#Multi axis robot control

Explore tagged Tumblr posts

Text

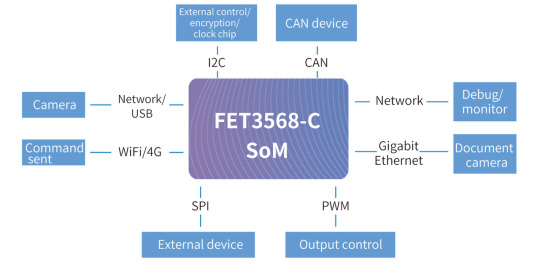

Application Solution for Multi-axis Robot Control Based on FET3568J-C CoM

Multi-axis robot control refers to the process of controlling the motion, position, and tasks of robots with multiple motion axes or joints. Multi-axis robots are typically comprised of multiple motors and joints, allowing them to move and perform various tasks across multiple degrees of freedom. Multi-axis robots are widely used in industry, manufacturing, healthcare, military, and service robots to improve production efficiency and perform various tasks.

The main core points for a multi-axis robot controller are as follows:

Joint control: The joints of a multi-axis robot are the basic units of its motion and are usually driven by motors. The control of each joint involves setting a target angle or position to achieve the desired movement.

Feedback control: Multi-axis robots are often equipped with sensors such as encoders, inertial sensors and vision sensors to provide real-time feedback. Feedback control allows the robot to correct motion errors and adjust its position and attitude to accommodate instabilities or external disturbances.

Task control: Multi-axis robot control also involves performing various tasks, such as grasping, assembling, welding, painting, and so on. Task control often requires advanced control algorithms and planners to implement complex action sequences.

Programming mode: Multi-axis robots can be controlled by different programming methods, including manual programming, off-line programming, teaching-based programming and automated programming. Each method has its own applicable scenarios and advantages.

Safety: Safety is very important in multi-axis robot control. Robots must be designed and operated to prevent hazardous situations and need to have emergency stop and collision detection.

Based on this, Forlinx brings FET3568J-C computer on module, which adopts a quad-core 64-bit Cortex-A55 industrial-grade processor with a main frequency of up to 2.0GHZ and integrates a 1TOPS arithmetic NPU internally.

With preempt rt87 patch, the system real-time: 10~50μs, can meet the different applications in the industrial field for real-time requirements.

Rich functional interfaces: 2xchannel Gigabit Ethernet, 3xchannel PCLE, 4xchannel independent USB, 3xchannel SATA3.0, 10xchannel UART, etc.

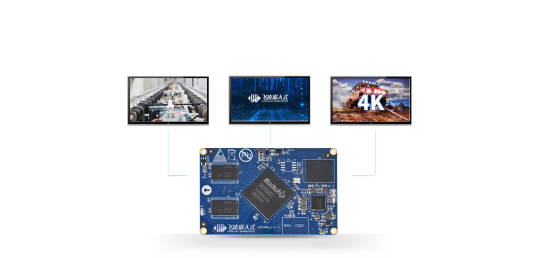

It has powerful multimedia and image processing capabilities, supports high-definition hard decoding in multiple formats, integrates dual-core GPU, and supports all mainstream modern image APIs.

Using the ARM architecture to implement a controller has many advantages, including:

Low Power Consumption: ARM processors typically have low power consumption, which makes them ideal for embedded systems and mobile devices, especially for applications that require long running times. Low power consumption helps to extend battery life and reduce the energy consumption of the device.

High Performance: Although ARM processors have low power consumption, they still provide excellent performance. ARM's different core designs are suitable for a variety of applications, from low-power microcontrollers to high-performance multi-core processors, which can meet the performance needs of a variety of controller applications.

Multi-core processing: ARM processors support multi-core processing, which means they can integrate multiple processing cores on a single chip for parallel processing and higher performance. This is useful for controllers that need to handle multiple tasks or multiple sensor inputs.

Flexibility: The ARM architecture is very flexible and can be customized to meet the needs of the application. The ARM architecture is very flexible and can be customized to meet the needs of the application.

Ecosystem support: ARM has a large ecosystem of development tools, operating systems, applications and third-party support. This makes it easier to develop and maintain ARM controller-based systems.

Cost-effectiveness: ARM processors are usually relatively cheap due to the widespread adoption and standardization of the ARM architecture This reduces manufacturing costs and helps create competitive controller products.

Wide Range of Applications: ARM processors are suitable for a wide range of applications, including embedded systems, the Internet of Things (IoT), automotive, industrial automation, medical devices, consumer electronics and communication devices. This means that the ARM processor can be reused in different controller applications.

Safety: ARM processors provide hardware-level security features that protect devices from malicious attacks and data leakage. This is important for controller applications that require a high degree of security.

Originally published at www.forlinx.net.

0 notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

Precision and Automation Redefined: Robotic Soldering Station in India – Powered by Ascomp Inc

As the demand for high-speed, precision-based electronics manufacturing continues to grow, manual soldering is no longer sufficient for maintaining consistency, safety, and throughput. Enter the robotic soldering station in India, a powerful innovation that brings automation to one of the most critical steps in PCB assembly. At Ascomp Inc, we supply cutting-edge robotic soldering solutions built for modern Indian factories—designed to enhance productivity, reduce human error, and ensure flawless results.

What is a Robotic Soldering Station?

A robotic soldering station is an automated machine equipped with programmable arms, temperature-controlled soldering tips, and precise motion control systems. It is used to automate repetitive soldering tasks on circuit boards, connectors, and terminal blocks.

Unlike traditional hand soldering, robotic soldering offers:

Consistent solder joints

Reduced operator fatigue

Greater speed and throughput

Lower rework and rejection rates

Better control over temperature and solder feed

Whether you're running a high-volume SMT line or a mid-scale EMS setup, a robotic soldering station in India delivers unmatched accuracy and repeatability.

Key Features of Ascomp Inc’s Robotic Soldering Systems

🤖 Multi-axis robotic arm for precise solder point control

🔥 Temperature-controlled iron tip with programmable profiles

🎯 Vision system and sensors for auto-alignment and inspection

💡 Custom jig fixtures to suit different PCB layouts

🛠️ Automated solder feeding system for consistent wire delivery

⚙️ User-friendly programming interface for custom routines

We also offer fume extraction integration and ESD-safe construction to meet electronics industry safety standards.

Ideal Applications

Our robotic soldering stations are suited for:

SMT and through-hole component soldering

Wire-to-board connections

Connector pin soldering

LED assemblies

Fine-pitch PCB assemblies

Automotive and EV electronics

Telecom and defense equipment manufacturing

Whether you're automating a high-speed production line or improving quality in low-volume, high-precision builds, Ascomp Inc has a model that fits your needs.

Why Invest in Robotic Soldering?

✅ Higher throughput with minimal manual intervention

✅ Lower training and labor costs

✅ Repeatable quality across thousands of units

✅ Fewer operator-related defects

✅ Improved traceability and data logging

It’s not just a tool—it’s a productivity multiplier for forward-thinking electronics manufacturers.

Why Choose Ascomp Inc?

📦 Ready stock of robotic soldering machines in India

🔧 Pre-sales guidance and post-installation support

💼 Integration with existing conveyor or workbench setups

🖥️ Training and programming assistance

🔄 Availability of spare parts and maintenance contracts

🛠️ Proven track record with EMS companies and R&D units

Our solutions are scalable, reliable, and fully customizable based on your board layout and workflow.

