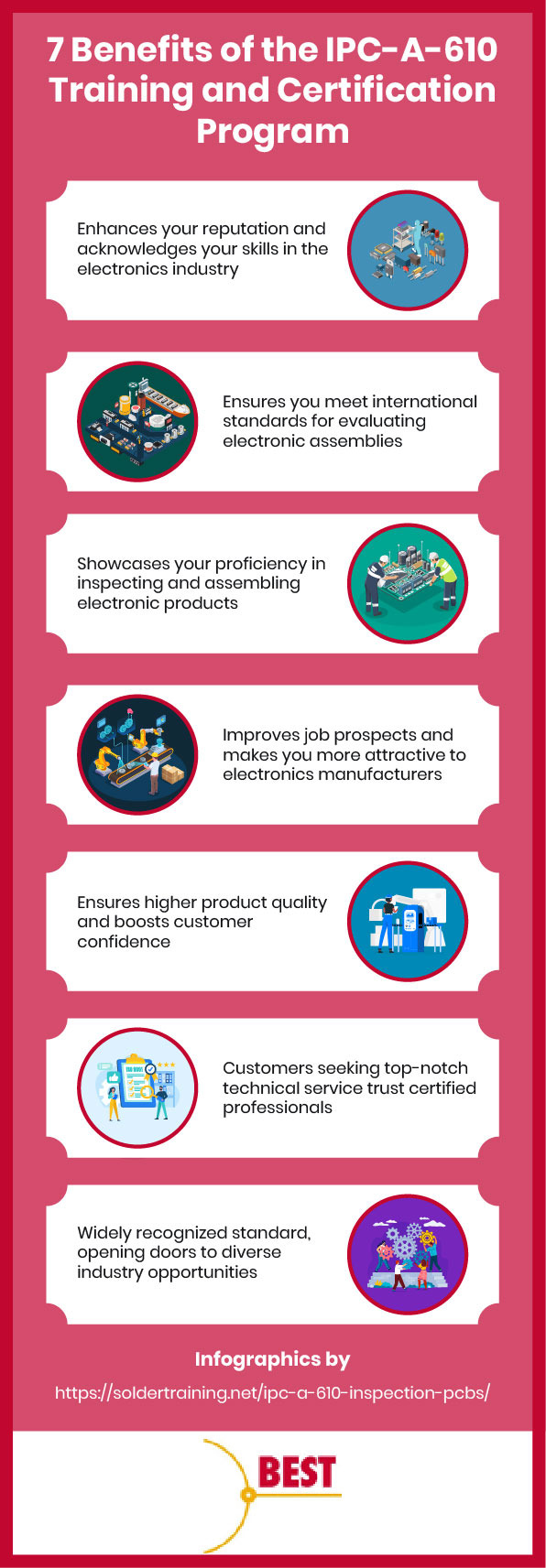

#IPC-A-610 Certification

Explore tagged Tumblr posts

Text

IPC-A-610 certification is an industry-standard document published by the Association of Connecting Electronics Industries (IPC). This widely recognized standard establishes the acceptability criteria for the assembly of electronic components, defining what is acceptable and what is not in terms of their artistry. To know more read this infographic: https://soldertraining.net/blog/benefits-of-ipca610-training-certification-program/.

0 notes

Text

Understanding CEM in Modern Electronics: A Practical Insight

Understanding CEM in Modern Electronics: A Practical Insight

In today’s complex electronics landscape, product innovation and efficient manufacturing go hand in hand. For engineers, designers, and procurement professionals, choosing the right electronics partner is no longer a matter of convenience—it’s essential to product success. At Arrival Electronics Limited, a company based in Arundel, West Sussex, clients find an experienced and well-established resource for navigating the ever-changing world of electronic components and contract manufacturing.

Whether you are developing a product prototype or managing large-scale production, understanding the value and structure of CEM—Contract Electronics Manufacturing—is key to maintaining consistency, reliability, and supply chain strength. This article breaks down the concept of contract electronics manufacturing in practical terms, why it matters, and what to consider when selecting the right partner for your business.

CEM Explained: How Outsourced Electronics Manufacturing Supports Product Success

CEM refers to the process where a company outsources some or all of its electronic manufacturing responsibilities to a third-party provider. These services can include the assembly of printed circuit boards (PCBs), box builds, cable assemblies, and even full system integration. For many businesses, this arrangement helps bridge the gap between concept and market delivery without investing in internal production facilities.

But the advantages of outsourcing electronic manufacturing are not limited to infrastructure savings. A seasoned provider brings value through quality control, compliance assurance, procurement efficiency, and reduced lead times. The focus is not just on manufacturing but on delivering consistent results across the entire product lifecycle.

The Role of Contract Manufacturing in Product Development

In the early stages of product development, design and testing cycles can be both time-intensive and cost-sensitive. Working with an experienced manufacturing partner during this phase ensures that designs are ready for production, not just in theory but in practice. This includes:

Design for Manufacture (DfM) input: Ensuring that designs can be replicated reliably at scale.

Component sourcing guidance: Helping identify component availability, pricing trends, and lifecycle risks.

Rapid prototyping: Allowing for multiple iterations and validation cycles before full production.

