#PCB SPST

Explore tagged Tumblr posts

Text

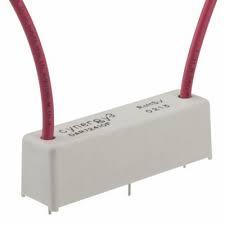

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/2-1415898-3-te-connectivity-5076008

PCB Mount Power Relay, Pin PCB Relay, Power windows, Power relay socket

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#TE Connectivity#1415898-3#Relays#Power Relays#Tyco Electronics#Socket power relay#PCB SPST#latching#PCB Mount#Pin PCB Relay#Power windows#Power relay socket#Power relay switch#Solid state relay#Power relay module#power relay 120v

1 note

·

View note

Text

The Ultimate Guide: What Makes Toggle Switches So Essential in Modern Electronics?

Introduction to Toggle Switches

Toggle switches are fundamental components in the world of electronics, offering a straightforward yet reliable way to control current flow in a circuit. Recognized by their iconic lever or handle, these switches have been a staple in both household and industrial applications for decades. From switching lights on and off to activating heavy-duty machinery, toggle switches have evolved to meet a range of electrical demands. Their mechanical resilience, tactile feedback, and wide design range make them highly valuable in today’s rapidly advancing electronic environments.

How Do Toggle Switches Work?

At the core, toggle switches operate through a pivoting lever that completes or breaks an electrical connection. When flipped, the internal mechanism either establishes a circuit (on) or disrupts it (off). These simple movements can control complex electronic systems. The toggle action is mechanically firm, offering clear user feedback and reducing the risk of accidental toggling, making it ideal for precision control.

Toggle switches come in various configurations based on:

Pole and Throw types (SPST, SPDT, DPST, DPDT)

Mounting styles (panel mount, PCB mount)

Actuator shapes and lengths (bat, flat, paddle)

Terminal types (solder lug, quick-connect, screw)

This level of diversity allows them to be tailored for countless electrical and hardware applications.

Why Are Toggle Switches So Widely Used?

The widespread popularity of toggle switches comes from a combination of practical benefits and engineering advantages. Whether in consumer electronics, aerospace systems, or automotive dashboards, toggle switches remain the go-to choice for reliable manual switching.

Key reasons behind their popularity include:

Ease of use with a familiar mechanical action

Durability under high switching cycles

Tactile control that provides immediate feedback

Low maintenance design and long lifespan

Customization with a range of toggle sizes, lever styles, and indicators

Their ability to withstand vibration, extreme temperatures, and electrical noise also makes them suitable for rugged environments.

Where Are Toggle Switches Commonly Found?

Toggle switches are incredibly versatile and can be found across various industries. Their adaptability makes them suitable for both low-voltage circuits and more complex power-control systems.

Some common applications include:

Consumer appliances like fans, lamps, and kitchen tools

Automotive dashboards for lighting, ignition, or accessory control

Aerospace and aviation systems where reliability is critical

Industrial machines to toggle operational modes or emergency shutdowns

Telecommunication equipment and control panels

Marine applications requiring waterproof or sealed toggles

Their physical structure also supports customization with LEDs, protective covers, or locking mechanisms to meet the needs of specialized fields.

What Types of Toggle Switches Are Available?

Understanding the variations in toggle switches is key to choosing the right component for your application. Below are the primary types of toggle switches based on pole and throw configurations.

SPST (Single Pole Single Throw) Used for simple on/off applications with a single circuit.

SPDT (Single Pole Double Throw) Switches a single input between two outputs, useful for changing modes or signal directions.

DPST (Double Pole Single Throw) Controls two circuits simultaneously with a single switch action.

DPDT (Double Pole Double Throw) Offers complex control by switching two inputs between two outputs each.

Toggle switches are also categorized by their switching actions such as:

Momentary switches which return to their default position after actuation

Maintained switches which remain in the selected position until toggled again

Additional custom features like illuminated tips, safety guards, and environmental sealing further enhance their flexibility.

What to Consider When Choosing a Toggle Switch?

When selecting a toggle switch for a specific application, several important factors must be considered to ensure compatibility, safety, and performance.

