#ISO Fire Testing Standards

Explore tagged Tumblr posts

Text

🔥 Lateral Spread of Flame Test – Essential for Fire Safety Compliance 🔥

Fire safety is critical in industries such as construction, transportation, aviation, and marine. The ISO 5658 Lateral Spread of Flame Test is designed to measure how fire propagates across the surface of materials. This test ensures that materials used in high-risk environments meet global fire safety regulations.

🔥 What is the ISO 5658 Lateral Spread of Flame Test?

The ISO 5658 test evaluates the fire performance of materials by exposing them to a controlled flame. This test determines:

Flame Spread Rate: How quickly fire spreads across the material's surface.

Ignition Time: The time it takes for the material to catch fire.

Burning Behavior: The reaction of the material when exposed to direct flame.

Industries such as railway, aerospace, and construction require this test to ensure fire-resistant materials are used in buildings, trains, aircraft, and marine vessels.

🌍 Why Choose KDM Global for Fire Testing Equipment?

At KDM Global, we manufacture high-quality fire testing equipment, including the ISO 5658 Lateral Spread of Flame Test Apparatus. Our advanced testing solutions ensure:

Precision & Accuracy: Reliable data for material safety certification.

Compliance with ISO 5658 Standards: Meeting global fire testing requirements.

Robust & Durable Equipment: Built for long-term, high-performance testing.

🚆 Industries That Require Lateral Spread of Flame Testing

Various industries rely on the ISO 5658 test to assess the fire behavior of materials:

🏗️ Construction: Fire-resistant materials for safer buildings.

🚄 Railway: Ensuring compliance with railway safety regulations.

✈️ Aerospace: Testing aircraft cabin materials for fire resistance.

🚢 Marine: Ensuring ship interiors meet safety standards.

🔍 Get the Best Fire Testing Equipment from KDM Global!

Looking for the most reliable fire testing machines? KDM Global's ISO 5658 Lateral Spread of Flame Test Apparatus is designed to provide accurate results for your fire safety compliance needs.

🌐 Learn More About Our Product: ISO 5658 Lateral Spread of Flame Test Apparatus

📌 Visit Our Website: KDM Global

📞 Contact Us: +91 8218470498 | +91 7983475310

Ensure fire safety compliance with KDM Global’s high-precision fire testing equipment today! 🔥

#Lateral Spread of Flame Test#ISO 5658#Fire Testing Equipment#Flammability Testing Machine#Fire Safety Testing#Flame Spread Rate#Ignition Time#Fire Retardant Materials#Building Fire Safety#Railway Fire Testing#Aerospace Fire Standards#Marine Fire Safety#Fire Resistance Test#Construction Fire Safety#Aircraft Fire Safety#Ship Fire Safety#High-Performance Fire Testing#Fire Safety Compliance#Fire Testing Laboratory#KDM Global#Best Fire Testing Equipment Manufacturer#Flammability Test Apparatus#Fire Retardant Material Testing#Industrial Fire Testing#Fire Testing Machines#ISO Fire Testing Standards#Fire Spread Measurement#Material Ignition Test#Railway Fire Compliance#Aviation Fire Resistance

0 notes

Text

7 Signs You’re Buying the Best TMT Bar for Construction

When building a home or structure meant to last generations, quality isn’t optional—it’s the foundation. Choosing the best TMT bar can make all the difference between a structure that endures and one that weakens with time. Right from the start, smart buyers should pay close attention to what goes into the making of these bars. That includes elements like HR coils and Super Rings, which directly affect strength, flexibility, and durability.

Low-grade TMT bars often compromise structural integrity. Cracks in walls, rusting frames, or poor resistance during quakes are all too common when corners are cut during purchase. So how do you spot the right choice in a sea of options?

Here are seven telltale signs you’re picking the best TMT bar for your construction project.

1. Raw Material Quality is Non-Negotiable

The first clue lies in the raw materials. High-grade HR coils are the backbone of premium TMT bars. These coils offer uniformity in composition, ensuring that the bar performs consistently under pressure. If your supplier can’t confirm the source and grade of HR coils used, it’s time to walk away.

2. Excellent Ductility with Super Rings Integration

TMT bars that incorporate Super Rings during processing offer better grip with concrete. This ensures higher bonding strength—an essential during earthquakes or heavy stress. The unique rib design these rings create enhances friction and structural cohesion.

3. Corrosion Resistance That Lasts

Structures often face harsh conditions—humidity, rain, and coastal winds. The best TMT bar includes anti-corrosive properties that come from a refined manufacturing process. If a bar rusts quickly or feels flaky at the surface, it won’t hold up in the long run.

4. Uniform Rib Pattern Across Length

Consistent ribbing—especially those shaped using Super Rings—makes a bar more dependable. It ensures equal bonding throughout, leaving no weak spots when embedded in concrete. Uniformity also signals that advanced rolling technology was used in manufacturing.

5. Certified Quality Control and Lab Testing

Top-tier manufacturers subject their bars to stringent quality tests—tensile strength, bend tests, elongation, and more. Ask for certifications. Brands that produce the best TMT bar don’t hesitate to share lab results. They know trust is built on proof, not promises.

6. Earthquake-Resistant Flexibility

Construction in seismic zones demands bars with excellent elongation properties. This flexibility often stems from how well the HR coils were processed and whether thermal treatment was uniformly applied. Without this, a bar may snap under stress instead of bending.

7. Transparent Branding and Reputation

Reputable brands make it easy to trace where their bars came from, how they were made, and what makes them reliable. They don’t hide the fact that HR coils and Super Rings play a pivotal role in delivering high-performance steel. If a supplier dodges questions or offers vague claims, they’re likely not offering the best TMT bar.

Conlusion

When all these signs align, it’s more than just a product—it’s peace of mind. Investing in a construction project is a long-term commitment, and quality should never be compromised for a quick bargain.

Recognizing these seven signs means moving beyond guesswork. It empowers buyers to make informed, confident decisions that keep people safe and properties strong. After all, the true strength of a building starts long before the first brick is laid—it starts with choosing the right steel.

FAQs

1. How can I test the quality of a TMT bar on-site? Check for uniform rib patterns, perform a bend test, and ask for mill test certificates from the supplier.

2. What role do HR coils play in TMT bars? HR coils determine the core strength and consistency of the bar—high-quality coils result in better durability and load-bearing capacity.

3. Are Super Rings necessary in TMT bars? Yes. Super Rings improve concrete bonding, reducing the chances of structural failure during stress or seismic activity.

#Bend test#Steel grade#TMT marking#ISO certified#Corrosion check#Crack test#High strength#Steel purity#Weldability#IS standard#TMT quality#Fire resistance#Seismic safe#TMT coating#Uniform ribs#Bar weight match#Length check#Lab tested bars#Trusted brands#Site safe steel

0 notes

Text

Understanding the Importance of Smoke Density Testing in Fire Safety

Understanding the Importance of Smoke Density Testing in Fire Safety

Introduction

Smoke density testing plays a crucial role in evaluating the fire performance of materials used in construction, transportation, and manufacturing industries. The Smoke Density Chamber ISO 5659 is widely used for measuring smoke emission levels under controlled conditions, ensuring compliance with international fire safety standards such as ISO 5659 and ASTM E662.

Why is Smoke Density Testing Important?

Ensures Fire Safety Compliance – Many industries must meet fire resistance and flammability standards before materials can be approved for use.

Reduces Fire Hazards – Lower smoke emission levels reduce visibility obstruction and toxicity, enhancing evacuation safety.