The value of this support is particularly noticeable in industries with tight regulatory requirements or highly customized designs. Knowing that your product is being assembled by a team familiar with these challenges adds a layer of assurance often missed when production is fragmented or uncoordinated.

Quality Control and Compliance in Electronics Manufacturing

Consistency is everything when it comes to electronics. A single deviation in assembly quality or component specification can compromise an entire batch of products. Reputable manufacturers implement rigorous quality control standards—often including ISO certifications and IPC-A-610 class ratings—to ensure production meets both industry standards and client expectations.

In addition, experienced production partners are frequently tasked with managing regulatory documentation. For sectors like medical, automotive, aerospace, and defence, regulatory compliance is not just about paperwork—it’s a vital part of risk management and long-term reliability.

With experienced providers, clients benefit from:

Traceability systems to track component origins and manufacturing data

Test procedures tailored to the client’s performance standards

Material compliance such as RoHS, REACH, and conflict mineral regulations

This commitment to precision manufacturing and documentation forms the foundation of long-term supply stability.

Supply Chain Management and Procurement

One of the most significant advantages of working with an experienced electronics manufacturing partner is procurement efficiency. The global electronics supply chain can be unpredictable—affected by material shortages, geopolitical issues, and currency fluctuations. A reliable provider has both the scale and supplier relationships to manage these challenges on your behalf.

By centralizing procurement and inventory management, the risk of component obsolescence, stockouts, and delivery delays is greatly reduced. Strategic sourcing, long-term supplier contracts, and access to authorized distribution channels allow clients to focus on core design and development tasks.

In many cases, these providers also help negotiate better pricing through consolidated purchasing volumes, improving overall cost-effectiveness without compromising on quality.

Customization and Flexibility in Electronics Manufacturing

Different companies have different requirements. Some need full assembly and testing; others only need PCB population or logistics support. A flexible production model is one that adapts to these varying levels of engagement.

For example, some clients may request:

Box build and enclosure integration

Cable and wire harness manufacturing

Programming and firmware upload

Functional testing and diagnostics

A well-structured manufacturing relationship allows businesses to adjust their production effort (either up or down) based on demand, without renegotiating contracts or reorganizing supply infrastructure. This adaptability is particularly important for startups, R&D teams, and businesses with seasonal product cycles.

The Importance of Local Manufacturing Support

While many companies consider offshore production due to lower costs, working with a local manufacturing partner still provides key advantages in terms of quality and communication. UK-based providers offer accessible collaboration, faster turnaround times, and streamlined logistics—all important factors in today’s competitive electronics environment.

Local manufacturing also contributes to:

Greater visibility during production runs

Faster issue resolution if engineering changes are required

Reduced transportation risks, especially for fragile or sensitive components

Working with a local partner ensures better control, particularly when dealing with niche products, custom builds, or compliance-heavy applications.

Trends in Electronics Manufacturing for 2025 and Beyond

As the demand for smarter, more integrated electronics continues to grow, so do the expectations placed on modern manufacturing services. Emerging technologies such as IoT-enabled devices, wearable electronics, and electric vehicle systems require a more advanced and flexible approach to assembly and testing.

In response, many manufacturing specialists are expanding their capabilities to include:

Microelectronics assembly

High-frequency RF product support

Environmentally controlled production environments

Long-term product lifecycle support

These advancements are not confined to high-volume production. Niche developers and innovators also benefit from working with partners that understand how to manage intricate designs and deliver dependable, high-quality builds.

Choosing the Right Manufacturing Partner

With so many electronics manufacturing options available, how do you decide which one is right for your project?

Here are five practical factors to consider:

Experience: Look for a provider with a strong track record in your specific industry. Practical experience brings valuable insight, especially when navigating technical designs and regulatory requirements.

Certifications: Confirm that the company holds relevant and current industry certifications, as these reflect adherence to recognized quality standards.

Transparency: A trustworthy partner will be clear about their production capabilities, timelines, and internal processes from the start.

Technical Support: It's beneficial to work with a team that offers design-stage assistance—not just assembly. Early input can prevent delays and reduce costs.

Location: Think about the practical benefits of working with a nearby provider, including easier communication, faster lead times, and simplified logistics.

By considering these factors carefully, you can reduce risk and improve the likelihood of a successful, long-term collaboration.

Why Contract Electronics Manufacturing Still Matters

In a world where electronics innovation is constant, outsourced production remains a vital service for product teams aiming to maintain focus and efficiency. It’s not just about handing off manufacturing—it’s about building the right partnerships. With increasing pressure to deliver quality products on time and within budget, working with a capable electronics manufacturing partner is a smart and strategic move.

This type of collaboration allows businesses to stay agile while drawing on technical expertise, stable supply chains, and reliable assembly processes. It helps bridge the gap between concept and product delivery—without the need for extensive internal infrastructure.

Conclusion

From component sourcing and design guidance to full assembly and product lifecycle support, Arrival Electronics Limited provides the practical expertise and trusted service needed in today’s competitive electronics industry. Located in West Sussex, the team works closely with clients across the UK and beyond, delivering dependable contract manufacturing solutions built on transparency, experience, and technical depth.

