#IEC Sockets and Connectors

Explore tagged Tumblr posts

Text

IEC power connectors are a standardized set of electrical connectors and plugs widely used to connect different electrical and electronic devices to power sources. These connectors are crafted to provide safety, compatibility, and user convenience across various applications. Get IEC sockets and connectors online at www.linvoxcorp.com

0 notes

Text

How to Choose the Right Industrial Plug and Socket for Your Business

Electrical equipment is essential to many businesses, whether for manufacturing, construction, or other industrial applications. Choosing the right industrial plug and socket for your business is crucial to ensure that your equipment runs smoothly and safely. With so many options available in the market, it can be challenging to pick the right one for your specific needs. Factors such as voltage, current, and frequency requirements, as well as environmental and safety considerations, all play a role in selecting the right plug and socket. As an expert in industrial equipment, we understand the importance of choosing the right plug and socket and can guide you through the process to ensure that your business operates safely and efficiently. In this article, we'll explore the key factors you need to consider when choosing the right industrial plug and socket for your business.

Understanding the Different Types of Industrial Plugs and Sockets

Before we dive into the factors you need to consider when selecting the right industrial plug and socket for your business, it's essential to understand the different types of plugs and sockets available in the market. There are several types of industrial plugs and sockets available, including:

BS EN 60309 (IEC 60309) Plugs and Sockets

BS EN 60309 (IEC 60309) plugs and sockets are commonly used in industrial and commercial applications, with a wide range of options available for different power ratings, voltages, and frequencies. They are designed to be robust, reliable, and easy to use, with a range of locking mechanisms available to ensure a secure connection.

CEE Plugs and Sockets

CEE plugs and sockets are commonly used in Europe and are similar to BS EN 60309 (IEC 60309) plugs and sockets, with a range of options available for different power ratings, voltages, and frequencies. They are designed to be robust, reliable, and easy to use, with a range of locking mechanisms available to ensure a secure connection.

NEMA Plugs and Sockets

NEMA plugs and sockets are commonly used in North America and are similar to BS EN 60309 (IEC 60309) plugs and sockets, with a range of options available for different power ratings, voltages, and frequencies. They are designed to be robust, reliable, and easy to use, with a range of locking mechanisms available to ensure a secure connection.

Understanding the different types of plugs and sockets available is essential when selecting the right one for your business. Let's explore the key factors you need to consider when choosing an industrial plug and socket.

Factors to Consider When Choosing an Industrial Plug and Socket

When selecting an industrial plug and socket, there are several factors you need to consider to ensure that it is the right fit for your business's needs. These factors include:

Voltage and Current Requirements

One of the most critical factors to consider when selecting an industrial plug and socket is the voltage and current requirements. You need to ensure that the plug and socket you select can handle the voltage and current that your equipment requires to operate safely and efficiently. If you select a plug and socket that cannot handle the voltage and current required, it can lead to equipment damage or even pose a safety risk to your employees.

IP Ratings and Environmental Factors

Another crucial factor to consider when selecting an industrial plug and socket is the environmental factors that your equipment will be exposed to. If your equipment will be exposed to harsh environments, such as extreme temperatures, moisture, or dust, you need to choose a plug and socket with a high IP rating to ensure that it can withstand these conditions. IP ratings indicate the level of protection provided by the plug and socket against dust and water penetration.

Durability and Reliability

Durability and reliability are also important factors to consider when selecting an industrial plug and socket. You need to ensure that the plug and socket you select can withstand the rigors of daily use in an industrial setting. A plug and socket that is not durable or reliable can lead to equipment downtime, which can have a significant impact on your business's productivity and profitability.

Compatibility with Equipment and Machinery

Compatibility with your equipment and machinery is another important factor to consider when selecting an industrial plug and socket. You need to ensure that the plug and socket you select is compatible with your equipment and machinery to ensure a secure and reliable connection. If the plug and socket are not compatible, it can lead to equipment damage or even pose a safety risk to your employees.

Safety Considerations

Safety is always a top priority in an industrial setting, and selecting the right industrial plug and socket is no exception. You need to ensure that the plug and socket you select meets all safety requirements and standards. Look for plugs and sockets that have been tested and certified by reputable organizations to ensure that they meet safety standards.

Common Mistakes to Avoid When Choosing Industrial Plugs and Sockets

When choosing an industrial plug and socket, there are several common mistakes that businesses make that can lead to equipment damage, safety risks, and decreased productivity. Avoid these mistakes to ensure that you select the right plug and socket for your business:

Choosing the Wrong Voltage and Current Ratings

Choosing a plug and socket with the wrong voltage and current ratings is a common mistake that businesses make. Ensure that you select a plug and socket that can handle the voltage and current required by your equipment.

Ignoring Environmental Factors

Ignoring environmental factors can lead to plug and socket failure and equipment damage. Ensure that you select a plug and socket with a high IP rating if your equipment will be exposed to harsh environments.

Sacrificing Durability and Reliability for Cost

Choosing a plug and socket based solely on cost can lead to equipment downtime and decreased productivity. Ensure that you select a plug and socket that is durable and reliable to ensure that it can withstand daily use in an industrial setting.

Failing to Check Compatibility

Failing to check compatibility with your equipment and machinery can lead to plug and socket failure and safety risks. Ensure that you select a plug and socket that is compatible with your equipment to ensure a secure and reliable connection.

Conclusion and Recommendations for Choosing the Right Industrial Plug and Socket for Your Business

Choosing the right industrial plug and socket for your business is crucial to ensure that your equipment runs smoothly and safely. When selecting a plug and socket, consider factors such as voltage and current requirements, environmental factors, durability and reliability, compatibility with equipment and machinery, and safety considerations. Avoid common mistakes such as choosing the wrong voltage and current ratings, ignoring environmental factors, sacrificing durability and reliability for cost, and failing to check compatibility. By following these guidelines, you can select the right industrial plug and socket for your business, ensuring a safe and efficient operation.

Also Read:

Industrial Plug and Sockets Manufacturing Company in Delhi, India

#industrialplugs#IndustrialSockets#IndustrialPlugandSockets#PlugsandSockets#connector#Industrial Panel Sockets#Industrial Wall Socket#Interlock Unit#Wall & Panel Inlet#Schuko Plug & Socket#CEE Plugs and Sockets#IEC 60309 Plugs and Sockets#NEMA Plugs and Sockets

0 notes

Text

Electrical Accessories Quality Inspection

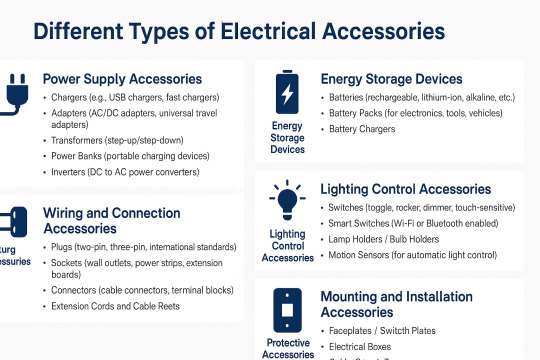

Electrical accessories include a wide range of components such as switches, sockets, plug, circuit breakers, cable lugs, terminals, conduits, and more.