Mandatory for Transportation Sectors – The aviation, railway, and automobile industries require smoke density testing for interior materials to improve passenger safety.

Key Features of the Smoke Density Chamber ISO 5659

Accurate Smoke Emission Measurement under controlled laboratory conditions.

Compliant with International Standards (ISO 5659, ASTM E662).

High-precision Optical System for measuring light transmission and smoke density.

Automated Test Process for efficient and repeatable testing.

Industries That Require Smoke Density Testing

The Smoke Density Test Apparatus is essential for industries such as: ✅ Construction & Building Materials – Ensures materials used in walls, ceilings, and floors meet safety norms. ✅ Automobile & Transportation – Used for testing cabin interiors, seats, and insulation materials. ✅ Aerospace & Railways – Determines the smoke toxicity levels in aircraft and train components. ✅ Polymer & Textile Industries – Evaluates flammability properties of synthetic materials.

Why Choose KDM Global for Smoke Density Testing Equipment?

At KDM Global, we are a trusted Smoke Density Test Apparatus Manufacturer in India, offering:

High-quality fire testing equipment with precise and reliable results.

Customizable solutions for various industry needs.

Worldwide shipping to ensure global compliance with fire safety standards.

🔗 Explore more about our Smoke Density Chamber ISO 5659.

Final Thoughts

Smoke density testing is vital for ensuring material safety in case of fire emergencies. Investing in a high-quality Smoke Density Chamber helps industries maintain compliance, safety, and reliability in their products.

📞 Contact us today for inquiries: 📧 Email: [email protected] 📞 Phone: +91 8218470498 | +91 7983475310

🚀 Stay compliant and prioritize fire safety with KDM Global!

Follow us on Social Media: 🔹 Facebook | 🔹 LinkedIn | 🔹 Twitter (X) | 🔹 YouTube | 🔹 Instagram | 🔹 Pinterest

#Smoke Density Chamber ISO 5659#Smoke Density Test Apparatus Manufacturer in India#Fire Testing Equipment Manufacturer#Flammability Testing Machine Manufacturer#Smoke Density Testing#ISO 5659 Smoke Density Test#Fire Resistance and Flammability Standards#Smoke Emission Levels#Fire Safety Testing#Construction Fire Testing#Automotive Smoke Density Testing#Aerospace Smoke Testing#Polymer Flammability Testing#Smoke Visibility Tester#UIC 564 Smoke Testing#Best Fire Testing Machine India#Fire Testing Equipment Supplier#Smoke Toxicity Testing#Smoke Measurement System

0 notes

Text

Best Practices for Safe and Efficient LV Electrical Installations in 2025

Introduction

Low Voltage (LV) electrical installations are the backbone of safe and reliable power distribution in residential, commercial, and industrial settings. In 2025, as energy demands rise and smart technologies evolve, following best practices in LV installations is more important than ever to ensure safety, efficiency, and compliance.

This blog outlines the latest best practices for designing, installing, and maintaining LV electrical systems according to international standards and industry trends.

What Is an LV Electrical Installation?

LV (Low Voltage) refers to electrical systems that operate at voltages up to 1000V AC or 1500V DC. These installations include:

· Electrical panels and switchboards

· Distribution circuits

· Lighting systems

· Sockets and fixed appliances

· Motor control systems

Proper LV installation ensures that power is distributed safely and efficiently without risk of fire, equipment failure, or personnel injury.

Why Best Practices Matter in 2025

In the age of smart buildings, renewable integration, and digital energy management, the quality of your LV installation affects:

· Operational reliability

· Energy efficiency

· System lifespan

· User safety

· Regulatory compliance

Failing to adhere to best practices can result in costly downtime, legal penalties, and even life-threatening hazards.

Top Best Practices for Safe and Efficient LV Electrical Installations

1. Conduct Detailed Load Analysis

Before starting any LV installation, carry out a comprehensive load assessment to determine the power requirements, load types, and future expansion needs. This ensures:

· Proper cable sizing

· Correct protection device selection

· Optimized system capacity

Use load flow software tools and factor in diversity and demand coefficients for accuracy.

2. Follow International Standards (IEC, NEC)

Compliance with recognized standards ensures installations meet safety and performance benchmarks. Key references include:

· IEC 60364 for LV electrical installations

· NEC (NFPA 70) for code-compliant wiring in the U.S.

· ISO 50001 for energy management integration

Also, refer to local electrical regulations where applicable.

3. Use Certified, High-Quality Components

Always use LV components from certified manufacturers — this includes:

· Circuit breakers (MCCBs/MCBs)

· Residual current devices (RCDs)

· Surge protection devices (SPDs)

· Busbars, cables, and enclosures

Poor-quality components may not withstand fault conditions, leading to short circuits, fires, or system failure.

4. Ensure Proper Cable Management and Sizing

Correct cable selection and layout are critical:

· Size cables based on current capacity, voltage drop, and ambient temperature

· Use LSZH (Low Smoke Zero Halogen) cables for fire safety

· Label and route cables cleanly using trays, ducts, and tie-downs

Improper cable management is a leading cause of overheating and system inefficiency.

5. Install Proper Earthing and Grounding Systems

An effective earthing system protects against:

· Electric shock

· Equipment damage

· Lightning surges

Use TT, TN, or IT systems as per the application and ensure resistance values are within acceptable limits (e.g., <1 ohm for sensitive equipment).

6. Use Protection Coordination and Selectivity

Install protective devices in a coordinated hierarchy to ensure:

· Quick isolation of faults

· Minimal disruption to unaffected areas

· Avoidance of cascading tripping

Selectivity between breakers and fuses enhances safety and ensures continuity of service.

7. Integrate Smart Monitoring and Control

Modern LV installations benefit from IoT-enabled devices and energy monitoring software. This helps with:

· Real-time energy usage tracking

· Predictive maintenance alerts

· Power quality monitoring

· Remote switching and control

Smart LV systems are increasingly used in data centers, green buildings, and industrial automation setups.

8. Conduct Periodic Testing and Maintenance

Post-installation, regular inspection and testing ensure sustained safety and performance. Best practices include:

· Thermal imaging to detect overheating

· Insulation resistance testing

· RCD trip time checks

· Earth loop impedance measurement

Document all tests and create a preventive maintenance schedule based on manufacturer recommendations and operating conditions.

Common Mistakes to Avoid

· Overloading circuits without upgrading breakers

· Skipping grounding in temporary setups

· Using outdated wiring diagrams

· Mixing incompatible components

· Neglecting ventilation in panel enclosures

Conclusion

Safe and efficient LV electrical installations in 2025 require more than just technical knowledge — they demand a proactive approach that combines regulatory compliance, technology integration, and quality workmanship. By following these best practices, contractors and facility managers can minimize risks, optimize performance, and build future-ready electrical systems.

Whether you’re designing a commercial building, upgrading an industrial site, or installing a smart home system, investing in safe LV practices today is the smartest move for tomorrow.

Connect With Us

Whether you’re a project engineer, contractor, facility manager, or developer — Almond Enterprise is ready to support your next electrical challenge with confidence and capability.

🔗 Visit: www.almondenterprise.com 📞 Contact: [email protected] | +974 33858416

6 notes

·

View notes

Text

Industrial Applications of Ball Valves: Why Industries Rely on Trusted Manufacturers for Flow Control

Across multiple industries, reliable fluid handling is essential to maintain operational efficiency and safety. At the heart of these systems are ball valves, known for their tight shut-off capabilities, ease of operation, and long service life. Choosing a trusted ball valve manufacturer plays a vital role in ensuring performance under demanding conditions.