If you're looking for a CEM provider who understands your challenges and delivers reliable, detail-oriented service, consider a partner with proven experience and a commitment to quality at every stage of your project.

0 notes

Text

How to Choose the Right EMS Provider in India for Quality and Faster Time-to-Market

Choosing the right Electronics Manufacturing Services provider in India can significantly impact your product quality, production efficiency, and speed to market. With India's growing reputation as a global electronics manufacturing hub, thanks to initiatives such as Make in India and robust infrastructure development, more businesses are turning to Indian EMS partners for their end-to-end electronic assembly needs.

In this answer, I’ll walk you through the key aspects to consider when selecting an EMS provider in India and how a trusted partner like Resolute GOC can help you accelerate innovation while maintaining high standards.

Why India for Electronics Manufacturing Services?

India has rapidly evolved into a preferred destination for electronics manufacturing for several reasons:

Cost Efficiency: Lower labor and operational costs make Indian EMS providers globally competitive.

Skilled Workforce: A large pool of engineering talent and trained technicians ensures production precision.

Government Support: Policies such as the PLI (Production Linked Incentive) scheme have incentivized electronics production.

Geopolitical Stability: Compared to some other Asian countries, India offers a more stable business environment.

What Should You Look for in an EMS Provider?

When evaluating an Electronics Manufacturing Services provider in India, consider the following factors:

1) Technical Capabilities: Look for a provider with extensive experience in Surface Mount Technology (SMT), Through-Hole Technology (THT), box builds, printed circuit board (PCB) assembly, testing, and final packaging. The more technically diverse the provider is, the more they can support your growth.

2) Quality Certifications: Your EMS partner should comply with international quality standards, such as ISO 9001, ISO 14001, IATF 16949 (for the automotive industry), and IPC-A-610. These certifications ensure that the manufacturer adheres to global quality benchmarks.

3) Design and Engineering Support: An ideal EMS partner should offer Design for Manufacturability (DFM) and Design for Testing (DFT) services to optimize your product from the early stages. Engineering support helps avoid costly mistakes later in the production cycle.

4) Scalability and Flexibility: Can the provider handle your volume requirements as you scale? Whether you're a startup launching a new product or an enterprise managing large-scale production, the ability to ramp up or down without compromising quality is critical.

5) Turnaround Time and Supply Chain: Efficient supply chain management and faster turnaround times will reduce your time-to-market. Look for a provider that maintains strong relationships with component suppliers and demonstrates expertise in managing supply chain risks.

6) Testing and Quality Assurance: A strong EMS partner will have automated and manual testing capabilities, including in-circuit testing, functional testing, burn-in testing, and environmental stress screening. This ensures product reliability and performance.

7) Aftermarket Services: Support doesn’t end with assembly. Services like repair, rework, and reverse logistics demonstrate a provider’s commitment to the entire product lifecycle.

How the Right EMS Partner Can Transform Your Business

Choosing a reliable EMS provider isn’t just about outsourcing production; it’s about establishing a strategic partnership that supports innovation and growth. Here's how:

Improved Product Quality: High-precision assembly processes, real-time monitoring systems, and rigorous quality assurance protocols ensure consistently high-quality output. This results in fewer returns, lower defect rates, and better customer satisfaction.

Faster Time to Market: A full-service EMS provider accelerates the design-to-delivery process. Their expertise in prototyping, tooling, and rapid manufacturing enables you to launch new products more quickly than if you were managing everything in-house.

Cost Reduction: From minimizing BOM (Bill of Materials) costs to reducing labor and operational expenses, EMS companies in India offer significant cost advantages without compromising quality.

Innovation Enablement: Providers like Resolute GOC support innovation with integrated services, including prototyping, product development, and scalable production. This means more time and resources for your team to focus on design and market strategy.

Why Consider Resolute GOC?

Resolute GOC is one of the leading Electronics Manufacturing Services providers in India, offering comprehensive solutions for companies across various sectors, including automotive, industrial, medical, telecom, and consumer electronics. Here’s what sets them apart:

Comprehensive Capabilities: SMT, PCB assembly, product design, and system integration under one roof.

State-of-the-Art Infrastructure: Modern facilities equipped with high-speed pick-and-place machines, AOI, X-ray inspection, and automated testing systems.

Scalability: From low-volume prototypes to high-volume production, Resolute GOC adapts to your needs.

Strong Engineering Backbone: Their engineering team offers DFM and DFT support to improve manufacturability and reliability.

Quality First Approach: Stringent quality control measures and internationally certified processes ensure consistency and compliance.

Whether you’re a startup looking to bring a prototype to life or an OEM seeking volume production, Resolute GOC can serve as a reliable partner throughout your product lifecycle.

Conclusion

Selecting the right Electronics Manufacturing Services provider in India is a strategic decision that influences your product’s success, your brand’s credibility, and your company’s bottom line. By focusing on capabilities, quality, scalability, and reliability, you can find a partner that not only meets your current manufacturing needs but also evolves with you.

As Indian EMS companies continue to invest in advanced technologies and quality frameworks, the opportunity to build globally competitive products has never been more accessible. Explore providers like Resolute GOC, who are well-positioned to deliver innovative, efficient, and scalable solutions tailored to your specific requirements.

