#MaterialsEngineering

Explore tagged Tumblr posts

Text

Job - Alert 🌿

🔬 Jetzt bewerben: Scientist (w/m/d) – Research Lead für draht-basierte Additive Fertigung (WAAM)

📍 LKR Leichtmetallkompetenzzentrum Ranshofen | AIT Austrian Institute of Technology

Gestalte die Zukunft der Industrie mit! Du hast ein Faible für innovative Schweißprozesse, Leichtmetalle und Additive Fertigung? Dann werde Teil des führenden Forschungsteams für WAAM-Technologien und bringe Schlüsselprozesse für Luftfahrt, Automotive & Co. auf das nächste Level! ✈🚘

🗓 Jetzt bewerben bis 31.05.2025

👉 Karriere starten am AIT:

https://www.academiceurope.com/job/?id=7601

0 notes

Text

Material Science

Materials Science is a dynamic and interdisciplinary field that explores the properties, structures, and applications of materials to drive advancements in technology, engineering, and science. By studying the atomic and molecular makeup of metals, ceramics, polymers, composites, and semiconductors, materials scientists develop new materials with enhanced properties. These innovations support industries such as aerospace, electronics, energy, and healthcare. From creating lightweight materials for sustainable energy systems to designing biocompatible materials for medical devices, Materials Science is at the forefront of solving global challenges.

Website : sciencefather.com

Nomination: Nominate Now

Registration: Register Now

Contact Us: [email protected]

#sciencefather#researcher#Professor#Lecturer#Scientist#Scholar#BestTeacherAward#BestPaperAward#MaterialsScience#MaterialsEngineering#Nanomaterials#Metallurgy#Ceramics#Polymers#Composites#Biomaterials#SmartMaterials#SustainableMaterials#EngineeringInnovation

0 notes

Text

Chiral Powers Next-Generation Electronics With Nanomaterials as It Raises $3.8m

More information: https://www.blogger.com/blog/post/edit/7484431261636362440/7216388672942310532

Visit : electronicmaterialsconference.com

For Enquiry: [email protected] Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WEMC#ElectronicMaterials#MaterialsScience#TechConference#Semiconductors#Nanotechnology#AdvancedMaterials#Innovation#Electronics#Research#MaterialsEngineering#FutureTech#MaterialProperties#ConferenceNetworking#TechTrends

0 notes

Text

Plastic Compounding Market Analysis: Trends, Innovations, and 2024 Forecast Study

Plastic Compounding Market: Exploring the Lucrative Trends, Growth Factors, and Projections

In recent years, the Plastic Compounding Market has witnessed significant growth, driven by a surge in demand across various industries worldwide. With a forecasted valuation of USD 72.3 billion by 2023 and a projected compound annual growth rate (CAGR) of 8.3% for the period 2023-2032, the market presents lucrative opportunities for investors, manufacturers, and stakeholders alike.

Understanding the Dynamics of the Plastic Compounding Market

Market Overview and Definition

The Plastic Compounding Market encompasses the process of blending different polymers with additives, fillers, and reinforcing agents to enhance their properties and performance for specific applications. This process plays a pivotal role in industries such as automotive, packaging, building & construction, electrical & electronics, and more.

Get a Totally Free PDF Sample Request Here@ https://dimensionmarketresearch.com/report/plastic-compounding-market/request-sample/

Key Takeaways

Targeted Audience

Segmentation by Material

Polyethylene (PE)

Polyethylene compounds find extensive usage in packaging, automotive components, and construction materials due to their versatility, durability, and recyclability.

Polypropylene (PP)

PP compounds are widely employed in automotive parts, consumer goods, and packaging owing to their high stiffness, heat resistance, and chemical inertness.

Polyvinyl Chloride (PVC)

PVC compounds are favored in construction, healthcare, and automotive sectors for their exceptional flame retardancy, weather resistance, and electrical insulation properties.

Polyethylene Terephthalate (PET)

PET compounds are prominently utilized in packaging applications, particularly for beverages and food products, due to their transparency, strength, and barrier properties.

Polycarbonate (PC)

PC compounds are valued for their impact resistance, optical clarity, and heat resistance, making them ideal for applications in automotive glazing, electronics, and medical devices.

Acrylonitrile Butadiene Styrene (ABS)

ABS compounds offer excellent mechanical strength, impact resistance, and surface finish, making them suitable for diverse applications ranging from automotive components to consumer electronics.

Others

This category encompasses a range of specialty compounds tailored to specific industry requirements, including polyamide (PA), polyurethane (PU), and thermoplastic elastomers (TPE).

