#MDPE PIPE MANUFACTURERS

Explore tagged Tumblr posts

Text

Dhananjay Polymers, Rajkot, Gujarat - Established in 2010, we are MDPE Pipe Fittings Manufacturers in Gujarat & Plumbing Pipes, HDPE Pipe etc.

0 notes

Text

MDPE and HDPE Pipe Market 2025

Medium-Density Polyethylene (MDPE) and High-Density Polyethylene (HDPE) pipes are widely used in various industrial and commercial applications due to their superior properties, including corrosion resistance, flexibility, and durability. MDPE pipes are known for their shock resistance and are predominantly used in gas distribution and plumbing applications. HDPE pipes, on the other hand, are utilized in water supply, sewage systems, and industrial pipelines due to their high strength and durability.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/664/global-mdpe-hdpe-pipe-forecast

Market Size

The MDPE and HDPE Pipe Market was valued at US$21,850 million in 2024 and is projected to reach US$32,700 million by 2032, growing at a CAGR of 5.2% during the forecast period. The increasing demand for durable and cost-effective piping solutions across industries, particularly in water supply and industrial applications, is fueling market growth.

The market's growth is driven by the increasing urbanization, rapid industrialization, and the growing need for efficient water management systems. Moreover, government initiatives focusing on infrastructural development and water conservation further boost the market demand.

Market Dynamics (Drivers, Restraints, Opportunities, and Challenges)

Drivers:

Growing Demand for Water Infrastructure – The increasing need for efficient water distribution and waste management systems is driving demand for HDPE and MDPE pipes.

Government Regulations and Policies – Governments across various regions are emphasizing the use of sustainable and environmentally friendly materials, boosting the adoption of MDPE and HDPE pipes.

Industrial Expansion and Urbanization – The rapid growth of industries and expanding urban infrastructure are significant factors propelling market growth.

Restraints:

High Initial Investment Costs – The cost of raw materials and manufacturing processes remains high, which could limit market penetration.

Availability of Alternatives – The presence of substitutes such as PVC and steel pipes poses a challenge to market expansion.

Opportunities:

Innovations in Pipe Manufacturing – The development of advanced, reinforced polyethylene pipes presents new growth opportunities.

Increasing Applications in Renewable Energy – The demand for durable piping solutions in solar and wind energy sectors is an emerging trend in the market.

Challenges:

Raw Material Price Fluctuations – Variability in the cost of polyethylene resins can impact the market.

Recycling and Environmental Concerns – While polyethylene pipes are durable, their recycling and disposal pose environmental challenges.

Regional Analysis

North America

The U.S. and Canada are leading the market due to the increasing adoption of advanced water management systems.

Government-led infrastructure projects and investments in oil and gas pipelines contribute significantly to market growth.

Europe

Germany, the UK, and France are key contributors to market expansion, with a strong focus on sustainable construction.

The EU's regulations promoting eco-friendly piping materials boost HDPE and MDPE adoption.

Asia-Pacific

China, Japan, and India dominate the market due to rapid industrialization and population growth.

Increasing investments in smart city projects and irrigation systems drive demand for HDPE and MDPE pipes.

South America

Brazil and Argentina are key markets, driven by government-led initiatives in water infrastructure development.

Middle East & Africa

The UAE and Saudi Arabia are investing in large-scale water supply and gas distribution projects, favoring the MDPE and HDPE market.

