#PCB Mount connector

Explore tagged Tumblr posts

Text

0 notes

Text

I have no idea why people send parts that don't match the listing. "aaaah looks close enough" my brother in christ it does not fit what I bought it for and is unsuitable as a replacement part! It's not likely that the buyer won't notice!

#tetranymous.txt#this has happened to me so many times in a row lately#only once I could make it work (phone battery)#but my xp gpu; the second xp gpu (replacement for the 1st) and now my phone's headphone jack?!?!#i'm kinda glad the connector is like 1/4 mil wider because then i'd be tempted to try it (likely not pin compatible)#it's not even as subtle as that. the wire is pointing the WRONG direction from both my old one and their listing photos. wrong length too#AND IT WAS TWELVE DOLLARS#if it was not for the laws of [NOT HAVING SURFACE MOUNT SOLDERING EQUIPMENT] then I would have [WORKING PART]#the jacks themselves are identical; it's the pcb; wire and connector that don't match (yknow. THE PART THAT MAKES IT WORK)#worst part is I CANNOT work out where I ordered the previous one from (that DID fit)#aaaaaaaaaaaa and I only found out it didn't match when I was about to instaaaaaaaaaall it. AFTER cleaning off all the old thermal paste#*sigh* this will probably be the last time I get parts from ebay unless I have no other choice#gonna go reassemble my phone now

4 notes

·

View notes

Text

Board Mount PCB Header, Wire Housings, Pin headers, Wire Socket Connectors

DT Series 2 Position Single Row Male Pin Grey Automotive Connector

0 notes

Text

Eteily Technologies India Pvt. Ltd.

SMA Female Straight 2 Hole Panel Mount Connector With 16mm Teflon

For More Info - https://eteily.com/12-rf-connectors

#eteily#technology#eteilyindia#battery#manufacturers#telecom#fiberglassantenna#mount#teflon#rf#antenna#GPS#marineantenna#connector#delhi

#RF Connectors#rf connector#RF Adapters#SMA Connector#PCB Mount#Panel/Flange Mount#TNC Connector#BNC Connector#SMC Connector#MCX Connector#UFL IPEX MHF#N Connector#MMCX Connector#UHF Connector#SMB Connector#QMA Connector#FME Connector#TS-9 Connector

0 notes

Text

https://www.futureelectronics.com/p/interconnect--pin-and-socket-connectors--header-plug-board-mount/bm04b-srss-tb-lf-sn-jst-4527065

Angled pin headers, Pin Connector, Board Mount PCB Header, PCB header plug

BM04B Series 1 mm Pitch 4 Position SMT Single Row Top Entry Shrouded Header

#JST#BM04B-SRSS-TB(LF)(SN)#Pin and Socket Connectors#Headers Connectors#PCB header plug#socket header#Board mount connector#Pin Connector#Board Mount PCB Header#Rectangular Connectors#receptacle socket#Header plug#Ribbon cable connector

1 note

·

View note

Text

#MCX Connector#rf connector in india#rf connectors#PCB Mount Connector#rf connector manufacturer#rf antenna price#sma rf connector

