#Load process monitor device driver

Explore tagged Tumblr posts

Text

Load process monitor device driver, system monitoring tools

ZXCT1109 Series Low Power Monitors Surface Mount Current Monitor - SOT-23

0 notes

Text

DXVK Tips and Troubleshooting: Launching The Sims 3 with DXVK

A big thank you to @heldhram for additional information from his recent DXVK/Reshade tutorial! ◀ Depending on how you launch the game to play may affect how DXVK is working.

During my usage and testing of DXVK, I noticed substantial varying of committed and working memory usage and fps rates while monitoring my game with Resource Monitor, especially when launching the game with CCMagic or S3MO compared to launching from TS3W.exe/TS3.exe.

It seems DXVK doesn't work properly - or even at all - when the game is launched with CCM/S3MO instead of TS3W.exe/TS3.exe. I don't know if this is also the case using other launchers from EA/Steam/LD and misc launchers, but it might explain why some players using DXVK don't see any improvement using it.

DXVK injects itself into the game exe, so perhaps using launchers bypasses the injection. From extensive testing, I'm inclined to think this is the case.

Someone recently asked me how do we know DXVK is really working. A very good question! lol. I thought as long as the cache showed up in the bin folder it was working, but that was no guarantee it was injected every single time at startup. Until I saw Heldhram's excellent guide to using DXVK with Reshade DX9, I relied on my gaming instincts and dodgy eyesight to determine if it was. 🤭

Using the environment variable Heldhram referred to in his guide, a DXVK Hud is added to the upper left hand corner of your game screen to show it's injected and working, showing the DXVK version, the graphics card version and driver and fps.

This led me to look further into this and was happy to see that you could add an additional line to the DXVK config file to show this and other relevant information on the HUD such as DXVK version, fps, memory usage, gpu driver and more. So if you want to make sure that DXVK is actually injected, on the config file, add the info starting with:

dxvk.hud =

After '=', add what you want to see. So 'version' (without quotes) shows the DXVK version. dxvk.hud = version

You could just add the fps by adding 'fps' instead of 'version' if you want.

The DXVK Github page lists all the information you could add to the HUD. It accepts a comma-separated list for multiple options:

devinfo: Displays the name of the GPU and the driver version.

fps: Shows the current frame rate.

frametimes: Shows a frame time graph.

submissions: Shows the number of command buffers submitted per frame.

drawcalls: Shows the number of draw calls and render passes per frame.

pipelines: Shows the total number of graphics and compute pipelines.

descriptors: Shows the number of descriptor pools and descriptor sets.

memory: Shows the amount of device memory allocated and used.

allocations: Shows detailed memory chunk suballocation info.

gpuload: Shows estimated GPU load. May be inaccurate.

version: Shows DXVK version.

api: Shows the D3D feature level used by the application.

cs: Shows worker thread statistics.

compiler: Shows shader compiler activity

samplers: Shows the current number of sampler pairs used [D3D9 Only]

ffshaders: Shows the current number of shaders generated from fixed function state [D3D9 Only]

swvp: Shows whether or not the device is running in software vertex processing mode [D3D9 Only]

scale=x: Scales the HUD by a factor of x (e.g. 1.5)

opacity=y: Adjusts the HUD opacity by a factor of y (e.g. 0.5, 1.0 being fully opaque).

Additionally, DXVK_HUD=1 has the same effect as DXVK_HUD=devinfo,fps, and DXVK_HUD=full enables all available HUD elements.

desiree-uk notes: The site is for the latest version of DXVK, so it shows the line typed as 'DXVK_HUD=devinfo,fps' with underscore and no spaces, but this didn't work for me. If it also doesn't work for you, try it in lowercase like this: dxvk.hud = version Make sure there is a space before and after the '=' If adding multiple HUD options, seperate them by a comma such as: dxvk.hud = fps,memory,api,version

The page also shows some other useful information regarding DXVK and it's cache file, it's worth a read. (https://github.com/doitsujin/dxvk)

My config file previously showed the DXVK version but I changed it to only show fps. Whatever it shows, it's telling you DXVK is working! DXVK version:

DXVK FPS:

The HUD is quite noticeable, but it's not too obstructive if you keep the info small. It's only when you enable the full HUD using this line: dxvk.hud = full you'll see it takes up practically half the screen! 😄 Whatever is shown, you can still interact with the screen and sims queue.

So while testing this out I noticed that the HUD wasn't showing up on the screen when launching the game via CCM and S3MO but would always show when clicking TS3W.exe. The results were consistent, with DXVK showing that it was running via TS3W.exe, the commited memory was low and steady, the fps didn't drop and there was no lag or stuttereing. I could spend longer in CAS and in game altogether, longer in my older larger save games and the RAM didn't spike as much when saving the game. Launching via CCM/S3MO, the results were sporadic, very high RAM spikes, stuttering and fps rates jumping up and down. There wasn't much difference from DXVK not being installed at all in my opinion.

You can test this out yourself, first with whatever launcher you use to start your game and then without it, clicking TS3.exe or TS3W.exe, making sure the game is running as admin. See if the HUD shows up or not and keep an eye on the memory usage with Resource Monitor running and you'll see the difference. You can delete the line from the config if you really can't stand the sight of it, but you can be sure DXVK is working when you launch the game straight from it's exe and you see smooth, steady memory usage as you play. Give it a try and add in the comments if it works for you or not and which launcher you use! 😊 Other DXVK information:

Make TS3 Run Smoother with DXVK ◀ - by @criisolate How to Use DXVK with Sims 3 ◀ - guide from @nornities and @desiree-uk

How to run The Sims 3 with DXVK & Reshade (Direct3D 9.0c) ◀ - by @heldhram

DXVK - Github ◀

109 notes

·

View notes

Text

Elevate Your E-commerce Game: Comprehensive Shopify CRO Services Guide

In the competitive world of e-commerce, standing out from the crowd and converting visitors into loyal customers is essential for success. Shopify, a leading e-commerce platform, offers robust tools to help store owners achieve this goal. However, understanding and leveraging these tools effectively requires a strategic approach to Conversion Rate Optimization (CRO). This guide will explore comprehensive Shopify CRO services that can elevate your e-commerce game and drive growth in 2024.

The Importance of Conversion Rate Optimization

Conversion Rate Optimization (CRO) is the practice of increasing the percentage of website visitors who complete a desired action, such as making a purchase or subscribing to a newsletter. For e-commerce businesses, optimizing conversion rates is crucial because it directly impacts revenue without the need to increase traffic. By focusing on improving the user experience and addressing potential barriers to conversion, businesses can significantly enhance their profitability.

Essential Shopify CRO Services for 2024

Personalized Customer Experiences : In 2024, personalization remains a key driver of conversions. Utilizing customer data to deliver tailored experiences, from personalized product recommendations to customized email campaigns, can make a significant difference. Shopify's advanced tools and integrations enable store owners to create unique shopping experiences that resonate with individual customers.

Mobile-First Optimization : With the majority of online shopping now happening on mobile devices, optimizing for mobile is no longer optional. Ensuring your Shopify store has a responsive design, fast loading times, and intuitive navigation is critical. Use tools like Google’s Mobile-Friendly Test to evaluate and enhance your store’s mobile performance.

Comprehensive A/B Testing : A/B testing, or split testing, involves comparing two versions of a webpage to identify which one performs better. This technique helps fine-tune elements such as headlines, images, and call-to-action buttons. Shopify integrates with various A/B testing tools, allowing for seamless experimentation and data-driven decisions.

Streamlined Checkout Process Reducing cart abandonment rates is a major focus for CRO. Simplifying the checkout process by minimizing steps, enabling guest checkout, and using auto-filled forms can significantly enhance the user experience. Shopify’s one-click checkout feature can also help speed up the purchasing process, leading to higher conversion rates.

