#Marshall Stability Testing Machine

Explore tagged Tumblr posts

Text

Top Asphalt Testing Lab Equipment Manufacturer in India

When it comes to precision and durability in road construction and bitumen testing, having the right equipment is crucial. Atico Export is a leading asphalt testing lab equipment manufacturer in India, known for delivering high-performance instruments trusted by civil engineering labs around the world.

In our latest blog, we cover everything from Marshall Stability Test Machines, Bitumen Testing Equipment, to Pavement Evaluation Tools – all essential for ensuring quality and safety in asphalt testing processes.

Whether you’re setting up a new testing lab or upgrading existing tools, this guide will help you make informed decisions.

#AsphaltTesting#LabEquipment#BitumenTesting#CivilEngineeringLabs#MarshallStabilityTest#Aticoindia#ConstructionTesting#RoadQualityTesting#TestingEquipmentManufacturer#EngineeringLabTools

1 note

·

View note

Text

Trusted Civil Engineering Laboratory Equipment Manufacturer for Advanced Infrastructure Testing

Introduction

Construction and interchange are an industry. Hence, precision and reliability are of utmost importance. From skyscrapers to bridges to highways, every structure is built on principles of good engineering. An upholder of this excellence is the civil engineering laboratory equipment of good quality used for testing and research.

This equipment is needed to test materials in universities and schools, government R&D labs, and commercial laboratories for material properties, soils, concrete strength, and structural integrity. This is where a trusted civil engineering lab equipment manufacturer comes into play, providing the needed tools for engineers to design safer, stronger, and smarter infrastructures.

The Importance of Civil Engineering Laboratory Equipment

Civil engineering is as much about theory as it is about real-life application. Laboratory testing helps students, researchers, and professionals understand how different materials behave under stress, environmental change, and various load conditions; It is where investing in quality lab equipment starts to matter.

Accurate Testing for Quality Assurance

Precise laboratory testing is the backbone of quality control for construction projects. Equipment such as compression testing machines, universal testing machines, and CBR apparatus ensures materials comply with national and international standards.

Enhancing Education and Skill Development

In schools, students experience lab work on real-time testing equipment. Such exposure prepares them for challenges in the industry while bridging the gap between theory and practical knowledge required in the field.

Driving Research and Innovations

Engineering colleges and research labs require advanced tools for R&D in varying sectors such as sustainable construction materials, earthquake resistance, and smart infrastructure. Good-quality instruments give rise to innovations.

Categories of Civil Engineering Laboratory Equipment

The reputed civil engineering lab equipment manufacturer boasts an enviable reputation for providing an extensive range of instruments in various critical testing fields:

Concrete Testing Equipment

Concrete is an important construction material in wide use. Testing its properties is perhaps the most important aspect of ensuring strength and durability. These include:

Compression Testing Machines

Slump Test Apparatus

Compaction Factor Apparatus

Concrete Mixers

Vibrating Tables

Soil Testing Equipment

Soil behavior is mainly governed by the foundation design. Soil testing instruments exist to evaluate strength, permeability, and bearing capacity:

CBR Testing Machines

Triaxial Test Apparatus

Proctor Compaction Molds

Direct Shear Test Devices

Unconfined Compression Testers

Cement and Bitumen Testing

The two important materials were everything about roads and infrastructure. Some of them are listed below:

Vicat Needle Apparatus

Le Chatelier Flask

Marshall Stability Test Apparatus

Ring & Ball Apparatus

Penetrometers

Structural Engineering Lab Equipment

Any tools involved in testing loads, forces, and deformations on structural elements such as beams and columns:

Universal Testing Machines (UTM)

Beam Testing Machines

Load Frames

Flexure Testing Machines

Surveying and Transportation Engineering Tools

Civil engineers also work with:

Auto Levels and Theodolites

Total Stations

Traffic Analysis Equipment

Road Roughness Meters

Pavement Test Systems

Features to Evaluate in a Reliable Manufacturer

What sets a manufacturer apart is that this selection impacts quality in testing and educational output. Here's what distinguishes a trusted civil engineering lab equipment manufacturer:

Certified Quality Standards

ISO, CE, and BIS-certified products should be sought after. This equipment satisfies international safety and performance standards when these certifications are present.

Too Many Products Under One Umbrella

From elementary school packages to university lab set-ups and industrial-grade testing machines, the ideal manufacturer offers it all to ensure compatibility.

Customization Options

Every institution and lab has different requirements. The ability to customize equipment to curriculum or test protocols adds immense value.

Strong Technical Support

Manufacturers provide installation and operating manuals as well as technical support, training, maintenance, and spare parts availability.

Global Reach With Local Expertise

A manufacturer with global experience understands the discrete regulations and can tailor solutions to different markets, be it India, Africa, the Middle East, or Southeast Asia.

Benefits of Modernizing Civil Engineering Labs

With the smart city and green construction arriving on the scene, it is high time that laboratories be upgraded with modern civil engineering testing apparatus. The foremost advantages include

More Accurate Testing

Digital load indicators, sensors, and automation improve the accuracy as well as the repeatability of results.

Improved Student Engagement

Modern equipment provides better visualization and interaction with the experiments by students.

Reduced Testing Time

Automatic machines reduce human error and increase the speed of testing processes, greatly enhancing productivity in academia and industry.

Sustainable Testing Practices

The newly sanctioned eco-friendly solution for laboratories gives better energy efficiency and lower material wastage, conducive to sustainable construction education.

Serving Educational, Research & Industrial Sectors

A versatile civil engineering laboratory equipment manufacturer serving different business segments:

Educational Institutions: Supply durable lab setups aligned with curricula to polytechnics, engineering colleges, and universities.

Research Laboratories: Provide precision-grade instruments for material research, structural simulations, and environmental impact studies.

For Construction and Infrastructure Companies: Provide field and lab instruments for real-time quality control of major infrastructure projects.

Why India is a Growing Hub for Lab Equipment Manufacturing

India is making a mark as a global manufacturing guarantor with world-class civil engineering lab equipment produced at competitive rates. Indian manufacturers—Tesca Global being a perfect example—are setting unmatched benchmarks for quality, permitting these firms to become the supplier of choice not only inside but also outside India.

Conclusion:

When searching for a civil engineering lab equipment manufacturer that best incorporates innovation, quality, and customer support, Tesca Global's reputation stands firmly established. For many decades, Tesca Global has successfully catered to civil engineering laboratory needs for education and industry. Therefore, we are pleased to offer:

A wide product range specifically catering to civil engineering laboratories:

Customizations for your specific testing needs

Globally recognized certifications

Installation, training, and lifetime support

For starting a lab for an emerging engineering college and modernizing equipment for infrastructural projects, trust Tesca Global for accuracy, durability, and performance in empowering engineers to build a safe tomorrow.

#laboratory equipment suppliers#educational lab equipments#developers & startups#civil engineering lab equipment

0 notes

Text

Choosing the Right Material Testing Laboratory in Abu Dhabi: What to Look For

Abu Dhabi, the capital of the United Arab Emirates, is a city known for its impressive skyline and ambitious infrastructure projects. The quality and safety of these projects depend heavily on the materials used, making the role of material testing laboratories crucial. Choosing the right material testing laboratory in Abu Dhabi can significantly impact the success of your construction project. This blog will guide you through the key factors to consider when selecting a material testing laboratory to ensure you make an informed decision.

Importance of Material Testing Laboratories

Material testing laboratory perform various tests to evaluate the physical, chemical, and mechanical properties of construction materials. These tests ensure that the materials meet the required standards and specifications, contributing to the safety, durability, and overall quality of the construction project. Some of the key reasons for conducting material testing include:

Safety: Ensuring that materials can withstand the intended loads and environmental conditions.

Compliance: Verifying that materials meet local and international standards and regulations.

Durability: Selecting materials that will last, reducing maintenance costs and enhancing the lifespan of structures.

Cost Efficiency: Preventing costly errors and rework by identifying material issues early in the construction process.

Key Factors to Consider When Choosing a Material Testing Laboratory

Accreditation and Certification

One of the most critical factors to consider when choosing a material testing laboratory is accreditation and certification. Accreditation from recognized bodies, such as the Emirates International Accreditation Centre (EIAC) or the International Organization for Standardization (ISO), ensures that the laboratory meets international standards for testing procedures, equipment, and personnel competency.