Competitor Analysis

The MDPE and HDPE Pipe Market is highly competitive, with key players focusing on expanding their production capacities and investing in R&D for product innovation. Some of the major companies include:

Aliaxis

Polypipe

Wavin

Radius Systems Ltd

Pipelife

Peak Pipe Systems

Durapipe

Market Segmentation (by Application)

Water Supply & Distribution

Gas Distribution

Sewage & Drainage Systems

Irrigation Systems

Industrial Piping

Telecommunication & Electrical Conduits

Market Segmentation (by Type)

PE80

PE100

By Material Type

Medium-Density Polyethylene (MDPE) Pipes

High-Density Polyethylene (HDPE) Pipes

By Diameter Size

Up to 20 mm

20 mm – 50 mm

50 mm – 110 mm

110 mm – 250 mm

Above 250 mm

By Pressure Rating

Low-Pressure Pipes

Medium-Pressure Pipes

High-Pressure Pipes

Key Company

Aliaxis

Polypipe

Wavin

Radius Systems Ltd

Pipelife

Peak Pipe Systems

Durapipe

Recent Developments:

1. GF Piping Systems Opens MDPE Pipe Manufacturing Plant in Cairo

In November 2024, GF Piping Systems, a division of Georg Fischer AG, inaugurated a new manufacturing facility in Cairo, Egypt. Developed through a joint venture with Egypt Gas and Green Coast Enterprises, the plant aims to meet the growing regional demand for reliable and sustainable infrastructure piping systems. The facility will produce Medium Density Polyethylene (MDPE) pipes and other specialized solutions to support energy efficiency and regional development.

2. Malpani Pipes Expands Product Line with PVC, HDPE, and MDPE Pipes

In February 2025, Malpani Pipes and Fittings Limited announced a significant expansion, introducing a new range of PVC pipes and enhancing production capacity. The expansion includes high-speed production lines for HDPE and MDPE pipes, adding 3,600 Metric Tonnes Per Annum (MTPA) to the company's total output. This initiative aims to improve manufacturing efficiency and strengthen Malpani Pipes' market presence.

3. WL Plastics Building $40M MDPE Pipe Plant in Texas

In June 2023, WL Plastics Manufacturing LLC announced the construction of a $40 million, 140,000-square-foot facility in Lubbock, Texas, dedicated to manufacturing MDPE pipes for the natural gas distribution market. The plant is expected to be fully operational by mid-2024, expanding WL Plastics' geographical footprint and product offerings across North America.

4. Alexander First Nation Opens HDPE Pipe Plant in Canada

In May 2024, Canada's Alexander First Nation invested C$15 million to open a polyethylene pipe plant in Edmonton, Alberta, becoming the first Indigenous community in Canada to operate such a facility. The 40,000-square-foot plant began operations in April 2024 with 15 employees running four HDPE extrusion lines, producing pipes for water and gas markets. The initiative aims to create jobs and support economic development within the community.

Geographic Segmentation

The MDPE and HDPE Pipe Market is segmented based on regions, including:

North America (U.S., Canada, Mexico)

Europe (Germany, France, UK, Italy, Russia, Nordic Countries, Benelux, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, Southeast Asia, India, Rest of Asia)

South America (Brazil, Argentina, Rest of South America)

Middle East & Africa (Turkey, Israel, Saudi Arabia, UAE, Rest of Middle East & Africa)

FAQ Section

1. What is the current market size of the MDPE and HDPE Pipe Market?

The MDPE and HDPE Pipe Market was valued at US$21,850 million in 2024 and is expected to reach US$32,700 million by 2032, with a CAGR of 5.2%.

2. Which are the key companies operating in the MDPE and HDPE Pipe Market?

Major players in the industry include Aliaxis, Polypipe, Wavin, Radius Systems Ltd, Pipelife, Peak Pipe Systems, and Durapipe.

3. What are the key growth drivers in the MDPE and HDPE Pipe Market?

Key drivers include rising demand for water infrastructure, government regulations promoting sustainable materials, and increasing industrial applications.

4. Which regions dominate the MDPE and HDPE Pipe Market?

Asia-Pacific, North America, and Europe are the leading regions, with strong demand in China, the U.S., Germany, and India.