High-Quality Visuals and Descriptive Content High-resolution images and detailed product descriptions are vital in convincing potential customers to make a purchase. Invest in professional photography and engaging copywriting to showcase your products effectively. Shopify’s built-in photo editing tools can help enhance the visual appeal of your store.

Leveraging Social Proof Social proof, such as customer reviews, testimonials, and user-generated content, can build trust and influence purchasing decisions. Shopify supports various apps, like Yotpo, that facilitate the collection and display of social proof on your store.

Effective Retargeting Campaigns Retargeting campaigns are essential for re-engaging visitors who have left your site without making a purchase. Shopify’s integration with advertising platforms like Facebook and Google Ads allows you to create targeted ads that remind potential customers of your products, encouraging them to return and complete their purchase.

Optimizing Site Speed and Performance A quick-loading website is essential for keeping visitors engaged and minimizing bounce rates. Regularly monitor your site’s speed using tools like Google PageSpeed Insights and optimize as needed. Shopify’s reliable infrastructure supports efficient traffic handling, but additional optimizations can further enhance performance.

Why OyeCommerz is Your Ideal CRO Partner ?

Choosing the right partner for your Shopify store’s CRO needs is essential for achieving optimal results. OyeCommerz is a premier e-commerce agency specializing in comprehensive CRO services, including migration, integration, and development. Here’s why OyeCommerz is the perfect choice:

Expert Migration Services : Migrating to Shopify from another platform can be a complex process. OyeCommerz simplifies this transition with expert migration services, ensuring that all your data, such as products, customers, and orders, is accurately and securely transferred. Their meticulous approach minimizes downtime and maintains your store’s SEO integrity.

Seamless Integration Services : Integrating various tools and systems with your Shopify store can enhance its functionality and streamline operations. OyeCommerz offers seamless integration services, connecting your store with essential systems like Shopify Customer Relationship Management Integration Services, Shopify Enterprise Resource Planning Integration Services, payment gateways, and more, ensuring smooth and efficient business processes.

Custom Development Services : Every e-commerce business has unique needs that require customized solutions. OyeCommerz provides bespoke development services to tailor your Shopify store to your specific requirements. Whether it’s custom themes, specialized apps, or unique functionalities, their expert development team ensures your store stands out and performs optimally.

Maximizing Impact with Combined Services : By combining migration, integration, and custom development services, OyeCommerz delivers a holistic approach to optimizing your Shopify store. A seamless migration ensures data integrity and continuity. Integrating essential tools enhances operational efficiency, while custom development addresses specific needs, creating a unique and effective online shopping experience.

Conclusion

In conclusion, elevating your e-commerce game in 2024 requires a strategic approach to Shopify CRO. By focusing on personalized experiences, mobile optimization, A/B testing, streamlined checkout processes, high-quality visuals, social proof, retargeting, and site performance, you can significantly improve your conversion rates. Partnering with experts like OyeCommerz can further enhance your efforts, providing comprehensive services that ensure your Shopify store not only attracts visitors but converts them into loyal customers.

#conversion rate optimization#cro#crm#erp#ecommerce#shopify#integration#migration#online store#oyecommerz#development#Shopify Customer Relationship Management Integration Services#Shopify Enterprise Resource Planning Integration Services

2 notes

·

View notes

Text

Compressed Load Cell Market: Forecast and Competitive Overview 2025–2032

Global Compressed Load Cell Market size was valued at US$ 284.6 million in 2024 and is projected to reach US$ 438.9 million by 2032, at a CAGR of 6.4% during the forecast period 2025-2032. The U.S. market accounted for 28% of global revenue in 2024, while China’s market is expected to grow at a faster CAGR of 6.8% through 2032.

Compressed load cells are precision force measurement devices designed to operate under compressive loads. These robust sensors convert mechanical force into electrical signals through strain gauge technology, enabling accurate weight and force measurement across industrial applications. Key product variants include analogue and digital compressed load cells, with analogue types currently dominating 62% of market share.

Market growth is being driven by increasing automation in manufacturing, stricter quality control requirements, and the expansion of material testing applications. The industrial sector remains the primary end-user, accounting for 45% of 2024 revenues, particularly in heavy equipment monitoring and process weighing systems. Recent developments include TE Connectivity’s 2023 launch of its Model 3130 high-capacity load cell series, featuring improved overload protection and temperature compensation for harsh environments.

Get Full Report : https://semiconductorinsight.com/report/compressed-load-cell-market/

MARKET DYNAMICS

MARKET DRIVERS

Industrial Automation Boom Accelerates Demand for Compressed Load Cells

The global surge in industrial automation adoption is creating substantial demand for precision measurement devices like compressed load cells. Manufacturing facilities across automotive, aerospace, and heavy industries are increasingly integrating automated systems that require accurate force measurement capabilities. Recent data indicates that over 80% of industrial facilities now use some form of automation, with compressed load cells becoming critical components in robotic assembly lines, quality control stations, and material testing applications. The transition to Industry 4.0 standards has particularly boosted adoption, as these sensors enable real-time monitoring and data collection essential for smart manufacturing processes. Several leading manufacturers have reported 20-25% annual growth in orders from automation integrators, reflecting this strong market trend.

Medical Equipment Advancements Drive Specialized Load Cell Requirements

The healthcare sector’s rapid technological evolution is creating new opportunities for compressed load cell applications. Modern medical devices, from surgical robots to advanced patient monitoring systems, increasingly incorporate miniature load cells for precise force measurement. The medical equipment market’s projected 7% annual growth directly correlates with rising demand for sensor components. Compressed load cells are particularly valuable in applications requiring high accuracy within compact form factors, such as prosthetic limb pressure sensors and minimally invasive surgical tools. Recent product launches in the rehabilitation equipment segment have specifically highlighted integrated load cell technology as a key differentiator, with manufacturers emphasizing durability and measurement consistency.

Transportation Safety Regulations Spur Market Growth

Stricter global transportation safety standards are accelerating compressed load cell adoption across vehicle and infrastructure applications. Regulatory mandates now frequently require weight monitoring systems in commercial vehicles, aircraft landing gear, and railway components – all areas where compressed load cells provide ideal solutions. The commercial vehicle sector alone accounts for approximately 35% of transportation-related load cell deployments. Emerging applications in electric vehicle battery pack monitoring and autonomous vehicle systems further expand market potential. Recent policy developments in multiple regions have specifically referenced load measurement accuracy requirements, driving OEMs to upgrade their sensor technologies.

MARKET RESTRAINTS

High Precision Requirements Limit Adoption in Cost-Sensitive Segments

While compressed load cells offer superior performance, their technical complexity and precision manufacturing requirements result in higher costs that deter price-sensitive markets. Entry-level industrial applications often prioritize affordability over measurement accuracy, opting for simpler sensor solutions. The price differential can exceed 200-300% between basic force sensors and high-end compressed load cells, creating a significant adoption barrier. Price pressures are particularly acute in developing markets, where budget constraints limit technology upgrades despite growing awareness of load cell advantages. This challenge is compounded by the need for compatible instrumentation and regular calibration, which adds to total cost of ownership.

Other Restraints

Supply Chain Vulnerabilities The compressed load cell market remains susceptible to disruptions in rare material supply chains, particularly for specialized strain gauge components. Recent geopolitical tensions and trade restrictions have created lead time uncertainties for certain critical materials, forcing manufacturers to maintain larger inventories and impacting production flexibility.

Technical Integration Challenges Implementing compressed load cells in existing systems often requires substantial engineering modifications, deterring retrofits. Compatibility issues with legacy equipment and the need for specialized installation expertise present additional hurdles, particularly for small and medium enterprises lacking in-house technical resources.

MARKET CHALLENGES

Technical Expertise Shortage Constrains Market Expansion

The compressed load cell industry faces a critical shortage of skilled professionals capable of designing, installing, and maintaining these precision measurement systems. As sensor technology becomes more sophisticated, the gap between available workforce capabilities and technical requirements continues to widen. Industry surveys indicate that over 60% of manufacturers struggle to find qualified personnel for quality control and field service roles. This talent shortage not only limits production capacity but also delays implementation timelines for end-users, potentially slowing overall market growth. The challenge is particularly acute in emerging markets where specialized technical education programs remain underdeveloped.

