#Regenerative Feedback Module

Explore tagged Tumblr posts

Text

The Siemens 6SN1145-1BA01-0BA2 Infeed/Regenerative Feedback Module is a reliable power module used in SINAMICS S120 drive systems. Designed for efficient energy management, it enables energy regeneration back to the power supply, reducing overall energy consumption. With its compact design and advanced technology, this module ensures stable operation and helps improve system performance in industrial automation. Ideal for controlling high-performance motors, it supports a wide range of applications. Buy the Siemens 6SN1145-1BA01-0BA2 at Auto2mation for trusted quality, fast shipping-your reliable partner in industrial automation solutions.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Siemens#Regenerative Feedback Module

0 notes

Text

Understanding the Siemens 611 Infeed/Regenerative Feedback Module

Siemens has long been a leading name in industrial automation, and their innovative solutions continue to set the bar for performance and efficiency. Among their most significant offerings is the Siemens 611 Infeed/Regenerative Feedback Module, an essential component in advanced industrial drive systems. When combined with the Siemens Digital Feed Drive, these modules offer exceptional power regeneration, efficient energy use, and enhanced system performance.

What is the Siemens 611 Infeed/Regenerative Feedback Module?

The Siemens 611 Infeed/Regenerative Feedback Module plays a pivotal role in energy recovery within modern industrial systems. It allows for the regeneration of excess energy that would otherwise be lost. This means that during braking or deceleration phases, the system recovers energy and feeds it back into the network, improving the overall energy efficiency of the operation. This regenerative process not only saves on energy costs but also contributes to reducing environmental impact by lowering energy consumption.

Benefits of the Siemens Digital Feed Drive

The Siemens Digital Feed Drive is a key part of the Siemens motion control portfolio, offering precise and dynamic control over industrial motors. When paired with the Siemens 611 Infeed/Regenerative Feedback Module, the Digital Feed Drive offers advanced functionalities such as smooth acceleration, deceleration, and energy-efficient operation. The intelligent control algorithms embedded in the Digital Feed Drive ensure that energy is always optimally utilized, even in complex industrial environments. Additionally, the system is designed to handle high loads and demanding applications, making it ideal for industries such as manufacturing, material handling, and automation.

How the Siemens 611 Infeed/Regenerative Feedback Module Improves Efficiency

The integration of the Siemens 611 Infeed/Regenerative Feedback Module with the Siemens Digital Feed Drive brings remarkable improvements in efficiency. Regenerating energy not only saves costs but also enhances the lifespan of other system components by reducing wear and tear caused by energy fluctuations. This system creates a more stable and reliable power environment for machinery, ensuring that processes run smoothly with minimal interruptions.

One of the critical advantages of this integration is its ability to support high-speed, high-precision applications without sacrificing performance or energy efficiency. It is an ideal solution for industries that require continuous operation at peak capacity, such as automotive manufacturing, robotics, and heavy-duty machining.

The Role of Siemens in Sustainable Automation

Siemens has always been at the forefront of sustainable innovation. By incorporating energy-efficient technologies such as the Siemens 611 Infeed/Regenerative Feedback Module into the Siemens Digital Feed Drive, the company has significantly advanced the drive toward more sustainable industrial automation. These technologies are not only designed to optimize energy consumption but also to minimize waste and reduce the environmental footprint of industrial operations.

Moreover, the seamless integration of the Siemens 611 Infeed/Regenerative Feedback Module with existing Siemens drive systems allows for smoother transitions to greener operations without requiring costly overhauls. This makes it an attractive option for companies looking to reduce energy consumption and improve their sustainability efforts without sacrificing productivity.

Conclusion

The Siemens 611 Infeed/Regenerative Feedback Module and Siemens Digital Feed Drive represent the cutting edge of industrial automation, combining energy regeneration with precise motor control. Their integration enhances efficiency, saves on energy costs, and supports sustainable practices in industries worldwide. As the demand for energy-efficient and environmentally friendly solutions continues to grow, these Siemens technologies will undoubtedly play a pivotal role in shaping the future of industrial automation.

0 notes

Text

Why SINAMICS G120 is the Preferred Choice for Industrial Drives

In this day's competitive industrial scenario, everything has to run faster, smarter, and energy-efficiently. The kind of drive system you choose will determine if operations succeed in manufacturing, processing, or materials handling. That has somewhat forced many industries worldwide to consider the SINAMICS G120 Drive of Siemens: a drive system that needs to possess a high degree of versatility and performance to answer current automation needs.

Learn more, How SINAMICS G120 Supports Energy-Saving in Industrial Applications

What is SINAMICS G120?

The Drive SINAMICS G120 is a frequency inverter that is modular and is meant for securing the speed and torque of three-phase motors. With such freeway capabilities, it found applications in a vast array of industrial processes: pumps, fans, conveyors, compressors, mixers, and others.

What distinguishes Drive G120 from its competitors is the smart idea behind it: basically, this means it consists of two main components, the Control Unit (CU) and the Power Module (PM), which can be combined and replaced separately. This makes it an extremely flexible choice, easily integrated into existing systems.

Why Choose the SINAMICS G120 Drive?

Some reasons why various industries choose this drive system include:

Energy Efficiency: Regenerative feedback and ECO mode assist in keeping electricity expenses low.

Integrated Safety Functions: Safe Torque Off (STO) and other safety features protect the operator and ensure compliance with international standards.

Seamless Communication: Through communications such as PROFINET, PROFIBUS, and Modbus RTU, it can be interfaced into most automation networks.

Reliable Performance: Superior motor control is provided for constant and variable torque applications.

Drive G120 in Real-Life Application

User industries report increased system efficiency, with reductions in maintenance and performance, occurring with the installation of the Drive SINAMICS G120. Thus, in water treatment plants or automated warehouses, the drive keeps operations running smoothly and reliably.

For example, applications that require conveyors with constant speed change between different loads will benefit greatly from the Drive G120 torque controlling capability to minimize mechanical wear and maximize output.

Simple Setup and Maintenance

The simple web server and powerful diagnostics make for a very user-friendly interface for the SINAMICS G120. Parameterization, monitoring, and fault diagnostics can also easily be carried out by your maintenance crew within a very short time, with or without specialized training.

Another aspect of the modular design is that the components can be individually replaced, thereby reducing downtime in the maintenance process or when upgrading.

Final Thoughts

If the automation system demands enhanced drive solutions, then the SINAMICS G120 by Naksh Technology Solutions LLP can be regarded as the choice facing modern times. It has been crafted to meet contemporary industrial requirements-powerfully, modularly, and safely. Siemens engineered it to over-deliver: from Drive G120 flexible configuration to seamless integration with your existing PLC or HMI setup.

Want to upgrade or optimize your system? Then the SINAMICS G120 Drive is just what your operation needs.

0 notes

Text

https://calonev.com/why-cal-on-evs-manufacturing-standards-set-a-new-benchmark-in-e-mobility/

Driving the Future of Green Mobility

India’s electric vehicle (EV) market is undergoing a revolutionary transformation, and at the heart of this shift stands CAL-ON EV, a company committed to reimagining mobility through precision, innovation, and sustainability. In an industry increasingly defined by performance, safety, and eco-consciousness, CAL-ON EV Manufacturing Standards have set an extraordinary benchmark in e-mobility manufacturing excellence.

This blog explores how CAL-ON EV’s quality assurance practices, cutting-edge production facilities, and relentless pursuit of sustainable electric vehicle manufacturing are elevating the brand as a symbol of reliable electric vehicles in India and global competitiveness.

