#OperationalCosts

Explore tagged Tumblr posts

Text

How AI Chatbot Solutions Reduce Operational Costs for Startups

Running a startup can be exciting, but managing high operational costs can be a big challenge. Many founders look for smart ways to save money without compromising on service quality. One of the best ways to do this is by using AI chatbot solutions.

These virtual assistants can handle repetitive tasks, provide 24/7 support, and help small teams do more with less. In this blog, let’s explore how AI chatbot solutions and automation solutions can help startups cut down their expenses and grow faster.

1. Reduce Customer Support Expenses

Hiring and training a full-time customer support team is costly, especially for startups with tight budgets. An AI chatbot can handle common customer queries instantly, such as order tracking, refunds, or FAQs.

When customers get instant answers, they’re happier, and your human agents can focus on more complex tasks. This way, you reduce the need for a large support team, which directly lowers your operational costs.

2. Automate Repetitive Tasks

Startups often waste valuable hours on repetitive tasks that don’t add much value. With the right automation solutions, AI chatbots can manage tasks like appointment scheduling, sending reminders, or even collecting customer feedback.

This automation frees up your team’s time so they can focus on important work like improving products or growing sales. The result? Better productivity and fewer expenses on extra staff or overtime.

3. Offer 24/7 Availability Without Extra Costs

Your customers may have questions at any time, day or night. Hiring staff to cover night shifts or weekends is expensive. AI chatbot solutions provide 24/7 service without any extra cost.

This means your startup can deliver great customer service round the clock while avoiding the high expense of extended hours or additional shifts.

4. Support Student Engagement and Mentorship

If your startup works in the education or EdTech sector, AI chatbots can play a big role in student engagement and student mentorship too.

For example, a chatbot can answer student queries, share resources, or guide students on assignments. They can also help mentors track progress and provide reminders to students. This reduces the workload for teachers and mentors while keeping students engaged.

5. Scale Easily Without Huge Investments

As your startup grows, you may get more customers or users. Scaling a human-only support team can be costly and time-consuming. AI chatbots can handle hundreds of conversations at once without extra cost.

This flexibility allows your startup to serve more customers without a huge jump in operational expenses. So, you’re ready for growth without worrying about hiring large teams right away.

6. Collect Valuable Insights

AI chatbot solutions don’t just answer questions — they collect valuable data too. You can track what questions customers ask most, what problems they face, and what they want.

These insights help you improve your products or services and make smarter business decisions. You don’t need to spend extra on surveys or research firms — your chatbot does it for you!

Final Thoughts

In today’s fast-paced startup world, finding smart ways to cut costs is crucial. AI chatbot solutions and automation solutions can handle repetitive tasks, reduce customer support costs, and help you scale your business without huge expenses.

If you’re in EdTech, they can even boost student engagement and student mentorship, giving your learners the instant help they need while saving your staff time.

By adding an AI chatbot to your startup toolkit, you can work smarter, serve your customers better, and invest your savings back into growth. It’s an efficient, modern way to stay competitive in any industry.

#AIChatbotSolutions#AutomationSolutions#Startups#OperationalCosts#EdTech#StudentEngagement#StudentMentorship#BusinessGrowth

0 notes

Text

#BusinessRates#Chemists#ClosureOfPharmacyChain#ClosureOfPharmacyChainOutlet#EmployerNationalInsurance#NationalLivingWage#OperationalCosts#PharmacyClosures#RetailParks#StoreClosures#StoreOpenings#UKHighStreets

0 notes

Text

#LenderFailures#MicrofinanceChallenges#FinancialPlanning#LoanManagement#CustomerRelationship#RiskAssessment#RegulatoryCompliance#OperationalCosts#TechnologyAdoption#ScalingOperations#MicrofinanceSoftware#FinancialSuccess#LenderTips#LoanManagementSoftware#DataDrivenDecisions#BankingSolutions#FinancialGrowth#LendingIndustry#MicrofinanceTrends#RiskManagementSolutions

0 notes

Text

Imagility vs. Traditional Methods: Cost-Benefit Analysis

In today's business environment, efficiency and cost-effectiveness are paramount. As organizations strive to streamline their operations, the approach to immigration management is evolving. Traditional methods, with their manual processes and extensive paperwork, are increasingly being compared to modern, automated solutions. A detailed cost-benefit analysis reveals the substantial advantages of adopting these advanced systems.