Let’s explore the significance of ball valves in various industrial settings and how a reliable valve manufacturer adds value beyond the product.

The Role of Ball Valves in Industrial Operations

Ball valves are quarter-turn devices featuring a spherical closure unit that regulates fluid flow. When aligned with the pipeline, the hole in the ball allows fluid to pass through freely. When turned 90 degrees, it blocks the flow entirely. This simple mechanism enables quick isolation and ensures minimal pressure drop across the system.

Key advantages include:

Leak-tight performance

Quick actuation

Low maintenance requirements

Long service life

Compatibility with automation systems

These properties make ball valves ideal for both critical and utility applications in process systems.

Types of Ball Valves for Industrial Use

A trusted industrial ball valve manufacturer typically offers a wide range of designs tailored to various process conditions:

Floating Ball Valve – Suitable for low- to medium-pressure applications, offering bidirectional sealing.

Trunnion Mounted Ball Valve – Designed for high-pressure and large-diameter pipelines, providing stability and reduced operating torque.

Full Bore and Reduced Bore Valves – Full bore minimizes flow resistance, while reduced bore offers a compact, economical alternative.

Three-Piece Design – Facilitates easy maintenance, cleaning, or part replacement without removing the valve from the pipeline.

Fire-Safe Valves – Equipped with secondary sealing systems that remain operational during fire emergencies.

Stainless Steel Ball Valve – Offers corrosion resistance for aggressive chemicals or high-purity applications.

Each type can be further customized with manual, pneumatic, or electric actuators, depending on operational requirements.

Ball Valve Applications Across Industries

Industrial systems require ball valves in a range of processes where control, safety, and efficiency are non-negotiable. Here are some examples of where these valves are applied:

Oil & Gas Sector: Used in storage tanks, pipelines, and gas distribution systems for safe and reliable isolation.

Chemical Processing: Essential for handling aggressive fluids, acids, and solvents under varying pressures.

Pharmaceutical Manufacturing: Hygienic designs are used in purified water systems, clean-in-place (CIP), and water for injection (WFI) lines.

Water & Wastewater Treatment: Employed in inflow/outflow regulation, filtration systems, and sludge management.

Power Generation: Utilized for steam and condensate line isolation in high-pressure applications.

Food & Beverage Industry: Sanitary-grade valves support hygienic fluid handling with minimal contamination risk.

The broad versatility of ball valves has made them indispensable in fluid control systems worldwide.

What to Look for in a Reliable Ball Valve Manufacturer

Not all valve suppliers offer the same level of reliability. A precision ball valve supplier should possess the expertise and capacity to meet both standard and complex requirements.

Key factors to evaluate:

Product Range: Ability to supply a variety of valve types and materials

Design Capability: Customization options for end connections, materials, and actuation

Compliance Standards: Conformance with API, ASME, ISO, and other relevant specifications

Quality Testing: In-house testing facilities for pressure, sealing, and fire safety performance

Documentation: Complete support with test certificates, material traceability, and third-party inspection reports

Value Beyond the Product

A dependable manufacturer provides more than just a valve—they deliver performance assurance. From initial specification to after-sales support, a trusted partner ensures that valves integrate seamlessly into the system and continue to perform over time.

One such trusted name in the valve industry is Freture Techno Pvt. Ltd. The company offers a full range of high-performance ball valves, known for engineering precision, reliability, and customization. Their valves are designed and tested to meet the demands of modern process industries.

#ball valves manufacturers#ball valve suppliers#ball valve types#ball valve exporters#freture techno

0 notes

Text

Leading Dust Collector Filter Bag Manufacturer for Industrial Excellence

In industrial filtration, selecting a reliable dust collector filter bag manufacturer is a strategic decision that directly affects system performance, environmental compliance, and operational cost. One standout in this space is ClipOn, a provider whose reputation for quality is built on engineering expertise and high-grade materials. As a top dust collector filter bag manufacturer, ClipOn serves a wide range of industries—including cement, chemical, metal, and food processing—ensuring safe, efficient, and compliant air filtration solutions.

Understanding the Role of a Dust Collector Filter Bag Manufacturer

At the heart of any dust collection system, the dust collector filter bag manufacturer must develop filter media that captures fine particulates while ensuring durability and airflow. ClipOn excels at furnishing precision-engineered filter bags made from robust fabrics like polyester, Nomex, acrylic, and PTFE-coated microfibers . These materials deliver high-efficiency filtration, reducing emissions and extending the performance lifecycle of baghouse systems in demanding operating environments.

High-Quality Materials and Specialized Finishes

The difference between a standard bag and one crafted by a top-tier dust collector filter bag manufacturer often comes down to material finish. ClipOn’s filter bags come with finishes such as PTFE membranes, acid-resistant coatings, hydrophobic and fire-retardant treatments. These advanced finishes not only enhance dust release during cleaning cycles but also protect fabrics from moisture, steam, and chemical exposure. Such specialization ensures filter bags maintain structural integrity and filtration efficiency over extended periods.

Custom Sizing for Diverse Applications

Dust collector systems are highly varied—ranging from pulse-jet and shaker collectors to reverse-air units. This complexity makes partnering with a reputable dust collector filter bag manufacturer essential. ClipOn offers custom sizing, various collar styles (snap-ring, cassette, rope), and bag types (cylindrical, star, envelope, RABH) to ensure precise fitment and airtight operation. Proper customization enhances baghouse efficiency and minimizes costly emissions or pressure drop issues.

Integration with Filter Cages and Structures

Filter bag performance is tightly linked to the cages that support them. A distinguished dust collector filter bag manufacturer seamlessly integrates bag designs with compatible cages. ClipOn pairs its filter bags with carbon steel, galvanized steel, or stainless steel cages featuring rounded edges and professional welding. This synergy extends bag life, reduces abrasion risk, and maintains system airflow during cleaning cycles.

Industry Use Cases and Performance Gains

ClipOn’s filter bags meet the demands of diverse industrial sectors. In cement and mining operations, their PTFE-coated bags resist high temperatures and abrasive dust, reducing downtime. Metal fabrication environments benefit from heat-resistant Nomex or acrylic options. For food and pharmaceutical applications, polyester bags meet stringent hygiene standards. Chemical plants rely on acid-resistant finishes. In each scenario, ClipOn’s tailored solutions improve working conditions, enhance process efficiency, and help maintain regulatory compliance.

Compliance, Standards, and Technical Expertise

A trusted dust collector filter bag manufacturer must also support compliance and quality. ClipOn maintains ISO quality management standards and adheres to emission norms. Their team provides pre-sales consultation, performance testing, and post-installation support. Certifications and transparent documentation underscore ClipOn’s ability to meet regulated filtration requirements in industries like pharmaceuticals and food production.

Real-World Case Study: Cement Plant Success

In one instance, a cement facility replaced its worn filter bags with ClipOn’s PTFE-coated bags and galvanized cages. This upgrade extended bag life by 30%, reduced downtime, and improved emissions performance. Proper media selection and custom cage support made the cleaning cycles more reliable, resulting in lower energy consumption and reduced maintenance costs. This case highlights the benefits of working with a capable dust collector filter bag manufacturer.

The Economic and Environmental Value

Choosing the right dust collector filter bag manufacturer delivers measurable returns. ClipOn’s filter bags minimize unscheduled replacements, lower fan energy usage due to optimized airflow, and support clean emissions to avoid fines. Facilities also benefit from improved visibility compliance and demonstrate responsibility toward environmental and worker safety. These advantages position ClipOn as a cost-effective and sustainable filtration partner.

