#Manufacturing Execution Systems

Explore tagged Tumblr posts

Text

Latest Manufacturing Software Development Companies 2025

Companies need advanced Software Development Companies to handle their operation need. This article represents the best Manufacturing Software Development Companies. Manufacturing Software development companies are rapidly growing. Manufacturers need trustworthy and feature-packed software automation development companies with the Internet of Things. In this article, we mentioned some best Manufacturing Software Development Companies in 2025. For more details, you can read this blog.

Read More - https://www.linkedin.com/pulse/top-manufacturing-software-development-companies-2025-haan-emani-hfbcf/

0 notes

Text

Manufacturing Execution Systems will be the most important part of smart manufacturing In 2025

Manufacturing Execution Systems (MES) have become the most important part of smart manufacturing in today's industries, which are changing very quickly. MES solutions are a key part of connecting production processes with real-time data analytics as businesses around the world move toward digital change. Not only are these systems useful for making operations more efficient, they are also the main force behind the fourth industrial revolution, which is making it possible for companies to reach new levels of quality, productivity, and sustainability.

What is a Manufacturing Execution Systems

A Manufacturing Execution System (MES) is a computer system that helps companies constantly monitor, manage, and improve their production processes. It makes sure that communication and data flow smoothly between enterprise resource planning (ERP) tools and operations on the shop floor. By combining data from machines, people, and materials, MES gives manufacturers useful information that they can use to make better decisions, cut down on waste, and raise the overall efficiency of their equipment (OEE) 14.

Key Trends That Will Shape MES in 2025

1. AI-Powered MES: Changing the Way Manufacturing Intelligence WorksThanks to artificial intelligence (AI), MES is becoming a dynamic, self-optimizing system. AI-powered algorithms make predictive repair, real-time production scheduling, and automated decision-making possible. AI can, for example, tell when equipment will break down before it does, which cuts down on downtime and boosts productivity. Over half of manufacturers will likely use AI-powered quality control and predictive repair systems by 2025. This will save them a lot of money and make their operations run more smoothly 15.

2. Edge computing: processing data in real-time at the source Source Edge computing is changing MES by bringing data processing closer to the factory floor. Edge computing cuts down on latency and makes sure that processes don't stop when the network goes down, unlike cloud computing, which uses remote servers. This technology is especially helpful in fields like medical devices and cars, where real-time tracking and finding problems are very important 17.

3. MES as a Service (MESaaS): The power to grow and change On the rise are cloud-based MES systems, also known as MES as a Service (MESaaS). MESaaS gives producers more ways to grow, lower start-up costs, and constant access to software updates. Most manufacturers will likely use cloud-based MES by 2025 to make their operations more flexible and speed up the digital revolution. 13.

4. IIoT Integration: Making Factories Smart When MES is combined with the Industrial Internet of Things (IIoT), plants become smarter and more linked. IIoT devices, like sensors and machines that are connected to the internet, send data to MES systems in real time that they use to track and improve production. This integration gives makers more information, lets them automate tasks, and sets up condition-based monitoring, which makes sure that everything always works at its best 17.

5. Sustainability: Making manufacturing more eco-friendly Manufacturers are putting sustainability at the top of their list of priorities, and MES systems are a big part of how they can reach these goals. Modern MES systems have tools for tracking carbon footprints, keeping an eye on energy efficiency, and cutting down on waste. Manufacturers can meet government rules, lessen their effect on the environment, and meet customer demands for greener production methods by using these tools 111.

What MES Does for Modern Manufacturing

Improving the efficiency of operations MES systems make production more efficient by giving real-time information about how machines are working, how resources are being used, and output schedules. This helps manufacturers find slow spots, improve workflows, and cut down on downtime, which leads to higher total efficiency 48.

Making sure of quality and compliance A very important part of MES is quality control. MES systems make sure that the quality of all products is always the same by keeping an eye on production in real time and finding problems early. MES also helps manufacturers follow industry rules and standards by keeping detailed records of all production actions 410.