The Shift from Traditional Methods

Traditional immigration management involves significant manual effort, leading to higher chances of errors, delays, and increased costs. This approach often lacks the automation and compliance features that modern technology can provide, making it less efficient and more time-consuming.

Key Points of the Cost-Benefit Analysis

1. Efficiency and Time Savings: Automation simplifies complex workflows and reduces the time required to process immigration cases. Unlike manual methods, automated systems handle repetitive tasks seamlessly, ensuring timely and accurate data entry.

2. Cost Reduction: By minimizing manual labor and reducing errors, automated systems can significantly lower operational costs. The analysis provides a detailed comparison of the cost implications of using modern technology versus traditional practices.

3. Improved Accuracy and Compliance: Advanced systems come with built-in compliance checks, reducing the risk of legal issues. This contrasts sharply with traditional methods, which often lack such features, leading to potential compliance risks.

4. Enhanced User Experience: Modern interfaces are designed to be user-friendly, making it easier for users to navigate and manage cases effectively. Traditional methods, with their cumbersome paperwork, can overwhelm users and slow down processes.

5. Scalability: Technology platforms are designed to scale with an organization's needs, handling increased case volumes effortlessly. Traditional methods may struggle to keep up with growing demands, leading to bottlenecks and inefficiencies.

Conclusion

The transition from traditional immigration management methods to modern, automated solutions presents significant improvements in efficiency, cost savings, and compliance. For those interested in exploring a detailed cost-benefit analysis, downloading the relevant whitepaper can provide comprehensive insights and practical examples of these benefits in action. To learn more about the advantages of these advanced systems, download our whitepaper on Imagility vs. Traditional Methods.

#CostBenefitAnalysis#ImmigrationManagement#Efficiency#Compliance#Automation#OperationalCosts#UserExperience#Scalability#Whitepaper

0 notes

Text

How to Cut Costs Without Affecting the Quality of Your Product: A Comprehensive Guide

In the competitive world of business, reducing expenses while maintaining high product quality is a constant challenge. Achieving this balance is essential for profitability and customer satisfaction. This comprehensive guide explores practical strategies to help you cut costs without compromising the quality of your product.

From optimizing supply chain management and implementing lean manufacturing principles to investing in technology and enhancing employee productivity, we'll cover a range of methods that can help your business thrive. Whether you're a small business owner or a corporate executive, these insights will equip you with the tools to improve your bottom line while delivering top-notch products.

Optimize Supply Chain Management Efficient supply chain management can lead to significant cost savings without sacrificing quality. Consider the following approaches: Build Strong Supplier Relationships: Foster good relationships with suppliers to negotiate better rates and terms. Bulk Purchasing: Buy in bulk to take advantage of volume discounts. Local Sourcing: Source materials locally to reduce transportation costs and lead times, which can also enhance quality control. Implement Lean Manufacturing Principles Lean manufacturing focuses on eliminating waste and improving efficiency. Key principles include: Value Stream Mapping: Identify and eliminate non-value-adding activities. Just-In-Time Production: Produce items only as they are needed to reduce inventory costs. Continuous Improvement (Kaizen): Encourage regular small improvements in processes to enhance efficiency and reduce costs. Invest in Technology and Automation Automation and technology can significantly reduce labor costs and increase efficiency. Robotic Process Automation (RPA): Automate repetitive tasks to free up human resources for more complex activities. Software Solutions: Utilize software for inventory management, order processing, and customer relationship management to improve accuracy and efficiency. Predictive Maintenance: Implement IoT and AI for predictive maintenance to reduce downtime and repair costs. Outsource Non-Core Activities Outsourcing can be a cost-effective solution for non-core business functions. Administrative Tasks: Outsource functions like payroll, HR, and accounting to specialized firms. Manufacturing: Consider outsourcing production to regions with lower labor costs, while ensuring strict quality control measures. Redesign Products for Cost Efficiency Product design can significantly impact production costs. Material Substitution: Use alternative materials that are less expensive but do not compromise on quality. Design for Manufacturability (DFM): Simplify product designs to make manufacturing processes more efficient. Standardization: Use standard components across different products to reduce variability and costs. Improve Energy Efficiency Reducing energy consumption can lead to substantial cost savings. Energy Audits: Conduct regular energy audits to identify areas for improvement. Energy-Efficient Equipment: Invest in energy-efficient machinery and lighting. Renewable Energy Sources: Consider using renewable energy sources such as solar or wind power to lower energy costs in the long term. Enhance Employee Productivity A motivated and efficient workforce can contribute to cost savings. Training and Development: Invest in employee training to improve skills and productivity. Incentive Programs: Implement incentive programs to motivate employees to perform better. Flexible Work Arrangements: Offer flexible working conditions to improve employee satisfaction and productivity. Streamline Marketing Expenses Marketing is essential, but it can be done cost-effectively. Digital Marketing: Use cost-effective digital marketing strategies like SEO, content marketing, and social media. Data Analytics: Utilize data analytics to measure the effectiveness of marketing campaigns and focus on the most cost-efficient channels. Partnerships and Collaborations: Partner with other businesses for joint marketing efforts to share costs.