#RoboticSolderingIndia#AscompInc#PCBAssemblyTools#ElectronicsAutomationIndia#SMTProductionIndia#AutomatedSolderingStation#IndustrialSolderingRobot#SolderingAutomation#ESDCompliantSoldering#PrecisionElectronicsIndia

0 notes

Text

The Mechatronic Design Engineer: Powering Automation with CODESYS

Mechatronic design engineering is a multidisciplinary field that blends mechanical engineering, electronics, control systems, and software development to create intelligent, automated systems. Mechatronic design engineers are at the forefront of innovation, designing solutions for industries like robotics, automotive, aerospace, and manufacturing. CODESYS, an IEC 61131-3-compliant development platform, is a critical tool for these engineers, enabling them to program and integrate control systems for complex mechatronic applications. This article explores the role of a mechatronic design engineer, how CODESYS supports their work, key responsibilities, required skills, and real-world applications, highlighting the impact of this profession on modern automation.

The Essence of Mechatronic Design Engineering

Mechatronic design engineering focuses on creating systems that integrate mechanical components, electronic circuits, sensors, actuators, and software to achieve precise, reliable performance. These systems, such as robotic arms, autonomous vehicles, or CNC machines, require seamless coordination between hardware and software. Mechatronic design engineers ensure that these components work together to meet performance, safety, and efficiency goals, making them essential in industries embracing Industry 4.0 and smart automation.

CODESYS is a cornerstone for mechatronic design engineers, offering a versatile, hardware-independent platform for programming embedded control systems. Its compliance with IEC 61131-3, support for multiple programming languages, and robust tools for simulation and debugging make it ideal for developing sophisticated mechatronic systems.

Responsibilities of a Mechatronic Design Engineer

Mechatronic design engineers undertake a variety of tasks to bring complex systems to life:

System Design and Integration: Designing integrated systems that combine mechanical structures, electronics, and control software to meet specific functional requirements.

Control System Programming: Developing control algorithms to manage sensors, actuators, and motion systems, ensuring precise operation.

Simulation and Testing: Using simulation tools to validate system performance before deployment, minimizing errors and risks.

Prototyping and Commissioning: Building prototypes, integrating components, and deploying systems in real-world environments.

Optimization and Troubleshooting: Analyzing system performance, debugging issues, and optimizing designs for efficiency and reliability.

Collaboration: Working with mechanical, electrical, and software teams to ensure cohesive system development.

How CODESYS Empowers Mechatronic Design Engineers

CODESYS provides a comprehensive environment tailored to the needs of mechatronic design engineers:

IEC 61131-3 Programming Languages: CODESYS supports Ladder Diagram (LD), Function Block Diagram (FBD), Structured Text (ST), Instruction List (IL), and Sequential Function Chart (SFC). These languages enable engineers to develop control logic for diverse applications, from simple discrete controls to advanced motion systems.

Hardware Flexibility: Compatible with PLCs and embedded controllers from vendors like Beckhoff, WAGO, and Siemens, CODESYS allows engineers to choose hardware that suits project budgets and requirements.

Motion Control Libraries: CODESYS offers libraries for motion control, supporting tasks like servo motor control, trajectory planning, and multi-axis coordination, critical for mechatronic systems like robotics.

Simulation and Debugging Tools: The built-in simulation mode enables testing without physical hardware, while debugging features like breakpoints and real-time monitoring help identify and resolve issues quickly.

HMI Development: CODESYS provides tools to create Human-Machine Interfaces (HMIs) for operator interaction, including graphical displays and web-based visualizations.

Communication Protocols: Support for EtherCAT, CANopen, Modbus, and OPC UA ensures seamless integration with sensors, actuators, and other devices in mechatronic systems.

Safety Standards: For safety-critical applications, CODESYS supports IEC 61508 (SIL 2/3), enabling engineers to design systems for industries like automotive and aerospace.

Example: Robotic Arm Control Program

Below is a sample Structured Text (ST) program for controlling a robotic arm’s position in a mechatronic system:

RoboticArmControl.st

plain

Show inline

This program implements a proportional control loop to adjust a robotic arm’s joint angle, ensuring precise positioning in a mechatronic application.

Essential Skills for Mechatronic Design Engineers

To succeed, mechatronic design engineers need a diverse skill set:

Multidisciplinary Knowledge: Proficiency in mechanical design, electronics, and control systems programming, including CODESYS and IEC 61131-3 languages.

Control Theory: Understanding of control algorithms, such as PID control, for precise system management.

Software Development: Experience with embedded systems programming and real-time operating systems (RTOS).

Problem-Solving: Analytical skills to troubleshoot and optimize complex systems.

Teamwork: Collaboration with cross-functional teams to integrate hardware and software components.

Adaptability: Staying updated with emerging technologies like IoT, AI, and cybersecurity.

Benefits of Using CODESYS

Streamlined Development: The integrated IDE and simulation tools reduce development time and errors.

Cost Efficiency: Hardware independence and code reusability lower project costs.

Scalability: CODESYS supports projects from small prototypes to large-scale industrial systems.

Flexibility: Multiple programming languages and protocols cater to diverse project needs.

Community Support: A global user base and resources like the CODESYS Store provide access to libraries and tutorials.

Applications in Industry

Mechatronic design engineers leverage CODESYS in various sectors:

Robotics: Developing control systems for industrial and collaborative robots.

Automotive: Designing ECUs for engine management, braking, and autonomous driving.

Manufacturing: Automating production lines, CNC machines, and material handling systems.

Aerospace: Controlling actuators and sensors in aircraft and spacecraft.

Medical Devices: Creating precise control systems for surgical robots and diagnostics.

Challenges in Mechatronic Design Engineering

Interdisciplinary Complexity: Integrating mechanical, electrical, and software components requires broad expertise.

Learning Curve: Mastering CODESYS and IEC 61131-3 languages can be time-intensive for beginners.

Resource Constraints: Embedded systems often have limited processing power, necessitating optimized code.

Safety Requirements: Meeting standards like IEC 61508 for safety-critical applications adds complexity.

Getting Started with CODESYS

To begin as a mechatronic design engineer using CODESYS:

Install CODESYS: Download the free IDE from the official website.

Learn Programming: Study IEC 61131-3 languages through tutorials and documentation.

Select Hardware: Choose a compatible PLC or embedded controller.

Develop and Simulate: Write control logic, test in simulation mode, and debug.

Deploy: Compile and deploy code to the target hardware.

Future Trends

As industries embrace digital transformation, mechatronic design engineers will increasingly use CODESYS for IoT-enabled systems, cloud-based monitoring, and AI-driven control. Support for protocols like OPC UA and MQTT positions CODESYS for smart manufacturing, while advancements in cybersecurity ensure its relevance in safety-critical applications.

Conclusion

Mechatronic design engineers by Servotechinc are key to creating the intelligent systems that drive modern automation, from robotics to autonomous vehicles. CODESYS empowers these professionals with a flexible, IEC 61131-3-compliant platform for programming, testing, and deploying control systems. Its robust features, hardware independence, and support for motion control and communication protocols make it indispensable for mechatronic applications. As technology advances, CODESYS and mechatronic design engineers will continue to shape the future of automation, delivering innovative, efficient, and reliable solutions.

0 notes

Text

Mogra Engineering gives you Leading Welding Positioner Manufacturer

Welding Positioners: Boosting Precision and Productivity in Modern Manufacturing

In today’s competitive industrial environment, manufacturers are constantly seeking tools and solutions that enhance productivity, ensure precision, and maintain safety. One such innovation that has transformed welding processes across industries is the welding positioner. If you're exploring products/welding-positioners/ to upgrade your facility, understanding their value, types, and applications is essential.

This blog delves into how welding positioners streamline operations, improve welding quality, and contribute to overall operational efficiency.