If you’re looking to optimize your electronics manufacturing strategy and expand your reach, India’s EMS landscape is ready; the only question is, are you?

0 notes

Text

How to Choose the Top 10 Electronics Manufacturing Companies in India

India is fast becoming a global hub for electronics manufacturing, driven by government initiatives like the Make in India program and PLI schemes. With hundreds of options available, choosing the top 10 electronics manufacturing companies in India can be overwhelming. Here's a practical guide to help you evaluate and select the right manufacturing partner for your needs.

1. Identify Your Manufacturing Needs

Start by understanding what services you require. Top electronics manufacturers in India offer:

PCB fabrication and assembly (PCBA)

SMT and through-hole assembly

Cable harnessing and box build

Functional and in-circuit testing

Choose a company whose capabilities match your product complexity—whether it’s for consumer electronics, automotive parts, or industrial systems.

2. Check Certifications and Quality Standards

The best manufacturers follow international quality systems such as:

ISO 9001 (Quality Management)

ISO 13485 (Medical Devices)

IATF 16949 (Automotive Electronics)

RoHS and REACH compliance

Also, confirm if they adhere to IPC-A-610 or J-STD-001 for PCB assembly quality. These standards help ensure product safety, reliability, and global market access.

3. Evaluate Experience and Industry Focus

Experience matters in electronics manufacturing. Companies that have served a variety of sectors like telecom, defense, healthcare, and automotive bring valuable expertise.

Check their years in business, client list, testimonials, and whether they support both startups and large OEMs. A company with a strong track record can deliver better consistency and support.

4. Assess Infrastructure and Technology

Top EMS companies invest in modern facilities with:

Automated SMT lines

AOI (Automated Optical Inspection)

X-ray inspection

ESD-safe environments

Cleanroom facilities (for sensitive products)

Also, look for scalability—can they handle your production volume from prototyping to mass manufacturing?

5. Review Communication and Support

Strong customer service is a must. Your ideal partner should provide:

A dedicated project manager

Transparent pricing and production updates

Online tracking of orders

Post-sales support and RMA services

Clear communication avoids delays and misunderstandings during production.

6. Use Verified Sourcing Platforms Like FindingMFG

To save time and reduce risk, consider sourcing through FindingMFG—a trusted platform that connects global buyers with verified electronics manufacturing companies in India. With FindingMFG, you can:

Get instant quotes from multiple EMS providers

Compare capabilities and certifications

Track your projects online

Ensure quality through vetted partners

Final Thoughts

Choosing the right electronics manufacturer in India is about more than location or cost. Focus on technical capabilities, certifications, experience, and communication. By using platforms like FindingMFG, you simplify sourcing and ensure you’re partnering with reliable, high-quality EMS providers.

0 notes

Video

youtube

Partnering with Reliable Manufacturers Choosing the right manufacturing partner is crucial for successful PCBA production. A reliable manufacturer ensures high-quality assembly, timely delivery, and cost-effective solutions. When evaluating potential partners, focus on their experience and certifications. Look for manufacturers with a proven track record in your industry. Certifications like ISO 9001 or IPC-A-610 indicate adherence to quality standards. Ask for references or case studies to assess their capabilities. Note: A manufacturer with in-house testing facilities can save you time and ensure consistent quality. Communication is another key factor. A good partner keeps you informed throughout the production process. They provide regular updates, address concerns promptly, and collaborate on design improvements. Transparent communication helps you avoid misunderstandings and ensures smooth project execution. Here’s a quick checklist for selecting a manufacturer: Verify their certifications and industry experience. Assess their production capacity and lead times. Confirm their ability to handle complex designs or high-volume orders. Evaluate their customer support and responsiveness. By partnering with a reliable manufacturer, you can focus on innovation while leaving the assembly process in capable hands. This collaboration ensures your PCBAs meet the highest standards of quality and performance. Printed Circuit Board Assembly (PCBA) remains a cornerstone of modern electronics, powering devices across industries. Its role in enabling innovation, from wearable technology to advanced medical equipment, highlights its significance. Recent advancements, such as miniaturization, 3D printing, and IoT integration, promise to reshape the industry in 2025. These innovations enhance efficiency, reduce costs, and open new possibilities for design. You can stay ahead by adopting best practices like thorough testing, quality control, and partnering with reliable manufacturers. These steps ensure your assemblies meet the highest standards, delivering reliable and efficient solutions for the future. #pcbassembly #ElectronicsManufacturing #AutomationInnovation #PCBAssembly #SolderFluxCleaning #UltrasonicCleaning #WaterBasedCleaning #IPCCompliance #EnvironmentalSustainability #ManufacturingExcellence #QualityAssurance #IndustrialAutomation #ElectronicsEngineering #LeanManufacturing #ProcessOptimization #HighTechManufacturing #CleanroomTechnology #ComponentProtection

0 notes

Text

Streamlining Electronics Production: How to Choose the Right PCB Assembly Manufacturer

In today’s fast-paced electronics industry, selecting the right PCB assembly manufacturer is critical to product performance, speed to market, and overall success. Whether you're developing consumer electronics, industrial systems, or IoT devices, a reliable partner for PCB board assembly and PCB manufacturing assembly ensures quality, consistency, and scalability.