5. What are the emerging trends in the MDPE and HDPE Pipe Market?

Emerging trends include the use of HDPE pipes in renewable energy sectors, increasing focus on eco-friendly materials, and advancements in pipe manufacturing technology.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/664/global-mdpe-hdpe-pipe-forecast

0 notes

Text

HDPE Pipe Fittings Manufacturer

For 15 years, MK Polyplast has reigned as Gujarat’s leading pipe and fitting manufacturer, renowned for unwavering quality, forward-thinking innovation, and affordability. Whether you need pipes, fittings, bathroom upgrades, or water storage solutions, MK Polyplast delivers excellence. Their Best Quality HDPE Pipes Fittings guarantee durability and reliability, while their High Quality MDPE Pipes stand the test of time. Choose MK Polyplast for all your piping needs and experience top-tier products with dedicated service. We are the best HDPE Pipe Fittings Manufacturer in Ahmedabad.

Modern piping systems require HDPE fittings because of their affordability, flexibility, and durability. Selecting the appropriate HDPE pipe fittings supplier is essential whether you require fittings for industrial, sewage, irrigation, or water supply applications. We are the best HDPE Pipe Fittings Provider in Ahmedabad.

1 note

·

View note

Text

Materials Used in Rotational Moulding

Rotational molding, or rotomolding, is an ingenious manufacturing process known for its ability to create hollow plastic products of various shapes and sizes. From kayaks and playground equipment to storage tanks and even intricate medical devices, rotomolding’s versatility is truly remarkable. But what makes all of this possible? The answer lies in the carefully selected materials that go into this fascinating process.

Polyethylene: The Rotomolding Champion

Polyethylene (PE) is the undisputed king of rotomolding materials. Its various forms dominate the industry due to a combination of factors:

Linear Low-Density Polyethylene (LLDPE): The most popular choice, LLDPE strikes a balance between flexibility and strength. It’s ideal for products that need a degree of impact resistance, such as toys, agricultural equipment, and automotive parts.

Medium-Density Polyethylene (MDPE): MDPE offers a bit more stiffness than LLDPE, making it suitable for containers, tanks, and outdoor furniture where rigidity is crucial.

High-Density Polyethylene (HDPE): This robust form of PE is known for its excellent chemical resistance and high-temperature tolerance. It’s commonly used for industrial tanks, chemical storage containers, and even kayaks that need to withstand harsh environments.

Cross-Linked Polyethylene (XLPE): XLPE takes the strength of HDPE to the next level through a process called cross-linking. This creates a tightly bonded molecular structure that makes XLPE incredibly tough and resistant to cracking. It’s used in demanding applications like underground pipes and high-performance tanks.

Beyond Polyethylene: Exploring Other Options

While polyethylene reigns supreme, other materials have found their niche in rotomolding:

Polypropylene (PP): PP is lighter and more cost-effective than PE, but it can be a bit more brittle. It’s often used for consumer products like luggage and outdoor furniture.

Polyvinyl Chloride (PVC): PVC offers exceptional chemical resistance and flame retardancy. It’s found in medical equipment, construction applications, and certain types of toys.

Nylon: Nylon boasts high tensile strength and wear resistance. It’s used in specialized products like military containers and certain industrial parts.

Enhancing Properties: The Role of Additives

To further customize the properties of rotomolded products, various additives are mixed into the base materials. These include:

UV Stabilizers: To protect products from the sun’s harmful rays and prevent fading.

Antioxidants: To slow down the degradation of plastics over time.

Flame Retardants: To improve fire safety in certain applications.

Colorants: To create a vast array of vibrant and custom colors.

The Future of Rotomolding Materials

The world of rotomolding materials is constantly evolving. Researchers are exploring new polymers and composite materials that could push the boundaries of what’s possible. These advancements may lead to even stronger, lighter, and more environmentally friendly rotomolded products in the years to come.

Choosing the Right Material: It’s All About the Application

The choice of material for a rotomolded product depends entirely on the intended use. Factors like strength, flexibility, chemical resistance, temperature tolerance, and even budget all play a role in the decision-making process.

In Conclusion

Rotational molding is a versatile and dynamic manufacturing process, and the materials used are the foundation of its success. Whether it’s the tried-and-true polyethylene or the specialized properties of other polymers and additives, the right material can make all the difference in creating a product that perfectly meets its intended purpose.