0 notes

Text

Socket mount wire, PCB mounted connectors, Socket mount, PCB edge connector

DTM Series 12 Position Dual Row Male Pin Right Angle Header Connector

0 notes

Text

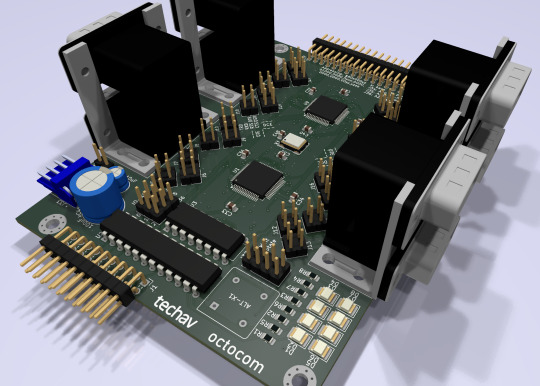

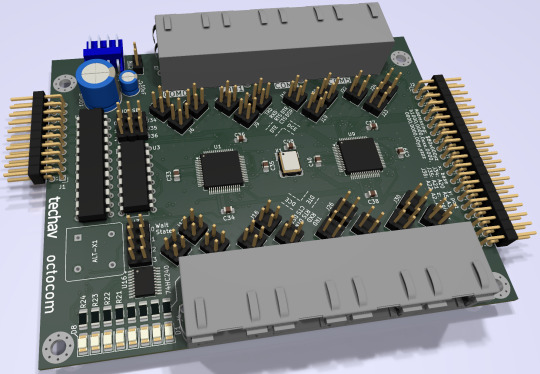

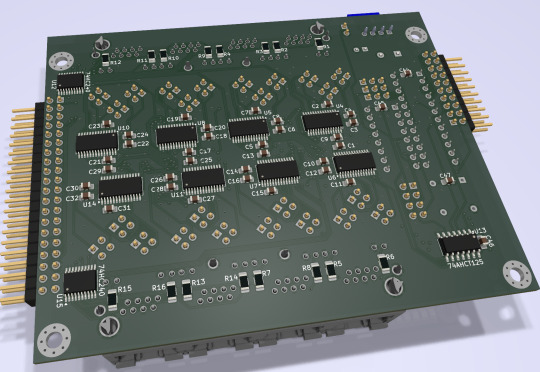

Sharing a Computer with More Friends

A few months ago I built an I/O expansion board for my homebrew 68030 project with a 4-port serial card to go with it, and got BASIC running for four simultaneous users. It worked, but not as well as I had hoped. I wanted to be able to run two of those serial cards to support 8 total users, but it had proven unstable enough that with just the one card I had to slow down the whole system to 8MHz.

So I designed a new serial card.

I had previously been running this computer without any issues at 32MHz with a mezzanine card with FPU & IDE as well as a video card. The main board by itself can clear 56MHz. Having to go all the way down to 8MHz just didn't sit well with me. I want this machine to run as fast as possible for its 8 users.

I put extra time into reviewing worst-case timing for all components and graphing out how signals would propagate. The 16C554 quad UARTs I'm designing around are modern parts that can handle pretty fast bus speeds themselves — easily up to 50MHz with no wait states on the 68030 bus — assuming all the glue logic can get out of the way fast enough.

Signal propagation delays add up quickly.

My first draft schematic used discrete 74-series logic for chip selection, signal decoding, timing, etc. At slower bus speeds this wouldn't have been a problem. But I want this thing to run as fast as possible. By the time critical signals had made it through all those logic gates, I was looking at already being well into one wait state by the time the UART would see a 50MHz bus cycle begin.

I needed something faster. I was also running low on space on the board for all the components I needed. The obvious answer was programmable logic. I settled on the ATF22V10 as a good compromise of speed, size, availability, and programmability. It's available in DIP with gate delays down to 7ns. Where discrete gates were necessary, I selected the fastest parts I could. The final design I came up with showed a worst case timing that would only need one wait state at 50MHz and none for anything slower.

It ended up being a tight fit, but I was able to make it work on a 4-layer board within the same footprint of my main board, putting some components on the back side. (It may look like a bunch of empty space, but there's actually a lot going on running full RS232 with handshaking for 8 ports).

New problem. I had blown my budget for the project. As much as I love those stacked DE9 connectors, they're expensive. And there's no getting around the $10 pricetag for each of those quad UARTs. Even using parts on-hand where possible, I was looking at a hefty Mouser order.

[jbevren] suggested using ganged RJ45 connectors with the Cisco pinout instead of stacked DE9, to save space & cut costs. [Chartreuse] suggested buffering the TTL serial TX/RX signals to drive the LEDs that are frequently included on PCB-mount RJ45 connectors. Both great ideas. I was able to cut 20% off my parts order and add some nice diagnostic lights to the design.

Two weeks later, I received five new PCBs straight from China. I of course wasted no time setting into starting to assemble one.

I really set myself up for a challenge on this one. I learned to solder some 25 years ago and have done countless projects in that time. But I think this might be the most compact, most heavily populated, most surface mount board I've ever assembled myself. (There are 56 size 0805 (that's 2x1.2mm) capacitors alone!)

After a few hours soldering, I had enough assembled to test the first serial port. If the first port worked then the other three on that chip should work too, and there's a great chance the other chip would work as well.

And it did work! After some poking around with the oscilloscope to make sure nothing was amiss, I started up the computer and it ran just fine at 8MHz.

And at 16MHz.

And at 25MHz.

And at 32MHz.

And at 40MHz.

And almost at 50MHz!