Voltage and current ratings to match circuit requirements

Number of poles and throws for the desired switching function

Mounting type for installation compatibility

Actuator style and length based on user accessibility

Environmental sealing for moisture, dust, or corrosive conditions

Material and contact plating for long-lasting conductivity

Designers and engineers often rely on data sheets and product guides to choose the most appropriate toggle switch configuration for their systems.

What Are the Benefits of Toggle Switches in Electronics?

Toggle switches contribute significantly to the efficiency, reliability, and functionality of modern electronics and control systems. Their integration offers key performance advantages:

Quick manual control in circuits where digital or touch interfaces are not ideal

Stable performance in high-vibration and harsh weather environments

Compact footprint with panel or board mounting options

Increased safety with locking or guarded toggle designs

Clear status visibility with maintained lever positions and LED indicators

These switches deliver consistent results across thousands of cycles, ensuring long-term value and operational trust.

Why Should You Invest in Quality Toggle Switches?

Purchasing quality toggle switches from reputable manufacturers or distributors ensures safety, efficiency, and regulatory compliance. Cheaper or untested switches may result in contact failures, overheating, or system malfunction. Certified toggles not only meet industry standards but also provide peace of mind in critical applications.

High-grade toggle switches also offer:

Better contact resistance

Higher lifecycle ratings

Stronger housing materials

Reduced signal interference

Improved mechanical feedback

Engineers, electricians, and hobbyists alike benefit from sourcing durable and certified components.

Conclusion: Are Toggle Switches Still Relevant Today?

Despite the advent of touchscreen panels and digital switching technologies, toggle switches remain irreplaceable in many domains. Their simplicity, reliability, and physical feedback make them ideal for situations where precision and manual control are required. From industrial machinery to custom electronics, toggle switches continue to bridge the gap between human intention and electrical execution.

For applications that demand tactile performance, robust design, and dependable switching—toggle switches are still one of the most practical and essential choices in electronic engineering.

0 notes

Text

Why Choose PCB Mount Reed Relays for Reliable Electronic Switching?

Introduction to PCB Mount Reed Relays

In the modern era of electronics, compact and reliable components are essential for designing efficient systems. One such crucial component is the PCB mount reed relay, known for its fast response, galvanic isolation, and space-saving design. These relays serve as indispensable tools in a wide array of industries, including automation, safety, communication, and consumer electronics. From microcontrollers to laptops and industrial tools, the role of these relays is vital in managing current flow and ensuring protection.

What Is a PCB Mount Reed Relay?

A PCB mount reed relay is an electromechanical device that consists of a reed switch enclosed within a glass tube and a magnetic coil wrapped around it. When an electric current flows through the coil, it generates a magnetic field that actuates the reed switch, allowing current to pass through. This compact design is directly mounted onto a printed circuit board (PCB), simplifying integration with other components such as capacitors, sensors, controllers, connectors, and microprocessors.

Key Features of PCB Mount Reed Relays

Compact size optimized for space-constrained PCBs

Low power consumption suitable for battery-operated electronics

High-speed switching with minimal delay

Galvanic isolation between control and output circuits

Long operational lifespan with minimal wear

High insulation resistance for signal integrity and safety

Why Should You Use PCB Mount Reed Relays?

Although numerous switching solutions exist, PCB mount reed relays stand out for their simplicity and effectiveness. These relays are especially beneficial where thermal management, compact design, and signal clarity are critical. Their integration is seamless with existing tools, cables, fuses, switches, and thermal pads.

Additionally, these relays improve the efficiency of safety systems, microcontroller circuits, and sensor-based applications. They are also widely used with oils and grips in automated manufacturing environments, delivering excellent mechanical performance under stress.

Common Applications Across Industries

PCB mount reed relays are used in many domains thanks to their versatility and precision.

Industrial Control Systems: Used in contactors, controllers, and relay modules

Telecommunications: Signal routing in modems and switches

Medical Equipment: In noise-sensitive, compact diagnostic tools

Test & Measurement: Integral to oscilloscopes and test jigs

Consumer Electronics: Found in laptops, gaming systems, and power tools

Automotive Electronics: Relay switching for sensors, fuses, and safety indicators

Benefits of PCB Mount Reed Relays

Let’s explore the major advantages of using reed relays in your PCB-based systems:

Space-Saving Design: Their small footprint allows more room for additional components such as capacitors, sensors, and switches

Electrical Isolation: Prevents voltage spikes and protects sensitive electronics

Fast Operation: Quick response ensures reliability in time-critical applications

Durability: With fewer mechanical parts, wear is reduced significantly

Cost-Effective: Offers an economical solution without sacrificing performance

These relays work efficiently with thermal pads and can be used in environments that involve varying temperatures, mechanical stress, or electrical noise.