Regular Financial Analysis Regular financial analysis helps identify areas where costs can be cut. Budget Reviews: Conduct frequent budget reviews to track spending and identify unnecessary expenses. Cost-Benefit Analysis: Perform cost-benefit analysis for major expenses to ensure they are justified. Benchmarking: Compare your costs with industry standards to identify areas for improvement. Conclusion Cutting costs while maintaining product quality requires a strategic approach that touches every aspect of your business. By optimizing your supply chain, embracing lean manufacturing, leveraging technology, outsourcing wisely, and continually seeking efficiency improvements, you can achieve significant cost savings without compromising on quality. Implement these strategies gradually and monitor their impact to ensure they deliver the desired results. Remember, the key is to find a balance that allows you to maintain high standards while improving your bottom line.

#CostCutting#BusinessEfficiency#QualityManagement#CostReduction#ProductQuality#BusinessSavings#OperationalEfficiency#LeanManagement#Budgeting#ExpenseReduction#BusinessStrategy#QualityControl#CostManagement#EfficiencyTips#FinancialPlanning#Productivity#SmartSavings#OperationalCosts#CostOptimization#BusinessGrowth

0 notes

Text

Rising Operational Costs: Cost-effective Strategies that Keep Your Forklifts Running Efficiently Without Breaking the Bank

Introduction: Hey there, fellow forklift owners in Malaysia! 🇲🇾 We get it – operational costs can feel like a constant battle. But fear not, because today, we’re diving deep into the world of operational efficiency. Let’s take on the challenge of rising costs and come out on top! 💪 Identifying Cost Factors: Operational costs can creep up on us if we’re not paying attention. Maintenance, fuel,…

View On WordPress

#collaborartiveproblemsolving#CostEffective#costfactors#EGAN#eganseries#forkliftmalaysia#forkliftnation#forklifts#lovelaughlift#operationalcosts#proactivemaintenance#refurbishedparts#trainingforefficiency

0 notes

Text

5 Proven Strategies to Minimize Bench Time in Your Firm

🔄 Extended Bench Time = Higher Attrition & Revenue Losses! When employees stay on the bench too long, disengagement creeps in, leading to higher turnover. ❌ Furthermore, it can result in higher #operationalcosts as companies continue to pay #employeesalaries without any revenue gains. The good news? With the right strategy, you can💡optimize #resourceutilization, ⚡ keep employees engaged, and 📊 reduce bench time! Read out the latest blog to learn how to minimize #benchtime in your organization.

Read More: Resource Management Software

#project management#project portfolio#resourceplanning#software#resource-allocation-software#saviom#project managers#resource-management-software#resourcemanagement#benchtime

0 notes

Text

The Role of Automatic Soldering

Enhancing Operational Efficiency in Electronics Manufacturing: The Role of Automatic Soldering In today’s rapidly evolving manufacturing landscape, where precision, speed, and reliability are non-negotiable, automatic soldering has emerged as a game-changing solution. Particularly in the electronics and electrical sectors, where component miniaturization and high-density boards are the norms, traditional soldering methods often fall short. Automatic soldering technology bridges this gap—delivering consistent results, reducing human error, and enhancing overall productivity.