If you are importing electrical accessories, it is always crucial to implement robust quality control management at the factories to minimize risks associated with safety failures and quality defects. Third-party on-site quality inspection at factories is an essential part of quality control management.

GIS Inspection (General Inspection Service) is a global provider in electrical accessories quality control inspection services. To ensure your electrical accessories products are safe and compliant, book a third-party inspection service today.

Book now

Content

Electrical Accessories Quality Control Inspection

The Importance of Electrical Accessories Inspection

The Different Types of Electrical Accessories We Inspect

Types of Third-party Electrical Accessories Quality Control

Essential Electrical Accessories Inspection Checklist during an onsite Inspection

International IEC Electrical Standards for Electrical Accessories

GIS Inspection for you Electrical Accessories Quality Control

Electrical Accessories Quality Control Inspection

GIS Inspection has served the needs of the electrical accessories industry through a wide range of quality assurance solutions for 20 years.

GIS Inspection continually adapts to changes in the electrical accessories industry by enhancing our existing quality solutions, expertise and methods. GIS Inspection aims to guarantee the quality of electrical accessories and create a trustful environment between buyers and manufacturers.

GIS Inspection’s range of quality assurance and quality control services for electrical accessories allows customers to solve non-conformities at each step of the production process and to ensure a high level of system compliance and stability.

Whether our clients are looking to optimize their quality management systems, improve the quality performance of their factories or suppliers, or control product quality, it is essential to demonstrate a high level of expertise and reliability.

The Importance of Electrical Accessories Inspection

Electrical accessories—including chargers, batteries, adapters, transformers, plugs, sockets, switches, and lamp holders—play a critical role in ensuring the safety, functionality, and reliability of electrical systems in both residential and commercial environments.

Electrical accessories that are poorly manufactured or defective can pose serious risks, such as short circuits, electric shocks, overheating, or even fire hazards. Quality inspection helps identify faulty insulation or exposed wiring and non-compliance with safety markings or certifications.

2. Compliance with Regulatory Requirements

Electrical accessories are subject to a variety of regulations depending on the destination market. Inspections help verify proper labeling and compliance marks (CE, CCC, FCC, etc.), and use of RoHS-compliant materials (no lead, mercury, cadmium, etc.). Early identification of non-compliant items avoids penalties, recalls, and shipment rejections.

3. Functional and Durability Testing

Beyond safety, inspections ensure the accessories function correctly under expected conditions. By verifying these parameters, manufacturers and buyers can ensure the product performs as advertised throughout its lifecycle.

4. Brand Reputation and Customer Trust

In the competitive electronics and hardware market, a single faulty accessory can lead to customer dissatisfaction, negative reviews, and brand damage. Quality inspection builds a foundation for consistent product quality and enhanced end-user safety and trust

The Different Types of Electrical Accessories We Inspect

We can inspect a large variety of electrical accessories such as:

Charges

Adapters

Transformers

Plugs

Sockets

Connectors

Extension Cords and Cable Reels

Switches

Lamp Holders

Remote controls

smart home systems.

Types of Third-party Electrical Accessories Quality Control

Audits for the Electrical Accessories Industry

Factory Audit: An independent assessment of the manufacturing facility’s capacity, machinery, and workforce to determine if they can meet production demands while maintaining product quality.

Supplier Audit: Checking the company’s legal information, bank information, human resources, export capabilities, and more. The inspectors perform supplier verification audit, evaluating

Pre-Production Inspection(PPI)

GIS inspectors onsite will evaluate the first 10%-30% units produced to ensure compliance with necessary criteria, brand specifications, quality requirements which can firmly establish whether the manufacturer will be able to deliver on the promise to produce a quality product using the correct materials and manufacturing process, and orders shipping on time.

During Production Inspection (DUPRO)

The electrical accessories will be examined for their appearance, construction, and function to ensure that quality requirements and specifications are met. Inspectors identify and rectify any defects, irregularities, or deviations from quality standards that may arise during production.

If issues are identified, inspectors collaborate with manufacturers to promptly implement corrective actions, preventing the production of substandard electrical accessorie products.

Pre-Shipment Inspection(PSI)

We will select a random sample of finished electrical accessories before shipment to ensure all items conform to the established quality criteria and functional requirements. Functional tests on electrical accessories are performed to ensure usability, efficiency, and safety.

Inspectors supervise the packaging process to verify that the electrical accessories are adequately protected for transportation. They also ensure proper loading onto shipping containers to prevent damage during transit.

Loading Supervision (LS)

The final but crucial step in the quality control process is properly preparing batches for shipping to destination markets. Loading Supervision (LS) is usually performed at the factory, forwarders warehouse, or port to verify count, confirm load, and seal the container.

Essential Electrical Accessories Inspection Checklist during an onsite Inspection

A comprehensive pre-shipment quality inspection checklist for electrical accessories is essential to ensure that all aspects of the product are inspected thoroughly. Here are some key areas to include in GIS quality assurance PSI checklist:

1. Quantity check

GIS inspectors count products and shipping cartons to verify that the correct quantity of an order has been finished which including PO quantity, shipment quantity, packed quantity, unpacked quantity, and unfinished quantity.

2. Workmanship Inspection

The GIS inspector will select a sample size according to the AQL standard, and conduct a visual check for any damages and flaws in workmanship and classify them as major, minor, or critical defects. The electrical accessories random inspection AQL standard is normally 1.5 for major defects, 4.0 for minor defects.

Read more: How to Use AQL for Quality Control Inspection?

3. Product description, style and color check

GIS Inspection will verify that the products conform to the specifications against PO, photos, and sample.

4. On-site test

The selected sample will undergo rigorous testing to ensure that it functions properly and meets safety standards.

The essential tests performed by our inspectors during an onsite inspection of electrical accessories:

Hi voltage check

Earth resistance check

Basic function check

Assembly check

Transportation drop test

Power consumption check

Product measurement Barcode readability check

Power cord length check

Internal check for workmanship

Speed check (no load)

Vibration Test

Noise Emission Test

5. Packaging

GIS inspectors will check the packing method and packing information to ensure that everything is accurate and safe for transportation. Inner and outer packaging are inspected to ensure that they meet client specifications, with results provided in the report.

6. Shipping mark check

Shipping mark check covers key quality aspects that help ensure products are safe, functional, and compliant with industry standards before reaching the market.