Making it possible to trace and see MES systems help manufacturers to keep track of products from the raw materials they use to the finished goods they make. In fields like drugs and food and beverage, where product safety and compliance are very important 48, this ability is a must.

Problems with Putting MES in Place: Integration and Complexity Putting in place a MES system can be hard because it needs to be connected to other business systems like ERP, SCADA, and others. A big problem 46 is making sure that data is consistent and works on all of these systems.

Adapting the Workforce When MES is used, processes and job roles often need to be changed, which means that full training programs are needed. Manufacturers need to spend money to improve the skills of their employees so that implementation and management go smoothly 46.

Concerns about cybersecurity Cyber threats can get into MES systems because they handle private work data. To keep their operations safe, manufacturers must put strong cybersecurity measures like advanced encryption and multiple layers of defense at the top of their list of priorities 111.

A Way to Get to Industry 5.0 with MES in the Future MES systems will change to support human-centered manufacturing as we move toward Industry 5.0. In this type of manufacturing, AI and robots will work together with humans to improve efficiency and creativity. In 2025, MES will be a key part of this change that will help factories become more flexible, environmentally friendly, and competitive 711.

Manufacturing Execution Systems (MES) are no longer a have; companies that want to do well in the digital age need them. MES is changing the way things are made and leading the way for smart manufacturing in the future by using AI, edge computing, IIoT, and environmental tools. As businesses change, using cutting-edge MES systems is going to be important for long-term success and operational excellence. Original Reference - https://bipjacksonville.com/manufacturing-execution-systems-will-be-the-most-important-part-of-smart-manufacturing-in-2025

0 notes

Text

Best Auditorium Chair Manufacturers in Chennai

Are you looking for high quality Auditorium Chair from top Auditorium Chair Manufacturers in Chennai? Then you can look at VR office. You can obtain any kind of chairs that are theatre Chair, Visitor Chair, Office Chair, College Auditorium Chairs, you can check out @ https://www.vrofficeneeds.com/

#Modular furniture Manufacturers in Chennai#Auditorium Chair Manufacturers in Chennai#College Auditorium Chairs in chennai#Modular Workstation Manufacturers in Chennai#Modular Office Workstation Manufacturers in Chennai#Modular Office Workstation in Chennai#Office Workstation in Chennai#Modular Workstation in Chennai#Modular Cluster Workstation Manufacturers in Chennai#Linear Workstation Manufacturers in Chennai#Seating Systems in Chennai#Executive Chair Manufacturers In Chennai#Office Chair Manufacturers in Chennai#Visitor Chair Manufacturers in Chennai#Lounge Furniture Manufacturers in Chennai#Sofa Manufacturers in Chennai#Office Furniture Manufacturers in Chennai#Office Furniture And Table Manufacturers In Chennai#Reception Table Manufacturers In Chennai#Conference Table Manufacturers in Chennai#Steel Table Manufacturers in Chennai#Wooden Furniture Manufacturers in Chennai#Filing Cabinet Manufacturers in Chennai#Storage Rack Manufacturers in chennai#Steel Storage Rack Manufacturers in chennai#Wooden Rack Manufacturers in Chennai#School furniture Manufacturers in Chennai#Educational Furniture Manufacturers in Chennai#Library Furniture Manufacturers in Chennai#Computer Furniture Manufacturers in Chennai