0 notes

Text

Best pipes for plumbing in India

Discover the best pipes for plumbing in India! Top PVC pipe manufacturers like Supreme Industries, Finolex Industries, Jain Irrigation, Ashirvad Pipes, Astral Pipes, and Prince Pipes lead the way. For hot water, CPVC pipes are the best, offering durability and high-temperature resistance. Skipper Limited is a top brand for CPVC pipes. PVC pipes resist corrosion and impact better than copper, making them ideal for high-traffic areas. Choose from a variety of options, including UPVC, CPVC, PPR, flexible plumbing pipes, MDPE, and composite pipes for all your plumbing needs. https://www.comaron.com/blog/pipe-brands-india

0 notes

Text

Comprehensive Guide to MDPE Pipe Fittings and HDPE Fittings Manufacturers

The sturdy PVC fittings from Mirajpipes.com may help you upgrade your plumbing system. For worry-free, leak-free pipes, put your trust in our quality. Buy today!

HDPE sprinkler pipes

0 notes

Text

https://waterboss.co.in/

HDPE PLB Pipes, MDPE Pipe fitting & Manufacturers offered by Dhananjay Polymers( Founder of Waterboss) from Rajkot, Gujarat, India.

0 notes

Text

Polyethylene Packaging 101: Understanding their Role in the Industry

Polyethylene is the most extensively used plastic globally, especially for packaging applications. Its longevity, versatility and affordability make it an ideal choice for different industries. Surfing the intricate world of packaging can be difficult due to the myriad properties and types available. Read on to understand the fundamentals of polyethylene packaging solutions and how to use them. Polyethylene product packaging serves as a cornerstone when it comes to modern packaging, renowned for its wonderful characteristics. Polyethylene caters to diverse industries, and its different forms are available, such as HDPE, LDPE, and LLDPE. Ranging from flexible pouches to rigid containers, polyethylene packaging safeguards products against chemicals, moisture and physical damage. They make a reliable choice for packaging requirements; polyethylene plays a key role in preserving product integrity and meeting unique demands.

Types of Polyethylene Packaging

Low-Density Polyethylene: LDPE is a flexible polyethylene type that is extensively used for packaging applications like shrink wraps, plastic bags and pouches. It provides strong resistance and is highly resistant to moisture, making it ideal for products that demand protection from external elements.

High-Density Polyethylene: HDPE is a robust and opaque type that is known for its strength and longevity. They are commonly used for bottles, jugs, jars and containers. HDPE provides amazing chemical resistance for food, beverages and household chemicals.

Linear Low-Density Polyethylene: LLDPE is a tough and flexible type of polyethylene that features a combo of LDPE and HDPE. They are commonly used for stretch wraps, industrial packaging and agricultural films due to their puncture resistance and stretchability.

Ultra-High Molecular Weight Polyethylene: This polyethylene type results in remarkable abrasion resistance and impact robustness. They are used for specifically crafted packaging applications like medical implants, conveyor components and protective liners.

Medium-Density Polyethylene: MDPE falls between high-density and low-density polyethylene in terms of properties and density. They are widely used for gas pipes, shrink films and film packaging. MDPE provides premium quality chemical resistance and toughness, making it ideal for various packaging requirements.

PROPERTIES OF POLYETHYLENE PACKAGING

Flexibility: Polyethylene packaging represents different degrees of flexibility based on the type used. LLDPE and LDPE are highly adaptable and flexible, which makes them ideal for flexible packaging applications like films and bags. HDPE, however, is rigid in nature, which makes it perfect for containers and bottles.

Chemical-Resistance: Polyethylene packaging provides robust resistance to various chemicals, including solvents, acids, and bases. This property makes it ideal for packaging different product types, including industrial chemicals, food and beverages, and industrial chemicals.

