#InjectionMouldingMachines

Explore tagged Tumblr posts

Text

Dynemech Anti-Vibration Technology Screw Support DLC Series Mounts

Designed especially to Reduce Vibration and Improve Machine Stability, Dynemech Anti-Vibration Technology DLC series mounts You only need to fix the Mount under the Machine using the given screw. Not essential to bolt the machine to the floor.

Dynemech Anti-Vibration Technology DLC Series It absorbs Low-Frequency Vibrations, so allowing your Machine to run more precisely. Easy levelling made possible by DLC Series Mounts defines both long-term performance and machine accuracy. DLC Mounts help minimize damage caused by continuous vibration regardless of the type of machine—plastic injection molding, die casting, or printing unit. They extend machine life, consistent output, and reduced maintenance needs.

Control of Vibration Using Dynemech Anti-Vibration Technology

One reliable brand among Vibration Control Solutions is Dynemech Anti-Vibration Technology. Our main goal is to let companies maximize machine performance by means of Vibration Reduction, Stability, and simplicity of use.

Dynemech’s Anti-Vibration products come in a variety of forms; among our most sold lines is the DLC Series. Since we know the several needs of different machines, we offer consistent, reasonable, tested in-real-world solutions.

Dynemech Anti-Vibration Technology indicates that you are selecting a company with Controlling Vibration as main emphasis. We want to level your operations and increase machine health.

Basic and robust screw supports for mountings

The Dynemech Anti-Vibration Technology Essential DLC Series consists in Screw Support Mounts. Installable these Mounts allow great simplicity. You basically run them under the machine. They absorb shocks and vibrations running and maintain a level and steady machine.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#Dynemech, #ScrewSupportMounts, #VibrationControl, #AntiVibration, #MachineMounts, #IndustrialEquipment, #ToolRoomMachines, #InjectionMouldingMachines, #DieCastingMachines, #VibrationIsolation, #MachineryStability, #EngineeringSolutions, #Manufacturing, #VibrationDampers, #DynemechVibrationTechnology, #VibrationMounts, #MachineTools, #IndustrialMachinery

Contact Us: +91-9810760131 Email: [email protected] Explore Our Solutions: vibrationmountsindia.com

#Dynemech#ScrewSupportMounts#VibrationControl#AntiVibration#MachineMounts#IndustrialEquipment#ToolRoomMachines#InjectionMouldingMachines#DieCastingMachines#VibrationIsolation#MachineryStability#EngineeringSolutions#Manufacturing#VibrationDampers#DynemechVibrationTechnology#VibrationMounts#MachineTools#IndustrialMachinery

0 notes

Text

Top Plastics Injection Moulding Machines Manufacturer in India | Shibaura Machine

Looking for high-quality plastics injection moulding machines in India? Shibaura Machine is a leading manufacturer, delivering precision-engineered solutions for diverse industries. With advanced technology and reliability, our machines ensure efficiency and superior production. Explore our range today!

1 note

·

View note

Text

Our workshop!

#injectionmouldingmachine #injectionmold

#injectionmachine #plasticmachine

#injectionmold#injectionmolding#injection#plasticmold#plasticmachine#plasticmolding#injection mold#Plast machine

0 notes

Text

The Super Plus Plastic Injection Moulding Machine is one of our premium products known for its high speed and accuracy. Designed using the finest raw materials, this machine is both robust and has a long life.

link:https://www.injectionmouldingmachine.co.in/super-plus.html

#Injectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinery#Injectionmouldingmachinerymanufacturer