What Is Automatic Soldering? Automatic soldering refers to the use of machines and robotic systems to perform soldering tasks that were traditionally done manually. These systems are designed to apply solder precisely and efficiently, whether through wave soldering, selective soldering, or robotic point soldering. Unlike manual methods, which are labor-intensive and vary based on technician skill, automatic soldering ensures high repeatability and precision, making it ideal for large-scale production lines and quality-driven industries.

Why Automatic Soldering Matters 1. Consistent Quality and Precision Automatic soldering systems follow exact parameters for temperature, timing, and positioning. This eliminates the inconsistencies found in manual soldering and ensures robust solder joints, which are critical for long-term device performance.

2. Increased Throughput In fast-paced industries like consumer and automotive electronics, saving time means saving money. Automatic soldering machines can work faster and more accurately than human operators, drastically increasing production speeds without compromising quality.

3. Reduced Labor Costs By automating repetitive tasks, manufacturers can significantly reduce reliance on manual labor, reassign skilled technicians to more complex duties, and lower operationalcosts over time.

4. Enhanced Safety Soldering involves high temperatures and potentially hazardous fumes. Automation minimizes human exposure to these risks, promoting a safer workplace environment. Applications of Automatic Soldering Across Industries Electronics Manufacturing Used extensively for PCB assembly, automatic soldering ensures tight quality control for devices ranging from smartphones to industrial controllers.

Automotive Sector As electric cars and driver-assistance systems become more common, car electronics need accurate and dependable soldering. Automatic systems help make sure these important safety parts stay reliable.

Telecommunication Equipment Devices used in communication networks have tightly packed circuit boards. Automated soldering is essential for creating reliable connections, especially in complex or hard-to-reach areas.

Medical Devices In an industry where precision can be life-saving, automated soldering offers the accuracy needed for implantable devices, diagnostic machines, and other sensitive equipment.

Choosing the Right Automatic Soldering Solution

When selecting an automatic soldering system, manufacturers should consider:

Type of Soldering Method: Wave, selective, or robotic soldering, based on product complexity.

Component Sensitivity: Ensure compatibility with heat-sensitive components.

Production Volume: Choose equipment that can handle your expected throughput.

Flexibility: Systems that adapt to varying board layouts are a plus in dynamic manufacturing settings.

The Sumitron Advantage in Soldering Solutions As more industries embrace automation, trusted partners like Sumitron provide more than just tools—they deliver integrated solutions. From ESD-safe soldering stations to robotic soldering systems, Sumitron offers a curated range of products to meet the exacting needs of today’s electronics manufacturers. With a deep understanding of industry requirements and a commitment to quality, Sumitron ensures every solution is tailored to maximize uptime, reduce errors, and future-proof your production line.

Looking Ahead: The Future of Soldering is Smart The future of automatic soldering is being shaped by Industry 4.0, with intelligent machines capable of real-time monitoring, predictive maintenance, and self-adjusting soldering profiles. As AI and IoT converge with manufacturing, automatic soldering systems will not only perform tasks—but also optimize and evolve with production needs.

Conclusion: Whether you're producing cutting-edge electronics or mission-critical automotive components, automatic soldering is no longer a luxury—it’s a necessity. With benefits that touch every aspect of manufacturing, from cost and quality to safety and speed, adopting this technology is a smart move for future-ready businesses.

Discover Sumitron’s range of soldering automation tools and elevate your production capabilities with solutions engineered for excellence.

1 note

·

View note

Text

"Market Dynamics and Projections for Turbocompressors (2024-2033)"

Turbocompressors are transforming high-performance industries with their ability to deliver exceptional efficiency and reliability in gas compression processes. These advanced machines utilize a turbine-driven compressor to boost air or gas pressure, making them indispensable in applications ranging from industrial processes and power generation to oil and gas extraction and aerospace engineering. By combining high-speed rotating elements with sophisticated aerodynamic designs, turbocompressors achieve superior performance and energy efficiency, handling high flow rates and pressures with precision. Their robust construction and advanced materials ensure durability and longevity, even in harsh operational conditions. With innovations in aerodynamics, materials science, and control systems, turbocompressors are becoming more efficient and versatile, contributing to the optimization of energy use and the reduction of operational costs. As industries demand increasingly efficient and reliable solutions, turbocompressors are set to play a crucial role in driving advancements and meeting the rigorous demands of modern high-performance applications.

