#PCB Solid State Relays

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/electromechanical--relays--solid-state-relays/cpc1976y-littelfuse-2201069

Solid State Relay Through Hole, what is a Solid State Relay, switching

CPC1976Y CPC1972 Series 2 A 600 V Solid State Relay Through Hole - SIP4

#Relays#Solid State Relays (SSRs)#CPC1976Y#Littelfuse#electromechanical relay#DPDT#PCB#PEWA#aromat#SPDT#Solid State Relay Through Hole#switching#Clare#Photovoltaic

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/2-1415898-3-te-connectivity-5076008

PCB Mount Power Relay, Pin PCB Relay, Power windows, Power relay socket

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#TE Connectivity#1415898-3#Relays#Power Relays#Tyco Electronics#Socket power relay#PCB SPST#latching#PCB Mount#Pin PCB Relay#Power windows#Power relay socket#Power relay switch#Solid state relay#Power relay module#power relay 120v

1 note

·

View note

Text

Global HVAC Duct-Cleaning Robots Market : Key Drivers, Significant Analysis And Future Scope

Global PCB Solid State Relays Market valued at USD X.X Billion in 2024 and is projected to reach USD X.X Billion by 2032, growing at a CAGR of X.X% from 2025 to 2032. Global PCB Solid State Relays Market: Significant Analysis The global PCB solid state relays market is experiencing robust growth driven by increasing adoption across diverse industries such as automotive, industrial automation, and consumer electronics. Advancements in semiconductor technology and the demand for reliable, compact, and energy-efficient switching solutions are key factors propelling market expansion. Projections indicate a steady CAGR over the next several years, fueled by rising investments in smart grid technologies and IoT integration. Additionally, the trend towards miniaturization and enhanced performance in electronic components further supports market momentum. Emerging applications in renewable energy and healthcare sectors offer new avenues for growth. Challenges related to high initial costs and thermal management are being addressed through innovation, enabling wider acceptance. Overall, the market outlook remains positive, with continuous improvements anticipated to drive adoption globally. Get the full PDF sample copy of the report: (Includes full table of contents, list of tables and figures, and graphs) @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Global PCB Solid State Relays Market Key Drivers Key drivers of the global PCB solid state relays market include the increasing need for efficient and durable switching devices in various electronic applications. The rise in automation and smart manufacturing processes has elevated demand for reliable relays that offer faster switching speeds and longer operational lifespans compared to traditional electromechanical relays. Additionally, growing awareness about energy conservation and the push for low-power consumption electronics encourage the use of solid state relays. The expanding automotive industry, with a focus on electric and autonomous vehicles, also fuels market growth. Moreover, the surge in consumer electronics requiring compact and silent operation components boosts demand. Continuous advancements in materials and circuit design further enhance performance, making PCB solid state relays an attractive choice across sectors. Global PCB Solid State Relays Market: Future Scope The future scope of the global PCB solid state relays market is promising, with substantial growth anticipated due to technological advancements and expanding applications. As industries increasingly adopt automation and digital solutions, the demand for compact, efficient, and reliable switching devices will grow significantly. Innovations in semiconductor materials and integration with smart technologies will enable improved relay performance and functionality. Additionally, emerging sectors such as renewable energy, electric vehicles, and healthcare instrumentation offer new growth opportunities. The ongoing trend toward miniaturization and multifunctional devices will further drive market expansion. Regional developments, particularly in Asia Pacific, will play a crucial role in shaping the market landscape. Overall, the future outlook suggests strong growth supported by increasing investments and evolving technological requirements. Refractive Optical Element Market Regional Analysis The Asia Pacific region holds a pivotal position in the refractive optical element market due to rapid industrialization and technological advancements. Growing demand from sectors such as telecommunications, consumer electronics, and healthcare fuels regional market growth. Countries in this region are investing heavily in research and development, improving manufacturing capabilities and adopting advanced materials. Increasing applications in augmented reality, virtual reality, and laser systems contribute to rising market opportunities. Additionally, expanding