Emerging Competitive Technologies Alternative force measurement technologies, including optical and capacitive sensors, are gaining traction in certain applications traditionally served by compressed load cells. While these alternatives currently lack the robustness and measurement range of load cells, their improving performance in specific niches creates competitive pressure. Some industry analysts predict these technologies could capture up to 15-20% of current load cell applications within the next decade, particularly in miniaturized and high-cycle applications where they offer potential advantages.

MARKET OPPORTUNITIES

Renewable Energy Sector Presents Untapped Potential

The rapid expansion of renewable energy infrastructure creates significant opportunities for compressed load cell applications. Wind turbine manufacturers increasingly incorporate load monitoring systems into blade and tower designs, while solar tracking systems benefit from precise force measurement in positioning mechanisms. The global wind energy market alone is projected to require over 500,000 specialized load cells annually by 2030. These applications often demand ruggedized designs capable of withstanding harsh environmental conditions, presenting both technical challenges and premium pricing opportunities for manufacturers that can deliver suitable solutions.

Smart City Initiatives Drive Infrastructure Monitoring Demand

Urban infrastructure modernization programs worldwide are creating new markets for structural health monitoring systems that utilize compressed load cells. Bridge safety monitoring, smart building technologies, and advanced public transportation systems all require precise force measurement capabilities. Pilot programs in major cities have demonstrated 30-40% improvements in maintenance efficiency through load cell-enabled predictive maintenance systems. As municipalities increasingly adopt IoT-enabled infrastructure management solutions, the demand for reliable, networked load measurement devices continues to grow. This trend is particularly pronounced in Asia-Pacific regions, where new urban development projects frequently incorporate smart technologies from initial construction phases.

Material Science Breakthroughs Enable Novel Applications

Advances in composite materials and nanotechnology are expanding the performance boundaries of compressed load cells, creating opportunities in previously inaccessible markets. New strain gauge materials with enhanced sensitivity and temperature stability enable applications in extreme environments, from deep-sea exploration to aerospace testing. Similarly, developments in wireless power and data transmission allow for completely self-contained load cell designs suitable for rotating machinery and mobile equipment. Manufacturers investing in these advanced material technologies gain competitive advantages in high-value market segments while establishing intellectual property barriers against lower-cost competitors.

COMPRESSED LOAD CELL MARKET TRENDS

Industrial Automation and Smart Factories Driving Demand for Compressed Load Cells

The global compressed load cell market is experiencing significant growth due to increasing adoption in industrial automation and smart manufacturing facilities. With Industry 4.0 implementations accelerating worldwide, manufacturers are incorporating precision weighing systems in production lines for quality control and process optimization. Compressed load cells play a critical role in these applications, offering high accuracy measurements in confined spaces. The market valuation reached $490 million in 2024, with projections indicating a robust 6.8% CAGR through 2032. Growth is particularly strong in pharmaceutical manufacturing and food processing industries where regulatory compliance mandates precise weight measurements at various production stages.

Other Trends

Healthcare Sector Adoption

Medical applications are emerging as a key growth segment for compressed load cells, driven by advancements in patient monitoring systems and surgical equipment. Hospitals are increasingly using these sensors in rehabilitation devices, patient lift systems, and medical beds to monitor weight distribution and prevent pressure injuries. The trend toward telehealth and remote patient monitoring has further increased demand for compact, high-precision load cells that can integrate with IoT-enabled medical devices. This healthcare segment is projected to grow at 8.2% annually through 2030.

Technological Advancements in Sensor Design

Manufacturers are focusing on developing next-generation compressed load cells with improved durability and measurement capabilities. Recent innovations include wireless load cells with battery-powered operation, smart load cells with integrated Bluetooth connectivity, and ultra-compact designs for space-constrained applications. The introduction of corrosion-resistant materials like titanium and specialized alloys has expanded usage in harsh industrial environments. Additionally, advancements in signal processing technology have enhanced measurement accuracy to ±0.02% of full scale, making these sensors viable for critical applications in aerospace and defense sectors.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Precision Drive Market Competition in Compressed Load Cell Segment

The global compressed load cell market features a semi-consolidated competitive landscape with AMETEK, FUTEK Advanced Sensor Technology, and Honeywell emerging as dominant players. These companies collectively held approximately 35-40% market share in 2024, according to industry analysis. Their leadership stems from comprehensive product portfolios covering both analogue and digital compressed load cells, coupled with strong distribution networks across North America and Europe.

METTLER TOLEDO and Vishay Precision Group have strengthened their positions through strategic acquisitions and expanded manufacturing capabilities. The companies reported year-over-year revenue growth of 8-12% in their industrial measurement segments during 2023-2024, with compressed load cells contributing significantly to this performance.

While established players dominate the premium segment, mid-sized companies like TE Connectivity and Interface, Inc. are gaining traction in emerging markets through competitive pricing and localized support. These firms have successfully penetrated the Asian market, particularly in China and India, where industrial automation demand continues to rise.

Regional players such as LAUMAS Elettronica (Italy) and Celmi (Spain) maintain strong positions in European specialty applications, particularly in food processing and pharmaceutical industries where precision measurement requirements are stringent.

List of Key Compressed Load Cell Manufacturers

AMETEK (U.S.)

FUTEK Advanced Sensor Technology, Inc. (U.S.)

Honeywell (U.S.)

METTLER TOLEDO (Switzerland)

Vishay Precision Group (U.S.)

TE Connectivity (Switzerland)

Interface, Inc. (U.S.)

HBM (Germany)

LAUMAS Elettronica (Italy)

Celmi (Spain)

Siemens (Germany)

WIKA (Germany)

GEFRAN (Italy)

Sherborne Sensors (U.K.)

Dini Argeo (Italy)

Segment Analysis:

By Type

Analogue Compressed Load Cell Segment Dominates Due to Widespread Industrial Adoption

The market is segmented based on type into:

Analogue Compressed Load Cell

Subtypes: High-capacity, Medium-capacity, Low-capacity

Digital Compressed Load Cell

By Application

Industrial Segment Leads Owing to High Utilization in Manufacturing and Process Industries

The market is segmented based on application into:

Industrial

Medical

Transportation

Others

By Capacity

Medium-capacity Segment Maintains Strong Position for General Industrial Applications

The market is segmented based on capacity into:

High-capacity (Above 100 tons)

Medium-capacity (10-100 tons)

Low-capacity (Below 10 tons)

By Technology

Strain Gauge Technology Remains Predominant Due to Reliability and Accuracy

The market is segmented based on technology into:

Strain gauge

Hydraulic

Piezoelectric

Others

Regional Analysis: Compressed Load Cell Market

North America North America is a mature yet highly competitive market for compressed load cells, driven by stringent industrial safety standards (OSHA, ANSI) and widespread automation adoption. The U.S. dominates with a projected 2024 valuation of $XX million, fueled by demand from aerospace (Boeing, Lockheed Martin) and advanced manufacturing sectors. Canada’s oil & gas industry is adopting explosion-proof load cells for hazardous environments, while Mexico’s automotive OEMs are integrating these sensors into production line robotics. The region faces pricing pressures due to commoditization of analog load cells, pushing manufacturers toward IoT-enabled digital solutions with real-time data analytics capabilities.

Europe European demand is shaped by the ATEX Directive’s explosion protection requirements and the push for Industry 4.0 compliance. Germany leads in precision manufacturing applications (65% of regional industrial demand), particularly in automotive test benches and pharmaceutical packaging lines. Scandinavian countries are early adopters of wireless load cells for offshore renewables maintenance. However, CE certification complexities and high labor costs constrain SME adoption. The market sees consolidation among mid-tier players – HBM and Flintec merged in 2022 to strengthen their position in custom load cell solutions.