Certification from reputable organizations like ASTM International or the American Concrete Institute (ACI) further validates the laboratory's adherence to industry standards. These certifications ensure that the laboratory follows best practices and maintains high-quality testing services.

Range of Services

A comprehensive range of testing services is essential for meeting all your material testing needs. The laboratory should offer a variety of tests for different materials, including:

Concrete Testing: Compressive strength, slump test, curing test, chloride ion penetration test.

Steel Testing: Tensile strength, bend test, impact test, chemical composition analysis.

Asphalt Testing: Marshall stability test, bitumen content test, aggregate crushing value test.

Soil Testing: Proctor compaction test, Atterberg limits test, bearing capacity test, soil classification test.

Aggregate Testing: Sieve analysis, specific gravity and water absorption test, abrasion test, soundness test.

Advanced Technology and Equipment

The accuracy and reliability of test results depend on the technology and equipment used by the laboratory. Ensure that the laboratory is equipped with state-of-the-art testing equipment and follows the latest testing methodologies. Advanced technologies, such as Universal Testing Machines (UTMs), spectrometers, and X-ray diffraction (XRD) machines, enhance the precision and efficiency of testing processes.

Qualified and Experienced Personnel

The expertise and experience of the laboratory staff play a crucial role in the quality of testing services. Ensure that the laboratory employs qualified and experienced personnel who are trained and certified in their respective fields. Regular training and certification programs, such as those offered by ASTM International and ACI, help maintain high standards of competency and expertise among the staff.

Quality Assurance and Control

A robust quality assurance and control system is essential for maintaining the accuracy and reliability of test results. The laboratory should have well-documented procedures for sample handling, testing, and reporting. Regular internal and external audits help ensure compliance with industry standards and continuous improvement in testing processes.

Turnaround Time

Timely delivery of test results is crucial for keeping your construction project on schedule. Inquire about the laboratory's turnaround time for various tests and ensure that they can meet your project deadlines. A laboratory with efficient processes and advanced technology can provide faster results without compromising on quality.

Reputation and References

The reputation of the material testing laboratory is a good indicator of the quality of its services. Look for laboratories with a proven track record of successful projects and satisfied clients. Ask for references and testimonials from previous clients to get an idea of their experience with the laboratory. A reputable laboratory will have positive reviews and a strong portfolio of completed projects.

Compliance with Local Regulations

Ensure that the material testing laboratory complies with local regulations and standards, such as the Abu Dhabi International Building Code (ADIBC) and the standards set by local municipalities. Compliance with these regulations is essential for obtaining necessary permits and approvals for your construction project.

Cost and Value

While cost is an important factor, it should not be the sole determinant when choosing a material testing laboratory. Consider the value that the laboratory provides in terms of accuracy, reliability, and comprehensive services. A slightly higher cost may be justified if the laboratory offers superior quality testing and faster turnaround times.

Steps to Choose the Right Material Testing Laboratory

Conduct Research

Start by conducting thorough research on material testing laboratories in Abu Dhabi. Use online resources, industry directories, and professional networks to identify potential laboratories. Compile a list of laboratories that meet your initial criteria.

Evaluate Credentials

Check the accreditation and certification status of the laboratories on your list. Ensure that they are accredited by recognized bodies and have relevant certifications from reputable organizations.

Assess Services and Capabilities

Review the range of services offered by each laboratory and their capabilities. Ensure that they can perform the specific tests required for your project and that they have advanced technology and equipment.

Visit the Laboratory

If possible, visit the laboratory to assess their facilities, equipment, and staff. A site visit will give you a better understanding of their capabilities and quality standards.

Request Proposals and Quotes

Request detailed proposals and quotes from the shortlisted laboratories. Compare their services, turnaround times, and costs. Evaluate the value they offer in terms of quality, reliability, and expertise.

Check References

Contact the references provided by the laboratories and inquire about their experience. Ask about the accuracy of test results, timeliness, and overall satisfaction with the laboratory's services.

Make an Informed Decision

Based on your evaluation, select the material testing laboratory that best meets your requirements. Consider factors such as accreditation, range of services, technology, expertise, reputation, and cost to make an informed decision.

Conclusion

Choosing the right material testing laboratory in Abu Dhabi is a critical decision that can significantly impact the success of your construction project. By considering factors such as accreditation, range of services, technology, expertise, reputation, and cost, you can select a laboratory that provides accurate and reliable testing services. A reputable material testing laboratory ensures the safety, durability, and compliance of your construction materials, contributing to the overall quality and success of your project.

0 notes

Text

PUNDIT UPV tester

Marshall Stability Equipment is essential for testing the stability and flow of asphalt mixtures. Widely used in civil engineering, it evaluates the durability and performance of road materials. Accurate and reliable, this equipment ensures high-quality pavement construction, aiding engineers in maintaining safe and efficient transportation infrastructure.

0 notes

Text

bituminous mixture multi-functions testing machine KZH-1A

bituminous mixture multi-functions testing machine KZH-1A bituminous mixture multi-functions testing machine 1. Introduction The bituminous mixture multi-functions testing machine adopts separated structure of loading frame and control system. The testing machine equips with low temperature environmental chamber and pressure loading system, can complete Marshall stability test of bituminous…

View On WordPress

0 notes

Text

Marshall Stability Testing Machine at Best Cost

Peak Technology is recognized manufacturers and suppliers of Marshall Stability Testing Machine which is equipped with premium-quality materials and ultra-modern techniques. Marshall Stability Test Machine is widely used by highway departments, contractors, engineers, testing laboratories, and other government organisations to test the stability of bituminous models. Our machine is available at an affordable cost in the marketplace to our valuable price.

Click Here for More Info: - https://peaktest.in/

0 notes

Text

Premium Quality Marshall Stability Testing Machine

Peak Technology is founded in the year 2010, our company best manufacturers of Marshall Stability Testing Machine with best services and cost and using high-class raw materials and the latest techniques to design our products. Our Marshall Stability Testing Machine is specially designed for measuring resistance to plastic flow of cylindrical specimens.

Features of Marshall Stability Testing Machine:-

Automatically calculates flow and stability values

Real time display of test graph.

Ethernet connecting for computer interface

Remote connection through Ethernet

USB flash disc for importing test results

0 notes

Link

Looking for Laboratory Drying Oven? You can count on us. The Testmak Laboratory Ovens have been designed for drying asphalt, soil, rock, concrete, aggregate, or similar materials. The oven capacity is 750 liters. The interior is manufactured from stainless steel and the exterior is robustly constructed from sheet steel finished in powder-coated paint.

1 note

·

View note

Photo

A reputed leading #manufacture of good quality #digital #marshall #stability #testing #machine for the testing of #bitumen in #civilengineering #quality #control #laboratory For further information: http://setestindia.com/marshall-stability-test-apparatus.html #ashphlat #concrete #exporter #supplier #india #delhi #aggregate #road #construction #material https://www.instagram.com/p/BwubYWYgJW2/?utm_source=ig_tumblr_share&igshid=893dmplfgaoc

#manufacture#digital#marshall#stability#testing#machine#bitumen#civilengineering#quality#control#laboratory#ashphlat#concrete#exporter#supplier#india#delhi#aggregate#road#construction#material

0 notes

Text

Space Life and Physical Sciences Research and Applications SpaceX-20 Experiments and Payloads

SpaceX - Dragon CRS-20 Mission patch. Feb. 29, 2020 Research on physical science and life sciences in space allows humans to both expand their knowledge of space and enhance their economic vitality on Earth. A series of physical science experiments testing micro gravity properties in space are driving global advances in science and technology. Through a number of innovative biological experiments, NASA is also finding new ways to help plants, animals and humans survive and thrive in spaceflight conditions. Investigations launching to the International Space Station on SpaceX’s 20th contracted commercial resupply services mission include the following: Physical Sciences Combustion Research From Fuel Efficiency to Flammability Several experiments will study combustion focusing on three primary goals: How can we improve fuel efficiency? How can we reduce combustion pollutants? How can we better prevent a fire inside a spacecraft? The Advanced Combustion via Microgravity Experiments (ACME) project is a series of six independent studies of gaseous flames that will be conducted in the Combustion Integrated Rack on board the orbiting laboratory.