infrastructure and government support for high-tech industries create a favorable environment for market expansion. The region’s cost-effective manufacturing and skilled workforce further attract global players to establish production hubs. These factors collectively drive significant growth in the Asia Pacific refractive optical element market, positioning it as a key contributor to the global industry. Download Full PDF Sample Copy of PCB Solid State Relays Market Report @ https://www.verifiedmarketresearch.com/download-sample/?rid=368234&utm_source=Glob-VMR&utm_medium=261 Key Competitors in the PCB Solid State Relays Market These companies are renowned for their broad product offerings, sophisticated technologies, strategic efforts, and robust market presence. Each competitor's primary advantages, market share, current events, and competitive tactics—such as collaborations, mergers, acquisitions, and the introduction of new products—are highlighted in the study. Omron TE Connectivity Sensata Technologies Celduc Relais Siemens ABB Rockwell Automation. Get Discount On The Purchase Of This Report @ https://www.verifiedmarketresearch.com/ask-for-discount/?rid=368234&utm_source=Glob-VMR&utm_medium=261 PCB Solid State Relays Market Trends Insights PCB Solid State Relays Market Trend Insights offers a thorough examination of the market's current and developing trends, providing insightful data-driven viewpoints to assist companies in making wise decisions. This study explores the major consumer trends, market forces, and technology developments influencing the sector. By Specifications By Load Type By Application By Geography • North America• Europe• Asia Pacific• Latin America• Middle East and Africa For More Information or Query, Visit @ https://www.verifiedmarketresearch.com/product/pcb-solid-state-relays-market/ Detailed TOC of PCB Solid State Relays Market Research Report, 2026-2032 1. Introduction of the PCB Solid State Relays Market Overview of the Market Scope of Report Assumptions 2. Executive Summary 3. Research Methodology of Verified Market Reports Data Mining Validation Primary Interviews List of Data Sources 4. PCB Solid State Relays Market Outlook Overview Market Dynamics Drivers Restraints Opportunities Porters Five Force Model Value Chain Analysis 5. PCB Solid State Relays Market, By Geography North America Europe Asia Pacific Latin America Rest of the World 6. PCB Solid State Relays Market Competitive Landscape Overview Company Market Ranking Key Development Strategies 7. Company Profiles 8. Appendix About Us: Verified Market Research®Verified Market Research® is a leading Global Research and Consulting firm that has been providing advanced analytical research solutions, custom consulting and in-depth data analysis for 10+ years to individuals and companies alike that are looking for accurate, reliable and up to date research data and technical consulting. We offer insights into strategic and growth analyses, Data necessary to achieve corporate goals and help make critical revenue decisions.Our research studies help our clients make superior data-driven decisions, understand market forecast, capitalize on future opportunities and optimize efficiency by working as their partner to deliver accurate and valuable information. The industries we cover span over a large spectrum including Technology, Chemicals, Manufacturing, Energy, Food and Beverages, Automotive, Robotics, Packaging, Construction, Mining & Gas. Etc.Having serviced over 5000+ clients, we have provided reliable market research services to more than 100 Global Fortune 500 companies such as Amazon, Dell, IBM, Shell, Exxon Mobil, General Electric, Siemens, Microsoft, Sony and Hitachi. We have co-consulted with some of the world's leading consulting firms like McKinsey & Company, Boston Consulting Group, Bain and Company for custom research and consulting projects for businesses worldwide. Contact us:Mr. Edwyne FernandesVerified Market Research®US:

+1 (650)-781-4080UK: +44 (753)-715-0008APAC: +61 (488)-85-9400US Toll-Free: +1 (800)-782-1768Email: [email protected]:- https://www.verifiedmarketresearch.com/ Global Gardening Equipment Market

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Panasonic AQY212EH Solid State Relay 550mA 60V SPST-NO 4-DIP

The Panasonic AQY212EH is a compact PhotoMOS Solid State Relay with SPST-NO contact. It handles up to 550mA and 60V AC/DC loads ideal for signal control automation and PCB mounting. Reliable, silent and efficient.

Key Specs

Load: 550mA, 60V AC/DC Type: SPST-NO (1 Form A) Mounting: Through Hole (4-DIP) On-State Resistance: Max 2.5Ω Temp Range: -40°C to +85°C Approvals: BSI, cURus

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#PanasonicRelay#AQY212EH#SolidStateRelay#PhotoMOS#SSRRelay#PCBMountRelay#MiniRelay#IndustrialRelay#SignalRelay

0 notes

Text

The Role of Circuit Protection Devices in Modern Electrical Systems

In today’s technology-driven world, the demand for safe, reliable, and efficient electrical systems has never been greater. From homes and offices to industrial plants and data centers, uninterrupted power is critical. Yet, electrical systems are vulnerable to faults such as short circuits, overloads, and ground faults that can lead to equipment damage, operational downtime, and even fire hazards. This is where circuit protection devices come into play.