Asia-Pacific APAC is the fastest-growing market (CAGR 7.2% 2024-2032), with China accounting for 40% regional share due to booming construction machinery production (+18% YoY). Japan’s emphasis on miniaturization drives demand for micro load cells in robotics, while India’s Make in India initiative boosts local sensor manufacturing. Southeast Asian food processing plants increasingly use stainless steel load cells for hygienic weighing. Price sensitivity remains acute, with domestic players like Zhenghua undercutting Western brands by 30-50%. Digital twin adoption in smart factories is creating new opportunities for networked load monitoring systems.

South America Market growth is uneven, with Brazil’s mining sector (Vale, Petrobras) driving bulk weighing demand and Argentina’s economic crisis suppressing industrial investment. Chile’s copper industry uses heavy-capacity load cells (>500t) for haul truck payload monitoring. Infrastructure gaps in product certification labs force reliance on imported, pre-certified load cells. Local assembly is emerging – Bráulio & Cia now produces IP68-rated compression load cells under license from European partners. Political instability continues to deter major FDI in regional sensor manufacturing facilities.

Middle East & Africa The GCC’s oilfield services sector is the primary adopter, using intrinsically safe load cells for drilling equipment monitoring. UAE’s logistics hubs deploy compression load cells in automated cargo handling systems. Africa’s growth is piecemeal – South African mining and Nigerian food processing account for 72% of Sub-Saharan demand. Import dependence remains high (85% of supply) due to limited local technical expertise in strain gauge manufacturing. Recent trade agreements are enabling Turkish and Indian manufacturers to gain market share with competitively priced offerings compliant with ISO 17025 standards.

Get a detailed Sample of the Market Research Report : https://semiconductorinsight.com/download-sample-report/?product_id=97913

Report Scope

This market research report provides a comprehensive analysis of the global and regional Compressed Load Cell markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Compressed Load Cell market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Analogue/Digital), application (Industrial, Medical, Transportation, Others), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. The U.S. market is estimated at USD million in 2024, while China is projected to reach USD million.

Competitive Landscape: Profiles of 40+ leading manufacturers including ACRN, ADOS, AMETEK, FUTEK, HBM, Honeywell, METTLER TOLEDO, and TE Connectivity, with their market shares and strategic developments.

Technology Trends: Assessment of emerging innovations in load cell design, materials, IoT integration, and smart sensor technologies.

Market Drivers & Restraints: Evaluation of industrial automation growth, accuracy requirements, versus cost pressures and supply chain challenges.

Stakeholder Analysis: Strategic insights for component suppliers, OEMs, system integrators, and investors in the measurement technology ecosystem.

The research employs primary interviews with industry experts and validated secondary data from financial reports, trade associations, and patent analysis to ensure accuracy.

Customisation of the Report

In case of any queries or customisation requirements, please connect with our sales team, who will ensure that your requirements are met.

Related Reports :

Contact us:

+91 8087992013

0 notes

Text

Silent Powerhouses: How igbt rectifiers Are Redefining Industrial Energy Conversion

Picture a bustling manufacturing floor at dawn. Conveyor belts glide, robotic arms pivot with precision, and high-power motors hum in perfect synchrony. All of this choreographed action relies on stable direct current—even though the utility grid delivers alternating current. Converting AC to DC might sound mundane, yet it’s the unglamorous heartbeat of virtually every modern factory, data center, and electric-rail system. Tucked inside control cabinets and power bays, igbt rectifiers are the silent powerhouses making this conversion cleaner, smarter, and dramatically more efficient.

From Diodes to Digital Brains

For decades, silicon diodes and thyristors dominated rectification. They were sturdy, inexpensive, and—let’s be honest—fairly dumb. They could only switch on and off in crude, bulk fashion, producing DC that was rife with voltage ripple and harmonic distortion. That was acceptable in an analog world, but today’s precision-driven operations need better. Enter the Insulated Gate Bipolar Transistor (IGBT): a semiconductor that marries the high-current capability of a bipolar transistor with the fast switching of a MOSFET.

When engineers embed IGBTs in rectifier topologies, the result is a new class of high-frequency converters capable of pulse-width modulation (PWM), soft-start functions, and active power-factor correction. Suddenly, rectification isn’t just about flipping waveform polarity—it’s about sculpting perfect current for sensitive loads, saving megawatts in the process.

A Day in the Life: Humanizing High Tech

Let’s walk in the shoes of Ananya, maintenance lead at a sprawling metro-rail depot in Bengaluru. She remembers the era when traction substations ran on mercury-arc or SCR rectifiers. “It was like taming a dragon,” she jokes. Voltage spikes chewed through bearings, transformers overheated, and harmonics crept back onto the grid. Then came the retrofit: a modular cabinet stuffed with igbt rectifiers. Overnight, the depot saw a 6 % drop in energy losses and, more surprisingly, quieter lines. “Passengers didn’t notice the upgrade,” Ananya says, “but my team sleeps better knowing the system’s self-diagnostics flag issues before they escalate.”

That’s the hidden human upside—less emergency call-outs, more predictive maintenance, and a work culture that shifts from crisis mode to optimization mode.

Under the Hood: Why IGBT Architecture Shines

High-Frequency Switching IGBTs can switch tens of kilohertz, shrinking bulky transformers and filters. Smaller magnetics mean lighter enclosures and better thermal management.

Low Conduction Losses Compared to MOSFETs at high voltage, IGBTs maintain lower on-state resistance, translating into cooler operation and longer component life.

Built-In Protection Advanced gate-driver ICs monitor temperature, current, and voltage in real time, shutting down the device within microseconds if thresholds are breached.

Bidirectional Capability Paired with appropriate circuitry, they enable regenerative braking in electric locomotives, feeding energy back to the grid instead of dumping it as heat.

Sustainability by Design

Energy efficiency isn’t just a line on a spec sheet—it’s a planetary necessity. Traditional 12-pulse SCR rectifiers often hover near 90 % efficiency under ideal loads. Modern PWM-controlled igbt rectifiers push beyond 97 %, slicing gigawatt-hours off cumulative utility bills over their service life. Multiply that by thousands of installations and you have a tangible dent in global CO₂ emissions.

Moreover, precise DC output means motors run cooler, electrolytic capacitors last longer, and upstream generators experience smoother load profiles. Less wear equals fewer raw materials mined, shipped, and processed for replacements—a virtuous cycle of resource conservation.

Beyond the Factory: Emerging Frontiers

Data Centers – Hyperscale operators love IGBT rectifiers for redundant, hot-swappable power shelves that squeeze more watts per rack while meeting stringent harmonic limits (IEEE 519).

Electrolysis for Green Hydrogen – Stable, low-ripple DC is crucial for membrane longevity. As electrolyzer farms scale into the gigawatt realm, PWM rectifiers slash idle losses and enable dynamic ramp-up tied to renewable generation.

EV Hyper-Chargers – Ultra-fast DC stations (350 kW and higher) rely on modular IGBT blocks to convert grid AC into tightly regulated DC that won’t fry delicate vehicle battery chemistries.

Challenges on the Road Ahead

No technology is perfect. IGBT modules are sensitive to over-voltage transients and require sophisticated snubber networks. Their thermal cycling limits call for meticulous heatsink design and, in harsh climates, liquid cooling. Meanwhile, wide-bandgap semiconductors—silicon carbide (SiC) and gallium nitride (GaN)—are nipping at IGBT heels, promising even faster switching and lower losses.

Yet cost remains king. For high-power (≥ 1 MW) applications, mature supply chains and proven robustness keep igbt rectifiers solidly in the lead. Hybrid topologies that mix SiC diodes with IGBT switches already deliver incremental gains without breaking budgets.

Skills and Workforce Implications

Technicians who once wielded soldering irons on analog boards now brandish oscilloscopes with gigahertz bandwidth to capture nanosecond edge transitions. Training programs are evolving: power-electronics courses in Indian ITIs and polytechnics now include gate-drive design, thermal simulation, and module-level repair practices.