Check a Report Sample!

International IEC Electrical Standards for Electrical Accessories

IEC 60884 and IEC 60309 – Standards for Plugs and Sockets

IEC 60884 Plugs and socket-outlets for household and similar purposes

IEC 60884 specifies common requirements and rules applicable to plugs and fixed or portable socket-outlets for AC only, with or without earthing contact, with a rated voltage greater than 50 V but not exceeding 440 V and a rated current not exceeding 32 A, intended for household and similar purposes, either indoors or outdoors.

IEC 60309 Plugs, fixed or portable socket-outlets and appliance inlets for industrial purposes

IEC 60309 specifies general requirement applicable to plugs, fixed or portable socket-outlets and appliance inlets hereinafter referred to as accessories, with a rated operating voltage not exceeding 1 000 V DC or 1 000 V AC with a frequency not exceeding 500 Hz and a rated current not exceeding 800 A, primarily intended for industrial use, either indoors or outdoors.

IEC 60320 on Appliance Couplers

The IEC 60320 set of international standards specifies safety and testing requirements for non-locking appliances as well as interconnection couplers connecting power supply cords to electrical appliances. Appliance couplers enable manufacturers serving the international market to produce a single electrical device for most of their diverse markets, having only to adapt or change cords for particular markets of exception.

IEC 60669 – Switches for Fixed Electrical Installations

IEC 60669 is a standard that specifies requirements for manually operated switches used in fixed electrical installations, whether indoors or outdoors. The standard includes mechanical and electrical endurance testing, resistance to heat and fire, insulation properties, and proper marking requirements.

IEC 60884-2-5 – Particular Requirements for Adaptors

IEC 60884-2-5 is part of the IEC 60884 series that deals with plugs and socket-outlets for household and similar purposes. It addresses the mechanical strength, temperature rise, insulation resistance, and constructional features specific to adaptors.

GIS Inspection for you Electrical Accessories Quality Control

GIS Inspection(General Inspection Service) is an international third-party quality control inspection company in China. GIS provides provide comprehensive safety and quality assurance services to help you ensure compliance with legislation enforced in multiple global markets. We have set up an inspection network covering China, Vietnam, Malaysia, India.

We conduct all inspections for electrical accessories as mandated by relevant laws and regulations. Thanks to our many years of experience and our comprehensive know-how, we are the right partner to stand at your side.

GIS only employs full-time inspectors. Our highly trained and experienced electrical & electronics inspectors are product experts who receive regular training in their field of specialization.

GIS product inspection services ensure that your products match your desired specifications. Contact our electrical accessories quality assurance experts to customize your inspection requirements.

Contact us

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Type :IEC320 C14 to C7 power adapter, plug: 3 pin male IEC 320 C14, receptacle: Figure 8 female IEC 320 C7 Compact Size :Right angle C14 male to C7 female conversion plug, compact and lightweight size, space saving, easy to store and carry. High Performance :Professional C14 3 pin male to C7 figure 8 female power plug connector, rated current: 2.5A/10A 250V Durable Material :The IEC320 C14 to IEC320 C7 converter is made of copper conductor and PVC shell, wear resistant, sturdy and durable. Wide Application :The IEC320 C14 to C7 conversion plug is suitable for computers, laptops, PDU chassis, UPS sockets, servers, printers, home appliances, etc. Specification: Product Size: C14 male: 4.1cmx2.9cmx2.1cm/1.61inchx1.14inchx0.83inch C7 female: 4.1cmx2.8cmx1.6cm/1.61inchx1.10inchx0.63inch Material: PVC Package Includes: 1 Power Adapter Note: Please allow slightly errors due to manual measurement and different monitors Product Type :Iec320 C14 To C7 Power Adapter, Plug: 3 Pin Male Iec 320 C14, Receptacle: Figure 8 Female Iec 320 C7 Compact Size :Right Angle C14 Male To C7 Female Conversion Plug, Compact And Lightweight Size, Space Saving, Easy To Store And Carry High Performance :Professional C14 3 Pin Male To C7 Figure 8 Female Power Plug Connector, Rated Current: 2.5A/10A 250V Package Includes:1 Power Adapter Please Prefer Description For More Information [ad_2]

0 notes

Text

Electric Wall Charger and EV Station Maintenance Checklist for Hassle-Free Charging

Introduction

Properly functioning electric wall chargers and stations are crucial for the convenience and efficiency of electric vehicles (EVs). A malfunctioning charger or station can lead to frustrating downtime, decreased charging speeds, and even safety hazards for your employees and customers.

To ensure hassle-free charging and maintain the performance of electric wall chargers and EV stations, you must invest in regular maintenance. Tercero Inc. offers extensive EV charging services, including charger maintenance and installation. This article examines the importance of regular EV wall charger repair, common issues with EV chargers, and when to call an expert.

Whether you are a station manager or own a charging station, this article will help you spot potential problems before they become significant, improve the quality of your service, and enhance customer and employee safety.

Key Components of an EV Wall Charger and Charging Station

1. Power Supply

The power supply is one of the main components of electric wall chargers. It converts the grid’s AC or DC electrical power into the appropriate voltage and current to charge the EV battery. The power supply typically consists of a transformer, rectifier, and control circuitry.

There are two types of power supply used in EV charging. They are:

AC (Alternating Current) power supply: This power supply is used by level 1 and level 2 chargers. The chargers take AC power from the grid and convert it to the correct voltage and current your battery needs to charge.

DC (Direct Current) power supply: This power supply is used by DC fast chargers. The chargers take high-voltage DC power from the grid and convert it into the voltage and current your electric vehicle needs to charge.

Any fault to the power supply can affect charging speed and damage your battery. It can also constitute a grave danger to employees and customers.

2. Connectors

EV charger connectors ensure that your battery gets the electric power it needs. They are plugged into your vehicle’s charging ports and an electric socket. The connectors charge your battery through small pins, which create a pathway through which electric current passes. The pins are designed to handle high amounts of electric current without getting hot.

There are different types of different types of connectors used for EV charging. They are:

Type 1 (SAE J1772): This connector has five pins and is commonly found in North America and Japan. Its relatively low power rating (handling up to 16 amps) makes it more suitable for slow and medium-speed charging.

Type 2 (IEC 62196): This connector has seven pins. It has a higher electric power rating (handling up to 43 kW) and is suitable for a faster charging experience. The type 2 connectors are commonly used in Europe and Australia.

CHAdeMO: This connector has a distinctive “gun” shape. It can handle up to 62.5 kW of power, making it highly suitable for DC fast chargers. The CHAdeMO connector is commonly used in Japan.

Combined Charging System (CCS): This connector combines the type 2 AC connector with two additional DC pins. It can handle up to 350 kW and is suitable for a faster and more stable charging experience.