This article will guide you through what to look for in a dependable manufacturer and how the right choice can simplify your electronics production process from design to delivery.

1. What Does a PCB Assembly Manufacturer Do?

A PCB assembly manufacturer is responsible for soldering components onto a printed circuit board (PCB) to build a fully functioning electronic assembly. This includes handling both surface-mount technology (SMT) and through-hole technology, depending on the design requirements.

Top-level assembly services often include:

Component sourcing and inventory management

SMD and through-hole component placement

Reflow and wave soldering

Functional testing and inspection

Final packaging and delivery

When choosing a partner, ensure they offer comprehensive PCB manufacturing assembly under one roof—this minimizes errors, reduces turnaround time, and simplifies communication.

2. Understanding the PCB Board Assembly Process

The PCB board assembly process involves several critical stages:

Stencil printing: Applying solder paste to the PCB using a stencil

Pick-and-place: Automated machines place components with high precision

Soldering: Typically done through reflow or wave soldering methods

Inspection: AOI (Automated Optical Inspection), X-ray (for BGAs), and manual checks

Testing: Functional and in-circuit testing to ensure proper performance

Each of these steps requires advanced machinery and expert oversight, making it essential to work with a manufacturer that has a proven track record and quality certifications such as ISO 9001 or IPC-A-610.

3. Benefits of Working with a Full-Service PCB Manufacturing Assembly Partner

A full-service PCB manufacturing assembly partner can manage your project from prototype to full-scale production. This has several benefits:

Speed: Faster time-to-market with streamlined production processes

Quality assurance: Consistent output with strict quality control standards

Cost-efficiency: Reduced overhead from consolidated services

Design support: DFM (Design for Manufacturability) feedback helps avoid costly errors early

Look for partners offering quick-turn PCB assembly services, low-volume prototyping, and high-volume scalability.

4. Key Features to Look for in a PCB Assembly Manufacturer

When evaluating manufacturers, ask these questions:

Do they offer both prototyping and volume production?

What is their standard lead time for PCB board assembly?

Can they handle complex, multi-layer boards?

Do they assist with sourcing hard-to-find components?

Are their facilities equipped for RoHS-compliant or lead-free production?

Also, check whether the manufacturer has experience in your specific industry—be it medical devices, automotive systems, consumer tech, or industrial automation.

Final Thoughts

Choosing the right PCB assembly manufacturer is more than a procurement decision—it’s a strategic partnership that impacts product quality, cost, and time to market. By partnering with a provider that offers end-to-end PCB board assembly and complete PCB manufacturing assembly services, you gain a competitive edge in both development speed and product reliability.

Whether you're an engineer, startup, or OEM, investing in the right assembly partner can make all the difference.

0 notes

Text

Hitech Circuits—Your Reliable Supplier for Premium PCB Assembly

At Hitech Circuits, we specialize in high-efficiency, high-precision surface mount technology (SMT) assembly, delivering unmatched capacity and quality for your PCB projects.

Our Capabilities:

1. Massive Daily Output

1 Million+ Components Placed Daily**: Powered by fully automated SMT lines (e.g., Fuji NXT, Siemens SIPLACE) and high-speed pick-and-place systems, we ensure rapid production scaling for both prototypes and bulk orders.

2. Advanced Packaging Expertise

QFN/BGA Mastery: Our precision equipment handles ultra-fine-pitch components, including QFN (0.3mm pitch) and BGA (down to 0.2mm ball diameter), with 99.99% placement accuracy.

X-Ray Inspection: 100% in-line X-ray verification for BGA solder joints, voids, and alignment defects, ensuring zero hidden faults.

3. End-to-End Quality Control

AOI + SPI Integration: Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) at every stage.

IPC-A-610/612 Compliance: Certified processes for mission-critical applications.

Why Choose Us?

Speed-to-Market: 48-hour prototype turnaround & 10-day mass production cycles.

Flexible MOQs: Support for small-batch R&D to 100k+ volume orders.

Global Material Sourcing: Access to a vetted network of component suppliers, reducing lead times.

Contact Us Today!

Let’s optimize your PCB assembly with speed, precision, and reliability.

Email:[email protected]

Tel & Whatsapp: +86-180333061378

Location: Building C, Suojia Technology Park, Hangcheng, Xixiang, Shenzhen, Guangdong, China

Authority certification: we're fully ISO9001:2015, ISO14001:2015 , UL (E354070) and RoHS certificated. You can reply on us for custom PCB production and Electronic assembly.

0 notes

Text

Aimtron: A Name You Can Trust for PCB Assembly Manufacturing Services in Illinois

When it comes to PCB assembly manufacturing services, quality and reliability are paramount. With Aimtron, you can trust that you're working with a leader in the industry, providing top-notch services in Illinois and beyond. Our commitment to excellence and customer satisfaction has earned us a stellar reputation in the field of electronics manufacturing.

Unparalleled PCB Assembly Services

At Aimtron, we pride ourselves on offering comprehensive PCB assembly services tailored to meet the unique needs of our clients. Our state-of-the-art facility in Illinois is equipped with cutting-edge technology and staffed by highly skilled professionals. We handle everything from prototyping to full-scale production, ensuring your project is completed with precision and efficiency.