Image above: The shape of a flame under microgravity conditions is visibly different from the long, tapered shape found on Earth. Five of the experiments are focused on improving how we use fuel on Earth. By developing computational models, scientists hope to improve the efficiency and reduce the pollutant emission in combustion machines. In addition, the computational simulation capability resulting from ACME could lead to reductions in the time and cost to design the next generation of combustion engines. Other ACME goals are to improve our understanding of combustion during limited fuel conditions where both optimum performance and low emissions can be achieved, as well as soot control and reduction – that is, oxygen-enriched combustion which would capture carbons before they were released into the air, and flame stability and extinction limits, as well as the use of electric fields for combustion control. The objective of the sixth experiment is focused on spacecraft fire prevention. Scientists want to improve their fundamental understanding of materials flammability such as extinction behavior and the microgravity conditions needed for sustained combustion. It will also help them assess the relevance of existing flammability test methods as they screen and select materials for future spacecraft. Principal Investigators: Richard Axelbaum, Ph.D. Washington University in St. Louis, Derek Dunn-Rankin, Ph.D. University of California, Irvine, Irvine, Chung (Ed) Law, Ph.D. Princeton University, Marshall Long, Ph.D. Yale University, James Quintiere, Ph.D. University of Maryland Developers: NASA Glenn Research Center ZIN Technologies Incorporated Turning up the Temperature on Materials Science with Liquid Metal For thousands of years, humans have produced glass, metal alloys, and other materials by placing a mixture of raw materials in a container - called a crucible – and heating them to a high temperature. But, as melting begins, a chemical reaction can occur between the materials and the crucible, causing imperfections and contaminations. So what if you could avoid using the crucible? You can – in space. Aboard the International Space Station, NASA will use the Japan Aerospace Exploration Agency’s Electrostatic Levitation Furnace (ELF) handles materials using a containerless processing technique. This allows researchers to reduce imperfections, provide enhanced fidelity of results, and investigate the behavior of high-temperature manufactured materials including oxides, semiconductors, insulators and alloys which are only possible in the microgravity environment of space.

Image above: Flight Engineer Serena Auñón-Chancellor of NASA monitors the arrival of the H-II Transfer Vehicle-7. The Japanese resupply ship delivered a new sample holder for the Electrostatic Levitation Furnace. The ELF will soon perform two new experiments: The Thermophysical Property Measurement investigation will study small (~2mm) spheres of metal to provide a better understanding of how to measure liquid metal properties. The knowledge gained will help researchers better understand how to maximize the levitators of each. NASA is part of an international team of researchers for the Origin Of Fragility In High-Temperature Oxide Liquids experiment that will, on the other hand, investigate what happens when high temperatures are applied to those same small spheres of various metal oxides. Oxides are a class of chemical compounds in which oxygen is combined with another element, in this case a metal. The spheres are heated by multiple laser beams to a high temperature, where the metal becomes a liquid. Metal oxides are developed for products such as thermal conductors and electrical insulators, and these liquids formed from these materials are expected to serve as precursors to products that are useful in advanced sensors, benefiting manufacturers and scientists designing new materials and manufacturing techniques that can be used both on Earth and in Space. ELF Thermophysical Property Measurement Experiment Principal Investigator: Douglas M. Matson, Ph.D., Tufts University Co-Investigator:Mikhail Krivilev, Ph.D., Udmurt State University, Russia High-Temperature Oxide Liquids Experiment Principal Investigator: Shinji Kohara, Ph.D., National Institute for Materials Science, Japan Co-Investigator: Richard Weber, Ph.D., Materials Development Inc. Developer: Japan Aerospace Exploration Agency, Space Environment Utilization Center A Closer Look at Complex Nanostructures for Future New Materials Take a close look at an object – any object – through an electron microscope, and you’ll see how it’s composed of micron-scale particles. How do those particles form and blend with each other to become that object? Welcome to the world of colloids and nanostructures. In chemistry, a colloid is a mixture in which one substance of microscopically dispersed insoluble or soluble particles is suspended throughout another substance, much like tapioca pudding. Scientists know temperature is a factor in determining how these microscopic particles bond with their surfaces and with each other. But another factor that’s been difficult to measure is the effect gravity has on these particles – until now.

Image above: NASA astronaut Karen Nyberg, Expedition 36 flight engineer, as she conducts a session with the Advanced Colloids Experiment (ACE)-1 sample preparation at the Light Microscopy Module in the Fluids Integrated Rack / Fluids Combustion Facility. The Advanced Colloids Experiment Temperature-2 (ACE-T-2) experiment will look at the complex structures of these micron-scale colloidal particles, and how they assemble in micro gravity conditions. Using the electron microscope on board the station, scientists will observe these particle interactions when different temperatures are applied to them. The experimental work emanates from an increasing demand for ever more complex, specifically designed micro and nano-scale structures for photonic and electric devices. Controlling how these complex 3D structures are assembled, however, is highly challenging. Through these experiments, and assisted by complex algorithms, scientists hope to gain a basic understanding of the assembly process to better grow complex nanostructured materials. These Colloidal and nano-particles are good candidates to become the building blocks of some of tomorrow’s new materials. Applications of nano and micro materials are rapidly growing: this new particulate matter finds increasing applications in all parts of modern life ranging from food and drug industry to coating and painting to everyday electronic devices. Principal Investigator: Peter Schall, Ph.D Co-Investigators: Gerard Wegdam, Ph.D., University of Amsterdam, Institute of Physics Simon Stuij, University of Amsterdam, Institute of Physics Piet Swinkels, University of Amsterdam, Institute of Physics Marco A. C. Potenza, Ph.D., University of Milan Developers: NASA Glenn Research Center Zin Technologies Incorporated There’s a relatively new technique that allows scientists to design and assemble complex three-dimensional structures from colloids. Those are particles of different sizes that are suspended in a fluid, similar in concept to how microbeads are suspended in liquid soap. The technique is known as nanoparticle haloing (NPH) which uses highly charged nanoparticles to stabilize much larger, non charged particles. It is thought that the nanoparticles create a charge layer by forming a cage, or Halo, around the larger particles.

Image above: Onboard the International Space Station of the ACE Modules taken during the ACE-T12 Module Configuration. On Earth, gravity plays a role in how well particles are suspended in a fluid. But, by allowing these structures to form in the microgravity on board the International Space Station for the Advanced Colloids Experiment-Nanoparticle Haloing (ACE-T-12) experiment, scientists hope to gain new insights into the relationship between the shape surface charge and concentrations of particles and the particle interactions. Microgravity allows for the monitoring of particle behavior for longer time periods than on Earth, and this experiment will allow the first observation of 3D aggregations formed by NPH. The resulting structure and its stability address fundamental issues in the science of condensed matter. Since self-assembled colloidal structures are vital to the design of advanced materials, this investigation will contribute to a fundamental understanding of nanoparticle haloing and the colloidal structures it creates. That lays the foundation for applying this technique to creating the next generation colloidal materials, including optically-based energy platforms and sensors, for use on Earth. Principal Investigators: Stuart J. Williams, Ph.D. University of Louisville Suzanne Smith, Ph.D. University of Kentucky Co-Investigator: Gerold Willing, Ph.D. University of Louisville Developers: NASA Glenn Research Center Zin Technologies Incorporated Space Biology Understanding Plant Defenses in Space Crews on future long-term space missions need to be able to grow their own food, and studies of how plants respond to microgravity are an important step toward developing that capability. The Biological Research in Canisters-Light Emitting Diode-002 (BRIC-LED)-002 investigation tests whether spaceflight affects the ability of plants to defend themselves against pathogens. Arabidopsis thaliana is a weed commonly found abutting the pavement on the back roads of Africa or Eurasia, popularly known as thale cress or mouse-ear cress. Arabidopsis is a model organism, commonly used by biologists due to its relatively small genome, making it ideal for research. Even though it has a complex multicellular frame, this particular weed is well-understood by scientists.