2 notes

·

View notes

Text

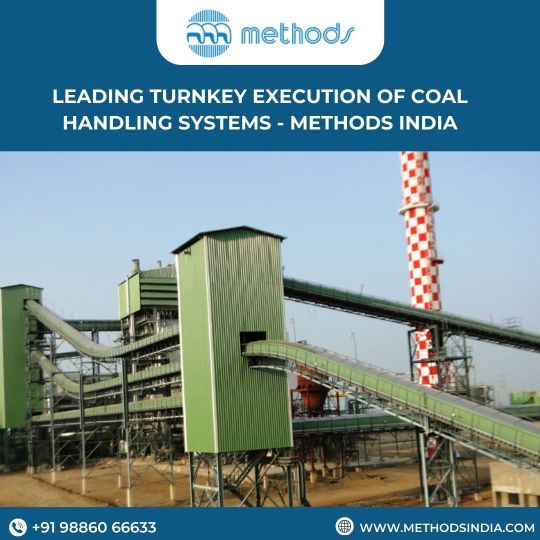

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

0 notes

Text

How Manufacturing Execution Systems Drive the Smart Factory Future

How Manufacturing Execution Systems Drive the Smart Factory Future

TThe digital revolution in the manufacturing sector is a movement rather than a slogan. And a main actor driving this change is Manufacturing Execution Systems (MES). MES is fast turning into a must-have in every smart factory’s arsenal in a time when speed, accuracy, and data-driven decision-making define success.

Define a manufacturing execution system.

Real-time monitoring, tracking, documentation, and process management for manufacturing is accomplished using a dynamic software solution known as a manufacturing execution system. Consider it as the digital link tying upper-level systems like ERP (Enterprise Resource Planning) to the shop floor. It provides manufacturers with insight into what is happening, when it is happening, and why, therefore enabling optimal control of everything from manufacturing planning to quality control.

Unlike conventional systems that run in silos, Manufacturing Execution Systems combine sensors, PLCs, and SCADA to provide a real-time view of your factory floor in concert with other tools. Lean production, waste reduction, and maximum throughput all depend on this kind of integration.

Why Manufacturing Execution Systems is Set to Trend in 2025?

Manufacturing Execution Systems are trending in 2025 mostly for a few main reasons:

Adoption of Industry 4.0 Companies are heavily funding smart manufacturing as Industry 4.0 emerges. Driven by syncing machines, operators, data in real-time, MES functions as the central nervous system to drive agility and responsiveness.

Resilience of the Supply Chain Manufacturers are laser-oriented on creating strong supply chains following the epidemic. All of which are vital in the dynamic market of today, MES helps forecast demand, effectively manage inventory, and fast adjust to changes.

Quality Assurance and Regulatory Compliance MES offers the documentation and traceability required for audits, quality control, and compliance as businesses , especially in pharmaceuticals, aerospace, and food & beverage , face tighter laws.

Labor and Skill Shortage By automating repetitive work, lowering reliance on manual labor, and enabling digital capture of tribal knowledge for future use, MES helps balance the labor scarcity.

Manufacturing Information System (MIS) versus MES

Although MES is sometimes included under Manufacturing Information Systems, it’s crucial to know the difference.

More focused on gathering and reporting historical data, Manufacturing Information System (MIS) aids managers in performance over time analysis.

Conversely, manufacturing execution systems run in real-time and let for instantaneous action and changes as events develop.

The sweet spot is when both systems cooperate: the MES feeds live data into the MIS so that decision-makers may see patterns and adjust their plans depending on real performance.

Essential Elements of a Modern MES Manufacturing execution systems of today are more advanced than they were years ago. These are some main characteristics promoting acceptance:

From human actions to machine condition, every detail is recorded as it occurs.

Dynamic changes schedules depending on real-time events including material shortages or equipment downtime.

Automatically points up flaws, follows accepted policies, and guarantees adherence to standards.

Track raw materials, components, and goods all around the production life.

Offering dashboards and KPIs like OEE (Overall Equipment Effectiveness), performance analytics helps to gauge success.

Advantages of Using Manufacturing Execution Systems sin Your Business Operations

MES has a difficult-to-overlook ROI. It offers value in your production process as follows:

Know exactly what’s going on the shop floor at all times.

Enhanced Efficiency: Find and remove cycle times, bottlenecks, and boost through-put.

Improved Product Quality: Standardize processes and guarantee constant production free of flaws.

Real-time data helps managers to act right away rather than depending on old reports.

Minimizing waste, downtime, and rework will help to significantly save over time.

