#Infeed Module

Explore tagged Tumblr posts

Text

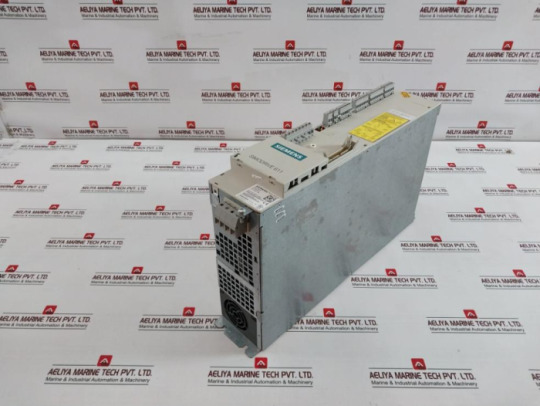

The Siemens Simodrive 611 Infeed Module 6SN1146-1AB00-0BA1 is a reliable power supply module designed for Siemens drive systems. It provides regulated power to connected drive units, ensuring smooth and efficient motor control. Ideal for industrial automation, this infeed module supports high-performance operations and protects against overload. With compact design and easy installation, it fits seamlessly into automation systems. Built for durability and long-term use, the Siemens 6SN1146-1AB00-0BA1 helps optimize system performance. Get this trusted Siemens solution from Auto2mation to enhance productivity and maintain system stability. Perfect for factories, CNC machines, and automated production lines.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Automation#manufacturing#Siemens Simodrive#Infeed Module

0 notes

Text

Understanding the Siemens 611 Infeed/Regenerative Feedback Module

Siemens has long been a leading name in industrial automation, and their innovative solutions continue to set the bar for performance and efficiency. Among their most significant offerings is the Siemens 611 Infeed/Regenerative Feedback Module, an essential component in advanced industrial drive systems. When combined with the Siemens Digital Feed Drive, these modules offer exceptional power regeneration, efficient energy use, and enhanced system performance.

What is the Siemens 611 Infeed/Regenerative Feedback Module?

The Siemens 611 Infeed/Regenerative Feedback Module plays a pivotal role in energy recovery within modern industrial systems. It allows for the regeneration of excess energy that would otherwise be lost. This means that during braking or deceleration phases, the system recovers energy and feeds it back into the network, improving the overall energy efficiency of the operation. This regenerative process not only saves on energy costs but also contributes to reducing environmental impact by lowering energy consumption.

Benefits of the Siemens Digital Feed Drive

The Siemens Digital Feed Drive is a key part of the Siemens motion control portfolio, offering precise and dynamic control over industrial motors. When paired with the Siemens 611 Infeed/Regenerative Feedback Module, the Digital Feed Drive offers advanced functionalities such as smooth acceleration, deceleration, and energy-efficient operation. The intelligent control algorithms embedded in the Digital Feed Drive ensure that energy is always optimally utilized, even in complex industrial environments. Additionally, the system is designed to handle high loads and demanding applications, making it ideal for industries such as manufacturing, material handling, and automation.

How the Siemens 611 Infeed/Regenerative Feedback Module Improves Efficiency

The integration of the Siemens 611 Infeed/Regenerative Feedback Module with the Siemens Digital Feed Drive brings remarkable improvements in efficiency. Regenerating energy not only saves costs but also enhances the lifespan of other system components by reducing wear and tear caused by energy fluctuations. This system creates a more stable and reliable power environment for machinery, ensuring that processes run smoothly with minimal interruptions.

One of the critical advantages of this integration is its ability to support high-speed, high-precision applications without sacrificing performance or energy efficiency. It is an ideal solution for industries that require continuous operation at peak capacity, such as automotive manufacturing, robotics, and heavy-duty machining.

The Role of Siemens in Sustainable Automation

Siemens has always been at the forefront of sustainable innovation. By incorporating energy-efficient technologies such as the Siemens 611 Infeed/Regenerative Feedback Module into the Siemens Digital Feed Drive, the company has significantly advanced the drive toward more sustainable industrial automation. These technologies are not only designed to optimize energy consumption but also to minimize waste and reduce the environmental footprint of industrial operations.

