#EngineeringInnovation

Explore tagged Tumblr posts

Video

youtube

Top 6 Wheel CNC Lathe Manufacturers in 2025 – Why HAISHU Leads

Discover the Top 6 Wheel CNC Lathe Manufacturers of 2025 in this video!

Learn why HAISHU Machinery and their CK Series Wheel CNC Lathes are transforming the industry.

🌟 Explore the full guide here: wheelcncmachine.com

📢 Labels/Tags: #WheelCNC #HAISHUMachinery #EngineeringInnovation

2 notes

·

View notes

Text

A well is drilled deep into the ground😲😆

#desiviralrecap#WellDrilling#GroundwaterExploration#BoreholeDrilling#WaterSource#DrillingLife#Hydrogeology#WaterWellConstruction#Sustainability#EngineeringInnovation#ConstructionLife#DailyGrind#NatureAndTechnolog#EnvironmentalAwareness#GreenLiving#EcoSolutions#SmartSolutions#WorkInProgress#LocalProjects#CommunityDevelopment#BuildingForTheFuture

1 note

·

View note

Text

Precision Process Equipment by U2 Stamp

Discover the excellence of U2 Stamp by Artson Engineering. Specializing in precision process equipment manufacturing, U2 Stamp ensures high standards and exceptional quality. Visit our website to explore our core competencies in delivering reliable and efficient process equipment.

#U2Stamp#ArtsonEngineering#ProcessEquipment#ManufacturingExcellence#QualityEngineering#IndustrialSolutions#PrecisionManufacturing#ReliableEquipment#EngineeringInnovation

2 notes

·

View notes

Text

Architectural Engineers In UAE

Are you seeking visionary Architectural Engineers to bring your designs to life in UAE? Look no further! Explore a curated list of top-notch architectural engineering firms on TradersFind. Unleash innovative designs with expertise you can trust.

Visit our Architectural Engineers category page to discover more! https://www.tradersfind.com/category/architectural-engineers

Connect with us on WhatsApp at +971 56 977 3623 to discuss your Architectural Engineers requirements.

#architecturalengineers#uaeengineering#constructionexcellence#buildingdesign#engineeringinnovation#topengineers#b2bplatform#tradersfind#projectsuccess#engineeringsolutions#uaeprojects#architectsofthefuture#engineeringprofessionals#b2bconnections#growyourbusiness#uaeconstruction#engineeringnetwork#buildbetter#engineeringexperts#businessgrowth#uae#UAEBusiness#business#B2B#b2bbusiness#dubai#abudhabi

2 notes

·

View notes

Text

Trusted Engineering for Instrumentation and Control Cables in Oil & Gas

MTK Supply International Corp delivers advanced engineering and project management services with a strong focus on Instrumentation and control cables Oil & Gas systems. Our expertise spans process automation, control system integration, and EPC services—from basic design through commissioning and startup.

With years of hands-on experience in industrial cabling and oilfield equipment deployment, we offer full lifecycle support that meets global industry standards.

At MTK, our tailored solutions help energy-sector engineering teams optimize operations, cut costs, and ensure efficient, reliable performance. Whether you're upgrading instrumentation or building a new Instrumentation and control cables Oil & Gas setup, you can count on our expertise to deliver results that last.

Audio version: Trusted Engineering for Instrumentation and Control Cables in Oil & Gas

#TrustedEngineering#InstrumentationCables#ControlCables#OilAndGasIndustry#OilAndGasEngineering#Cables#EngineeringExcellence#IndustrialSafety#OilFieldTech#EnergySolutions#CablesInOilAndGas#Infrastructure#EngineeringInnovation#TechInOilGas#ReliableCables#Automation#ControlSystems#ProfessionalEngineering#EngineeringForEnergy

0 notes

Text

🔹 "Sloka Infra Solutions" 🌊 From Glacial Lakes to Power Dams: 🔍 How Bathymetric Surveys Are Shaping Uttarakhand’s Water Future. 📞 Call: +91 8074692090 🌐 Visit: https://slokainfrasolutions.com/blogs/bathymetric-survey-in-uttarakhand/ 📧 Mail: [email protected]

