#Machining

Explore tagged Tumblr posts

Text

I swear to fucking god, I am going to drag every god damn engineer off their asses away from their monitors and force them to run these god damn milling programs that way they get a good understand about what the phrase ORDER OF OPERATIONS MEAN!!!!!!

For fucks sake the amount of interdependencies built into the tool paths is going to drive me mad I cannot simply adjust a single depth of cut why would I have to?! The maths told them that they could run every single tool off of a single offset.

If you are an engineer that follows me do every god damn shop guy a favor and take your head out of your ass, stop arguing with me when I have a problem with your programs I dont care what the math says to me that is barely anything more than educated guess work god damn it.

84 notes

·

View notes

Text

"Zero tolerance machining" NO!!!!! I am going to kill you. This doesn't exist. It's a stupid phrase. For advertising or whatever. If you genuinely think you've achieved "Zero tolerance" you have a #metrology #skillissue. I'm going to kill you. What's next, huh? When your machines advance even more? Negative tolerance? Short-sighted marketing. Just say the tolerance, that should be impressive enough. Regular people think "5 thou" is crazy, you will be ok. You don't need to lie about the world.

#Yes this is about the wire edm parts that are being reblogged and sexualized#ALSO!!! I'm pretty confident that each part is made of MULTIPLE pieces of metal#YES you can get really good tolerances with an EDM which is how those parts are possible BUT there has to be space for the wire to go#Two pieces are cleanly put together and then probably finished on a different machine so they look like one piece#If one piece was being machined into two pieces and then put back together there would be a larger gap. The end result wouldn't be as cool#Correct me if I'm wrong though I don't have a ton of experience with EDM in general#Machining#○

77 notes

·

View notes

Text

GE STEAM TURBINE & GENERATOR ROTORS ON FLOOR OF BLDG. 60, SCHENECTAOY WORKS.

17 notes

·

View notes

Text

bear creek NC

23 notes

·

View notes

Text

I made washers today

#hey g its me#.120 width .680 diameter .400 inner diameter#machining#this is the first thing ive made without a print. kinda hyped tbh#also with like a .010 tolerance. i didnt get it dead on but the original washer was so chewed up#just did my best guess. client liked it#said its perfect. no one is the wiser...

5 notes

·

View notes

Text

Steel swarf. Steel changes colour as it gets hot and these pieces got particularly hot.

7 notes

·

View notes

Text

Carl Edvard Johansson – Scientist of the Day

Carl Edvard Johansson, a Swedish tool maker, died Sep. 30, 1943, at the age of 79. In the 1890s, Johansson worked for a rifle factory in Eskilstuna...

learn more

#Carl Edvard Johansson#precision#machining#histsci#histSTM#19th century#20th century#history of science#Ashworth#Scientist of the Day

11 notes

·

View notes

Text

I’ve been a welder/machinist for 6 years now and I’ve listened to Les Mis at work since day one. If I’m not listening to some smutty fanfic, there’s a big chance I’m singing One Day More like I’m on broadway. This is the image it brings to mind. Super niche. I always picture the women in my shop with me. It makes more sense than it should

#les mis#les miserables#enjolras#eponine#cosette#victor hugo#theatre#musical theatre#theatre kid#welding#machining#machinist#woman welder#blue collar woman

45 notes

·

View notes

Note

I'm afraid to ask but are you using "explode" just to mean something went wrong or did they literally explode :o

Oh I mean EXPLODE quite literally frankly im amazed how little damage there was as the end mills I was running were in about 6-7 major chunks with small fragments of them just about everywhere.

Carbide is scary shit since the internal stressors of it as a material make it prone to exploding and shattering almost like glass when things go wrong with speeds feeds and tool paths

34 notes

·

View notes

Text

I love lathe work. I grind these funny tools that my coworkers think won't work. But they always make sense for my application.

The latest is a "heavy" style tool for aluminum. Slightly negative backrake, normal side rake, tip radiused only 40 thou or so. No secondary angles for chip thinning, or shear plane alteration, etc.

Just a slightly sharp brick of steel with the right clearance angles and a chipbreaker. It's perfect for the slow, torque-y lathe I'm running, as quick to touch up as it would be to switch inserts, and most importantly, it makes cooler chips than other tools would.

Check these things out:

Chips with the tool fed straight on. I increased my feed til I got perfect c's and 6's, and backed off just a bit. This is what chips look like when all the forces are straight towards the chuck, and kept in an equilibrium that doesn't quite break the chip.

When i needed to turn some shoulders, I rotated the toolholder a couple degrees. I could feed a little harder before breaking the chip, and there was now some directionality to the chip formation. That means I could make these tightly coiled lil snail guys.