Moreover, the seamless integration of the Siemens 611 Infeed/Regenerative Feedback Module with existing Siemens drive systems allows for smoother transitions to greener operations without requiring costly overhauls. This makes it an attractive option for companies looking to reduce energy consumption and improve their sustainability efforts without sacrificing productivity.

Conclusion

The Siemens 611 Infeed/Regenerative Feedback Module and Siemens Digital Feed Drive represent the cutting edge of industrial automation, combining energy regeneration with precise motor control. Their integration enhances efficiency, saves on energy costs, and supports sustainable practices in industries worldwide. As the demand for energy-efficient and environmentally friendly solutions continues to grow, these Siemens technologies will undoubtedly play a pivotal role in shaping the future of industrial automation.

0 notes

Text

Injectable Vial Filling Machine

Injectable Vial Filling Machine or Vial Liquid Filling Machine perform liquid medicine filling operations into vials. Vial filler does nitrogen purging, liquid filling and rubber stoppering operations onto glass vials. Machine available in different filling stations of two head, four head, eight head and twelve head which provide different production output. Machines are compact in size hence less size sterile room requirements. It meet all pharmaceutical requirements in modern technologies. The main structure of the injectable vial filler includes stainless steel cabinet, laminar air flow unit, infeed turn table, conveyor belt, filling nozzles, piston or peristaltic pump, outfeed turn table, vibrator bowl and chute for rubber bungs, pneumatic modules and electrical control panel with an AC drive, PLC, and HMI.

Adinath International is profound manufacturer of injectable vial filling machines in India with 6500 in total machine installations across the world. We are having different types of vial filling machines in which small vial filling machine is choice of R&D laboratories, research institutions and small scale productions. High speed vial filling machines are suitable choice among medium and large scale pharmaceutical production house. Sturdy mechanism, less maintenance and easy to operate are the pillars which makes Adinath as one of the established vial filling machines manufacturer in India.

0 notes

Text

6ES7158-0AD01-0XA0 Mô đun ET200S

6ES7158-0AD01-0XA0 Mô đun ET200S

SKU: 6ES7158-0AD01-0XA0

Thông số kỹ thuật: SIMATIC DP, DP/DP coupler Coupling module for connecting of two PROFIBUS DP networks redundant current infeed

👉 Xem thêm: https://thanhthienphu.vn/6es7158-0ad01-0xa0/

#đạilýsiemens, #thanhthienphu, #thanh_thien_phu, #dai_ly_siemens_viet_nam, #thiếtbịđiênsiemens, #thietbidiensiemens, #đạilýsiemenstạiviệtnam, #thanhthiênphú, #dailysiemens

0 notes

Text

Siemens 6AG2531-7NF10-4AB0 SIPLUS S7-1500

Siemens 6AG2531-7NF10-4AB0 SIPLUS S7-1500 AI 8xU/I HS TX rail based on 6ES7531-7NF10-0AB0 with conformal coating, -40??+70 ??C, OT4 with ST1/2 (+85 ??C for 10 minutes), analog input module 16-bit resolution, accuracy 0.3%, 8 channels in groups of 8, common mode voltage 10 V; diagnostics; hardware interrupts 8 channels in 0.0625 ms including infeed element, shielding bracket and shield…

0 notes

Text

Revolutionizing textile troduction: thomas höpfl discusses Mahlo’s cutting-edge orthopac RXVMC-20

For many decades, the German machine manufacturer Mahlo GmbH + Co KG has been synonymous in the textile industry with straight fabrics and state-of-the-art straightening technologies. The market leader has now further developed it’s proven straightening concept and adapted it to the challenges of its customers. We are talking about the new Orthopac RXVMC-20 automatic straightening machine, and Sales Manager Thomas Höpfl is on hand to answer any questions.

Question: Thomas, thank you for taking the time to speak with us on the topic of optimizing textile production. Let’s dive right in. At ITMA Europe last year, Mahlo presented the prototype of its latest product development Orthopac RXVMC-20. Now the first machine is installed at a customer. Can you give us an overview of the new straightening concept?