Future Innovations and Ongoing Support

ClipOn continues to innovate in filtration design and materials. They are experimenting with nanofiber coatings for superior dust capture, anti-static fabrics to prevent dust ignition, and membrane technologies that reduce pressure drop. ClipOn’s commitment to technical support ensures clients stay ahead of evolving regulatory and sustainability trends.

In conclusion, a qualified dust collector filter bag manufacturer serves as more than a vendor—they are a strategic partner in industrial air quality management. ClipOn’s combination of advanced materials, tailored design, compatible cages, and regulatory compliance makes them a top choice for filtration solutions. Through customization, longevity, and performance, ClipOn reinforces its leadership and expertise in dust collection technology, driving efficiency and cleaner operations across industries.

0 notes

Text

Hyphen Cables – Premier Manufacturer of Single and Multi-Core Cable Wires in India

In the ever-evolving world of electrical and electronic systems, the need for dependable and high-performance wiring solutions is paramount. Whether for residential, commercial, or industrial applications, single and multi-core cables wires manufacturers are vital for ensuring smooth power distribution and signal transmission. Among the top manufacturers in India, Hyphen Cables has established itself as a trusted and innovative brand, offering a comprehensive range of single and multi-core cable wires that meet stringent quality and safety standards.

Understanding Single and Multi-Core Cables

Single-core cables consist of one conductor, typically used where minimal power or signal transmission is required. These are ideal for domestic wiring, small machinery, or compact electrical devices.

Multi-core cables, on the other hand, contain two or more conductors, each insulated individually and enclosed in a common sheath. These cables are widely used in control panels, industrial equipment, communication systems, and complex installations requiring multiple connections within a single cable system.

The type of cable used often depends on the specific needs of the application, and choosing the right manufacturer plays a critical role in ensuring performance, durability, and safety.

Why Choose Hyphen Cables?

Hyphen Cables, one of India’s most reputed cable manufacturers, specializes in the design and production of both single and multi-core cable wires. With a focus on quality, innovation, and customer satisfaction, Hyphen offers products that cater to diverse sectors, including residential, infrastructure, manufacturing, power, and automation.

Some of the key features of Hyphen’s cable offerings include:

High-Grade Conductors: Manufactured using high-purity electrolytic copper or aluminum for superior conductivity.

Advanced Insulation: Use of FR, FRLS, PVC, and XLPE insulation materials to ensure thermal stability and flame resistance.

Durable Sheathing: Designed to withstand mechanical wear, moisture, chemicals, and environmental stress.

Flexible Construction: Especially in multi-core cables, flexibility is critical for easy installation in tight or complex spaces.

Custom Solutions: Available in various core configurations, sizes, and voltage ratings to suit project-specific needs.

Quality Assurance and Certifications

Hyphen Cables is ISO-certified and strictly adheres to national and international manufacturing standards such as IS 694, IS 1554, and IEC norms. All cables undergo rigorous quality control tests in state-of-the-art in-house labs, including tests for insulation resistance, tensile strength, voltage endurance, and fire resistance.

This unwavering commitment to quality has made Hyphen a preferred supplier for clients in sectors ranging from residential real estate to large-scale industrial plants.

Applications Across Industries

Hyphen’s single and multi-core cables are widely used in:

Building and domestic wiring

Control panels and switchgear

Power distribution networks

Automation and instrumentation

Renewable energy systems

Conclusion

For organizations and contractors seeking reliable, high-performance cabling solutions, Hyphen Cables stands out as one of India’s most dependable manufacturers of single and multi-core wires manufacturers. Combining technical expertise with a customer-focused approach, Hyphen delivers cables that not only meet today’s requirements but are also built to last well into the future.

Choose Hyphen Cables — where quality, performance, and trust go hand in hand.

Visit:- https://www.hyphencables.com/single-multi-core-flexible-wires-cables.html

0 notes

Text

Trusted Vermiculite Fireproof Coating Manufacturer, Supplier & Service Provider in Pune, India 🔥🧱

Looking for expert vermiculite fireproof coating services in Pune or a reliable vermiculite fireproof coating manufacturer in India? Look no further than Ugam Chemicals — a pioneer in advanced fire protection solutions using vermiculite-based coatings for steel structures and concrete surfaces.

We are a leading vermiculite fireproof coating manufacturer in Pune and one of the most trusted suppliers across India. Our products are designed to enhance fire resistance and thermal insulation, especially in high-risk industrial and infrastructure environments.

✅ Our Vermiculite Fireproof Coating Services:

Vermiculite fireproof coating services in Pune and India

Vermiculite fireproof coating manufacturer in Pune and India

Vermiculite fireproof coating suppliers in Pune and India

Our vermiculite-based spray coatings are highly effective for:

Fireproofing of structural steel in commercial and industrial buildings

Protection of tunnels, ducts, and concrete surfaces

Thermal insulation in refineries, factories, and warehouses

🔒 Why Choose Ugam Chemicals?

✔️ ISO-certified vermiculite fireproof coating manufacturer in India

✔️ High-build coating systems for efficient fire protection

✔️ In-house R&D and lab-tested materials

✔️ On-site application services throughout Pune, Maharashtra, and across India

✔️ Trusted vermiculite fireproof coating suppliers in Pune with bulk order capability

Our commitment to quality and safety makes us the preferred partner for vermiculite fireproof coating services in India, helping clients meet building codes, industrial safety standards, and insurance requirements.

🔥 Protect your property and equipment with certified vermiculite fireproof coating solutions by Ugam Chemicals. Whether you're a contractor, consultant, or developer, we deliver coatings that perform under extreme heat and fire exposure.

🔗 Visit Now: https://ugamchemicals.com/vermiculite-fireproof-coating.html

#vermiculite fireproof coating services in pune#vermiculite fireproof coating services in india#vermiculite fireproof coating manufacturer in pune#vermiculite fireproof coating manufacturer in india#vermiculite fireproof coating suppliers in pune#vermiculite fireproof coating suppliers in india.

0 notes

Text

Top Testing Parameters for Fashion Footwear: From Material to Performance

Fashion footwear is more than just a style statement—it must deliver comfort, durability, safety, and functionality. To meet these expectations and regulatory requirements, fashion footwear testing plays a crucial role. Testing labs evaluate a range of parameters, from raw materials to finished product performance, ensuring footwear quality aligns with consumer demands and industry standards.

In this comprehensive blog, we explore the top testing parameters for fashion footwear that manufacturers and brands should prioritize to create durable, safe, and high-performing shoes.

1. Material Testing: The Foundation of Quality Footwear

a. Raw Material Identification and Verification

Before production, testing labs verify materials such as leather, textiles, rubber, and synthetic polymers to ensure they match specifications. This helps detect material substitutions or inconsistencies that could affect quality.

b. Chemical Safety Testing

Materials used in footwear may contain harmful substances such as heavy metals, formaldehyde, phthalates, and azo dyes. Labs test for compliance with chemical regulations including:

REACH (EU)

CPSIA (USA)

California Proposition 65

This protects consumers from toxic exposure and ensures legal compliance.

c. Colorfastness

Footwear materials are tested for resistance to color fading or bleeding due to:

Water exposure

Perspiration

Light (UV exposure)

Rubbing or abrasion

Good colorfastness maintains the aesthetic appeal throughout product life.

2. Mechanical Testing: Ensuring Durability and Strength

a. Flexing and Fatigue Tests

Footwear is subjected to repeated bending to simulate walking and running. The test evaluates how well the materials and construction withstand mechanical stresses without cracking or delaminating.

b. Abrasion Resistance

Testing outsole and upper materials for wear under friction ensures longevity, especially for soles exposed to rough surfaces.

c. Adhesion and Bond Strength

The durability of sole-to-upper bonding is critical. Labs measure adhesive strength to prevent sole detachment during use.

d. Tensile and Seam Strength

Stitching and seams are tested for strength to ensure they hold under tension and movement without failure.