Image above: NASA astronaut Jack Fischer installing the Biological Research In Canisters (BRIC) Light Emitting Diode (LED) for future BRIC-LED experiments. While this particular plant does well in defending itself against pathogens on Earth, the results of this investigation could have important implications for any plant grown on board as part of a crew’s life support system. Specifically, researchers will grow the Arabidopsis plants in orbit grown for a period of up to 14 days. Then, crew members will apply a bacterial compound that triggers the plant’s defense responses. After one hour, they preserve the plant samples, and after a period of 12-24 hours, they freeze the samples using the ultra-cold freezer on the station. The plants are stored there until they return to Earth for analysis. Research on plant function in microgravity also contributes to a better understanding of basic plant processes, which could support development of better agricultural practices on Earth. Principal Investigator: Simon Gilroy, Ph.D. University of Wisconsin-Madison Testing Hardware for Space Gardens Future long-duration space missions will require crew members to grow their own food. Before they do, they’ll need to better understand how plants respond to microgravity and other challenges not found on Earth, and also refine the systems and procedures to support plant growth. VEG-PONDS-03 will evaluate how plants - in this case lettuce - grow in a newly developed plant growth system known as PONDS, or Passive Orbital Nutrient Delivery System. On Earth, gravity naturally forces rainwater down into the ground to nourish a plant’s roots. The PONDS units have features that are designed to bypass the lack of gravity in order to distribute water. They are also able to increase the plant’s oxygen exchange and provide sufficient room for root growth.

Image above: Howard Levine, Ph.D., a research scientist at NASA's Kennedy Space Center, reviews the growth of several tomato plants in a laboratory in the Space Station Processing Facility. The tomato plants are growing in the Veggie Passive Orbital Nutrient Delivery System (PONDS). Red romaine lettuce was chosen for the testing because it has a baseline for its growth from several previous experiments in the Vegetable Production System (Veggie) where crew members grew and ate it in space. The plants are grown in mixtures of arcillite, a porous material. Prior to launch, the PONDS units are packed with arcilite and time-release fertilizer, just like you use in potting soil at home. In space, the PONDS units are placed in the Veggie facility and supplied with water to initiate plant growth. Observations on plant tissue samples will provide insight regarding any growth differences when compared with control plants grown on Earth. Additional tests aim to monitor the microbial changes that are present in space grown crops, providing baseline data for future food production efforts. VEG-PONDS-03 is a direct follow-on to the VEG-PONDS-01 and VEG-PONDS-02 hardware and plant growth validation tests. VEG-PONDS-01 tested growth of a single organism: Mizuna mustard. VEG-PONDS-03 now includes Dragoon Lettuce, Red Russian Kale, Extra Dwarf Pak Choi, Wasabi Mustard, and Red Romaine Lettuce. By demonstrating plant growth in this newly developed system, crew members may soon be able to grow even more crops, from new leafy greens to dwarf fruit plants in space. Back on Earth, scientists are already exploring how the technology used in the Veggie plant growth facility could be adapted for use in roof top gardens in densely populated areas where there is little room for growing plants. Principal Investigators: Howard G. Levine, Ph.D. NASA Kennedy Space Center Ye Zhang, Ph.D. NASA Kennedy Space Center Developer: NASA Kennedy Space Center Researching Cellular Response to Radiation Of all the risks associated with long term space travel, one of the most hazardous is exposure to radiation – these invisible particles have sufficient energy to change or break DNA, which can damage or kill a cell. Too much exposure can lead to health problems ranging from short to long term effects. Radiation particles emanate from galactic cosmic rays originating outside our solar system, and by the Sun during solar flares. Crew members aboard the space station receive some protection from Earth’s atmosphere and magnetic field, but radiation will become are much bigger challenge when they travel to the Moon or Mars.

Image above: This illustration depicts the two main types of radiation and how the magnetic field around Earth affects the radiation in space near Earth. To better understand the biological impact of space radiation on cells, NASA launched a long-term radiation exposure experiment called Evaluation of ISS Environmental Radiation Damage on Cryopreserved Mammalian Cells (Rad-Dorm) to the space station in late 2018 and will return aboard Dragon in April. Prior to launch, cryopreserved cells were placed into biological canisters. On board the space station, the canisters containing the frozen cells were placed in the Minus Eighty Degree Laboratory Freezer (MELFI) and then transferred to another even colder freezer at minus 160C. Scientists will analyze DNA damage and other cellular features to better understand how different cells respond to long duration exposure to space radiation. This data will provide valuable information for evaluating the biological impact of true space radiation and assisting in radiation risk assessments. Also, it potentially will benefit other radiation research on Earth, giving researchers a better understanding of how cells respond to exposure of different radiation sources. Principal Investigator: Ye Zhang, Ph.D. NASA Kennedy Space Center Co-Investigators: Abba C. Zubair, Ph.D. Mayo Clinic Jacksonville Honglu Wu, Ph.D. NASA Johnson Space Center Hardware Developer: NASA Kennedy Space Center Jacobs (Test and Operations Support Contract) Payload Developer: Jacobs (Test and Operations Support Contract) MEI Technologies This life science and physical science research was funded by, or in collaboration with, the Space Life and Physical Science Research and Applications division at NASA headquarters. Stay informed on other exciting SLPSRA research initiatives: https://www.nasa.gov/directorates/heo/slpsra Related links: Commercial Resupply: http://www.nasa.gov/mission_pages/station/structure/launch/index.html Space Station Research and Technology: https://www.nasa.gov/mission_pages/station/research/index.html International Space Station (ISS): https://www.nasa.gov/mission_pages/station/main/index.html Images, Text, Credits: NASA/Carlyle Webb. Greetings, Orbiter.ch Full article

18 notes

·

View notes

Link

via Politics – FiveThirtyEight

The U.S. doesn’t have what it needs to fight the novel coronavirus. N95 respirator masks are emergency room workers’ ideal line of defense against the small particles of spittle that can transmit COVID-19. It’s a banal-looking medical product — like a baseball straining under a small tarp of synthetic cloth — but its mundanity doesn’t make it easy to find. A recent NBC News survey of health care workers reported widespread rationing of N95 masks in hospitals. The country also doesn’t have enough ventilators — machines that assist breathing — and the need for those will be a matter of life and death in the coming days. There are around 160,000 ventilators in U.S. hospitals and only 16,600 ventilators in the Strategic National Stockpile, according to a recent report from the Center for Public Integrity. New York state alone is requesting an additional 30,000. While it’s unclear how many ventilators the country might need in the coming weeks and months, one estimate from a 2005 Department of Health and Human Services pandemic simulation put the number at 742,500.

The shortage of critical supplies has led many public officials to ask President Trump to make full use of a little-known-until-a-week-ago law, the Defense Production Act. So far Trump has been reluctant to fully deploy it, to the consternation of many (including those in his own party). White House statements on the use of the DPA have been muddled, suggesting a deeper bureaucratic confusion about how to even implement the act. But even with the law’s powers in full use, the pandemic has revealed America’s precarious place in the global marketplace as just another buyer, rather than an industrial fortress ready for a fight on its own shores.

Passed in 1950 in response to the Korean War, the DPA allows the government to jump the supply chain line for needed goods in the midst of emergencies — it was invoked in 2017 to procure supplies for hurricane victims, for example — and authorizes it to incentivize the production of needed supplies.

Trump’s stance on deploying the DPA fully has been hazy, and his statements about the gravity of the supply shortage has varied — during a Thursday evening appearance on Fox News, he cast doubt on New York’s need for 30,000 ventilators. On March 18, he said that he would be “invoking the Defense Production Act just in case we need it.” The administration has said it would use some powers in the act, like the one that goes after hoarding and price-gouging of emergency supplies and one that requires companies to prioritize government contracts and allows the federal government to allocate emergency resources (it’s not clear how efficiently that’s actually being done yet). But groups like the U.S. Chamber of Commerce have reportedly lobbied the Trump administration against using the law to its full effect. The past week has seen Democratic lawmakers and former national security officials pillorying Trump for what they see as inadequate use of the law. New York Gov. Andrew Cuomo said on Tuesday, “I do not understand the reluctance to use the federal Defense Production Act to manufacture ventilators. If not now, when?”

The short answer is that’s not quite how the law works.

Those familiar with the workings of the DPA are quick to note its implementation is not a panacea. Dave Kaufman was in charge of DPA authorities in his role at FEMA during the Obama administration. He told me that there seems to be a fundamental public misunderstanding of what the law can do. “It’s being talked about in the media as restructuring the economy a la WWII. It’s not actually really that — it’s a powerful authority, don’t get me wrong, but it’s not nationalization of industry, which is kind of the way we’re talking about it.” Industrial leaders like General Motors Co. reportedly balked at the idea of the White House invoking the DPA.