Thomas Höpfl: Good morning, and thank you for having me. The Orthopac RXVMC-20 is our latest innovation designed specifically for processing textiles with high distortion dynamics, particularly in the knitwear sector. It’s a sophisticated system that combines control and regulation to offer maximum control over the straightening process.

Q: What makes the Orthopac RXVMC-20 stand out from conventional straightening systems?

T.H.: The key differentiator is its ability to handle textiles with highly variable distortions effectively. Traditional methods struggle with the inconsistencies often found in knitted fabrics, which can be influenced by numerous factors such as the sewing together of short pieces and the type of knitted fabric. Our system uses independently controllable and adjustable straightening modules that provide a high level of precision and control, thanks to advanced scanning and evaluation electronics.

Q: Can you elaborate on how the system works?

T.H.: Certainly. The Orthopac RXVMC-20 consists of two straightening modules, each individually controllable and driven. Distortion sensors at the infeed of the first module detect any fluctuations before they reach the straightening rollers. These rollers are then adjusted using stepless hydraulic or electric drives. A self-optimizing, AI-enhanced control algorithm ensures a highly precise and fast response to these detected distortions. Additionally, there is another distortion detection system at the outlet of the second module that catches any residual distortion, ensuring it is corrected.

Q: That sounds impressive. How does this system benefit textile companies in practical terms?

T.H.: The most significant benefit is the ability to meet high-quality standards regarding permissible residual distortion, which is crucial in the textile industry today. This system not only improves the quality of the finished product but also reduces waste and increases efficiency. For instance, lower profits due to non-compliance with residual distortion values are now avoidable. This system ensures that companies can maintain consistent quality, thereby increasing their competitiveness in the market.

Q: Could you share an example of a company that has implemented this system and the results they have seen?

T.H.: Of course. Tintoria Finissaggio 2000, a renowned textile finishing company, recently installed the Orthopac RXVMC-20. They specialize in a wide range of finishing treatments for various fabrics. After equipping their new stenter with our system, they saw significant improvements in quality and efficiency within just a few months. The owners, Dino Masso and Marco Bardelle mentioned that their expectations were far exceeded by the results.

Q: That’s quite an endorsement. What was the feedback from Tintoria Finissaggio 2000 specifically?

T.H.: They were very pleased with the precision and rapid response of the system. Dino Masso and Marco Bardelle highlighted that their high hopes for the Orthopac RXVMC-20 were more than met. They experienced a substantial enhancement in their production process, which is a testament to the system’s effectiveness and reliability.

Q: It seems like the Orthopac RXVMC-20 is set to make a significant impact in the textile industry. What are Mahlo’s plans for the future with this technology?

T.H.: We are continuously working on innovations to further refine our systems. The success of the Orthopac RXVMC-20 has encouraged us to explore new ways to integrate AI and advanced control algorithms into our products. Our goal is to offer even more efficient and precise solutions to meet the evolving needs of the textile industry.

Q: Thank you, Thomas. It’s been great learning about the Orthopac RXVMC-20 and Mahlo’s contributions to textile manufacturing. We look forward to seeing how this technology evolves.

T.H.: Thank you for the opportunity to share our advancements. We’re excited about the future and committed to continuing our role as a leader in textile process control systems.

Mahlo GmbH + Co. KG belongs to the worldwide leading manufacturers of measuring, control, and automation systems for the textile and finishing industry as well as the coating, film, and paper sectors. Mahlo is located in Saal on the Danube in lower Bavaria but operates worldwide: Five branch offices in Italy, Belgium, Spain, China, and the U.S. serve as support stations for the key markets. Numerous international agencies and service stations offer customer support throughout the whole world.

0 notes

Text

SINAMICS S120- An Enhanced Automation Solution

The modular solution for high-performance motion control applications in the building of industrial plants and machines is the SINAMICS S120 drive. Tailored solutions can be executed through various elements and features that are best synchronized. For example, servo or vector capabilities in coordinated drives and high-performance single-motor drives (multi-axis applications). The SINAMICS S120 drive is a system that provides increased productivity, flexibility, and performance for its users.

