#InjectionMouldingMachine

Explore tagged Tumblr posts

Text

Optimizing Plastic Injection Moulding Precision with Dynemech Screw Support Mounts

In many industries (for example, automotive, medical, consumer goods, and electronic), Plastic Injection Moulding is a vital manufacturing process. Plastic Injection Moulding typically requires high accuracy and consistency in the moulding process. So, the stability and performance of an injection moulding machine will impact the quality of the products you make, the longevity of the machine and production ability.

One area that gets neglected in many assessments, and has relied solely on the machine manufacturer’s recommendation, is the mounting solution for the injection moulding machine. A poorly supported base can transmit vibration, surfaces that are poorly levelled, defective parts and wear on machine components at a rate much higher than with a well-mounted machine. Dynemech Screw Support Mounts can provide a high-performance solution for plastic injection moulding machines that allows for less chucking flexibility with vibration isolation, which is a vital component for manufacturing consistent quality moulded parts.

Challenges Faced in Injection Moulding without Proper Mounting

Machine Vibrations: Fast injection cycles and high-pressured clamping forces create vibrations that can transferthrough the shop floor, affecting nearby machines and plant stability.

Uneven Foundation: Factory floors are rarely level. A misaligned machine will create uneven parting line pressure on the part, resulting in flashing, dimension discrepancies, and increased rejects...

Time Consuming Installation: Anchoring machine foundations in the traditional way and grouting the anchors can take a long time to get the machine commissioned, and also complicate relocation or layout changes...

Diminished Machine Life: Continuous vibration and misalignment of machine results in excessive wear on ball screws, guide ways, and hydraulic systems...

Why Dynemech Screw Support Mounts Are the Ideal Solution

Dynemech Screw Support Mounts are designed for industrial use where stability and alignment is critical in supporting machinery. Included in the mounts are a robust steel body, damping elements and a screw levelling system. The mounts eliminate civil foundation for easy, rapid and precise machine installation of injection moulding machines, without compromising vertical alignment. The mounts isolate the machine from floor vibrations, and an unconstrained but rigid base protects critical parts from the extreme life of the injection moulding process, having minimal disturbance.

Key Features and Benefits

1. High Load-Bearing Capacity:

Dynemech Screw Support Mounts are designed to support the static and dynamic loads of heavy-duty plastic injection moulding machines including toggle and hydraulic machines.

2. Precision Levelling:

The mounts have fine-pitched threaded screws which allow operators to accurately level machines, even uneven factory floors - maintaining perfect parallelism of the two halves of the mould.

3. Excellent Vibration Isolation:

The elastomeric anti-vibration pad in the base absorbs shocks, machine related vibrations and structure-borne noise, resulting in more comfort for operators and greater stability of nearby machinery.

4. No Grouting Needed:

No foundation bolts (anchoring) needed. Machines can be installed, levelled, and commissioned quickly, reducing setup time. And machines can be repositioned easily when a layout change is required.

5. Better Product Quality:

A level and stable foundation prevents moulded parts from showing better repeatability, even consistent dimensions and better surface finish. This reduces scrap and rework while increasing productivity.

6. Increased Machine Life:

Reduced vibration and less structural stress on a machine's internal components will help lengthen the life of the machine while lowering maintenance costs as time goes on.

7. Easy Retrofitting and Mobility:

Machines that are already in place can easily be retrofitted with Dynemech Screw Support Mounts with little to no downtime. Machines that are mounted on Dynemech supports can easily be moved and relevelled.

Applications Across Moulding Operations

Dynemech Screw Support Mounts are effective for applications such as:

Horizontal and Vertical Plastic Injection Moulding Machines

All electric and hydraulic injection moulders

Multi-cavity moulding machines

Machines that manufacture precision parts for the automotive, medical or electronic industry

High-speed, thin-wall mounding and high-pressure, thick part mounding

No matter if you are running a high-volume production or low-volume, precision moulding, the foundation of your operation, keeping your machines vibration-free and accurately levelled, is paramount to your success.

Choose Dynemech for Reliable, Long-Term Mounting Solutions

Dynemech Systems has been a trusted partner in anti-vibration and machinery mounting solutions for over two decades. Our Screw Support Mounts are engineered with deep technical insight into the demands of modern manufacturing. Backed by a nationwide support team and robust product testing, Dynemech offers both standard and custom mount configurations to suit your specific machine requirements.

To learn more:

🔗 https://www.vibrationmountsindia.com/products/

#PlasticInjectionMoulding #InjectionMouldingMachine #MouldingPrecision #DynemechMounts #ScrewSupportMounts #AntiVibrationSolutions #MachineStability #VibrationControl #IndustrialMachinery #ManufacturingSolutions #MachineryMounts #InjectionMouldingIndia #EngineeringExcellence #LevellingMounts #SmartManufacturing #Dynemech

📞 Contact Us: +91-9810760131 📧 Email: [email protected] 🌐 Explore Our Solutions: vibrationmountsindia.com

#dynemech#PlasticInjectionMoulding#InjectionMouldingMachine#MouldingPrecision#DynemechMounts#ScrewSupportMounts#AntiVibrationSolutions#MachineStability#VibrationControl#IndustrialMachinery#ManufacturingSolutions#MachineryMounts#InjectionMouldingIndia#EngineeringExcellence#LevellingMounts#SmartManufacturing

0 notes

Text

Top Plastics Injection Moulding Machines Manufacturer in India | Shibaura Machine

Looking for high-quality plastics injection moulding machines in India? Shibaura Machine is a leading manufacturer, delivering precision-engineered solutions for diverse industries. With advanced technology and reliability, our machines ensure efficiency and superior production. Explore our range today!