For young engineers, this field offers a blend of hands-on tinkering and digital analytics. Predictive-maintenance dashboards stream real-time data—junction temperatures, switching losses, harmonic spectra—turning power rooms into high-tech command centers.

Final Reflections: Small Silicon, Massive Impact

It’s easy to overlook the humble converter tucked behind a metal door. But in the grand choreography of electrification, igbt rectifiers are the quiet conductors, synchronizing renewable surges, feeding smart grids, and keeping industry humming. They exemplify how incremental innovations—faster switches, smarter firmware, better cooling—compound into game-changing efficiency.

Next time you glide on an electric train, boot up a cloud server, or see a wind farm blinking on the horizon, remember: somewhere underneath, tiny gates are opening and closing thousands of times a second, silently shaping the clean-energy era. And that is technology worth celebrating, even if it never seeks the spotlight.

0 notes

Text

Digital Fault Recorder Market to Reach US$ 783.2 Mn by 2034

The global digital fault recorder (DFR) market, valued at US$ 478.2 million in 2023, is forecast to grow at a steady CAGR of 4.6% between 2024 and 2034, reaching US$ 783.2 million by 2034. As electric grids become more complex and power demand surges across regions, the role of DFRs—also known as grid fault data recorders—has evolved from simple data loggers to critical tools in achieving operational excellence, grid reliability, and safety.

Role of DFR in Smart Grid Stabilization

At the heart of the DFR’s value proposition lies its ability to detect, record, and analyze electrical disturbances within the grid. Be it a voltage dip, short circuit, or frequency deviation, a digital fault recorder captures the event in detail, helping operators to quickly isolate and resolve faults. This proactive approach ensures minimal downtime and optimizes fault response.

Modern grids rely heavily on substation automation systems, where DFRs play a pivotal role. These recorders help in maintaining operational continuity, especially during high-voltage load cases or abnormal conditions. By permanently logging events, they provide a trail of evidence critical for post-event diagnostics and system optimization.

Market Drivers: Substation Automation and WAMS

A primary driver of the DFR market is the increased adoption of substation automation and Wide Area Monitoring Systems (WAMS). According to the International Energy Agency, global electricity demand grew by 2.2% in 2023, with countries such as China, India, and Southeast Asia leading the surge. In response, utilities are embracing automation to ensure seamless and reliable power delivery.

Substation automation integrates hardware, software, and communication systems to remotely monitor and control electrical assets. This enables automatic fault detection, enhances decision-making speed, and improves power distribution efficiency. Intelligent Electronic Devices (IEDs), often integrated with DFRs, can process fault data in real-time and trigger corrective actions.

Meanwhile, WAMS use synchronized phasor measurements and real-time analytics to provide operators with a wide-angle view of the entire grid. When paired with DFRs, these systems can offer enhanced situational awareness and allow grid operators to manage faults across vast geographical areas with precision.

IIoT’s Contribution to Fault Management

The incorporation of the Industrial Internet of Things (IIoT) is further accelerating the growth of the DFR market. IIoT facilitates scalable fault identification across power distribution systems using cloud infrastructure, real-time sensors, and edge computing.

For utilities managing a growing number of power distribution zones, IIoT-enabled DFRs help localize faults more efficiently, reduce downtime, and improve customer satisfaction. With the ability to compare fault patterns against historical databases, IIoT systems aid in predictive maintenance and reduce operational costs.

Regional Spotlight: Asia Pacific Leads the Charge

The Asia Pacific region dominated the digital fault recorder market in 2023 and is expected to retain its lead through 2034. The region’s growth is attributed to massive investments in grid modernization across India, China, and Japan. As urbanization intensifies and electrification programs expand, the need for uninterrupted and clean power has risen sharply.

Governments are not only investing in new infrastructure but also upgrading existing substations with DFR-integrated automation systems. Additionally, countries in the Middle East and Africa, such as UAE, Kuwait, and Qatar, are making strides toward 100% electrification, presenting new growth opportunities for DFR vendors.

Competitive Landscape and Innovation Trends

Leading companies in the DFR market are consistently innovating to enhance functionality, accuracy, and ease of use. For example, AMETEK Power Instruments launched the TR-3000, a configurable DFR solution with up to 14 digital inputs per module, offering flexible deployment in complex grid scenarios.

Similarly, OMICRON’s TWX1, introduced in 2020, supports fault localization and protection relay testing, aligning with the growing demand for portable and user-friendly solutions.

Prominent players such as General Electric (GE), Siemens Energy, Qualitrol, ABB, Schneider Electric, SEL, and Doble Engineering are strengthening their foothold through product innovation, regional expansion, and strategic partnerships.

Conclusion: Preparing for a Resilient Energy Future

The growing complexity of electric grids, driven by decentralized power generation, renewable integration, and increasing load demands, necessitates high-performance monitoring systems. Digital fault recorders have emerged as a cornerstone technology, ensuring fast fault identification, data analysis, and operational reliability.

As automation and IIoT technologies continue to influence power infrastructure, DFRs are expected to play an even more critical role in fault management and grid stability. Market players who invest in smart, scalable, and interoperable DFR solutions will be well-positioned to capitalize on the evolving needs of the global power sector.

0 notes

Text

North America Building Automation Systems (BAS) Industry: Driving the Future of Smart Buildings

The North America Building Automation Systems (BAS) Industry is undergoing a rapid transformation, fueled by digitization, sustainability targets, and the rising demand for intelligent building solutions. The industry, valued at USD 37.31 billion in 2024, is expected to reach USD 88.48 billion by 2034, growing at a robust CAGR of 9.0% during the forecast period. From HVAC automation to energy analytics, the industry is central to the region’s transition toward green and smart infrastructure.

Industry Overview

Building Automation Systems are centralized, interconnected networks of software and hardware designed to control a building's mechanical, electrical, and security systems. In North America, the BAS industry is scaling up due to:

Rising energy costs and environmental regulations that encourage automation for efficiency.

Smart city initiatives that include BAS in government and municipal infrastructure.

Post-pandemic upgrades in HVAC and air quality monitoring for health and safety compliance.

Widespread adoption of IoT, AI, and data analytics, which optimize operational efficiency.

The industry is no longer limited to new buildings. There is a large push in the retrofit sector where older structures are being modernized with wireless and modular BAS solutions.

Industry Trends and Advancements

1. Integration of IoT and Edge Devices

IoT sensors and edge computing are now essential in BAS architecture. They offer real-time decision-making and improved data processing, enabling instant response to occupancy, lighting, or temperature changes.

2. Cybersecurity and Data Privacy in BAS

As systems become more connected, the industry is investing heavily in encryption protocols, multi-factor authentication, and network segmentation to protect against cyber threats.

3. AI-Driven Predictive Maintenance

AI models analyze historical and live data to forecast equipment failures and optimize performance. This reduces unplanned downtime and lowers operational expenses.

4. Emphasis on Sustainability

The BAS industry is central to green building certification (e.g., LEED, Energy Star) and Net Zero goals. Smart energy management and integration with solar or wind power systems are now industry norms.

5. Cloud-Based and SaaS BAS Solutions

Cloud-native BAS platforms enable remote monitoring, mobile access, and scalability. Subscription-based models are also helping small- to mid-sized facilities adopt advanced automation affordably.

6. Integration with BIM (Building Information Modeling)

BAS is increasingly being embedded in BIM systems for better lifecycle management, energy simulation, and 3D visualization of building performance.

Industry Segmentation

By Offering

Hardware: Sensors, controllers, and actuators form the foundation of BAS installations.

Software: Centralized dashboards, analytics, and control platforms are now the growth drivers of the industry.

Services: Integration, retrofitting, monitoring, and optimization services are a key revenue stream.