Overview of Strengths:

Enhanced machine performance is possible with SINAMICS S120, regardless of whether the application calls for continuous material webs or cyclic, highly dynamic processes. These industries include packaging and printing machines, machines for processing plastics, textiles, paper, and wood, cranes and hoisting gear, handling and assembly systems, machine tools, rolling mills, test beds, and machines in the renewable energy sector.

Universal:

Power and control performance can be freely combined thanks to SINAMICS S120's architecture.

Centralized control intelligence enables greater flexibility.

Free performance selection for vector and servo control

Precise:

reduced lifecycle expenses for the plant's operation.

With the Totally Integrated Automation (TIA) engineering platform, all components may be parameterized, programmed, and commissioned without causing any disruptions to the system.

The primary functionality is implemented with elaborate “embedded” software.

Universal, standardized safety concept – Safety Integrated

STO, SBC, SS1, SS2, SOS, SLS, SDI, SSM, SLP, SP, and SBT are examples of integrated safety functions.

smooth execution of safety features in compliance with PL d (EN ISO 13840-1) and SIL 2 (EN 61508)

System Overview:

High-performance applications can be served by a modular system like the SINAMICS S120 drive system. For multi-axis applications, it provides coordinated DC/AC drives as well as single AC/AC drives. On the other hand, modular plant and machine concepts are also available in a distributed version.

Types of construction – Advanced single- and multi-axis applications using modular drive systems.

Blocksize (AC/AC):

The SINAMICS S120 Blocksize (AC/AC) is a high-performance frequency converter, often known as a servo drive, that consists of a power module and control unit. Its power range is very wide, ranging from 0.55 kW to 250 kW.

Blocksize (DC/AC):

The booksize-format SINAMICS S120 (DC/AC) converter or servo drive is made up of a control unit, an infeed, and a motor module. It can produce power in the range of 1.6 kW to 107 kW.

Chasis (DC/AC):

The SINAMICS S120 DC/AC Chasis is a high-performance frequency converter, often known as a servo drive, that is comprised of a motor module, infeed, and control unit. Its power range is incredibly wide, spanning from 110 kW to 6840 kW.

Chasis (AC/AC):

The SINAMICS S120 Chasis (AC/AC) is a high-performance frequency converter that includes a motor module, infeed, and control unit within the chassis. It can handle power levels between 110 and 250 kW.

SINAMICS Cabinet Modules:

SINAMICS S120 Cabinet Modules-2 are control cabinets that are ready to connect and have undergone type testing. They are designed to maximize the benefits of the SINAMICS S120 Chasis 2 built-in units and are suitable for all customer solutions. 4.8 kW to 5700 kW is the power range.

SINAMICS S120 CM Application Marine Drive:

SINAMICS S120 Cabinet Modules- Custom cabinets with all the benefits of the S120 CM standard system, designed for the marine industry. Power spectrum: 560 kW–5700 kW.

Distributed servo drive S120M:

Compact and ready to connect, the distributed SINAMICS S120M drive unit consists of an integrated power unit (Motor Module) and a synchronous servo motor with multi-turn absolute encoder. Range of power: 0.25 kW to 1.1 kW.

To summarize, the robust SINAMICS S120 AC Drive has been produced as an adaptable solution to a huge range of industrial purposes, including those based on harsh operating environments. One reason for this is the modular nature of its design, which combines maximum flexibility with state-of-the-art control features to meet stringent power consumption targets while adapting easily to changing demands. Therefore, by incorporating SINAMICS S120 into your automation plant, you will be able to improve running costs in the short term and protect yourself from technological obsolescence in the future. Encompass the brilliance of Siemens engineering through SINAMICS S120 for limitless productivity and creativity.