The kind of DPA powers that Cuomo and the media have largely been talking about are the ones vested in Article III of the act. That portion of the law is meant to “create, maintain, protect, expand, or restore domestic industrial base capabilities essential for the national defense.” To go about that, the government is authorized to provide loans and loan guarantees to stimulate domestic production of needed goods, to make agreements to purchase products on a long term basis in order to encourage the production of needed goods and “to procure and install equipment in private industrial facilities,” in the words of a Congressional Research Service analysis of the DPA.

Kaufman said that invocation of the DPA isn’t always needed to get a job done. “You could also just make a commitment to a multi-year procurement and send the pricing signal to the market to stimulate development of supply,” he said. Ford, 3M and GE Healthcare pledged this week to jump-start production of ventilators and masks, though they didn’t give a timeline for the needed scale-up of production — it would likely be months. (On Friday morning, Trump tweeted that “General Motors MUST immediately open their stupidly abandoned Lordstown plant in Ohio, or some other plant, and START MAKING VENTILATORS, NOW!!!!!!” As Ohio Rep. Tim Ryan quickly pointed out, GM no longer owns the plant.)

But with N95 masks and ventilators, many of which are made overseas, things are tricky. “DPA authority is great to talk about, but if the commodities don’t exist here in the scale and quantity needed for demand, claiming the first off the line for what does exist is not really solving the problem,” Kaufman said, referring to the DPA power that allows the government to jump the supply chain.

China is a major producer of N95 masks and ventilators and the U.S. is competing for emergency supplies manufactured there, much like the rest of the world. It’s a stark reminder that despite Trump’s trade wars and inflammatory rhetoric, China remains a manufacturing behemoth. Well before the coronavirus pandemic began, the U.S.’s reliance on China for key goods dismayed government officials. A September 2019 NBC News report detailed the alarm of national security officials over how dependent the U.S. is on Chinese-manufactured pharmaceutical products. A Council of Foreign Relations analysis from December 2019 noted the rapid growth of the Chinese medical device manufacturing sector, aided by its government’s protectionist policies.

There is some production of the needed emergency products in the United States. 3M is a major producer of respirator masks: A spokesperson said in an email that it makes them in two locations in the U.S., South Dakota and Nebraska. A March 22 statement from 3M’s CEO noted that the company produces 35 million respirators per month and that “more than 500,000 respirators are on the way from our South Dakota plant to two of the more critically impacted areas, New York and Seattle.” At the time of publication, it was unclear how the masks would be apportioned to each region.

Governors have asked the federal government to take control of the allocation of ventilators and masks by using the DPA. Under Title I of the law — which technically, the Trump administration has said it has put into effect — the federal government can take charge of the allocation of emergency supplies. It’s not clear how well it’s doing that or communicating its plans to the states. South Dakota Gov. Kristi Noem, the chief executive of the state that produces so many N95 masks, expressed frustration during a call with Trump last week. “I need to understand how you’re triaging supplies,” she said, with other governors on the line. “I don’t want to be less of a priority because we’re a smaller state or less populated,” she said. According to The New York Times, Trump assured her that would “never” happen. Subsequently, the report noted, “Ms. Noem’s telephone line was disconnected.” Illinois Gov. J.B. Pritzker was referring to similar allocation concerns when he said that his state was “competing” with other states and federal agencies on the open market for emergency medical supplies.

Confusion over how or whether the Trump administration is using the DPA has grown over the last few days, a worrisome sign given the bureaucratic organization needed to oversee so many moving parts of government and industry that should ostensibly be working together. News came from the White House this week that the production of 60,000 testing kits had been expedited under the auspices of the act, but FEMA later said that in the end, it hadn’t needed to invoke the DPA. In an email to FiveThirtyEight over the weekend, a FEMA spokesperson wrote that it was “actively engaged with private industry partners through the National Business Emergency Operations Center. One outcome from this engagement is the stand-up of a cell that is coordinating needs and sourcing re-supply for the community-based testing sites.” Over the course of the week, it became clear that FEMA’s newly established Supply Chain Stabilization Task Force, headed by Rear Adm. John Polowczyk, was the agency’s attempt at centralizing interactions with private industry.

If a recent Democratic proposal from the Senate is any indication, there is a worry about the administration’s ability to marshal and organize critical information from private companies in the time of crisis. The proposal calls for basic information-gathering provisions, like an assessment of the country’s emergency medical protective gear, a point person to communicate with states and companies, and a hotline for companies to call for information.

Banal bureaucratic organization problems seem, for now, to be blunting the collective power of American capitalism in a time of crisis.

7 notes

·

View notes

Note

Pidge with someone tampering with her food? Like on a planet and Hunk Allura and pidge are invited, they offer them food but Pidge and Hunk eat some (Hunk is quickly pulled away so he doesn't eat enough for the poison to affect him) and they try and take Pidge because she's passing out from the "poison") thank you so so much!!!

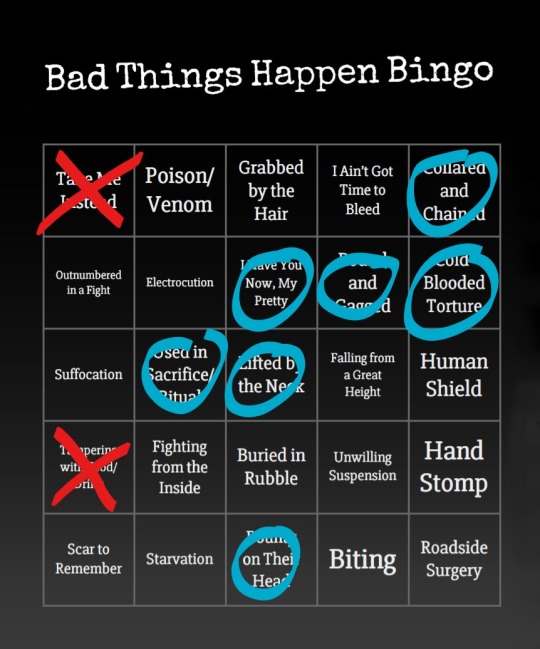

Administrative stuff: This is for the @badthingshappenbingo, in the Voltron: Legendary Defender Fandom.

Red has been done, blue requested.

*PSST*: You can also read this on AO3.

Yikes. This is about 3100 words.

“Pidge, you gotta try this,” Hunk gushes.

“No.”

“C’mon, just a bite,” he wheedles.“It tastes just like hazelnuts.”

“No, Hunk.”

“Fine, fine,” Hunkrelents, and returns to his own plate. But Pidge can feel him watching her outof the corner of his eye.

“What?” she finallysnaps - quietly, she can be diplomatic too.

“Nothing!” he sayshastily. “I just-” here we go“-are you sure you’re ok? I know this was a pretty big let-down.”

And suddenly, eating is lookinglike a better option than talking to Hunk. Pidge grabs a spoonful of whateverthis newest alien gunk is on her plate and shoveled it into her mouth, barelytasting the weird flavor. Hazelnuts, her ass. This stuff is nothing likeanything on Earth.

Damnit, Hunk is still watchingher.

“I’m fine,” she saysshortly. “It’s just a setback. Stop pussyfooting around for once and leaveme alone.”

“We’ll find them, Pidge,”Hunk says steadily, and he’s so warm,so fucking comforting that she nearlyloses her shit right there and the only alternative is to shove more terriblealien food into her mouth, chew, swallow, and repeat the process until he getsthe message and leaves her alone.

And he does, he’s damnperceptive, that’s what clued him in in the first place, but now she thinks shemight have screwed up because he’s not gushing about the food anymore, andLance is shooting her a chastising look before turning to devote his entireattention to Hunk and before long the two of them have excused themselves fromthis latest banquet with one of their hosts, going to seek out yet anotheralien sunset, and Pidge can’t find the motivation to get up and find them toapologize so she stays, letting the joyful atmosphere batter at her rockysolitude. It’s great, really. Another planet liberated, another victorysnatched from the Galra’s grasping claws, but the air is bitter, like theaftertaste of what Hunk swore was hazelnuts, tainted by Pidge’s own personalmetric for success or failure. Still no leads on her father and brother. She’sbeen through every scrap of data the Galra on this planet had, every scrap ofdata from every mission they’ve been on, and she’s no closer to finding herfamily than when she hunched on the roof of the Garrison, seeking fruitlesslyfor confirmation of what she knew in her heart, data to back up her bone-deepconviction that her family was alive, somewhere.It’s been over a year since she left that lost, lonely little girl behind onthe roof, and she’s got jack-shit to show for it.