2 notes

·

View notes

Photo

Our company Ningbo Leadway Machinery Technology Co.,ltd is professional injection molding machines manufacturer. We were involved in ITALY OEM machines project since 2006. So we are professional in design and make European style injection machines. And we are the first supplier (maybe the only one) involved in making Eurostyle injection machines. Our quality is the most close to European machines quality. Our quality is leading in China. We can compete with Haitian in quality. Our machines are strong clamping, fast injection, energy saving, high precision, user-friendly which is mainly for mid-high end use. Now we have deleoped Italy, Spain, Czech, Poland, Tunis, Iran, India, Philipine, Malaysia, Russia, Mexico, Brazil, Argentina, Peru, etc. @fuhrungplasticinjectionmachine www.fuhrung.com [email protected] whatsapp:008618969867076 injection,injection molding,machine,plastic injection machine,injection molding machine,injection machine,plastic injection molding machine,plastic,eva injection moulding machine,injection moulding,pet preform injection molding machine,machines,injection machines,pu injection machine,pvc injection machine,lsr injection machine,mold injection machine,sound injection machine,top 50 injection machine,badge injection machine #injectionmoldingmachine #plasticinjectionmachine #injectionmachines #injectionmoldingmachines #injectionmouldingmachine #plasticinjectionmoldingmachine #injectionmouldingmachines #injectionmachinesize #specialistusedinjectionmachine #injectionmachinescrewdesign #injectionmachineforsale #injectionmachinesecondhand #injectionmachinetechnician #injectionmachinesetting #injectionmachineryturkey #verticalinjectionmouldingmachine #injectionmachinetraining #injectionmachinesumitomo #injectionmachinenozzle #injectionmachinebrands #injectionmachinetiebar #injectionmachinetoggle #injectionmachinecost #injectionmachinecalculation #injectionmachineinpoland #injectionmachineendcapangle (at China) https://www.instagram.com/p/BzPKMx0gPPK/?igshid=8to0gxba1p45

#injectionmoldingmachine#plasticinjectionmachine#injectionmachines#injectionmoldingmachines#injectionmouldingmachine#plasticinjectionmoldingmachine#injectionmouldingmachines#injectionmachinesize#specialistusedinjectionmachine#injectionmachinescrewdesign#injectionmachineforsale#injectionmachinesecondhand#injectionmachinetechnician#injectionmachinesetting#injectionmachineryturkey#verticalinjectionmouldingmachine#injectionmachinetraining#injectionmachinesumitomo#injectionmachinenozzle#injectionmachinebrands#injectionmachinetiebar#injectionmachinetoggle#injectionmachinecost#injectionmachinecalculation#injectionmachineinpoland#injectionmachineendcapangle

0 notes

Photo

Milacron Q Series 2k is the best home appliances manufacturer machine. Our Q Series 2k injection moulding machine is specially designed for making home appliances and two-component products.

1 note

·

View note

Text

Technology | Surelock Plastics| Technical Machineries

#PickandPlaceRobots#MoistureConditioningSystem#RawMaterialCentralConveyingSystem#AutoDozingEquipment#AutomatedPowderCoatingMachine#InjectionMouldingMachine#CNCMachine

0 notes

Text

Dynemech Anti-Vibration Technology: Enhance, Precision, and Capability

Machines for Vertical Plastic Injection Moulding Machine on Dynemech Spring Viscous Dampers

Never before have precision and reliability been so crucial in high-speed manufacturing global of today. Machines for vertical plastic injection moulding.

Dynemech Spring Viscous Dampers come into play here. These dampers provide a higher degree of performance, durability, and accuracy in Vertical Plastic Injection Moulding operations since they are specifically made to handle vibration and operating stability difficulties. Your moulding equipment's base becomes secure with Dynemech Spring Viscous Dampers, which lowers disruptions and boosts production and productivity.

Why Are Injection Moulding Machines the Best Fit for Dynemech Spring Viscous Dampers?

1. A Device with Double Damping for Better Vibration Isolation

The innovative double-damping mechanism of Dynemech Spring Viscous Dampers uses helical steel springs and a high-viscosity viscous liquid. The capacity to isolate the machine from floor and machine-borne vibrations and strike a broad vibration frequency range is unmatched by such an advanced system.

Even with big weights or high-speed cycles, the moulding machine's stability and repetitiveness are enhanced by vibration damping. When producing moulding components consistently, stability becomes crucial, particularly in applications requiring great accuracy.

2. Increased Equipment Durability Due to Less Wear and Tear

Your machine's lifespan may be shortened by dynamic forces and vibrations that cause unusually high equipment wear and tear. This issue is resolved with Dynemech Spring Viscous Dampers, which efficiently absorb and dissipate vibrations, lessening the effect of dynamic forces on the parts of the moulding machine.

Outcome?

A notable decrease in the mechanical strain on your machinery, which translates into more seamless operation, fewer malfunctions, and an extended lifespan. Your investment in machinery is safeguarded, which will eventually yield higher profits.

3. Improved Product Quality and Production Consistency

In plastic Injection Moulding, even a small misalignment can result in flaws like flash, scrap components, or dimensional problems. When it comes to high-speed or high-pressure moulding processes, this is particularly crucial. Dynemech's dampers prevent micro-shift or deflection of machine parts by maintaining the moulding machine's alignment, stability, and horizontal operation.

Your manufacturing runs are more reliable as a result, and the quality of the parts is the same throughout the entire batch. Your production and profitability increase because there is less unpredictability, which results in fewer defective components and a higher overall yield.