For more information visit here

#sinamics s120#siemens servo drive s120#sinamics s120 modular high performance drives#Siemens Automation Products#Siemens#Siemens Industrial Automation

0 notes

Text

The Siemens 6SN1145-1BA01-0BA2 Infeed/Regenerative Feedback Module is a reliable power module used in SINAMICS S120 drive systems. Designed for efficient energy management, it enables energy regeneration back to the power supply, reducing overall energy consumption. With its compact design and advanced technology, this module ensures stable operation and helps improve system performance in industrial automation. Ideal for controlling high-performance motors, it supports a wide range of applications. Buy the Siemens 6SN1145-1BA01-0BA2 at Auto2mation for trusted quality, fast shipping-your reliable partner in industrial automation solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemens#Regenerative Feedback Module

0 notes

Text

Siemens 611 Simodrive Infeed Module: Repair & Supply Tips

The Siemens 611 Simodrive Infeed Module plays a crucial role in CNC machines and automated systems. It ensures a smooth and stable power supply, making it an essential component for precision operations.

However, like any industrial part, it can experience wear, malfunctions, or breakdowns over time. When that happens, you need to decide whether to repair or replace it.

This guide will help you navigate Siemens 611 Simodrive Infeed Module repair & supply, ensuring that your CNC systems stay operational with minimal downtime.

Understanding the Siemens 611 Simodrive Infeed Module

The Siemens 611 Simodrive Infeed Module is a critical component in drive systems. It regulates power distribution, supports energy recovery, and maintains efficiency in CNC machines.

When this module fails, your entire system can experience power fluctuations or complete shutdowns. That’s why proper maintenance and quick Siemens 611 Simodrive Infeed Module repair & supply are essential.

Common issues include:

Overheating due to excessive load or poor ventilation.

Power failures caused by faulty capacitors or circuit board damage.

Communication errors disrupting CNC machine performance.

Component wear from prolonged usage.

Recognizing these problems early can prevent costly downtime and further damage.

When to Repair vs. Replace the Siemens 611 Simodrive Infeed Module

If your Siemens 611 Simodrive Infeed Module malfunctions, you have two options: repair or replacement.

When to Repair

If the damage is minor, like capacitor failure or a simple circuit board issue.

When the repair cost is significantly lower than a replacement.

If your machine relies on specific settings that would be difficult to replicate with a new module.

When to Replace

If the module has sustained severe damage, making repair impractical.

When spare parts are scarce or difficult to source.

If your system requires an upgrade for better efficiency and performance.

A professional Siemens 611 Simodrive Infeed Module repair & supply service can assess the condition of your module and recommend the best course of action.

Finding Reliable Siemens 611 Simodrive Infeed Module Supply

Sourcing a replacement module can be challenging, especially if you're dealing with an older system. When looking for a reliable Siemens 611 Simodrive Infeed Module repair & supply provider, consider these factors:

1. Supplier Reputation

Choose a trusted supplier with positive reviews and a track record of providing quality parts.

2. Warranty & Support

Ensure the supplier offers warranties or guarantees on the module and provides technical support.

3. Compatibility Assurance

Confirm that the module matches your CNC system’s specifications to avoid integration issues.

4. Refurbished vs. New Parts

Refurbished modules can be a cost-effective alternative to new ones. However, they should be tested and certified to function like new.

Why CNC Robot Parts Matter for Your System

Your CNC machines depend on more than just the Siemens 611 Simodrive Infeed Module. Various CNC robot parts work together to ensure smooth operations.

If your machine is down due to a faulty infeed module, it’s a good idea to inspect other CNC robot parts, such as:

Servo motors – Ensure they receive stable power from the infeed module.

Control boards – Check for communication errors or malfunctions.

Power supplies – Verify that voltage levels remain consistent.

By maintaining both the Siemens 611 Simodrive Infeed Module and other CNC robot parts, you can improve system longevity and performance.

Final Tips for Siemens 611 Simodrive Infeed Module Repair & Supply

To keep your CNC machines running smoothly, follow these key tips:

Perform regular maintenance – Prevent failures by checking for overheating, dust buildup, and worn components.

Work with professionals – Trust experienced technicians for accurate Siemens 611 Simodrive Infeed Module repair & supply services.

Keep spare parts available – Reduce downtime by having critical CNC robot parts on hand.

Test after repair or replacement – Always verify functionality before full integration.

By following these guidelines, you can ensure that your CNC systems remain reliable and efficient. Whether you choose repair or replacement, a proactive approach will save you time and costs in the long run.

