#Material Handling Equipments

Explore tagged Tumblr posts

Text

Material handling equipment (MHE) is literally the backbone of logistics and supply chain operations. From a factory to a warehouse, distribution centre, or construction site, this equipment is used to move, store, regulate, and protect products and materials.

0 notes

Text

A Manual Chain Pulley Block with Trolley is a reliable and efficient lifting solution used in various industries for lifting, positioning, and transporting heavy loads. It consists of a manual chain pulley block combined with a trolley, which allows smooth horizontal movement along an I-beam or monorail system. This system is widely used in workshops, warehouses, factories, construction sites, and shipyards due to its simplicity, durability, and cost-effectiveness.

Key Features

Smooth & Precise Lifting Operated manually using a hand chain mechanism.

Durable & Heavy-Duty Construction Made from high-strength alloy steel for long-lasting performance.

Effortless Movement Integrated trolley allows smooth horizontal load transportation.

Overload Protection Equipped with safety features to prevent excess load lifting.

Corrosion-Resistant Coating Protects against rust and wear in harsh environments.

#Electric Chain Hoist Manufacturers#Electric Chain Hoist#Material Handling Equipment#Material Handling Equipments Manufacturers#Material Handling Equipments

0 notes

Text

0 notes

Text

#meshinesindia#Scissor Lift#Home Elevator#Hydraulic Goods Lift#Dumb Waiter#Scrap Baling Press#Hydraulic Press#Baling Press#Filter Press#Material Handling Equipments

1 note

·

View note

Text

#Safety equipment suppliers in Dubai#personal safety products#business#Traffic safety product suppliers UAE#Road safety equipment suppliers Dubai#Safety equipment distributors#Material handling equipments

1 note

·

View note

Text

Material Handling Equipments, Hydraulic Pallet Truck Manufacturer! Futureindustries.in

Title: Revolutionizing Industrial Material Handling: Future Industries Pvt. Ltd. - Your Trusted Goods Lift Manufacturer

Introduction

Welcome to the world of seamless industrial material handling, where efficiency and safety are paramount. Future Industries Pvt. Ltd. takes immense pride in being a leading Goods Lift Manufacturer, delivering cutting-edge solutions to businesses across various industries. With our state-of-the-art facilities based in Ahmedabad, we have solidified our position as the go-to Industrial Goods Lift Manufacturer, providing top-notch Hydraulic Goods Lifts that redefine efficiency and reliability.

Industrial Goods Lifts Manufacturer: Our Commitment to Quality

At Future Industries Pvt. Ltd., quality is not just a buzzword; it's a philosophy ingrained in everything we do. As an experienced Industrial Goods Lifts Manufacturer, we understand that each business has unique material handling needs. Therefore, we offer a diverse range of goods lifts meticulously designed to suit various industrial applications. From compact lifts for small-scale operations to heavy-duty giants capable of handling substantial loads, our offerings cater to businesses of all sizes.

Engineering Excellence: Unveiling Our Hydraulic Goods Lift Manufacturer Expertise

What sets Future Industries Pvt. Ltd. apart from the competition is our unwavering commitment to engineering excellence. As a Hydraulic Goods Lift Manufacturer, we harness the power of cutting-edge technology to craft lifts that are not only robust and durable but also efficient and user-friendly. Our team of skilled engineers and designers collaborate to develop custom solutions that seamlessly integrate into your existing workflow, optimizing productivity and safety.

Safety First: Industrial Goods Lifts Designed for Secure Operations

Safety is the foundation of every product we manufacture. Our Industrial Goods Lifts are equipped with the latest safety features, adhering to international standards. From anti-fall systems and emergency stop buttons to overload protection mechanisms, we leave no stone unturned in ensuring that your workforce can handle goods with peace of mind. At Future Industries Pvt. Ltd., we believe that a safe working environment is a productive working environment.