Modern circuit protection is not just about preventing damage — it’s about ensuring continuity, safety, and smart integration. In this article, we’ll explore the evolving role of circuit protection devices, their types, latest advancements, and their significance in contemporary electrical infrastructure.

1. What Are Circuit Protection Devices?

Circuit protection devices are components specifically designed to detect abnormal electrical conditions and interrupt current flow to prevent damage. They act as sentinels within electrical circuits, ensuring safety by isolating faults swiftly and efficiently.

They serve three core purposes:

· Prevent equipment damage

· Ensure personnel safety

· Maintain system integrity and reliability

2. Why Circuit Protection Is More Crucial Than Ever

With the proliferation of sensitive electronics, automation systems, and renewable energy integrations (like solar PV and EV charging systems), electrical systems have become more complex. Any anomaly — like a power surge or insulation failure — can cascade into massive disruptions.

Moreover, industries now emphasize:

· Minimizing unplanned downtime

· Adhering to global safety standards (IEC, UL, NEC, etc.)

· Achieving energy efficiency and sustainability goals

Therefore, modern circuit protection must go beyond basic protection — it must be intelligent, adaptable, and communicative.

3. Key Types of Circuit Protection Devices

Let’s dive into the main categories of protection devices used in today’s electrical systems:

3.1. Fuses

Fuses are the oldest form of protection, containing a metal wire that melts when excessive current flows. While inexpensive and reliable, they must be replaced after each fault.

Applications: Domestic panels, transformers, automotive systems.

3.2. Circuit Breakers (MCB, MCCB, ACB, VCB)

These are automatic switches that trip when a fault is detected. Unlike fuses, circuit breakers can be reset after operation.

MCB (Miniature Circuit Breaker): Protects against overload and short circuits in low-current circuits.

MCCB (Molded Case Circuit Breaker): Suitable for higher power ratings; includes adjustable trip settings.

ACB (Air Circuit Breaker): Used in LV distribution systems.

VCB (Vacuum Circuit Breaker): Common in medium-voltage systems.

3.3. Residual Current Devices (RCDs) / RCCBs

Detect earth leakage faults and protect against electric shock by sensing imbalance between live and neutral conductors.

Applications: Residential buildings, hospitals, and public spaces.

3.4. Surge Protection Devices (SPDs)

Protect systems from transient over voltages caused by lightning strikes or power switching.

Modern Trend: Tiered surge protection (Type 1, 2, and 3 SPDs) in smart grids and renewable systems.

3.5. Overload and Thermal Relays

Used primarily in motor circuits to protect against sustained overloads that cause overheating.

3.6. Electronic Circuit Protection

Solid-state devices like PTC thermistors, TVS diodes, and electronic circuit breakers are widely used in digital electronics and PCB-level protection.

4. Latest Trends in Circuit Protection

4.1. Smart and IoT-Enabled Protection

Circuit breakers are now integrated with IoT platforms, offering real-time diagnostics, remote monitoring, and predictive maintenance.

Example: Smart MCCBs and ACBs that alert operators before failure occurs.

Application: Industrial 4.0 plants, smart homes, critical infrastructure.

4.2. Arc Fault Detection Devices (AFDD)

AFDDs detect dangerous arc faults that traditional breakers miss, especially in aging wiring systems. Now mandated in some international electrical codes.

4.3. Integration with Energy Management Systems

Modern protection devices communicate with Building Management Systems (BMS) and Energy Management Systems (EMS) to optimize loads, reduce energy loss, and monitor system health.

4.4. Modular and Compact Designs

With space being a premium in panels, devices are now designed to be more modular, compact, and DIN-rail mountable without compromising performance.

5. Circuit Protection in Key Sectors

Industrial Sector

Protection devices are essential in high-load, high-risk environments. Motor control centers (MCCs), power distribution units (PDUs), and automation lines heavily rely on MCCBs, overload relays, and SPDs.

Data Centers

Uninterrupted power and quick fault isolation are mission-critical. Here, selective coordination using advanced circuit breakers ensures fault isolation without total shutdown.