1. The Foundation of Excellence: High-Quality EV Manufacturing in India

When it comes to high-quality EV manufacturing, CAL-ON EV Manufacturing Standards lead the charge by combining advanced automation, smart technologies, and precision engineering in EVs. The company leverages a state-of-the-art EV plant in India, equipped with AI-driven quality checks, robotic assembly lines, and lean production techniques that prioritize zero defects.

This focus on best practices in EV production has enabled CAL-ON to meet and exceed the most stringent EV safety standards in India, ensuring not only world-class performance but also driver and passenger safety.

2. Quality Assurance Beyond Industry Norms

CAL-ON EV quality assurance begins at the design table and continues through every stage of production. From component sourcing to final testing, CAL-ON integrates next-gen EV manufacturing systems that facilitate real-time feedback and automated quality control checkpoints.

Such robust quality control in EV production has helped CAL-ON build trust among its customers and industry partners. The rigorous inspection process—covering electrical safety, battery endurance, structural integrity, and software calibration—ensures that every vehicle meets benchmark EV production in India.

3. Innovation at the Core of CAL-ON EV Manufacturing Standards

Innovation isn’t just a buzzword at CAL-ON—it’s a philosophy. The brand’s R&D teams are constantly testing and implementing cutting-edge EV technology in India, including regenerative braking systems, advanced battery management, and IoT-enabled smart dashboards.

This spirit of CAL-ON electric vehicle innovation keeps the company ahead of the curve in delivering future-ready electric vehicles. It also fuels its mission of green technology in EVs, using lightweight composite materials, recyclable components, and energy-efficient assembly lines.

4. Smart Manufacturing in E-Mobility: An Industry Benchmark

Smart manufacturing in e-mobility is not just about digitizing processes—it’s about creating a connected ecosystem where every component, sensor, and module communicates seamlessly. CAL-ON EV Manufacturing Standards utilize predictive analytics, digital twins, and cloud-connected monitoring systems to anticipate issues before they arise and optimize production in real time.

This integration of technology and talent supports superior EV design and testing, enabling quicker prototyping, reduced production time, and improved reliability of end products.

5. Sustainability Built Into Every EV

The journey toward sustainable electric vehicle manufacturing involves minimizing carbon footprints and maximizing energy efficiency. CAL-ON’s facilities are designed for solar integration, rainwater harvesting, and responsible waste management. Its supply chain is curated to include vendors who align with green technology in EVs and follow ethical sourcing.

From eco-friendly paints to recyclable battery packs, sustainability is an integral part of CAL-ON EV Manufacturing Standards, underscoring their role as leaders in the Indian electric vehicle manufacturing benchmarks space.

6. Setting the Gold Standard for EV Safety in India

In the arena of EV safety standards in India, CAL-ON is a name synonymous with trust. Vehicles undergo over 200 individual safety tests, including frontal and side impact simulations, battery explosion resistance, and water-wading performance.

The company’s approach to best practices in EV production ensures all vehicles meet or exceed Bharat NCAP and AIS 038 safety requirements. Safety features like advanced driver-assistance systems (ADAS), traction control, and fail-safe battery cut-offs highlight their commitment to building reliable electric vehicles in India.

7. Precision Engineering in Every Bolt and Circuit

One of the defining traits of CAL-ON EV Manufacturing Standards is the company’s dedication to precision engineering in EVs. Whether it’s a bolt, wire, or sensor, every component is meticulously tested and positioned to achieve optimum performance and durability.

Such a focus on detail allows CAL-ON to perfect the balance between performance and economy, shaping vehicles that are both exhilarating to drive and cost-efficient to own.

8. The Indian EV Industry Growth and CAL-ON’s Role

The rapid Indian EV industry growth has been fueled by supportive policies, urbanization, and environmental awareness. But it’s brands like CAL-ON that are setting tangible benchmarks in EV manufacturing standards in India.

By aligning their processes with international certifications and constantly upgrading to newer technologies, CAL-ON is not just keeping pace—it is leading. The brand’s strategy is a case study in e-mobility manufacturing excellence, showcasing what’s possible when vision, technology, and talent converge.

9. Future-Ready and Built to Last

Future-ready electric vehicles are more than just EVs with modern tech-they are designed to evolve. With over-the-air (OTA) updates, modular battery architecture, and smart connectivity features, CAL-ON’s vehicles are built with tomorrow in mind.

Such a forward-thinking approach is embedded in CAL-ON EV Manufacturing Standards, ensuring longevity, scalability, and upgradability—traits that will be crucial as India transitions toward full-scale e-mobility.

10. The Benchmark for the EV Ecosystem in India

In a highly competitive market, CAL-ON EV Manufacturing Standards are helping redefine what it means to build an electric vehicle in India. Their model inspires confidence across stakeholders-customers, investors, government bodies, and supply chain partners.

This has led to the emergence of a new standard for benchmark EV production in India, paving the way for an ecosystem that’s not only profitable but also sustainable and socially responsible.

Conclusion: CAL-ON is the Future of EV Manufacturing in India

In conclusion, CAL-ON EV Manufacturing Standards represent more than just technical superiority-they embody a vision for smart manufacturing in e-mobility, rooted in sustainability, safety, and innovation. By consistently adhering to high-quality EV manufacturing, maintaining rigorous EV safety standards in India, and driving CAL-ON EV quality assurance, the company is spearheading a future where green mobility solutions in India are the norm, not the exception.

Whether you are an EV enthusiast, a policymaker, or a business looking to invest in the Indian electric vehicle manufacturing benchmarks, CAL-ON’s journey offers a roadmap to success. Their relentless commitment to next-gen EV manufacturing in India makes them the brand to watch in the electrified era ahead.

Also Read: Made in India, Built for the Future: The Manufacturing Journey of CAL-ON EV

📘 Facebook || 📸 Instagram || 💼 LinkedIn || 🎯 YouTube

#electric vehicles#electric vehicle sales#sustainable transportation#calonev#electric scooters#electric vehicle innovation

0 notes

Text

Exosomes Hair Injection Therapy Price: What You Need to Know

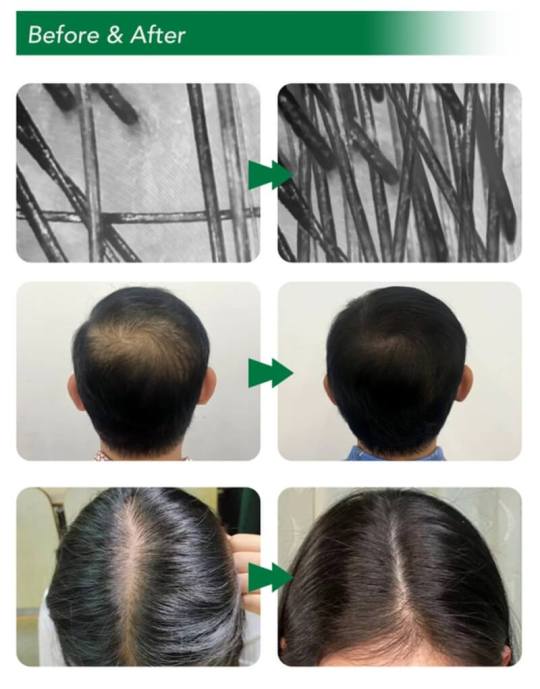

Hair loss affects millions globally, and the demand for non-surgical, scientifically backed treatments continues to grow. One of the most advanced solutions available today is exosome-based therapy. Those searching for information on exosomes hair injection therapy price are often looking for a treatment that is not only effective but also rooted in cutting-edge science. Among the options available, Exobloom® stands out for its safety, efficacy, and regenerative potential. For inquiries about our product range, don’t wait to contact us.