3. Performance Testing: Safety and Comfort

a. Slip Resistance

One of the most important safety parameters, slip resistance tests measure the shoe’s grip on wet and dry surfaces. Standards include:

ASTM F2913

ISO 13287

BS 7976 Pendulum Test

Footwear with high slip resistance reduces the risk of falls.

b. Impact and Compression Resistance

These tests assess the shoe’s ability to absorb shocks and withstand pressure, crucial for comfort and protection.

c. Water Resistance and Breathability

Outdoor and sports footwear undergo tests for waterproofing and moisture vapor transmission to keep feet dry and comfortable.

d. Thermal Resistance

For specialized footwear, thermal insulation or heat resistance testing ensures performance in extreme conditions.

4. Safety and Regulatory Compliance Testing

a. Flammability Testing

Some fashion footwear contains materials that need flammability testing to meet standards such as:

16 CFR Part 1610 (U.S.)

ISO 15025 (International)

This minimizes fire hazards.

b. Dimensional Accuracy and Labeling

Accurate sizing, labeling, and care instructions are tested to meet consumer protection regulations and retailer requirements.

5. Environmental and Sustainability Testing

a. Life Cycle Assessment (LCA)

Evaluates environmental impact from raw material sourcing to disposal, helping brands develop eco-friendly footwear.

b. Carbon Footprint Testing

Measures greenhouse gas emissions associated with footwear production.

c. Biodegradability and Recycling Potential

Tests assess the shoe’s end-of-life environmental impact.

How Testing Labs Conduct These Parameters

Testing labs use advanced equipment and follow internationally recognized standards such as ASTM, ISO, EN, and AATCC. The testing process involves:

Sample Conditioning: Controlling temperature and humidity for consistency

Mechanical Testing Machines: For flexing, abrasion, and tensile strength

Chemical Analysis Instruments: Like ICP-MS for heavy metals, HPLC for organic compounds

Slip Testing Devices: Pendulum testers or tribometers for coefficient of friction

Environmental Chambers: For thermal and moisture tests

Labs generate detailed reports that help manufacturers improve design, material selection, and production processes.

Why These Testing Parameters Matter

Parameter

Importance for Footwear

Material Quality

Ensures safety, comfort, and appearance

Mechanical Durability

Prevents premature wear and product failure

Performance

Enhances user safety and comfort

Compliance

Meets legal and market regulations

Environmental Impact

Supports sustainability and brand responsibility

Conclusion

Fashion footwear testing spans a wide range of parameters—from material chemistry to performance on slippery floors. Testing labs play an essential role in validating these aspects, helping brands deliver high-quality, durable, and safe products that satisfy consumers and comply with regulations.

By focusing on these top testing parameters, footwear manufacturers can enhance product reliability, reduce returns, meet market demands, and foster a sustainable future.

#Fashion Footwear Testing#Testing Lab near me#Testing Lab in Delhi#Footwear Testing#Footwear Testing Lab

0 notes

Text

Civil Defense Approved Lab Dubai: Key Services for Construction Compliance | +971 554747210

Dubai's construction industry is booming, driven by ambitious urban development, cutting-edge architecture, and global investments. However, along with innovation and growth comes the critical need for safety, quality, and regulatory compliance. One of the key components in ensuring that construction materials and systems meet the city’s stringent safety standards is the involvement of a Civil Defense Approved Lab.

A Civil Defense Approved Lab in Dubai plays a vital role in helping builders, contractors, developers, and manufacturers meet the mandatory fire and life safety codes enforced by the Dubai Civil Defense (DCD). These labs conduct certified testing and offer technical evaluations essential for product approvals, building permits, and fire safety certifications.

In this blog, we will explore how Civil Defense Approved Labs support construction compliance in Dubai, the services they offer, and why working with one is crucial for any construction project in the region.

What Is a Civil Defense Approved Lab?

A Civil Defense Approved Lab is a testing laboratory accredited and recognized by the Dubai Civil Defense authority to perform specific tests related to fire safety, building materials, electrical systems, and product performance. These labs are required to meet rigorous standards of:

Technical competency

Equipment calibration and maintenance

Compliance with ISO/IEC 17025 (testing and calibration laboratories)

Consistent testing methodologies and reporting practices

Test results from non-approved labs are not accepted by Dubai Civil Defense for regulatory approvals, making Civil Defense Approved Labs indispensable for construction compliance.

Why Is a Civil Defense Approved Lab Crucial for Construction Projects in Dubai?

Dubai’s UAE Fire and Life Safety Code of Practice mandates the use of certified materials, systems, and equipment in all buildings. Whether it’s a residential tower, commercial complex, or industrial facility, every component that impacts safety must be tested and approved through a certified process.

Key Reasons for Involvement of Civil Defense Approved Labs:

✅ Mandatory for construction permits and project approvals ✅ Ensures compliance with local and international fire safety standards ✅ Prevents delays due to rejected materials or failed inspections ✅ Protects lives, property, and the integrity of construction projects

Key Services Offered by Civil Defense Approved Labs in Dubai

Civil Defense Approved Labs in Dubai provide a comprehensive suite of services that support various stages of the construction process—from material selection and product procurement to final safety certification.

1. Fire Resistance Testing

This is one of the most critical services in construction compliance. Fire resistance testing evaluates how building components withstand fire over time.

Tested Components:

Fire-rated doors

Fire-resistant walls, floors, and ceilings

Glass and glazing systems

Fire dampers

Purpose:

To ensure the structure maintains integrity during a fire

To allow safe evacuation and emergency response

To comply with EN 1364, BS 476, and ASTM E119 standards

2. Flammability and Flame Spread Testing

Materials used in construction—especially for interiors—must not contribute to fire growth. Flammability testing ensures materials don’t ignite easily or spread fire quickly.

Tested Materials:

Wall and ceiling panels

Plastic and polymer finishes

Decorative items and insulation

Purpose:

To minimize fire load within enclosed spaces

To prevent flashover conditions

To comply with standards such as ISO 5660 and EN 13501-1

3. Smoke and Toxicity Testing

Smoke inhalation is a leading cause of fire-related fatalities. Labs evaluate the amount and composition of smoke produced by burning materials.

Tested Items:

Electrical cables

Polymer insulation

Wall finishes and ceiling tiles

Purpose:

To reduce smoke density for clearer visibility

To limit exposure to toxic gases like CO and HCN

To comply with ISO 5659-2 and ASTM E662

4. Electrical Safety and Cable Testing

Electrical fires are common in both residential and commercial structures. Civil Defense Approved Labs conduct electrical cable testing to ensure:

Flame retardancy

Low smoke emission

Halogen-free performance

Thermal stability

Applicable Standards: IEC 60332, BS 6387, EN 50575

5. Testing of Fire Protection Equipment

The lab evaluates whether fire safety systems and equipment function reliably under emergency conditions.