Renewable Energy Systems

Solar PV and wind energy systems require specialized protection like DC fuses, DC MCBs, and SPDs to handle fluctuating currents and external conditions.

EV Charging Infrastructure

As EV adoption grows, protection against earth faults, surges, and over currents becomes vital. Type B RCDs and DC-rated breakers are commonly used.

6. Best Practices for Effective Circuit Protection

Conduct regular audits to ensure protection is aligned with system changes.

Use coordinated protection schemes to prevent nuisance tripping.

Integrate remote monitoring tools for predictive fault management.

Comply with international standards (e.g., IEC 60947, UL 489, NEC 2023).

Choose quality over cost — premium devices reduce long-term risks.

7. The Future of Circuit Protection

The evolution of circuit protection is moving toward autonomous fault detection, AI-driven diagnostics, and energy-efficiency synergy. Innovations like self-healing circuits and blockchain-based energy fault logging are already being piloted in smart grids.

As the electrical landscape becomes more digitized and decentralized, circuit protection will no longer be an afterthought — it will be the foundation of resilient, future-ready electrical systems.

Conclusion

Circuit protection devices are the unsung heroes of modern electrical infrastructure. They provide the foundation for safe, stable, and efficient operation in a world increasingly dependent on continuous power. As systems evolve, so must our approach to protection — prioritizing intelligence, integration, and innovation.

Whether you’re designing an industrial panel, a residential smart home, or a utility-scale solar farm, investing in modern circuit protection isn’t optional — it’s essential.

#electrical#electrical equipment#electrical supplies#dubai#united arab emirates#circuit breaker#flexible circuit board

1 note

·

View note

Text

Relay Market Key Highlights and Future Opportunities Till 2035

The new market research report titled ‘Relay Market’, published by Roots Analysis offers a comprehensive study of the global market, while estimating the overall market size and the size and share of the key regional segments of the global market over historical period, as well as the projected timeline of 2025-2035.

The relay market size is projected to grow from USD 10.28 billion in 2025 to USD 21.03 billion by 2035, representing a CAGR of 7.416%, during the forecast period till 2035. The anticipated market growth is accredited to the significant surge in demand across the regional and global markets for the products and services offered by the Relay industry.

The latest study provides readers with a granular analysis of the major developmental elements of the global market, potential business avenues, and the overall market dynamics. The report has been specially curated to offer a deep understanding of the competitive terrain of the global market, highlighting the leading market rivals, their market positions, product portfolios, gross revenue shares, profit margins, pricing analysis, sales network & distribution channels, and financial standing.

Type of Relay

Electrochemical

Thermal Reed

Time Solid State

Type of Voltage

Low

Medium

High

Type of Mounting Type

DIN Rail

Panel

PCB

Plug-In

End User

Aerospace

Automotive

Communications

Defense and Military

Energy and Power

Industrial

Other

Geographical Regions

North America

US

Canada

Mexico

Other North American countries

Austria

Belgium

Denmark

France

Germany

Ireland

Italy

Netherlands

Norway

Russia

Spain

Sweden

Switzerland

UK

Other European countries

Asia

China

India

Japan

Singapore

South Korea

Other Asian countries

Latin America

Brazil

Chile

Colombia

Venezuela

Other Latin American countries

Middle East and North Africa

Egypt

Iran

Iraq

Israel

Kuwait

Saudi Arabia

UAE

Other MENA countries

Rest of the World

Australia

New Zealand

Other countries

Leading Market Players

ABB

Churod Electronics

Eaton

Electronic Relays India

Fuji Electric

General Electric

Mitsubishi Electric

Omron

Panasonic

Phoenix Contact

Rockwell Automation

Schneider Electric

Siemens

TE Connectivity

The latest research report specializes in the in-depth analysis of the macroeconomic and microeconomic factors affecting the Relay Market development. The report also concentrates on the regulatory framework that is shaping the future of the global market. New and existing pricing structures, emerging application areas, and upcoming investment opportunities have also been detailed in the report. The report further studies the projected growth factors that are expected to influence the market dynamics over the forecast timeframe.

