#EngineeringMaterials

Explore tagged Tumblr posts

Text

When comparing alumina tubes, quartz tubes, and silicon carbide tubes, each material offers distinct advantages and drawbacks based on factors like temperature resistance, mechanical strength, chemical resistance, and cost. Here’s a detailed comparison to help you choose the best option for your specific application:

Temperature Resistance

Alumina Tubes:

Withstand temperatures up to 1800°C or more, particularly when made from high-purity alumina (99.7% or higher).

Suitable for extreme high-temperature environments, such as furnaces and kilns.

Quartz Tubes:

Can withstand temperatures up to 1100°C.

Suitable for moderate temperature applications but not ideal for extremely high temperatures.

Silicon Carbide Tubes:

Have the highest temperature resistance of the three, handling temperatures up to 1600–2400°C depending on the grade.

Ideal for applications involving extremely high heat and harsh environments, such as high-temperature furnaces or combustion chambers.

Mechanical Strength

Alumina Tubes:

Excellent mechanical strength and durability, making them resistant to wear and stress at high temperatures.

Can withstand heavy mechanical and thermal loads.

Quartz Tubes:

Fragile compared to alumina and silicon carbide. Quartz is more prone to breaking under mechanical stress or impact, making it less durable.

Silicon Carbide Tubes:

Superior mechanical strength and hardness, making them highly resistant to wear, abrasion, and thermal stress.

Often preferred in environments with high mechanical loads.

Thermal Shock Resistance

Alumina Tubes:

Good thermal shock resistance, but not as high as quartz. Rapid heating and cooling can cause cracking if not managed carefully.

Quartz Tubes:

Excellent thermal shock resistance. Quartz can withstand sudden changes in temperature without cracking, making it useful in applications where rapid heating or cooling occurs.

Silicon Carbide Tubes:

Moderate thermal shock resistance, better than alumina but not as good as quartz. Silicon carbide is tough, but extreme temperature fluctuations can still pose a challenge.

Chemical Resistance

Alumina Tubes:

Highly resistant to chemical attack, especially from most acids and bases. Ideal for processes involving reactive chemicals at high temperatures.

Quartz Tubes:

High resistance to chemical corrosion, particularly in oxidizing environments. However, it can be attacked by strong alkaline substances at high temperatures.

Silicon Carbide Tubes:

Extremely resistant to chemical corrosion from a wide range of chemicals, including strong acids and alkalis. This makes it suitable for highly corrosive environments.

Electrical Insulation

Alumina Tubes:

Excellent electrical insulator at high temperatures, making it ideal for applications where electrical insulation is crucial (e.g., thermocouple protection).

Quartz Tubes:

Also a good electrical insulator, although alumina is generally preferred when higher thermal stability and electrical insulation are needed.

Silicon Carbide Tubes:

Not a good insulator, as silicon carbide has some electrical conductivity, especially at high temperatures. It’s more suitable for applications where electrical conductivity is not a concern.

Cost

Alumina Tubes:

Typically, mid-range in terms of cost. They offer a balance between performance and price, particularly for high-temperature applications requiring strength and durability.

Quartz Tubes:

Generally more affordable than alumina or silicon carbide, especially for moderate temperature applications. However, the fragility may lead to more frequent replacements.

Silicon Carbide Tubes:

More expensive than both alumina and quartz due to their superior properties. However, their durability and high-temperature resistance can justify the cost in demanding applications.

Applications

Alumina Tubes:

Used in furnaces, thermocouple protection, kiln furniture, high-temperature processing, powder processing, and scientific research.

Preferred when both high-temperature resistance and mechanical strength are required.

Quartz Tubes:

Used in optics, semiconductor processing, light sources, and moderate temperature applications where thermal shock resistance is critical.

Suitable for applications with rapid heating/cooling cycles but moderate temperature limits.

Silicon Carbide Tubes:

Used in high-temperature furnaces, combustion systems, heat exchangers, and abrasive environments.

Ideal for extreme temperature applications and environments with high mechanical or chemical stress.

Durability and Longevity

Alumina Tubes:

High durability, especially in high-temperature or chemically aggressive environments, leading to longer life spans compared to quartz.

Quartz Tubes:

Less durable due to their fragility, leading to shorter lifespans in environments with mechanical or thermal stress.

Silicon Carbide Tubes:

Highly durable, with excellent resistance to wear and tear, especially in abrasive or chemically corrosive environments.

#AluminaTubes#QuartzTubes#SiliconCarbideTubes#MaterialScience#HighTemperatureMaterials#IndustrialMaterials#FurnaceTechnology#ThermalResistance#MechanicalStrength#ChemicalResistance#ThermalShockResistance#MaterialComparison#EngineeringMaterials#HighTempApplications#CeramicMaterials#MaterialSelectionGuide#KilnTechnology#IndustrialEngineering#HeatResistantMaterials#AdvancedMaterials#ScientificResearchMaterials#ThermalInsulation#IndustrialFurnaces#MaterialDurability#ElectricalInsulation

2 notes

·

View notes

Text

Are you looking for quality Plastic Mold Steel in India?

When it comes to molding dreams, Virat Special Steels doesn’t just offer steel—it crafts possibilities!

DIN 2738 is the go-to choice for the plastic mold industry, especially when dealing with those big, beefy steel mold components. It’s like the reliable friend who handles high-temperature settings and tough mechanical conditions without breaking a sweat.

And guess what? Virat Special Steels offers Plastic Mold Steel (High Hard) with a hardness range of 410-420 BHN. They also provide Modified 2738 (HH) steel, specifically designed for plastic mold manufacturers. These steels are suitable for applications requiring high hardness and durability, making them ideal for creating molds that withstand significant wear and tear during the molding process.

It’s got better polishability than its cousin, 1.2312 (AISI P20+S). So, whether you’re molding plastic widgets or creating intricate shapes, DIN 2738 has your back like a trusty sidekick.