4. Dependable Performance in Changing Operating Environments

With fluctuating forces in the ejection cycle, clamp action, and injection stroke, Injection Moulding machines function in dynamic environments.

Dynemech Spring Viscous Dampers are made to withstand varying forces without compromising their functionality. Even in high-stress situations or during heavy-duty activities, their robust design can readily provide steady damping.

Tighter tolerances and shorter cycle times are possible with Dynemech Pvt. Ltd. dampers because the machines stay steady and aligned as they move through the many stages of operation. Maintaining this level of consistency is essential for reducing downtime and raising overall machine efficiency.

5. Low Maintenance and Simple Installation

Dynemech Spring Viscous Dampers are incredibly simple to install and maintain, even with their sophisticated technology. With little interruption to production, the dampers may be effortlessly incorporated into your current plastic injection moulding setup.

Furthermore, you can concentrate on production rather than worrying about routine maintenance or part replacement thanks to their low-maintenance design. For both small businesses and huge manufacturing facilities where downtime must be prevented, it is a simple solution.

Conclusion: Use Dynemech Spring Viscous Dampers to Improve Your Moulding Operations

Whether you are in charge of a large manufacturing plant or a single Vertical Injection Moulding Machine, including Dynemech Spring Viscous Dampers will guarantee that your business stays at the forefront of performance, accuracy, and productivity. With smoother machine cycles, better part quality, and longer machine life, these dampers offer a complete solution to vibration-related problems.

Manufacturers may extend the life of their machines, optimize their processes, maintain strict tolerances, and shorten cycle times by incorporating Dynemech Pvt. Ltd. dampers. If the foundation is solid, every shot matters, and when you work with Dynemech Pvt. Ltd., your Injection Molding Machines are prepared to always give their best effort.

To learn more about our products: https://www.vibrationmountsindia.com/products/

#InjectionMoulding, #PlasticMoulding, #ManufacturingExcellence, #DynemechDampers, #VibrationIsolation, #PrecisionEngineering, #MachineStability, #IndustrialMachinery, #ProductivityBoost, #QualityControl, #PlasticParts, #MouldingMachines, #PerformanceEnhancement, #ManufacturingInnovation, #InjectionMouldingMachines, #EfficiencyInManufacturing, #Dynemech, #DampingTechnology, #HighPrecisionManufacturing, #MachineHealth, #VibrationDampers

Contact Us: +91-9810760131; +91-9911145131

Email: [email protected]

Explore Our Solutions: vibrationmountsindia.com

#InjectionMoulding#PlasticMoulding#ManufacturingExcellence#DynemechDampers#VibrationIsolation#PrecisionEngineering#MachineStability#IndustrialMachinery#ProductivityBoost#QualityControl#PlasticParts#MouldingMachines#PerformanceEnhancement#ManufacturingInnovation#InjectionMouldingMachines#EfficiencyInManufacturing#Dynemech#DampingTechnology#HighPrecisionManufacturing#MachineHealth#VibrationDampers

0 notes

Text

Injection Transfer Moulding Machine:FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

http://www.shaktiind.net/ Shakti Industries - Manufacturer and Exporter of Injection Transfer Moulding Machine,FEP Lined Valve Machine,PFA impeller Machine,PVDF Lined Pump Machine,PFA Lined Pump Machine,Transfer Molding Machine,FEP Lined Valve Machine,Transfer Molding Machine Ahmedabad

#injectionmouldingmachine#manufacturer#exporter#supplier#ahmedabad#PFAimpellermachine#FEPLinedValveMouldingMachineAhmedabad#PFALinedPumpMachine#TransferMoldingMachineAhmedabad

0 notes

Text

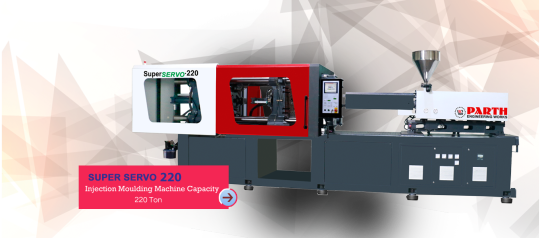

The Super Servo machine is powered by the robust Servo motor and powerful VDP pump. This Hydraulic Injection Moulding Machine comes with 5 stage opening and closing control for better safety.