Suddenly it’s all too much andnot enough, too much input and not enough distance and she shoves her chairback to desert the banquet abruptly, ignoring Allura’s disapproval. Thecoalition can go fuck themselves, because if they can’t help her find herfamily then what good are they? Besides, these aliens seem a little too interested in the paladins and theirbond with the lions. She’s had to fend off one too many questions that probejust a little too deep, are a little too personal to her connection with Green.

Distantly, she’s aware that thisis just frustration and too little sleep on top of an extended adrenaline crashon top of more than a year of tension and doubt speaking, but in this moment itfeels much better to let anger course through her hot and swift, buoying herwith a feeling of power and force which that distant part of her knows willfade to cold ash all too quickly.

The corridors in this place areall curved, echoes of the buildings’ outer walls, and it’s all very lovely fromthe air but she can’t seem to find a straight line to her lion for the life ofher and right now all she needs is Green, her cool analytics and rationalprocesses which will bring Pidge back to the mindspace in which she’s at herbest. She’s not the most well-versed in dealing with emotions, others’ or herown, and so when everything crashes over her like it has tonight she’s often ata loss in how to break free of vicious emotional currents that can’t beexplained or sorted or put away.

She needs Green. She needs herfucking lion, like, yesterday. It’s getting harder to breathe, and these damncurvy corridors are fucking with her depth perception and that distant part ofher is piping up again, is this apanic attack? Physical symptoms are similar – elevated heartrate and shortnessof breath colliding to produce dizziness, her temperature perception is off,it’s hot and then cold, shit herecomes nausea. Not a panic attack, then, her analysis provides helpfully.Probably poison. Something about that banquet wasn’t safe for humanconsumption. Fucking hazelnuts.

“Green,” she whispers,curling over herself as she finds stability against the wall. She’s got anemetic in her first-aid kit, if she could just get to her lion. But she’s lost,now, she thinks she was headed the right direction when she left the banquethall but everything is spinning and she’s not even sure if she’s crouched onthe floor or lying on the wall. Maybe the gravity is switching up on her? No,she’s just falling, sliding down the wall to land on her ass and even that’snot good enough because her traitorous spine is curving, bending to deposit heraching head on the floor and maybe she should just sleep this off. That soundslike a great idea, actually, until her analytic side screams at her to get up,keep moving, find someone because ifshe goes to sleep she might die and that gives her enough of a push to rollover and try to get her legs underneath her once more.

She manages to get to her knees,but she keeps tipping forward when she tries to clamber to her feet so she optsto crawl. She leans against the wall as she creeps forwards, using it to remindher of what equilibrium should feel like because she sure as shit can’t keep itstraight for herself. Her vision is greying out, pulsing in time with thenausea in her gut, and her lungs keep squeezing tighter and tighter. Where iseveryone? Why hasn’t she come across anyone?Oh god, the last thing she said to Hunk was so shitty. She can’t remember whatshe said to any of the others, but it probably wasn’t anything more than civil,if that. If she can make it through this she’ll be nicer. And she’ll puttogether a food testing kit for each of the paladins. Really, it’s a miraclenone of them have accidentally ingested something fatal before now. Green,where’s Green? She needs Green.

A pair of feet enter herappallingly narrow field of vision, standing firm and upright with annoyingease. She sinks back to a hunched, seated lean against the wall, using itsstolid support to tip her pounding head up until she meets the gaze of one ofthe aliens hosting them. What are they called again?

“He…lp,” she manages to rasp out.

The alien watches her for aminute, while Pidge’s vision tunnels further, grey leaching inwards inexorablywhile her ribs squeeze tighter and tighter against her lungs. He’s not going todo anything, she realizes. He’s just going to stand there and watch her die.Maybe they think if Voltron loses a paladin while on their planet that one oftheir own will be chosen. Maybe they’re secretly still in league with theGalra. But that doesn’t make sense. She can’t think well without oxygen,apparently.

Pidge tips herself backwards,ready to worm-crawl away from the alien who’s still watching her if that’s what it will take, but the suddenshift in her center of gravity proves to be too much for her overstrainedsystem, and blackness crashes in to take her.

*

When she wakes, she’s strapped toa table, and the spike in the heart monitor they’ve put on her wipes out anychance she had of faking unconsciousness in order to evaluate the situation.

With subtlety off the menu, Pidgeopts for belligerence. “What the fuck are you idiots doing?” she demands,testing the straps they’ve put on her while they’re hopefully distracted by herrunning her mouth. “I’m a Paladin of Voltron. We literally just saved your entire planet from the Galra. Let me go,before this goes further than you can smooth over with an apology.”

The alien ignores her, insteadreaching across Pidge to pull a contraption that resembles a cross between adentist’s mobile x-ray machine and an optometrist’s phoropter over her torso.It’s getting harder to push her fear aside, and the adrenaline from her awakeninghas worn off, leaving her drained and empty. Pidge casts her mind out forGreen, pulling desperately on the tenuous thread of their connection. It’s hardto marshal the focus necessary to connect with her lion; she’s still feelingthe effects of whatever it was that she ate, nausea and dizziness and tightlungs all conspiring to muddy her thoughts and dull her mind.

The alien finishes hispreparations and peers around the edge of the machine at her. “We have askedyour princess to explain to us the bond between paladin and lion, and we havesought the same answers from each of you, but you will not share this knowledgewith us, and we are forced to take what should have been freely given. This isyour last chance to elucidate the bond to us.”

“Why do you want to know?” Pidgedemands. “Voltron saved your planet.” She pauses to fight the nausea and try tobreathe. It’s getting harder, and she feels a pale, petty satisfaction at thethought that they probably won’t get to study her as much as they want if shecontinues to deteriorate at this rate. “This is pretty shitty thanks,” shemanages, “to kidnap someone who just risked life and limb for your people.”

While she talks, she’s stillreaching for Green, pushing past everything that hurts to bridge the distancebetween and her and her lion. Dimly, she feels the connection snap into place evenas her vision greys out further, and the alien’s retort washes over her in ajumble of indecipherable sound. But even as her body is failing her, Green’spresence surges through her mind, lending clarity where she can’t marshal herown, analyzing the situation with her while sending a constant flow ofassurance that she’s on her way. Pidge tunes the alien out, cataloguing her symptomsfor Green, helping her lion assemble them into a file for the rest of her teamwhen they arrive. She’s pretty sure she won’t be up to explaining anythingherself.

Cause: high probability of ingestion of a substancetoxic to human biology, likely at the feast.

Symptoms: gradual onset of shortness of breath, leading toelevated heartrate, approximately fifteen doboshes after beginning ingestion ofthe suspected substance. Note to Hunk:that stuff did not taste like hazelnuts. A sample should be obtained foranalysis and synthesis of an antidote.

Shit they’re drawing blood – no, Green, keep the file going.

Symptoms, continued: Dizziness presented next, though whether aneffect of the substance or a result of previous symptoms undetermined. Nauseabegan soon after. Seems resistant to actual emesis, however. Suggestion: tryinducing emesis to evacuate whatever’s still in my stomach. Vision is greyingout, progressing steadily towards complete loss of sight. Symptoms combinedlead to pervasive muscle weakness, inability to stand. Oh, and balance is affectedas well.

What was that? Pidge snaps out of her compilation of the file forGreen at the trembling of the room around her. Oh. It’s Green. The room shakes harder, sending instrumentsrattling off of trays and sending her captors into a babbling frenzy. Pidgehears Lance’s blaster and Hunk’s shoulder cannon going off, and beyond that thecrashing that usually results when Keith and Shiro start throwing peoplearound.

It all erupts at once, Greenbreaking through the wall while the team charges through the door on the other sideand subdue the aliens that managed to keep their feet in the shower of rubble. Somethingglances off of Pidge’s ribs, and a smaller spray of sharp rocks skates acrossher face. She closes her eyes, since she can’t see anymore anyway.