To get detailed Modified 2738 (HH) steel industrial grade steels, visit the website – www.viratsteels.com

Learn more: https://www.viratsteel.in/materials/premium-quality-high-hardness-plastic-mold-steel-supplier-in-india/

Contact us today to learn more about our products and services! 🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#din2738#plasticmouldsteels#plastic mould steel#p20ni#SteelSupplier#SteelIndustry#IndustrialSolutions#EngineeringMaterials

2 notes

·

View notes

Text

Buying GI Blind Flanges: A Step-by-Step Guide

GI Blind Flanges are a critical part of piping systems, used to close off pipe ends securely. Their applications span industries such as oil and gas, water treatment, and chemical processing. This guide breaks down what GI blind flanges are, their advantages, and how to purchase them effectively.

1. Understanding GI Blind Flanges

A GI Blind Flange is a solid disk with no central hole, designed to block the flow in a piping system by sealing off the pipe ends. Made from galvanized iron, these flanges offer enhanced resistance to corrosion, making them perfect for use in harsh conditions.

2. Advantages of GI Blind Flanges

Corrosion-Resistant: The galvanization process helps protect the flange from rust and corrosion, increasing its lifespan.

Cost-Effective: Compared to stainless steel flanges, GI blind flanges are typically more affordable while maintaining reliability.

Easy to Install: These flanges are designed for quick installation, saving both time and labor costs during setup.

Multiple Sizes Available: GI blind flanges come in a wide range of sizes, catering to different piping needs.

Handles High Pressure: GI blind flanges are built to withstand significant pressure, ensuring the piping system’s integrity under stress.

3. Price Range for GI Blind Flanges

Prices vary based on size and supplier, but here’s an approximate breakdown:

Small Sizes (½ inch to 2 inches): ₹60 - ₹180 per piece.

Medium Sizes (3 inches to 8 inches): ₹180 - ₹700 per piece.

Large Sizes (10 inches and above): ₹700 - ₹2,500 or more per piece.

4. Steps to Buy GI Blind Flanges

Identify Your Specifications: Determine the exact size and type of flange you need for your specific application.

Research Trusted Suppliers: Look for suppliers with good reputations for selling GI blind flanges. Reputable platforms include:

Udhhyog: Buy GI Blind Flanges

IndiaMART

TradeIndia

Alibaba

Compare Prices: Gather quotes from multiple suppliers to ensure you’re getting the best deal for your budget.

Check Product Quality: Verify that the flanges comply with industry standards and are manufactured to meet your project’s requirements.

Review Shipping Options: Don’t forget to factor in shipping costs and delivery timelines when finalizing your purchase.

Complete Your Purchase: Once you’ve chosen the right supplier, proceed with the order and monitor the shipping to ensure timely delivery.

#GIBlindFlange#IndustrialFlanges#PipeFlanges#GalvanizedIron#PipingSystems#IndustrialSupply#CorrosionResistance#PipingSolutions#EngineeringMaterials#Infrastructure#Udhhyog#FlangeManufacturers#FlangesAndFittings#IndustrialEquipment#SteelIndustry#OilAndGasIndustry#WaterTreatment#BuyFlanges#ConstructionMaterials#MechanicalEngineering#PipeFittings#UdhhyogSteel#BlindFlange

5 notes

·

View notes

Text

Polyurea Material for Modern Engineering 😮😆

#desiviralrecap#Polyurea#PolyureaCoating#EngineeringMaterials#ModernConstruction#WaterproofingSolutions#ProtectiveCoatings#ConstructionInnovation#DurableMaterials#IndustrialCoatings#AdvancedEngineering#PolyureaTechnology#FloorCoatings#SprayCoatings#CorrosionProtection#ConcreteProtection#SmartConstruction#BuildingMaterials#InnovationInEngineering#SurfaceProtection#SealantSolutions

1 note

·

View note

Text

#StainlessSteel#SteelTube#MetalFabrication#IndustrialSupplies#EngineeringMaterials#SteelIndustry#MetalWorks#SteelFabrication#TubeWelding#PrecisionEngineering

0 notes

Text

Why Electrical Engineers Choose UNISIL Varnishes

By Mane Grigoryan

When you think about protecting electrical components, the first thing that comes to mind probably isn’t varnish. But for electrical engineers, varnish is often the silent hero. It’s the last line of defense between reliable performance and catastrophic failure.

And at UNISIL—based in Hungary and operating across the USA—our varnishes are formulated to quietly deliver where it matters most: insulation, durability, and consistency.

But let’s step back a moment. What exactly is electrical varnish?

In simple terms, it’s a specialized coating applied to windings, coils, or electronic assemblies to insulate, protect, and sometimes even enhance heat dissipation. Think motors, transformers, generators—anything with copper winding that’s expected to run hot, resist moisture, and stay stable over time.

Now, not all varnishes are created equal. Some are rigid, brittle, or degrade in high humidity. Others give off unpleasant fumes during curing—an issue for both safety and regulatory compliance. That’s where silicone-based varnishes step in, especially the type we formulate at UNISIL.

Silicone varnishes aren’t just better—they’re different.

They offer excellent dielectric properties, meaning they insulate against high voltages without breaking down. They’re also highly resistant to thermal cycling—expanding and contracting with changing temperatures without cracking. This flexibility is crucial in applications like electric motors or inverters where heat fluctuates rapidly.

One of our clients—an industrial fan manufacturer in the Midwest—was struggling with early failure in motor coils. Their previous varnish was too stiff, causing microcracks over time. We replaced it with a flexible silicone varnish from our product range. It cured quickly, handled thermal shock, and didn’t off-gas during application. The failure rate dropped dramatically within six months.

That’s the kind of quiet reliability electrical engineers need. No drama. Just performance.

What else sets UNISIL varnishes apart? Customization. We don’t believe in off-the-shelf for complex systems. Our team adjusts viscosity, cure profile, and even color when needed. For low-volume, high-spec applications—say, aerospace or defense—we’ll work directly with engineers to meet precise design requirements.

And of course, we test. Dielectric strength. Arc resistance. Surface breakdown voltage. Our labs don’t just check boxes—they simulate real-world abuse.

Still, it’s not only about performance. Regulatory compliance plays a big role too. We ensure our varnishes meet RoHS, REACH, and relevant UL standards. Some even meet food-contact safety levels—not for eating, obviously, but because they’re clean and stable enough to be used in sensitive production environments.

Now, varnish might seem like a small part of a big machine. But for electrical engineers, it’s a make-or-break layer. The wrong varnish can lead to overheating, premature failure, or even fire. The right one? It becomes invisible—just doing its job, year after year.