What Determines the Exosome Hair Therapy Price?

The exosomes hair injection therapy price varies based on biologics complexity, regional costs, and supply chain efficiency. While prices in the U.S. and Europe tend to be higher due to regulations and overhead, markets like South Korea offer competitive exosomes hair injection price without compromising quality.

Exobloom® is a premium product within this space. It is processed through an advanced nanofiltration and purification method, ensuring the exosomes maintain high purity and biological activity. Dermax, the exclusive supplier of Exobloom®, has strategically located distribution centers in Germany, the U.S., China, and South Korea, allowing clinics to benefit from more localized pricing and faster delivery. Have a question? We’re just a click away—contact us now.

Exosomes Hair Injection Price: A Worthwhile Investment?

If you are wondering whether the exosomes hair injection therapy price is worth it, consider the biological mechanism behind the treatment. Exobloom® works by delivering high-purity exosomes directly to the scalp, where they modulate the local cellular environment. These exosomes are bioactive, meaning they can communicate with dermal papilla cells and other follicular components to:

- Prolong the anagen (growth) phase of hair

- Inhibit inflammation and DHT-related follicle miniaturization

- Stimulate angiogenesis (formation of new blood vessels) around hair roots

- Enhance the via bility and density of existing follicles

Compared with PRP (Platelet-Rich Plasma) therapy, which relies on the patient’s own platelets, or mesotherapy which involves diluted active ingredients, Exobloom® introduces a consistent, cell-free regenerative element. This not only reduces variability in outcomes but also makes it an ideal solution for individuals who may not respond well to traditional hair loss treatments.

How Exobloom® Enhances Exosome Hair Therapy

Exobloom® is formulated to ensure maximum compatibility with the human scalp environment. It undergoes rigorous testing for sterility, particle uniformity, and bioactivity. The exosomes used in Exobloom® are extracted from well-characterized mesenchymal stem cell lines under GMP-certified conditions. This ensures:

- High exosome yield per treatment vial

- Stable composition free from unwanted proteins or cell debris

- Long shelf life when stored under proper conditions

Furthermore, Exobloom® contains a blend of natural growth factors and signaling molecules that are instrumental in hair regeneration. Unlike less purified alternatives, its composition allows for better absorption and interaction at the cellular level, thus potentially delivering faster and more visible results.

Clinical Efficacy and Patient Satisfaction

Preliminary clinical feedback and case studies have shown encouraging results with Exobloom®. Patients often report noticeable improvements in hair density, reduced shedding, and a healthier scalp environment within 6 to 12 weeks of treatment. Dermatologists and aesthetic physicians have also cited its ease of integration into existing treatment protocols and its compatibility with procedures like microneedling or low-level laser therapy.

When considering the exosome hair therapy price, it is important to factor in these clinical benefits. The cost is not just for the physical product but also for a more holistic hair restoration experience that potentially offers superior results compared to conventional approaches. Discover more about our offerings by getting in touch with us.

Why Professionals Prefer Exobloom® for Hair Regeneration

Medical aesthetics professionals consistently turn to Exobloom® for its reliability and documented performance. It is a preferred choice not only due to its high exosome purity but also its ability to integrate easily into various treatment protocols. With over two decades of experience in aesthetic medicine and distribution across more than 80 countries, Dermax has established itself as a trusted leader in regenerative therapies.

In the context of exosomes hair injection price, Exobloom® offers unmatched value by delivering consistent quality, safety, and performance. Clinics that adopt Exobloom® also benefit from Dermax's robust after-sales support, flexible return policies, and rapid response times for international clients.

Feel free to reach out to us for more information about our products.

Source: https://www.dermaxmed.com/exosomes-hair-injection-therapy-price-what-you-need-to-know.html

0 notes

Text

How the Siemens G120 Drive Enhances Industrial Automation

Industrial automation needs operations to work ever so efficiently and reliably because these are two primary factors which influence any process toward its successful accomplishment. This led Siemens, the world's largest supplier of automation and drive technology, to invent the SINAMICS G120 drive, one of the most advanced variable frequency drives-to really show how energy can be saved, systems improved, and basically the control of processes made easier across different industries.

What is the SINAMICS G120 Drive?

The SINAMICS G120 drive is somewhat of a modular frequency converter characteristic of good motor control, with balance on its energy efficiency versus its flexibility. This drive finds applicability in segments including manufacturing, automotive, food processing, and chemical plants. It can cater to ever-simple to much-complicated applications.

The modular design thus enables the user to configure the G120 drive flexibly, either by choosing different power modules or control units for its application. This design feature is further beneficial in terms of being able to repair and service the G120 drive, contributing to limiting downtime and minimizing costs associated with maintenance.

Some Features of the Siemens G120 Drive

1. Modular Design: The modular architecture of the Siemens G120 drive separates the control unit from the power module and allows great flexibility for customization. Separation of the two components allows independent component replacement and hence minimizes maintenance downtime and costs.

2. Excellent Safety Features: Safety is of the utmost importance in industrial practice. The G120 drive features integrated safety functions, including Safe Torque Off (STO) and Safe Stop (SS1), which provide a comfortable level of safety with minimal use of additional hardware.

3. High Energy Efficiency: When it comes to reducing operational expenses, energy efficiency is of prime interest to various businesses. Features such as regenerative feedback contribute to energy efficiency while helping SINAMICS G120 drives minimize their carbon footprint and aid their sustainability drive.

4. Comprehensive Communication: The Siemens G120 drive supports a comprehensive array of communication protocols—PROFINET, PROFIBUS, and Modbus—to allow truly seamless integration into existing automation systems. This makes connection enhanced and allows for real-time data monitoring to improve system performance.

5. Straightforward Operation and Commissioning: The drive is equipped with a user-friendly interface, including easy parameterization, which provides quick configuration and simple operation. The commissioning process has been greatly simplified with SINAMICS Startdrive software to enable quick setup and parameter changes.

Applications of SINAMICS G120 Drive

The application areas of the G120 drive are highly flexible and varied:

Pumps and Fans – Speed control optimization and energy saving.

Conveyance and Material Handling – Smooth acceleration and deceleration allow precise control.

Machine Tools – Improves the precision with which cutting, drilling, and milling operations are done.

HVAC – Controls all air conditioning and ventilation units much better.

Textile and Paper Industry- Motion control with precision enhances the performances of various production lines.

Reasons to Choose Siemens G120 Drive

For outstanding performance, flexibility, and reliability, the Siemens G120 drive is preferred by industries around the globe. Here are some distinguishing features of this drive:

Build tough and ready for the worst industrial environments.

Easy integration within Siemens automation systems.

Technically advanced, ready for the 4th Industrial revolution.

Global support by Siemens service and maintenance.

Conclusion

The SINAMICS G120 drive is, in fact, an advanced solution for industries in pursuit of energy-saving motion control technology, effective technology, and reliability. For these reasons, its modular design, safety features, and interconnectivity have made it the choice of many industries wanting to optimize their automation processes. Whether in manufacturing, material handling, or HVAC applications, the G120 drive by Naksh Technology Solutions LLP boasts high performance and operational efficiency.