MES in Use: Practical Application Let’s examine how a worldwide automobile parts company changed its processes with a Manufacturing Execution System.

The company battled uneven quality, regular equipment breakdowns, and missing delivery dates prior to MES. After applying MES:

Forecasting maintenance helped to lower machine downtime by 27%.

Real-time quality warnings helped to cut product flaws by 32%.

As scheduling got more accurate, on-time deliveries rose by 19%.

Thus, the outcome Better bottom line and more client happiness.

Cloud-Based MES: The Future Frontier

Rising cloud-based MES is among the most fascinating developments for 2025. Moving MES to the cloud will help manufacturers to enjoy:

Reduced upfront expenses — no on-site hardware needed

Monitoring remotely and gaining access

Scalability for worldwide projects

Faster updates and deployment

Key enabler of the digital factory are Cloud MES platforms, which are also simpler to interact with with other digital tools in the ecosystem including IoT platforms and AI-based analytics engines.

The Ahead Road Manufacturing has a flexible, linked, data-driven future. Center of this vision is manufacturing execution systems. MES systems are not only enabling manufacturers keep up but also helping them lead as they develop with artificial intelligence, machine learning, and predictive analytics.

Investing in a MES now will help your company future-proof rather than only maximize production. MES offers the competitive edge modern producers require in a world when milliseconds count and customer expectations are sky-high.

Last Notes Unquestionably, a Manufacturing Execution System is valuable whether you run a small batch operation or a large-scale worldwide plant. Together with a strong Manufacturing Information System, MES may open a new chapter of profitability, accuracy, and manufacturing capacity.

original reference – https://medium.com/@txdigitalteam/how-manufacturing-execution-systems-drive-the-smart-factory-future-10ec6194c7d0

0 notes

Text

The Importance of Manufacturing Execution System in Industry 4.0

Industry 4.0 marks a transformative era in manufacturing, defined by the integration of digital technologies to create smart factories. Central to this transformation is the Manufacturing Execution System (MES), which connects machines, systems, and humans in real-time. MES is pivotal in enhancing manufacturing processes, ensuring high standards in production, and enabling lean manufacturing principles.

Quality Management and Manufacturing Execution System

Quality management within Manufacturing Execution System is crucial for maintaining high production standards. MES captures and validates essential data such as results, comments, specifications, recipes, and procedural documents. This real-time data monitoring enables manufacturers to control quality effectively, providing insights through trends, statistics, and notifications to preempt potential issues. Additionally, MES generates test certificates and quality documentation, ensuring compliance with industry standards and customer requirements. By tracing quality issues back to their origin, MES fosters accountability and maintains customer trust.

MES Intelligence for Operational Efficiency

The intelligence component of MES significantly enhances decision-making on the shop floor. Manufacturing Execution System supports intelligent auto allocation and diversion, enabling optimal, real-time decisions. By continuously analyzing operating parameters, MES helps reduce failures and improve efficiency. This intelligence-driven approach minimizes waste, ensures effective resource utilization, and promotes a culture of continuous improvement in manufacturing.

Operational Flexibility and Security

MES enhances operational flexibility and security, crucial elements in the Industry 4.0 landscape. It allows manufacturers to adapt quickly to changing production demands and conditions, ensuring agility and competitiveness. Enhanced security measures within MES protect critical data and systems from potential threats, safeguarding the integrity of manufacturing operations.

Lean Manufacturing and MES

Lean manufacturing focuses on minimizing waste while maximizing productivity. MES plays a critical role in implementing lean principles by providing real-time data and insights that identify inefficiencies and streamline production processes. End-to-End (E2E) integration within Manufacturing Execution System connects various shop floor systems, such as CNC machines, Human-Machine Interfaces (HMI), and Supervisory Control and Data Acquisition (SCADA) systems. This integration ensures seamless production schedule downloads and parameter alignment, reducing errors and inefficiencies.