Remember what I said about my timing graphs showing one wait state for 50MHz? The computer actually booted up and ran just fine at 50MHz. The problem was when I tried typing in a BASIC program certain letters were getting switched around, and try as I might, BASIC just refused to 'RQN' my program. It was pretty consistently losing bit 3, likely from that signal having to travel just a tiny bit farther than the others. A problem that will probably be resolved with an extra wait state.

Good enough for a first test! A few hours more and I finished assembling the card.

I did have some problems with cleaning up flux off the board, and I had to touch up a few weak solder joints, but so far everything seems to be working. I've updated my little multi-user kernel to run all 8 users from this new card and it's running stable at 40MHz.

I need to update my logic on the 22V10 to fix a bug in the wait state generator. I would love to see this thing actually running at 50MHz — a 25% overclock for the 40MHz CPU I am currently running. I also want to expand my little kernel program to add some new features like the ability to configure the console serial ports and maybe even load programs from disk.

I hope to bring this machine with a collection of terminals and modems this June to VCF Southwest 2025 for an interactive exhibit that can be dialed into from other exhibits at the show.

#wrap030#multi-user BASIC#EhBASIC#homebrew computer#motorola 68030#68030#mc68030#motorola 68k#vcfsw#vcfsw2025#Retrocomputing#rtc#retrotech crew

31 notes

·

View notes

Text

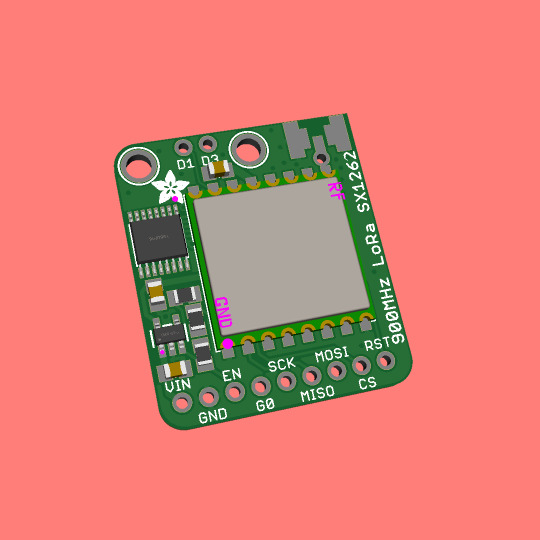

The SX1262 is an updated LoRa chip, so we made a breakout 📡🔧🔄

We got a hot tip to check out the Semtech SX1262 (https://www.digikey.com/short/504bpwww) - compared to our classic SX127x series of "RadioFruit" boards (https://www.adafruit.com/product/3072) the '1262 has lower power usage and longer range as well as some more options for spread-spectrum and extra modulation protocols. Most folks will probably use it for LoRa / LoRaWAN. The pinout is slightly different, so a few changes were made to the classic PCB. We also had some extra room, so we tossed in mounting holes. With this design, you can use wire, uFL, or SMA antennas - just solder whichever connector you desire. Note that the new chips are not software-compatible, so some driver tweaks will be needed to make it work. Coming soon.

#adafruit#lora#semtech#sx1262#longrange#lowpower#wirelesscommunication#radiotechnology#pcbdesign#antennadesign#iotdevices

8 notes

·

View notes

Text

#rf connector#RF Connectors#RF Adapters#SMA Connector#PCB Mount#Panel/Flange Mount#TNC Connector#BNC Connector#SMC Connector#MCX Connector#UFL IPEX MHF#N Connector#MMCX Connector

0 notes

Text

Okay, now for a weird thrift store find that I couldn't resist picking up:

This exquisite little box was $5. The front and back are covers made of curved metal that fit over the central shell. As best as I can tell from the label text — I can't find any documentation online about the company on the badge, let alone the device — it's the front-end amplifier for an electrocardiogram machine. Electrodes would be plugged into the colored pin connectors and the actual data would go to an oscilloscope or plotter via the BNC connector on the back. The mode switch has two positions, and the toggle switch marked "Test" springs back into the up position when you hit it.

Inside it's also interesting. The main circuit PCB is mounted to the top of the chassis, and seems to mostly be support for the giant Analog Devices 274J, which from context is some kind of hybrid amplifier package, though I also can't find any information on it. (Anyone with access to AD's databooks from the 1970s, please help with this!) The power supply appears to be an encapsulated ±15VDC from 120VAC job, and it's clamped down to the bottom corner, possibly for heat sinking. The only date I could quickly find is on it, August of 1975 — so this couldn't have been built before then, but as a commercial product was probably made within a year or two afterwards.