Moisture Barrier: Polyethylene packaging offers a robust barrier against moisture, preventing the contact of water vapor and maintaining the product’s integrity. This property is essential for products that are sensitive to moisture, including food items, electronics, and pharmaceuticals.

Toughness: Polyethylene packaging is resistant and has high toughness, protecting packaging products from damage during transit, handling and storage. This ensures that your products arrive at their destination in pristine condition, lowering the risk of product loss and returns.

Recyclability: When it comes to sustainability, polyethylene product packaging is biodegradable, making it an eco-friendly choice for packaging applications. Recycled polyethylene can be used to manufacture new packaging products, lowering the need for virgin plastic and reducing the overall environmental impact.

Understanding the types, properties and best practices associated with polyethylene packaging is essential for effectively utilizing this versatile material in packaging applications. By selecting the right type of polyethylene, optimizing its properties and following best practices for usage, businesses can ensure the integrity and performance of their packaging solutions while minimizing environmental impact. Are you ready to adopt polyethylene or heavy-duty plastic bags for your unique needs? Connect with the best manufacturer.

0 notes

Text

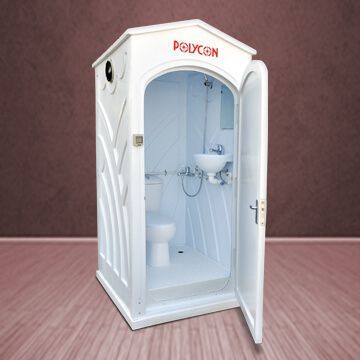

Polycon Gulf Ltd: A Leader in Quality Manufacturing for the UAE

Polycon Gulf Ltd., a subsidiary of the prestigious Al Nasser Industrial Enterprises LLC, stands as a leading manufacturer of high-quality products across various sectors. Established in 1993, Al Nasser Industrial Enterprises boasts a strong presence in the AGCC region, with manufacturing facilities spanning steel, polymers, fabrication, and industrial intermediates. Polycon Gulf Ltd. itself is a market leader in the UAE, recognized for its unwavering commitment to quality and exceptional customer service.

Polycon offers a diverse range of products, including:

- Water Tanks: Available in various sizes and configurations, Polycon's water tanks are ideal for residential, commercial, and industrial applications.

- Road Barriers: Polycon's robust track barriers ensure safety and traffic control on roadways across the UAE.

- Portable Restrooms: Polycon provides high-quality portable restrooms for events, construction sites, and other temporary needs.

- Inspection Chambers: Polycon offers durable inspection chambers for various underground applications.

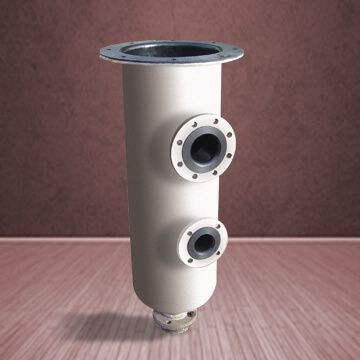

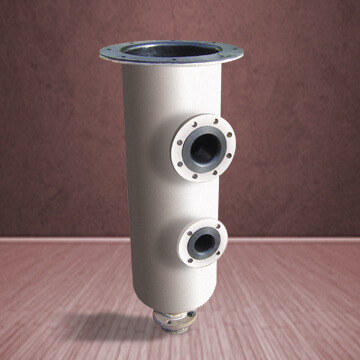

- Rotolining Services: Polycon provides expert rotolining services for enhancing the interior surfaces of carbon steel pipes and tanks.

Polycon prioritizes the use of medium-density polyethylene (MDPE) in its manufacturing process. This environmentally friendly material offers exceptional resistance to both physical and chemical damage, ensuring the longevity and reliability of Polycon's products.

Driven by a clear mission to create safe, strong, and durable products through continuous innovation, Polycon consistently strives to explore new applications and push boundaries within the industry. Their vision is to solidify their position as the leading rotomolding company in the GCC, achieved through unwavering commitment to innovation, best practices, and stringent quality standards.