Machine Control and MES

Machine control within Manufacturing Execution System involves generating Process Data Interface (PDI) instructions that guide equipment operations. This precise control enhances consistency and quality, reducing variability and improving overall product standards. By maintaining stringent control over the manufacturing process, MES supports lean manufacturing goals of reducing waste and improving efficiency.

Real-Time Monitoring and Issue Response

MES enables real-time monitoring of production, allowing manufacturers to respond quickly to defects or delays. This proactive approach minimizes downtime and optimizes resource allocation, fundamental to lean manufacturing principles.

FG and WIP Inventory Management

MES tracks Work-in-Progress (WIP) at each production stage, generating real-time finished goods (FG) and WIP inventory records. By computing input material consumption using the Bill of Materials (BOM), Manufacturing Execution System updates WIP and raw materials (RM) inventory accurately. This real-time tracking reduces waste, avoids overproduction, and helps maintain optimal inventory levels.

RM Inventory Management

MES manages Material Requirements Planning (MRP) based on pending orders, available inventory, and existing purchase requisitions (PR) and orders (PO). It ensures RM is consumed in alignment with FG and WIP production at each stage. Manufacturing Execution System also facilitates the transfer of materials from stores to lines and tracks RM usage, ensuring efficient inventory management.

RM Inventory Control

Manufacturing Execution System defines minimum and maximum RM thresholds, generating orders to prevent overstocking and stockouts. This ensures uninterrupted production, maintaining a smooth manufacturing process.

As manufacturing evolves, the role of Manufacturing Execution System is becoming increasingly critical. It is no longer just a tracking tool but a comprehensive solution for managing the entire manufacturing lifecycle. With advancements in AI, cloud computing, IoT, and sustainability, MES drives innovation, growth, and adaptability. Manufacturers that leverage MES effectively will be better positioned to succeed in the evolving industrial landscape, achieving higher efficiency, quality, and agility.

0 notes

Text

MES System

Explore our comprehensive MES system, designed to streamline manufacturing processes and enhance production efficiency. Our MES courses cover key aspects of this essential Manufacturing Execution System, providing in-depth knowledge and practical skills for a competitive edge in your industry. Enroll today to master MES.

Get more details at: www.companysconnects.com/manufaturing-execution-system-mes

#pharmacovigilance courses#drug regulatory affairs certification#CSV Certification#Manufacturing Execution System

0 notes

Text

SAP S4 Training

Empower your professional journey with SAP S4 Training. Dive into a transformative learning experience, blending theory and practical application. Acquire proficiency in SAP's revolutionary ERP suite, positioning yourself as a sought-after expert in the ever-evolving realm of enterprise solutions.

Read More at: www.skillbee.co.in/certificatation-course-on-sap-s4-hana

1 note

·

View note

Text

Top 10 Manufacturing Execution Systems with Remote Monitoring Capabilities in 2025

Manufacturing Execution Systems (MES) help factories improve operations. These systems track production, monitor machines, and offer real-time updates. Many companies also want remote monitoring in their MES tools. This helps managers keep an eye on production from anywhere. Choosing the right system is not easy because there are many options.

Here is a list of the top 10 MES solutions in 2025 that include remote monitoring features. These platforms support smart manufacturing and offer clear benefits for industrial use.

1. Siemens Opcenter

Siemens Opcenter supports real-time production control. It also provides remote dashboards for monitoring factory data. Many manufacturers prefer it for complex operations.

2. Rockwell FactoryTalk

FactoryTalk offers solid MES functions. It also allows managers to access performance metrics from mobile devices. This helps reduce response times during issues.

3. GE Digital Proficy

Proficy is known for its user-friendly interface. It provides data tracking and remote alerts. It also fits well with both small and large plants.

4. Honeywell Manufacturing Execution System

Honeywell’s MES includes tools for quality control and machine tracking. Its remote monitoring view offers a detailed status of plant performance.