What Are Welding Positioners?

Welding positioners are mechanical devices designed to rotate, tilt, or elevate a workpiece to achieve the best possible welding angle. They allow welders to access hard-to-reach areas without compromising on ergonomics or weld quality. The core purpose of using welding positioners is to maintain a constant and comfortable working position for the welder while ensuring that the welding torch maintains a consistent angle and distance from the work surface.

If you're browsing products/welding-positioners/ on industrial equipment websites, you'll typically find a wide range of models tailored for different workloads, weld types, and automation needs.

Why Use Welding Positioners?

Improved Weld Quality Consistent positioning leads to uniform welds. A stable and controllable setup reduces errors, spatter, and undercuts. Welding positioners allow for precision alignment, resulting in cleaner and stronger weld joints.

Increased Productivity Welders no longer need to manually reposition heavy workpieces. With automated rotation and tilting, welding time is reduced significantly. Searching for products/welding-positioners/ is a smart move for workshops aiming to increase output with fewer man-hours.

Enhanced Safety Handling large or oddly shaped components can be hazardous. Positioners eliminate the need for overhead cranes or manual lifting, reducing risks and workplace injuries.

Operator Comfort and Ergonomics Welders can work in the most comfortable and ergonomic positions, reducing fatigue and improving focus—an essential factor for long welding sessions.

Types of Welding Positioners Available

If you're scanning through products/welding-positioners/ categories, you’ll come across different types, each suited to specific requirements:

1. Rotary Welding Positioners

These rotate the workpiece on a horizontal or vertical axis. They are ideal for circular welds, such as pipe welding.

2. Head and Tailstock Positioners

These units support and rotate large and heavy workpieces between two points. They’re commonly used for structural welding in industries like aerospace and shipbuilding.

3. Tilt and Turn Positioners

These devices tilt and rotate the workpiece simultaneously, offering multi-axis flexibility. Perfect for complex geometries or multi-angle welding jobs.

4. Benchtop Welding Positioners

Compact and perfect for smaller workshops, benchtop units are designed for light-duty tasks, such as jewelry making, art, or light fabrication.

5. Elevating Positioners

They adjust the height of the workpiece to match the welder’s height or the automation system’s requirements—excellent for robotic welding integrations.

When selecting from products/welding-positioners/ online or through catalogs, choosing the right type depends on the weight, size, and shape of the materials you work with.

Key Features to Look for in Welding Positioners

Whether you're a fabrication shop or a large-scale manufacturing unit, your choice from products/welding-positioners/ should be guided by functionality and durability. Here are must-have features:

Load Capacity: Ensure it supports your heaviest workpiece.

Speed Control: Variable speed rotation offers greater precision.

Tilt Range: Some positioners tilt up to 135° or more for maximum accessibility.

Remote Control or Foot Pedals: Hands-free operation enhances efficiency.

Sturdy Base and Clamping Mechanism: Vital for safety and stability.

Applications of Welding Positioners Across Industries

The growing popularity of products/welding-positioners/ is due to their versatility. Some industries where welding positioners are indispensable include:

Automotive Industry: For assembling frames, exhausts, and suspension systems.

Oil & Gas Sector: Pipe welding, flange work, and pressure vessel fabrication.

Aerospace: Lightweight alloy components require precision welds at challenging angles.

Shipbuilding: Structural welds and large components are made manageable with heavy-duty positioners.

Metal Art and Sculpture: Artists use light-duty welding positioners for intricate work.

Manual vs. Automated Welding Positioners

If you're exploring products/welding-positioners/, you’ll need to decide between manual and automated models:

Manual Positioners are cost-effective, ideal for small-scale operations, and offer simple controls.

Automated Positioners are integrated with robotic arms or CNC systems. They are perfect for high-volume production and repeatable accuracy.

For smart factories or businesses scaling up, automated solutions are an investment in both speed and consistency.

How to Choose the Right Welding Positioner?

Here’s a quick checklist to help you choose from the vast catalog of products/welding-positioners/:

Workpiece Dimensions: Measure size and weight to match with positioner specs.

Welding Processes: MIG, TIG, or Stick welding may require different setups.

Production Volume: High-frequency welding demands higher durability and automation.

Operator Skill Level: Ease of use is crucial for manual operations.

Budget: Balance cost with long-term ROI and productivity.

Consulting an industrial solutions provider can help you narrow down the best options tailored to your specific use case.

Maintenance Tips for Welding Positioners

To ensure longevity and peak performance from your selected products/welding-positioners/:

Regularly inspect gears and motors for wear.

Clean clamping jaws and rotating surfaces after each use.

Lubricate moving parts as per manufacturer instructions.

Check control panels and wiring for faults or wear, especially in automated units.

Proactive maintenance reduces downtime and extends the lifespan of your equipment.

Conclusion: Why Invest in Welding Positioners

As the demand for faster, safer, and more precise welding increases, investing in top-tier products/welding-positioners/ becomes a game-changer for fabrication and manufacturing businesses. These devices not only simplify complex welds but also reduce errors, improve safety, and enhance operator productivity.

Whether you're a small workshop or an industrial plant, choosing the right welding positioner from a trusted supplier ensures your team delivers consistent, high-quality welds—project after project.

So, if you're planning to modernize your welding operations, don’t overlook the power of a well-selected welding positioner. Explore our wide range of products/welding-positioners/ and transform your production line with tools built for the future.

Read More at:

0 notes

Text

Gyroscope Industry Powering Precision Across Smart and Autonomous Systems

The Gyroscope Industry is undergoing rapid evolution as modern devices and systems demand higher motion sensitivity and orientation accuracy. From smartphones to unmanned aerial vehicles, gyroscopes serve a critical role in providing stable and reliable movement sensing. The industry was valued at USD 2.1 billion in 2023 and is expected to surpass USD 3.5 billion by 2032, registering a compound annual growth rate of 5.6 during the forecast period.

Key Trends Defining the Gyroscope Industry

Multiple high-impact trends are shaping the gyroscope industry:

Rapid growth in demand for MEMS gyroscopes in consumer electronics

Accelerated adoption in autonomous vehicles and drones

Integration of gyroscopes in industrial automation and robotics

Enhanced defense navigation and targeting systems

The emergence of VR, AR, and wearable fitness trackers

As motion tracking becomes vital to digital interfaces, the gyroscope industry continues to diversify its reach across sectors.

Segment Insights

By Technology

MEMS (Micro-Electro-Mechanical Systems) gyroscopes are the most widely adopted due to their low cost and compatibility with compact devices.

Fiber Optic Gyroscopes (FOG) and Ring Laser Gyroscopes (RLG) serve defense and aerospace where ultra-precise navigation is critical.

By Sensor Configuration

Single-Axis Gyroscopes are utilized in simple control systems and industrial tools.

Three-Axis and Six-Axis Systems dominate in drones, AR/VR headsets, and autonomous vehicles, offering complete spatial data.

By Packaging

Standalone Gyroscopes are decreasing in demand but still common in legacy equipment.

Integrated IMUs (Inertial Measurement Units) that combine gyroscopes with accelerometers and magnetometers are increasing in industrial and consumer devices.

End-User Industry Applications

Consumer Electronics

Mobile phones, gaming consoles, and VR systems utilize gyroscopes to detect rotation, gestures, and screen orientation, making this the largest end-use industry segment.

Automotive Sector

Autonomous driving, vehicle stability control, and in-car navigation rely heavily on multi-axis gyroscopes to detect changes in direction and motion.

Aerospace and Defense

Guided missiles, aircraft navigation systems, and submarines deploy high-grade gyroscopes to ensure mission-critical orientation control and inertial tracking.