Tested Products:

Fire extinguishers

Smoke detectors and alarms

Fire sprinklers and suppression systems

Fire hose reels

Purpose:

To validate performance during actual fire incidents

To verify system activation and response time

To comply with NFPA and UL standards

6. Material Composition and Environmental Testing

Some materials degrade over time, especially under harsh weather conditions. These labs also test products for:

Resistance to UV, heat, and humidity

Structural degradation and corrosion

Compliance with environmental and sustainability requirements

Used For:

Outdoor cladding

Sealants and adhesives

HVAC and mechanical enclosures

7. Document Support and Regulatory Submission

Beyond testing, Civil Defense Approved Labs assist clients with:

Test documentation

Product certification files

Preparation of technical dossiers for DCD approval

Consultancy for compliance strategies

This service is especially valuable for manufacturers and contractors unfamiliar with Dubai’s local regulations.

Who Should Work with Civil Defense Approved Labs?

If your construction project involves safety-critical systems or fire-rated materials, working with a Civil Defense Approved Lab is non-negotiable.

Common Stakeholders:

Architects and consultants – for material selection and design validation

Developers and contractors – for project certification and building permits

Manufacturers and importers – for product approvals and market access

MEP engineers – for verifying electrical and fire protection systems

Facility managers – for annual inspections and fire code compliance

Benefits of Partnering with a Civil Defense Approved Lab in Dubai

✅ Official DCD recognition – All test reports are accepted by Dubai Civil Defense ✅ Faster approvals – Avoid resubmissions or non-compliance rejections ✅ Trusted accuracy – High-tech equipment and trained personnel ensure precision ✅ Local regulation expertise – Navigate complex codes with professional guidance ✅ Support for international standards – Align with NFPA, EN, BS, ASTM, ISO

Final Thoughts

Construction in Dubai is held to some of the highest safety and quality standards in the world. Failing to meet those standards can result in costly delays, rework, or rejection of critical building components. Working with a Civil Defense Approved Lab in Dubai ensures that your construction materials and systems are tested, certified, and fully compliant with the UAE Fire and Life Safety Code.

Whether you're sourcing fire doors, installing HVAC systems, or procuring building materials, a Civil Defense Approved Lab provides the technical assurance needed for construction compliance, legal certification, and occupant safety.

0 notes

Text

Plastic Components for Railway Interiors: Seats, Panels, and Beyond

In the rapidly evolving railway industry, plastic components are becoming a preferred choice for interior applications due to their durability, weight-saving properties, design flexibility, and cost-effectiveness. From seating systems to interior panels, plastic parts are redefining the standards of comfort, safety, and efficiency in both passenger trains and metro rail systems.

In this blog, we’ll explore the growing role of plastic components in railway interiors, the benefits they offer, and the range of applications that go beyond just seats and panels.

🚄 Why Plastics Are the Future of Railway Interiors

The modern railway sector demands materials that are lightweight, fire-resistant, easy to maintain, and aesthetically appealing. Traditional materials like metal and wood, although strong, are often heavy, prone to corrosion, and costlier to fabricate.

This is where engineering-grade plastic components for railways come in. They offer:

Weight Reduction: Reducing the weight of railway coaches leads to lower fuel consumption and improved energy efficiency.

Cost-Effective Manufacturing: Injection moulding and thermoforming allow mass production of intricate parts at a lower cost.

Design Versatility: Plastics can be easily shaped into complex geometries, offering flexibility in coach design.

Safety Compliance: Modern plastics meet fire-retardant (FR) and low-smoke, low-toxicity (LST) standards required for rail applications.

Corrosion Resistance: Unlike metals, plastics do not rust, making them ideal for long-term use in high-humidity environments.

🪑 Common Plastic Components Used in Railway Interiors

1. Train Seat Structures & Cushions

Material Used: Glass-filled nylon, polycarbonate, polypropylene.

Advantages: Ergonomic design, easy cleaning, and durability.

Additional Features: Fire-retardant grades and UV resistance.

2. Interior Wall & Ceiling Panels

Applications: Coach sidewalls, roof panels, and partitions.

Material: ABS, PVC, FRP (fiber-reinforced plastic).

Benefits: Lightweight, impact-resistant, good surface finish for painting or lamination.

3. Window Frames and Trim

Properties: High dimensional stability, excellent weather resistance.

Material: Polycarbonate blends, rigid PVC.

4. Lighting Housings & Fixtures

Material Used: Polycarbonate for its high impact strength and heat resistance.

Benefits: Safe for LED integration and fire-safe.

5. Luggage Racks & Storage Units

Material: Thermoplastics with high tensile strength.

Features: Molded with integrated handles and rounded edges for passenger safety.

6. Flooring Subsystems

Plastic-based subfloors: Provide insulation, reduce vibration, and resist moisture.

7. Ventilation & Ducting Components

Designed for air circulation systems, often using fire-rated polycarbonate or ABS blends.

🔧 Manufacturing Technologies in Plastic Rail Components

Leading manufacturers use advanced techniques like:

Injection Moulding: For high-precision parts like seat shells and panel joints.

Thermoforming: For large surface panels and ceiling trays.

3D Printing (Additive Manufacturing): For prototyping and low-volume, customized parts.

These methods ensure consistent quality and allow cost-effective scaling.

🏭 Plastic Component Manufacturer for Railway Industry – What to Look For

When sourcing plastic parts for railway interiors, OEMs and Tier-1 suppliers must partner with manufacturers who:

Comply with EN 45545-2 (fire protection in railway vehicles)

Offer ISO 9001/TS 22163 certified production

Have in-house design, tooling, and testing capabilities

Support customized solutions based on client specifications

At JaiRaj Group, we specialize in custom plastic components for the railway industry, offering solutions that meet international quality and safety standards. From lightweight coach interiors to rugged ventilation systems, we provide high-performance railway plastic parts tailored to your needs.

1 note

·

View note

Text

Why Smart Builders Trust Certified TMT Saria Manufacturers Over Local Alternatives

TMT saria manufacturer—that’s where real construction confidence begins. Builders today face a critical choice: opt for cheap local dealers or trust certified TMT bar manufacturers whose every inch of steel is tested, traceable, and trustworthy. The difference isn’t just price. It’s the entire foundation of your structure’s integrity.

The Backbone of Every Build: Why TMT Steel Matters

Every skyscraper, bridge, or dream home stands tall because of what lies hidden—the steel that holds it together. A TMT Saria bar isn't just another product; it’s the lifeline of a building. But not all steel is made equal, and not all suppliers are built on the same principles.

Local Dealers vs. Certified TMT Saria Manufacturers—A Hidden Gap

The local vendor might offer a tempting price, but what about quality control? Certified TMT Saria manufacturers follow strict national standards, conduct regular lab tests, and use cutting-edge machinery. Local alternatives? Often none of the above.

Consistency in Strength and Quality

Certified TMT bar manufacturers don’t guess—they guarantee. Each TMT Saria bar is uniform in tensile strength and elongation. This isn’t just paperwork; it’s the reason why structures withstand decades of stress and strain.

Advanced Manufacturing for Earthquake Resistance

The process matters. Thermo-mechanically treated bars have a specific core structure that helps absorb shockwaves. Certified TMT saria manufacturers engineer their bars for this—local brands often skip the science.

Rust Protection and Longevity

High-grade TMT saria bars come with corrosion resistance—a critical feature in coastal or humid regions. Rust may start invisibly but eats away at the heart of your structure. A certified product offers zinc coating, controlled chemical composition, and quality checks.

National Standards and ISO Certification

A certified TMT Saria manufacturer adheres to IS 1786 standards and often holds ISO 9001 certification. This means each batch is inspected, verified, and documented—reducing room for error to zero.

Heat Resistance in High-Temperature Zones

India's diverse climate demands resilience. Certified TMT bar manufacturers test their bars for high thermal resistance—a silent lifesaver in case of fire.