That mindset—engineering with quiet precision—is what we at UNISIL believe in. It’s also what earned us a nomination for the 2025 Go Global Awards, hosted this November in London by the International Trade Council. And while it’s an honor to be recognized, it’s the people we’ll meet—engineers, innovators, manufacturers—that excites us most. This event isn’t just about awards. It’s a forum for problem-solvers to connect and shape the future.

Because in industries like ours, excellence doesn’t scream. It hums. Like a motor winding spinning perfectly, thanks in part to the right varnish.

So next time you flip a switch or start a motor, remember: somewhere in there, likely invisible, is a silicone varnish doing its part to keep the current flowing.

Quietly. Reliably. Just as it should.

#ElectricalInsulation#SiliconeVarnish#UNISIL#EngineeringMaterials#MotorProtection#DielectricCoatings#GoGlobalAwards2025#Hungary#USA#ManeGrigoryan

0 notes

Text

Structural Composites Market: Transforming Aerospace, Automotive & Energy Sectors

The structural composites market has witnessed significant growth in recent years, driven by advancements in material science and increasing demand across multiple industries, including aerospace, automotive, construction, and wind energy. Structural composites, often referred to as composite materials, are made by combining two or more materials that are superior in performance than individual components. These materials are lightweight, durable, corrosion-resistant, and provide enhanced mechanical strength, making them ideal for a wide range of applications.

Get a Free Sample Report - https://www.skyquestt.com/sample-request/structural-composites-market

The global structural composites market is expected to continue its growth trajectory, driven by technological innovations, increased awareness of environmental sustainability, and the rising demand for lightweight, high-performance materials. By 2032, the market is poised to expand significantly, with substantial contributions from key sectors, including aerospace and defense, automotive, and wind energy.

Market Size and Forecast

The global structural composites market was valued at USD 50.43 billion in 2024 and is projected to reach USD 94.81 billion by 2032, growing at a compound annual growth rate (CAGR) of 7.54% during the forecast period from 2025 to 2032.

Several factors contribute to the market's growth, including the increasing demand for lightweight materials, the rising need for energy-efficient solutions, and advancements in composite manufacturing technologies. Composites are particularly attractive for industries where strength-to-weight ratios are critical, such as in aerospace and automotive applications.

Key Market Segments

1. By Resin Type:

- Epoxy Resin: Epoxy resins are the most widely used in structural composites due to their superior mechanical properties, resistance to moisture, and excellent bonding capabilities.

- Polyester Resin: Used predominantly in automotive and construction applications, polyester resins are a more cost-effective option.

- Vinyl Ester Resin: Offering a balance between performance and cost, vinyl ester resins are used in applications like marine and automotive industries.

2. By Fiber Type:

- Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber composites are extensively used in aerospace, automotive, and sports equipment.

- Glass Fiber: Glass fibers are the most commonly used fibers in structural composites. They are cost-effective and widely used in construction, marine, and transportation sectors.

- Aramid Fiber: Aramid fiber composites offer high impact resistance and are used in applications that require ballistic protection, such as in defense and automotive sectors.

3. By Application:

- Aerospace & Defense: The aerospace industry remains a dominant sector for structural composites due to the material’s lightweight and high-strength properties. Aircraft manufacturers are increasingly adopting composites to reduce fuel consumption and improve efficiency.

- Automotive: Lightweight composite materials are essential for the automotive sector to improve fuel efficiency and reduce carbon emissions. With growing demands for electric vehicles (EVs), the automotive industry is turning to composites for body parts, interiors, and under-the-hood components.

- Wind Energy: Wind turbine blades are commonly made from composite materials, as they provide the necessary durability and strength while reducing the overall weight of the turbines.

- Construction: Structural composites are finding increasing applications in the construction sector, particularly in bridges, beams, and support structures, where strength and corrosion resistance are paramount.

- Marine: Composites are used in boat and ship construction due to their resistance to corrosion, weight reduction, and durability.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/structural-composites-market

Regional Market Analysis

1. North America: North America is one of the largest markets for structural composites, driven by the aerospace and automotive industries in the U.S. and Canada. The region is home to major aerospace manufacturers such as Boeing and Lockheed Martin, which are heavily investing in composite materials for aircraft manufacturing. Additionally, the push for fuel-efficient vehicles in the automotive sector continues to bolster the demand for lightweight materials.

2. Europe: Europe is another key market for structural composites, with strong demand coming from the automotive and wind energy sectors. The region's commitment to reducing carbon emissions and improving energy efficiency is a key driver of market growth. Leading countries like Germany, France, and the U.K. have seen significant investment in renewable energy infrastructure, including wind farms that rely on composite materials for turbine blades.

3. Asia-Pacific: The Asia-Pacific region is expected to experience the fastest growth in the structural composites market. The expanding automotive and construction industries in countries like China, Japan, and India are major factors contributing to the region's rapid market expansion. Moreover, the increasing investments in renewable energy and the aerospace sector in countries like China are fueling demand for structural composites.

4. Latin America and Middle East & Africa: The Latin American market for structural composites is gradually growing due to the construction and automotive sectors' increasing adoption of lightweight materials. Similarly, the Middle East and Africa region is showing promising growth, particularly in the aerospace and defense sectors, where composites are used for aircraft components.

Key Market Drivers

1. Increasing Demand for Lightweight Materials: One of the primary drivers of the structural composites market is the increasing demand for lightweight materials. Industries such as aerospace, automotive, and wind energy are seeking to reduce the weight of their products to improve fuel efficiency, reduce carbon emissions, and increase overall performance.

2. Advancements in Composite Manufacturing: Technological advancements in composite manufacturing techniques, such as automated fiber placement (AFP) and resin transfer molding (RTM), are making it easier and more cost-effective to produce high-quality composites. These advancements have made composites more accessible to a wide range of industries.

3. Environmental Sustainability: The growing emphasis on sustainability and environmental responsibility is driving the adoption of composite materials. Composites can help reduce fuel consumption and energy use in transportation, which aligns with global sustainability goals. Additionally, the longer lifespan and recyclability of certain composite materials make them attractive for companies seeking to minimize their environmental impact.