#SlokaInfraSolutions#BathymetricSurvey#WaterMapping#UttarakhandProjects#GlacialLakeSurvey#HydropowerDevelopment#DamConstruction#WaterFuture#SurveyingIndia#HimalayanInfrastructure#EnvironmentalEngineering#GeospatialTechnology#WaterResourceManagement#EngineeringInnovation#SmartInfrastructure

0 notes

Text

HIL Testing: Elevating Embedded System Validation

Hardware-in-the-Loop (HIL) testing is a transformative approach in engineering, enabling the validation of embedded systems by integrating real hardware with simulated environments. Widely adopted in industries such as automotive, aerospace, and industrial automation, HIL testing ensures reliability, safety, and performance before deployment. By replicating real-world conditions in a controlled setting, it bridges the gap between software simulation and physical testing. This article delves into the principles, process, applications, benefits, challenges, and future of HIL testing in modern engineering.

What is HIL Testing?

HIL testing is a real-time simulation technique that connects physical hardware, such as an electronic control unit (ECU) or actuator, with a virtual model of its operating environment. The system uses a real-time simulator to run mathematical models that mimic physical conditions—e.g., vehicle dynamics, temperature variations, or electrical loads—while the hardware responds as it would in reality. This interaction allows engineers to assess functionality, detect faults, and refine designs without requiring a fully assembled prototype. Tools like dSPACE, National Instruments, and MathWorks Simulink are commonly employed for HIL setups.

How HIL Testing Works

The HIL testing process follows a structured workflow:

Model Development: Engineers create a digital representation of the system’s environment using simulation software.

Hardware Setup: The hardware under test (HUT) is connected to the simulator via interfaces like CAN, Ethernet, or analog I/O.

Simulation Execution: The simulator generates inputs (e.g., sensor data) and sends them to the HUT, which processes them and returns outputs.

Analysis: Results are monitored and evaluated to verify performance, stability, and compliance with specifications.

Iteration: Based on findings, adjustments are made, and tests are rerun.

For instance, in automotive applications, HIL testing might simulate road conditions and engine behavior, allowing an ECU to adjust fuel injection, with engineers analyzing the response for optimization.

Key Components of HIL Testing

A typical HIL system includes:

Real-Time Simulator: A high-performance computer or dedicated hardware running the simulation model with precise timing.

Hardware Under Test (HUT): The actual component, such as a controller or sensor, being validated.

Interface Hardware: Bridges the simulator and HUT, handling signal conversion and communication.

Simulation Models: Mathematical representations of the system’s environment, tailored to specific test scenarios.

Test Management Software: Tools for automating tests, logging data, and visualizing results.

Benefits of HIL Testing

HIL testing offers numerous advantages:

Cost Savings: Eliminates the need for multiple physical prototypes, reducing material and labor expenses.

Risk Reduction: Safely tests hazardous or extreme conditions without endangering hardware or personnel.

Early Validation: Identifies issues during development, preventing costly redesigns later.

Repeatability: Ensures consistent test conditions, unlike variable real-world environments.

Time Efficiency: Accelerates development by enabling parallel testing of multiple scenarios.

Applications of HIL Testing

HIL testing is critical across various sectors:

Automotive: Validates ECUs for engine management, anti-lock braking systems (ABS), and advanced driver-assistance systems (ADAS), simulating driving dynamics.

Aerospace: Tests flight control units and avionics under simulated aerodynamic and environmental conditions.

Robotics: Ensures precise coordination between sensors, actuators, and controllers in robotic systems.

Power Electronics: Optimizes control systems for renewable energy devices like solar inverters.

Medical Devices: Verifies the reliability of embedded systems in equipment like ventilators or infusion pumps.

Challenges in HIL Testing

Despite its benefits, HIL testing presents challenges:

Model Accuracy: Inaccurate simulations can lead to unreliable results, requiring high-fidelity models.

Complexity: Setting up and maintaining HIL systems demands expertise in hardware and software integration.

Hardware Costs: Initial investment in simulators and interfaces can be substantial.

Real-Time Constraints: Ensuring simulations match the timing of physical systems is technically demanding.

Scalability: Expanding HIL setups for larger, interconnected systems can be difficult.