0 notes

Text

Unlocking Hope: Promising Research in Autism Treatment Centers in UAE

In the realm of autism treatment, constant advancements pave the way for a brighter future. Families and individuals affected by autism spectrum disorder (ASD) often seek promising therapies and interventions to enhance their quality of life. Amidst this pursuit, researchers worldwide are tirelessly working to unravel groundbreaking treatments. In the United Arab Emirates (UAE), autism treatment centers stand at the forefront, integrating innovative approaches to support individuals with ASD.

Gene Therapy: Illuminating Possibilities

Gene therapy, a burgeoning field, holds immense promise in revolutionizing autism treatment. Researchers are delving into the genetic underpinnings of ASD, aiming to target specific genes associated with the disorder. In UAE-based autism treatment centers, collaborative efforts are underway to explore gene-editing techniques that could potentially mitigate the core symptoms of ASD. By addressing genetic anomalies, gene therapy offers a ray of hope for individuals and families navigating the complexities of autism.

Stem Cell Therapy: Nurturing Potential

Stem cell therapy emerges as another frontier in the quest for effective autism treatments. In the UAE, research initiatives are exploring the regenerative capabilities of stem cells to ameliorate neurological impairments characteristic of ASD. By harnessing the regenerative properties of stem cells, clinicians aim to restore neuronal function and foster neurodevelopmental progress in individuals with autism. This pioneering approach underscores the commitment of autism treatment centers in UAE to embrace cutting-edge therapies.

Neurofeedback: Rewiring Neural Pathways

Neurofeedback, a non-invasive therapeutic technique, offers promising avenues for managing autism spectrum disorder. Within UAE's autism treatment centers, clinicians leverage neurofeedback to modulate brain activity and enhance self-regulation skills in individuals with ASD. By providing real-time feedback on brainwave patterns, neurofeedback enables personalized interventions tailored to the unique needs of each individual. As research in this field progresses, neurofeedback emerges as a valuable tool in augmenting behavioral and cognitive outcomes for individuals with autism.

Virtual Reality Therapy: Immersive Interventions

Virtual reality (VR) therapy emerges as a novel approach to address the sensory and social challenges faced by individuals with autism. In UAE-based autism treatment centers, VR technology is harnessed to create immersive environments conducive to social skill development and sensory integration. By simulating real-life scenarios in a controlled setting, VR therapy offers a safe space for individuals to practice social interactions and sensory modulation techniques. This innovative modality underscores the commitment of autism treatment centers in UAE to embrace holistic and immersive interventions for individuals with ASD.

Gut-Brain Axis Interventions: Nourishing Neurodiversity

The intricate connection between the gut and the brain unveils new opportunities for interventions in autism treatment. Research exploring the gut-brain axis sheds light on the role of gut microbiota in modulating neurodevelopment and behavior. In UAE-based autism treatment centers, clinicians adopt a multidisciplinary approach that incorporates dietary interventions, probiotics, and gut health assessments to support neurodiverse individuals. By addressing gut health, these interventions aim to alleviate gastrointestinal symptoms and enhance overall well-being in individuals with ASD.

Conclusion:

In the dynamic landscape of autism treatment, the horizon brims with promise and potential. Within the UAE, autism treatment centers spearhead innovative research initiatives aimed at enhancing the lives of individuals with ASD. From gene therapy to virtual reality interventions, these centers embrace cutting-edge approaches that transcend conventional boundaries. As research progresses and technologies evolve, the journey towards unlocking the full potential of individuals with autism continues, guided by a shared vision of empowerment and inclusion. In the pursuit of excellence, autism treatment centers in UAE stand as beacons of hope, illuminating pathways towards a brighter future for neurodiverse communities.

0 notes

Text

The Ultimate Guide to Servo Motion Controllers: Everything You Need to Know

The Kinetix 5700 servo drives offer a wide power range and great power density in a small frame and are suited for machines with high power and numerous axes. They have two Ethernet ports for Device Level Ring and linear topologies, single and dual axis inverters, and cutting-edge snap-fit bus technology. Incorporated safety features on the drives include Safe Torque Off, Safe Stop, and Safe Monitoring. They provide LC filters, onboard diagnostics, common DC bus voltage management, and regenerative bus services. Servos provide high performance and accuracy for driving machinery in either rotational or linear motion. As there is frequently considerable integration between servo systems and PLC-based automation systems and customers, it is crucial to take communications and interoperability elements into account when choosing servo motion controllers and motors.

kinetix 5700 servo drive are made for machines that need a lot of power and have a lot of axes. There are single-axis and dual-axis inverters with hardwired (drive-based) and integrated (drive-based and controller-based) safety features.

Features

Kinetix Servo Drives 5700

offers a wide 1.6...112 kW power range;

delivers outstanding power density in a small frame;

supports a variety of feedback mechanisms for servo and induction motors.

contains modules with two axes

enables quick and easy installation and assembly using state-of-the-art snap-fit bus technology.

promotes the use of a single cable for both feedback and motor power.

It has two Ethernet ports capable of supporting Device Level Ring (DLR) and linear topologies.

CIP Security capabilities support a defense-in-depth cybersecurity strategy.

Kinetix 5700 Integrated Safety Servo Drives

consists of built-in or built-in safety measures

A built-in safety device reduces the overall system wiring.

cutting-edge safety tools like Safe Torque Off, Safe Stop, and Safe Monitoring

KINETIX Offers Regenerative Bus Services

It conducts common DC bus voltage management throughout the entire range of AC input voltages, which helps to lower overall energy consumption.

Onboard diagnostics for power quality monitoring with real-time analytics over EtherNet/IP

A built-in LC filter minimises cabinet space and installation costs.

Setup and Operation Without Tuning

It automatically fine-tunes each axis, accounts for unanticipated physics, and corrects for operational applications with variable inertia using Load Observer real-time tuning technology.

Analytics are provided via virtual torque sensing, which also helps to spot irregularities.

Lower resonance using various adaptive tuning methods notch filters for monitors

The use of electrical servo drives, also known as motion controllers, and related servomotors to move the machinery is most frequently referred to as motion control. Servos can drive machinery in a rotational or linear motion when they are coupled directly or through mechanisms. When compared to less capable systems, they can be more difficult to develop, procure, install, and commission. However, once in use, they are dependable and effective. More importantly, servos offer the high level of performance and accuracy that many applications demands.

It is crucial to consider the communications and interoperability aspects when specifying servo motion controllers and motors since there is frequently a high level of integration between servo systems and PLC-based automation systems and consumers are seeking for more Internet of Things data.

0 notes

Note

Thank you. You have been busy of late and I do not wish to take more of your time than necessary. But I could use your insight!

I have observed that the adaptive, crystalline lattice structure of the Hexcore is not merely a conduit for arcane energy but an active participant in biochemical reactions. The Hexcore now resonates at a frequency that, when exposed to organic matter, appears to catalyze molecular reconfiguration.

It seems to function by interfacing with the intrinsic electromagnetic fields of living cells, altering their metabolic pathways and inducing morphological changes. The phenomenon suggests an adaptive feedback loop in which the Hexcore not only transmits energy, but also responds dynamically to biological input. This is, of course, what we had hoped to achieve, but the input is not through merely manual manipulation of a runic interface, but by the direct introduction of biological structures themselves!

I suspect the core is triggering a form of accelerated cellular differentiation, possibly through quantum entanglement with biological substrates. This is, of course, still highly theoretical speculation, which is why I need your help.