Elevating Efficiency: The Advantages of Our Goods Lifts

Investing in a Future Industries goods lift brings forth a plethora of advantages. Firstly, our lifts significantly reduce the manual effort required for material handling, streamlining operations and minimizing downtime. This, in turn, leads to enhanced efficiency and cost savings for your business. Secondly, the versatility of our lifts allows for seamless transportation of goods between different floors, maximizing the utilization of available space. With our goods lifts, witness a transformation in your material handling processes like never before.

Customer-Centric Approach: Partnering for Success

At Future Industries Pvt. Ltd., we prioritize customer satisfaction above all else. Our customer-centric approach revolves around understanding your unique requirements and providing tailor-made solutions that align perfectly with your business goals. Our dedicated support team is always ready to assist you, from the selection of the ideal goods lift to after-sales service and maintenance. With us as your partner, rest assured that your material handling needs are in safe hands.

Conclusion

In conclusion, Future Industries Pvt. Ltd. stands tall as a pioneer Goods Lift Manufacturer, empowering businesses with innovative Industrial Goods Lifts designed for optimum performance and safety. As a Hydraulic Goods Lift Manufacturer, we take pride in our engineering expertise, unwavering commitment to quality, and customer-centric approach. Elevate your material handling processes to new heights with our state-of-the-art goods lifts and experience the seamless synergy of efficiency and safety for your industrial operations. Choose Future Industries Pvt. Ltd. and step into a future of limitless possibilities.

0 notes

Text

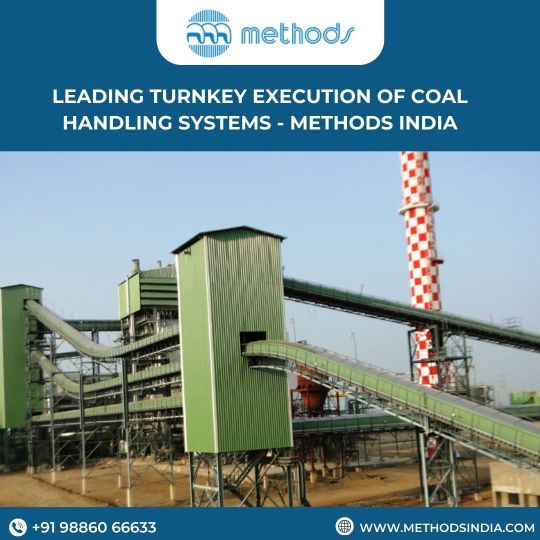

Leading Turnkey Execution of Coal Handling Systems - Methods India

In the realm of material handling, Methods India stands out as a leader in providing Turnkey execution of Coal Handling Systems. The products from Methods India are made with a focus on efficiency, safety, and simplicity. This allows for simple maintenance, which guarantees smooth operation. These turnkey solutions are designed to make moving and storing bulk materials easier.

The organization's dedication to quality has secured its standing as one of the top players in the bulk material handling sector. Find out how Methods India's innovative ideas can help you streamline your coal handling operations.

To contact us, Click on the link below- https://methodsindia.com/contact-information/

#Turnkey execution of Coal Handling Systems#Turnkey execution of Bulk Material Handling Systems#Independent Design House#Bagasse Handling Systems#Bulk material handling equipment manufacturers in Bangalore

2 notes

·

View notes

Text

Selecting the right equipment can have a big impact on your operations' overall productivity, safety, and efficiency in the ever-changing field of material handling. Appropriate selection of material handling equipment is essential whether you oversee a manufacturing plant, warehouse, or distribution center. Bhupati Engineering is Best material handling equipment manufacturers in India. If you are facing any difficulty to choose material handling equipment. Contact us

#Material Handling Equipment Manufacturers in India#Material Handling Equipment Suppliers in India#Material Handling Equipment Manufacturers#Material Handling Equipment Suppliers#material handling

2 notes

·

View notes

Text

15 Ton Overhead Cranes For Steel Slabs Handling

IntroductionManufacturing Process of Double Girder Overhead CranesUtilization of Double Girder Overhead Cranes in the Steel IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction In the world of industrial logistics, efficiency, strength, and reliability are the key characteristics that dictate the quality of equipment. We’re excited to bring forth a prime illustration…