Future Trends in HIL Testing

The future of HIL testing is shaped by emerging technologies:

Artificial Intelligence (AI): AI enhances test coverage by generating complex scenarios and predicting outcomes.

Cloud Integration: Enables remote HIL testing, fostering collaboration and reducing infrastructure costs.

Digital Twins: Real-time digital replicas improve accuracy and support continuous validation.

Advanced Communication: Supports protocols like 5G and Ethernet for faster data exchange.

Sustainability: Focuses on energy-efficient testing to align with green engineering goals.

The growth of autonomous vehicles, IoT devices, and Industry 4.0 drives the need for more advanced HIL testing solutions, ensuring robust performance in smart systems.

Role in the Development Lifecycle

HIL testing is integral at multiple stages:

Design Phase: Validates early concepts and control strategies.

Testing Phase: Confirms hardware meets requirements under simulated conditions.

Pre-Production: Ensures readiness before mass manufacturing.

Post-Deployment: Supports diagnostics and updates for fielded systems.

Career Opportunities

HIL testing expertise opens doors to roles like HIL engineer, systems validation specialist, and simulation analyst. Opportunities abound in automotive, aerospace, and tech industries, with certifications in tools like dSPACE or NI VeriStand enhancing employability. The field offers competitive salaries and growth potential as demand for embedded system validation rises.

Conclusion

HIL testing is a cornerstone of modern engineering, providing a safe, efficient, and accurate method to validate embedded systems. Its ability to simulate real-world scenarios while interfacing with hardware ensures reliability and performance across industries. Despite challenges, advancements like AI and cloud computing promise to enhance its effectiveness. As technology evolves, HIL testing will remain vital in developing innovative, dependable solutions for the future.

#HILTesting#EmbeddedSystems#SystemValidation#EngineeringInnovation#AutomotiveTech#AerospaceEngineering#RealTimeSimulation#TechAdvancement#IndustrialAutomation#SafetyTesting

0 notes

Text

0 notes

Text

#MitsubishiElectric#MitsubishiElectricCup#IndustrialAutomation#EngineeringInnovation#SkillDevelopment#FutureEngineers#Automation#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Avoid common PCB design mistakes that cause failures, production delays, and increased costs. Poor component placement, ignoring DFM, and weak grounding can all affect performance. Learn how to design smarter and build reliable products. Visit: www.auckam.com

#PCBDesign#ElectronicsEngineering#PCBManufacturing#DFM#SignalIntegrity#EmbeddedDesign#PCBLayout#ElectronicsDesign#IoTDesign#HardwareDesign#AuckamTechnologies#TechSolutions#EngineeringInnovation#SmartManufacturing#AvoidPCBErrors

0 notes

Text

Bisso 80 machinery😲😆

#desiviralrecap#Bisso80Machinery#Bisso80Tech#ReliableMachinery#BuiltForIndustry#BissoEngineering#IndustrialMachinery#MachineryExperts#EngineeringInnovation#HeavyEquipment#MachineryWorld#ConstructionMachinery#EquipmentForSuccess

1 note

·

View note

Text

#aerospace#HARTING#IndustrialAutomation#ConnectorTechnology#EngineeringInnovation#Timestech#electronicsnews#technologynews

0 notes

Text

Deep Hole Drilling Machines Market Size The global deep hole drilling machines market reached USD 624.1 Million in 2024 and is projected to hit USD 951.7 Million by 2033, growing at a CAGR of 4.8%. 🚀 Rising demand from multiple industries, automation trends, and innovative product variants are propelling this market forward. 💡 From aerospace to automotive, precision is everything—deep hole drilling tech is at the center of it all!

0 notes

Text

Engineered to be Stable. Designed to Perform. Dynemech Anti-Vibration Technology

In each industrial installation, Precision and Reliability begin from the ground level. At Dynemech Anti-Vibration Technology, we appreciate that even the most sophisticated machinery can't deliver at its optimum without a solid foundation. That's why we provide an extensive line of Anti Vibration Technology to remove vibrations, enhance machine performance, and prolong equipment life.