But, if harnessed correctly, this could revolutionize regenerative medicine, cellular augmentation, or even neural enhancement.

If we can isolate the variables governing its interactions, we may unlock a new frontier in Hextech innovation. However, the unpredictable nature of these interactions raises ethical and safety concerns. Modulating such energy without precise control could lead to unintended mutations or systemic failure.

I have been refreshing my knowledge of molecular biology. I may have to consult a friend in the Undercity in the coming days who is better versed in such matters.

Jayce, have you a moment? I should like to speak to you at length about some promising data I have gathered from the Hexcore. Its implications are profound.

@askviktor

Of course, I’ll make time for you. I’d love to discuss our invention to improve it. I believe it has enormous potential that we need to harness. After all, we’re here to help people and change the world. I want to pursue that goal with you, Viktor.

#jayce talis#arcane#viktor#arcane rp#viktor arcane#arcane viktor#viktor my beloved#jayce x viktor#viktor x jayce#viktor league of legends#viktor lol#arcane roleplay#arcane rp blog#viktor roleplay#viktor rp#hexcore#hextech

73 notes

·

View notes

Text

The World Below You Fades I.

Plug into BigSky and instantly elevate your sound into the stratosphere. The world below you fades i.. The philosophy behind our blueSky Reverberator is simple—take a ridiculously powerful SHARC DSP a.. In setting out to design Brigadier, we determined to take a brilliant-powerful SHARC DSP and dedicate al.. Our journey begins with the early recording studios of the '50s and '60s. Since assimilating Damage Control Effects in 2009, Strymon has wasted no time expanding its alrea.. The magical mixture of tremolo and reverb is the earliest instance of a perfect guitar effects.. Some may say we're driven. When our engineers lock themselves in our sound design labs for mont.. Extended management for TimeLine, BigSky, and Mobius. Need to unlock the complete performance of T.. Everything you love about studio optical compressors … right at your toes. With the Orbit dBucket Flanger, we've painstakingly recreated every facet of a number of the greates.. The Tap Favorite presents every thing you love about the Favorite Switch however with the addition of a .. Once we determined to create a studio-class stereo delay results pedal, we knew we should go properly beyo.. This little purple magnificence was designed to emulate and recreate sounds from some basic vintage analog flangers, ones you’ve heard on a whole lot, if not thousands, of recordings, but with some modern performance as well. Let’s take a look at the controls and go from there, shall we? The Speed knob adjusts the, nicely, velocity of the LFO (Low-Frequency Oscillation), and the Width adjusts the LFO’s general depth. Regen controls the feedback intensity, and works at the side of the primary two controls to provide a marvelous array of flanged tones. The combo knob is a welcome addition to a flanger, and varies the quantity of your guitar’s dry sign that will get mixed in with the Orbit’s wet sign, for complete management over how the impact shapes your tone and sound. The final most important knob is called Manual, and this one sets the delay time for the flanging, working with the Width and Regen controls for maximum visibility. Next up, we’ve obtained a couple of toggle switches for much more versatility and experimentation. Coming with a combination of high function entrance-panel control, it allows the users to De-tune the chorus-like sounds to the intense and stunning sound of the jet airplane. Thus, it will likely be proper to say that adopting this instrument, modern musicians can simply get the sound results of the traditional tones. If https://guitareffectspedalz.com/strymon-orbit-review-best-dbucket-flanger-pedal/ be instructed, this is one in all the key elements that may be accounted past the large popularity of this product. In phrases of those features, this product will certainly impress the new customers, giving them the finest expertise. The deep-modifying characteristic, and the intensive I/O have impressed the customers. It enables the users to dial the sound of the pedal with the best perfection and in a fashion that helps the performance. Offers the widest scopes of choices when it comes to the Vintage Swooch and Flanging of Analog Sound. Highly Customisable that enables the users to supply some distinctive and exclusive sound. The instrument comes with foot switch that makes it simpler for the users to manage the sound in addition to to preset the system, as and when needed. This mechanism makes the gadget all of the more person-friendly. The manufacturer has incorporated 2 switches of premium quality and 5 Knobs that the person can use for advantageous-tuning the performance of the pedal. Each control in this system comes with some secondary feature for subsequent editing of the sound. Options for guide and computerized controls. Expression Pedal input has been integrated that permits management on actual-time. Clips recorded with PRS McCarty DC245 20th Anniversary into a Matchless Avalon 35 combo. In relation to flangers and phasers, I’m normally a bit more vital than I'm of different effects. To me, they can become tiresome a lot faster than delays or even different time-based mostly effects. However, there are times when they can add some magic if you employ them sparingly. For example, I personal a vintage Ibanez FL9 Flanger that I absolutely love, however only for one particular sound. But the Orbit opens up a lot more prospects in the modulation realm. And that’s because it sports activities an array of controls for altering the pace, width, regeneration, combine, and delay time of the flanging. You may also change the phase of the wet/dry combine and significantly alter the vary of the impact with the threeway Feedback swap. However the three-place LFO switch is the Orbit’s coolest control. It selects between a logarithmic sweep (even frequencies), a linear sweep (which accelerates via the excessive bands and slows down by the decrease ones), and Thru 0, which phases in and out of excessive and lower fidelities. I believe once you hear a Strymon chorus, reverb or delay thru your rig you can be converted LOLZ. Anyhow, I figured their flanger had to be a minimum of nearly as good as the others I have tried and owned (all the usual suspects) - my biggest gripe about this flanger is the price. Strymon Orbit Flanger can cowl all of that territory and so far more. The pedal is completely silent ON or OFF. As in Zero hum. Totally silent footswitching. The onboard favourite switch is sort of handy (which does save from having to purchase a Strymon favorite swap). 70's/80's RUSH oscillating watery chorus sound. The pedal is fairly gentle but properly-built, like a tank. Open it up and move the jumpers and it may be configured to output L/R stereo. A Mix management. Yes! So you can dial up more of your specific weirdness or calm it all down and let your original sign move via with just a style of flanger riding in the combination. Any new-wave guitarist, 70's/80's cowl band participant, any alt-rock to metallic to shoegazer to ambient post-rock guitar player would profit from this pedal. So - is it so much of money? Yes, but all of the flanger you'll ever need and then some. Shout out to my friend Aaron Smith at Sweetwater who delivers one of the best music retailer buyer expertise I have ever had each and every time I deal with him. Thanks so much, Aaron.

1 note

·

View note

Text

Version 447

youtube

windows

zip

exe

macOS

app

linux

tar.gz

I had a great week. The database should be a bit faster when doing file work, and I have fixed several annoying bugs. It will take your client a few seconds to update this week, maybe a minute or two if you have millions of files.

multi column lists

I gave the weird column widths another go. Some users had this fun but quite annoying situation where a dialog with a list could grow magically wider before their eyes, maybe 20 pixels four times a second, until it reached their monitor width. Other users (me included) had a handful of lists still growing or shrinking a few pixels on every reopen.

So I drilled down into the logic again and improved things. Some calculations are now more accurate, some are more precise, and I think I fixed the runaway growth situation. Let me know how you get on, and sorry for the trouble!

performance improvements

Thanks to profile feedback from users, I discovered some file routines that were working inefficiently, particularly on very large clients. Mostly unusual jobs like 'get all the trashed files that are due for deletion' or 'get the repository update files I still need to process'. It was mostly when you were looking at a small domain when a very large 'my files' domain was right next door, getting in the way of the query. Having done lots of similar improvement work for tags, I updated how files are stored this week. Several big tables are now split into many smaller pieces that do not interfere with each other. This was actually a long overdue job, so I am happy it is done.

