#led pcb

Explore tagged Tumblr posts

Text

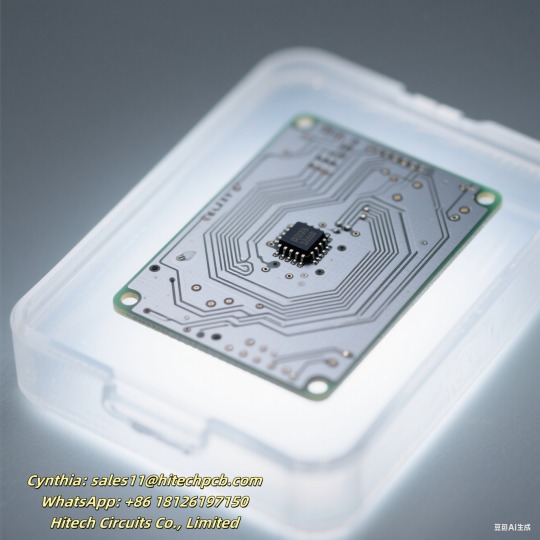

One-stop PCB assembly service and PCB manufacturing supplier -- Hitechpcba

As a leading one-stop electronics manufacturing services provider in China, Hitech Circuits Co., Limited offers high quality, cost effective and quick turn PCB board products, Printed Circuit board, PCB assembly, electronics assembly manufacturing, Electronic parts components sourcing services for your new products development.

With mature supply chain, talented design team, advanced manufacturing techniques and quality control systems, Hitech Circuits Co., Limited is able to provide one-stop electronics manufacturing services and solution for our customers to help them stand out in the marketplace.

5 notes

·

View notes

Text

4. Our Competitive Advantages, excellent PCBA manufacturer - Hitech Circuits from China

What sets us apart from other PCBA suppliers? Here are the key advantages we bring to the table:

Advanced Manufacturing Capabilities: Equipped with state-of-the-art SMT (Surface Mount Technology) lines, automated inspection systems, and cleanroom facilities, we can handle complex PCBA projects with high precision and efficiency. Whether you need small-batch prototypes or large-scale production, we have the capacity to deliver on time.

Strict Quality Control: Our quality control process is comprehensive, covering every stage of production. We utilize Automated Optical Inspection (AOI), X-ray inspection, and functional testing to detect and rectify any defects before shipment. This ensures that you receive PCBA with zero compromises on quality.

Flexible Customization: We work closely with you to understand your specific requirements. From design optimization to component selection, our team of experts provides valuable insights to help you achieve the best results. Whether you need a unique form factor, specific materials, or specialized testing, we can tailor our solutions to fit your needs.

Cost-Effective Solutions: We strive to offer competitive pricing without sacrificing quality. By optimizing our supply chain, streamlining production processes, and leveraging economies of scale, we can provide cost-effective PCBA solutions that help you maximize your profit margins.

Timely Delivery: We understand the importance of meeting deadlines in the electronics industry. Our efficient production planning and robust supply chain management ensure that your PCBA orders are delivered on time, every time. This helps you stay on schedule with your product launches and meet market demands.

Whether you're a startup launching a new product or an established company looking to optimize your supply chain, we have the expertise and resources to support your goals. Contact us today to discuss your PCBA requirements and discover how we can help you achieve excellence in your electronic devices. Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

0 notes

Text

Nice Aluminum PCB LED board in Lighting Industry

High-Performance Aluminum PCB LED Boards: Illuminating the Future with Precision from China

In the dynamic lighting industry, efficiency, durability, and thermal management are paramount. Aluminum PCB LED boards have become the backbone of modern lighting solutions, offering unparalleled performance for both commercial and residential applications. As a global manufacturing powerhouse, China has risen to the forefront of producing high-quality aluminum PCB LED boards that meet the stringent demands of the lighting sector. This article explores how these boards are transforming the industry and why Chinese manufacturers are trusted partners for innovation and reliability. Please send PCB files to [email protected] to get a quote now!

What Are Aluminum PCB LED Boards?

Aluminum PCBs (printed circuit boards) are metal-clad substrates designed to dissipate heat efficiently, making them ideal for high-power LED applications. The structure typically includes:

Aluminum Base Layer: Acts as a heat sink, rapidly transferring heat away from LED components.

Thermal Insulation Layer: A dielectric material (e.g., ceramic-filled polymer) that electrically isolates the circuit while maintaining thermal conductivity.

Circuit Layer: Copper traces etched to connect LEDs and other components.

These boards excel in applications requiring prolonged operation, high brightness, and compact designs, such as LED bulbs, streetlights, automotive lighting, and industrial fixtures.