Polycon's dedication to quality is evident in their meticulous design process, utilizing advanced analytical methods to optimize product thickness and minimize stress and deflection. This meticulous approach ensures that Polycon products can withstand heavy hydrostatic loads, offering years of reliable service. Furthermore, Polycon adheres to strict quality control measures aligned with the requirements of DIN ISO 9001:2008, guaranteeing the highest quality standards at every stage of production.

Whether you require water storage tanks in Abu Dhabi, portable restrooms for your next event, or any other product from their extensive range, Polycon Gulf Ltd. stands as a trusted and reliable partner in the UAE.

#Good Company For Water Tank#Horizontal Tank Suppliers In Al AIN#Water Tank Sharjah#Best Water Tank Supplier In Al AIN#Road Barriers In Uae#Best Quality Water Tank In Abudhabi

0 notes

Text

HDPE PLB PIPE MANUFACTURERS | MDPE PIPE MANUFACTURERS

HDPE PLB Pipes, MDPE Pipe fitting & Manufacturers offered by Dhananjay Polymers( Founder of Waterboss) from Rajkot, Gujarat, India.

HDPE PLB PIPE MANUFACTURERS, MDPE PIPE MANUFACTURERS

0 notes

Text

Vikas Ecotech Secures INR 200 Million Coal Supply Orders from Prism Johnson Limited

Vikas Ecotech Limited is delighted to announce the reception of orders amounting to approximately INR 200 Million for the supply of coal to the esteemed cement manufacturer, 'Prism Johnson Limited' (Cement unit II), which is promoted by the Rajan Raheja Group. The execution of this order will commence within the next 15 days and is scheduled for completion by 31 October 2023.

Vikas Ecotech Limited has been actively exploring business prospects within the Energy Segment, encompa08.ssing both traditional energy sources prevalent in India and the emergent domains of Renewable and Green Energy. The company has entered the conventional energy market through the supply of coal, a key energy source in India, with the intent to establish a solid presence in the Energy business segment. Concurrently, the company is also pursuing opportunities within innovative and futuristic Clean, Green, and Renewable Energy Materials and Products, including Solar, Gas, and cutting-edge Hydrogen Fuel Cells.

Opportunities in the Energy Segment: India's ongoing industrialization and urbanization are anticipated to place substantial demands on its energy sector and policy landscape. Despite India's energy consumption per capita being less than half of the global average, over 80% of the country's energy requirements are met by three conventional fuels: coal, oil, and solid biomass. Coal has long been a cornerstone of electricity generation and industrial expansion, maintaining its position as the predominant energy source. Simultaneously, oil and its imports have risen significantly due to increased vehicle ownership and road transportation.

While biomass, particularly fuelwood, constitutes a decreasing share of the energy mix, it remains prevalent as a cooking fuel. Despite progress in expanding the usage of LPG in rural regions, a significant portion of the Indian population, approximately 660 million individuals, still relies on traditional cooking fuels and technologies. Contemporary sources such as natural gas and renewable energy options have started gaining traction. Notably, solar Photovoltaics (PV) has experienced remarkable growth, with substantial resource potential and the convergence of policy support and technology cost reduction, positioning it as the most economical option for new power generation.

About Vikas Ecotech Limited:

Vikas Ecotech Ltd., headquartered in New Delhi, specializes in the production of Specialty Polymer & Specialty Additives and Chemicals for the Plastics & rubber industries. Its applications span diverse fields such as Agriculture, Infrastructure, packaging, electrical, footwear, pharmaceuticals, automotive, medical devices, components, and other consumer goods. The company holds the distinction of being the sole manufacturer of Organotin (Heat Stabilizers for Vinyl applications) in India, equipped with in-house R&D facilities. It is also one of the few global manufacturers with the capability to produce this product from Tin Metal to its final form. In addition to its core raw material businesses, Vikas Ecotech has expanded its product portfolio to include several consumer end-products, including Infrastructure Products like Steel Pipe Fittings and MDPE Pipes for Gas applications.