View On WordPress

#coil handling#coil industry cranes#coil lifting#coil loading cranes#coil transport#crane design#crane manufacturing#crane operations#crane safety#girder cranes#heavy-duty cranes#high-capacity crane#hoisting equipment#industrial cranes#load management#material handling#overhead cranes#steel coil production#steel coil storage#steel coils

4 notes

·

View notes

Text

Accidents at Construction Sites: Causes, Consequences, and Prevention Measures

Introduction Construction sites are bustling hubs of activity, where skilled labor, heavy machinery, and various materials come together to create magnificent structures. However, they are also high-risk environments where accidents can and do happen. Accidents at construction sites can lead to injuries, fatalities, and financial losses. In this article, we will explore the causes, consequences,…

View On WordPress

#accident consequences#accident investigation#accident prevention#construction accident statistics#construction hazards#construction industry accidents#Construction Safety#construction site accidents#construction site fatalities#construction site insurance#construction site risks#emergency response plans#hazard assessments#hazardous materials handling#legal consequences#occupational safety#personal protective equipment#project delays#safety culture#safety measures#safety training#site inspection#worker safety#workplace injuries#workplace safety guidelines

2 notes

·

View notes

Text

Material handling is a significant activity of nearly every company involved in the handling, storage, control, and safeguarding of material as it moves through the manufacturing-distribution-use-disposal cycle.

0 notes

Text

Because commodities must constantly be moved from one place to another, industries such as nuclear power plants, chemicals, paint, and others rely heavily on material handling services. Businesses can use advanced machinery for this purpose.

Choose the correct manufacturer. It can make all the difference when it comes to material handling equipment. Purchase high-quality machinery. It can help you streamline your operations. It happens to increase output and save costs. How do you select the best manufacturer out of so many options In order to combat this? This guide will give you a list of crucial factors to take into account when selecting the leading producers of material handling equipment. These criteria will be applied while evaluating Venus Engineers' product offerings, specifications, and details.

Although it might appear self-evident

Although it may seem apparent, the type of materials being used should be taken into account initially. Examples of what could be regarded as this include tires, spools, coils, pallets, and similar items.

Determining the appropriate duties is crucial

Consider the duties at hand as well as any pertinent environmental elements, such as the ceiling height, rack type, and aisle width. Although there are many possibilities, in general, the equipment's price will increase in direct proportion to how small the aisle it can operate in.

Every potential communication cannot be anticipated

It is impractical to expect all filling, palletising, and conveying applications to be reliable. Equipment that can perform the work is necessary if your application calls for the regular filling and moving of heavy-duty containers such as drums, weighing scales, pails, or totes.

#Material Handling Equipments Manufacturers#Material Handling Equipment#Material Handling Equipments

0 notes

Note

(ᵔᴥᵔ)

Okay so I recorded a video of me getting a no-hit run on Fantoccio, but unfortunately my computer is weak, and the video has approximately 2.3 frames per second. Enjoy if you can

#i already had to turn all the graphics settings down just to get it to run smoothly#and it ran smooth while i was playing it!#but my computer couldn't handle both running the game and recording the screen#anyway just kinda wanted to show off#if i had a nickel for every time i got attached to a hard challenge in a demo i'd have 3 nickels#there's something so pure about demos you know?#no exp no items no currency no progression#just raw gameplay#that's more of an “individual level” thing than a demo thing#but demos bring that experience to games that would otherwise be consumed by distractions like equipment or exp#specifically monster hunter#in games like monster hunter the answer to a difficult challenge is “get better gear”#people like to say “your character doesn't level up in monster hunter your SKILLS do”#but that becomes more literal than they intended when you realize that stronger armor gives you better skills and stats#your character absolutely levels up in monster hunter but by equipment instead of exp#but in a demo? there's no equipment no materials no super-powerful consumable items#there's just a vampire elder dragon and the butterknife they gave you to fight with#this probably doesn't apply to Billie Bust Up tho it's just a music-platformer#definitely buying it when it comes out#ka asks