Industrial Automation

Gyroscopes help robots, conveyors, and heavy machinery maintain balance and motion control in smart factories and warehouses.

Medical and Wearables

Wearable devices and medical instruments use gyros for motion tracking, patient monitoring, and stabilizing surgical robotics.

Regional Analysis

Asia-Pacific dominates the industry in terms of manufacturing and consumer adoption, especially in electronics.

North America leads in defense, aerospace, and high-end automotive applications.

Europe maintains a robust position in industrial robotics and luxury vehicles.

Middle East and Africa and Latin America are emerging regions contributing to industry expansion via telecom, transportation, and military investments.

Key Players in the Gyroscope Industry

The industry is shaped by innovation and scale from global players including:

STMicroelectronics

Bosch Sensortec GmbH

Analog Devices Inc

Honeywell International Inc

Murata Manufacturing Co Ltd

InvenSense (TDK Corporation)

KVH Industries Inc

Safran Sensing Technologies

Northrop Grumman Corporation

EMCORE Corporation

These players focus on enhancing sensor accuracy, reducing form factors, and integrating gyroscopes with broader sensor suites.

Conclusion

The gyroscope industry continues to evolve in response to growing demand for motion-sensing capabilities across consumer, industrial, and defense applications. With advancements in MEMS technology and integration into smarter systems, the industry is set to maintain steady growth and expand into new domains.

Trending Report Highlights

Explore related markets shaping the future of sensors and smart technology:

Barcode Scanner Market

United States Managed Services Market

SEA Robotic Process Automation Market

SEA Led Lighting Market

Hand Tools Market

0 notes

Text

Global Force Sensors Market Set to Grow at ~7% CAGR Through 2031

The global force sensors market is on track to grow at a CAGR of about 6.96% through 2031, driven by increased industrial automation, booming automotive innovation, widespread IoT adoption, and growing presence in medical, wearable, and consumer device applications.

To Get Sample Report: https://www.datamintelligence.com/download-sample/force-sensors-market

Key Market Drivers & Opportunities

A. Industrial Automation & Robotics Rapid uptake of Industry 4.0 and automation in manufacturing, driven by robotics performing tasks like grinding, assembly, and precision handling, is a major catalyst. Force sensors enable accurate control and detection in real-time, minimizing errors and increasing production reliability.

B. Automotive & ADAS Force sensors are increasingly essential in automotive systems used in brake pressure control, seat occupancy detection, steering systems, and occupant safety in autonomous vehicles. EV and ADAS development are fueling strong adoption in the automotive sector.

C. IoT & Smart Sensor Trends IoT and smart manufacturing require connected sensors capable of condition monitoring, predictive maintenance, and remote diagnostics. Force sensors integrated with digital outputs and communication protocols deliver real-time insights across applications.

D. Miniaturization & Wearables Emerging wearable tech and compact medical devices rely on MEMS-based, ultra-thin, accurate force sensors. Miniaturization supports integration in prosthetics, haptic-feedback gadgets, fitness trackers, and robotics, expanding market use cases.

E. Medical & Healthcare Applications Medical devices from prosthetic hands to rehabilitation robots demand precise force measurement. An aging population and chronic disease growth are increasing adoption, enabling safer surgical tools and effective patient rehabilitation systems.

Restraints & Challenges

Miniaturization Difficulties: Making sensors small without losing sensitivity is technically complex, limiting use in ultra-compact devices.

Development Lead Time: Designing, prototyping, and testing high-precision force sensors is time-consuming.

Volatile End-Use Demand: Fluctuations in sectors like automotive or industrial automation can impact sensor demand and production planning.

Regional Trends

North America: Currently holds the largest market share, driven by its automotive, defense, and consumer electronics sectors. Asia‑Pacific: The fastest growing region, supported by rising automotive and electronics manufacturing in China, India, Japan, and South Korea. Strong EV growth and IoT innovation bolster demand. Europe: Growth supported by aerospace, defense, water and gas infrastructure automation, and smart industry initiatives.

Latest Industry News & Trends from Key Regions

United States: Manufacturers are introducing new smart mini-force sensors with IO-Link integration, enabling predictive maintenance and PLC compatibility in automotive assembly lines. Japan: Japan’s industrial smart sensor market reached about USD 2.26 billion in 2024 and is expected to grow at a 12.7% CAGR through 2033, driven by AI-enabled sensing in manufacturing and demand in electric/hybrid vehicle programs.

Technology Trends & Innovation

Smart Mini Force Sensors: Compact, digitally-enabled products are integrating signal processing, offering real-time monitoring and predictive analytics in tight spaces.

Stretchable & 6-Axis Force Sensing: Cutting-edge academic research into flexible, multi-axis sensors supports tactile robotic control and soft robotics applications.

Optical, Piezoresistive & Ultrasonic Technologies: Non-contact sensing methods are gaining traction in applications requiring high precision or hygienic operation.

Competitive Landscape

The market is highly fragmented with global and regional players competing through innovation, acquisitions, and product extensions. Key companies include Tekscan, TE Connectivity, Texas Instruments, Sensitronics, ATI Industrial Automation, Kistler, FUTEK, Omron, and others, each focusing on niche technologies or application-focused solutions.

Strategic Outlook & Growth Opportunities

Expand Smart Sensing Solutions: Offer force sensors with advanced features smart communication, analytics, predictive alerts to support Industry 4.0 deployments.

Invest in Miniaturization R&D: Target wearable and medical sectors by developing highly accurate, compact MEMS-based devices.

Localize Production in Asia-Pacific: Tap into high-growth automotive and electronics sectors with regional manufacturing and localized partnerships.

Promote Cross-Sector Adoption: Target adjacent markets such as consumer electronics, biotech, aerospace, and smart appliances.

Collaborate with Robotics and EV Innovators: Align with emerging sectors like robotics, EVs, and autonomous systems for early-stage integration.

Conclusion

The global force sensors market is positioned for sustained growth, powered by industrial automation, automotive innovation, smart sensor adoption, and expanding applications in healthcare and wearables. Despite technical challenges around scaling down and product development cycles, demand remains strong across global industries. Market leaders who invest in smart sensing platforms, miniaturization, and regional expansion will emerge as industry frontrunners.

0 notes

Text

What is a gyroscope used for drone or robot?

A gyroscope is a sensor used to measure angular velocity. Its core function is to sense the rotational motion and attitude changes of an object. It can be applied to various fields that require navigation, positioning or stable control. ER-MG-057, as a high-performance single-axis MEMS gyroscope (angular velocity sensor), has become an ideal choice for many professional fields due to its excellent performance and reliable design. Precise measurement and stable output Wide range: ER-MG-057 has a wide range of measurement up to ±400°/s, which can meet the angular velocity monitoring needs of various dynamic scenes, covering high-speed rotation scenes (such as drone maneuvers and high-speed operation of robotic arms). Excellent stability: tactical-level high precision, zero bias instability as low as 1°/hr, angle random walk (ARW) 0.2°/√hr, 0.1dps ultra-low noise, 200Hz bandwidth combined with 2kHz data output rate, real-time capture of instantaneous angular velocity changes, and response delay of only 2ms. High integration and high reliability Ceramic LCC surface mount package, with airtight packaging to protect the core MEMS structure, is only 11x11x2mm in size, easy to integrate into various systems, and RoHS certified. Supports 5V (4.75~5.25V) power supply, power consumption is only 35mA, with low power consumption, default internal synchronization mode, optional external synchronization, compatible with multi-system architecture. Can work stably in strong shock (12g RMS) and vibration (1000g 5ms 1/2 sine wave) environment, suitable for high vibration scenarios such as aviation drones and unmanned vehicles. Application scenarios Navigation and positioning: suitable for scenarios such as inertial navigation system (INS), drones and autonomous driving. Combined with accelerometers, position, speed and direction are calculated by measuring the angle change and acceleration of movement. Precision instruments and stabilization systems: Ensure precise control and attitude stability of mechanical movement, and improve the real-time and accuracy of target tracking. UAV/aircraft stabilization: Provides data for the flight control system to sense the attitude changes (pitch, roll, yaw) of the aircraft, so that it can adjust the motor speed to keep the aircraft hovering steadily or flying according to instructions. Ship/vehicle stabilization system: Large ships use gyro stabilizers to reduce roll; provide reliable attitude data support for autonomous driving. Robot balance and control: Help robots sense tilt angles and maintain their own balance and motion control.