There isn't much to say beyond 'your client should be a bit faster with files now', but let me know how you get on anyway. Mostly you should have fewer lag spikes as background jobs go about their work, but you may notice the duplicates system going a bit faster and general file searches working better too.

Some users with very large sessions have also reported CPU lag with the new session saving system. Thanks again to some user profiles, I was able to speed up session save, particularly for pages with tens or hundreds of thousands of thumbails. The next step will be optimising downloader page save, so if you have a lot of heavy downloaders, I would be interested in some profiles.

In that vein, I significantly improved the profile mode (help->debug->profile mode) this week. All the modes are now merged into one, and all the popup spam is gone. It now makes a new log file every time you turn it on, and only the most useful information is logged. I will keep working here to get more and more information profiled so we can nail down and eliminate slow code.

I have altered core components of the database this week, and it unfortunately caused some bit rot in older update routines. 447 cannot update databases older than 411, and it may have trouble updating before 436. If either of these apply to you, the client will error out or warn you before continuing. I'd like to know what happens to you if you are v411-435 so I can refine these messages.

And while I have tested this all back and forth, there may be a typo bug in some of the more unusual queries. I am sorry ahead of time if you run into any of these--send me the traceback and I'll fix them up.

full list

misc:

fixed drag and dropping multiple newline separated urls onto the client when those urls come from a generic text source

pages now cache their 'ordered' file id list. this speeds up several little jobs, but most importantly should reduce session save time for sessions with tens of thousands of files

common file resolutions such as 1920x1080 are now replaced in labels with '1080p' strings as already used in the duplicate system. also added 'vertical' variants of 720p, 1080p, and 4k

when a page preview viewer gets a call to clear its current media when it is not currently the page in view, it now recognises that properly. this was happening (a 'sticky' preview) on drag and drops that navigated and terminated on other pages

the various 'retry ignored' commands on downloaders now give an interstitial dialog where you can choose to retry 'all', '404s', or 'blacklisted' files only

manage tag siblings/parents now disables its import button until its data is loaded. imports that were clicked through before loading were being forgotten due to tangled logic, so for now I'll just disable the button!

reduced some more spiky database I/O overhead from the UI's perspective (now savepoints are performed after a result is returned, just like I recently did with transaction commit)

duplicate potentials search will now update the y in its x/y progress display if many files have been imported since the search was started and x becomes larger than y (due to y secretly growing)

fixed the default 'gelbooru md5' file lookup script. if you have a lookup script with this name, it will be updated to my new default automatically. I don't really like fixing this old system, but I am not sure when I will fit in my big rewrite that will merge it with the normal downloader system, so this is a quick fix for the meantime

if you are one of the users who had weird unfixable 404 update file problems with the PTR, please try unpausing and doing a metadata resync one more time this week. fingers crossed, this is fixed. please let me know how you get on too, fixed or not, and also if you have had 'malformed' database problems in the past

.

multi column lists:

improved the precision of longer text pixel_width->text and text->pixel_width calculations, which are particularly used in the multi-column list state saving system. another multi-column size calculation bug, where lists could grow by 1 character's width on >~60 character width columns on every dialog reopen, is now fixed

multi-column lists should now calculate last column width more precisely and accurately regardless of vertical scrollbar presence or recent show/hide

the snapping system that locks last column size to 5-character multiples can now snap up or down, increasing error tolerance

I added a hack to stop the bug some people had of multi-column lists suddenly growing wide, up to screen width, in a resize loop. I think it works, but as I cannot reproduce this error, please let me know how you get on. resizing the options->external programs panel seems to initiate it reliably for those users affected

.

profile mode:

all debug profile modes (callto, db, server, menu, pubsub, and ui) are now merged into one mode under help->debug

this new mode no longer spams popups, and it only prints 'slow' jobs to the profile log

it also makes a new profile log every time it is turned on, using mode start timestamp rather than client boot timestamp, and when profile mode is turned off, there is a popup summary of how many fast and slow jobs passed through during the log time

touched up profile code, timing thresholds, summary statements, and the help

.

special update rule this week:

due to the big file storage rework this week, there's some bit rot in older update routines. 447 cannot update databases older than 411, and it _may_ have trouble updating before 436. if this applies to you, the client will error out or warn you before continuing. I'd like to know what happens to you if you are v411-435 so I can refine these messages

.

boring database refactoring:

the primary current, deleted, pending, and petitioned files tables are now split according to service, much as I have done with mapping tables in the past. this saves a little space and accelerates many file calculations on large clients. if you have a client database script or patch that inspects 'current_files' or 'deleted_files', you'll now be looking at client_files_x etc.., where x is the service_id, and they obviously no longer have a service_id column

a new file storage database module manages these tables, and also some misc file deletion metadata

refactored all raw file storage updates, filters, and searches to the new module

the mappings and new file storage database modules are now responsible for various 'num files/mappings' metadata calculations

most file operations on smaller domains, typically trash or repository update files, will be significantly faster (since the much larger 'my files' table data isn't fattening the relevant indices, and worst case query planning is so much better)

cleaned up a ton of file domain filtering code as a result of all this

physical file deletion is now much faster when the client has many pending file uploads to a file repository or IPFS service

complicated duplicate file operations of many sorts should be a _little_ faster now, particularly on large clients

searching files with 'file import time' sort should be a little faster in many situations

tag repositories no longer bother going down to the database level to to see if they have any thumbnails to sync with

everyone also gets a local file id cache regen this week, it may take a few seconds on update

next week

Next week is a cleanup week. I would like to continue my long term database refactoring job, breaking the code into neater and saner pieces that will also support some neat future maintenance jobs. I also want to bring back the vacuum maintenance command with some new UI.

0 notes

Text

Weekly Recap From the Expedition Lead Scientist, week of December 18, 2017

ISS - Expedition 54 Mission patch. Dec. 29, 2017 (Highlights: Week of December 18, 2017) - Last week aboard the International Space Station, crew members received more than 4,800 pounds of research equipment, cargo and supplies that will support dozens of the more than 250 ongoing investigations aboard the orbiting laboratory from the recent SpaceX Dragon commercial resupply. In addition to unpacking tons of new research materials, the space station also welcomed three new crew members– NASA’s Scott Tingle, Roscosmo’s Anton Shkaplerov and Norishige Kanai of the Japan Aerospace Exploration Agency (JAXA). The crew members explored research in the fields of microbiology, animal biology and cellular biology.

Image above: The SpaceX Dragon delivered more than 2 tons of science and supplies to the International Space Station. Here, it is seen off the coast of Indonesia ahead of docking to the orbiting laboratory. Image Credit: NASA. Arthrospira B, an ESA investigation, is an important step in making improvements in the area of closed regenerative life support systems in space, which will help in making future human exploration missions beyond low-Earth orbit a reality. This week, NASA astronaut Mark Vande Hei retrieved four Arthrospira experiment containers and transferred them to the Columbus module, where they were assembled and installed into the Biolab Incubator. The development of these kinds of regenerative life support systems for spaceflight could also be applied to remote locations on Earth where sustainability of materials is important. The Cell-Science Validation investigation houses an enhanced cell culture platform that provides undisturbed culture maintenance, including feedback temperature control, medical grade gas supply, perfusion nutrient delivery and removal of waste and automated experiment manipulations. This week, Vande Hei removed the Bioculture System from the SpaceX-13 delivery vehicle and installed it into EXPRESS Rack 7. This incubator supports a wide diversity of tissue, cell, and microbiological cultures and experiment methods to meet spaceflight research experiment goals and objectives.