3 notes

·

View notes

Text

Maintenance Best Practices for Bulk Material Handling Equipment Longevity

In industrial operations, bulk material handling equipment is often the backbone of productivity, tirelessly moving everything from grains to minerals and aggregates. The continuous demands placed on conveyors, hoppers, silos, and other systems mean that their reliability is non-negotiable. Breakdowns can lead to costly downtime, missed deadlines, and significant financial losses. Therefore, ensuring the longevity and optimal performance of your bulk material handling equipment isn't just good practice; it's essential for sustained operational efficiency and profitability. At Meto Systems, we understand the critical role these machines play and are committed to providing material handling solutions that emphasize durability and minimal maintenance, helping you protect your investment in bulk material handling equipment for the long haul.

Implementing Regular Inspection for Bulk Material Handling Equipment

A cornerstone of equipment longevity is a robust schedule of regular inspections for all bulk material handling equipment. This isn't merely about spotting obvious failures; it involves a meticulous check of all components, from belts and rollers to motors and sensors. Early detection of wear and tear, misalignment, or minor damage can prevent major malfunctions down the line. Consistent visual and tactile inspections of your bulk material handling equipment allow for proactive intervention, addressing small issues before they escalate into costly repairs or extended downtime.

Strategic Lubrication for Bulk Material Handling Equipment

Proper lubrication is the lifeblood of moving machinery, and bulk material handling equipment is no exception. Bearings, gears, and other friction points require precise and timely application of the correct lubricants to reduce wear, prevent overheating, and ensure smooth operation. Over-lubrication can be as detrimental as under-lubrication, leading to contamination or seal damage. Developing a tailored lubrication schedule and using the recommended lubricants for your specific bulk material handling equipment is crucial for preserving its mechanical integrity and extending its lifespan.

Proactive Component Replacement for Bulk Material Handling Equipment

Wearable parts are an unavoidable reality in any machinery, especially with bulk material handling equipment subjected to constant abrasive forces. Belts, idlers, pulleys, and liners have finite lifespans, and attempting to extend their use beyond their recommended service intervals is a false economy. Proactive replacement of these components, based on manufacturer guidelines and operational hours, prevents cascading failures that can damage more expensive parts of your bulk material handling equipment. This foresight minimizes unplanned downtime and maintains operational consistency.

Ensuring Proper Alignment of Bulk Material Handling Equipment

Misalignment is a silent killer of efficiency and a major contributor to premature wear in bulk material handling equipment. Conveyor belts can track incorrectly, leading to edge damage; shafts can experience excessive vibration, damaging bearings and seals. Regular checks and precise adjustments for alignment across all moving parts are critical. Investing in specialized tools and training for your maintenance team to correctly align your bulk material handling equipment will significantly extend its operational life and reduce energy consumption.

Thorough Cleaning and Decontamination for Bulk Material Handling Equipment

Accumulation of dust, grime, and material residue can severely impact the performance and longevity of bulk material handling equipment. These build-ups can lead to corrosion, impede moving parts, and even create fire hazards, especially when dealing with combustible materials. Implementing a strict cleaning regimen, tailored to the specific materials being handled, ensures that your bulk material handling equipment remains free from corrosive agents and operational obstructions. A clean machine is not just aesthetically pleasing; it's a longer-lasting one.

Utilizing Predictive Maintenance for Bulk Material Handling Equipment

Moving beyond traditional preventive maintenance, predictive maintenance leverages technology to anticipate potential failures in bulk material handling equipment. Techniques such as vibration analysis, thermal imaging, and oil analysis can detect subtle changes indicating impending issues, allowing for maintenance to be scheduled precisely when needed, rather than on a fixed timetable. This data-driven approach optimizes maintenance efforts for your bulk material handling equipment, reducing unnecessary interventions and maximizing uptime.

Training and Skill Development for Bulk Material Handling Equipment

The expertise of your maintenance team is paramount to the longevity of your bulk material handling equipment. Well-trained technicians who understand the intricacies of each machine, its specific maintenance requirements, and best practices for troubleshooting can make a significant difference. Continuous education and skill development programs ensure your team is equipped with the latest knowledge and techniques to effectively service your bulk material handling equipment, preventing errors and enhancing overall maintenance quality.