Expertise in PCB Design

In addition to our assembly services, Aimtron specializes in PCB design. Our team of experienced engineers works closely with clients to develop innovative and effective solutions. We understand that each project is different, and we customize our designs to meet your specific requirements. With our expertise, you can be confident that your PCB design will be optimized for performance and manufacturability.

Commitment to Quality

Quality is the cornerstone of Aimtron's PCB assembly manufacturing services. We adhere to strict industry standards and employ rigorous quality control measures throughout the production process. From the selection of raw materials to the final inspection, every step is meticulously monitored to ensure the highest level of quality and reliability. Our dedication to quality has earned us numerous certifications, including ISO 9001 and IPC-A-610.

Serving a Wide Range of Industries

Aimtron's PCB assembly services cater to a diverse array of industries, including telecommunications, medical devices, automotive, consumer electronics, and more. Our versatile capabilities and extensive experience allow us to handle projects of all sizes and complexities. Whether you need a small batch of prototypes or a large-scale production run, we have the expertise and resources to deliver exceptional results.

Customer-Centric Approach

At Aimtron, we believe in building strong, long-lasting relationships with our clients. Our customer-centric approach ensures that we understand your needs and provide personalized solutions that exceed your expectations. We are committed to delivering exceptional value, timely delivery, and unparalleled support throughout the entire project lifecycle.

Conclusion

When it comes to PCB assembly manufacturing services in Illinois, Aimtron is a name you can trust. With our expertise in PCB design, commitment to quality, and customer-centric approach, we are dedicated to helping you achieve success in your electronics manufacturing projects. Partner with Aimtron and experience the difference that a trusted industry leader can make.

#pcbassembly#pcbassemblymanufacturer#pcbassemblyservices#pcbassemblyservice#electronicsmanufacturing#PCBassemblyManufacturingServicesinIllinois

0 notes

Text

Unlocking Excellence: The Journey to Become a Certified IPC Trainer (CIT)

From the world of fine craftsmanship and accuracy in electronics manufacturing! The IPC certification Trainee (CIT) credential is a must-have for anyone looking to advance their career and make a positive impact on the dynamic electronics industry. It is only offered by IPC-approved training facilities like Blackfox.

We'll explore the value of CIT soldering certification, the training requirements, and the advantages it offers to individuals and businesses in this blog.

Why Select Certification in CIT?

The electronics sector requires highly qualified workers to guarantee the dependability and quality of electronic assemblies. The purpose of the CIT certification is to empower employees in businesses, self-employed consultants, and instructors at colleges and universities. Let's examine the main justifications for CIT certification among prospective professionals:

Industry Recognition: In the electronics manufacturing sector, the CIT certification is well-known. It is evidence of a person's skill and dedication to upholding standards of excellence.

Program for "Training the Trainer": The IPC certification is basically a "train-the-trainer" initiative. After passing the exam, candidates will have the information and abilities needed to instruct other people in their company or at a school as Certified IPC Specialists (CIS).

Comprehensive Training Materials: CITs can conduct application-level (CIS) IPC training with the IPC materials that Blackfox, an IPC-authorized training center, provides. This includes current details on soldering methods, industry standards, and best practices for electronic assembly.

The Process of CIT Training

The path to becoming a Certified IPC Trainer is demanding but worthwhile. Let's go over the main stages of the CIT training procedure:

1. Prerequisite Knowledge: Before beginning the CIT certification process, candidates usually have a strong background in electronics and soldering procedures.

CIT candidates receive instruction in the IPC-A-610 standard, which outlines the requirements for acceptable electronic assemblies. This training ensures a thorough understanding of industry standards and requirements.

2. Assessment of Hands-On Skills: Practical application is a key component of the CIT certification. Candidates participate in a practical skills evaluation where they demonstrate their soldering abilities and application of IPC standards.

3. Certification Exam: An extensive test covering the IPC-A-610 standard is the last obstacle. Succeeding candidates exhibit their command of the subject and dedication to upholding standards in the production of electronics.3

Advantages of Certification in CIT

Getting certified as a CIT opens doors to a lot of advantages for people and their companies:

Enhancement of Skill: CITs' overall skill set is improved by their increased understanding of soldering methods, electronic assembly procedures, and IPC standards.

Credibility in the Industry: The CIT certification is a symbol of excellence that gives professionals in the electronics manufacturing sector respect and credibility.

Cost savings: Having in-house trainers helps organizations cut costs related to errors and rework, as well as the need for outside training services.

Constant Learning: To keep CITs abreast of the latest developments in technology and industry best practices, they are provided with regular updates on industry standards.

Joining Blackfox as a Certified IPC Trainer is more than just obtaining a credential—it's a pledge to excellence in the electronics manufacturing industry. Whether you work in the industry as a professional or as an instructor, earning your soldering certification and CIT certification guarantees that you contribute significantly to upholding the highest standards in electronic assembly and opens doors to new opportunities.

Visit Blackfox's IPC-authorized training facility in Delaware to start your journey toward CIT certification and discover your potential as a leader and educator in the exciting field of electronics.