5. AVEVA Manufacturing Execution System

AVEVA delivers strong analytics and cloud access. Its remote features help in decision-making without needing physical presence on the shop floor.

6. Dassault Systèmes DELMIA Apriso

DELMIA Apriso supports real-time visibility. It helps connect production lines across locations. Its remote access helps global teams stay aligned.

7. ABB Ability Manufacturing Operations Management

ABB’s MES platform offers deep insights into factory operations. It includes tools for monitoring equipment health and energy usage remotely.

8. Plex Smart Manufacturing Platform

Plex includes native cloud architecture. It helps manage inventory and quality in real time. Its mobile-ready dashboards simplify remote monitoring.

9. Oracle Manufacturing Cloud

Oracle’s MES solution includes automation features and remote views. It supports flexible production models and works well across industries.

10. SAP Digital Manufacturing Cloud

SAP offers advanced MES tools with machine learning. It helps manufacturers adjust workflows quickly. Remote access helps improve visibility and collaboration.

Key Features You Might Find Useful:

Real-time production tracking

Mobile or web-based dashboards

Alert systems for downtime or quality drops

Integration with ERP and IoT platforms

Scalable options for different plant sizes

Solving the Selection Challenge

Many businesses feel lost while choosing the best manufacturing execution system. The wide range of choices leads to confusion. Some systems are too complex. Others do not offer enough support for monitoring outside the plant.

This blog helps narrow down the top options based on remote access, features, and ease of use. Each solution supports the shift toward smarter, more connected factories.

Factories need tools that support fast decisions. Remote monitoring adds value because it keeps operations visible and reduces delay. These MES systems help companies stay flexible and efficient in 2025.

0 notes

Text

Top Auditorium Chair Manufacturers in Chennai

VR Office Furniture’s are of best quality and every of these is vastly relaxed and robust. We are the top Auditorium Chair Manufacturers in Chennai. We manufacture and supply a broad variety of office chair, seminar chairs, theatre Chair, Visitor Chair, auditorium chair and College chairs in trendy, contemporary and attractive designs. Auditorium and theatre chairs are important components of venues intended to host events, performances, conferences, and presentations. Refer www.vrofficeneeds.com

#Auditorium Chair Manufacturers in Chennai#Modular furniture Manufacturers in Chennai#Modular Workstation Manufacturers in Chennai#College Auditorium Chairs in chennai#Theatre chair Manufacturers in chennai#Modular Office Workstation Manufacturers in Chennai#Modular Office Workstation in Chennai#Office Workstation in Chennai#Modular Workstation in Chennai#Modular Cluster Workstation Manufacturers in Chennai#Linear Workstation Manufacturers in Chennai#Seating Systems in Chennai#Executive Chair Manufacturers In Chennai#Office Chair Manufacturers in Chennai#Visitor Chair Manufacturers in Chennai#Lounge Furniture Manufacturers in Chennai#Sofa Manufacturers in Chennai#Office Furniture Manufacturers in Chennai#Office Furniture And Table Manufacturers In Chennai#Reception Table Manufacturers In Chennai#Conference Table Manufacturers in Chennai#Steel Table Manufacturers in Chennai#Wooden Furniture Manufacturers in Chennai#Filing Cabinet Manufacturers in Chennai#Storage Rack Manufacturers in chennai#Steel Storage Rack Manufacturers in chennai

0 notes

Text

#Manufacturing Execution System Market#Manufacturing Execution System Market size#Manufacturing Execution System Market share#Manufacturing Execution System Market trends#Manufacturing Execution System Market analysis#Manufacturing Execution System Market forecast

0 notes

Text

The Role of Manufacturing Execution System (MES) in Modern Manufacturing

In the rapidly evolving manufacturing industry, the pursuit of greater efficiency, superior quality, and thorough traceability has become crucial. A Manufacturing Execution System (MES) plays a key role in meeting these demands, acting as the essential bridge between enterprise resource planning (ERP) systems and the shop floor. By offering real-time visibility and control over production processes, MES empowers manufacturers to keep pace with the growing demands of modern production.