Cracks, Bends, and Construction Failures

Using unverified steel is like installing a fake foundation. Structural failures often begin with microscopic flaws—flaws local, uncertified TMT Saria bars don’t detect, let alone fix.

No Traceability, No Accountability

Bought steel from a local shop? Good luck tracing it back when things go wrong. Certified manufacturers log every batch, every test—a paper trail that protects builders from blame.

Long-Term Costs vs. Upfront Savings

Cheap bars today could mean renovation tomorrow. Or worse, collapse. The smart builder doesn’t cut corners—they cut risk. Certified TMT saria may cost marginally more but save crores in structural failures and legal issues.

No Support in Case of Structural Audit

When clients demand safety documentation or government audit checks roll in, local bars can’t provide certifications. Certified manufacturers can. That peace of mind? Priceless.

Builders Aren’t Just Building Homes; They’re Building Trust

Clients don’t see the steel—but they feel the difference in safety, in lifespan, and in resale value. Builders who choose certified TMT Saria manufacturers send a message: This building is made to last.

Clients Ask Questions—Trusted TMT Bar Manufacturers Have Answers

How strong is the bar? Is it fire-resistant? Is it ISI certified? Smart builders love these questions—because their choice of certified TMT bar manufacturer comes with ready answers and documentation to prove it.

Build What’s Worthy of Lasting

Great construction doesn’t start with blueprints. It starts with decisions. The decision to choose certified TMT Saria bars over unverified, inconsistent local alternatives could be the one that defines a building’s legacy—or its collapse.

Trust is not a feature. It’s a material. And only certified TMT manufacturers offer it.

#certified TMT bars#TMT Saria price#TMT bar quality#best TMT brands#ISI TMT steel#trusted TMT bars#TMT for builders#TMT vs local steel#steel for homes#TMT Saria guide#top TMT brands#buy TMT online#rustproof TMT#fireproof TMT bar#earthquake TMT#TMT bar strength#safe building steel#TMT Saria cost#construction bars#TMT steel test

0 notes

Text

How to Identify High-Quality Substitutes of Plywood

In today’s fast-evolving construction and interior design industry, the demand for durable, eco-friendly, and versatile materials has led to a growing interest in alternatives to plywood. While plywood has long been a staple for furniture and home fittings, its limitations—especially in terms of moisture resistance, termite vulnerability, and environmental impact—have prompted homeowners and architects to explore better options.

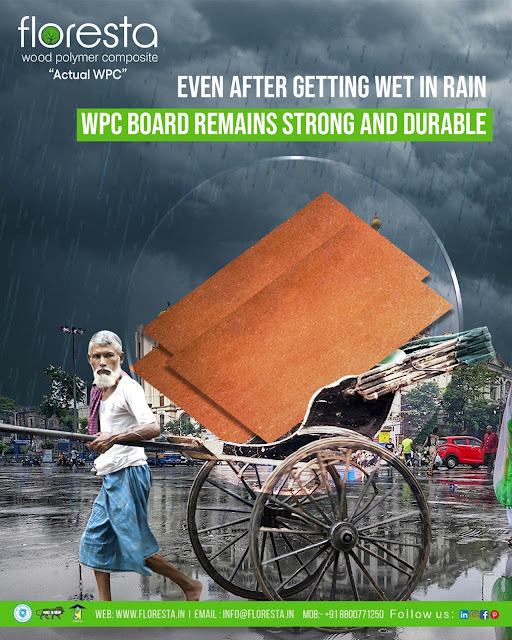

One such popular alternative making waves in the market is WPC (Wood Plastic Composite). Brands like Floresta are leading the way in offering high-performance materials like WPC Doors and boards that are reliable and long-lasting. But with so many options out there, how can you identify a high-quality substitute for plywood?

1. Check for Water Resistance

A major reason for switching to alternatives to plywood is the need for moisture-resistant materials. High-quality WPC boards or doors, like those from Floresta, are 100% waterproof. When selecting an alternative, ensure the product resists water absorption and does not warp, swell, or delaminate over time.

2. Look at Material Composition

The strength and stability of any plywood substitute depend on its core composition. Premium WPC Doors are made from a blend of wood fibers and thermoplastics, which ensures excellent mechanical strength and dimensional stability. Avoid low-grade products that use fillers or recycled plastic of uncertain origin.

3. Termite and Borer Resistance

One of plywood's biggest drawbacks is its susceptibility to termite attacks. A high-quality alternative to plywood, such as WPC from Floresta, is inherently termite- and borer-proof. Always ask the supplier for certification or documentation that confirms pest resistance.

4. Evaluate Surface Finish and Workability

A good substitute should offer a smooth surface finish for easy lamination or painting. WPC products from trusted brands are easy to machine, screw, or nail—just like wood—making them ideal for customized furniture or modular designs. Test a sample to see how well it responds to cutting and routing.

5. Assess Fire Retardant Properties

For safety-conscious homes and commercial spaces, materials with fire-retardant properties are essential. Many advanced WPC boards and doors, including those from Floresta, come with self-extinguishing properties, making them a safer option over traditional plywood.

6. Check the Brand’s Reputation

Choosing a reliable brand is just as important as choosing the material. Established companies like Floresta have built their name on consistency, innovation, and quality assurance in the WPC Doors and board segment. Go with brands that have transparent manufacturing practices and positive customer reviews.

7. Certifications and Testing

Top manufacturers provide certifications for environmental compliance, durability, and material safety. Look for substitutes that meet ISO standards or other national/international benchmarks. These certifications are an assurance of long-term value and reliability.

Final Thoughts

As design trends evolve and sustainability takes center stage, alternatives to plywood are becoming the new standard. Whether you're renovating your home or planning a commercial project, investing in high-quality materials like WPC Doors can drastically improve durability, safety, and aesthetics.

Among the leading brands, Floresta stands out for its innovation, product variety, and commitment to quality. Their range of WPC products is not only built to last but also designed to offer superior performance across all modern applications.

Also, Read:

Why WPC Doors Are the Best Alternative to Waterproof Plywood Doors

Top WPC Sheet Manufacturers in India You Can Trust

0 notes

Text

Automated Flash Point Analyzers in Petroleum Quality Control

The flash point of a petroleum product—the lowest temperature at which vapors above the liquid ignite in the presence of an ignition source—is a critical safety and quality parameter. Traditionally, determining flash point relied on manual Pensky-Martens or Cleveland open cup methods, which are labor-intensive, subject to operator variability, and require significant warm-up times. Over the past decade, however, automated flash point analyzers have revolutionized routine quality control in refineries, laboratories, and distribution facilities.

Principle of Operation

Automated flash point analyzers typically use a closed-cup configuration, conforming to ASTM D93 standards. A small sample is placed in a sealed cup equipped with a temperature sensor and drugged stirrer. Heating is precisely controlled via a programmable microprocessor, raising the sample temperature at a uniform rate (often 1–6 °C/min). At defined intervals (for example every 1 °C rise), a miniature electric ignition source is introduced into the vapor space. The instrument’s optical sensor then detects the appearance of a flame or “flash”—automatically recording the corresponding temperature. Because the cup is closed, volatile compounds remain contained, improving repeatability and safety.

Key Features and Benefits

Automation and Reproducibility

Compared to manual methods, the automated process minimizes human error. Programmable routines ensure consistent heating rates, stir speeds, and ignition intervals, leading to repeatability within ±0.5 °C. The analyzer’s microprocessor logs all test parameters and results, creating an audit trail in digital or printed form.

Safety Enhancements

Closed-cup systems contain hazardous vapors, reducing operator exposure and risk of accidental fires. Many units feature built-in safety interlocks, flammable vapor detectors, and emergency ram dump functions that rapidly seal the sample cup in case of volatility anomalies.