#Turbocompressor #HighPerformance #GasCompression #IndustrialEfficiency #PowerGeneration #AerospaceEngineering #OilAndGas #EnergyOptimization #AdvancedMaterials #RotatingElements #Aerodynamics #EnergyEfficiency #IndustrialProcesses #Reliability #TechInnovation #FlowRates #PressureBoost #Durability #OperationalCosts #FutureOfEngineering

0 notes

Text

Transforming Fleet Management..!!

EV Rides' Fleet management has evolved with advanced telematics and data-driven solutions. With real-time tracking, optimized routes, and improved driver efficiency, your EV fleet's productivity soars. Data insights optimize operations and reduce costs, and #advancedtelematics provides real-time data for informed decision-making. But that's not all. At EV Rides, we specialize in energy optimization strategies for electric vehicles. Our solutions maximize efficiency and extend battery life, ensuring your EV fleet performs at its best for optimal performance and longevity. Ready to revolutionize your EV fleet management? Join us at EV Rides and harness the power of cutting-edge technology to drive your success. Visit our website at https://evrides.in to learn more and embark on a transformative journey for your EV fleet.

#TRiDE Mobility - EV Rides#ev#fleetmanagement#telematics#reducecosts#energyefficiency#operationalcosts#productivity#batteryhealth#battery

0 notes

Photo

Our #CCM solution helps #enterprises meet customer demands by #digitization in shortest possible time. Here's how it helped a leading #bank save upto 90 crores per month, processed 26 million interactive #communications and saved huge #operationalcosts. Read this case study here https://bit.ly/3Qu44qa

#digitaltransformation #customercommunications #ai #cx #data #Iot #technology #informationtechnology #artificialintelligence #banking #telecommunications #insurance #financialservices

0 notes

Text

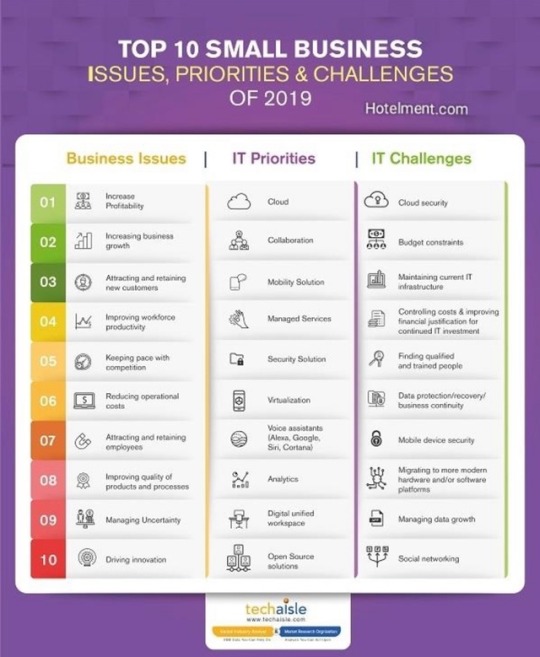

Top 10 Small Business

Issues, Priorities, & Challenges 2019

- Business Issues

1. Increase #Profitability

2. Increase #BusinessGrowth

3. Attracting & Retaining #NewCustomers

4. Improving Workforce #Productivity

5. Keeping Pace with #Competition

6. Reducing #OperationalCosts

7. Attracting & #RetainingEmployees

8. Improving Products/Processes #Quality

9. Managing #Uncertainty

10. Driving #Innovation

- IT Priorities

1. #Cloud

2. Collaboration

3. #MobilitySolution

4. Managed Services

5. #SecuritySolution

6. Virtualization

7. #VoiceAssistants

8. #Analytics

9. Digital Unified Space

10. Open Source Solutions

- IT Challenges

1. #CloudSecurity

2. Budget Constraints

3. Maintaining Current #ITinfrastructure

4. Controlling Costs & Improving Financial Justification for Continued IT investment

5. Finding Qualified & Trained People

6. #DataProtection/Recovery/#BusinessContinuity

7. Mobile Device Security

8. Migrating to More Modern Hardware and/or Software Platforms

9. Managing #DataGrowth

10. #SocialNetworking

...

Selected by Hotelment.com

Source:

Techaisle

Link: https://lnkd.in/dQ855b6

#Business #IT #Hotelment

Post #167 [] Like, Comment, Share

Follow Hotelment.com Linkedin Page

0 notes