0 notes

Text

In the forefront of #ElectronicsManufacturing, Avalon Best EMS Company stands out with its exemplary #PCBAssembly processes. We’re excited to share insights into Avalon's dedicated approach to manufacturing that not only ensures #QualityAssurance but also streamlines rapid prototyping and volume manufacturing to meet today’s dynamic market demands. Understanding PCB Assembly: Printed Circuit Board assembly is the heart of functional electronic circuits. It's not just about soldering components; it's about ensuring lasting connectivity and performance. The Importance of High-Quality Assurance: Reliable electronic products hinge on stringent quality control. Avalon's robust measures are the bulwark against defects, guaranteeing customer satisfaction and #BusinessSuccess. Avalon’s Capabilities: Swift chip mounting for #RapidPrototyping. Flexible production lines for any volume. Advanced SMT lines for complex assemblies. Ensuring Excellence: State-of-the-art AOI and X-ray inspections. Rigorous quality control from start to finish. A highly skilled workforce trained in cutting-edge assembly techniques. Avalon holds prestigious ISO 9001:2015 and IPC-A-610 certifications, reflecting a relentless pursuit of quality. By choosing Avalon, you choose a partner dedicated to excellence. Save time, cut costs, and ensure your products stand out in the market. Join the ranks of satisfied clients who trust Avalon for their PCB assembly needs. Visit https://lnkd.in/gbEj6nz6 for more information. https://www.avalontec.com/contact/ https://www.avalontec.com/blog/pcb-assembly/

#AvalonEMS#Electronics#ManufacturingExcellence#QualityControl#PCBManufacturing#Innovation#TechIndustry#electronics#electronicsindustry#electronicmanufacturing Avalon Technologies Limited Sienna Corporation Sienna ECAD Technologies Private Limited

0 notes

Text

youtube

BEST Inc.'s training methods align with industry standards. The electronics company provides technicians with wide-ranging certification courses. Their IPC-A-610 certification program is an industry-consensus program that includes training, certification, and instructional materials that align with IPC-A-610 criteria. This training and certification program is well-known in the electronics industry. Those that want to join IPC A-610 training can contact BEST Inc. To know more, watch this video or visit their website: https://soldertraining.net/ipc-a-610-inspection-pcbs/.

0 notes

Text

QUALITY ENGINEER 3149762

JOB ID: 3149762 FULL-TIME ONSITE ROLE WITH PAID RELOCATION Our esteemed client, an industry leader in Aerospace, Aviation, and Defense, is seeking a highly skilled individual for a challenging role in Quality Engineering based in Dayton, Ohio. This opportunity comes with numerous benefits, including a generous bonus structure. QUALITY ENGINEER POSITION Location: Dayton, Ohio, United States Industry: Aerospace / Aviation / Defense Scheduled work from home days Job Category: Manufacturing - Quality Client: Award-Winning Global Leader Responsibilities - Develop and execute project quality plans, witness-points, and quality records for compliance. - Collaborate with diverse teams to address and resolve non-conformances effectively. - Perform dimensional and visual inspections on various components, utilizing scales, calipers, and gauges. - Analyze and summarize data, generating insightful reports and pivot tables. - Ensure Lessons Learned are considered in new proposals and programs. - Witness and audit hardware and software development processes to ensure adherence to standards. - Contribute to continuous improvement initiatives in processes and execution. - Review and approve drawings and work instructions as needed. - Identify needs/causes/trends and present analysis for potential resolutions. - Create inspection criteria for in-process and final inspection based on blueprints, drawings, schematics, and specifications. - Read, understand, and apply written work instructions, procedures, specifications, and standards. - Ensure regulatory, procedural, and contractual requirements are met during product development/introduction. Qualifications Minimum Qualifications - U.S. Citizen. - High school diploma or equivalent. - 5 years of hands-on experience with inspection of electronic, mechanical, and/or electro-mechanical components and assemblies. - Strong quantitative and analytical skills. - Strong oral and written communication skills, excellent customer relationship building skills, and strong interpersonal and leadership skills. Preferred Qualifications - Strong commitment to quality, safety, and processes, coupled with flexibility to meet evolving needs. - Meticulous attention to detail. - Ability to offer guidance or direction to other personnel, as needed. - Experience with aerospace industry standards such as AS9100, AS9102, and AS9145 (APQP). - Experience working on electronics/electromechanical assemblies. - Familiarity with ESD protocols and practices. - Capability to coordinate multiple projects simultaneously. - Proficiency in standard Microsoft Office programs. - Understanding of root cause & corrective action methods. - Proven analytical and organizational abilities. - Ability to lead initiatives of moderate scope and impact. - Experience reviewing/generating FAIs in accordance with AS9102. - Quality auditor experience is advantageous. - IPC J-STD 001/610 and 620 certification. JOB ID: 3149762 Read the full article

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVQGx

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVHXk

0 notes

Text

BEST Inc. Offers Certification Training for IPC-A-610 and IPC-A-620 Standards

http://dlvr.it/SwVGQB

0 notes

Text

Choosing the Right PCB Fabrication Company for High-Quality SMD PCB Assembly

In the fast-paced world of electronics manufacturing, selecting the right PCB fabrication company is critical to ensuring high-quality SMD PCB assembly. Whether you are developing consumer electronics, industrial equipment, or medical devices, partnering with a reliable PCB manufacturer can determine the success of your product.