Choosing the Right PCB Mount Reed Relay

While selecting a reed relay, it’s important to match it to your system requirements. Here are a few key considerations:

Voltage and Current Ratings: Should align with the application’s specifications

Coil Resistance: Must be compatible with the driver circuit

Contact Form: Choose from SPST or SPDT based on circuit needs

Switching Speed: Essential for high-frequency switching systems

Thermal Conditions: Ensure compatibility with oils, thermal materials, and connectors

Proper selection ensures effective integration with components like fuses, LEDs, grips, switches, and contactors.

Tips for Mounting and Maintenance

Even though reed relays require little maintenance, following these tips can help ensure long-term performance:

Mount relays away from heat-sensitive areas and near thermal pads

Use appropriate cables and connectors to minimize interference

Clean contact points with safe oils or electronic-grade cleaners

Routinely check for solder integrity on the PCB

Place protection components like fuses or circuit breakers in series

This helps increase safety, enhance signal performance, and extend the life of microcontrollers, controllers, and capacitors on the same board.

The Future of PCB Mount Reed Relays in Electronics

As industries shift toward more compact and intelligent systems, reed relays will continue to evolve with better contact materials, faster switching times, and higher insulation standards. Their compatibility with advanced microprocessors, switches, and thermal solutions makes them ideal for the next generation of electronics, including IoT devices, safety modules, and industrial automation systems.

Conclusion

PCB mount reed relays are reliable, compact, and highly efficient components designed to perform consistent switching operations in a wide range of electronics. Whether you are designing circuits for consumer electronics, automotive systems, or industrial tools, integrating reed relays can enhance functionality, safety, and overall circuit performance.

With their ability to interface smoothly with connectors, sensors, capacitors, fuses, switches, and even thermal pads, these relays are undoubtedly a must-have in any modern PCB layout. For those looking to create durable and high-performance systems, choosing the right reed relay is a step in the right direction.

0 notes

Text

Omron G2RL-1A-E2-CV-HA DC12 Relay – 12V DC 16A SPST-NO Compact Low Profile Power Relay

The Omron G2RL-1A-E2-CV-HA DC12 is a high-performance, low-profile general-purpose relay designed for powerful switching in a compact footprint. With a 12V DC coil voltage, this SPST-NO (1 Form A) relay can handle up to 16A continuous current and up to 23A maximum switching current, ideal for HVAC, automation panels, power control systems, home appliances, and industrial electronics. Its solder pin and through-hole mounting make it PCB-friendly, while the silver alloy contacts ensure reliable conductivity and long-term durability.

Key Features:

Coil Voltage: 12V DC Contact Form: SPST-NO (1 Form A) Rated Current: 16A (Max Switching: 23A) Switching Voltage: Up to 440 VAC / 300 VDC Coil Resistance: 360 Ohms Coil Current: 33.3 mA Power Consumption: 400 mW

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#OmronRelay#G2RLRelay#12VRelay#PowerRelay#SPSTRelay#LowProfileRelay#HighCurrentRelay#IndustrialRelay#AutomationRelay#OmronIndia#ElectronicRelay#RelayModule#CompactRelay#HVACRelay#RelayForPCB

0 notes

Text

How to Choose the Right Rocker Switch for Your Project

Whether working on an electronic DIY project or upgrading a piece of equipment, selecting the right rocker switch is crucial for functionality and safety. With many types available, it’s important to understand your needs before choosing.

What Is a Rocker Switch?

A rocker switch is an electrical switch that rocks back and forth when pressed, instead of tripping or toggling. It's commonly used to turn devices on and off and is popular in both residential and industrial applications due to its simplicity and durability.

Types of Rocker Switches

There are different types of rocker switches based on design and function:

1. Single Pole Single Throw (SPST)

Controls one circuit.

Simple on/off functionality.

Ideal for basic appliances and lights.

2. Single Pole Double Throw (SPDT)

Switches between two outputs.