1 note

·

View note

Text

Our workshop!

#injectionmouldingmachine #injectionmold

#injectionmachine #plasticmachine

#injectionmold#injectionmolding#injection#plasticmold#plasticmachine#plasticmolding#injection mold#Plast machine

0 notes

Text

The Super Plus Plastic Injection Moulding Machine is one of our premium products known for its high speed and accuracy. Designed using the finest raw materials, this machine is both robust and has a long life.

link:https://www.injectionmouldingmachine.co.in/super-plus.html

#Injectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinery#Injectionmouldingmachinerymanufacturer

2 notes

·

View notes

Photo

Milacron Q Series 2k is the best home appliances manufacturer machine. Our Q Series 2k injection moulding machine is specially designed for making home appliances and two-component products.

1 note

·

View note

Video

instagram

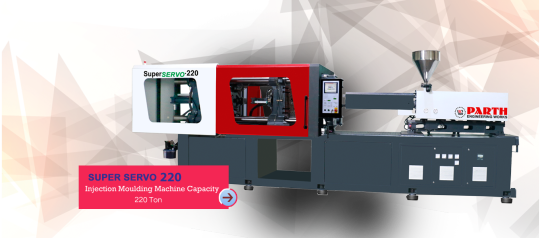

On early morning customers from North Africa came to visit our factory. He is interested in 220 ton injection molding machines and decide to take our injection machines. He think our machines are better than others. #plasticinjectionmoldingmachine #plasticinjectionmoldingmachines #plasticmoldinjectionmachines #plasticinjectionmolding #mold #injectionmold #injectionmolding #injectionmoulding #injectionmoldingmachine #injectionmouldingmachine #plasticinjectionmolding #injectionmalaysia #machinedemoulageparinjection #plastikenjeksiyon #plastikpacking #plastikenjeksiyonmakinası https://www.instagram.com/p/BrMdoefD1uV/?utm_source=ig_tumblr_share&igshid=1154g5un4d0nt

#plasticinjectionmoldingmachine#plasticinjectionmoldingmachines#plasticmoldinjectionmachines#plasticinjectionmolding#mold#injectionmold#injectionmolding#injectionmoulding#injectionmoldingmachine#injectionmouldingmachine#injectionmalaysia#machinedemoulageparinjection#plastikenjeksiyon#plastikpacking#plastikenjeksiyonmakinası

1 note

·

View note

Text

Technology | Surelock Plastics| Technical Machineries

#PickandPlaceRobots#MoistureConditioningSystem#RawMaterialCentralConveyingSystem#AutoDozingEquipment#AutomatedPowderCoatingMachine#InjectionMouldingMachine#CNCMachine

0 notes

Text

Dynemech Anti-Vibration Technology Screw Support DLC Series Mounts

Designed especially to Reduce Vibration and Improve Machine Stability, Dynemech Anti-Vibration Technology DLC series mounts You only need to fix the Mount under the Machine using the given screw. Not essential to bolt the machine to the floor.

Dynemech Anti-Vibration Technology DLC Series It absorbs Low-Frequency Vibrations, so allowing your Machine to run more precisely. Easy levelling made possible by DLC Series Mounts defines both long-term performance and machine accuracy. DLC Mounts help minimize damage caused by continuous vibration regardless of the type of machine—plastic injection molding, die casting, or printing unit. They extend machine life, consistent output, and reduced maintenance needs.

Control of Vibration Using Dynemech Anti-Vibration Technology

One reliable brand among Vibration Control Solutions is Dynemech Anti-Vibration Technology. Our main goal is to let companies maximize machine performance by means of Vibration Reduction, Stability, and simplicity of use.

Dynemech’s Anti-Vibration products come in a variety of forms; among our most sold lines is the DLC Series. Since we know the several needs of different machines, we offer consistent, reasonable, tested in-real-world solutions.

Dynemech Anti-Vibration Technology indicates that you are selecting a company with Controlling Vibration as main emphasis. We want to level your operations and increase machine health.