Most electric vehicles have a built-in connector that fits your region’s standards, but some models allow you to switch between connector types. When choosing a connector, ensure it is compatible with your charging needs and battery specifications.

3. Charging Cable

The charging cable is the line that connects and carries electric current from the electric wall charger to the EV’s battery. It consists of the connector that attaches to the EV and the cable itself. The cable is made of high-strength materials like aluminum and copper to withstand the weight of various EVs.

Several types of EV charging cables are available. The kind you need will depend on your vehicle’s make and model. Type 1 cables are commonly used in North America and Japan, while type 2 cables are popular in Europe.

4. Control Board

The control board is your charging station’s central processing unit (CPU). It manages the charging process and ensures the EV battery is not overwhelmed by the current it receives. A well-designed control board is essential for a charging station’s safety, efficiency, and reliability. Its sub-components include a microcontroller, voltage and current sensors, relays and contactors, a communication interface, and more.

5. Smart Features

Smart features in EV chargers enhance convenience and functionality. Some examples of smart features in EV chargers include mobile apps, touchscreen, RFID card readers, and more.

Importance of Regular EV Wall Charger Maintenance

Like any technology, maintaining your EV wall charger is very important. Here are some reasons why:

1. Optimal Performance

Regular maintenance ensures that your EV charger operates at optimal capacity. This not only results in a faster and more efficient charge but also in a more efficient use of electricity.

2. Safety

Chargers, especially those used frequently, will acquire wear and tear, making them a safety hazard if they are not properly maintained. Issues like frayed cables or loose connections can cause electric shocks or fire outbreaks.

3. Longevity

EV chargers are built to last, but regular maintenance can significantly prolong their lifespan. Overlooking minor issues can lead to more significant problems, necessitating costly repairs and replacements.

4. Cost Efficiency

Proactive maintenance helps identify and fix minor issues before they become more significant and expensive problems.

5. Peace of Mind

Regular maintenance gives you comfort and peace of mind, knowing your charger is in good condition, especially when going on a long trip.

Common Issues Requiring EV Charger Repair

Some of the most common signs that your electric wall charger requires repair and maintenance are:

1. External Damage

Any damage to the body of your EV charger can affect charging efficiency and compromise the safety of persons and property.

2. Exposed Wiring

The wiring is supposed to be inside the charging cable. If it is outside, you should get it fixed immediately, as it constitutes a safety hazard.

3. Slow Charging Speed

If your charger takes longer to charge thank it used to, it is best to call for an inspection.

EV Charging Station Maintenance Checklist

1. Daily or Weekly Maintenance Tasks

Here are some daily and weekly tasks to help keep your EV charger in good working condition:

Visual Inspection: Check the charger for damage, corrosion, and other wear and tear signs.

Cleanliness: Ensure the charger and surrounding areas are free of dirt, dust, and moisture.

Software Updates: Check for available software updates and apply them as necessary to ensure your charger remains compatible with evolving charging needs.

2. Monthly or Quarterly Checks

Here are some monthly and quarterly checks to keep your EV charger in good working condition:

Cable and Connector Inspection: Inspect charging cables for signs of wear, damage, or corrosion.

Charger Firmware Updates: Check for available firmware updates and apply them to ensure you stay up-to-date with evolving safety and industry regulations.

Charger Calibration: Verify the charger is properly calibrated and functioning within the manufacturer’s rules.

3. Annual Maintenance Tasks

Here are some yearly maintenance tasks for your EV charging station:

Arc Fault Detection: Verify the charger’s arc fault detection system is functioning correctly.

Ground Fault Protection: Test the charger’s ground fault protection system to ensure it’s working correctly.

Electrical Connections: Inspect and tighten all electrical connections to prevent loose connections.

When to Call for EV Charging Station Repair Services

You should call for professional repair services for the following EV issues:

Electrical shock or fire

Complete loss of power

Overheating

Slow charging

Charging errors

Visible damage

Cable damage

Connect issues

If you experience any of these issues, calling and scheduling electric wall charger repair services is always best.

Tips for Proactive Maintenance

1. Regular Inspections

Set a routine to inspect your charging station for signs of wear and tear, damage, and corrosion. Often times this can be done remotely.

2. Software and Firmware Updates

Regularly check the manufacturer’s website for updates and apply them as soon as they become available.

3. Cleanliness

Keep the area around the EV charger and charging station free of dust, debris, dirt, and other substances that can affect the charger’s efficiency or cause damage.

Conclusion

Regular electric wall charger repair is crucial to ensuring the safe, efficient, and reliable operation of EV charging stations. By performing daily, weekly, and yearly maintenance, you can prevent unexpected downtime, ensure safety, and optimize charging performance. Contact Tercero Inc. for a free quote to schedule regular EV charging inspections and maintenance today.

Original Source: https://terceroinc.com/blog/ev-wall-charger-maintenance-checklist/

0 notes

Text

Schneider Miniature Relay RXM4AB1FD

AEC switchgear provided Schneider Miniature Relay RXM4AB1FD RXM miniature relays are part of Harmony Electromechanical Relays. This is a plug in relay to be mounted on a RXZE socket. It is a 4 C/O relay with current rating of 6A, control circuit voltage of 110 V DC. It also offers one-step loackable test button and mechanical indicator for contact status. The testbutton is activated momentarily by pushing the blue pushbutton on the front and locked by flipping up the green part.

The mechanical indicator is next to the testbutton, where an orange flag indicates the relay contact status. Workablity for hard-wired logic automated systems to complement the functions of industrial progammable logic controllers (PLCs). Its design is fit for industrial machines, packaging, textile, HVAC, automation control panels, low/medium voltage switchgear, motor controls, PLC Interfaces, power supplies, building or medical equipment, lighting controls. It is a green premium product and conforms to international standard and certifications like IEC, CE, UL, CSA, EAC, Lloyd's, RoHS and REACH. RXM Relay should be used with a RXZE socket (screw clamp, screw connector, push-in terminal). To protect against vibrations, plastic/metal clamp can be added to the socket. Protection modules and marking legend are also available.

It is sold in lots of 10 and reference includes relay only. The RXM plug-in relays are a series of industrial plug-in relays designed for both simple and complex automation systems and available with 2 CO (12A), 3 CO (10A), 4 CO (6A) contacts, 4 CO (3A) low level contacts.

For More Information

https://www.linkedin.com/company/aec-ahmedabad-electric-corporation/mycompany/

0 notes

Text

AC Power Sockets in Industrial and Medical Applications: Ensuring Safety and Reliability

AC power sockets play a crucial role in both industrial and medical settings, where safety, reliability, and specialized requirements are paramount. This article will explore the design considerations and innovative solutions for power sockets tailored for these demanding environments, ensuring they meet the strict standards of performance, durability, and safety.