Useful for switching between power sources or functions.

3. Double Pole Double Throw (DPDT)

Controls two separate circuits.

Suitable for more complex systems requiring reversible current flow.

Key Factors to Consider When Choosing a Rocker Switch

1. Electrical Rating

Check the voltage and current rating. Using a rocker switch with the wrong rating may result in overheating or failure. Always ensure the switch can handle your device’s electrical load.

2. Mounting Style

Determine how the switch will be installed:

Panel Mount: Fits into a panel cut-out.

PCB Mount: Designed to solder directly onto circuit boards.

3. Switch Function

Do you need the switch to stay in place or return to its original position?

Maintained Rocker Switch: Stays in the on/off position until changed manually.

Momentary Rocker Switch: Returns to its original position when released (commonly used in doorbells or reset functions).

4. Actuator Style and Size

Rocker switches come in various shapes and sizes. Consider:

Ergonomics (ease of use)

Visibility (illuminated options for dark environments)

Aesthetic (matching the device design)

5. Environmental Conditions

Will the rocker switch be exposed to dust, water, or extreme temperatures? Look for:

IP ratings for water/dust resistance.

UV-resistant materials for outdoor use.

Sealed switches for industrial environments.

6. Illumination Options

Some rocker switches have built-in LED or neon lights to indicate status. Illuminated rocker switches are ideal for dashboards, control panels, or low-light conditions.

Common Applications of Rocker Switches

Household appliances (e.g., coffee makers, fans)

Automotive dashboards

Industrial machines

Marine and RV electrical panels

Power strips and surge protectors

Choosing the right rocker switch depends on understanding your project's requirements—electrical load, environment, and functionality. Always refer to technical specifications and, if in doubt, consult a professional to ensure safety and performance.

#rocker switch#off road vehicle parts#off road parts and accessories#off road accessories las vegas#motorsports

0 notes

Text

"DIL Switch Solutions: Precision Control for Compact Electronics"

In today’s fast-paced electronics market, engineers and designers demand components that blend reliability with space-saving innovation. Enter the 2 Way Low Profile DIL Switch—a compact, high-performance solution tailored for applications where precision and durability are non-negotiable.

Why Choose the 2 Way Low Profile DIL Switch? Crafted from robust PPS housing, this DIL switch ensures exceptional thermal stability and resistance to wear, even in demanding environments. Its ultra-slim profile (2.54mm lead pitch) makes it ideal for densely packed PCB designs, while gold-plated brass contacts guarantee low-resistance connectivity and long-term signal integrity. With an 8N operating force, users enjoy tactile feedback without compromising on responsiveness—a critical feature for consumer electronics, industrial controls, and IoT devices.

Key Features and Specifications

Space Efficiency: The 7.62mm row pitch and end stackability enable seamless integration into multi-switch configurations, optimizing board real estate.

Enhanced Durability: Engineered to withstand 25mA at 24VDC, this DIL switch delivers consistent performance across thousands of cycles.

Simplified Assembly: Precisely molded PPS components reduce assembly time, lowering production costs without sacrificing quality.

Applications That Benefit From medical devices requiring fail-safe controls to smart home systems demanding minimalist designs, the 2 Way Low Profile DIL Switch adapts effortlessly. Its SPST contacts ensure reliable on/off functionality, while the low-profile structure supports sleek, modern product aesthetics.

Elevate Your Design with Proven Reliability Don’t let bulky switches limit your innovation. The 2 Way Low Profile DIL Switch combines cutting-edge engineering with user-centric design, empowering your team to create smaller, smarter, and more reliable electronics.

Ready to Integrate Premium DIL Switches? Visit our product page to explore technical specifications or contact our engineering support team for customized solutions. Transform your next project with components built to exceed expectations—choose the 2 Way Low Profile DIL Switch today.