I haven't dared plug it in, much less hook electrodes to it. (I actually do have electrodes on hand, but they're the sort that put electricity into your body via a TENS unit, not the sort that read muscular or nerve impulses.) And I'll probably wind up gutting it and building something interesting into the case, as I don't think there's a ton of value in maintaining or restoring this kind of medical discard. But it's a lovely device, inside and out.

2 notes

·

View notes

Text

Why Should You Rely on Connector Wrenches for Precision and Safety?

Introduction to Connector Wrenches

Connector wrenches are essential tools engineered to simplify the tightening and loosening of connectors in a wide variety of electrical, electronic, and mechanical assemblies. Unlike generic wrenches, connector wrenches are specially designed to provide optimal torque control, ensuring secure connections without damaging delicate components. Their role is increasingly important in precision-driven industries, from telecommunications and aerospace to electronics manufacturing and data centers. The compact design and compatibility with hard-to-reach spaces make these tools a must-have for technicians and engineers working with connectors, sensors, cables, microcontrollers, and other sensitive components.

Why Are Connector Wrenches So Important?

Connector wrenches serve as the interface between quality installation and long-lasting performance. Whether assembling fiber optic cables or tightening RF connectors in communication equipment, these wrenches ensure a perfect fit and torque consistency, reducing the risk of signal loss or component failure.

Their significance extends across multiple fields:

In electronics, they provide careful application of pressure, preserving internal components.

In safety-critical environments, they prevent under-tightening or over-tightening, which can compromise functionality.

In thermal and high-frequency environments, they help maintain signal integrity and reduce potential system malfunctions.

With the rise in automated systems, robotics, and microelectronic devices, connector wrenches have become more refined, precise, and essential.

What Are the Key Features of a Connector Wrench?

Connector wrenches are built with attention to detail, functionality, and durability. The best models are manufactured using high-grade materials like stainless steel or anodized aluminum, and are compatible with various connector types and industry standards.

Key features include:

Ergonomic handles that provide a comfortable, anti-slip grip during repetitive tasks

Torque-limiting designs to prevent damage to sensitive terminals or threaded connectors

Slim or angled profiles to access connectors in tight or obstructed areas

Interchangeable heads to work with different connector sizes or standards

Non-magnetic materials to ensure safety in environments with magnetic-sensitive components like capacitors, sensors, and microprocessors

These design features make connector wrenches versatile for professionals working with thermal pads, controllers, contactors, and other high-performance equipment.

How Are Connector Wrenches Used in Industry?

Connector wrenches are utilized across several technical sectors where precise connectivity is essential. In telecommunications, for example, connector wrenches are commonly used to install coaxial or fiber connectors. In the aviation and aerospace industry, they’re instrumental in ensuring vibration-resistant terminations. In electronics, especially during PCB assembly or repair, connector wrenches help technicians maintain uniform pressure on connector housings, cable grips, and solderless terminals.

They are also integral in:

Automotive electronics installation and diagnostics

Sensor placement in industrial automation systems

Power connector setup in energy distribution equipment

Secure mounting of thermal systems involving heatsinks or fans

Connector wrenches not only streamline workflows but also improve the longevity and safety of complex systems.

What Types of Connector Wrenches Are Available?

There is a wide range of connector wrenches, each tailored for specific applications or connector types. Selecting the right wrench ensures compatibility and precision.

Common types include:

Fixed-head connector wrenches for specific connector sizes and types

Adjustable connector wrenches for handling multiple dimensions with one tool

Torque-limiting connector wrenches with calibrated mechanisms for consistent tightness

T-handle and L-handle styles that enhance torque application in confined spaces

Ratcheting connector wrenches for high-efficiency repetitive tasks

Insulated connector wrenches designed for working with electrical connectors in live circuits

Selecting the correct type ensures compatibility with connectors in tools, switches, safety modules, microcontrollers, and more.

Where Are Connector Wrenches Most Commonly Applied?

Connector wrenches are ubiquitous in various high-tech and industrial environments. Their ability to handle components without risking deformation makes them especially useful in sensitive electrical and data systems.