link:https://www.injectionmouldingmachine.co.in/super-servo.html

#HydraulicInjectionmouldingmachine#Injectionmouldingmachines#Injectionmouldingmachinerymanufacturer#PlasticInjectionmouldingmachineManufacturers

0 notes

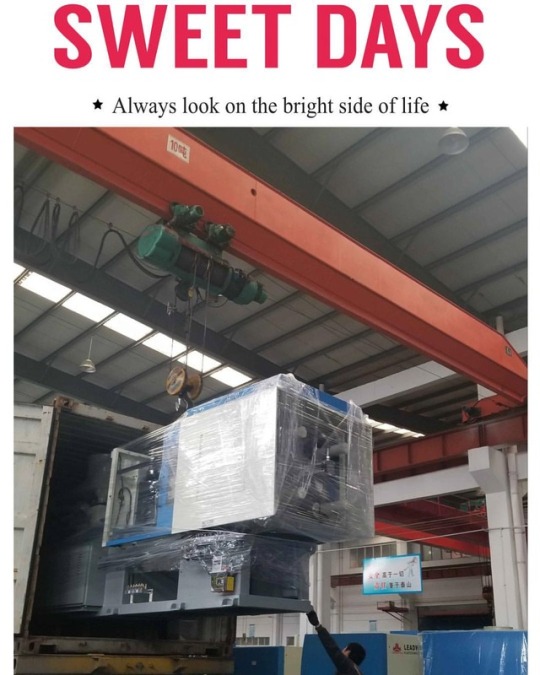

Photo

This 180 ton plastic injection molding machines are being loaded into container. This injection machines will go for Philippines Manila. Meanwhile. There is another container loading 220 ton injection machines for Tunis. #philippines #tunis #manila #manilaphilippines #envasesplasticos #plasticinjectionmolding #plasticinjection #plasticinjectionmold #plasticinjectionmolds #injectionmolding #injectionmoulding #injectionmoldingmachine #injectionmold #injectionmouldingmachine #injectionmould #injectionmoulds #injectionmouldingmachines #injectionmoulders #plasticindustry #arabplast2019 #chinaplas2019 #plasticware #plasticitems #plasticinjectionmoldingmachine #monday (在 Manila, Philippines) https://www.instagram.com/p/BsVAc3ijMvq/?utm_source=ig_tumblr_share&igshid=1n2xxaj8wa530

#philippines#tunis#manila#manilaphilippines#envasesplasticos#plasticinjectionmolding#plasticinjection#plasticinjectionmold#plasticinjectionmolds#injectionmolding#injectionmoulding#injectionmoldingmachine#injectionmold#injectionmouldingmachine#injectionmould#injectionmoulds#injectionmouldingmachines#injectionmoulders#plasticindustry#arabplast2019#chinaplas2019#plasticware#plasticitems#plasticinjectionmoldingmachine#monday

0 notes

Photo

Omega Servo is the best plastic food container making machine of Milacrone India. This injection moulding machine comes with a unique prefill cylinder design and a twin-cylinder injection unit. The Robust Performer OMEGA series of machines have a proven track record in the industry. They serve a wide variety of applications across industries.

0 notes

Text

Comparison of advantages and disadvantages of injection molding and 3D printing

Injection molding is a traditional industrial manufacturing technology. By injecting molten material into the mold, this manufacturing technique can quickly shape your product, and then the material will cool down and reach the final solid shape.3D printing is a process. You can use a 3D printer to produce parts without creating a mold. You only need a 3D printing model file, and there are many different 3D printing technologies and materials available on the market.What are the advantages of injection molding?Injection molding has great advantages, it can be produced in large quantities, and has high precision and perfect repeatability. When using plastic injection molding, you can choose from a variety of materials. There can be thousands of changes for each material through additives, each of which leads to different characteristics. Material weight, cost, flexibility, just for plasticity and possibilities, seem to be endless.What are the advantages of 3D printing?The use of 3D printing has many advantages, making it a true complement to traditional manufacturing techniques. First of all, 3D printing is very suitable for product iteration. For a long time, 3D printing has been considered a rapid prototyping technology. This is no longer the case, because it has also become a reliable manufacturing technology. However, quick and easy prototyping is still one of the best advantages provided by this manufacturing technology. When using 3D printing, you can print the project for testing, use the 3D printing modeling software to make all the modifications, and then print again to confirm the changes. The flexibility of this process will help you save time and money, but it can also help you improve your product design.

more: http://lisongmachine.com/news/industry-news/comparison-of-advantages-and-disadvantages-of-injection-molding-and-3d-printing.html

0 notes