Our product range is designed for actual usage. Be it with CNC machines, Compressors, Injection moulding machines, textile machines, printing presses, or heavy press units, Dynemech Anti-Vibration Technology has the ideal Vibration Isolation Solution for you.

Our products range from:

Wedge Mounts for precise machine levelling and shock damping

Spring Isolators for dynamic equipment

Air Springs for sensitive devices

Shock Mounts for heavy impact absorption

Rubber Pads and Bushings for shock absorption

Precision tool Anti Vibration Platforms

And much more.

All the products are Engineered to deliver superior Vibration Isolation Performance with simplicity in installation and servicing. The designs ensure even load distribution, reduce Vibration, and help maintain machinery alignment for years. Your machines work better, are less repair-prone, and consistently deliver quality output this way.

Our products are not just useful; they're investment-worthy for your operational success. All Dynemech Anti-Vibration Technology products are crafted and manufactured with high-quality materials and go through high-level quality check procedures to make them long-lasting, efficient, and safe. We take pride in being TUV SUD ISO 9001 certified and make in India partner, reflecting our emphasis on quality and innovation.

At Dynemech Anti-Vibration Technology, we’re not just about products. We’re a technology partner focused on solving real challenges on the factory floor. Since our founding, we’ve worked closely with industries across India and the globe to provide custom Vibration Control Solutions backed by expert support.

Our vision is straightforward: To offer a solid foundation to each machine, in each industry. We're confident that if machines are solid, productivity follows, and businesses prosper.

Feel the Dynemech Anti-Vibration Technology difference—where engineering and reliability come together, and your machines receive the stability they need.

To learn more about our products: https://www.Vibrationmountsindia.com/products/

#Dynemech, #AntiVibration, #MachineStability, #Dynemech, #VibrationControl, #IndustrialSolutions, #MadeInIndia, #EngineeringInnovation, #PrecisionMachining, #VibrationIsolators, #MachineMounts, #SpringIsolators, #RubberPads, #VibrationReduction, #HeavyMachinerySupport, #StableMachines, #FactorySolutions, #IndustrialMounts, #TUVCertified, #ManufacturingSupport, #CNCStability

Phone: +91-9810760131

Email: [email protected]

Website: www.vibrationmountsindia.com

#Dynemech#AntiVibration#MachineStability#VibrationControl#IndustrialSolutions#MadeInIndia#EngineeringInnovation#PrecisionMachining#VibrationIsolators#MachineMounts#SpringIsolators#RubberPads#VibrationReduction#HeavyMachinerySupport#StableMachines#FactorySolutions#IndustrialMounts#TUVCertified#ManufacturingSupport#CNCStability

0 notes

Text

Rotary Seals - Jacketed spring Energised Rotary Seals

Introducing Jacketed Spring Energised Rotary Seals — the ultimate solution for high-speed rotary applications that demand reliability, chemical resistance,

Contact: 080-48519779 https://triumphseals.com/portfolio-item/rotary-shaft-seals-supplier-in-bangalore/

#RotarySeals#SpringEnergisedSeals#JacketedSeals#IndustrialSeals#PTFESeals#HighPerformanceSeals#SealTechnology#MachinerySolutions#EngineeringInnovation#MechanicalSeals#HydraulicSeals#SealingSolutions#PrecisionEngineering#CustomSeals#SealExperts

0 notes

Text

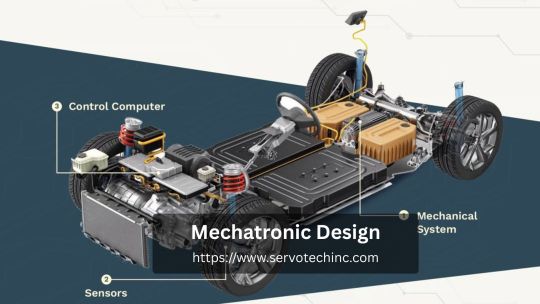

Mechatronic design integrates mechanical, electronic, and control systems for innovative, efficient engineering solutions.

#MechatronicDesign#EngineeringInnovation#SmartSystems#RoboticsTechnology#ControlEngineering#MechanicalDesign#ElectronicsIntegration#AutomationTech#InnovativeSolutions#TechAdvancement

0 notes