1. Power Sockets for Medical Equipment

In healthcare environments, power sockets must meet stringent requirements to ensure the safety of patients and healthcare providers. Medical-grade power sockets need to comply with specific standards that address electromagnetic compatibility (EMC), sterilization, antimicrobial properties, and continuous stable power supply.

1.1 Meeting Electromagnetic Compatibility (EMC) Requirements

Medical equipment often operates in environments filled with a variety of electronic devices. Therefore, it is crucial that power sockets used in these settings do not emit or be affected by electromagnetic interference (EMI). Power sockets for medical applications must comply with EMC standards such as IEC 60601-1-2, which outlines the EMC requirements for medical electrical equipment.

Shielding Techniques: To minimize EMI, power sockets can incorporate shielding techniques such as the use of metal housings and filtered connectors. These designs help prevent electromagnetic waves from interfering with sensitive medical devices.

Filtered Power Inputs: Using filtered power inputs can further reduce the risk of EMI. These filters block high-frequency interference signals, ensuring that only clean, stable power is supplied to medical equipment.

1.2 Providing Sterile and Antimicrobial Surfaces

Hospitals and clinics require sterile environments to prevent infections. Power sockets used in these settings need to feature designs that facilitate easy cleaning and offer antimicrobial properties.

Antimicrobial Materials: Power sockets made from antimicrobial materials can inhibit the growth of bacteria and other microbes on their surfaces. These materials, such as antimicrobial plastics or coatings, are effective in maintaining hygiene standards in healthcare settings.

Smooth and Seamless Design: Power sockets with smooth, seamless designs are easier to clean and disinfect. These sockets minimize the accumulation of dust and bacteria, reducing the risk of contamination.

1.3 Ensuring Continuous and Stable Power Supply

In medical settings, power interruptions can have serious consequences. Power sockets for medical equipment must ensure continuous and stable power supply to prevent disruptions during critical medical procedures.

Uninterruptible Power Supply (UPS) Integration: Power sockets with built-in UPS capabilities can provide backup power during outages, ensuring that essential medical equipment continues to operate without interruption.

Redundant Power Systems: Using redundant power systems in medical environments can further enhance reliability. These systems provide multiple power sources, so if one source fails, the other can continue to supply power.

1.4 Compliance with Medical Standards

Power sockets used in medical equipment must comply with international standards to ensure safety and reliability. Standards such as IEC 60320 and IEC 60601 specify the requirements for connectors and power supply equipment used in medical devices. Compliance with these standards is essential to meet the regulatory requirements of different countries and regions.

2. High-Durability Power Sockets for Industrial Environments

Industrial environments often involve harsh conditions, such as exposure to extreme temperatures, moisture, dust, and chemicals. Power sockets used in these settings need to be designed for high durability and reliability to withstand these challenges.

2.1 High-Temperature and Corrosion-Resistant Materials

Industrial power sockets must endure high temperatures and corrosive environments without degrading. Using advanced materials is key to achieving this durability.

Heat-Resistant Materials: Power sockets made from heat-resistant plastics, ceramics, or metals can withstand high operating temperatures without melting or deforming. These materials maintain the integrity of the socket under extreme conditions.

Corrosion-Resistant Coatings: In industrial environments where chemicals are present, power sockets with corrosion-resistant coatings are essential. Materials such as stainless steel or specially treated plastics can provide protection against chemical exposure, prolonging the lifespan of the socket.

2.2 Waterproof and Dustproof Design

Power sockets in industrial settings must be protected against water and dust ingress to ensure reliable operation.

IP Ratings: Industrial power sockets often have high Ingress Protection (IP) ratings, such as IP65 or IP67, indicating their ability to withstand water jets and dust ingress. These ratings are achieved through robust sealing mechanisms and materials that prevent contaminants from entering the socket.

Sealed Connections: Using sealed connections and gaskets can enhance the waterproof and dustproof capabilities of power sockets. These designs ensure that no moisture or dust can penetrate the socket, maintaining its reliability even in harsh environments.

2.3 Mechanical Robustness

Industrial power sockets must be mechanically robust to endure physical impacts, vibrations, and heavy usage.

Reinforced Housings: Power sockets with reinforced housings made from durable materials such as metal or impact-resistant plastics can withstand physical impacts and provide long-lasting performance.

Vibration-Resistant Design: In environments with constant vibrations, such as manufacturing plants, power sockets need to be designed to resist loosening or damage. Features like secure mounting options and vibration-damping materials can improve the durability of these sockets.

2.4 Safety and Compliance

Ensuring safety in industrial environments is crucial. Power sockets must comply with safety standards to protect workers and equipment.

Overload and Short-Circuit Protection: Industrial power sockets should include overload and short-circuit protection to prevent electrical faults that could lead to fires or equipment damage. These protective features disconnect the power supply when an overload or short circuit is detected, enhancing safety.

Compliance with Safety Standards: Power sockets used in industrial applications must comply with relevant safety standards, such as IEC 60947-3 for low-voltage switchgear and controlgear. Compliance with these standards ensures that the power sockets can safely operate in industrial environments.

Conclusion

The design of AC power sockets for medical and industrial applications requires a deep understanding of the specific demands and challenges of these environments. In medical settings, power sockets must meet strict standards for EMC, hygiene, and uninterrupted power supply, while in industrial environments, durability, resistance to harsh conditions, and mechanical robustness are essential. By focusing on these requirements, manufacturers can develop power sockets that provide safe, reliable, and efficient power solutions, supporting the critical operations of both medical and industrial applications.

en.dghongju.com

1 note

·

View note

Text

Geez, it's been so long I had to look up how to crimp the little spring contacts that fit into molex connectors onto wires.

(I should have added a fistful of those crimp-on insulated quick-disconnect terminals to one of my electronics orders. See, I've got to run wires from the switched IEC socket that'll sit in the wall of my case, which has connectors for three of those, to a terminal strip, and from the terminal strip to the power supply. The power supply uses molex connectors — 3x for the input, and 4x for the dual output — and its grounding is through its mounting holes, which is why I worry about having a grounded chassis inside the wooden box. And the terminal strip is in the chain so I have the facilities in place to parallel in more power supplies if/when I need them.)

(I should also put together a little 2HP module that just displays whether the Eurorack voltage lines are hooked up right, as a power indicator up front. Oh, too many projects...)

0 notes

Text

Understanding the Different Types of Industrial Plugs and Sockets

In the industrial world, the importance of reliable and robust electrical connections cannot be overstated. Industrial plugs and sockets are the backbone of electrical connectivity, providing the critical link between power sources and industrial equipment. Balaji Switchgears understands this necessity and offers a wide range of high-quality industrial plugs and sockets designed to meet the diverse needs of various industrial applications.