Customize Your Request with our Experts@ https://dimensionmarketresearch.com/enquiry/plastic-compounding-market

Segmentation by Application

Automotive

The automotive industry extensively utilizes plastic compounds for interior and exterior components, under-the-hood parts, and lightweighting initiatives to enhance fuel efficiency.

Packaging

Plastic compounds play a pivotal role in the packaging sector, offering solutions for rigid and flexible packaging applications, including bottles, films, containers, and closures.

Building & Construction

In the building and construction sector, plastic compounds are employed in pipes, fittings, profiles, insulation materials, and roofing membranes due to their durability, corrosion resistance, and cost-effectiveness.

Electrical & Electronics

Plastic compounds serve critical functions in electrical and electronic applications such as cables, connectors, housings, and insulating materials, providing thermal stability, electrical insulation, and flame retardancy.

Optical Media

Optical media applications utilize plastic compounds for manufacturing CDs, DVDs, Blu-ray discs, and optical storage devices, requiring high clarity, dimensional stability, and scratch resistance.

Industrial Machinery

Plastic compounds are incorporated into various industrial machinery components, including gears, bearings, housings, and conveyor belts, to improve performance, reduce maintenance, and extend service life.

Others

Additional applications include medical devices, consumer goods, textiles, and agricultural products, demonstrating the versatility and adaptability of plastic compounds across diverse industries.

Key Factors Driving Market Growth

Recent Developments (2023-2024)

In 2023 and 2024, the plastic compounding market witnessed several notable developments, including:

FAQs (Frequently Asked Questions)

1. What is plastic compounding, and how does it differ from simple polymer processing?

Plastic compounding involves blending polymers with additives, fillers, or reinforcements to modify their properties, whereas simple polymer processing typically involves shaping or molding polymers into finished products without significant alteration of their composition.

2. What are the primary factors driving the demand for plastic compounds in the automotive industry?

The automotive industry's demand for plastic compounds is driven by factors such as lightweighting initiatives, fuel efficiency requirements, design flexibility, and cost-effectiveness compared to traditional materials like metal.

3. How do environmental concerns influence the development of plastic compounds?

Environmental concerns drive the development of eco-friendly plastic compounds by promoting the use of recycled materials, bio-based additives, and sustainable manufacturing practices to minimize environmental impact and promote circular economy principles.

4. What role do plastic compounds play in the packaging industry?

Plastic compounds play a crucial role in the packaging industry by offering solutions for rigid and flexible packaging applications, providing barrier properties, shelf life extension, and visual appeal while meeting regulatory requirements and consumer preferences.

5. How do technological advancements contribute to the growth of the plastic compounding market?

Technological advancements in compounding processes enable manufacturers to produce high-performance compounds with enhanced properties, processing efficiency, and cost-effectiveness, thereby driving innovation and market growth.

6. What are the emerging applications of plastic compounds in niche markets?

Emerging applications of plastic compounds in niche markets include 3D printing filaments, medical implants, smart textiles, and specialty consumer products, showcasing the versatility and adaptability of plastic materials across diverse industries.

#PlasticCompounding#MarketAnalysis#IndustryInsights#GrowthTrends#Innovation#MarketResearch#PolymerScience#MaterialsEngineering#Sustainability

0 notes

Text

𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬 𝐂𝐥𝐚𝐬𝐬𝐢𝐟𝐢𝐜𝐚𝐭𝐢𝐨𝐧: Materials are categorized into various classes, including metals, ceramics, polymers, composites, and semiconductors. Each class has unique properties and is suited for specific applications.

𝐏𝐫𝐨𝐩𝐞𝐫𝐭𝐢𝐞𝐬 𝐨𝐟 𝐌𝐚𝐭𝐞𝐫𝐢𝐚𝐥𝐬: Materials scientists study the physical, mechanical, electrical, thermal, and chemical properties of materials.

Visit @ https://symbiosisonlinepublishing.com/materialsscience-engineering/

#engineering#nanotechnology#nanotech#materialscience#materials#materialsengineering#materialsresearch#metalmaterials#newenergymaterials#polymers#Ceramicmaterials#MicroelectronicMaterials#bioengineeringmaterials#bioengineering#biomedicalmaterials#compositematerials#functionalmaterials#materialsprocessingtechnology#sciencejournal#journals#journal#publication#publishing#symbiosisonlinepublishing#pubmed#peerreview#openaccess#openaccessjournal

0 notes

Text

#metallurgicalengineering#materialsengineering#materialsscience#engineering#careers#futureproof#growth#innovation#technology#sustainability

1 note

·

View note

Text

Material science

Material science is an interdisciplinary field focused on understanding the properties, structure, and performance of materials—from atomic-level arrangements to real-world applications. It bridges physics, chemistry, and engineering to develop innovative materials like nanomaterials, smart polymers, and biomimetic structures for use in energy, electronics, medicine, and sustainable technology. Advances in material science are critical for breakthroughs in energy storage, lightweight composites, semiconductors, and environmentally friendly alternatives.