“Pidge, oh my god, Pidge, wake up!”It’s Hunk. She hears his bayard dematerialize and then his hands are cuppingher face, fingers tapping gently while someone else fumbles at the strapsaround her wrists. Cold fingers – Lance. Someone else is taking the vein tapout of her arm – Keith?

“’M here,” she mumbles. Heroxygen shortage is starting to worry her. “Poi..s’n, Hunk,” she twitches her handto tap at his. “File. In Green.” She has to stop, take a minute to try tobreathe, while he lifts her, cradling her against his big warm chest like ababy and she can’t even find it in herself to be annoyed by the position. It’snice, this time.

“It’s gonna be okay,” he rushes. “It’sgonna be okay. We’ll get you a pod, just stay with me.”

Oh, pod. Probably not going towork. “Not… pod. Poison,” she manages. “File. In Green.” They’re heading up.Sounds like a ramp. Green? Oh, there she is.

“Yeah, we’re in Green. She’s lettingShiro fly her back to the castle. We’re almost there, hang on.”

“No… Hunk. File. In Green.” Howmany times does she have to say this? She’s wasting precious oxygen.

“What file?” Lance picks up on it.“There’s a file here in Green?”

Speaking is too much, now, so shetips her head forward against Hunk’s chest and it must be enough because shehears Lance tapping through Green’s logs. Pidge nudges at Green to bring Pidge’slog to the forefront of the system display.

“Poi…son,” she manages one moretime, and now she really needs to focus on breathing so they’re just going tohave to figure the rest out for themselves.

“Dios,” Lance breathes. “It was the food. That hazelnut stuff.”

Finally.

“Oh, god,” Hunk moans. “You and Iboth ate some too, Lance, why aren’t we sick?”

“You’re bigger than her,” Keithobserves. “And you both only ate a little. Pidge ate a bunch.”

Gee, thanks, Keith. Way to callout a girl on her eating habits.

“We can’t use the pods,” Shirorealizes. “They don’t work on illnesses, and this is too close to a disease.”

“She says we’ll need a sample foran antidote,” Lance continues.

“I’ll go get it,” Keith saysdarkly, and Pidge has a sudden vision of him stomping through the curved halls,fighting his way through their former allies (because she’ll be damned if theylet this particular planet join the coalition after this) in a quest forhazelnut gunk. The thought forces a huff of a laugh out past her laboringlungs, but that was a bad idea because now she’s choking, fighting to get backthe air she just lost. Hunk adjusts her position against him, his large hand rubbingcircles on her back, and it helps a little but she’s still panting for air, blindand achy and dizzy and nauseous and unable to throw up and she just reallyhates this so much.

Green touches down in the castle’shangar, and even though she can’t see she feels it when Hunk stands andeverything spins wretchedly.

“Keith, wait, Keith-” it’s Lance,chasing after the red paladin, judging by the sound of his rapid-fire footsteps.“Wait, Keith, Dios, idiota, I’ve got some of the hazelnut gunk!”

“What?” everyone choruses, andPidge would join in, too, if she could. How the hell did he pull that off?

“It really does taste likehazelnuts,” he says apologetically. “I only tasted a little bit, but we’ve gotthat space cocoa, and I was hoping we could make something like Nutella, butnow that’s seeming like a really bad idea-”

“I could kiss you right now,Lance,” Hunk half-sobs. “Bring it to the medbay, quick.”

Pidge loses track of things for alittle while after that. She focuses on trying to breathe, on the too-slow intakeof oxygen, trying to keep as much of it as she can when every exhale seems to addto the tightness squeezing her lungs further closed.

Something covers her nose andmouth, and she panics for a moment until oxygen rushes in, and she’s never feltso grateful for anything in her life. She gulps it greedily while Hunk andCoran discuss her over her head, using the file from Green and the sample Lancekept to synthesize an antidote.

She loses a bit more time, awashin dizzy nausea and unable to see beyond the field of grey that encompasseseverything when she bothers to open her eyes. The oxygen is helping, but it’sstill hard to breathe and harder to think, so she drifts until something pricksher arm and slowly, so slowly, she feels the relief creep through her body. Thenausea is the first to settle, then the dizziness, and then her lungs easewhile her sight fades back in.

Hunk is leaning over her, hissmile watery and wavery but still there, and Coran hovers at her other elbow, adjustingthe flow from the bag of antidote that’s hooked up to the needle in her arm.Everyone else is at the foot of the bed, Lance and Keith and even Shiro andAllura, and they’re not her family by blood or by name but damnit if they haven’tshoved their way into her heart anyway. Her space family is weird and most ofthe time she doesn’t appreciate them nearly enough, but they’re still here forher, even when she fucks up.

And speaking of which – “Hunk,”she says, rejoicing in the feel of breath flowing freely in and out of her lungs.“I was a major jerk at the banquet. I’m sorry, man.”

“Don’t even worry about it,” Hunksniffs. “I already forgot. You were just upset, I get it.”

“Good,” Pidge breathes, feelingher eyes slip closed again. Being poisoned really takes it out of her, apparently.

“Rest, Number Five,” Coran says. “You’vegot some recovery to come, still. That substance was quite toxic to yoursystem.”

That sounds fun. But the firstpart was good. She’ll take a nap. And when she’s feeling better, she’ll makethose food-testing kits for everyone.

24 notes

·

View notes

Text

Flexulaceous Testing Machine

Flexural testing is a non-invasive manner of measuring typically the strain over a framework, component or component by using a good apparatus that is powered by flex. This is certainly used simply by manufacturers as being an approach to verify the load distribution inside constructions before manufacturing them. This is also used in structural analysis to check stresses and traces. The device features been available given that the early 1960's and is largely used by metallic producers and strength engineers as being a test out methodology for exhaustion testing and tensile strength testing regarding steel members. Additionally it is used to style and make multi-span structural members. There happen to be many benefits and advantages of employing flexural testing inside the manufacturing environment. The test provides fast diagnosis involving problems such because stress corrosion damage.��Marshall Stability Test Machine accumulated during the tests can be compared in order to the data attained in quality studies and inspection. This helps in quick recognition of the problem and proper restoration or replacement may be done on time. Flexural testing is really a cost effective option for fast strength analysis and maintenance programs. It is able to acquire relevant data from very few check points and consequently the reliable info set for long term comparisons against real data. When choosing a Flexural Tests Machine, you need to make sure that the tools meets your demands. It must accomplish all your requirements and requirements. An individual should make positive it is portable plus easy to use, while it will be used frequently. Typically the equipment should likewise be robust plus have the capacity to handle dynamic load and high tons. This kind associated with equipment should be designed for heavy obligation applications, so that will the operator in addition to maintainability of the equipment remain a priority. The equipment ought to also have the particular ability to differentiate between mechanical in addition to dynamic tests and also have a good diagnostic and reporting center. Before the test subject matter matter must be prepared in detail plus well understood. This can include the specification, description, design, procedure, dimension data, and results of the test. The particular test engineer should ensure that check methods and methods are documented. All relevant supporting application should be set up and evaluated before the testing commences. The Flexulaceous Evaluation Machine must meet your specific demands and can end up being customized as per your specifications. The device need to have a flip-up construction with high quality components which usually are simple to maintain. The test will be able to detect any flaw and defect in the design right from the beginning and the particular results ought to be reproducible. Flexulaceous testing is ideal for pre-construction, construction industry mainly because well as producing industries. Flexural assessment offers maximum value for your money. It will save you time, money and a whole lot of effort that you might have otherwise wasted. Flexural testing is typically the best option available for the structure industry or producing industry. If an individual do not desire to throw away cash plus time on re-testing the equipment, get a new Flexulaceous Assessment Machine.

0 notes

Text

12 Best Compound Bow for under 300 USD for 2020

Are you looking for the best compound bow for under 300 USD?

I’ll try to give you options for every budget whether you have $100, $200, $300, under $400, $500 or $ 800 to spend on your favorite compound bow or crossbow or recure bow.

So, no matter which one of the best bows you may likely choose, you’ll be in the wallet friendly range of $ 100 to $300.

Best compound bow for under 300

I delve deep into what I consider the best compound bows under $300. These are the top recommended picks packed with host of bow accessories.