0 notes

Text

TE Connectivity, 3-1461491-6, Relays, Power Relays

PCN Series 3 A SPST (1 Form A) 24 VDC PCB Mount Slim General Purpose Power Relay

0 notes

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/3-1461491-6-te-connectivity-5315767

Power relay switch circuit, Power relay socket, Panasonic Electric Works

PCN Series 3 A SPST (1 Form A) 24 VDC PCB Mount Slim General Purpose Power Relay

#Relays#Power Relays#3-1461491-6#TE Connectivity#switch circuit#Power relay socket#Panasonic Electric Works#4 pin relay wiring diagram#SPDT#SPST#latching power relays#24VDC Power relay#12VDC power relays#Power relays by Potter

1 note

·

View note

Text

Rơ le G6B-1114P-FD-US DC24 Omron

Rơ le G6B-1114P-FD-US DC24 Omron hoạt động ổn định với điện áp định mức DC24 V, chức năng rơ le ổn định 1 phía, form tiếp điểm SPST-NO, cầu đấu PCB, form tiếp điểm SPST-NO. Đáp ứng các tiêu chuẩn ứng dụng an toàn, khoa học.

#role#omron#hoplongtech

Thông tin chi tiết xem thêm tại: https://hoplongtech.com/products/g6b-1114p-fd-us-dc24

0 notes

Text

Omron G2RL-1A-E-DC24 Power Relay – 24VDC 16A SPST-NO, Low Profile, PCB Mount

The Omron G2RL-1A-E-DC24 is a reliable and compact general-purpose power relay with a 24V DC coil and SPST-NO (1 Form A) configuration. This low-profile relay offers a high switching capacity of 16A at up to 440 VAC or 300VDC, making it ideal for use in industrial control systems, appliances, automation equipment, and more. Its solder pin termination and through-hole mounting ensure easy integration on PCBs.

Key Features:

Coil Voltage: 24V DC Contact Form: SPST-NO (1 Form A) Current Rating: 16A

Switching Voltage: Up to 440 VAC / 300 VDC Low Power Consumption: 400 mW Mounting Style: Through Hole (Solder Pin) Contact Material: Silver Alloy (Ag) Compact Size: 29mm x 12.7mm x 15.7mm Coil Resistance: 1.44 kΩ Operating Temperature Range: -40°C to +85°C

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#OmronRelay#G2RLRelay#24VRelay#PowerRelay#SPSTRelay#LowProfileRelay#PCBMountRelay#IndustrialRelay#GeneralPurposeRelay#ElectronicRelay#OmronIndia#RelayForAutomation#AutomationComponents#HighCurrentRelay#RelayIndiaMart

0 notes

Text

0 notes

Text

Simplify PCB Power Relays: How Does a PCB Relay Work?

Introduction to PCB Power Relays

As an electronics enthusiast, you may have come across the term “PCB power relay" in your projects or research. But what exactly is a PCB power relay, and how does it work? In this article, we will delve into the world of PCB power relays, exploring their components, design, and most importantly, their function and purpose.

What is a PCB Power Relay?

A PCB power relay, also known as a printed circuit board power relay, is an electromechanical device that allows the control of high-power electrical circuits through low-power signals. It is an essential component in many electronic devices and systems, providing an interface between the control circuit and the load circuit.

The Function and Purpose of a PCB Power Relay

The main function of a PCB power relay is to control the flow of electrical current in a circuit. When a low-power signal, such as a voltage or current, is applied to the relay's coil, it generates a magnetic field that attracts or releases a set of contacts. These contacts, in turn, open or close the circuit, allowing or interrupting the flow of electricity to the load.

The purpose of a PCB power relay varies depending on the application. In some cases, it is used for power switching, where it controls the flow of electricity to devices such as motors, lamps, or heaters. In others, it acts as a protective device, safeguarding the circuit from overloads or short circuits. Power relays are also commonly employed in automation systems, industrial control panels, and telecommunications equipment.

Components and Design of a PCB Power Relay

To understand how a PCB power relay works, it is crucial to familiarize yourself with its components and design. The main elements of a typical PCB power relay include the coil, contacts, and the magnetic system.

The Coil

The coil is the primary component of a PCB power relay responsible for generating the magnetic field. It is usually made of copper wire wound around a bobbin or a magnetic core. The number of turns and the gauge of the wire determine the coil's resistance and the amount of current required to energize the relay.

The Contacts

The contacts of a PCB power relay are the crucial link between the control circuit and the load circuit. They are made of conductive materials, such as silver or gold-plated alloys, to ensure efficient electrical conduction and minimize contact resistance. PCB power relays can have various contact configurations, including single-pole, single-throw (SPST), single-pole, double-throw (SPDT), and double-pole, double-throw (DPDT).