0 notes

Text

Introduction Robotics is advancing at a record rate. One of the fascinating innovations leading the way is the Unitree Go2 AI Robotic Dog. This advanced quadruped robot integrates mobility, AI, and practical applications into an intelligent, effective system. It represents a move towards interactive and autonomous robotic systems in practical applications. Let us discover how Unitree Go2 is transforming robotics and why it is so special. What is Unitree Go2 AI Robotic Dog? Unitree Go2 is a futuristic robot dog designed for mobility, autonomy, and real-time interaction. Unitree Robotics created the robot featuring advanced engineering and AI-powered intelligence. It has: • 4-legged dynamic structure for increased agility and balance • A robust AI module with GPT functionality • Live voice response and recognition • Intelligent sensor-based advanced navigation This dog is not only for show—it's designed to deliver, to work in any situation, from classrooms to search and rescue. Key Features of Unitree Go2 1. AI Intelligence The Go2 also comes equipped with an embedded AI model that enables it to: • Recognize and respond to voice commands • Plan movement paths • Develop habits gradually It's like having a clever companion that walks, hears, and responds. 2. High-Speed Mobility Due to its multi-axis control and high-torque motors, the Go2 can: • Max 5 m/s run • Ascend stairs and walk on uneven ground • Recover rapidly from falls This makes it especially suitable for dynamic, uncertain environments. 3. Advanced Sensor Suite It uses: •\tLiDAR for environment mapping • Depth cameras for obstacle avoidance • Inertial Measurement Units (IMUs) for balance and stability These help the robot move around and interact with its surroundings safely. Applications of the Unitree Go2 in Daily Life Security and Surveillance The robot dog can patrol restricted areas, guard against invasions, and offer live video streams. With unrestricted movement and 360-degree vision, it is most ideal for automated security systems. Search and Rescue In disaster situations, Go2 can reach unstable ground that wheeled robots or humans cannot. It can detect motion, voice, and warm bodies to find survivors. Learning and Research Tool Students and educators use Go2 to study AI, robotics, and computer programming. Its SDK allows for full customization, making it perfect for tech schools and universities. Why Robots Such As Go2 Are The Future Robots such as Unitree Go2 are: • Increased efficiency in industries • Improved working conditions in risky situations • Enhanced learning materials for students With advancing technology through robotics, smart machines will aid in daily activities, research, and rescue missions. Ethics and Safety Issues As much as innovation is thrilling, one ought • Set limits on autonomous action • Encourage openness in data gathering • Provide human control and responsibility Robots should be tools, not threats. Developers must consider societal and ethical impacts. Conclusion Unitree Go2 AI Robotic Dog is revolutionary. Combining agility, intelligence, and practicality into daily existence, it's not an appliance—it's a peek at the future. As intelligent robotics gain access to the domestic, laboratory, and field applications, the time has come. The Go2 establishes an extremely high standard for what can be achieved when engineering and AI are combined. References • Official product page: https://www.xboom.in/unitree-go2-ai-robotic-dog

0 notes

Text

Top Mechanical Engineering Trends in 2025: What’s Shaping the Industry

Mechanical engineering is evolving at a breakneck pace, fueled by cutting-edge technology and a global push for efficiency and sustainability. In 2025, several trends are capturing the attention of professionals and businesses across the United States. From automation to sustainable design, these developments are reshaping the future of the industry. Below, we dive into the most sought-after mechanical engineering topics, optimized for readers searching for the latest innovations.

1. Automation and Robotics in Manufacturing

Automation remains a cornerstone of modern mechanical engineering. Robotics, integrated with artificial intelligence (AI), is revolutionizing manufacturing by enhancing precision, reducing costs, and boosting productivity. Automated systems are now capable of handling complex tasks, from assembly lines to quality control. In the U.S., industries like automotive and aerospace are heavily investing in collaborative robots (cobots) that work alongside humans, improving efficiency without compromising safety.

For cutting-edge automation solutions, companies like An Thanh Tech provide advanced tools and expertise to optimize manufacturing processes.

2. 3D Printing and Additive Manufacturing

Additive manufacturing, particularly 3D printing, is transforming how mechanical engineers design and produce components. This technology allows for rapid prototyping, customization, and the creation of complex geometries that traditional methods can’t achieve. In 2025, 3D printing is widely adopted in industries such as healthcare, aerospace, and automotive, where lightweight, durable parts are in high demand. The ability to print metal alloys and composites has further expanded its applications.

3. Sustainable Design and Green Engineering

Sustainability is no longer optional—it’s a priority. Mechanical engineers are focusing on eco-friendly designs to reduce energy consumption and environmental impact. Innovations like energy-efficient HVAC systems, biodegradable materials, and renewable energy integration are gaining traction. In the U.S., government incentives and consumer demand for green solutions are driving companies to adopt sustainable practices, making this a top concern for engineers.

4. Industry 4.0 and Smart Manufacturing

Industry 4.0, the fourth industrial revolution, is all about connectivity and data-driven decision-making. Mechanical engineers are leveraging the Internet of Things (IoT), big data, and machine learning to create smart factories. These facilities use real-time data to optimize production, predict maintenance needs, and minimize downtime. In 2025, U.S. manufacturers are prioritizing smart technologies to stay competitive in a global market.

For high-quality mechanical engineering solutions tailored to Industry 4.0, check out An Thanh Tech for innovative tools and services.

5. CNC Machining Advancements

Computer Numerical Control (CNC) machining remains a critical technology in mechanical engineering. Recent advancements, such as multi-axis machining and AI-driven precision, have made CNC systems faster and more accurate. These improvements are vital for industries requiring high-precision components, like aerospace and medical device manufacturing. In the U.S., the demand for skilled CNC machinists and advanced equipment continues to grow.

Why These Trends Matter

These trends—automation, 3D printing, sustainable design, Industry 4.0, and CNC machining—are not just buzzwords; they represent the future of mechanical engineering. They address the U.S. market’s need for innovation, cost-efficiency, and environmental responsibility. By staying ahead of these trends, engineers and businesses can remain competitive in a rapidly changing landscape.

For those looking to implement these technologies, partnering with experts like An Thanh Tech can provide the tools and support needed to succeed. Stay informed, stay innovative, and shape the future of mechanical engineering in 2025 and beyond.

1 note

·

View note

Text

OPC UA Field eXchange (UAFX)

OPC UA Field eXchange (UAFX) is a new generation of field layer communication standard launched by the OPC Foundation, which aims to solve the core pain points of the long-standing coexistence of multiple protocols and poor device interoperability in the field of industrial automation. As an extension of the OPC UA standard, UAFX realizes end-to-end standardized data interaction from the control layer to field devices through a unified information model and communication framework, providing key infrastructure for Industry 4.0 and smart manufacturing. Its core value lies in breaking the technical barriers of traditional fieldbuses, enabling devices from different manufacturers to achieve plug-and-play interconnection without relying on dedicated gateways, while meeting the stringent requirements of modern industry for real-time, security and flexibility.