Typical applications include:

Networking installations involving coaxial, SMA, or fiber connectors

Aerospace electronic equipment where vibration-resistant assembly is vital

Medical devices requiring delicate yet firm connection fittings

Industrial automation systems incorporating sensors, thermal components, and fuses

Consumer electronics involving microprocessors, LEDs, and compact controllers

Renewable energy systems for secure connection of high-power terminals and capacitors

These tools are ideal for use during both installation and maintenance phases.

What Are the Benefits of Using the Right Connector Wrench?

Using the right connector wrench can enhance performance, increase safety, and reduce rework. As systems become increasingly compact and complex, the precision offered by connector wrenches becomes even more valuable.

Key benefits include:

Enhanced reliability of electrical and mechanical connections

Minimization of torque-related connector damage

Efficient installation and maintenance of components such as switches, thermal pads, and cables

Reduction in installation time and human error

Compliance with technical standards in regulated industries

The result is a cleaner, more stable connection with increased system performance and reduced maintenance costs.

How to Choose the Ideal Connector Wrench?

Choosing the right connector wrench depends on various factors such as the type of connector, environment, access space, and required torque.

Consider the following criteria:

Material durability and resistance to wear

Ergonomic design suited for extended use

Compatibility with specific connector types (e.g., SMA, N-Type, DIN)

Availability of torque control if precision is critical

Magnetic safety when working near microelectronics

Size and weight for ease of transport in fieldwork

Investing in a quality wrench tailored to your workflow can make all the difference in precision and efficiency.

Final Thoughts

Connector wrenches play a vital role in ensuring reliable, secure, and professional-grade connectivity across electronics, automation, communications, and industrial applications. As the demand for high-performance systems increases, the importance of using precise tools like connector wrenches becomes evident. These tools enhance system performance, improve safety, and prolong the lifespan of critical components.

Whether you're an electronics technician working with sensors and microcontrollers or an engineer installing power connectors and thermal solutions, connector wrenches are your trusted companion for clean, secure, and efficient assembly. Explore quality options from trusted brands and elevate your toolkit for modern-day applications.

0 notes

Text

How PCB Connectors Power Compact and Reliable Electronic Assemblies

Devices are shrinking, but expectations are rising. Whether it’s in smart lighting, factory control units, or automation systems, size is getting smaller, and reliability? Non-negotiable.

As electronics move toward denser, multi-functional designs, dependable interconnections become the unsung heroes holding these systems together. One of the most trusted realities stems from not properly seeing and often underappreciating PCB Connectors.

What Are PCB Connectors? Types and Where They Are Used

PCB connectors are mechanical interfaces that join a printed circuit board with another PCB, wire, or an external device. They are found almost everywhere in today's applications-from smart thermostats to LED drivers, programmable logic controllers, and small industrial sensors.

Types vary, and their structure depends heavily on form and function. Here's a snapshot:

The wire-to-board connectors: It is used to connect external wiring to the board.

Board-to-board connectors: Very much given for modular arrangements or compact layering.

Wire-to-wire connectors: Less frequent but may be required in some routing cases.

Pluggable connectors: These allow for installing some components without the mundane toil of doing it by hand and also can be quickly taken off and replaced.

Now here’s where it gets interesting: the ideal connector doesn’t just transfer signals or power. It prevents vibration failure, allows easy wiring, and maintains integrity across thermal cycles, all while helping devices get smaller and smarter.

Why WAGO’s PCB Connectors Are a Game-Changer for Compact and Tough Assemblies

WAGO's engineering approach cuts through the clutter. They’re not just making smaller components; they’re optimizing how those components function under stress, over time, and in the tightest spaces.

Now, PCB connectors, particularly the tool-free lever models WAGO offers, bring tangible advantages. Right in the middle of your control unit or LED module, these connectors make installation so much easier and faster, and still ensure that over 30+ terminations maintain solid contact under vibration or movement. They’re especially appreciated in tight builds where space constraints don’t leave room for error, or for a screwdriver.

Key Features That Matter:

Tool-free connection: You don’t need to reach for any special gear. Just lift, insert, press, done.

Vibration-proof reliability: Spring-pressure technology holds tight, even in mobile or high-motion applications.

Compact footprint: Helps reduce overall product size, vital for miniaturization goals.

Multiple conductor types: Whether it's stranded, solid, or fine-stranded, compatibility isn’t an issue.