0 notes

Text

Automatic Vial Filling & Stoppering Machine

Automatic Vial Filling and Stoppering Machine (vial filler) is uses for the filling and rubber stoppering of injectable liquid vials. Adinath provides a variety of Vial Filling Machines those are appropriate for use in the pharmaceutical sector. Our Automatic Eight Head Vial Filling Machine can fill up to 12000 vials per hour, which is suitable for medium-sized batches. Our Automatic Two/Four Head Vial Filling Machine can fill up to 3600 to 7200 vials per hour, which is appropriate for medium-sized and small batches. Our Automatic Twelve Head Vial Filling Machine can fill up to 18000 vials per hour for large batch productions. Our vial filling machines adhere to cGMP regulations and are simple to use. In addition to the stainless steel piston pump that comes standard with our machine for liquid filing, we can also provide peristaltic pumps upon special customer request for even more filling precision.

Vial filling machine is effective equipment for filling sterile liquid into glass vials. Bulk loading of vials can be performed onto infeed turn table of the machine. Vials then accumulate and transferred one by one to conveyor belt of the machine. During movement vials reaches to the filling station. Filling station is having nozzles for nitrogen purging and liquid filling operations. According to filling head one/two/four/six/eight/twelve filling nozzles installed onto machine for filling operations. At filling station machine performs nitrogen flushing, liquid filling and nitrogen flushing operations in sequential manner. Once filling is done then vials transferred to stoppering unit for stoppering operations.

Machine equipped with inbuilt rubber stoppering unit for rubber bunging operations. After filling vials transfer to rubber stoppering station where vial pick up stoppers one by one from the stopper chute. Further vial passes through below SS 316L roller which in turn stopper pressing operations. Duly stoppered vials further get collected on exit end of conveyor for further capping operations.

The main structure of the Automatic Vial Filling Machine includes an SS cabinet, a safety cabinet with a door, a laminar air flow unit, an infeed turn table, a conveyor belt with Delrin slats for a piston or peristaltic pump, an outfeed turn table, a vibrator bowl and chute for rubber bungs, pneumatic modules, and an electrical control panel with an AC drive, PLC, and HMI.

We have option of CE mark machine upon specific user requirements. We can also provide 21 CFR Part 11 automation package for specific requirements. We provide IQ, OQ, DQ validation protocols for pharmaceutical GMP requirements. We provide lifetime support of spare parts for our supplied machines.

0 notes

Text

A mobile line shaft comes at a standard size

Multiple parcel carriers use mobile line China Mining Conveyor Belt Manufacturers within the depot network including DPD, Hermes, Yodel, Parcelforce, and DHL. Therefore, it was no surprise that the client needed one to handle the increased number of parcels coming through their depot.When L.A.C. Conveyors & Automation first spoke with the client, they made it clear they needed a conveyor solution to aid in handling the number of parcels coming through their warehouses.Having successfully designed, built, and installed several conveyors for several renowned international delivery service, the client could be rest-assured they were in capable hands.Due to the flexibility of a mobile conveyor system, the roller conveyor systems can be used in various layouts to match the needs of the volume of parcels coming through the client’s site.The build and set up a time for a mobile line shaft conveyor is quick and can be ready to operate within several hours. They can be integrated within existing systems and equipment such as x-ray scanners, barcode readers, data capture cameras, and box strapping machines just to name a few.Due to the short setup times, it’s no surprise that multiple carriers have been using mobile line shaft conveyors within the depot network.