The study is inclusive of a comprehensive analysis of the commonly used marketing and promotional strategies adopted by the key market players. Taking into account the existing market development factors, historical events, and recent market trends, the study presents a balanced opinion on the future scenario of theRelay Market. It thus supports its opinion by discussing the key corporate strategies, such as mergers & acquisitions, takeovers, joint ventures, and strategic alliances, used by the market players to strengthen their global footprint.

Research Methodology

Our analysts have performed an accurate examination of the various aspects of the global market leveraging avant-garde primary and secondary sources of data collection. The report has gathered the necessary data and information from several reliable sources. Additionally, the report offers many strategic recommendations for companies involved in this ever-growing business sector to help them attain a competitive edge in the Relay Market.

Thank you for reading our report. Kindly get in touch with us to know more about the report or to receive a customized copy of it. Our team will ensure the report is tailored according to your [email protected].

0 notes

Text

0 notes

Link

0 notes

Text

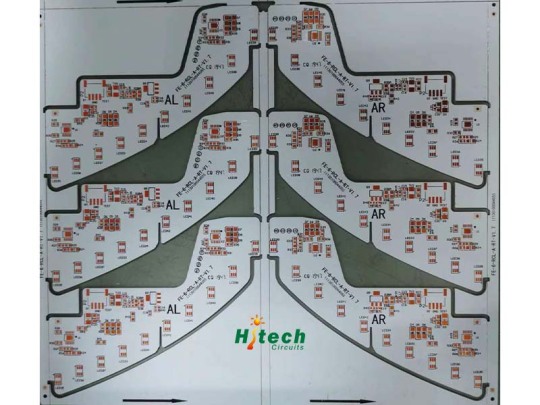

Main usages and applications of aluminium PCB board:

Audio devices: input, output amplifiers, balanced amplifiers, audio amplifier, preamplifier, power amplifier etc.

Power Supply: switching regulator, DC / AC converter, SW regulator .

Telecommunications electronic equipment: high-frequency electric amplifiers, filtering appliance, transmitter circuit etc .

Office automation equipment: electric motor, drivers etc .

Automotive: electronic regulator, ignition, power controllers etc .

Computer: CPU board, floppy drive, power device etc .

Power Modules: converter, solid-state relay, power rectifier bridges etc .

Lamps Lighting: with the promotion of energy-saving lamps, Aluminum base PCB , are widely used on LED lights.

0 notes

Text

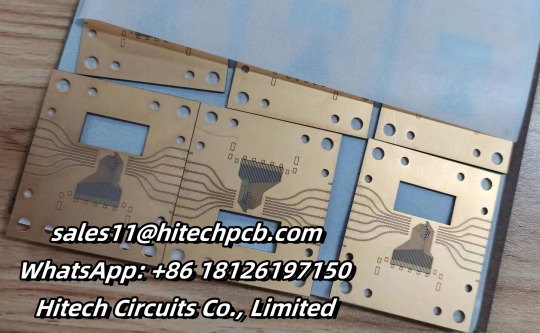

Why use ceramics for circuit boards?

Ceramic circuit boards are actually made of electronic ceramics material and can be made into various shapes. Among them, the ceramic circuit board has the most outstanding characteristics of high temperature resistance and high electrical insulation performance, and has the advantages of low dielectric constant and dielectric loss, high thermal conductivity, good chemical stability, and similar thermal expansion coefficient of the component, and Ceramic printed circuit boards are produced using LAM technology, a laser rapid activation metallization technology. Used in LED field, high power semiconductor module, semiconductor cooler, electronic heater, power control circuit, power mixing circuit, intelligent power component, high frequency switching power supply, solid state relay, automotive electronics, communication, aerospace and military electronics Component.

Unlike traditional FR-4 (glass fiber) , ceramic materials have good high-frequency performance and electrical properties, and have high thermal conductivity, chemical stability and thermal stability. The ideal packaging material for a generation of large-scale integrated circuits and power electronics modules.