It’s not hype; it’s practical design thinking that shows up in real-world use. Engineers know that rework, time, and failure risk are all minimized when connectors just work, and WAGO’s models do.

Where Are These PCB Connectors Actually Used?

In a nutshell, anywhere you need strong connections in confined areas. However, the following top-use cases illustrate their adaptability:

1. Systems of Lighting

With their secure yet small form factors, PCB connectors help ensure reliable power delivery without the need for large wiring terminals, making installation easier in tight spaces or suspended fixtures, whether you're wiring LED drivers or building modular lighting tracks.

2. Industrial Automation

You’ve got multiple sensors, signal pathways, and real-time controls packed into a DIN-rail-mounted controller, these connectors simplify wire management, reduce error margins, and allow rapid replacement during maintenance cycles, directly impacting uptime and system resilience.

3. Machine and Motion Control Panels

In dynamic systems exposed to continuous vibrations or movement, PCB connectors, when properly rated and tested for such environments, ensure that your control board doesn’t just survive, it performs optimally even after thousands of hours in operation.

Conclusion: The Right Connector Isn’t Just a Part, It’s a Strategic Choice

Here’s what it comes down to, your choice of connector can either amplify your product’s reliability or quietly sabotage it. The push toward smaller, smarter, more interconnected electronics means that interconnect quality can't be an afterthought.

When PCB connectors are engineered for tool-free use, vibration resistance, and compact layout, like WAGO’s solutions, they don’t just fit into your assembly. They elevate it. And in a space where every millimeter and every second counts, that makes all the difference.

According to a 2024 report by MarketsandMarkets, the global PCB connector market is projected to reach $17.3 billion by 2028, driven by automation, smart devices, and the rapid miniaturization of electronics.

Need help integrating high-performance connectors into your product design? Now’s the time to evaluate your current setup—and upgrade where it truly counts.

0 notes

Text

"Why Wire-to-Board Connectors Matter in Today's Tech Landscape"

In the ever-evolving landscape of electronics and electrical engineering, wire-to-board (WTB) connectors are fundamental components that provide a secure, efficient link between a set of discrete wires and a printed circuit board (PCB). Despite their small size, these connectors are indispensable in a wide range of applications—from consumer electronics and automotive systems to industrial machinery and telecommunications.Get more news about Wire-to-board Connector,you can vist our website!

What Are Wire-to-Board Connectors? Wire-to-board connectors are used to route electrical signals or power from individual wires onto a printed circuit board. Unlike board-to-board connectors that facilitate connections between PCBs or wire-to-wire connectors that link individual wire sets, WTB connectors interface directly between a cable harness and the board, typically through soldering or press-fit terminals. This facilitates modular design, ease of maintenance, and scalable manufacturing.

They consist of two primary components: the plug (housing the wires) and the receptacle or header (mounted on the PCB). These connectors are available in various pitches (the center-to-center spacing between pins) and configurations (vertical or right-angle orientations), making them adaptable for a variety of design constraints and spatial limitations.

Key Features and Considerations Designers and engineers often evaluate several critical factors when selecting WTB connectors:

Current and Voltage Ratings: Depending on the application, connectors must meet safety and performance thresholds.

Pitch Size: Fine-pitch connectors (≤1 mm) allow for compact design, while larger pitches offer greater robustness.

Locking Mechanisms: Latch or friction locks ensure secure connections that resist vibration or accidental disconnection.

Material and Plating: Contact materials, often copper alloys with gold or tin plating, influence conductivity and longevity.

Environmental Resilience: Some WTB connectors are designed for harsh environments with resistance to moisture, dust, or high temperature.

Applications Across Industries The versatility of wire-to-board connectors is reflected in their widespread use across diverse industries:

Consumer Electronics: Used in smartphones, laptops, and wearable devices for internal signal and power connections.

Automotive: Essential for infotainment systems, sensors, and electronic control units (ECUs), where compact, vibration-resistant connectors are critical.

Medical Equipment: Connectors must meet stringent reliability and safety standards in devices like diagnostic equipment and patient monitors.

Industrial Automation: WTB connectors facilitate modular assembly and simplify maintenance for sensors, controllers, and interface devices.