What is the Best Compound Bow for under 300 USD?

I round up and deep dive into the 12 best bows that cost less than $300.

These include compound bows for kids, youth, men, women, teenagers, beginners and adult pros alike.

These 12 Best Compound bows give you the perfect speed, durable structure, 100% accuracy and lightweight, as well as noise/vibration free.

1. Bear Archery Cruzer Lite Compound Bow — Top pick Best Compound Bow 2020 under $300.

The Bear Archery Cruzer Lite Compound Bow is a versatile bow that boasts of 290 fps speed.

It has a smoother draw and perfect as a starter bow option for shooters who want to grow with their archery skill levels.

This compound bow is incredibly flexible, easy to adjust to fit your style and frame as well as setup.

Related: 17 Best Compound Bow Ever Made — Reviewed, Tested & Ranked for 2020

With its top grade capabilities and high quality, it’s a first good bow for beginning and young archers.

Bear Archery Cruzer Lite is a little lightweight bow that meets archers’ expectation with its draw weights at 5 lbs easy pull.

This can be adjusted to 45 lbs for young hunters.

Its draw length range is adjustable from 12” to 27”

Features

Shoots up to 290 feet per second.

Extremely lightweight and weights only 3.2 lbs.

No need for a bow press since Allen wrench allows for easier adjustments.

Ready to hunt bow with fire trophy ridge accessories.

12” — 27” draw length range

5–45 lbs draw weight

Includes nock loop, peep sight, stabilizer, quiver, whisker biscuit and sight.

Advanced grip design

Eliminate hand torque for enhanced accuracy.

2. Diamond Archery Prism Right Hand Compound Bow — Great value Best Compound Bow for Target Shooting Under $ 300

If you are thinking about buying a bow for you teenager kids, the Diamond Archery Prism Compound bow is highly recommended because it provides extreme adjustability and versatility.

The Diamond Prism Bow by Bowtech has a limb system that allows for adjustability from 5 lbs to 55 lbs for heavy impact hunting and shooting practice.

It is very powerful, easy to use, accurate, and smooth to draw and has remarkable dual cam system.

Your children can use it as they grow due to its adjustable poundage and draw length as needed.

This little bow is equipped and ready to shoot and hunt out of the box and available in several colors and camouflage too.

Its rotating draw length modules provides kid archer 12 inches of auto adjustment.

Features

Draw weights: 5–55 lbs

295 max arrow velocity feet per second

80% effective let-off

3.2 lbs mass weight

31 inches axle to axle

Draw length: 18–30 inches

3. SereneLife Complete Compound Bow & Arrow Accessory Kit

The SereneLife Complete Compound Bow and Arrow Accessory Kit is a lightweight and portable size bow that provides a serious hunting performance, for young archers, expert shooters, hunters or beginners to shoot their target object with precision and accuracy.

You can target and hunt as well as take your big game to the next level with great performance and success that SereneLife Compound bow package offers.

It is a professional outdoor archery for adults, teenagers and kids.

It is perfect for a variety of archers with its draw weight of 30–70 lbs and 23.5” — 30.5” draw length.

The cams are made of machined aluminum and weigh 3.9 lbs only.

This bow can accelerate up to 320 fps and depends on the arrows used.

The bow comes with high quality accessories including an arrow quiver, rubber damper and a stabilizer.

Features

Bow weight: 3.9 lbs

Right hand Bow

Draw length: 23.5” — 30.5”

Up to 320 feet per second IBO rating

70–75% let-off

Axle to axle: 30”

7.4“ brace height

Aluminum alloy riser with high intensity.

4. Escalade Sports Bear Archery Species RTH Package — Best Compound Bow for Hunting

The Escalade Sports Bear Archery Species RTH Package is a great first-time option bow for recreational shooters or adult bow hunters.

The package comes with all accessories you need to get started including Nock Loop, Trophy Ridge 4-pin sight, peep sight, trophy ridge 5 arrow quiver, trophy ridge whisker biscuit.

The limb dampeners reduce shock and vibration and make your shooting noise free.

Features

Ready to hunt package comes with high quality accessories.

320 fps speed

80% let off

6 ¾“ brace height

Draw length range: 25” — 32”.

31 axle to axle

55–70 lbs draw height

4.0 lbs bow weight

Color: Real tree Edge Camo

5. SAS fued 70 Lbs Compound Bow Travel Package — Best Used Compound Bows

If you are looking for a top performing compound bow to handle your hunting adventure, then I strongly recommend SAS fued 70 lbs compound package.

This bow comes with cam systems that allow archers to generate huge amount of kinetic energy into the bow-ready to shoot a target.

SAS fued is extremely fast and can achieve arrow speed up to 300 feet per second.

This compound bow is easy to adjust draw length and weight and is ideal for experts and beginners.

To ensure accurate shot placement and stability, the split limb design combined with cut out riser to eliminate hand shock and vibration.

30 inch aluminum or carbon arrows are recommended for SAS fued bow and are suitable for bow hunting and shooting.

Features

Draw length: 19” — 31”

25–70 lbs draw weight

4.1 lbs net weight which is light and perfect for beginners.

Accelerates up to 300+ fps max speed.

6. Southland Archery Supply SAS Scorpii 55 Lb 29” Compound Bow — Best Lightweight Compound Bow

The Southland Archery Supply SAS Scorpii 55 Lb 29” Compound Bow is designed to provide shooters with the highest quality gear for hunting or target shooting.

This powerful compound bow is highly adjustable from 19–29” draw length and shoots at 260 fps.

The compact & lightweight bow features a 28” axle to axle capability with a compressed ABS limbs.

Southland Archery Supply SAS Scorpii 55 Lb 29” remains an affordable option for a beginner who gets started in bow hunting.

It is perfect for adults and teens too.

Features

260 feet per second maximum speed

30–35 lbs draw weight

Axle to Axle: 28”

Adjustable draw length from 19” — 29”.

7 ½“ brace height

Net weight at 3.3 lbs

68% let off.

7. PSE Archery Mini Burner Compound Bow Kit for youth, Kids & Beginner

The PSE Archery Mini Burner Compound Bow is an ideal first bow for youth that gives you a great first archery experience.

It offers draw weights up to 40 lbs and 16” — 26½“ draw length range for developing archers.

This highly adjustable draw length range grows with young archer and beginners.

Its accessory package comes with three carbon arrows, a 3-pin sight, stabilizer, and arrow quiver and arrow rest.

PSE Archery rig features Mini SF Split limbs, lightweight riser, comfortable rubber panel grip, cable guard and the PSE FC cam system.

Features

Available in right and left hand

Draw weight: 29–40 lbs

6 5/8“ brace height

Draw length: 16 to 26½“

26“ Axle to Axle

65% let-off

2.7 lbs mass weight

Maximum limb bolt turns: 10

8. Bear Archery Wild — Best Compact Compound Bow for Deer Hunting

The Bear Archery Wild is a great bow in terms of shootability and designed for an average archer.

This compact compound bow was engineered with a focus on great value and high quality material for hunting.

When it comes to hunting, quality fishing and outdoor gear, the Bear Wild compound bow is lightweight, affordable, durable and portable as well as easy to draw and shoot.

The Bear Archery wild shoots at 310 fps, with an S7 single cam bow, comfortable and smooth let-off for steady aim and accuracy with 7.25” brace height and 32–25” axle to axle. It is a great choice also for tall guys who are just getting started with archery.

This bow is more forgiving and beneficial for beginner archers who have less arrows shots under their belt.

Features

80% let off

7.75“ brace height

4.0 lbs weight

32.25” AtA length

24” — 31” draw length

310 fps IBO speed

40 lbs — 70 lbs draw weight

Riser construction material: aluminum

Both right and left handed available

Composite limb construction material

5 color choices to choose from.

9. Barnett TS390 Crossbow 390 feet per second compound crossbow 4 x 32 scope Equipped with Two 20 inch Arrows

The Barnett TS390 Compound Crossbow offers a smooth and efficient draw and the adjustable stock makes it easier for archers with short stocky arms to shoot comfortable without any problem.

It’s lightweight and super strong with overall construction helping with silent operation and accuracy.

Despite its lightweight, the compound crossbow shoots arrows at 390 fps speed.