The company's securities are listed on BSE (Scrip Code: 530961) and NSE (Scrip Code: VIKASECO) stock exchanges.

0 notes

Link

These mdpe pipe manufacturers will be used for any project, no matter how large, including the construction of a house, an irrigation system, a hydro system, or a sewerage system.

0 notes

Text

Comprehensive Guide to MDPE Pipe Fittings and HDPE Fittings Manufacturers

MDPE Pipe Fittings

What is MDPE?

MDPE, or Medium Density Polyethylene, is a type of polyethylene characterized by its flexibility and resistance to impact. It is widely used in the gas and water industries due to its robustness and ease of installation.

Applications of MDPE Pipe Fittings

Gas Distribution: MDPE pipes are commonly used for gas distribution networks because of their ability to withstand high pressures and resist environmental stress cracking.

Water Supply: These fittings are ideal for potable water supply systems due to their resistance to corrosion and chemical leaching.

Industrial Applications: MDPE is used in various industrial processes where a durable and flexible piping solution is required.

Types of MDPE Fittings

Couplers: Used to connect two pipes of the same diameter.

Elbows: Allow pipes to change direction, usually available in 90 and 45-degree angles.

Tees: Facilitate branching of a pipe into two directions.

End Caps: Seal the end of a pipe.

HDPE Fittings

What is HDPE?

HDPE, or High-Density Polyethylene, is known for its high strength-to-density ratio. It is used in a variety of applications due to its durability and resistance to impact and chemicals.

Applications of HDPE Fittings

Water Distribution: HDPE pipes and fittings are extensively used in water distribution due to their ability to handle both high pressure and harsh environmental conditions.

Sewage Systems: Their resistance to chemicals and abrasion makes HDPE fittings ideal for sewage and drainage systems.

Agricultural Irrigation: HDPE is used in irrigation systems for its flexibility and long service life.

Types of HDPE Fittings

Reducers: Used to connect pipes of different diameters.

Saddles: Allow for branch connections without cutting the main pipe.

Flange Adapters: Facilitate the connection of HDPE pipes to metal pipes or valves.

Stub Ends: Used in conjunction with backing rings to form flanged connections.

Leading Manufacturers of MDPE and HDPE Fittings

Georg Fischer Piping Systems

Georg Fischer is a global leader in the manufacture of plastic piping systems, including MDPE and HDPE fittings. Their products are known for high quality, innovation, and reliability.

Fusion Group

Specializing in polyethylene pipes and fittings, Fusion Group offers a comprehensive range of MDPE and HDPE solutions. Their products meet international standards and are used in various industries worldwide.

Plasson

Plasson provides an extensive range of fittings for both MDPE and HDPE pipes. Known for their durability and ease of installation, Plasson fittings are widely used in gas, water, and industrial applications.

Aliaxis

Aliaxis is a leading HDPE fittings manufacturer of advanced plastic piping systems, including both MDPE and HDPE fittings. Their global presence and commitment to sustainability make them a preferred choice for many projects.

0 notes

Link

Waterboss Leading PVC Pipe & Fittings, PVC Pipe Reducer, PVC Tee & PVC Elbow, MDPE Pipe, Flow Control & HDPE Pipe manufacturer in Rajkot, Gujarat. Get more information Call: 9974465026 Now!

#pvc pipe manufacturer in Rajkot#pipe manufacturer in Rajkot#hdpe pipe manufacturer in Rajkot#mdpe pipe manufacturer in rajkot

1 note

·

View note

Text

Polycon Gulf Ltd: A Leader in Quality Manufacturing for the UAE

Polycon Gulf Ltd., a subsidiary of the prestigious Al Nasser Industrial Enterprises LLC, stands as a leading manufacturer of high-quality products across various sectors. Established in 1993, Al Nasser Industrial Enterprises boasts a strong presence in the AGCC region, with manufacturing facilities spanning steel, polymers, fabrication, and industrial intermediates. Polycon Gulf Ltd. itself is a market leader in the UAE, recognized for its unwavering commitment to quality and exceptional customer service.