The Magnetic System

The magnetic system of a PCB power relay consists of a ferromagnetic core and an armature. When the coil is energized, the magnetic field created by the coil attracts the armature, which is mechanically linked to the contacts. This attraction causes the contacts to move, either opening or closing the circuit, depending on the relay's design and specifications.

How Does a PCB Power Relay Work?

Now that we have a basic understanding of the components, let's explore how a PCB power relay works in practice. The operation of a PCB power relay can be divided into three main stages: the resting state, the activation state, and the switched state.

Resting State

In the resting state, the relay is not energized, and the contacts are in their default position. Depending on the relay's design, this default position can be either open or closed. For example, in a normally open (NO) relay, the contacts are open in the resting state, while in a normally closed (NC) relay, the contacts are closed.

Activation State

When a voltage or current is applied to the coil, it creates a magnetic field that attracts the armature. This attraction causes the armature to move, which, in turn, moves the contacts. If the relay is normally open, the contacts will close, completing the circuit and allowing the flow of current to the load. Conversely, if the relay is normally closed, the contacts will open, interrupting the circuit.

Switched State

Once the coil is de-energized, the magnetic field dissipates, and the armature returns to its original position due to factors such as spring tension. As a result, the contacts also return to their default position, either open or closed, depending on the design of the relay. This completes the switching action, and the relay is ready for the next cycle.

Advantages and Applications of PCB Power Relays

PCB power relays offer several advantages that make them a popular choice in various applications. One of the key advantages is their ability to handle high-power loads while being controlled by low-power signals. This feature allows for efficient and reliable control of electrical circuits, making PCB power relays indispensable in industries such as manufacturing, automotive, and telecommunications.

Another advantage of PCB power relays is their compact size. Since they are designed to be mounted directly onto printed circuit boards, they occupy minimal space, making them suitable for applications where size constraints are a concern. Additionally, they are relatively easy to install and replace, reducing downtime and maintenance costs in case of failure.

The applications of PCB power relays are wide-ranging. They are commonly used in automotive systems, such as power windows, central locking, and fuel pumps. In industrial settings, they play a vital role in controlling motors, pumps, and solenoids. In the field of telecommunications, PCB power relays are utilized in devices like switches, routers, and modems. These relays also find their place in renewable energy systems, home appliances, and medical equipment.

Understanding Different Types of PCB Power Relays

PCB power relays come in a variety of types, each suitable for specific applications and requirements. The most common types include general-purpose relays, latching relays, solid-state relays, and automotive relays.

General-purpose relays are versatile and can be used in a wide range of applications. They are available in different configurations, contact ratings, and coil voltages, making them suitable for both low-power and high-power switching.

Latching relays, also known as bistable relays, have the ability to maintain their contact position even after the coil is de-energized. They are commonly used in applications where power consumption and heat generation need to be minimized.

Solid-state relays (SSRs) differ from traditional electromechanical relays as they use semiconductor devices and optocouplers to control the switching action. SSRs offer advantages such as silent operation, long lifespan, and fast switching speeds. They are often used in applications where high switching frequency and low power consumption are critical.

Automotive relays are specifically designed to withstand the harsh conditions and high electrical demands of automotive systems. They are frequently used in vehicle lighting, wiper control, and ignition systems.

Choosing the Right PCB Power Relay for Your Application

Selecting the right PCB power relay for your application is crucial to ensure optimal performance and reliability. Several factors should be considered, including contact ratings, coil voltage, switching speed, and environmental conditions.

Firstly, determine the required contact rating, which specifies the maximum current and voltage that the relay can handle. This rating should be compatible with the load circuit's electrical characteristics to prevent damage or failure.

The coil voltage is also an essential parameter to consider. Ensure that the relay's coil voltage matches the voltage available in your control circuit. Operating the relay with a higher or lower coil voltage than specified can lead to improper functioning or complete failure.

The switching speed of a PCB power relay is another critical factor, especially in applications where fast response times are required. Consider the relay's datasheet or technical specifications to determine its switching speed and choose accordingly.

Lastly, take into account the environmental conditions in which the relay will operate. Factors such as temperature, humidity, vibration, and shock can significantly impact the relay's performance and lifespan. Choose a relay that is specifically designed to withstand the environmental conditions of your application.