By System Type

HVAC Automation Systems: The most widely adopted, as HVAC consumes the highest energy in buildings.

Lighting Automation: LED integration, motion sensors, and daylight harvesting are driving this segment.

Security and Surveillance: Biometric systems, CCTV, and access control are commonly integrated.

Fire Safety and Life Systems: Code compliance and real-time emergency response features make this a growing segment.

By Connectivity

Wired BAS: Preferred for reliability in large, complex buildings.

Wireless BAS: Favored in retrofits and smaller buildings due to flexibility and lower installation cost.

By End User

Commercial Buildings: Offices, malls, and hotels make up the largest share due to high energy loads and tenant demand.

Industrial Facilities: Automation ensures production efficiency and facility security.

Healthcare: Hospitals require stringent air quality, access control, and operational continuity.

Government and Public Sector: School campuses and transport hubs integrate BAS to meet sustainability mandates.

Residential Buildings: Smart home trends are expanding the industry into new territories.

Regional Dynamics in North America

United States: Leads the BAS industry with innovation hubs, top-tier vendors, and progressive energy codes.

Canada: Invests in public infrastructure retrofits and green building certifications, fostering BAS adoption.

Mexico: BAS is emerging in commercial developments and industrial corridors, supported by foreign investment.

The industry benefits from regional factors such as:

Utility rebate programs and tax incentives.

Demand for occupant-centric features like comfort customization and real-time alerts.

Rising cybersecurity regulations affecting building IT/OT integration.

Key Companies in the BAS Industry

The North American BAS industry includes multinational giants and innovative niche players:

Johnson Controls

Honeywell International Inc.

Siemens AG

Schneider Electric

ABB Ltd.

Carrier Global Corporation

Delta Controls

Distech Controls

Rockwell Automation

These firms invest in R&D, strategic acquisitions, and long-term service contracts to strengthen their footprint in this growing industry.

Strategic Industry Developments

Partnerships with Smart City Initiatives: BAS providers collaborate with municipalities for wide-scale implementations.

Acquisition of AI/ML Startups: Companies are acquiring predictive analytics firms to enhance their platform intelligence.

BAS-as-a-Service Models: A shift toward recurring revenue via managed BAS services is reshaping the business model.

Conclusion

The North America Building Automation Systems (BAS) Industry is at the forefront of transforming the built environment. As sustainability, cost efficiency, and occupant health become top priorities, the industry will continue to expand through advanced software platforms, integration services, and intelligent devices. Companies that offer scalable, secure, and future-ready BAS solutions are best positioned to lead the next phase of smart building evolution.

Trending Report Highlights

Explore the next wave of high-impact electronics and automation market opportunities:

Certificate Testing Market

Chip Resistor Market

Digital Thermometer Market

Commercial Display Market

Connected Living Room Market

0 notes

Text

High-Power Rectifiers Market Emerging Trends Transforming Industrial Power Systems

The high-power rectifiers market is witnessing significant transformation driven by technological advancements, rising energy demands, and the need for improved efficiency in industrial operations. High-power rectifiers are essential for converting alternating current (AC) to direct current (DC) in applications requiring high-voltage and high-current supply. These devices are critical across a range of sectors including power utilities, electrochemical processing, electric arc furnaces, railway traction systems, and renewable energy integration. As industrial infrastructure modernizes and the shift towards electrification accelerates, several emerging trends are shaping the future trajectory of this market.

Integration with Smart Grid Systems

One of the most prominent trends in the high-power rectifiers market is their growing integration with smart grid technologies. As utilities upgrade legacy grids to improve load balancing, efficiency, and fault detection, high-power rectifiers are being adapted to work in tandem with intelligent monitoring and control systems. These rectifiers are increasingly being embedded with digital interfaces and sensors that enable real-time diagnostics, remote monitoring, and predictive maintenance, thereby enhancing operational reliability and lifespan.

Surge in Demand from Green Energy Applications

The transition to renewable energy sources is another key driver influencing the high-power rectifiers market. With increased investment in solar photovoltaic plants, wind farms, and hydroelectric facilities, there is a corresponding demand for high-capacity rectifiers to ensure consistent and efficient power conversion. These systems are particularly crucial in storing renewable energy in battery systems or integrating it into high-voltage DC (HVDC) transmission lines, which require stable rectification systems to handle variable input loads.

Advancements in Semiconductor Materials

Recent innovations in semiconductor technologies, particularly the adoption of silicon carbide (SiC) and gallium nitride (GaN), are enabling the development of high-power rectifiers with superior performance characteristics. These wide-bandgap materials offer higher thermal conductivity, voltage tolerance, and switching speeds compared to traditional silicon-based rectifiers. This allows rectifiers to operate at higher frequencies with greater efficiency, making them ideal for compact, high-performance industrial systems. As manufacturing costs for SiC and GaN devices decrease, their adoption in high-power rectifiers is expected to rise significantly.

Growing Adoption in Electrochemical and Metallurgical Processes

High-power rectifiers are indispensable in electrochemical industries, especially in applications such as metal electrolysis, electroplating, and anodizing. With the revival of infrastructure projects and increasing demand for metals like copper, aluminum, and zinc, industries are scaling up their production facilities. Modern rectifiers now offer precise control over voltage and current, which is crucial for maintaining product quality in such processes. Additionally, there is a rising trend towards using energy-efficient rectifiers that reduce electricity consumption and lower carbon emissions in metallurgical operations.

Customization and Modular Design

Industrial end-users are increasingly seeking customized high-power rectifier solutions tailored to specific application needs. This has led manufacturers to develop modular rectifier systems that offer scalability and flexibility. Modular designs not only facilitate easier maintenance and upgrades but also enable rapid deployment in remote or space-constrained environments. This trend is particularly relevant in mining operations, offshore platforms, and mobile power stations where adaptability and resilience are key requirements.

Expansion in Railway Electrification Projects

As countries invest in railway electrification to reduce dependence on fossil fuels, high-power rectifiers are becoming a vital component of traction substations. These systems are required to supply reliable DC power for electric locomotives and auxiliary systems. The ongoing electrification of rail networks in regions such as Asia-Pacific, Latin America, and parts of Africa is driving demand for rugged, high-efficiency rectifier units that can withstand harsh operating conditions while maintaining high performance.

Emphasis on Energy Efficiency and Sustainability

Environmental concerns and regulatory pressures are compelling industries to adopt energy-efficient rectification technologies. Modern high-power rectifiers now come with features like low harmonic distortion, soft-start capabilities, and regenerative energy systems that contribute to overall energy savings. Manufacturers are focusing on creating eco-friendly designs that minimize energy waste and contribute to sustainability goals, a trend that is increasingly resonating with environmentally conscious stakeholders.

Digital Twin and Predictive Maintenance

The implementation of digital twin technology is another cutting-edge trend impacting the high-power rectifiers market. By creating a virtual replica of the physical rectifier system, operators can simulate various operational scenarios, optimize performance, and predict maintenance needs. This approach helps in reducing unplanned downtime and extending the service life of the equipment. Predictive maintenance powered by AI and IoT is gaining traction among large-scale industrial users for its cost-efficiency and effectiveness.

Conclusion

The high-power rectifiers market is undergoing a dynamic evolution, influenced by innovations in materials, automation, energy integration, and sustainability. As industries continue to digitize and decarbonize, the demand for smarter, more efficient rectification systems will only intensify. Manufacturers that embrace these emerging trends and invest in R&D for next-generation technologies will be best positioned to capture the expanding opportunities in this essential industrial sector.

0 notes

Text

The Power of Custom Web Development to Accelerate Your Business

In today’s hyperconnected digital landscape, your website is no longer just a presence—it’s a performance platform. A well-developed website serves as the face of your brand, a sales engine, and a core driver of user engagement. We understand that great web development is not just about writing code—it’s about creating experiences, solving problems, and driving measurable business growth.

