

5. Environmental Control

Maintain stable room temperature and humidity levels to prevent expansion/contraction of machine components.

Keep the UTM free from vibrations and excessive air currents, which may influence readings.

How to Calibrate a Universal Testing Machine

Calibration is the process of verifying and adjusting the machine’s accuracy by comparing its output to a known standard. Calibration should be performed:

At least once a year (or more frequently for critical applications).

Whenever the machine is relocated to a new environment.

After major repairs or part replacements.

Step-by-Step Calibration Process

1. Verify Calibration Standards

Before beginning, ensure that calibration is performed using certified reference standards that comply with:

ASTM E4 for force calibration.

ISO 7500-1 for verification of static uniaxial testing.

ISO 9513 for extensometer calibration.

2. Prepare the Machine for Calibration

Ensure the machine is clean and free from obstructions.

Warm up the system for 30-60 minutes to stabilize sensors.

Position the load cell and crosshead in a neutral state.

3. Conduct Load Verification

Apply a known reference weight or force to the load cell.

Compare displayed results with the certified reference values.

Adjust calibration settings if deviations exceed allowable tolerance limits.

4. Verify Crosshead Movement and Displacement Sensors

Use a certified displacement gauge to check crosshead travel.

Compare measured displacement vs. actual displacement.

Adjust settings if any significant error is detected.

5. Test Repeatability and Linearity

Perform multiple load tests at different force levels.

Ensure that readings are consistent across different trials.

Check for linearity by plotting results and verifying deviations.

6. Document Calibration Data

Record all measurements before and after adjustments.

Generate a calibration certificate detailing:

Load cell accuracy.

Displacement sensor accuracy.

Testing conditions.

Many companies opt for third-party calibration services accredited by ISO/IEC 17025, ensuring traceability to national metrology institutes.

Common Calibration and Maintenance Mistakes to Avoid

Skipping Routine Checks – Minor issues, if ignored, can lead to major failures.

Using Incorrect Load Standards – Always use certified weights and reference materials.

Failing to Recalibrate After Relocation – Moving a UTM can impact its alignment and accuracy.

Overloading the Load Cell – This can cause permanent deformation and inaccurate readings.

Ignoring Software Updates – Outdated software may cause data errors and test inconsistencies.

Conclusion

Maintaining and calibrating a Universal Testing Machine is critical for ensuring accurate, reliable, and repeatable test results. Proper care involves routine inspections, cleaning, lubrication, and software checks, while regular calibration ensures compliance with industry standards.

By following these best practices, businesses can maximize the lifespan of their UTM, improve testing accuracy, and maintain compliance with regulatory requirements. Investing in proper maintenance and calibration ultimately leads to better quality control, improved research data, and safer products across various industries.

0 notes