International Chemistry Scientist Awards

Website: chemistryscientists.org

Contact us: [email protected]

Nominate now: https://chemistryscientists.org/award-nomination/?ecategory=Awards&rcategory=Awardee

#sciencefather#researchawards#Professor,#Lecturer,#Scientist,#Scholar,#Researcher#MaterialScience #Nanomaterials#Biomaterials#SmartMaterials #AdvancedMaterials#EnergyStorage#SustainableMaterials#MaterialsEngineering#MaterialsInnovation#FunctionalMaterials#MaterialsCharacterization#CompositeMaterials#MaterialsResearch#PhysicsAndChemistry #NextGenMaterials

👉 Don’t forget to like, share, and subscribe for more exciting content!

Get Connected Here: =============

Blogger :https://www.blogger.com/blog/post/edit/6961521080043227535/467226973388921229

Twitter : https://x.com/chemistryS79687

Pinterest : https://in.pinterest.com/chemistryaward/

Instagram: https://www.instagram.com/alishaaishu01/

Youtube : https://www.youtu

be.com/channel/UCAD_pDvz3ZHqv_3hf-N0taQ

0 notes

Text

CATL’s Battery Innovations: A Masterclass in Electrochemical R&D

At its Super Tech Day, CATL showcased three technologies redefining energy storage through advanced materials science and rigorous R&D. Here’s the scientific breakdown:

1. Shenxing Gen 2 Superfast Charging Battery

🔹12C Charging Mechanism: Utilizes a gradient electrode architecture with alternating layers of single-crystal NCM (LiNiCoMnO₂) and conductive graphene. This design shortens lithium-ion diffusion paths to <2 μm, enabling 520 km of range in 5 minutes (CLTC).

🔹Low-Temperature Electrolyte: A LiPF6-LiFSI dual-salt system with fluoroethylene carbonate (FEC) and vinylene carbonate (VC) additives creates a self-healing SEI layer, reducing dendrite growth at -10°C. Operando Raman spectroscopy confirmed stable SEI formation during 15-minute fast charges.

🔹Thermal Management: Vapor chamber cooling between electrode tabs, validated through 3D thermal imaging, maintains cell temperatures below 70°C during 12C pulses.

2. Freevoy Dual-Power Battery

🔹Heterogeneous Electrode Design: Combines LFP (LiFePO₄) and NCM (LiNiCoMnO₂) cathodes via a bi-directional DC/DC converter, enabling simultaneous high-energy and high-power outputs. In-situ X-ray diffraction revealed minimal phase separation during 12C charging.

🔹Self-Healing Anode: Prestored lithium reservoirs (5% excess Li) compensate for SEI growth, achieving <2% capacity fade/1,000 cycles in autonomous driving mode. Atomic force microscopy (AFM) showed SEI thickness stabilization at ≈50 nm after 500 cycles.

🔹Thermal Resilience: Phase-change material (PCM) layers between cells, using paraffin wax doped with graphene, maintain pack temperature uniformity within ±2°C during 4C discharge.

3. Naxtra Sodium-Ion Battery

🔹Prussian White Cathode: Na₂Mn[Fe(CN)₆] with Mn³⁺/Mn²⁺ redox tuning achieves 155 mAh/g capacity at 3.8V average voltage, closing the gap with lithium-ion. Synchrotron X-ray absorption spectroscopy (XAS) confirmed manganese’s dominant redox role.

🔹Biomass-Derived Anode: Pine-derived hard carbon with 0.5–2 nm micropores, synthesized via CO₂ activation, delivers 290 mAh/g capacity through solvent co-intercalation. Small-angle neutron scattering (SANS) mapped optimal pore distributions.

🔹Cryogenic Electrolyte: EC/PC/FEC ternary solvent with NaPF₆ salt remains amorphous at -40°C, proven by differential scanning calorimetry (DSC) showing no crystallization peaks down to -50°C.

These innovations resulted from 8+ years of R&D, including >10,000 cycle tests and collaborations with 15 global research institutes.

What advancements in battery technology are you most excited about? Share your thoughts and join the conversation!

#BatteryScience #Electrochemistry #CATL #MaterialsEngineering #SustainableTech

0 notes

Text

7th Edition of International Material Scientist Awards | 25-26 April 2025 | Berlin, Germany #sciencefather

Material Scientist Awards celebrate outstanding achievements in materials science, recognizing breakthroughs in research, development, and applications. These awards honor individuals and teams who push the boundaries of innovation, contributing to advancements in technology, sustainability, and industry practices.