As a recognized leader in the field, we deliver custom website solutions designed for real-world impact. We specialize in responsive, high-performance websites tailored to your brand goals, user needs, and market dynamics. Whether you’re a startup, a growing eCommerce business, or a large enterprise, we offer a development roadmap that aligns perfectly with your digital vision.

Our team brings together a versatile blend of design creativity, technical expertise, and strategic thinking. Using cutting-edge technologies such as HTML5, CSS3, JavaScript, React, Vue.js, PHP, Laravel, WordPress, and Shopify, we craft fully customized websites that are intuitive, scalable, and SEO-friendly.

At the core of every project is responsive web design, ensuring your website functions flawlessly across all screen sizes and devices. From mobile-first design strategies to cross-browser compatibility and performance optimization, we ensure your site loads fast and delivers seamless user experiences that keep visitors engaged and drive conversions.

What makes us stand out is our commitment to SEO-driven development. Every website we build is designed to rank. We implement clean coding structures, fast-loading pages, schema markup, and search engine best practices from the very beginning. This not only enhances visibility but also boosts your authority in competitive search landscapes.

Our web development process is collaborative and client-centric. We begin with thorough discovery and planning, followed by UX wireframes, UI design, backend architecture, and agile development sprints. Every stage is transparent, with consistent updates and feedback loops to ensure your input shapes the final output.

Post-launch, our engagement continues. We provide website maintenance, technical support, performance monitoring, and digital strategy alignment, ensuring your website continues to evolve alongside your business. We don’t just hand off a site—we help you grow with it.

With a proven track record of serving clients across diverse industries and geographies, we are proud to be a trusted technology partner. We’ve helped brands build smarter digital infrastructures, elevate user experiences, and scale their online presence effectively.Ready to elevate your digital presence? Partner with the top web development company in Ahmedabad to transform your vision into a dynamic, user-centric website that drives results and fuels your business growth. Let's create something extraordinary together.

#web development company#web developer in ahmedabad#web development agency#web development firm#website development company#website developer in ahmedabad#custom web development#website development in ahmedabad#web development in ahmedabad

0 notes

Text

Exploring the Digital Logistics Market: Opportunities and Challenges

Digital Logistics Market Growth & Trends

The global Digital Logistics Market reached an estimated USD 29.18 billion in 2023 and is projected to expand significantly at a compound annual growth rate (CAGR) of 18.4% from 2024 to 2030. This robust growth is primarily fueled by the rapid expansion of the e-commerce sector, ongoing technological advancements, and the critical need for businesses to mitigate supply chain disruptions and maintain operational continuity.

Understanding Digital Logistics

Digital logistics involves leveraging digital technologies to manage, optimize, and automate logistics and supply chain operations. It integrates various digital tools and platforms, enhancing the efficiency, visibility, and adaptability of moving goods from suppliers to customers.

Benefits of Digital Logistics Solutions

Digital logistics solutions offer a multitude of advantages, including enhanced efficiency, improved visibility, and substantial cost reduction. By automating and optimizing logistics processes, businesses can reduce manual labor, minimize errors, and accelerate operations. Real-time tracking and monitoring capabilities provide greater transparency, enabling companies to manage their supply chains more effectively. Furthermore, these solutions empower companies to scale operations and adapt to dynamic market demands with greater ease.

Key Growth Drivers

The exponential rise in e-commerce has generated immense demand for efficient, fast, and flexible logistics solutions. Digital logistics technologies are crucial for managing the complexities of e-commerce supply chains, ensuring rapid order fulfillment, real-time tracking, and streamlined returns management. As businesses increasingly globalize, managing international logistics becomes more intricate. Digital logistics solutions are indispensable for coordinating global supply chains, managing cross-border shipments, and navigating diverse regulatory requirements, all of which contribute to market expansion.

Technological Advancements Powering the Market

Companies are increasingly harnessing Artificial Intelligence (AI) and Machine Learning (ML) to predict demand, optimize routes, and reduce delivery times. By analyzing vast datasets, these technologies can anticipate disruptions, adjust logistics plans in real-time, and enhance decision-making. Internet of Things (IoT) devices provide real-time data on shipment location, condition, and status. Sensors embedded in containers and vehicles monitor critical factors like temperature, humidity, and shock levels, which are vital for sensitive goods such as pharmaceuticals and perishables.

Innovation in Action

Continuous innovation and the launch of new technological solutions for logistics operations are significantly propelling market growth. For example, in July 2024, C.H. Robinson Worldwide, Inc. introduced Digital Dispatch. This advanced load-matching platform, powered by AI and data science, provides real-time, personalized load recommendations based on carriers' search history and preferences. This innovation drastically reduces the time carriers spend searching for freight, leading to faster and more relevant matches. Consequently, carriers can secure loads more quickly, optimize their routes, increase earnings, and minimize empty miles. Digital Dispatch is currently available for small carriers, with plans for future expansion to larger operators.

Curious about the Digital Logistics Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Digital Logistics Market Report Highlights

The solution segment dominated the market in 2023 and accounted for more than 64.0% share of global revenue.

The cloud segment dominated the target market in 2023 and accounted for more than 75.0% share of global revenue.

The transportation management segment dominated the market in 2023 and accounted for more than 31.0% share of global revenue.

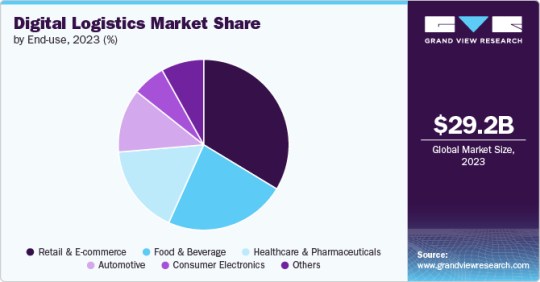

The retail & e-commerce segment dominated the market in 2023 and accounted for more than 33.0% share of global revenue.

North America dominated the global digital logistics market and accounted for a revenue share of over 36.0% in 2023.

Digital Logistics Market Segmentation

Component Outlook (Revenue, USD Million, 2017 - 2030)

Solution

Services

Deployment Outlook (Revenue, USD Million, 2017 - 2030)

Cloud

On-premises

Application Outlook (Revenue, USD Million, 2017 - 2030)

Transportation Management

Warehouse Management

Order Management

EDI

Others

End-use Outlook (Revenue, USD Million, 2017 - 2030)

Retail & E-commerce

Automotive

Healthcare & Pharmaceuticals

Food & Beverage

Consumer Electronics

Others

Download your FREE sample PDF copy of the Digital Logistics Market today and explore key data and trends.

0 notes

Text

Energy & Power Quality Meters Market Drivers Include Grid Modernization, Industrial Automation, and Rising Energy Efficiency Needs

The energy & power quality meters market is witnessing substantial growth, propelled by several dynamic and interconnected drivers that span industries and geographies. As energy systems become more complex and demand for uninterrupted, clean, and efficient power grows, the role of power quality meters becomes increasingly critical. These meters help monitor, manage, and optimize power usage while detecting anomalies that could affect system performance. The market’s expansion is being driven by technological, regulatory, economic, and environmental factors, positioning these meters as indispensable components in modern energy infrastructure.

One of the primary market drivers is grid modernization and the growing need for smart energy management. Power grids across the world are undergoing transformative upgrades to meet the rising demand for renewable integration, distributed generation, and energy storage systems. Power quality meters play a vital role in these smart grid initiatives by providing real-time data on power parameters such as voltage, current, harmonics, and frequency. Utilities rely on this information to detect and address power quality issues, reduce energy losses, and ensure consistent delivery across aging and overloaded infrastructure.

In parallel, the rise of industrial automation and digitization is significantly fueling market demand. Manufacturing plants, data centers, and commercial complexes are deploying advanced power quality meters to enhance process reliability and protect sensitive equipment. Automated systems, including robotics and programmable logic controllers (PLCs), require stable and clean power to function optimally. Even small voltage sags or surges can lead to downtime or equipment damage. Energy and power quality meters provide visibility into power anomalies and trends, allowing timely corrective actions and reducing costly disruptions.