Leading Manufacturers of PCB Power Relays

When it comes to choosing a reliable PCB power relay, it is essential to consider reputable manufacturers known for their quality and performance. Some of the leading manufacturers in the industry include Omron, TE Connectivity, Panasonic, Siemens, and Schneider Electric.

Omron, for instance, is a renowned manufacturer offering a wide range of PCB power relays suitable for various applications. Their relays are known for their high-quality construction, excellent performance, and long lifespan.

TE Connectivity is another trusted name in the field of PCB power relays. They provide a comprehensive selection of relays, catering to different industries and requirements. Their relays are known for their durability, versatility, and advanced features.

Other notable manufacturers like Panasonic, Siemens, and Schneider Electric also offer a diverse range of high-quality PCB power relays, ensuring reliability and performance in demanding applications.

Conclusion: The Importance of PCB Power Relays in Electronics

In conclusion, PCB power relays play a vital role in the world of electronics, enabling the control of high-power circuits through low-power signals. Understanding their components, design, and operation is essential for anyone working with electronic devices or systems.

By demystifying PCB power relays, we have gained insight into their function, purpose, advantages, and applications. We have explored different types of relays and discussed the factors to consider when choosing the right one for your application. Additionally, we have highlighted leading manufacturers known for their quality and reliability.

Next time you encounter a PCB power relay in your projects, remember its significance in providing efficient and reliable control of electrical circuits. Whether you're working on an industrial automation system, a telecommunications device, or a home appliance, PCB power relays are the unsung heroes ensuring seamless operation and protection of your electronics.

0 notes

Text

Omron G2RL-1A-E DC12 Power Relay – 12V DC 16A SPST-NO (1 Form A) Sealed PCB Mount Relay

The Omron G2RL-1A-E DC12 is a high-performance general-purpose power relay featuring a 12V DC coil and SPST-NO (1 Form A) contact capable of handling up to 16A. Designed for through-hole PCB mounting, this sealed relay offers flux protection, Class F coil insulation, and high switching capacity—ideal for HVAC, home appliances, industrial automation, and control panels.

Key Features:

Coil Voltage: 12V DC Contact Form: SPST-NO (1 Form A) Current Rating: 16A Switching Voltage: 440VAC / 300VDC Sealed Type: Flux Protected Mounting Style: Through Hole (PC Pin) Operate/Release Time: 15 ms / 5 ms Temperature Range: -40°C to +85°C Contact Material: Silver Alloy (Cadmium Free)

📦 Bulk orders available – DM us or call to get the best price!

📞 Contact Today : +919810987429

📥 Enquire Now : [email protected]

#OmronRelay#G2RLRelay#12VRelay#PowerRelay#SPSTRelay#PCBMountRelay#FluxProtectedRelay#HighCurrentRelay#IndustrialRelay#HomeApplianceRelay#AutomationRelay#ThroughHoleRelay#ElectronicComponents#RelayIndiaMart#GeneralPurposeRelay

0 notes

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-6-te-connectivity-2059108

What Is a Power Relay, latching power relays, power relay switch circuit

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#Relays#Power Relays#1415898-6#TE Connectivity#module#power relay de-energized#power relay switch#latching power relays#power relay switch circuit#Power relay socket#Power windows#switch on/off#power relay control circuit

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-1-te-connectivity-4164750

Non latching, Socket power relay, DPST relays, DPDT relays, Power Relay Module

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#Relays#Power Relays#1415898-1#TE Connectivity#operating current automotive relay#PCB Mount General Purpose#240VAC#Socket#DPST relays#DPDT relays#Module#Power relay socket#Relay module#electromagnetic coil#latching power relays

1 note

·

View note

Text

https://www.futureelectronics.com/p/electromechanical--relays--power-relays/1415898-1-te-connectivity-9946344

General purpose relay socket, industrial relays, PCB relay, power relay switch

RT1 Series SPST (1 Form A) 16 A 12 V PCB Mount General Purpose Power Relay

#TE Connectivity#1415898-1#Relays#Power Relays#latching relay#power relay assembly#24VDC Power relay#module#General purpose relay socket#industrial relays#PCB relay#switch#Panasonic electric works#110VAC power relays#latching

1 note

·

View note