Image above: NASA astronaut Mark Vande Hei prepared the Zebrafish experiment unit for the Zebrafish Muscle 2 investigation. Image Credit: NASA. In microgravity conditions, the postural muscles undergo atrophy because of prominent decrease in their gravity-dependent activity. The Zebrafish Muscle 2, a JAXA investigation, studies muscle atrophy in microgravity. Following the arrival of SpaceX-13, Vande Hei and NASA astronaut Joe Acaba worked to prepare and transport the Zebrafish Experiment Units (EUs) into the Minus Eighty Degree Celsius Laboratory Freezer for ISS (MELFI). The results from the next three days of Zebrafish Muscle 2 operations will help to determine whether atrophy of muscles under microgravity also occurs in zebrafish, and why that muscle atrophy occurs in microgravity. Sarcopenia, or muscle loss or atrophy, is a current problem in the health industry on Earth and in space. The Rodent Research-6 investigation studies the efficacy of both a drug compound and a nano-channel drug delivery implant, for their use in the treatment of muscle loss in future spaceflight, and in the treatment of patients with muscle wasting diseases or conditions on Earth. Vande Hei and Acaba readied the habitats in preparation for the investigation’s arrival on Dragon. Upon arrival, health checks were completed on the rodents.

Image above: Seeds for APEX-05 investigation, planted in petri dishes, are grown within the Veggie plant growth facility. Image Credit: NASA. The Assessing Osteoblast Response to Tetranite™ in Microgravity Conditions to Induce Osteoporosis (Synthetic Bone) investigation grows bone cells in the presence of a commercially available bone adhesive, and a new product called Tetranite™. Determining how well Tetranite™ integrates with bone cell cultures can also inform general strategies for addressing bone loss in space. Last week, Acaba completed the first microscopy of four Synthetic Bone Biocells, two of which were re-inserted into the Space Automated Bioproduct Laboratory (SABL) for continued incubation and growth. Results from this investigation could help to inform strategies for addressing bone loss in space. Other work was done on these investigations: APEX-05, BRIC-LED-001, JAXA Low Temp PCG #2, Payload Card-X, STaARS BioScience-2, Cell-Free Epigenome, Lighting Effects, Marrow, Multi-Omics, Space Headaches, ACE-T-6, DOSIS-3D, MagVector, Area PADLES, BEAM, JEM Internal Ball Camera, Made in Space Fiber Optics and Personal CO2 Monitor. Related links: SpaceX Dragon commercial resupply: https://www.nasa.gov/mission_pages/station/research/news/resupply_critical_science_to_ISS Minus Eighty Degree Celsius Laboratory Freezer for ISS (MELFI): https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Facility.html?#id=56 Rodent Research-6: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7423 Tetranite™ in Microgravity Conditions to Induce Osteoporosis (Synthetic Bone): https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7374 Space Automated Bioproduct Laboratory (SABL): https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Facility.html?#id=1148 APEX-05: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1775 BRIC-LED-001: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7461 JAXA Low Temp PCG #2: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=2031 Lighting Effects: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=2013 Marrow: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1673 Multi-Omics: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1689 Space Headaches: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=174 ACE-T-6: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1707 DOSIS-3D: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=177 MagVector: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1070 Area PADLES: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=877 BEAM: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1579 JEM Internal Ball Camera: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7516 Made in Space Fiber Optics: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=7388 Personal CO2 Monitor: https://www.nasa.gov/mission_pages/station/research/experiments/explorer/Investigation.html?#id=1839 Space Station Research and Technology: https://www.nasa.gov/mission_pages/station/research/index.html International Space Station (ISS): https://www.nasa.gov/mission_pages/station/main/index.html Images (mentioned), Text, Credits: NASA/Michael Johnson/John Love, Lead Increment Scientist Expeditions 53 & 54. Greetings, Orbiter.ch Full article

20 notes

·

View notes

Text

Why SINAMICS G120 is a Game-Changer in Industrial Drive Systems

In this fast-moving world of industrial automation, a fast response is a must and so is flexibility. Be it packaging machines, conveyors, textile machines, or HVAC systems, the user will want a reliable solution that manages motion control accurately. That is where SINAMICS G120 comes in: one of the most versatile variable frequency drives aimed at being amongst the best in performance, safety, and convenience of integration.

Learn more, How SINAMICS G120 Supports Energy-Saving in Industrial Applications

What Makes SINAMICS G120 So Special?

There are so many VFDs around, but the G120 Drive is an intelligent power and adaptability system. With modularity at the heart of design, the Drive G120 allows the control unit and power module to be chosen independently so as to best meet the application requirements. This modularity brings minimal downtime and easier maintenance, rendering it extremely attractive to OEMs and system integrators.

Key Capabilities of the SINAMICS G120:

The very high energy efficiency is gained through regenerative feedback and eco-mode.

Safety Integrated Functions including Safe Torque Off (STO) and Safe Stop (SS1).

Modular design that is flexible and can be notified for configuration as well as upgrading.

Large power range from 0.55 kW to 250 kW.

Interfacing with full integrity with PROFINET, PROFIBUS, and other common field buses.

Whether retrofitting older systems or designing new ones from scratch, the SINAMICS G120 Drive assures that your application becomes more smooth, smarter, and efficient to run.

G120 Drive in Motion

Suppose a bottling plant requires speed and torque control across multiple conveyor belts. With Drive G120, operators optimize performance, limit energy consumption, and observe system health in real-time, meaning throughput is increased, downtime is reduced, and operations are rendered sustainable.

Easy Integration and Maintenance

The web server and diagnostic tools of the SINAMICS G120 allow for real-time observation and quick troubleshooting. Having one spatially on-site or remotely accessing the system would enable issues to be rectified smoothly, assuring operations with minimum intervention from the operator.

Final thoughts

For industrial requirements, if a drive system needs to be reliable, intelligent, and readily functional, the SINAMICS G120 by Naksh Technology Solutions LLP is a future-proof solution that grows as your systems progress. The SINAMICS G120 Drive can deliver energy efficiency, safety compliance, and integration.

Ready, then, to get your automation down with Drive G120? See for yourself how this could expedite your business operations and productivity.

0 notes

Text

Siemens VFD Drives: Energy-Efficient and Precision Control

What are VFD Drives?

VFD Drives are called Variable Frequency Drives (VFDs), and they're the most sophisticated apparatus designed to control both speed and torque of electric motors by varying the frequency and input voltage. They are commonly used, and in their place, come energy performance, motor lifetime enhancements, and better control of motor operations.

How Do VFD Drives Work?

VFDs are fundamentally made of three components, namely:

Rectifier: which actually converts the AC power source into DC.

DC Bus: which serves to filter and store DC energy.

Inverter: which will reconvert the DC back to a variable AC power with the ability to adjust both frequency and voltage.

VFDs in simple terms control the frequency with which an electric motor operates and so help speed control of the motors, thus making them the right choice when it comes to the dynamic requirements of the industry.

Key Features of VFD Drives

Energy Efficiency: It is a power-saving device and, in this case, matches motor speeds with perfect definition to requirements.

More Controlled: The motors can now accelerate and decelerate more smoothly.

Improved Motor Life: Minimizes mechanical stress by reducing wear and tear.