Website Link: https://materialscientists.com/

Nomination Link: https://materialscientists.com/award-nomination/?ecategory=Awards&rcategory=Awardee

Contact us: [email protected]

#sciencefather #materialscience #innovationawards #sustainablematerials #technologyadvancements #materialsengineering #researchawards #chemistry #physics_wallah_best_ever_motivation #engineering #nanotechnology #biomaterials #metallurgy #awardwinning #scientificexcellence #sciencediscovery

Social media link

LinkedIn: https://www.linkedin.com/feed/

Twitter: https://x.com/materialsc123

Pinterest: https://in.pinterest.com/materialscientistaward/

Blogger: https://www.blogger.com/u/0/blog/posts/6887070445429612373?pli=1

0 notes

Text

🛡️🔬 Nanoengineered Coatings: The Ultimate Shield for Semiconductors!

Nanoengineered semiconductor coatings are revolutionizing corrosion protection by leveraging advanced nanomaterials and surface engineering to enhance the durability of metals in extreme environments. These coatings utilize ultrathin semiconductor films embedded with nanostructures that provide superior resistance against oxidation, moisture, and chemical degradation.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS32678 &utm_source=SnehaPatil&utm_medium=Article

By integrating materials like graphene, transition metal dichalcogenides (TMDs), and conductive polymers, these coatings form a self-healing barrier that prevents metal deterioration at the atomic level. Unlike traditional corrosion-resistant coatings, nanoengineered solutions offer higher conductivity, enhanced mechanical strength, and adaptive self-repair capabilities, making them ideal for applications in aerospace, marine, automotive, and energy industries.

Industries are increasingly adopting nano-coating technologies to improve reliability and longevity of critical infrastructure, including semiconductor fabs, offshore platforms, and high-performance electronics. Recent advancements in atomic layer deposition (ALD), plasma-enhanced chemical vapor deposition (PECVD), and sol-gel nanocoatings have enabled the development of ultra-thin, transparent, and highly conductive protective layers. These coatings not only prevent corrosion but also enhance thermal stability, resist electrochemical wear, and improve semiconductor device performance in harsh environments. As the demand for high-efficiency, eco-friendly protective solutions rises, nanoengineered semiconductor coatings are emerging as a game-changer in material science, ensuring sustainable and long-lasting protection for next-generation technologies.

#nanoengineeredcoatings #corrosionprotection #semiconductorcoatings #nanotechnology #nanomaterials #advancedcoatings #metalscience #surfaceengineering #selfhealingcoatings #graphene #thinfilmtechnology #smartcoatings #industrialinnovation #materialsengineering #protectivetechnology #conductivecoatings #antioxidation #wearresistantcoatings #electrochemicalprotection #futurematerials #plasmaengineering #advancedmaterials #nanolayercoatings #thermalprotection #coatingtechnology #atomiclayerdeposition #metalcorrosion #highperformancecoatings #nextgenmaterials #semiconductorprotection #energyindustry #marinetechnology #automotivecoatings #nanotechapplications #sustainabilityinmaterials #materialscience

0 notes

Text

Aerospace Floor Panels: $3.9B to $6.8B by 2034

Aerospace Floor Panels Market plays a vital role in the design and functionality of modern aircraft, focusing on the materials that make up the floors of both commercial and military aircraft. These panels are essential for providing structural integrity, safety, and comfort, ensuring the efficient operation of aircraft during flight. Made from lightweight yet durable materials such as composite materials, aluminum, and advanced polymers, aerospace floor panels are designed to withstand the rigorous conditions of aviation while maintaining high performance.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11166 &utm_source=SnehaPatil&utm_medium=Article

The demand for aerospace floor panels has been growing in line with the expanding aviation industry. Commercial aviation is witnessing rapid growth, with an increasing number of passengers and a surge in new aircraft orders. Military aircraft also require specialized floor panels to support their demanding operations. The use of advanced materials like carbon fiber-reinforced plastics has enabled manufacturers to produce lighter, stronger, and more fuel-efficient floor panels, aligning with the industry’s push for sustainability and cost-efficiency.

Moreover, the shift toward more eco-friendly and fuel-efficient aircraft designs has further driven the demand for high-quality aerospace floor panels. These panels contribute to reducing the overall weight of aircraft, improving fuel efficiency, and enhancing the safety of passengers and crew. Additionally, manufacturers are focusing on integrating noise-reducing technologies into floor panels, enhancing passenger comfort on long-haul flights.