Polycon offers a diverse range of products, including:

Water Tanks: Available in various sizes and configurations, Polycon's water tanks are ideal for residential, commercial, and industrial applications.

Road Barriers: Polycon's robust track barriers ensure safety and traffic control on roadways across the UAE.

Portable Restrooms: Polycon provides high-quality portable restrooms for events, construction sites, and other temporary needs.

Inspection Chambers: Polycon offers durable inspection chambers for various underground applications.

Rotolining Services: Polycon provides expert rotolining services for enhancing the interior surfaces of carbon steel pipes and tanks.

Polycon prioritizes the use of medium-density polyethylene (MDPE) in its manufacturing process. This environmentally friendly material offers exceptional resistance to both physical and chemical damage, ensuring the longevity and reliability of Polycon's products.

Driven by a clear mission to create safe, strong, and durable products through continuous innovation, Polycon consistently strives to explore new applications and push boundaries within the industry. Their vision is to solidify their position as the leading rotomolding company in the GCC, achieved through unwavering commitment to innovation, best practices, and stringent quality standards.

Polycon's dedication to quality is evident in their meticulous design process, utilizing advanced analytical methods to optimize product thickness and minimize stress and deflection. This meticulous approach ensures that Polycon products can withstand heavy hydrostatic loads, offering years of reliable service. Furthermore, Polycon adheres to strict quality control measures aligned with the requirements of DIN ISO 9001:2008, guaranteeing the highest quality standards at every stage of production.

Whether you require water storage tanks in Abu Dhabi, portable restrooms for your next event, or any other product from their extensive range, Polycon Gulf Ltd. stands as a trusted and reliable partner in the UAE.

#best water tank supplier in al ain#road barriers and safety barriers in abudhabi#sports track barriers in abudhabi#water tank suppliers near me#dual face pallets in uae#rotolining price in uae

0 notes

Text

Vikas Ecotech Limited’s Business update — Specialty Polymer Compounds Division

Vikas Ecotech Limited, a New Delhi-based company specializing in Specialty Polymer & Specialty Additives and Chemicals for the Plastics & rubber industries, is delighted to present the latest updates from its Specialty Polymer Compounds Division.

Over the years, the company has witnessed significant growth, with its Specialty Compounds and Chemicals business experiencing consistent year-on-year growth of more than 30% following the Covid-19 Crisis. Vikas Ecotech is proud to announce the acquisition of fresh orders worth over INR 200 Million in line with its commitment to expanding and diversifying its customer base.

These new orders have resulted in esteemed names joining the company's customer profile, including prominent industry leaders such as Olectra Greentech Limited, Polycab India Limited, DCW Limited, Khadim India Limited, Paragon Footwears, and various others within their respective product segments.

About Vikas Ecotech Limited:

Vikas Ecotech Ltd. is an organization dedicated to the business of Specialty Polymer & Specialty Additives and Chemicals for Plastics & rubber industries. With applications spanning Agriculture, Infrastructure, packaging, electrical, footwear, pharmaceuticals, automotive, medical devices and components, and other consumer goods, Vikas Ecotech caters to a diverse range of industries.

Notably, Vikas Ecotech stands out as the sole manufacturer of Organotin (Heat Stabilizers for Vinyl applications) in India. Equipped with in-house R&D facilities and boasting expertise in manufacturing the product from Tin Metal to the final stage, the company is among the select few worldwide with this technology.

In addition to its conventional raw material business, Vikas Ecotech has extended its product portfolio to encompass numerous consumer (final) products, including Infrastructure Products like Steel Pipe Fittings and MDPE Pipes for Gas applications.

Vikas Ecotech's securities are listed on the BSE (Scrip Code: 530961) and NSE (Scrip Code: VIKASECO).

0 notes