Main advantages:

1. Higher thermal conductivity

2. be assembled in high density

3. Good insulation

4. The solder ability of the substrate is good and the use temperature is high

5. More matching coefficient of thermal expansion

6. Low frequency loss

7. A harder, lower resistance metal film aluminum oxide ceramic circuit board

8. Free of organic constituent, resistant to cosmic rays, high reliability in aerospace and long service life

9. The copper layer does not contain an oxide layer and can be used for a long time in a reducing atmosphere.

If you want to know ceramic PCBs, please feel freely to contact Cynthia at [email protected]

0 notes

Text

Experimental Principle of High and Low Temperature Thermal Shock Chamber

The high and low temperature thermal shock chamber has a large testing space and is a batch or electronic and electrical component for industrial manufacturers and material research. It can be used as electronic, electrical components, automation components, semi-finished products, metals, chemical materials, communication components, defense industry, aerospace, and PCB based electronic chips for material research and industrial manufacturers; The degree of tolerance under continuous temperature changes of instantaneous high and low temperatures, and the chemical changes and physical injuries caused by thermal expansion and contraction under rapidly changing temperature difference conditions. Rapid changes in temperature difference in high and low temperature thermal shock chambers: 1. The product has a beautiful appearance, reasonable structure, advanced technology, excellent material selection, simple operation, and reliable equipment performance. 2. Double chamber hanging basket structure, the upper high temperature chamber, the lower low temperature chamber, the impact mode is the high temperature chamber, the low temperature box stops, through suspension and up and down movement, the test piece is quickly moved into the high temperature chamber to realize the cold and hot impact test. 3. The measuring device used is a large human-machine dialogue type human-machine interface controller with a Chinese and English LCD screen, which can set various complex programs. The program settings adopt human-machine dialogue, which is easy to operate, easy to learn, stable and reliable. 4. Adopting advanced circulating air design, the indoor temperature is uniform, avoiding any dead corners; Perfect safety protection devices to avoid any safety hazards and ensure the long-term reliability of the equipment. The experimental principle of a high and low temperature thermal shock chamber: The high and low temperature thermal shock chamber is composed of seven parts: a high temperature chamber, a low temperature storage chamber, a test box body, a control system, a heating system, a refrigeration system, and a drainage system. High temperature chamber: The central controller detects the real-time signal from the temperature sensing element, compares it with the set temperature signal, and obtains a comparison signal. The PID logic circuit of the instrument outputs a signal to control the conduction or shutdown time ratio of the solid-state relay, and adjusts the output power of the heater to achieve automatic temperature control. Low temperature chamber: The temperature status inside the chamber is determined by the working status of the heater, evaporator, and fan in the air duct. After being throttled by the expansion valve, the refrigerant flows into the evaporator in the working chamber, absorbs the heat in the working chamber and vaporizes, causing the temperature of the working chamber to decrease; The vaporized working fluid is sucked in by the compressor and compressed into high-temperature and high-pressure gas, which enters the condenser and condenses into a liquid, After undergoing a screening program and being throttled through an expansion valve, it enters the evaporator in the studio again to absorb heat and vaporize before being sucked in and compressed by the compressor. Working in such a reciprocating loop, the temperature of the studio drops to the set temperature requirement Impact temperature testing room: The instrument automatically controls the high and low temperature air valves, switches between low temperature or high temperature storage rooms, and forms a closed circuit air circulation system with the high temperature chamber or low temperature chamber, quickly reaching the target temperature of the test. The temperature status inside the test chamber is determined by the working status of the heater, evaporator, and fan in the air duct. The forced axial flow "dispersed" loop air is used in the laboratory chamber to work, which can greatly improve the fluctuation, uniformity and other parameters of equipment operation. The performance indicators of the high and low temperature impact test chamber are as follows: The accuracy is reflected by the difference between the set value and the actual detection value. The common point is the uniformity and fluctuation of the chamber body. The "mid test" uses high and low temperature resistant circulating fans in both high and low temperature areas, with internal temperature cycling. No matter how uniform the temperature is, it will not exceed ± 3 ℃, and the fluctuation of the chamber body is ± 0.5 ° C (when the impact stabilizes and returns to the stable chamber at constant temperature). The technical indicators for weighing the functions of the high and low temperature thermal shock chamber include impact activity, temperature conversion speed, accuracy, etc. High and Low Temperature Thermal Shock Chamber can be used in the temperature shock test and fast-changing temperature test in a wide range such as aviation, air space, electronic components and material research. HLST-500T has two separate chambers: high temperature chamber and low temperature chamber. Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab. Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test. Please feel free to contact us if you need any support. Tech Dep: [email protected], Cell/WhatsApp:+8615317907381 Sales Dep: [email protected], Cell/WhatsApp:+8618117273997 Read the full article

0 notes