The Aerospace Floor Panels Market is expected to continue expanding as airlines, aircraft manufacturers, and defense contractors increasingly invest in advanced, lightweight materials. With ongoing technological advancements and a greater emphasis on passenger comfort and operational efficiency, the future of aerospace floor panels looks promising.

#aerospacefloorpanels #aircraftdesign #aviationmaterials #lightweightcomposites #advancedpolymers #aircraftflooring #carbonfiber #fuel efficiency #aerospaceindustry #passengercomfort #aviationinnovation #militaryaircraft #commercialaviation #aircraftinteriors #aerospaceengineering #floorpaneltechnology #aviationcomfort #sustainableaviation #aircraftmaintenance #defenseindustry #fuel-efficientaircraft #airlinerevolution #noisecontrol #aviationarchitecture #materialsengineering #aviationmanufacturing #aircraftsafety #aircraftstructuralcomponents #flooringdesign #aircraftconstruction #compositepanels #innovativeaerospace

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

World Electronic Materials Conference December 16-18, 2024 | Singapore

More information: electronicmaterialsconference.com

For Enquiry: [email protected] Nomination Link :https://x-i.me/emcnom Get Connected Here: ================== Facebook : https://www.facebook.com/profile.php?id=61556074815651 Twitter : https://twitter.com/PencisE28647 Pinterest : https://in.pinterest.com/electronicconference/

#WEMC#ElectronicMaterials#MaterialsScience#TechConference#Semiconductors#Nanotechnology#AdvancedMaterials#Innovation#Electronics#Research#MaterialsEngineering#FutureTech#MaterialProperties#ConferenceNetworking#TechTrends

0 notes

Text

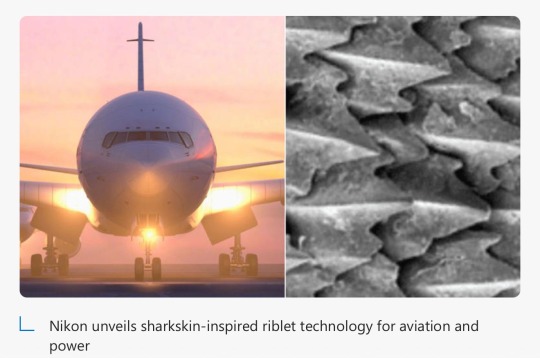

Sky Sharks, Meet Sharknado! Tech Innovation From Nikon! - IMRAN™

This news item caught my attention today. Even though I had not (and would not) see the movies Sky Sharks or Sharknado, the movie references came to mind immediately.

"Nikon unveils sharkskin-inspired riblet technology for aviation and power" ( https://lnkd.in/ebTXK9qW ). It basically is a biomimetic technology which mimics the amazing surface structure of shark skin. Nikon’s proprietary laser processing creates riblets which are artificial microstructures which resemble the fine scales on a shark’s skin. The materials have many applications from aviation to power generation.

© 2025 IMRAN™

#IMRAN #Nikon #sharks #puns #moviereferences #materialsengineering #biometrics #innovation #news #aviation Nikon

0 notes

Text

𝐌𝐞𝐭𝐚𝐥𝐬: Metals are one of the most common materials used in engineering applications. MSE researchers study the properties of metals, such as their strength, toughness, and corrosion resistance, and develop new methods for processing metals to improve their properties. 𝐂𝐞𝐫𝐚𝐦𝐢𝐜𝐬: Ceramics are materials that are made from inorganic compounds, such as clay, sand, and glass. They are often used in applications where high temperatures or corrosion resistance are required.

Visit: https://symbiosisonlinepublishing.com/materialsscience-engineering/

#engineering#nanotechnology#nanotech#materialscience#materials#materialsengineering#materialsresearch#metalmaterials#newenergymaterials#polymers#Ceramicmaterials#MicroelectronicMaterials#bioengineeringmaterials#bioengineering#biomedicalmaterials#compositematerials#functionalmaterials#materialsprocessingtechnology#sciencejournal#physics#chemistry#journals#journal#publication#publishing#symbiosisonlinepublishing#pubmed#peerreview#peerreviewed#peerreviewedjournals

0 notes

Text

Looking for OTMT1006 Materials Engineering Assignment Help!! Download solution for University Assessments!! Order Now on WhatsApp: +44 141 628 6080!!

#OTMT1006 #MaterialsEngineering #AssignmentHelp #Solution #AssessmentHelp #OnlineTutor #topassignmenthelpservices #UKtopwritingservice #AskTutor #GillinghamAssignmentHelp #HND #BTEC #AssessmentWritingService #UK

0 notes