Introduction to Industrial Plugs and Sockets

Industrial plugs and sockets differ significantly from their domestic counterparts. They are engineered to handle higher voltages and currents, withstand rough handling, resist environmental hazards, and maintain connectivity in demanding industrial environments. The design and manufacturing of these connectors follow stringent standards to ensure safety, durability, and compatibility across different systems and regions.

Types of Industrial Plugs and Sockets

The types of industrial plugs and sockets can be categorized based on several factors, including pin configuration, voltage and frequency ratings, degree of protection, and specific applications.

Pin Configurations: The number of pins in an industrial connector can range from two to five or more. The configuration depends on whether the system is single-phase or three-phase, with additional pins for neutral and earth connections. Common configurations include 2P+E (two poles plus earth), 3P+E (three poles plus earth), and 3P+N+E (three poles plus neutral plus earth).

Voltage and Frequency Ratings: Industrial connectors are designed to accommodate a wide range of voltages, typically up to 1000 V DC or AC. The current ratings can go up to 800 A for heavy-duty applications. Frequency ratings are also considered, with some connectors rated for frequencies up to 500 Hz.

Protection Degrees: The degree of protection provided by an industrial plug or socket is indicated by its IP rating. For example, an IP44 rating signifies protection against solid objects larger than 1 mm and water splashing from all directions. An IP67 rating offers complete protection against dust ingress and temporary immersion in water.

Specifications of Industrial Plugs and Sockets

Adherence to international standards is crucial for ensuring the safety and interoperability of industrial connectors. The IEC 60309 standard is widely recognized in this regard, providing guidelines for color codes, dimensions, configurations, voltage, frequency ratings, and degrees of protection.

Color Codes: To prevent accidental mismatches that could lead to equipment damage or safety hazards, IEC 60309 specifies color codes for different voltage ratings. For instance, blue indicates a voltage rating of up to 250 V (AC), red signifies 400 V (AC), while yellow represents 1000 V (AC or DC).

Dimensions: The standard also defines precise dimensions for plugs and sockets to ensure a secure fit that prevents accidental disconnections.

Configurations: The layout of pins is standardized according to IEC 60309 configurations. This uniformity ensures that plugs from one manufacturer can be used with sockets from another without compatibility issues.

Applications

Industrial plugs and sockets find applications across a broad spectrum of industries:

Manufacturing: They power machines that perform cutting, welding, shaping, or assembly operations.

Construction: Robust connectors are used on construction sites where they are exposed to dust, moisture, and mechanical stress.

Hazardous Environments: In areas with explosive gases or combustible dust, specially designed connectors with higher protection ratings are employed.

Conclusion

Selecting the right type of industrial plug or socket is paramount for maintaining operational efficiency and safety standards in any industrial setting. Balaji Switchgears‘ extensive range of industrial connectors ensures that businesses can find the perfect match for their specific requirements.

For detailed product specifications or assistance in choosing the right connector for your application, reach out to us!

Originally Published at:

1 note

·

View note

Text

Exploring Line Filters in Ghaziabad

Enhancing Water Quality: Exploring Line Filters in Ghaziabad

To safeguard your air-powered equipment and your finished goods, untreated compressed air must have dirt and particles filtered out. Filters, however, also impact the effectiveness and functionality of your air system. Sarvap Solutions set out to develop a brand-new, revolutionary filter line that is extensive and dynamic, energy-efficient and requires the least amount of maintenance.

Sarvap solutions line filters were created with performance and energy efficiency in mind. They provide you with unmatched performance because of their high-quality parts! In fact, our components guarantee ideal sealing inside the filter housing, facilitate easy removal, provide corrosion resistance, deliver strength and stability to the element, reduce oil carryover, and enhance coalescence performance, among many other benefits.

Line filters in Ghaziabad

These filters prevent 230-volt low-voltage power supply disturbances at a device's power supply connector. At the same time, they stop connected devices from returning potential interference frequencies to the low-voltage network via the socket. They are often inserted in the connecting plugs and adjusted for the devices' power requirements. The issue, which is not limited to medical equipment, is what is known as leakage currents, which are brought on by the connection of interference suppression capacities to the protective conductor. Modern filters have, which is so low by technical standards that it satisfies UL/IEC regulations. A common component of line filters is an IEC socket with built-in electronics (chokes and capacitors). Some variants also include fuses and a power switch. There are furthermore line filters for PCB installation.

Get consistent quality line filters.

Many electronic equipment emit interference during regular operation, which interferes with or disables the use of other electronic devices. Either electromagnetic radiation or conductivity can cause interference. Only things in direct physical touch with the interference-generating circuit are subject to conducted interference. Radio Frequency Interference (RFI), also known as radiating interference, propagates through radio waves and interferes with surrounding equipment. A power supply or computer, for example, has a lot of components in a small area that might cause a lot of interference. By obstructing the high-frequency signals that cause interference, EMI/RFI power line filters are specifically made to reduce interference with other equipment. In order to keep your gadget operating properly without interfering with other equipment, EMI/RFI filters block both incoming and outgoing interference.

Acceptable amounts of interference cancellation are provided by single-phase EMI/RFI filters. The finest interference negation is offered by three-phase filters when large degrees of noise dampening are required. The voltage, current, and leakage current ratings of EMI/RFI filters are used to classify them. Sarvap Solutions has the line filter you require, no matter the application.

Line filters used in power supplies

The power supply circuit produces high-frequency noise when AC power is provided, which may interfere with nearby electrical devices. EMI Filters are made up of passive parts like resistors, capacitors, and inductors that are coupled in series to create LCR circuits. These circuits help to block high-frequency noise by giving it a low-impedance path to travel to the ground. For AC/DC Power supplies, our single-phase EMI filters are ideal. If we were to utilize our standard single-phase PCB mountable filter (MF530) for boat-level protection, we could also have to use our single-phase chassis mountable filters (MF410, MF430).

#Industrial IoT Based Solutions#Network -Tower Light#Beacons#Low Cost EMS#Scada & Reporting#Drive in Ghaziabad

0 notes

Text

2 pin Power Cable

What Is a 2 Pin Power Cable?

Whether you're connecting a kettle or a PC, you need the right kind of power cord. Thankfully, desktop graphics cards are fairly power-efficient, and a single 6-pin connector will usually suffice for most cases. However, NVIDIA's decision to create a bespoke 12 pin power connector for their top-of-the-line RTX series GPUs has added some confusion to an otherwise fairly straightforward part of PC building.

Depending on your region, you'll either have a non-polarized plug with two straight blades or a polarized plug with a third round or U-shaped ground pin. Non-polarized plugs are usually used in electrical outlets in the home or on the female end of extension cords, while polarized plugs are typically found on the male end of appliance couplers (also known as receptacles). The ground pin is longer than the other two and provides a safety path for excess current to drain to the earth in case of a short circuit.