Versatile Applications: It is widely applicable to many motor types, both induction and synchronous.

Popular Siemens VFD Drives

Siemens provides a whole lot of VFD drivers for many industrial implementations. Below are the most important kinds of Siemens' VFD drives:

SINAMICS V20: The SINAMICS V20 is a highly economic, compact, and simple VFD drive for basic motion control applications. The simplicity of use enables small to medium-sized plants to make the best of it. Key features include:

Rapid commissioning with minimal setup.

Energy-saving modes for effective power usage.

Reliable performance in harsh environment

SINAMICS G120: The SINAMICS G120 motor drive is flexible and modular, application-neutral for many industrial requirements. Modular construction enables a wide variety of combinations of power modules with all control units. Further characteristics include:

Integrated safety functions as advanced safety features.

High energy efficiency with regenerative feedback.

Flexible communication interfaces for seamless integration into automation systems.

SINAMICS S120: The high performance of the SINAMICS S120 allows drive operation in applications that require sophisticated motor control. It is suitable for execution tasks that demand accuracy and rapid response in highly dynamic situations such as a robot or high-speed machining. The following features:

Scalability for multi-axis applications.

Superior motor control with high precision and stability.

Advanced diagnostics and monitoring for proactive maintenance.

Siemens has developed these VFD drives in reflection to precise needs, ranging from simple and cost-effective solutions to high end and performance driven applications.

Applications of VFD Drives

The use of variable-frequency drives in different industries is beneficial in improving efficiency and cutting down on operational costs:

1. HVAC systems: Variable frequency drives are used to operate the speed of the placed fans and pumps, providing operational efficiency in heating, ventilation, and air conditioning systems while saving significantly in energy consumption.

2. Industrial Automation: High Speed Rail VFDs facilitate more efficient productivity and low downtime through the ability to provide accurate motor control for speed and direction of conveyors to manufacturing assembly lines.

3. Water Treatment Plant: Variable Frequency Drives improve energy efficiency by affecting pump control adjustment for the instantaneous flow requirements of water.

4. Mining and Oil: The VFDs actuate the heavy-duty equipment such as crushers, mills, and drill rigs in relatively hostile environments.

5. Agriculture: VFD drives pumps in irrigation systems effectively controlling the water flow using pumps, thus reducing energy consumption and costs related to operations.

Benefits of VFD Drives

Cost Saving: Lower energy consumption will reduce electricity bills.

Flexibility: Variability for different motor speed and application.

Reduced Repairs: Decreased mechanical wearing, fewer failures.

Environmentally Friendly: Reduces energy wastage, thus sustainable.

Choosing VFD Drive Wisely

The selection of appropriate VFD is contingent upon several factors, which include the following:

Motor Specifications: This includes power rating, voltage, and type of motor.

Application Requirements: Such as the kind of load and the precision of control

Environmental Conditions: These conditions include operational temperatures, humidity, spatial constraints, etc.

Budget Considerations: Use costs versus upfront costs with long-term savings.

Conclusion

VFD drives by Naksh Technology Solutions a necessity for modern manufacturing operations—give maximum efficiency, control, and reliability to any application. Whether you need energy savings in HVAC systems or sophisticated controlling motions for manufacturing processes, VFDs are the ultimate solution. Siemens has an entire range of VFD models available for projects, so businesses can find an appropriate VFD to suit their operational objectives and budgets.

With these Siemens VFD drives, create the revolution in industrial processes that you have been looking for to make your operations as efficient and sustainable as you require, or even go beyond.

0 notes

Text

The Ultimate Guide to Servo Motion Controllers: Everything You Need to Know

The Kinetix 5700 servo drives offer a wide power range and great power density in a small frame and are suited for machines with high power and numerous axes. They have two Ethernet ports for Device Level Ring and linear topologies, single and dual axis inverters, and cutting-edge snap-fit bus technology. Incorporated safety features on the drives include Safe Torque Off, Safe Stop, and Safe Monitoring. They provide LC filters, onboard diagnostics, common DC bus voltage management, and regenerative bus services. Servos provide high performance and accuracy for driving machinery in either rotational or linear motion. As there is frequently considerable integration between servo systems and PLC-based automation systems and customers, it is crucial to take communications and interoperability elements into account when choosing servo motion controllers and motors.

kinetix 5700 servo drive are made for machines that need a lot of power and have a lot of axes. There are single-axis and dual-axis inverters with hardwired (drive-based) and integrated (drive-based and controller-based) safety features.

Features

Kinetix Servo Drives 5700

offers a wide 1.6...112 kW power range;

delivers outstanding power density in a small frame;

supports a variety of feedback mechanisms for servo and induction motors.

contains modules with two axes

enables quick and easy installation and assembly using state-of-the-art snap-fit bus technology.

promotes the use of a single cable for both feedback and motor power.

It has two Ethernet ports capable of supporting Device Level Ring (DLR) and linear topologies.

CIP Security capabilities support a defense-in-depth cybersecurity strategy.

Kinetix 5700 Integrated Safety Servo Drives

consists of built-in or built-in safety measures

A built-in safety device reduces the overall system wiring.

cutting-edge safety tools like Safe Torque Off, Safe Stop, and Safe Monitoring

KINETIX Offers Regenerative Bus Services

It conducts common DC bus voltage management throughout the entire range of AC input voltages, which helps to lower overall energy consumption.

Onboard diagnostics for power quality monitoring with real-time analytics over EtherNet/IP

A built-in LC filter minimises cabinet space and installation costs.

Setup and Operation Without Tuning

It automatically fine-tunes each axis, accounts for unanticipated physics, and corrects for operational applications with variable inertia using Load Observer real-time tuning technology.

Analytics are provided via virtual torque sensing, which also helps to spot irregularities.

Lower resonance using various adaptive tuning methods notch filters for monitors

The use of electrical servo drives, also known as motion controllers, and related servomotors to move the machinery is most frequently referred to as motion control. Servos can drive machinery in a rotational or linear motion when they are coupled directly or through mechanisms. When compared to less capable systems, they can be more difficult to develop, procure, install, and commission. However, once in use, they are dependable and effective. More importantly, servos offer the high level of performance and accuracy that many applications demands.

It is crucial to consider the communications and interoperability aspects when specifying servo motion controllers and motors since there is frequently a high level of integration between servo systems and PLC-based automation systems and consumers are seeking for more Internet of Things data.

0 notes

Text

Energy Feedback Unit

The energy feedback feeds the regenerative electric energy generated in the process of motor speed regulation to the power grid, avoiding the energy loss caused by the resistance heating of the conventional energy-consuming braking unit, thereby achieving a considerable energy-saving effect, and also realizing wind power and solar energy. Waiting for grid-connected power generation.

Features of Energy Feedback Unit

Energy-efficient,, 97% of renewable energy is fed back to the grid;

More comprehensive inverter module protection;

The heat loss is less than 3%, which greatly improves the working environment;

Safe and reliable, the equipment has full fault protection;

Full-range noise filtering, self-contained reactor, can be directly connected to the grid;

Will not cause interference to the power grid and surrounding electrical equipment;

The inverter is operated in four quadrants, and the power saving rate is 20~50%;

Strong environmental adaptability, -40 ° C (plus temperature control loop), 70 ℃ environment can operate normally; energy feedback is widely used in dynamometers, mine winches, belt conveyors, port lifts, centrifugal equipment, etc.;

https://www.micnodrive.com/products/energy-feedback-unit.html

0 notes