Another critical driver is the increased emphasis on energy efficiency and sustainability. Organizations across sectors are actively seeking ways to optimize their energy usage to lower operational costs and reduce carbon emissions. Power quality meters support these initiatives by offering precise consumption insights, load profiling, and demand tracking. This enables facility managers and energy consultants to identify inefficiencies, correct poor power factor issues, and implement targeted energy-saving strategies. The global push for carbon neutrality and green building certifications further accelerates the deployment of these monitoring tools.

Regulatory mandates and government policies are also pivotal in driving the market forward. Countries across North America, Europe, and Asia-Pacific have implemented standards and incentives that require or encourage the use of energy monitoring systems. These include mandates for energy audits, minimum energy performance standards, and grid compliance requirements. By helping companies meet these regulations and improve energy reporting, power quality meters not only support compliance but also enhance transparency and accountability.

In the commercial and residential sectors, the demand for uninterrupted and quality power is at an all-time high due to the widespread use of electronic devices, HVAC systems, and smart home technologies. As power quality disturbances can damage appliances and reduce energy efficiency, residential and commercial buildings are increasingly integrating power monitoring solutions. This trend is especially noticeable in high-density urban environments and commercial hubs, where energy usage is intense and continuous.

The expansion of renewable energy systems is another major force shaping the market. Solar and wind installations, both on-grid and off-grid, require precise energy flow monitoring to ensure compatibility with the main grid and avoid voltage fluctuations. Power quality meters enable renewable energy developers and operators to manage bidirectional energy flows, maintain grid stability, and optimize output. As renewable energy becomes more mainstream, these meters will play a central role in enabling a smooth and efficient energy transition.

Technological advancements are amplifying these drivers by making power quality meters more intelligent, compact, and affordable. Modern meters now come with features like remote monitoring, cloud integration, wireless communication, and AI-driven analytics. These innovations make it easier for companies of all sizes to deploy and maintain monitoring systems, even across large or distributed operations. The rising adoption of Internet of Things (IoT) platforms in energy management also complements power quality meters by creating interconnected networks for real-time performance visualization and automation.

Lastly, the increasing frequency of power outages, voltage disturbances, and blackouts due to climate change and grid stress is raising awareness of power quality issues. Businesses and utilities alike are prioritizing investments in power quality monitoring to enhance system resilience, ensure continuity, and protect infrastructure. As power becomes more decentralized and digital, the importance of maintaining quality and reliability cannot be overstated.

In conclusion, the drivers behind the energy & power quality meters market are diverse and deeply rooted in the evolving energy landscape. From smart grids and industrial automation to sustainability goals and regulatory compliance, these forces collectively push the market toward rapid innovation and widespread adoption. As the demand for clean, efficient, and stable power grows, power quality meters will remain central to achieving these energy goals.

0 notes

Text

Steady Growth Ahead: Vertical Injection Molding Market at 4.3% CAGR

The global Vertical Injection Molding Machine market, valued at USD 806.8 million in 2022, is set to expand at a robust CAGR of 4.3% between 2023 and 2031, reaching an estimated USD 1.2 billion by the end of 2031. This growth is propelled by technological advancements, rising demand for lightweight components across industries, and increasing integration of robotics and computerized molding processes.

Market Overview

Vertical injection molding machines feature a vertically oriented clamping and injection unit, leveraging gravity to enhance precision and energy efficiency. Their compact footprint makes them ideal for space-constrained production lines. Predominantly used in insert molding where pre-placed metal or other components are overmolded with plastic these machines serve diverse sectors including automotive, electronics, medical, packaging, and consumer goods.

Market Drivers & Trends

Energy Efficiency: Vertical machines consume less energy than their horizontal counterparts by minimizing continuous movement of clamping units.

Robotic Integration: Automation from component loading to part removal is driving productivity and quality. Manufacturers like Newbury offer C-Frame rotary table designs with turnkey robotic integration.

Lightweight Components Demand: The shift toward lighter plastic parts in automotive and electronics for fuel efficiency and portability is boosting demand.

Compact Footprint: Limited factory space in urbanized regions favors vertical designs, optimizing floor layouts.

Latest Market Trends

Hybrid Technologies: Blending hydraulic and electric drives to balance high clamping force with precision and lower maintenance costs.

All-Electric Vertical Machines: Gaining traction in cleanroom and medical device manufacturing for zero-emission operation.

IoT-Enabled Monitoring: Real-time data analytics to predict maintenance needs and minimize downtime.

Sustainable Materials: Compatibility with bio-based resins and recycled plastics to meet environmental regulations.

Key Players and Industry Leaders

ARBURG GmbH + Co KG

The Japan Steel Works, LTD.

Nissei Plastic Industrial Co., Ltd

Sumitomo Heavy Industries

Engel Austria

Milacron Holdings Corp

Tayu Machinery Co., Ltd

Wittmann Battenfeld GmbH

Shibaura Machine (Toshiba Machine Co., Ltd)

Pratishna Engineers Ltd

Toyo Machinery & Metal Co., Ltd.

Husky Injection Molding Systems Ltd.

Niigata Machine Techno Co., Ltd.

Preview essential insights and takeaways from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82265

Recent Developments

February 15, 2023: ARBURG’s Allrounder 470 H hybrid machine debuts, offering up to 30% energy savings and reduced carbon footprint compared to conventional models.

December 2022: JSW’s JLM3000-MGIIeL sets a new benchmark with its record 3,000-ton mold clamping force, addressing the needs of large-scale automotive and aerospace component production.

Q1 2024: Engel Austria unveiled its tie-barless vertical machine, enabling faster mold changeovers and expanded mold accessibility.

Q2 2024: Sumitomo introduced an integrated IoT platform across its vertical machine line, allowing remote diagnostics and process optimization.

Market Opportunities

Automotive Lightweighting: Rising adoption of plastic parts for interior panels, under-hood components, and structural elements.

Medical Device Manufacturing: Growth in single-use and precision-critical components, such as syringes, diagnostic cartridges, and implantable devices.

Consumer Electronics: Miniaturization trends demand complex, high-precision plastic housings and connectors.

Packaging Innovation: Demand for customized closures, caps, and tamper-evident designs in food, beverage, and personal care segments.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers new OEM and contract manufacturer partnerships.

Future Outlook

Analysts anticipate that continued R&D investment will yield machines with smarter controls, lower energy footprints, and greater flexibility for multi-material molding. The push toward Industry 4.0 will further accelerate adoption of vertical presses with embedded sensors, predictive maintenance algorithms, and seamless integration into fully automated production lines. By 2031, the market is expected to witness:

Wider Hybrid Adoption: Hybrid machines capturing significant market share by combining the strengths of hydraulic and electric systems.

Expanded All-Electric Use Cases: Particularly in sectors requiring ultra-clean operation and minimal noise.

Enhanced Circularity: Greater compatibility with recycled and bio-based polymers to meet sustainability targets.

Market Segmentation

Segment

Sub-Segment

Input Material

Plastic; Rubber; Others

Clamping Force

Up to 20 T; 21–40 T; 41–50 T; 51–70 T; 71–80 T; 81–100 T; > 100 T

Type

Hydraulic; Electric; Hybrid

Automation Grade

Automatic; Semi-automatic

End-Use

Consumer Goods; Automotive & Aerospace; Agriculture & Waste Management; Medical & Science; Electrical & Electronics; Construction; Packaging; Others

Regional Insights

Asia Pacific: Held the largest share in 2022 due to rapid automotive and consumer goods production, and ongoing urbanization driving factory expansions.

Europe: Accounted for 32.4% of the market in 2022, with strong demand for high-precision medical and automotive components; expected to remain stable through 2031 (~31.8%).

North America: Growing emphasis on reshoring and automation in plastics manufacturing; rising investment in electric vehicle components.