Trends and Innovations Modern trends push the boundaries of connector miniaturization and performance. As electronic devices become more compact and sophisticated, the demand for high-density connectors with increased signal integrity and EMI shielding continues to grow. Additionally, some manufacturers are integrating features like surface-mount technology (SMT) compatibility and automated cable termination to streamline production and assembly.

Another key trend is the development of eco-friendly, RoHS-compliant connectors to meet global environmental standards while ensuring high performance. With the rise of Industry 4.0 and the Internet of Things (IoT), wire-to-board connectors are playing an increasingly strategic role in enabling smart, connected systems.

Conclusion Although often overlooked compared to high-profile semiconductors or processors, wire-to-board connectors are vital enablers of modern electronic innovation. Their reliability, precision, and adaptability allow designers to build smaller, more powerful, and more efficient systems. As technology continues to advance, the humble WTB connector will remain a quiet but essential hero in the background—connecting ideas to reality, one circuit at a time.

0 notes

Text

Eteily Technologies India Pvt. Ltd.

N(F) B/H To SMA(F) RF Adapter SKU:ET-NFS-BH-SFS

For More Info - Contact Us - 9343643799 📞 👉Website - https://eteily.com/

#eteily#eteilyindia#technologies#telecom#rf#antenna#telecommunication#screwmount#connector#sma#adapter#delhi#mumbai

#RF Connectors#rf connector#RF Adapters#SMA Connector#PCB Mount#Panel/Flange Mount#TNC Connector#BNC Connector#SMC Connector#MCX Connector#UFL IPEX MHF#N Connector#MMCX Connector#UHF Connector

0 notes

Text

Electronics Manufacturing: Trends and Industry Insights

In an industry defined by continuous development and exacting standards, electronics manufacturing is a critical driver of modern technology. From everyday consumer goods to complex industrial systems, the journey of each component begins with thoughtful engineering, rigorous production practices, and strong supplier relationships. Based in Arundel, West Sussex, Arrival Electronics Limited stands at the heart of this field, working closely with clients to meet the evolving needs of today’s electronic markets.

This article explores the inner workings of the electronic components industry—what drives it, the trends shaping it, and what decision-makers should understand when choosing the right components or partners. Whether you're a design engineer, purchasing manager, or systems integrator, a clear understanding of this sector will help support better outcomes for your business and your customers.

Understanding the Electronics Manufacturing Process

The process involves assembling electronic components into complete, functional products ready for use or distribution. This can include simple printed circuit board assemblies or more intricate systems involving hundreds of interconnected parts. The process demands consistent quality, traceability, and efficient logistics from start to finish.

The primary stages include:

Component Sourcing: Reliable supply chains and vetted manufacturers are essential. Components must meet specifications, often under strict time constraints and regulatory compliance requirements.

PCB Assembly: Surface mount technology (SMT) and through-hole assembly are key methods used in creating circuit boards. Attention to detail is vital here, as even minor errors can result in failure during testing or deployment.

Testing and Inspection: Functional tests, visual inspections, and X-ray analysis are just some of the methods used to confirm product reliability. These steps help ensure products perform as intended once installed.

Final Assembly and Packaging: After testing, products are assembled into enclosures, labeled, and prepared for shipment, often requiring anti-static handling, thermal protection, or precise labeling practices.

Producing electronic products requires more than tools and machines—it’s about consistency, communication, and adapting to specific project demands.

Key Trends Shaping Today’s Production Landscape

As technology progresses, the electronics sector must constantly adjust. Here are several trends affecting the direction of the industry:

1. Miniaturization

Devices are shrinking, but performance expectations remain high. Engineers must work with tighter tolerances and more complex component configurations. This puts pressure on design and manufacturing teams to align on specifications early in the project lifecycle.

2. Demand for Custom Solutions

Many industries—such as medical, aerospace, and renewable energy—are looking for specialized circuit designs rather than one-size-fits-all solutions. Manufacturers that can provide flexible production runs, in-depth technical consultation, and fast turnarounds are in demand.

3. Supply Chain Resilience

The global component shortage has made it clear how critical supply chain visibility and reliability are. Businesses are increasingly working with sourcing partners that can offer a wide selection of inventory, cross-reference alternatives, and reduce exposure to delays.

4. Sustainability in Manufacturing

There is growing interest in sustainable production practices, including RoHS compliance, lead-free soldering, and energy-efficient factory environments. Electronics manufacturers must respond by implementing responsible processes and working with suppliers who share the same values.