These aren't the most perfectly efficient chips that could be made. There's plenty of problems with this method of doing things, in a general sense. But in this specific case, there is no difference, so I will be silly with it.

My only regret is that I haven't figured out anything artsy I can do with these chips yet. If i can't figure something out soon, they'll get recycled.

2 notes

·

View notes

Text

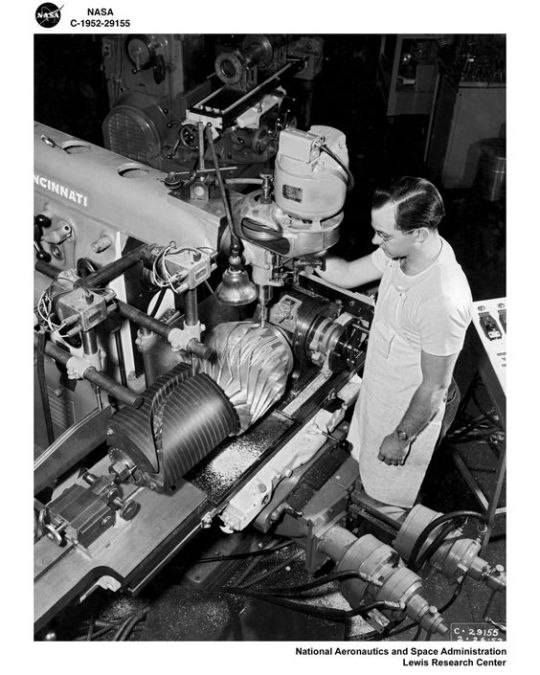

complex machining

23 notes

·

View notes

Text

The most beautiful girl is

the one who concentrates on her work,

would you agree?

paycnc.com

#girl #machining

3 notes

·

View notes

Text

I think one of the most interesting parts of my (thus short) career as a mechanical engineer is that we are taught all sorts of first-principles physics and complex science. And then it turns out that geometric dimensioning and tolerancing, one of the most important and fundamental areas of knowledge for mechanical design and manufacturing and assembly to the point that anybody even incidentally involved in it industrially is aware of it and why it is used, was not only not taught to us during our college education but was in fact not mentioned once at any point even during our drafting courses.

#Okay sure “well you don't need to know all of it to do most things”#“well you can probably pick it up on the job I guess”#I feel like it's still pretty important to know the existence of!!!#“yeah well if you were a good engineer you would have found out about it on your own”#I AM PAYING MONEY TO GET AN EDUCATION WHAT DO YOU THINK I AM TRYING TO DO BY DOING THAT#WHOSE IDEA WAS THIS??#Also lowkey GD&T is pretty fun#engineering#machining#stem#nerd shit#scienceblr#mathblr#before you get mad for me tagging this mathblr I think a lot of you would get a kick out of learning about GD&T#it's an interesting intersection of geometry and statistics

3 notes

·

View notes

Text

Discover Victora Auto's State-of-the-Art Quality Testing Facility

At Victora, every component is crafted with precision and excellence. From contour testing for ultimate accuracy to advanced thread monitoring that guarantees safety and efficiency, we leave no room for compromise. Our commitment to perfection continues with the CMM ensuring compliance with stringent standards, while our surface roughness testing ensures a flawless finish every time. Built on a foundation of trust, Victora’s products not only meet the highest quality benchmarks but also foster lasting relationships. Learn More: www.victora.co.in

#Victora#VictoraAuto#QualityAssurance#BesQuality#QualityInspection#CoordinateMeasuringMachine#ContourTesting#ThreadMonitoringSystem#XRayVisionSystem#AdvancedTechnology#TechnicalAdvancements#TechnologyUdgradations#PrecisionEngineering#MetalEngineering#ExcellenceInQuality#Metallurgy#Stamping#Forging#Machining#AluminumCasting#InvestmentCasting#AssembledComponents#TubeAndRodBending

2 notes

·

View notes

Text

I love talking to people who work in the same field that I do. A couple days ago I was hanging out with some friends from high school, and we were talking about someone else that we graduated with. One of my friends goes, "Yeah, he went to go work at ____ machine shop, and was fired within the week. He must've crashed a machine or otherwise fucked something up pretty badly."

We all nod. This tracks with everything that I know of the guy. My friend continues, "I get to visit different shops as part of my training, and guess what I saw?" We all wait expectantly.

"The shop only does fixture work!"

Everyone is dying of laughter. How do you fuck up fixture work that badly. In three days. Hilarious. What the fuck. This joke wouldn't land with many people but by god did it find its target audience.

7 notes

·

View notes