One of the standout features of MES is Track Genealogy, which allows manufacturers to trace the movement of materials throughout the entire production process — from raw materials (RM) to intermediate materials (IM) and finally to finished goods (FG). This detailed traceability is vital for identifying the root causes of defects, pinpointing improvement areas, and effectively handling customer complaints. By tracking the genealogy from RM to FG, MES facilitates the generation of FG numbers linked to key RM batch numbers, ensuring full transparency and accountability throughout the production cycle. This capability helps maintain high-quality standards and ensures regulatory compliance.

Another critical aspect of Manufacturing Execution System is the Shop-floor to Top-floor Integration, which provides real-time monitoring of various production parameters. These include inventory levels, order progress, production defects, delays, stoppages, yield, and production losses. This comprehensive visibility enables stakeholders at all organizational levels, from shop floor operators to top executives, to monitor operations seamlessly. Access to real-time data supports informed decision-making, allowing manufacturers to quickly address production issues, minimize downtime, and boost overall productivity.

Additionally, insights derived from MES data are essential for continuous improvement. Manufacturers can analyze historical data to detect trends and inefficiencies, enabling proactive process enhancements. This ongoing feedback loop ensures that production processes are consistently optimized, contributing to long-term operational success.

E2E Integration within MES is another cornerstone of its functionality. By connecting with Level 1 and Level 2 systems such as CNC machines, HMIs, and SCADA systems, MES enables the direct download of production schedules and parameters to shop floor equipment. This synchronization reduces errors and inefficiencies by ensuring that all production stages are aligned. Moreover, MES captures actual production data (PDO) from these systems, with a manual data capture option available for lines without Level 1 and Level 2 systems. This flexibility ensures data integrity across various production scenarios.

In summary, a Manufacturing Execution System (MES) is an indispensable tool for modern manufacturing. Its features — such as Track Genealogy, Shop-floor to Top-floor Integration, and E2E Integration — allow manufacturers to enhance efficiency, improve quality, and ensure compliance. By leveraging real-time data and fostering continuous improvement, MES helps manufacturers make informed decisions and maintain competitiveness in a dynamic market.

0 notes

Text

Manufacturing Execution Systems (MES) Market Size Growth Set to Surge Significantly during 2024-2031

Manufacturing Execution Systems (MES) market has witnessed substantial growth in recent years, becoming a pivotal component in modern manufacturing processes. MES is a comprehensive software solution that plays a crucial role in managing and optimizing manufacturing operations on the shop floor. Its primary objective is to enhance production efficiency, reduce errors, and provide real-time insights into the manufacturing process. As industries increasingly embrace automation and digitization, the MES market is poised for continued expansion. The concept of MES is widely recognized and used in manufacturing sectors such as automotive, semiconductor, electronics, food processing, pharmaceuticals, aerospace, medical devices, and textiles. Elements such as scheduling, maintenance management, quality, time, and attendance fall within the scope of MES and are used in all industries.

To Know the Global Scope and Demand of the Manufacturing Execution Systems (MES) Market | Request for Sample PDF: https://www.sanglobalresearch.com/enquiry/manufacturing-execution-systems-mes-market

One of the key drivers propelling the growth of the MES market is the relentless pursuit of operational excellence by manufacturing enterprises. MES enables companies to streamline their production processes, improve overall efficiency, and minimize waste. By providing real-time visibility into production metrics, MES empowers decision-makers to make informed choices, optimize resource utilization, and reduce production costs. The demand for MES solutions is further fueled by the need for better compliance with regulatory standards and industry norms, ensuring that manufacturers adhere to quality and safety standards.

Moreover, the growing trend of Industry 4.0 and smart manufacturing has been a significant catalyst for the MES market's expansion. As manufacturing facilities embrace the integration of IoT (Internet of Things) devices, sensors, and data analytics, MES becomes the linchpin connecting these technologies. MES not only facilitates communication between various manufacturing components but also helps in harnessing the power of data for predictive analytics and proactive decision-making. The ability of MES to foster connectivity and data-driven insights positions it as a crucial enabler for the digital transformation of manufacturing processes.