Why Quality and Compliance Matter More Than Ever

When it comes to production and assembly, quality is more than a buzzword—it's a measurable requirement. A faulty capacitor or misaligned connector can result in expensive system failures, regulatory issues, or even safety concerns.

To meet modern expectations, manufacturers must:

Follow ISO-certified procedures

Maintain full traceability of components

Ensure regulatory compliance across target markets (CE, UL, REACH, etc.)

Maintain strong documentation for every stage of the process

Choosing a manufacturing partner with a deep understanding of international standards and a history of consistent delivery helps reduce risks and keeps projects on track.

What Sets Our Manufacturing Services Apart

Our approach is built around delivering practical, cost-effective manufacturing solutions tailored to meet each customer’s unique requirements. By applying lean manufacturing principles, we help clients reduce waste, improve efficiency, and gain measurable value in every step of the process.

Key benefits include:

Lower inventory demands

Reduced total acquisition costs

Supply chain resilience through multiple inventory locations

Improved product quality

Consistent, on-time delivery you can rely on

What to Consider When Choosing a Technical Assembly Partner

Finding a reliable service provider is about more than pricing or proximity. Here are key factors to evaluate:

1. Technical Expertise

Look for teams that can interpret your bill of materials (BOM), understand the application of each component, and make suggestions where appropriate. This ensures that your products are not only assembled correctly but also designed for success.

2. Supplier Relationships

Does the provider have access to a wide range of reputable manufacturers? Can they offer alternatives when primary parts are unavailable? These questions are especially important during global shortages or when dealing with niche specifications.

3. Project Flexibility

Can they accommodate small production runs or prototype builds? Can they ramp up to meet large-scale demand? Flexibility ensures that your partner can adjust alongside your project’s lifecycle.

4. Transparent Communication

Regular updates, clear technical feedback, and documentation of every phase help create confidence. Projects that lack open communication are more likely to experience delays and misunderstandings.

5. End-to-End Support

From early-stage design reviews to post-sale technical queries, the most reliable firms remain actively involved throughout the entire process. They provide ongoing value and ensure long-term reliability, not just short-term assembly.

Meeting Industry Demands: A Practical Approach

The sector serves a wide range of industries, including automotive, medical, aerospace, defense, consumer goods, and industrial automation.. Each sector has its own regulatory environment, tolerances, and expectations for delivery timeframes.

For instance:

Medical devices often require cleanroom assembly and documentation to meet stringent approval standards.

Automotive components must withstand harsh environmental conditions and vibration without performance degradation.

Aerospace systems demand redundancy, traceability, and exact part performance for mission-critical applications.

As these requirements grow more complex, manufacturing partners must respond with tailored approaches—balancing engineering support, materials expertise, and practical experience.

Building Long-Term Success with Trusted Partners

Supply chain challenges, new materials, evolving regulations—these realities require ongoing adaptation. Companies that treat production as a strategic function rather than a transactional service gain a competitive edge.

To succeed, it's essential to work with a partner that:

Understands your industry

Invests in continuous improvement

Keeps up with changing compliance rules

Prioritizes reliability over shortcuts

This is where experience matters. Businesses with a consistent record of on-time delivery, error-free builds, and in-depth component knowledge provide a firm foundation for long-term growth.

About Arrival Electronics Limited

Located in West Sussex, Arrival Electronics Limited is an independent electronic component supplier with deep roots in the electronics manufacturing sector. Known for its technical approach, reliable stock availability, and excellent customer support, the company serves clients across a wide range of industries—including automotive, broadcast, industrial, and aerospace.

Their team offers more than just product sourcing—they offer insight. They collaborate with manufacturers and design engineers to ensure all supplied parts meet application-specific needs. Whether supporting high-mix production or long-term component supply, Arrival Electronics Limited provides dependable service and extensive market knowledge that adds lasting value.

Final Thoughts

Electronics manufacturing is not just a mechanical process; it's a critical function that supports the quality, safety, and performance of the technology we depend on every day. Businesses that understand its nuances are better positioned to deliver products that work as intended, meet compliance goals, and perform reliably over time.

For companies seeking support in this complex space, Arrival Electronics Limited stands as a resourceful and experienced partner. With technical insight, customer dedication, and a clear understanding of today’s component landscape, they help businesses navigate the challenges and practical realities of bringing modern electronic products to market.

0 notes