A mobile line shaft comes at a standard size of 912mm wide and 850mm height; however, other conveyor widths can be designed to match what the mobile line shaft system will be used for.The package sizes for a mobile line shaft conveyor system can be any length on a straight, on a curve the max size is 1200w x 800h with a minimum parcel size of 150w x 150h with a suggested maximum parcel weight of 50kg/m, however, this can always be adjusted for bespoke projects to ensure the conveyor system meets the customer requirements.What are mobile conveyor systems comprised of?The mobile conveyor systems consist of short (up to six metres) sections, or modules, which fasten together to form a complete material handling system.Whilst each module has its own drive unit, the power and emergency circuits are fully linked, offering the benefits of a fixed conveyor system with the added advantages of being a mobile conveyor system.One control panel can drive up to 10 motors so the conveyor system could go up 60m long through a combination of straights, curves, and mergers of one control panel.This mobile conveyor solution offers the availability to add or remove modules as required and can match the change required in their depot centres.Mobile line shaft conveyor systems can be modularised as workstations and this makes it a great fit for a depot and parcel delivery service provider. As depending on what the required need is or what department it would be working in it can be moved to match the layout required.For example, if required within an e-commerce business, or delivery hub, the conveyor system could be used as part of an infeed system in the morning to bring the product into the building and then reconfigured later in the day for the packaging and the sending out process.The challengeDue to the client needing a bespoke mobile line shaft conveyor solution, L.A.C. drew up a new design of the mobile line shaft conveyors that needed to be implemented and used by the client.All the mobile conveyor units needed to be fully reversible, usable for heavy-duty items, available in different colours to match with the colour sectioning of the warehouse, and modular so they could be switched in and out of the conveyor system quickly.The client needed a mobile roller conveyor solution due to the different floor plans the parcel delivery warehouse had to workaround.Therefore, the roller conveyors needed to be fully mobile and reconfigurable, individually driven for each section, have a control station to ensure full control over the system and each section, and toggle clamps to connect the different modular units to various parts of the system.What was the solution?

By providing the mobile roller conveyors the client was able to process up to 3,000 items per hour which helped reduce time and cost and ultimately resulting in an efficient system. Due to be the plug and play technology offered with the mobile conveyor systems, there were minimal installation costs for the client, and they could be installed in a time-effective manner.A benefit of a mobile line shaft conveyor system is the fact it requires little technological know-how, therefore easy to maintain, set up, and maintenance engineers to do any required work on one.This mobile line shift conveyor system allowed the mail delivery client to unload, sort, and load a wide variety of loose mail in a more efficient and cost-effective manner, helping our client meet their customer’s service level agreements and keeping their relationships healthy by not missing their lead times.About L.A.C. Conveyors & AutomationWho we are: Founded in 1992, L.A.C. Conveyors & Automation are a leading UK supplier who’ve been successfully supplying conveyor systems, belt conveyors, roller conveyors, automation, and robotic solutions to the UK’s blue-chip industry. Located in Bulwell, Nottingham, L.A.C. are known for their outstanding customer service, continual support, flexibility, and bespoke service. With a full in-house service team, and an engineering team who’ve worked together over 20 years, L.A.C. covers all aspects of control system design, build and associated software, and ongoing support.What we do: L.A.C. has a wealth of experience supplying conveyor systems and robotic solutions to a range of industries including automotive, aerospace, food and beverage, heavy engineering, and logistics. L.A.C. design, assemble, incorporate testing, and deliver with training and after-sales support for a smooth handover. With an in-house mechanical design team, project managers, and engineers, all the builds are undertaken on the five-unit 60,000 sq. ft premises.

0 notes

Text

Siemens 6AG2532-5HD00-4AB0 SIPLUS S7-1500

Siemens 6AG2532-5HD00-4AB0 SIPLUS S7-1500 AQ 4xU/I ST TX rail based on 6ES7532-5HD00-0AB0 with conformal coating, -40??+70 ??C, OT4 with ST1/2 (+85 ??C for 10 minutes), analog output module 16-bit resolution, accuracy 0.3%. 4 channels in groups of 4, diagnostics; substitute value including infeed element, shielding bracket and shield terminal. Model: 6AG2532-5HD00-4AB0Categories: SIPLUS…

0 notes

Photo

Siemens Simodrive 611 Drive Converter Module Infeed Power 2-Axis Control Boards https://ift.tt/2UtyNcg

0 notes

Text

How does Parcel Sortation Systems Will grow in Upcoming Years? Know about Challenges, Industry Analysis

The parcel sortation system industry has changed considerably over the past few years with technological development. Automation technology has positively impacted every end-user industry and the adoption of different automated technologies are consistently growing in both developed and developing regions. The manufacturing industry is one of the early adopters of automated technologies, which is majorly attributed to the increasing labor cost and ageing population.