4. Growth in Aerospace and Automotive Sectors: The aerospace and automotive industries continue to be significant consumers of structural composites, with major companies like Boeing, Airbus, and Tesla adopting advanced composites in their products. The shift toward electric vehicles (EVs) is expected to further boost the demand for lightweight composite materials.

Take Action Now: Secure Your Structural Composites Market Today - https://www.skyquestt.com/buy-now/structural-composites-market

Challenges

Despite the significant growth prospects, the structural composites market faces several challenges, including:

- High Production Costs: The cost of producing composite materials, especially carbon fiber, remains high, which can limit their widespread adoption in cost-sensitive industries.

- Complex Manufacturing Processes: The manufacturing of structural composites requires specialized equipment and expertise, which can make it difficult for small and medium-sized enterprises to enter the market.

- Recycling Issues: While certain composites are recyclable, the recycling of composite materials remains a challenge, particularly for thermoset composites.

Top Players in Structural Composites Market

Owens Corning (USA)

Toray Industries, Inc. (Japan)

Teijin Limited (Japan)

Mitsubishi Chemical Holdings Corporation (Japan)

Hexcel Corporation (USA)

SGL Carbon (Germany)

Huntsman International LLC. (USA)

Solvay (Belgium)

Gurit Holding AG (Switzerland)

BASF SE (Germany)

3M (USA)

Hexion Inc. (USA)

Johns Manville (USA)

Saint-Gobain (France)

Kordsa (Turkey)

Lanxess AG (Germany)

China Jushi Co., Ltd. (China)

Avient Corporation (USA)

Borealis AG (Austria)

Celanese Corporation (USA)

Read Structural Composites Market Report Today - https://www.skyquestt.com/report/structural-composites-market

The global structural composites market is poised for significant growth through 2032, driven by increasing demand for lightweight, high-performance materials across industries such as aerospace, automotive, and wind energy. The continued advancement in manufacturing technologies and a growing focus on sustainability will play key roles in shaping the market's future. However, challenges related to production costs, manufacturing complexity, and recycling must be addressed to unlock the full potential of structural composites in the coming years. With ongoing research and development, the market is expected to witness the emergence of innovative solutions that will further expand the scope of composites in various industries.

#StructuralComposites#CompositeMaterials#MaterialsScience#AdvancedMaterials#CompositesMarket#SmartMaterials#GlobalMarketTrends#EngineeringMaterials#HighPerformanceMaterials#LightweightMaterials#AerospaceEngineering#AutomotiveInnovation#WindEnergy#SustainableConstruction#GreenEnergy#MarineEngineering#ElectricVehicles#EVMaterials#DefenseTechnology#InfrastructureInnovation

0 notes

Text

How many types of solder bars are there?

Solder bars play a crucial role in metal joining applications across various industries — from electronics and automotive to plumbing and electrical assembly. Despite being small in size, the type of solder bar you choose can significantly impact the strength, conductivity, and reliability of the joint.

So, how many types of solder bars are there? The answer depends on composition, application, and whether the bar is lead-based or lead-free.

Let’s take a closer look.

🔹 1. Tin-Lead Solder Bars (Sn-Pb)

This is the most traditional type of solder bar, commonly used in the past across many industries. It consists primarily of tin (Sn) and lead (Pb), and is available in different ratios.

Common Ratios:

60/40 (60% Tin, 40% Lead)

63/37 (Eutectic alloy) – Offers a sharp melting point at 183°C, which makes soldering faster and cleaner.

Advantages:

Smooth flow and excellent wettability

Strong, reliable joints

Cost-effective

Disadvantages:

Not environmentally friendly (due to lead content)

Restricted in many countries due to health and safety regulations (e.g., RoHS)

Best for: Legacy systems, industrial applications where RoHS compliance is not required.

🌿 2. Lead-Free Solder Bars

With global regulations pushing for safer, non-toxic materials, lead-free solder bars have become the industry standard in consumer electronics and industrial manufacturing.

These bars contain tin as the base metal, alloyed with other metals like copper, silver, or bismuth.

Common Lead-Free Compositions:

SAC305 – Tin (96.5%), Silver (3%), Copper (0.5%)

Sn-Cu – Tin (99.3%), Copper (0.7%)

Sn-Bi – Tin and Bismuth (used for low-temperature applications)

Advantages:

Environmentally safe and RoHS compliant

Good mechanical strength and thermal stability

Excellent for high-reliability applications

Disadvantages:

Higher melting points compared to leaded solder

Can be more expensive due to silver content

Best for: Electronics, consumer products, automotive, medical devices.

🧪 3. Specialty Solder Bars

These solder bars are designed for specific industrial requirements and may have unique alloy compositions or surface treatments to enhance performance.

Examples Include:

High-Silver Solder Bars – Provide excellent conductivity and joint strength; used in aerospace, defense, and precision electronics

Low-Residue Solder Bars – Leave minimal flux residue; ideal for cleanroom environments

Antioxidation Coated Solder Bars – Prevent surface oxidation during storage and reflow processes

Advantages:

Tailored for niche applications

Improved long-term performance

Consistent quality under challenging environments

Best for: Aerospace, solar panels, military-grade electronics, medical instruments.

📌 Summary Table

Solder Bar TypeMain CompositionRoHS CompliantApplicationTin-Lead (Sn-Pb)Tin + Lead❌Traditional soldering, legacy equipmentSAC305Tin + Silver + Copper✅General electronics, SMT assemblySn-CuTin + Copper✅Electrical wiring, plumbingSn-BiTin + Bismuth✅Low-temp applications, sensitive componentsSpecialty BarsVaries (Silver-rich, coated)✅High-reliability industries

🔧 Choosing the Right Solder Bar

The ideal solder bar for your process depends on:

Required melting temperature

Mechanical and electrical performance needs

Regulatory compliance (e.g., lead-free requirements)

Environmental conditions of the application

Compatibility with automated or manual soldering systems

🏭 Hiflo Solders – Trusted Manufacturer of Quality Solder Bars

At Hiflo Solders, we manufacture a full range of:

Tin-Lead Solder Bars

Lead-Free Solder Bars (SAC, Sn-Cu, Sn-Bi)

Specialty Custom Alloys

Solder products designed for optimal flow, strength, and conductivity

With decades of expertise and a commitment to quality, our products are widely used in PCB assembly, electrical manufacturing, and industrial soldering lines.