Surface Mount Device (SMD) technology has revolutionized modern circuit board assembly by allowing manufacturers to place components directly onto the surface of printed circuit boards. This method provides better performance, higher reliability, and increased efficiency compared to traditional through-hole assembly. However, achieving these benefits requires expertise in both PCB fabrication and SMD assembly. This article explores key factors in selecting a PCB fabrication company that specializes in SMD PCB assembly and what you should look for to ensure top-tier quality.

The Importance of PCB Fabrication in SMD PCB Assembly

Before discussing how to choose a PCB fabrication company, it is essential to understand the role of PCB fabrication in the SMD PCB assembly process. A well-manufactured PCB provides a solid foundation for mounting SMD components. The precision of fabrication affects signal integrity, electrical performance, and durability of the final product.

A high-quality PCB fabrication company ensures:

Accurate layer alignment: Multi-layer PCBs require perfect alignment to avoid electrical failures.

Precise trace width and spacing: Proper trace routing ensures optimal signal transmission and prevents short circuits.

High-quality substrate materials: The right materials improve thermal performance and durability.

Reliability of vias and solder mask: Essential for long-term circuit performance.

Poor PCB fabrication leads to defects such as misaligned components, electrical shorts, and weak solder joints, affecting the overall functionality of the assembled board.

Key Factors to Consider When Choosing a PCB Fabrication Company

Selecting the right PCB fabrication company is a crucial decision that impacts product quality, cost, and lead times. Below are the essential factors to evaluate:

1. Experience and Industry Expertise

A reputable PCB fabrication company should have extensive experience in handling SMD PCB assembly projects. Look for manufacturers with a proven track record in your industry, whether it is automotive, aerospace, medical devices, or telecommunications.

2. Manufacturing Capabilities

Ensure the company has advanced facilities and cutting-edge machinery for precision fabrication and assembly. Key capabilities to check include:

Fine-pitch component placement for high-density PCBs.

Automated Optical Inspection (AOI) to detect defects.

X-ray inspection for checking solder joints in complex assemblies.

BGA, QFN, and other advanced packaging capabilities.

3. Quality Control and Certifications

A reliable PCB fabrication company follows strict quality control standards to deliver flawless SMD PCB assembly. Look for certifications such as:

ISO 9001 for quality management.

IPC-A-610 for assembly standards.

RoHS compliance for environmentally friendly manufacturing.

UL certification for safety standards.

4. Turnaround Time and Scalability

Timely delivery is essential for businesses that operate on strict deadlines. Choose a company that offers:

Quick prototyping services.

Flexible production runs (small to large-scale).

Efficient supply chain management to avoid delays.

5. Customization and Design Support

A great PCB fabrication company provides design support to optimize manufacturability. Services like Design for Manufacturability (DFM) and Design for Testability (DFT) help reduce errors and improve production efficiency.

Benefits of Partnering with a Reliable PCB Fabrication Company

Working with an experienced PCB fabrication company that specializes in SMD PCB assembly offers several advantages:

1. Improved Product Performance

High-quality fabrication ensures superior electrical conductivity, heat dissipation, and mechanical strength, leading to reliable PCBs that perform optimally under various conditions.

2. Cost Efficiency

Efficient manufacturing processes reduce material waste and labor costs, helping businesses achieve better cost savings without compromising quality.

3. Faster Time to Market

A streamlined production process enables rapid prototyping and mass production, allowing companies to launch their products faster.

4. Reduced Defects and Failures

Strict quality control measures prevent defects such as cold solder joints, misaligned components, and signal integrity issues, resulting in long-lasting, high-performance PCBs.

Trends in PCB Fabrication and SMD PCB Assembly

The electronics industry is constantly evolving, and PCB fabrication companies are adopting new technologies to enhance SMD PCB assembly processes. Key trends include:

1. Miniaturization and High-Density PCBs

With consumer electronics getting smaller, manufacturers are focusing on ultra-thin PCBs with fine-pitch components to accommodate compact designs.

2. Lead-Free and Eco-Friendly Manufacturing

Companies are shifting towards RoHS-compliant materials and lead-free soldering processes to meet environmental regulations.

3. AI and Automation in Assembly

Artificial intelligence and robotics are improving precision and efficiency in PCB assembly, reducing human error and increasing production speed.

4. Flexible and Rigid-Flex PCBs

Industries such as medical and automotive electronics are demanding flexible PCBs that can bend without breaking, leading to innovation in materials and design.

Conclusion

Selecting the right PCB fabrication company is a critical step in ensuring high-quality SMD PCB assembly. By evaluating factors such as experience, manufacturing capabilities, quality certifications, and turnaround time, businesses can make informed decisions that lead to superior PCB performance and long-term reliability.

With advancements in SMD PCB assembly technology, manufacturers that invest in innovation, automation, and eco-friendly processes will continue to lead the industry. Whether you are developing cutting-edge consumer gadgets or complex industrial equipment, partnering with the right PCB fabrication company will help you achieve excellence in electronics manufacturing.

0 notes