A power cable is an insulated stranded wire conductor that links the plug and the adapter or socket to transmit electrical currents between them. It is usually made of copper with a layer of plastic or other protective material to reduce electromagnetic interference. Its length can range from 6.6 to 32.8 ft (2 to 10 m). Power cords are often identified by their IEC or IEC 60320 type or marking, which defines the type of plug and mating appliance inlet they connect to.

Power cords are typically 2-core or 3-core, which refers to the number of conductors inside the flexible cord. Most of the time, a power cord will have one live or hot wire that's colored black (North America) or brown (Internationally). The other wire is neutral and is colored white. Occasionally, the cord will also have a third wire that's smaller than the other two and is called the earth or grounding wire.

When it comes to powering our devices, the humble 2 pin power cable might not get much attention. We tend to take them for granted, plugging them in and forgetting about them. But have you ever stopped to think about just how important these little cables are? They are the backbone of modern technology, providing the necessary connection between our devices and the power source.

What makes the 2 pin power cable so fascinating is its simplicity. With just two pins, this cable can transmit electrical current to power a wide range of devices, from laptops and televisions to smartphones and game consoles. It may seem like a small thing, but without it we would be left in the dark - quite literally! In today's fast-paced world where we rely heavily on technology, having a reliable and efficient power supply is essential.

But what sets the 2 pin power cable apart from other types of cables? One major advantage is its compact size. The two pins allow for easy insertion into standard sockets without taking up too much space. This makes it ideal for traveling or situations where space is limited. Additionally, its simple design means it is less prone to damage or wear and tear compared to more complex cables with multiple connectors.

The humble 2-pin power cable may not be the most glamorous or talked-about piece of technology, but it plays a crucial role in our modern lives. From charging our smartphones to powering small appliances, this unassuming cable connects us to the world of electricity. Its simplicity is its strength - with just two pins and a flexible cord, it effortlessly carries electrical current and allows us to tap into the energy that drives our devices.

One interesting aspect of the 2-pin power cable is its universality. It seems like no matter where you go in the world, you can almost always find an outlet that matches this simple design. This standardization has simplified power supply logistics and made it easier for manufacturers to produce devices for global consumption. It's also worth noting that despite being widely used, these cables often go unnoticed by users who take their reliability for granted.

Another fascinating feature of the 2-pin power cable is its potential for customization and personalization. While most people are content with using generic cables that come with their devices, there is a growing market for specialized and aesthetically pleasing options. Some companies now offer cables in various colors or patterns to match individual preferences or blend seamlessly with home decor. This customization not only adds a touch of personal style but also offers practical benefits such as easy identification when multiple cables are plugged into an outlet.

Although often overlooked, the 2 pin power cable plays a vital role in keeping our electronic gadgets up and running smoothly. Its simplicity and compact size make it an indispensable accessory for any tech-savvy individual.

Is it safe to use a 3 pin power cable on a 220v to 110v transformer for a water distiller? As long as the transformer is rated for your distiller's voltage and power consumption, yes. However, it's important to follow all safety precautions when using a transformer to avoid overloading and overheating. You should always check the manufacturer's specifications for your specific device. And remember to always unplug your equipment when you're not using it. Otherwise, you could cause a short circuit that can result in damage to your device or personal injury. Also, you should only use an extension cord or adapter that is rated for the voltage and wattage of your transformer. It's also a good idea to keep your power cords as short as possible to prevent overheating. You should also avoid using an extension cord that is damaged or frayed. You should never attempt to repair a power cord by yourself, as it may expose you to high levels of electricity and cause injury or even death. Instead, contact a professional electrician to inspect and repair the power cord for you.

0 notes

Text

@brutish-impulse said:

So what do you call these?

This is an IEC 60320 C14 to C5 adapter.

Back in the day, double-ended C13 cables were pretty common so that you could use one wall socket to power your PC and your monitor. Nowadays a lot of monitors use the smaller C5 cables to power a power brick and so you can't do that, but I figured "hey this has to exist".

A great thing about the IEC 60320 standard is that the male and female/cable and appliance ends of the connectors have distinct codes (odd numbers for cable/female, even for appliance/male, and a letter code for interconnect cables) so searching for specific items is fairly easy compared to a lot of other connector standards.

I love it when I concoct the perfect search term and use it and immediately find exactly what I was looking for

42 notes

·

View notes

Text

Boost Efficiency with Y Type Industrial Connector Socket 3P 16A 380V-415V

When high-voltage industrial applications demand precision and resilience, the Y Type Industrial Connector Socket 3P 16A 380V-415V emerges as the ultimate solution. Certified to IEC60309-1 and IEC60309-2 standards, this blue-colored, waterproof, and anti-corrosion socket is engineered for heavy-duty environments. Perfect for manufacturing units, HVAC systems, or machinery requiring 380V-415V power, its 2P+E configuration ensures safe, stable connectivity while minimizing downtime.

Key Features of Y Type Industrial Connector Socket 3P 16A Designed for 16A current and 380V-415V voltage ranges, this IP44-rated socket excels in dusty or damp conditions. The 6h mechanical endurance guarantees longevity, even under frequent use, while its corrosion-resistant build withstands harsh industrial settings. As an OEM factory-direct product, it matches premium quality standards at a competitive price—no compromises on performance or affordability.

Why Invest in This Industrial-Grade Socket?

30-Day 100% Refund Policy: Validate its performance without risk.

OEM Pricing Advantage: High-grade components, lower costs.

Global Compliance: IEC-certified for seamless integration.

Elevate your operations with the Y Type Industrial Connector Socket 3P 16A 380V-415V today. Contact us to place orders or discuss bulk discounts. Ensure consistent power delivery and reduce maintenance costs—opt for a connector built to exceed expectations.

Act Now—Exclusive Pricing for Limited Time! Don’t let outdated connectors hinder productivity. Choose the Y Type Industrial Connector Socket 3P 16A 380V-415V for reliability, durability, and unmatched value. Reach out today to secure your supply or request a custom quote—transform your power infrastructure now!

0 notes

Text

Industrial Plugs and Sockets are the Future Driving the Power Connection

Industrial Plugs and Sockets are the Future Driving the Power Connection What is Industrial Plug & Socket and Why is it so important to use them instead of traditional Plugs and Sockets?• Industrial Plug and Socket are mainly used to provide a secured connection and acts as a link between the main power supply and the end-use of the product. They are generally used in hazardous environments such as oil refineries, gas plants, chemical factories, etc. where the level of safety required is very high.

They may be waterproof, fireproof/flameproof as per requirement, and have an interlocking ability to safeguard the connection along with a switch to prevent any accidental disconnection of the live plug.