🔗 For professional-grade soldering results, choose the right alloy — choose Hiflo.

📩 Interested in bulk orders or custom formulations? Contact our technical team today!

#SolderBars#HifloSolders#LeadFreeSolder#SnPb#SAC305#ElectronicsManufacturing#PCBAssembly#SolderingSolutions#EngineeringMaterials#ManufacturingInnovation#IndustrialSoldering#MetalAlloys#SmartSoldering

0 notes

Text

Explore top-quality cold drawn stainless steel pipe, tubing, seamless pipe, carbon steel pipe, and metal pipe by Heavy Metals & Tubes – precision-engineered for industrial excellence.

#StainlessSteelPipe#StainlessSteelTubing#ColdDrawnSteel#SeamlessPipe#MetalPipe#CarbonSteelPipe#IndustrialPipes#SteelManufacturing#HeavyMetalsAndTubes#SteelSolutions#PipingSolutions#PrecisionPipes#SteelIndustry#EngineeringMaterials#MadeInIndia"

0 notes

Text

Monel 400 Fastener Manufacturer, Supplier & Exporter

Introduction to Monel 400 Fasteners

In industries where corrosion resistance and durability are paramount, Monel 400 fasteners have carved out a significant niche. Made predominantly from a nickel-copper alloy, Monel 400 is celebrated for its superior resistance to seawater, acidic media, and caustic substances. As industries like marine, oil & gas, chemical processing, and power generation demand materials that can withstand harsh environments, Monel 400 fasteners have emerged as a top choice.

As a leading Monel 400 Fastener Manufacturer, we understand the technical demands and exact specifications required for critical applications.

What is Monel 400?

Monel 400 is a single-phase alloy predominantly consisting of:

Nickel (63% minimum)

Copper (28-34%)

Trace amounts of iron, manganese, carbon, and silicon

This composition imparts Monel 400 with outstanding strength and corrosion resistance over a broad temperature range, making it particularly resistant to:

Seawater corrosion

Hydrofluoric acid

Sulfuric acid

Alkalis

High-velocity saltwater and steam

Types of Monel 400 Fasteners

As a specialized manufacturer, we offer a comprehensive range of Monel 400 fasteners, including:

1. Bolts

Hex Bolts

Heavy Hex Bolts

Stud Bolts

U-Bolts

J-Bolts

Anchor Bolts

Eye Bolts

Machine Bolts

2. Nuts

Hex Nuts

Heavy Hex Nuts

Lock Nuts

Nylock Nuts

Wing Nuts

Cap Nuts

3. Screws

Hex Head Screws

Socket Head Screws

Self-Tapping Screws

Machine Screws

Wood Screws

4. Washers

Flat Washers

Spring Washers

Lock Washers

Beveled Washers

5. Custom Fasteners

Precision-made according to customer drawing and specification

Applications of Monel 400 Fasteners

Because of their superior corrosion resistance and robust mechanical properties, Monel 400 fasteners find widespread application in:

Marine Engineering

Offshore Oil & Gas Platforms

Shipbuilding

Chemical Processing Plants

Heat Exchangers

Pumps and Valves

Desalination Plants

Nuclear Industry

Aerospace Components

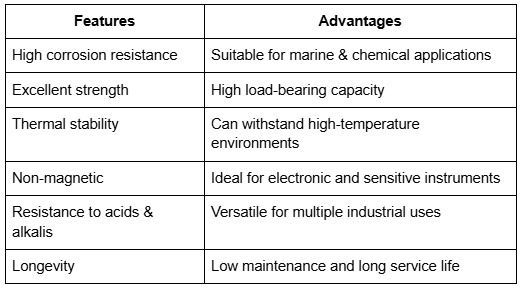

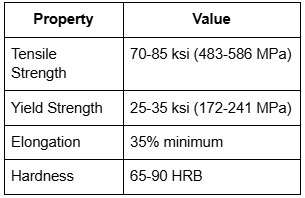

Key Features & Advantages

Chemical Composition of Monel 400

Mechanical Properties of Monel 400

Why Choose Us as Your Monel 400 Fastener Manufacturer?

As a trusted Monel 400 Fastener Manufacturer, Supplier, and Exporter, we provide:

Strict Quality Control: Every batch undergoes thorough inspection and testing.

Customized Solutions: Fasteners manufactured as per ASME, ASTM, DIN, ISO, BS, EN standards.

Global Delivery: Serving clients in the USA, Europe, the Middle East, Asia, and Africa.

Competitive Pricing: Direct manufacturer pricing without compromising on quality.

Quick Turnaround Time: Fast production and delivery to meet urgent project deadlines.

After-Sales Support: Full technical support even after product delivery.

Standards & Specifications We Follow

ASTM B164 / B865 / B366

ASME SB-164 / SB-865 / SB-366

DIN, ISO, EN Standards

Testing & Certifications

Our Monel 400 fasteners are tested as per international standards for:

Tensile strength

Hardness

Impact resistance

Intergranular corrosion test

PMI (Positive Material Identification)

Ultrasonic testing

Third-party inspection (on request)

Certificates provided include:

Mill Test Certificate (EN 10204 3.1/3.2)

Raw material certificate

Third-party inspection reports

NACE Compliance (if required)

Export Destinations

We supply Monel 400 fasteners to several countries, including:

USA

Canada

Germany

UAE

Saudi Arabia

Qatar

Singapore

Malaysia

Australia

South Africa

UK

Europe

Conclusion

Monel 400 fasteners offer an ideal solution for industries requiring exceptional corrosion resistance, high strength, and long-term reliability. As a leading manufacturer, we combine world-class manufacturing practices with stringent quality control to deliver fasteners that meet the highest industry standards. Whether you need standard sizes or custom designs, we can fulfill all your fastener requirements globally.

Frequently Asked Questions (FAQ)

1. What makes Monel 400 fasteners special?

Monel 400 fasteners provide outstanding corrosion resistance in seawater and chemical environments, combined with high strength and durability, making them perfectly suited for harsh and demanding conditions.

2. Can you manufacture custom-size Monel 400 fasteners?

Yes, we offer fully customized manufacturing services based on client drawings, sizes, and specifications.

3. Do you provide third-party inspection reports?

Yes, third-party inspections and certification are available on request.