For Sample Brochure Click here

The demand for parcel sortation systems among the end user industries is consistently growing attributing to the fact that, the manufacturing industries are rapidly increasing their production in order to meet the surging customer demands. Parcel sortation system is an integral part of any warehousing and distribution centers which reduces the manual tasks of shipping and checking orders in a fulfillment operation. The ecosystem for Parcel Sortation System, involves the component providers, system integrators, consultants, and end-user of these systems.

Increase in the production volume of consumer goods is boosting the market for parcel sortation systems. Also, significant growth in E-commerce sector is also boosting the growth of the global market. However, technological complexities associated with the use of parcel sortation system may restrain the market growth during the forecast period. Further, growing demand in the warehouse management system and an overall reduction in the cost of parcel sortation system are expected to deliver ample growth opportunity to the industry players in the near future.

Parcel Sortation Systems Market - Company Profiles

Bastian Solutions Inc.

Daifuku Co. Ltd.

Dematic

Honeywell Intelligrated

Murata Machinery, Ltd.

Interroll Holding GmBH

Invata Intralogistics

Beumer Group

Viastore Systems Inc.

Vanderlande Industries B.V.

The companies are highly participating in new product developments to hold their position in the global parcel sortation system market. For instance, in 2018, Dematic made an advancement in the product distribution with the Dematic Roller Non-Contact Accumulation (RNCA) platform. The platform provides a variety of options for product takeoff from sortation systems - horizontal, decline, powered and gravity variants offer compact and controlled singulation. Also, Interroll developed a new infeed, hence expanding its modular platform solutions enabling efficient material flow. The new infeed modules are perfectly designed to work with Interroll crossbelt sorters.

0 notes

Video

youtube

Vision System on 75ml - Pet All Mfg Inc

The Pet All Mfg Inc provides Complete Vision Inspection Module (CVIM) which is a standalone, complete unit with its own drive, plus infeed and outfeed conveyors. It has with 5 cameras, 4 on the side and 1 on the top for the inspection and leak testing of plastic bottles. Visit: https://www.petallmfg.com/leak-detectors.php for more information.

0 notes

Text

مطلب جدید انتشار یافت در https://goo.gl/6zYkZC

بسته بندی آب معدنی

بسته بندی آب معدنی

نسل جدید ماشین های بسته بندی آب معدنی

بدون نیاز به پلاستیک بسیار کارآمد و مقرون بصرفه که افزایش فروش را بهمراه خواهد داشت

جهت بسته بندی آب معدنی و کلیه صنایع آشامیدنی

بسته بندی آب معدنی

Krones AG said since installing its LitePac packaging system, the Bracca Group has increased sales by

more than 30%.

The Bracca Group was the first water bottler to operate the system worldwide.

The LitePac process looks to replace shrink films for secondary packaging for PET bottle

six-packs by producing strapped packs with an integrated handle.

The machine, the EvoLite packer, includes a container infeed module and a container strapping module.

In the infeed module, the containers are divided into two continuous lane flows.

Four strapping units then create the LitePac packs in the container-strapping module.

German beverage packaging machinery manufacturer Krones says the development

was driven by its goal to create a resource-economical alternative to shrink film-wrapped packs.

According to Krones, the LitePac strapping can be up to 50% less costly than shrink film.

Krones calls this process “invisible” packaging.

“Meaning sustainability in the truest sense of the word, embracing both ecological aspects and resource-economy to responsible perfection,” the company stated.

The Italian supermarket chain Unes is the first food and beverage retailer to sell the Bracca Group’s mineral water brand Presolana U! in the new LitePac.

Unes had actually set the ball rolling when the company initiated a project aimed at reducing the packaging for the mineral water brand.

Evnetually Krones and the Bracca Group joined forces, and together invested a substantial amount of work in this project.

In January 2011, Bracca ordered the EvoLite machine, which was integrated into the firm’s 24,000 bph PET line in a bypass configuration, and all the conveyors linked up.

0 notes