Faster Throughput

Modern analyzers can complete a flash point determination in as little as 5–10 minutes per sample—up to 50 % faster than manual methods. Instruments often offer “quick test” modes, which use an accelerated heat rate and wider ignition intervals for preliminary screening, followed by a confirmatory detailed run if needed.

Compliance and Reporting

Instruments are designed to meet ASTM D93, ISO 2719, and IP 34 standards. Built-in software can generate customizable reports, flag out-of-spec results, and interface with LIMS (Laboratory Information Management Systems) via Ethernet or USB. This seamless connectivity streamlines data management within modern petroleum laboratories.

Applications

Fuel production and storage: Ensuring gasoline, kerosene, and diesel meet flash point specifications for safe handling and transport.

Marine and aviation fuels: Verifying stringent flash point requirements (e.g., jet fuel minimum flash point 38 °C) to comply with international regulations.

Lubricants and specialty oils: Evaluating base stocks and additives to guarantee consistent performance under varying thermal conditions.

Maintenance and Calibration

Automated analyzers require periodic maintenance to ensure sensor accuracy and mechanical reliability. Routine checks include verification of the temperature probe (using certified calibration baths), inspection of the ignition electrodes, and replacement of seals and O-rings. Many manufacturers provide auto-calibration kits or service contracts to maintain compliance.

Future Developments

Emerging technologies integrate rapid infrared heating and non-contact optical detection, further reducing test times and maintenance burdens. Coupled with AI-driven diagnostics, next-generation flash point analyzers will predict maintenance needs, self-optimize test parameters based on sample type, and offer cloud-based data analytics for global quality assurance networks.

Automated flash point analyzers exemplify how advanced instrumentation enhances safety, accuracy, and efficiency in petroleum testing—critical for both regulatory compliance and operational excellence.

0 notes

Text

Powering Precision: How PVC Wire and Cable Manufacturers Empower PEB Manufacturers

In the fast-paced world of industrial construction, Pre-Engineered Buildings (PEBs) have become the gold standard for efficiency, cost-effectiveness, and durability. These steel structures are widely used across factories, warehouses, showrooms, and industrial plants. But what keeps these mighty steel skeletons functional, safe, and efficient? One often-overlooked answer lies beneath the surface — PVC wires and cables.

Let’s explore how PVC wires and cables manufacturers play a crucial role in supporting the PEB manufacturing ecosystem.

1. Electrical Backbone of Every PEB Structure

PEBs might be all about steel and structure, but without proper electrical infrastructure, they’re just shells. PVC insulated wires and cables form the electrical backbone of every PEB setup — powering everything from lighting systems to heavy machinery.

High-quality PVC wires offer:

Heat resistance, essential in industrial environments

Long lifespan, even under heavy load

Fire retardancy, increasing the safety standards of PEB facilities

This is where reliable PVC wire manufacturers step in — ensuring seamless power distribution without compromise.

2. Speed and Ease of Installation

PEB projects are known for their quick turnaround times, often completed in weeks rather than months. Electrical wiring must keep up with this pace. PVC wires are preferred because:

They are flexible and lightweight, ideal for fast deployment.

They can be custom-manufactured to meet specific voltage or insulation requirements.

Manufacturers can deliver bulk orders with precision, aligning with tight project schedules.

PEB manufacturers often rely on their electrical partners to meet this demand without delays — making trusted wire and cable suppliers essential project collaborators.

3. Customization for Industry-Specific Needs

Different industries require different types of PEB setups — and their electrical needs vary just as much. Whether it’s a temperature-controlled warehouse, a data center, or a heavy manufacturing unit, PVC cable manufacturers can customize products based on:

Voltage ratings

Environmental resistance (UV, moisture, chemical exposure)

Flame resistance

Load handling

This flexibility makes them indispensable to PEB manufacturers working across diverse sectors.

4. Long-Term Collaboration and Quality Assurance

Just like steel quality defines the longevity of a PEB structure, wire quality defines the safety and performance of its operations. Reputed PVC wire manufacturers offer:

Rigorous quality testing

Certifications like ISI, RoHS, and ISO

Long-term supply partnerships

Such consistency allows PEB manufacturers to offer turnkey solutions with confidence in both structural and electrical integrity.

Conclusion: Building the Future Together

As infrastructure continues to grow in complexity and scale, the collaboration between PEB manufacturers and PVC wires & cables manufacturers becomes even more vital. The synergy between steel structure and safe wiring ensures that modern industrial facilities are not just built fast — but built to last.

Visit:- https://www.ambicacables.com/pvc-wires-and-cables.html

0 notes

Text

Hyphen Cables – A Trusted Name Among Industrial Cable Manufacturers in India

In today’s rapidly advancing industrial landscape, the need for reliable and high-performance cabling solutions is more critical than ever. Industrial cables are the backbone of power distribution, automation, and control systems across factories, plants, and infrastructure projects. Among the leading industrial cable manufacturers in India, Hyphen Cables has carved a niche for itself by delivering top-tier products that combine quality, durability, and innovation.

The Importance of Industrial Cables

Industrial cables are designed to perform in demanding environments, where exposure to heat, chemicals, mechanical stress, and electrical interference is routine. These cables are used to power heavy machinery, transmit control signals, and connect critical equipment in sectors like manufacturing, oil & gas, power generation, cement, and infrastructure.

A reliable industrial cable ensures minimal downtime, safety in operations, and long-term efficiency—factors that make choosing the right manufacturer essential.

Hyphen Cables: Engineering Excellence

Hyphen Cables has emerged as a trusted manufacturer of a wide range of industrial cables, offering tailored solutions to meet the diverse requirements of modern industries. With years of experience and a strong commitment to quality, the company has gained recognition for producing cables that meet both Indian and international standards, including IS, IEC, and BS norms.

Key offerings from Hyphen Cables include:

LT Power and Control Cables

Instrumentation Cables

Flexible Industrial Cables

Fire-Resistant and Flame-Retardant Cables

PVC and XLPE Insulated Cables

Each product is manufactured using high-grade materials and advanced production technologies, ensuring superior performance under challenging conditions.

Quality that Sets Standards

Hyphen Cables emphasizes stringent quality control at every stage of production. Their in-house testing laboratories are equipped with the latest equipment to conduct electrical, mechanical, and environmental tests. Every cable is tested for insulation resistance, conductor continuity, flame retardance, and voltage endurance to ensure it meets or exceeds required specifications.

The company holds ISO certifications and complies with BIS standards, a testament to its unwavering focus on safety, consistency, and reliability.

Customization and Client-Centric Approach

What sets Hyphen Cables apart from many other industrial cable manufacturers is its flexibility and customer-centric approach. The company offers customizable solutions in terms of cable size, insulation material, sheathing type, and voltage grade. This adaptability allows clients to source cables that fit their exact operational requirements, reducing costs and improving system efficiency.

Hyphen’s extensive distribution network and prompt customer service further enhance its position as a preferred cable supplier across India and even in export markets.

Conclusion

As industries evolve and become more technology-driven, the demand for robust, high-performance industrial cables continues to grow. Hyphen Cables stands at the forefront of this change, offering engineered solutions that combine innovation, quality, and durability.

For businesses seeking a reliable partner in industrial cable manufacturer, Hyphen Cables delivers not just products, but long-term performance and peace of mind. With a proven track record and a commitment to excellence, Hyphen continues to set benchmarks in India’s industrial cable sector.

Visit:- https://www.hyphencables.com/industrial-cables.html

0 notes