4. Can Monel 400 fasteners be used in high-temperature environments?

Yes, they perform well at elevated temperatures, maintaining strength and corrosion resistance.

5. What is your delivery time?

We maintain a sufficient stock of standard sizes and offer fast delivery for custom orders, depending on order volume and complexity.

#Monel400#MonelFasteners#HexBolt#HexNut#NickelCopperAlloy#AnankaFasteners#FastenerManufacturer#EngineeringMaterials#PrecisionEngineering#IndustrialSupply#BoltsAndNuts#MetalAlloys#Blog#Articles#Monel400Fasteners#tumblr#blog tumblr

0 notes

Text

Buy Precision 316 Metric Rods Online – USA Delivery Available

Looking for high-quality 316 stainless steel rod products for your industrial, fabrication, or engineering applications? At Alexandria Precision, we specialize in supplying precision ground 316 metric rods that meet the exacting standards of today’s industries. Whether you're machining complex parts or need corrosion-resistant rods for marine environments, our products deliver strength, precision, and performance.

Let’s explore why 316 metric rods are the trusted choice across multiple industries—and how you can conveniently order them online with fast shipping across the USA.

What Makes 316 Stainless Steel Rods Unique?

316 stainless steel is a high-performance austenitic alloy valued for its exceptional resistance to corrosion, particularly in harsh, chloride-heavy settings like marine environments and chemical processing facilities. Its added molybdenum content makes it more resilient than 304 stainless steel, particularly against pitting and crevice corrosion.

Key Properties of 316 Stainless Steel Rods:

Excellent corrosion resistance in saltwater and chemical environments

High tensile strength and durability

Non-magnetic and easy to fabricate or weld

Temperature-resistant for use in both hot and cold applications

Because of these advantages, 316 stainless steel rod is commonly used in:

Marine equipment

Pharmaceutical and food processing equipment

Medical devices

Aerospace components

Industrial machinery

Why Choose Precision Ground 316 Metric Rods?

When tolerances matter, standard rods just won’t cut it. Precision-ground rods offer the dimensional accuracy and surface finish required for high-performance parts.

Our 316 metric rods are:

Centerless ground to h6 tolerances

Available in a wide range of metric diameters

Supplied in custom lengths as per your requirements

Manufactured with strict quality control for consistent results

These rods are ideal for precision machining, CNC applications, and tight-tolerance components.

Alexandria Precision – Your Trusted Source

At Alexandria Precision, we’re more than just a supplier—we’re a reliable partner for engineers, machinists, and business owners who demand precision.

We offer:

A large in-stock inventory of 316 metric rods

Online ordering with secure checkout

Cut-to-length service

USA-wide delivery with fast turnaround times

Friendly, knowledgeable customer support

We provide precision-ground 316 stainless steel rod products that meet the needs of industries ranging from aerospace to manufacturing—all from a single trusted source.

Applications Across Industries

316 metric rods are highly versatile and used in a range of fields:

Medical Equipment: Non-reactive and easy to sterilize

Aerospace: Lightweight, durable, and corrosion-resistant

Food & Beverage: Compliant with sanitation standards

Energy & Power: High resistance to chemical exposure and temperature extremes

Industrial Manufacturing: Ideal for bushings, shafts, and guide rails

No matter your industry, we make it easy to buy 316 metric rods online with confidence.

Need Help Choosing the Right Size?

We know that choosing the right diameter and length is critical. Our website includes a detailed size chart, and our team is always ready to help you select the perfect fit for your application.

FAQs – 316 Stainless Steel Metric Rods

What’s the difference between 316 and 304 stainless steel rods?

The key difference is that 316 stainless steel contains molybdenum, which greatly enhances its resistance to corrosion, particularly in environments with chlorides or strong chemicals. This makes 316 the preferred choice for marine, coastal, and industrial chemical applications, whereas 304 is better suited for general-purpose use.

Can I request custom cut lengths?

Yes! We offer cut-to-length service for all our rods so you receive exactly what you need—no more, no less.

Do you ship across the USA?

Yes, we ship across the USA with quick and dependable service—most orders are packed and shipped within just 1–2 business days.

Are your 316 metric rods centerless ground?

Yes, all our rods are precision-ground to h6 tolerances using the centerless grinding method to ensure a smooth surface finish and accurate dimensions.

Can I use these rods for medical-grade applications?

Yes, 316 stainless is commonly used in medical tools and equipment because of its excellent corrosion resistance and non-reactive properties.

Quick Summary

316 stainless steel rods deliver outstanding strength, excellent corrosion protection, and tight dimensional accuracy—ideal for tough industrial applications. With Alexandria Precision, you can confidently buy 316 metric rods online and get fast delivery across the USA—backed by quality you can trust.

#316StainlessSteel#StainlessSteelRods#MetricRods#PrecisionGround#AlexandriaPrecision#ManufacturingSolutions#IndustrialSupplies#MetalFabrication#EngineeringMaterials#CNCMachining#AerospaceEngineering#MarineGradeSteel#IndustrialComponents#BuyOnlineUSA#MadeInUSA#CustomMetalParts#FastShippingUSA#ShopIndustrial

0 notes

Text

Are you looking for Quality #DieSteel in India? Ready to elevate your projects with top-quality die steel? Contact Virat Special Steels Pvt. Limited!

Contact Us Today !

Discover Quality Die Steel with VIRAT SPECIAL STEELS PVT. LIMITED , INDIA. As the leading die steel supplier in Delhi NCR and India, Virat Special Steels takes pride in delivering exceptional quality and reliability. Specializing in DB6 / DIN 2714 / AISI L6, we offer top-notch solutions for your industrial needs.

Why Choose Virat Special Steels?

Premium Quality, our die steel products adhere to the highest industry standards, ensuring durability and performance.

Wide Range, explore our extensive selection of DB6, DIN-1.2714, AISI L6, and more, tailored to meet diverse application requirements.

Reliable supplier, with years of expertise, we've established ourselves as a trustworthy partner for businesses in need of superior die steel.

Partner with Us for Success: Whether you're in manufacturing, engineering, or tooling, Virat Special Steels is dedicated to providing the right die steel solutions for your projects. Our commitment to quality and customer satisfaction sets us apart.