Core Functions and Applications of OPC UAFX

I. Key Features

1. Cross-vendor Interoperability

Enables seamless communication between controllers/devices from different brands through standardized OPC UA information models

Supports three-tier communication architectures: Controller-to-Controller (C2C), Controller-to-Device (C2D), and Device-to-Device (D2D)

2. Real-time Data Exchange

Delivers deterministic communication via Ethernet TSN and 5G networks

Achieves microsecond-level synchronization using UDP/IP (IEEE 802.1AS)

3. Unified Engineering Configuration

Built-in Connection Manager for automatic secure link establishment

Supports integration with standard engineering tools (e.g., FDT/DTM, AML)

4. Advanced Diagnostics

Real-time monitoring of device health (network latency, packet loss, etc.)

Asset Information Model (AIM) for full lifecycle data tracking

5. Secure Communication

Inherits OPC UA's native X.509 certificate authentication and AES-256 encryption

Complies with both functional safety (IEC 61508) and cybersecurity (IEC 62443) standards

II. Industrial Applications

1. Smart Factories

Plug-and-play configuration for PLCs, robots, AGVs, etc.

Use case: Multi-brand robot collaboration in automotive welding lines

2. Process Automation

Eliminates protocol conversion between DCS and field instruments (flow meters/temperature transmitters)

Application: Direct data transmission from smart instruments to MES in petrochemical plants

3. Motion Control

Enables precision synchronization (<1μs jitter) for servo drives and CNC equipment

Typical scenario: Multi-axis synchronization in packaging machinery

4. Energy Management

Standardized monitoring for PV inverters, energy storage PCS, etc.

Implementation: Gateway-free data acquisition for wind farm SCADA systems

III. Technical Advantages

IV. Implementation Benefits

Lower TCO: 30+% reduction in protocol conversion hardware costs

Faster Deployment: 50% shorter engineering configuration time

Higher OEE: Predictive maintenance reduces unplanned downtime

Currently supported by leading automation vendors like ABB and Siemens, UAFX is expected to achieve widespread adoption in discrete manufacturing by 2025. This standard is particularly suited for Industry 4.0 scenarios demanding high real-time performance and multi-vendor device integration.

0 notes

Text

Automation Boom Fuels Growth in Motion Control Drive Market to $8.4 Billion by 2031

The global motion control drive market encompassing servo drives, stepper drives, and variable frequency (VFD) drives was valued at US$ 4.9 billion in 2022. Driven by the surge in automation, robotics, and precision motor control requirements, the market is forecast to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 through 2031, reaching US$ 8.4 billion by the end of the forecast period. Motion control drives regulate voltage, current, speed, and position of motors in applications ranging from CNC machining and semiconductor manufacturing to packaging, automotive, and materials handling.

Market Drivers & Trends

Automation & Industry 4.0 Adoption: Increasing deployment of automation across manufacturing verticals is fundamentally reshaping production lines. Motion control drives, which ensure precise and synchronized movements in robotic arms, conveyor systems, and automated assembly lines, are integral to Industry 4.0 ecosystems.

Integration of IoT & AI: Smart factories require drives that can self-diagnose, self-tune, and communicate performance data. The integration of Internet of Things (IoT) connectivity and artificial intelligence (AI) within drives enables predictive maintenance, reduced downtime, and optimized energy usage.

Compact & Modular Designs: Space constraints and the need for flexible machine layouts have spurred demand for compact drive systems. Solutions such as Bosch Rexroth’s ctrlX DRIVE and Rockwell Automation’s ArmorKinetix series offer modular, scalable form factors that simplify installation and support mobile and portable applications.

Energy Efficiency & Sustainability: With global pressures to reduce energy consumption and carbon footprints, manufacturers are adopting high-efficiency drives that minimize losses and recover regenerative energy—key considerations for sectors like automotive, aerospace, and materials handling.

Latest Market Trends

Self‑Tuning Servo Drives: Advanced digital servo drives can now autonomously adjust motor, drive, and feedback parameters to optimize performance. These self‑tuning capabilities reduce the need for manual calibration of control loops and enhance overall system robustness.

Multi‑Axis Synchronization: As multi-axis robots and gantry systems grow more prevalent, drives capable of precise, coordinated control across several axes are in high demand. Enhanced synchronization features enable smoother motion profiles and greater throughput.

Embedded Safety Functions: Functional safety is increasingly embedded into drive platforms, offering integrated safety monitoring, safe torque off (STO), and safe motion functions. This reduces the footprint and complexity of additional safety components in automated machinery.

Cloud‑Based Drive Management: Vendors are launching cloud‑connected platforms for remote configuration, firmware updates, and performance monitoring, enabling centralized management of distributed drive fleets.

Key Players and Industry Leaders

The motion control drive market remains fragmented, with a diverse set of global and regional players competing on innovation, customization, and service:

ABB Ltd.

Siemens AG

Rockwell Automation Inc.

Bosch Rexroth

Mitsubishi Electric Corporation

Schneider Electric SE

Delta Electronics, Inc.

OMRON Corporation

YASKAWA Electric Corporation

Toshiba Corporation

Allied Motion, Inc.

Advanced Micro Controls, Inc.

Fuji Electric Co., Ltd.

Emerson Electric Co.

HIWIN Corporation

Nidec Motor Corporation

These companies remain at the forefront through continuous R&D investment, strategic acquisitions, and partnerships to expand product portfolios and regional footprints.

Unlock crucial data and key findings from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=52011

Recent Developments

August 2023: Kollmorgen expanded its AKD2G servo drive portfolio, introducing higher amperage models with enhanced safety features and SD card backup, plus a graphical display for simplified multi-axis setup.

May 2023: ABB completed the acquisition of Siemens’ low-voltage NEMA motor business, strengthening its portfolio of integrated motor‑and‑drive solutions for North American markets.

2022: WEG acquired Gefran’s Motion Control Business Unit, gaining full ownership of variable frequency drives, DC converters, and specialized servo drives to bolster its automation offerings.

June 2021: Bosch Rexroth launched its ctrlX DRIVE system—a compact, scalable drive platform designed for easy integration into mobile and space-optimized machinery.

August 2023: Rockwell Automation unveiled Allen‑Bradley ArmorKinetix servo drives that mount directly to motors, simplifying machine assembly and improving performance flexibility.

Market Opportunities

Emerging Economies: Rapid industrialization in Southeast Asia, Latin America, and parts of Eastern Europe is driving demand for mid‑range automation solutions—an opportunity for manufacturers to introduce cost‑effective drive systems.

Smart Manufacturing Upgrades: Legacy factories undergoing digital transformation need retrofit‑friendly drive solutions with IoT connectivity and embedded safety, presenting a sizable aftermarket for system integrators.

Sustainable Energy Projects: Renewable energy installations, including solar trackers and wind turbine pitch control systems, require robust drives optimized for harsh environments and long service intervals.

Customized Solutions: Increasingly, end‑users demand turnkey, application‑specific drive packages—bundling drives with built‑in safety, condition monitoring, and domain‑specific software tools.

Future Outlook

Over the next decade, the motion control drive market will continue to evolve along several axes:

Digitalization: Drives will become central nodes in digital value chains, sending real‑time telemetry to cloud‑based analytics platforms for AI‑driven optimization.

Integration: We can expect tighter integration of drives with higher‑level controllers—blurring the lines between PLC, motion controller, and drive in next‑generation architectures.