Conclusion

The sustained efficiency and extended lifespan of your bulk material handling equipment are direct reflections of your commitment to robust maintenance practices. By diligently implementing regular inspections, precise lubrication, proactive component replacement, and ensuring proper alignment, you safeguard your significant investment. Furthermore, a focus on cleanliness, leveraging predictive maintenance technologies, and continuous training for your personnel will elevate your maintenance strategy from reactive to truly proactive. Meto Systems, as a leader in material handling solutions, advocates for these best practices, recognizing that a well-maintained system for bulk material handling equipment is the cornerstone of uninterrupted productivity and long-term operational success for any industrial facility.

0 notes

Video

youtube

Customized 5 Tons Battery Operated Trackless Transfer Cart #tech #machin...

#youtube#battery operated transfer cart#material handling equipment#platform structure transfer car#flatbed transfer trolley#steering trackless transfer vehicle#tech#machine#transporter

0 notes

Text

Top 10 Tips for Goods Tail Lift Maintenance

When it comes to running a smooth logistics or warehouse operation, maintaining your Goods Tail Lift is essential. Goods tail lifts play a critical role in the safe and efficient loading and unloading of goods. A well-maintained lift not only improves performance but also extends the equipment’s lifespan, enhances safety, and reduces long-term operational costs.

Here are the top 10 expert tips for effective Goods Tail Lift maintenance:

Conduct Regular Visual Inspections

Before each use, inspect the goods tail lift for any signs of damage, wear, or loose components. Look out for oil leaks, cracked welds, frayed wires, or hydraulic fluid levels. Early detection of issues can prevent more serious mechanical failures.

Keep the Lift Clean

Dust, debris, and spilled cargo can accumulate on the tail lift, affecting its functionality. Regularly clean the platform, hinges, and hydraulic components to ensure smooth operations. Use a mild detergent and avoid high-pressure washing near electrical components.

Lubricate Moving Parts

Lubrication is vital for maintaining the lift’s moving components such as hinges, joints, and rollers. Use recommended lubricants and follow the manufacturer’s guidelines. Lubricating at regular intervals reduces friction and prevents rust and wear.

Check Hydraulic System Performance

The hydraulic system is the powerhouse of a Goods Tail Lift. Monitor the hydraulic fluid levels and check for any leaks. Replace the fluid as recommended by the manufacturer to ensure efficient lift movement and avoid breakdowns.

Ensure Proper Electrical Functioning

Inspect the wiring, switch connections, and control boxes. Make sure there are no exposed wires or corroded terminals. Faulty electrical systems can lead to malfunctioning lifts or safety hazards.

Test the Emergency Controls

Every goods tail lift is equipped with emergency stop buttons and manual override systems. Test these features regularly to ensure they work properly in case of a failure or emergency.

Monitor the Load Capacity

Avoid exceeding the recommended load capacity of the lift. Overloading not only wears out the lift faster but also poses serious safety risks. Make sure your team is trained to distribute weight evenly and stay within operational limits.

Schedule Routine Professional Servicing

While daily checks are important, a professional technician should service your Goods Tail Lift at regular intervals. They can perform in-depth diagnostics, check alignment, recalibrate the system, and replace worn-out parts.

Replace Worn Components Promptly

Delaying the replacement of worn-out parts like bearings, bolts, or hydraulic hoses can lead to major issues. Keeping a stock of essential spare parts can minimize downtime and ensure uninterrupted service.

Maintain a Maintenance Logbook

Track every inspection, repair, and replacement done on the lift. A maintenance log helps identify recurring issues, ensures compliance with safety standards, and can be valuable for warranty or insurance purposes.

Conclusion

Maintaining a Goods Tail Lift doesn’t have to be complicated. With routine checks, proper servicing, and a proactive maintenance approach, you can ensure the lift operates safely and efficiently for years to come. Investing time and resources in maintenance not only improves productivity but also ensures the safety of your team and the integrity of the cargo being transported.

0 notes