Learn More: https://www.viratsteels.com/din-2714.html

Any further queries feel free to contact us : 📩 Email: [email protected] or 📞 Call: +91 98140 21775

#ludhiana#india#viratsteels#viratspecialsteels#toolsteelsupplier#gurugram#iso9001#IndustrialMaterials#ManufacturingExcellence#EngineeringMaterials#MachiningSteel#ToolandDie#SteelAlloys#db6 steel#pune#gurgaon#din 2714#aisil6

2 notes

·

View notes

Text

Jindal MS Seamless Pipe is a high-quality, durable pipe designed for various industrial applications. Known for its strength and corrosion resistance, it is ideal for use in construction, oil and gas, and manufacturing sectors.

#JindalMSSPipe#SeamlessPipe#JindalSteel#MSPipe#IndustrialPipes#SteelPipes#ConstructionMaterials#OilAndGas#PipeFittings#SteelProducts#HeavyDutyPipes#EngineeringMaterials

4 notes

·

View notes

Text

Understanding Carbon Steel Plates: Grades & Applications

Carbon steel plates are essential components in various industrial sectors, offering exceptional strength, versatility, and cost-efficiency. These plates are manufactured in a wide range of grades to meet the diverse demands of industries such as construction, shipbuilding, pressure vessel manufacturing, oil and gas, and heavy equipment fabrication.

As global demand for robust and durable materials continues to rise, working with reliable carbon steel plate suppliers becomes increasingly critical. This guide provides an overview of key carbon steel plate grades, their applications, and what to look for when selecting a carbon steel plate manufacturer.

What Is a Carbon Steel Plate?

A carbon steel plate is a flat-rolled steel product with carbon as the main alloying element. Depending on the carbon content—low, medium, or high—the plate’s mechanical properties vary in terms of hardness, strength, ductility, and weldability.

Carbon steel plates are favored for their strength-to-weight ratio, affordability, and broad usability. From structural frameworks and bridges to boilers and storage tanks, carbon steel remains one of the most widely utilized metals in the world.

Key Grades of Carbon Steel Plate

The performance of a carbon steel plate in a given application largely depends on its grade. Below are the most widely used grades that conform to ASTM standards:

1. ASTM A36 Plate

ASTM A36 steel plate is one of the most commonly used carbon steel plates. It is known for its excellent weldability, moderate strength, and good formability, making it ideal for structural applications.

Typical Uses: Construction beams, platforms, bridge components, and machinery parts

Advantages: Easy to machine, weld, and fabricate

Industry Reference: A36 carbon steel plate

2. ASTM A283

The ASTM A283 specification includes low and intermediate tensile strength carbon steel plates, particularly Grades A, B, C, and D. These are often chosen for general-purpose fabrication in environments with less critical mechanical requirements.

Applications: Storage tanks, base plates, structural supports

Benefits: Economical and easy to process

3. ASTM A516

ASTM A516 steel plate is designed for use in pressure vessels and boilers operating in moderate to low temperatures. It comes in Grades 55, 60, 65, and 70, with Grade 70 being the most widely used due to its strength and notch toughness.

Applications: Pressure vessels, heat exchangers, reactors, and process tanks

Features: Superior strength, resistance to brittle fracture

Common Product: ASTM A516 Grade 70

High Carbon Steel Plate

A high carbon steel plate contains a higher percentage of carbon (typically above 0.6%), offering significantly increased hardness and tensile strength. However, this comes at the cost of reduced ductility and weldability.

Applications: Wear plates, cutting tools, heavy-duty industrial equipment

Characteristics: High abrasion resistance, strong under heavy stress

Due to their robust properties, high carbon steel plates are typically used in applications where mechanical wear is a concern.

Advantages of Carbon Plate Steel Products

Carbon plate steel products deliver a range of benefits:

Strength and Durability: Suitable for structural and load-bearing applications

Cost-Effective: Less expensive than stainless or alloy steel alternatives

Workability: Can be cut, welded, and formed easily in most grades

Availability: Offered in standard and customized sizes by leading carbon steel plate suppliers

Selecting a Trusted Carbon Steel Plate Manufacturer

Partnering with a reputable carbon steel plate manufacturer ensures consistent quality, compliance with international standards, and timely delivery. Reputable carbon steel plate suppliers typically provide:

A comprehensive inventory of standard grades such as ASTM A36, ASTM A283, and ASTM A516

Custom thicknesses and dimensions to suit specific project needs

Certified mill test reports (MTRs) and traceability documentation

Quality control processes, including ultrasonic and impact testing

Global shipping capabilities and competitive pricing

By working with experienced suppliers, customers can streamline procurement, minimize risk, and ensure optimal material performance.

Industries and Applications

Carbon steel plates are a cornerstone in numerous industries:

Construction: Structural components, commercial buildings, infrastructure projects

Oil & Gas: Offshore platforms, storage tanks, pressure piping

Shipbuilding: Hulls, decks, and frames

Power Generation: Boilers, turbines, heat exchangers

Mining & Heavy Equipment: Wear-resistant plates and high-load bearing components

The material’s adaptability across different operating conditions—from ambient to high-pressure and low-temperature environments—makes it indispensable in industrial operations.

Conclusion

Carbon steel plate remains a preferred material for critical infrastructure and industrial projects due to its mechanical strength, versatility, and economic value. Understanding the distinctions between grades such as ASTM A36, ASTM A283, and ASTM A516 is essential for choosing the right material for the job.

Sourcing from established carbon steel plate suppliers ensures not only product quality but also compliance with international specifications. Whether you require a standard ASTM A36 steel plate or a robust high carbon steel plate, choosing the right supplier is key to project success.

Emirerri Steel offers a wide range of carbon steel plate solutions with an emphasis on quality, precision, and customer service. For inquiries or technical assistance, connect with our team today and discover why we are a trusted name among carbon steel plate manufacturers worldwide.

#CarbonSteel#SteelPlates#SteelGrades#MetalFabrication#EngineeringMaterials#ConstructionMaterials#Manufacturing#SteelApplications#StructuralSteel#MaterialScience

0 notes

Text

Top 7 Benefits of Stainless Steel 316L Boiler Tubes for High-Performance Industrial Applications

Stainless Steel 316L boiler tubes are a cornerstone in industries like power generation, chemical processing, and oil and gas. Their unique properties make them ideal for high-pressure and high-temperature environments. This article explores the key benefits of using Stainless Steel 316L boiler tubes, highlighting why they are a preferred choice for reliable and efficient systems.