They may be Single Phase or Three Phase in nature depending upon their specification and current taking capacity.

• After Industrial Plugs & Sockets came into existence, certain regulations and norms were established globally to standardize its specification, nature and follow standard manufacturing practice for easy identification of the products and interchangeability. The standard defined by the IEC for Industrial Plugs & Sockets, Couplers, and Outlet was IEC 60309.

•There is a range of Categories of Products available under Industrial Plugs and Sockets:

1. Industrial Plugs:

• Standard Plug• Inlet / Reverse Plug• Low Voltage Plug• Event Plug• Reefer Container Plug• Multi-Function Plug• Heavy Voltage & Current-Carrying Plug

2. Industrial Connectors:

• Standard Connector• Low-Voltage Connector• High Voltage Connector• Event Connector• Reefer Container Connector

3. Industrial Sockets:

• Panel Mounting Socket• Angular Socket• Reefer Container Socket• Multi Connection SocketCamLock:

• There is a different type of Industrial Plug and Socket that has limited use and is commonly used in the Entertainment Industry, commonly referred to as Powerlocks or Camlocks. They are Single Pole in nature and so 5 of them are required to make a set and to fulfill all the three phases, neutral and earthing (ground). They have a rating of 250Amp, 400Amp & 660 Amp.

• They follow a unique standard color code for easy identification as follows: Brown, L1 Black, L2 Grey, L3 Blue, Neutral Green, EarthIndustrial Plugs & Sockets have a wide range of applications where it is commonly used:

• Entertainment and Event Industry for the heavy lighting• Film Sets and Studios• Tunnels• Construction Sites

• Adventure Parks• Industrial Kitchen• Railways• Airports• Reefer Container• Ships and Yachts

• Military They have various specifications in terms of their type, which differentiates one from another in terms of its Ampere, Voltage, Earthing Pin (3h or 6h), etc. It is always recommended to buy them in ABS material as it is proven to withstand extreme conditions and is likely to have a longer life whereas PVC material is likely to melt under extreme conditions and could lead to serious accidents. Difference Between Industrial Plug & Socket and household / commonly used Plug & Socket? A lot of them feel that Industrial Plugs & Sockets and household / commercial plugs & sockets are nearly the same and there is not a vast difference between them so I will talk about the few distinct differences that separate the two majorly.

1. Current Rating• Industrial Plugs and Sockets have a higher Ampere Rating starting from 16A which goes up to 660A.• Standard Plugs & Sockets have an Ampere rating of 6A, 10A, and 16A.

2. Material• Industrial Plugs are sockets are generally made of a very high- quality Plastic, preferably PA6 material, often called Nylon 6 is sometimes blended with ABS to provide the best results to enhance its durability, reliability and can withstand high temperature. These are normally found in the protection rating of IP44, IP55, IP67 & IP68 which makes me waterproof, weatherproof, flameproof, etc.

• Standard Plugs are made up of lower quality Plastic as it has less current and Ampere to withstand and it does not have extra protection in terms of being waterproof or weatherproof.

3. Color Coding

• Industrial Plugs and Sockets have a special color-coding where Single Phase stands for Blue and Three Phase stands for Red as per IEC standards. Also, Camlocks have a unique codification which multiple colors as it is a single pole.

• Normal household plugs and sockets are always in white color.

4. Product Life

• A high quality and branded Industrial plugs and sockets like POWER N PACK or Marechal can easily work for 5-7 years or even more depending upon its usage and how it's handled.

• Standard Plugs and Sockets are having a standard quality and need to be replaced every 6- 12 months for its smooth use. Industrial Plugs and Sockets are actually a very important aspect of Safety and I personally feel that it has to be well taken care of to avoid some serious accidents. I believe few things have to be taken into consideration before buying them.

• Material of the product: I prefer ABS / PA6 material without any compromise because we are not just talking about power supply but worker/ staff associated with the machine these are connected to.

• Design & its Ergonomic structure: I feel that with continuous advancements and innovation, the latest design should be preferred which is robust and sturdy in nature.

• Warranty: I personally feel that if a company believes in its product, it would definitely provide a warranty for the same and thus it makes it easier to opt.

• Price: If it is fairly priced and has all the above qualities then I definitely feel, you should go for it. I have researched a lot over this and can say it with a lot of confidence that the manufacture of the best industrial plugs and sockets based on their quality and durability are POWER N PACK, SCAME, MARECHAL, etc.

1 note

·

View note

Text

Schneider Miniature Relay RXM4AB1P7

AEC switchgear provided Schneider Miniature Relay RXM4AB1P7 RXM miniature relays are part of Harmony Electromechanical Relays. This is a plug in relay to be mounted on a RXZE socket. It is a 4 C/O relay with current rating of 6A, control circuit voltage of 230 V AC 50/60 Hz. It also offers one-step loackable test button and mechanical indicator for contact status.

The testbutton is activated momentarily by pushing the red pushbutton on the front and locked by flipping up the green part. The mechanical indicator is next to the testbutton, where an orange flag indicates the relay contact status. Workablity for hard-wired logic automated systems to complement the functions of industrial progammable logic controllers (PLCs). Its design is fit for industrial machines, packaging, textile, HVAC, automation control panels, low/medium voltage switchgear, motor controls, PLC Interfaces, power supplies, building or medical equipment, lighting controls. It is a green premium product and conforms to international standard and certifications like IEC, CE, UL, CSA, EAC, Lloyd's, RoHS and REACH. RXM Relay should be used with a RXZE socket (screw clamp, screw connector, push-in terminal). To protect against vibrations, plastic/metal clamp can be added to the socket. Protection modules and marking legend are also available.

It is sold in lots of 10 and reference includes relay only. The RXM plug-in relays are a series of industrial plug-in relays designed for both simple and complex automation systems and available with 2 CO (12A), 3 CO (10A), 4 CO (6A) contacts, 4 CO (3A) low level contacts.

For More Information

https://www.linkedin.com/company/aec-ahmedabad-electric-corporation/mycompany/

0 notes

Text

Monoprice 105294 15ft 14AWG Power Cord Cable w/ 3 Conductor PC Power Connector Socket, 15A (NEMA 5-15P to IEC-320-C13) Black

Monoprice 105294 15ft 14AWG Power Cord Cable w/ 3 Conductor PC Power Connector Socket, 15A (NEMA 5-15P to IEC-320-C13) Black

Price: (as of – Details) Whether the power cable that came with your equipment are too long or too short you can find replacement cables in the perfect length right here. The standard 3 prong wall plug (NEMA 5-15p) to PC connector (IEC C13) cable was made commonplace by PC power supplies. Today they can be found providing power connections for many different products such as computers monitors…

View On WordPress

0 notes