However, the MES market does face certain restraints that could impact its growth trajectory. Implementation costs and the complexity of integrating MES with existing systems pose challenges for some businesses. Small and medium-sized enterprises, in particular, may find the initial investment in MES implementation daunting. Additionally, concerns about data security and the potential disruptions during the transition phase can act as deterrents for organizations considering MES adoption. Overcoming these challenges requires careful planning, collaboration with experienced MES providers, and a phased approach to implementation.

Despite the hurdles, the MES market is poised for growth due to various favorable factors. The increasing demand for customized and configurable MES solutions tailored to specific industry requirements is creating new opportunities for market players. MES vendors are focusing on developing user-friendly interfaces and scalable solutions to cater to a diverse range of manufacturing environments. The emphasis on scalability ensures that MES can adapt to the evolving needs of businesses, making it a sustainable and future-proof investment.

Furthermore, the emphasis on sustainability and eco-friendly manufacturing practices is driving the adoption of MES. Manufacturers are leveraging MES capabilities to monitor and optimize energy consumption, reduce waste, and adhere to environmental regulations. As businesses increasingly recognize the importance of corporate social responsibility, MES becomes a strategic tool for aligning manufacturing operations with sustainable practices.

In conclusion, the Manufacturing Execution Systems market is witnessing robust growth driven by factors such as the pursuit of operational excellence, the advent of Industry 4.0, and the demand for sustainable manufacturing practices. While challenges such as implementation costs and integration complexities exist, the overall trajectory of the MES market is positive. As industries continue to prioritize efficiency, connectivity, and sustainability, MES will remain a crucial technology in the evolving landscape of modern manufacturing.

Market segment by players, this report covers

ABB

Accenture

Andea Solutions

Aptean

Dassault Systemes

Emerson

Eyelit

Fujitsu

GE Digital

HCL Technologies

Honeywell

IBASEt

Krones

Market Segmentation

The Manufacturing Execution Systems (MES) market is split by Type and by Application. For the period 2024-2031, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of value.

Market Segment by Type

On-Premises

On-Demand

Hybrid

Market Segment by Application

Beverages or Brewing Industrial

Refineries and Petrochemicals

Pharmaceuticals

Chemicals and Specialty Chemicals

Automotive

Machine or Plant Construction

Metal or Paper

Market segment by regions, regional analysis covers

North America (United States, Canada, and Mexico)

Europe (Germany, France, UK, Russia, Italy, and Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Australia and Rest of Asia-Pacific)

South America (Brazil, Argentina and the Rest of South America)

Middle East & Africa (Turkey, Saudi Arabia, UAE, Rest of Middle East & Africa)

Our More Reports:

Marketing Automation Market: https://sanglobalresearch.com/report/marketing-automation-market/3032

Software Consulting Market: https://sanglobalresearch.com/report/software-consulting-market/3020

Customer Data Platform Market: https://sanglobalresearch.com/report/customer-data-platform-market/3016

Visit Our Blogs:

Thank you for reading the report. The report can be customized as per the requirements of the clients. For further information or query about customization, please reach out to us, and we will offer you the report best suited for your needs.

About Us:

At San Global Research Report, we pride ourselves on our commitment to quality and accuracy. Our team of experienced researchers utilizes a combination of quantitative and qualitative methods to ensure that our findings are both accurate and reliable. With a strong emphasis on responsiveness, transparency, and collaboration, we work closely with our clients to understand their objectives and deliver actionable insights. Learn more about our research approach and how it can benefit your business.

Contact Us:

Address: Gera Imperium Rise, Phase 2 Hinjewadi, Pune, India

San Global Research | Web: http://www.sanglobalresearch.com

Direct Line: +91 9209275355

E-mail: [email protected]

0 notes