Safety & Compliance: As regulatory standards evolve, drives will natively support functional safety protocols (e.g., TÜV‑certified safety functions) to simplify machine approvals.

Miniaturization: Advances in power electronics will permit further size reduction, enabling distributed, embedded drive solutions in compact robotics and wearable exoskeletons.

Buy this Premium Research Report and access vital insights and analysis – https://www.transparencymarketresearch.com/checkout.php?rep_id=52011<ype=S

Market Segmentation

By Type: AC Drives, DC Drives

By Product Type: Servo Drives, Stepper Drives, VFD Drives

By Axis: Single‑Axis, Multi‑Axis

By Precision: Very High Precision, High Precision, Standard

By End‑Use: Semiconductor & Electronics, Food & Beverage, Aerospace & Defense, Automotive, Paper & Printing, Pharmaceuticals, Metals & Machinery, Others

Regional Insights

Asia Pacific: Held the largest share in 2022, driven by heavy investments in manufacturing automation and robotics in China, Japan, South Korea, and India. China’s shrinking labor force and rising robotics installations (81,600 units in 2021, up 30%) underpin strong demand.

North America: Growth fueled by automotive electrification, semiconductor fab expansions, and food & beverage upgrades—coupled with strategic investments by ABB and Rockwell.

Europe: Focus on Industry 4.0 and sustainability is driving adoption of energy‑efficient drives, particularly in Germany, Italy, and the U.K.

Latin America & MEA: Emerging manufacturing hubs in Brazil, Mexico, and UAE present opportunities for mid‑tier drive manufacturers.

Why Buy This Report?

Comprehensive Analysis: Detailed market segmentation, quantitative forecasts (US$ Bn & million units), and historical data spanning 2017–2022.

Strategic Insights: In‑depth qualitative analysis, including drivers, restraints, opportunities, key trends, Porter’s Five Forces, value chain, and competitive landscape.

Company Profiles: Thorough profiles of leading players—covering corporate strategy, financials, product portfolios, M&A, and recent developments.

Decision‑Making Support: Actionable recommendations for new market entrants, technology licensors, system integrators, and investors seeking to capitalize on emerging applications and regional growth hotspots.

Multi‑Format Delivery: Available in PDF and Excel formats, facilitating integration with internal reporting and strategic planning processes.

Explore Latest Research Reports by Transparency Market Research: SMT Equipment Market: https://www.transparencymarketresearch.com/smt-equipment-market.html

Motion Control Drive Market: https://www.transparencymarketresearch.com/motion-control-drive-market.html

3D Printing Medical Devices Market: https://www.transparencymarketresearch.com/3d-printing-medical-devices-market.html

Nano Positioning Systems Market: https://www.transparencymarketresearch.com/nano-positioning-systems-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Laser Welding Machine Market Growth Trends and Industry Forecast Analysis

The Laser Welding Machine Market is undergoing rapid transformation, fueled by the demand for precision manufacturing, automation, and energy efficiency across industries. As global industries shift towards smarter production systems, laser welding is emerging as a preferred technology due to its accuracy, speed, and adaptability. This blog delves into the major growth trends influencing the market and presents a forecast analysis highlighting what lies ahead.

Rising Adoption Across Key Industries

Laser welding machines are no longer confined to specialized applications. Today, they are integral to diverse sectors such as automotive, electronics, aerospace, construction, and medical devices. This expansion is attributed to:

The need for minimal thermal distortion in welding.

High-speed operation with improved joint strength.

Compatibility with a wide range of metals and alloys.

Automotive manufacturers, for example, are leveraging laser welding for lightweight materials and complex geometries in electric vehicle production, accelerating adoption on a global scale.

Shift Toward Automation and Industry 4.0 Integration

The integration of laser welding machines with automated systems, such as robotics and AI-driven controls, is redefining modern manufacturing. As part of the Industry 4.0 revolution, businesses are seeking welding solutions that can seamlessly fit into smart factory environments.

Key trends include:

Integration with robotic arms for high-speed precision welding.

Real-time monitoring through machine learning algorithms.

Remote diagnostics and predictive maintenance capabilities.

These advancements are boosting operational efficiency and reducing downtime, making laser welding a key enabler of future-ready manufacturing.

Demand for High-Precision Welding in Electronics and Medical Devices

The miniaturization trend in electronics and medical instruments requires ultra-precise joining methods, where traditional welding techniques fall short. Laser welding's pinpoint accuracy is driving its adoption in these sectors.

Forecast Insight: The market is expected to witness robust growth from compact electronics manufacturers and surgical device makers who demand micro-welding capabilities with minimal thermal stress.

Focus on Energy Efficiency and Environmental Compliance

With rising energy costs and stricter environmental regulations, manufacturers are prioritizing energy-efficient solutions. Laser welding machines consume less energy compared to traditional welding techniques while offering higher output per unit of electricity consumed.

Environmental and operational benefits include:

Lower material wastage due to precision targeting.

Cleaner processes with reduced emissions.

Minimal post-weld cleanup, saving water and chemicals.

These factors are enhancing the appeal of laser welding in sustainability-focused industries.

Technological Innovations Driving Market Differentiation

Rapid advancements in fiber laser technology, beam delivery systems, and cooling mechanisms are pushing the boundaries of what laser welding machines can achieve.

Emerging innovations include:

Multi-axis welding heads for complex parts.

Adaptive welding systems that adjust parameters in real time.

Compact, mobile laser welding units for field applications.

Manufacturers that innovate in terms of power output, size flexibility, and automation readiness are likely to gain a competitive edge in the coming years.

Regional Market Dynamics and Growth Hotspots

While North America and Europe continue to lead in technological maturity, Asia-Pacific is emerging as the fastest-growing regional market due to its booming industrial sector and expanding infrastructure projects.

Key growth areas by region:

Asia-Pacific: Rapid industrialization, particularly in China and India, is spurring demand for advanced welding systems.

North America: Focus on automotive innovation and aerospace engineering is driving high-value machine demand.

Europe: Strong emphasis on green manufacturing and automation integration fuels adoption.

These regional dynamics highlight the global expansion and localized opportunities for machine vendors.

Barriers and Challenges to Watch

Despite optimistic growth projections, the market faces a few challenges that stakeholders need to navigate:

High initial investment: Laser welding machines can be expensive, particularly for small and medium-sized enterprises.

Skilled labor shortage: Operation and maintenance require trained professionals, which are in limited supply.

Complex setup and customization: Some systems require significant calibration based on application needs.

Addressing these hurdles through user-friendly interfaces, training programs, and scalable pricing models will be crucial for continued market expansion.

Industry Forecast: What to Expect

As per industry projections, the laser welding machine market is expected to grow at a steady pace through 2025 and beyond. Key factors driving this outlook include:

Continuous innovation in fiber and disk laser technology.

Integration with AI and digital manufacturing ecosystems.

Expansion into newer verticals such as renewable energy and consumer electronics.

Vendors focusing on modular design, IoT compatibility, and cost-effective solutions will lead the next wave of market disruption. As companies invest more in automation, the demand for reliable and smart welding solutions is set to soar.

Conclusion

The laser welding machine market stands at the intersection of innovation and industrial demand. With industries prioritizing precision, energy efficiency, and automation, the appeal of laser-based welding solutions is stronger than ever. From automotive giants to electronics innovators, businesses are turning to laser welding to future-proof their production lines and remain competitive in an evolving market landscape.

As technological capabilities grow and regional markets open up, stakeholders who invest in adaptive pricing, customer education, and post-sale support will be best positioned to lead. The road ahead for the laser welding machine market is paved with opportunity — for those ready to weld the future together.