1. Superior Corrosion Resistance

Stainless Steel 316L is renowned for its excellent corrosion resistance, particularly in harsh environments. The addition of molybdenum (2-3%) enhances its ability to withstand pitting and crevice corrosion, especially in chloride-rich settings like marine or chemical processing applications. This makes 316L boiler tubes ideal for industries where exposure to corrosive substances is common, ensuring long-term reliability and reduced maintenance costs.

SEO Keywords: Stainless Steel 316L corrosion resistance, boiler tubes for harsh environments, pitting resistance in boiler systems.

2. Low Carbon Content for Enhanced Weldability

The "L" in 316L stands for low carbon, which minimizes carbide precipitation during welding. This property makes Stainless Steel 316L boiler tubes easier to weld without compromising structural integrity. Welded joints remain strong and corrosion-resistant, making these tubes suitable for complex boiler designs and heat exchanger systems.

SEO Keywords: 316L boiler tubes weldability, low carbon stainless steel, welded boiler tube applications.

3. High-Temperature Strength and Durability

Stainless Steel 316L boiler tubes offer exceptional strength and durability at elevated temperatures. They maintain their mechanical properties in high-heat environments, making them ideal for boilers and heat exchangers operating under extreme conditions. This durability translates to longer service life and fewer replacements, saving costs for industries.

SEO Keywords: High-temperature boiler tubes, durable 316L stainless steel, heat exchanger tubing.

4. Versatility Across Industries

From power plants to pharmaceutical manufacturing, Stainless Steel 316L boiler tubes are versatile enough to meet diverse industry needs. Their ability to handle high-pressure steam, aggressive chemicals, and fluctuating temperatures makes them suitable for applications in:

Power Generation: Efficient heat transfer in boiler systems.

Chemical Processing: Resistance to corrosive chemicals.

Oil and Gas: Durability in high-pressure pipelines.

Pharmaceuticals: Hygienic and non-reactive surfaces for clean systems.

SEO Keywords: Stainless Steel 316L applications, versatile boiler tubes, industry-specific tubing solutions.

5. Cost-Effective Long-Term Investment

While Stainless Steel 316L boiler tubes may have a higher upfront cost compared to other materials, their longevity and low maintenance requirements make them a cost-effective choice. Reduced downtime, fewer repairs, and resistance to corrosion and wear ensure a lower total cost of ownership over time.

SEO Keywords: Cost-effective boiler tubes, 316L stainless steel longevity, low maintenance tubing.

6. Eco-Friendly and Recyclable

Stainless Steel 316L is 100% recyclable, making it an environmentally friendly option for industries aiming to reduce their carbon footprint. Its durability also means fewer replacements, contributing to sustainable operations. Choosing 316L boiler tubes aligns with eco-conscious practices without compromising performance.

SEO Keywords: Eco-friendly boiler tubes, recyclable stainless steel, sustainable industrial tubing.

7. Compliance with Industry Standards

Stainless Steel 316L boiler tubes meet stringent industry standards, such as ASTM A213 and ASME SA213, ensuring quality and safety in critical applications. This compliance gives industries confidence in the reliability and performance of these tubes for their boiler and heat exchanger systems.

SEO Keywords: ASTM A213 316L boiler tubes, ASME SA213 compliant tubing, industry-standard boiler tubes.

Why Choose Stainless Steel 316L Boiler Tubes?

The combination of corrosion resistance, high-temperature strength, weldability, and versatility makes Stainless Steel 316L boiler tubes a top choice for demanding industrial applications. Whether you're operating a power plant, chemical facility, or pharmaceutical production line, these tubes deliver unmatched performance and reliability. Their eco-friendly properties and compliance with industry standards further enhance their appeal, making them a smart investment for long-term operational success.

SEO Keywords: Why choose 316L boiler tubes, high-performance stainless steel tubing, reliable boiler tube solutions.

Conclusion

Stainless Steel 316L boiler tubes offer a perfect balance of durability, corrosion resistance, and cost-effectiveness. Their ability to perform in extreme conditions while meeting industry standards makes them indispensable for modern industrial systems. By choosing 316L boiler tubes, businesses can ensure efficient operations, reduced maintenance, and sustainable practices, all while achieving long-term cost savings.

#industrial#manufacturer#MetalIndustry#SteelManufacturing#CorrosionResistantSteel#SteelSheetsAndPlates#IndustrialMaterials#SteelFabrication#EngineeringMaterials#MetalProcessing#HighPerformanceSteel#StainlessSteelApplications#ChemicalIndustrySteel#MarineGradeSteel#HeavyDutySteel#SteelIndustryNews

0 notes

Text

Carbon Steel API 5L X52 PSL 1 Pipes & Tubes Exporters In India

Metinox Overseas is a leading supplier of Carbon Steel API 5L X52 PSL 1 / API 5L X52 PSL 2 Pipes & Tubes in Mumbai. We specialize in providing high-quality products at the most feasible rates, ensuring customer satisfaction and reliability.

API 5L X52 Pipes are designed for the transportation of corrosive and non-corrosive fluids and gases at high pressures. These pipes are manufactured with a chemical composition including carbon, manganese, potassium phosphorous, molybdenum, chromium, silicon, and sulfur, providing excellent mechanical properties. The API 5L X52 Seamless Pipe exhibits a minimum tensile strength of 60,200 psi and a minimum yield strength of 42,100 psi, making it suitable for various applications.

API 5L X52 PSL1 Welded Pipe is produced by welding pieces of steel together with the help of a filler, offering ease of maintenance and long-lasting durability. X52 ERW Pipe boasts high resistance against corrosion and stress, with wall thickness ranging from 2.11mm to 24.61mm. Additionally, the API 5L Gr X52 HIC Pipeline offers good resistance against pitting induced by hydrogen in various applications.

#highperformancesteel#heavydutysteel#industrialmaterials#engineeringmaterials#corrosionresistantsteel#chemicalindustrysteel#stainlesssteelapplications#metalindustry#marinegradesteel#metalprocessing

0 notes