Basic and robust screw supports for mountings

The Dynemech Anti-Vibration Technology Essential DLC Series consists in Screw Support Mounts. Installable these Mounts allow great simplicity. You basically run them under the machine. They absorb shocks and vibrations running and maintain a level and steady machine.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #ScrewSupportMounts, #VibrationControl, #AntiVibration, #MachineMounts, #IndustrialEquipment, #ToolRoomMachines, #InjectionMouldingMachines, #DieCastingMachines, #VibrationIsolation, #MachineryStability, #EngineeringSolutions, #Manufacturing, #VibrationDampers, #DynemechVibrationTechnology, #VibrationMounts, #MachineTools, #IndustrialMachinery

Contact Us: +91-9810760131 Email: [email protected] Explore Our Solutions: vibrationmountsindia.com

#Dynemech#ScrewSupportMounts#VibrationControl#AntiVibration#MachineMounts#IndustrialEquipment#ToolRoomMachines#InjectionMouldingMachines#DieCastingMachines#VibrationIsolation#MachineryStability#EngineeringSolutions#Manufacturing#VibrationDampers#DynemechVibrationTechnology#VibrationMounts#MachineTools#IndustrialMachinery

0 notes

Text

Injection Transfer Moulding Machine:FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

http://www.shaktiind.net/ Shakti Industries - Manufacturer and Exporter of Injection Transfer Moulding Machine,FEP Lined Valve Machine,PFA impeller Machine,PVDF Lined Pump Machine,PFA Lined Pump Machine,Transfer Molding Machine,FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

#injectionmouldingmachine#manufacturer#exporter#supplier#ahmedabad#PFAimpellermachine#FEPLinedValveMouldingMachineAhmedabad#PFALinedPumpMachine#TransferMoldingMachineAhmedabad

0 notes

Text

The Super Servo machine is powered by the robust Servo motor and powerful VDP pump. This Hydraulic Injection Moulding Machine comes with 5 stage opening and closing control for better safety.

link:https://www.injectionmouldingmachine.co.in/super-servo.html

#HydraulicInjectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinerymanufacturer#PlasticInjectionmouldingmachineManufacturers

0 notes

Photo

Omega Servo is the best plastic food container making machine of Milacrone India. This injection moulding machine comes with a unique prefill cylinder design and a twin-cylinder injection unit. The Robust Performer OMEGA series of machines have a proven track record in the industry. They serve a wide variety of applications across industries.

0 notes

Text

Comparison of advantages and disadvantages of injection molding and 3D printing

Injection molding is a traditional industrial manufacturing technology. By injecting molten material into the mold, this manufacturing technique can quickly shape your product, and then the material will cool down and reach the final solid shape.3D printing is a process. You can use a 3D printer to produce parts without creating a mold. You only need a 3D printing model file, and there are many different 3D printing technologies and materials available on the market.What are the advantages of injection molding?Injection molding has great advantages, it can be produced in large quantities, and has high precision and perfect repeatability. When using plastic injection molding, you can choose from a variety of materials. There can be thousands of changes for each material through additives, each of which leads to different characteristics. Material weight, cost, flexibility, just for plasticity and possibilities, seem to be endless.What are the advantages of 3D printing?The use of 3D printing has many advantages, making it a true complement to traditional manufacturing techniques. First of all, 3D printing is very suitable for product iteration. For a long time, 3D printing has been considered a rapid prototyping technology. This is no longer the case, because it has also become a reliable manufacturing technology. However, quick and easy prototyping is still one of the best advantages provided by this manufacturing technology. When using 3D printing, you can print the project for testing, use the 3D printing modeling software to make all the modifications, and then print again to confirm the changes. The flexibility of this process will help you save time and money, but it can also help you improve your product design.

more: http://lisongmachine.com/news/industry-news/comparison-of-advantages-and-disadvantages-of-injection-molding-and-3d-printing.html

0 notes

Photo

fuhrungplasticinjectionmachine Yüksekkalitede plastik enjeksiyon makinelerikaliplama makinesi satin almak istiyorsanlz, www.fuhrung.com adresiniAvrupa tarzl plastik enjeksiyon en üst seviyededir. Tabii ki, fiyatlar yüksektalep ediliyor. Plastik kalip enjeksiyonmakinelerinde herhangi bir profesyonel, için en iyi seçenek. Kaliteli bir enjeksiyon ziyaret etmeli ve [email protected] veyawhatsapp ile iletisime geçmelisiniz: Butedarikçi yalnizca yüksek performanslt makinelerine odaklanmaktadir. Çin'de kaliteama cazip. Simdi dünya çapinda ajanlarlütfen yukaridaki bilgilerle temasa geçiniz. #love #photooftheday #injectionmachine #chinaplas #injectionmolding #plastics #injectionmoulding #plastic #plasticfactory #injectionmold#leadwayimm #fuhrung #tradefair#injectionmouldingmachine #leadway#fuhrungimm #plasticindustry #injectionmoldingmachine #plasticinjectionmachine https://www.instagram.com/p/B96SoziA-D7/?igshid=1nmo0ips0f2jz

#love#photooftheday#injectionmachine#chinaplas#injectionmolding#plastics#injectionmoulding#plastic#plasticfactory#injectionmold#leadwayimm#fuhrung#tradefair#injectionmouldingmachine#leadway#fuhrungimm#plasticindustry#injectionmoldingmachine#plasticinjectionmachine

0 notes