#LaserWeldingMarket#IndustrialAutomation#SmartManufacturing#WeldingTechnology#FiberLaserInnovation#WeldingForecast2025

0 notes

Text

Siemens Drive: Powering Precision, Efficiency, and Innovation in Industry

In a fast-moving arena where industrial automation and motion control essentially control the producibility and manufacture of goods, the Siemens Drive family has become the microscopy for reliability and performance and flexibility. Be it to manage the manufacturing line or optimize energy usage in a facility or offer smooth motion control for robotics, Siemens solutions provide everything for drives, such as Siemens VFD Drive and Siemens Servo Drive.

Understanding Siemens Drive Technology

Siemens Drives are essentially very advanced electronic devices that control motor speed, torque, and direction. These are indispensable in modern industries for driving motors with precision and also prescribe energy efficiency and ease of integration with automation systems. A categorization of Siemens Drives will show them classified as:

Variable Frequency Drives (VFDs).

Servo Drives.

DC Drives.

All of them are tailor-made to suit specific applications so that industries can find their perfect match according to their operational convenience.

Siemens VFD Drive: Versatility and Energy-Efficient

A Siemens VFD Drive control a standard AC motor by changing the motor's speed and torque through varying its frequency and voltage. The flagship SINAMICS series comprises various models like the G120 and S120, all known for the vast degree of versatility and application of very advanced technologies.

Key Features of Siemens VFD Drives

Energy Savings: By varying motor speeds in tandem with process requirements, Siemens VFD Drives enable heavy industries to significantly curb their electricity consumption and operational cost.

Advanced Communication: The drives stand behind the new communication protocols such as Profinet, Modbus, and Ethernet/IP, ensuring real-time data exchange and integration with automation systems.

Robust Construction: Siemens VFD Drives are built to function in harsh industrial environments, and there are variants with IP65 protection for water and dust.

Simple to Operate: An operator is guided intuitively past all steps of configuration, commissioning, and diagnostics by means of SINAMICS Startdrive within the TIA Portal.

Safety: Features such as Safe Torque Off (STO) and advanced diagnostics enhance safety and reliability in operation.

Applications of Siemens VFD Drives

Siemens VFD Drives have found their application in:

Pumps, fans, and compressors

Conveyor systems and mixers

HVAC systems

Water/wastewater treatment

Renewable energy applications (wind turbines, solar trackers)

With their adaptability and energy-saving potential, they become a must-have for any industry striving to implement the best possible solutions for performance improvement and sustainability planning.

Siemens Servo Drive-Perfect and Dynamic Control

Where high levels of accuracy, speed of response, and complexity of motion are involved, the Siemens Servo Drive is the first choice. The SINAMICS S210 and S120 series are developed for the most demanding tasks in robotics, packaging, CNC machines, and multi-axis motion control.

Some Key Attributes of the Siemens Servo Drives

Precision: The drives shall have real-time feedback and adaptive control systems, thus ensuring that motors and machinery are perfectly synchronized.

Dynamic Performance: These Siemens drives perform well in application areas where speed of acceleration and deceleration as well as precision in positioning are of essence.

Multi-axis Capability: The drives also have the ability for the control of complicated coordinated movements across multiple axis, useful for robotics and automated assembly line operations.

Easy Integration: Made for integration with the Siemens automation platform, in this way ensuring easy engineering and commissioning.

Applications of Applications of Siemens Servo Drives

Robotics and pick-and-place systems

Packaging and labeling machines

CNC machining centers

Automated assembly lines

Siemens Servo Drives offer speed and responsiveness tailored for contemporary, high-speed manufacturing.

Why choose Siemens Drives?

All-Inclusive Portfolio: From simple motor control to the most sophisticated motion solutions, Siemens offers drives for every industry and every application.

Integrated Automation: Siemens Drives also integrate very smoothly with PLCs, HMIs, and SCADA, allowing one control and monitoring platform.

Warranty and Support: With the seal of global acceptance of Siemens, these drives are furnished with sturdy materials to ensure durability and long-lasting performance.

Scalability: Modular construction offers the possibility to upgrade and expand easily along with an increase in operational needs.

Selection of a Correct Siemens Drive

According to your application needs:

For energy savings and general motor control, a VFD Drive by Siemens should be the best choice, for example, the SINAMICS G120.

High-precision motion and multi-axis tasks require the application of a Siemens Servo Drive such as SINAMICS S120 or S210.

For legacy systems or heavy-torque DC applications, Siemens provides DC drives in ample varieties.

When selecting a drive system, consider aspects such as motor type, load, required precision, and integration needs.

Conclusion: Partner with Naksh Technology Solutions LLP

To harness the true capability of Siemens Drive technology, it comes almost as a necessity to have an informed and a reliable partner by your side. Naksh Technology Solutions LLP deals in Siemens automation products, providing expert assistance in genuine solutions and continuous support through the journey of your drive-related needs. Whether you require a Siemens VFD Drive for energy efficiency or a Siemens Servo Drive for precision motion, Naksh Technology Solutions LLP will ensure smooth integration and the best performance of your installation.

Make Naksh Technology Solutions LLP your preferred partner and let the innovation, reliability, and efficiency brought about by Siemens Drives become a reality in present-day industry.

0 notes

Text

Gyro Sensor Market Size Strategic Trends in End-Use Applications

The Gyro Sensor Market Size is experiencing robust growth, fueled by its integration in consumer electronics, aerospace, autonomous vehicles, and industrial systems. With a projected value of USD 6.4 billion by 2032 and a CAGR of 9.7%, the market size reflects the surging global demand for motion detection and orientation sensing technologies.

As applications diversify, gyro sensors are now essential in gaming consoles, drone navigation, wearable devices, and vehicle safety systems. Their miniaturized designs and enhanced accuracy are driving demand across both high-end and cost-sensitive sectors.

Market Segmentation

By Product Type:

MEMS Gyroscopes

Ring Laser Gyroscopes

Fiber Optic Gyroscopes

Hemispherical Resonator Gyroscopes

By End-Use:

Consumer Electronics

Aerospace & Defense

Automotive

Industrial Machinery

Healthcare

By Geography:

North America

Europe

Asia-Pacific

Middle East & Africa

Latin America

Trends Impacting Market Size

Sensor Fusion: Integrated systems combining gyros with accelerometers and magnetometers are boosting demand.

Wearables & IoT: Rising demand for smartwatches and connected healthcare is contributing to market expansion.

ADAS Growth: Increasing investments in Advanced Driver Assistance Systems are amplifying gyro deployment in vehicles.

Segment Insights

MEMS-based gyros continue to hold the largest market share due to their dominance in mobile electronics and gaming. High-end FOG and RLG units are essential in aviation and defense for their superior stability and long-term drift performance.

End-User Insights

Consumer Electronics: Smartphones, tablets, and gaming devices use multi-axis gyros to enhance user interaction.

Automotive: Used in ESC (electronic stability control), rollover detection, and adaptive cruise control.

Aerospace: Offers precise inertial navigation and guidance in aircraft and missiles.

Industrial: Automated machinery and guided robotics depend on gyros for orientation.

Healthcare: Medical robotics and rehabilitation tools are adopting gyro sensors for motion tracking.

Key Players

Notable manufacturers driving the market size include:

STMicroelectronics

Bosch Sensortec

InvenSense (TDK)

Analog Devices

Honeywell International

Murata Manufacturing

KVH Industries

Northrop Grumman

Sensonor

Epson Electronic

Trending Report Highlights

Hand Tools Market

India Electromechanical Components Market