Why Aluminum PCB LED Boards from China?

Chinese manufacturers have mastered the art of producing aluminum PCB LED boards that balance performance, cost, and scalability. Here’s why they dominate the global market:

1. Superior Thermal Management

LEDs generate significant heat, and inefficient dissipation can lead to premature failure or reduced brightness. Chinese-made aluminum PCBs utilize advanced dielectric materials with high thermal conductivity (e.g., 1.0–3.0 W/m·K), ensuring heat is efficiently transferred from LEDs to the aluminum base. This extends LED lifespan and maintains consistent luminosity, even in demanding environments.

2. Precision Engineering & Customization

China’s manufacturing ecosystem offers:

Laser Drilling and Etching: For intricate circuit patterns and micro-vias, enabling compact, high-density LED arrays.

Customizable Designs: Tailored shapes, thicknesses (1.0–3.0 mm), and surface finishes (e.g., HASL, ENIG) to meet specific lighting requirements.

Flexible Scaling: From prototypes to mass production, ensuring quick turnaround for startups and enterprises alike.

3. Cost-Effective Production

By leveraging automated production lines and localized supply chains, Chinese suppliers deliver aluminum PCBs at competitive prices without compromising quality. This cost efficiency is critical for price-sensitive markets like consumer lighting and automotive accessories.

4. Rigorous Quality Assurance

Leading manufacturers adhere to international standards such as ISO 9001, UL certification, and RoHS compliance (ensuring environmental safety). Testing protocols include:

Thermal Cycling Tests: Validating performance under extreme temperature fluctuations.

Current Load Testing: Ensuring stable conductivity under high-power conditions.

Microscopic Inspection: Guaranteeing flawless circuit alignment and solderability.

5. Innovation in Eco-Friendly Lighting

As sustainability becomes a global priority, Chinese producers are pioneering aluminum PCBs for energy-efficient LED systems. These boards support smart lighting solutions, such as dimmable LEDs and IoT-connected fixtures, reducing energy consumption and carbon footprints.

Key Applications in the Lighting Industry

Aluminum PCB LED boards from China are revolutionizing diverse sectors:

Commercial & Residential Lighting

LED Bulbs and Panels: Enhanced heat dissipation allows for slimmer designs and longer lifespans.

Decorative Lighting: Custom-shaped boards enable creative architectural and ambient lighting.

Automotive Lighting

Headlights and Taillights: High thermal resistance ensures reliability in compact, high-temperature environments.

Interior Lighting: Thin, lightweight boards ideal for dashboard and cabin LEDs.

Industrial & Outdoor Lighting

Streetlights and Floodlights: Withstand harsh weather and provide consistent illumination.

High-Bay Lighting: Durable boards for warehouses and factories with 24/7 operation.

Horticultural Lighting

Grow Lights: Optimized thermal performance supports UV/IR LEDs for indoor farming.

Case Study: Boosting Efficiency in Smart Streetlights

A European smart city project partnered with a Chinese manufacturer to develop aluminum PCB LED boards for energy-saving streetlights. The boards’ superior heat management reduced operating temperatures by 30%, extending LED lifespan by 40% while cutting maintenance costs. Integrated with motion sensors, the system achieved a 50% reduction in energy use, showcasing the synergy of Chinese engineering and green innovation.

Why Partner with Chinese Suppliers?

End-to-End Solutions: From design support to logistics, manufacturers offer comprehensive services.

R&D Collaboration: Joint development for cutting-edge lighting technologies like COB (Chip-on-Board) LEDs.

Global Compliance: Products meet EU CE, REACH, and North American safety standards.

Conclusion

In an era where lighting technology drives sustainability and smart living, aluminum PCB LED boards stand as a cornerstone of innovation. Chinese manufacturers, with their blend of technical expertise, rigorous quality control, and cost leadership, are empowering businesses worldwide to deliver brighter, smarter, and longer-lasting lighting solutions.

Illuminate Smarter. Choose Aluminum PCB LED Boards Made in China.

For more, please visit https://hitechcircuits.com/pcb-products/aluminum-pcb/

0 notes

Text

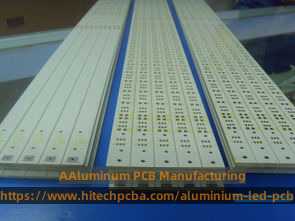

We can deal with aluminum PCB prototypes and small-volume orders without restricting the minimum order quantity. We offer fast turnaround aluminum PCB prototypes that enable you to go to market early, which can be a significant source of our competitive advantage. https://www.hitechpcba.com/aluminium-led-pcb

0 notes

Text

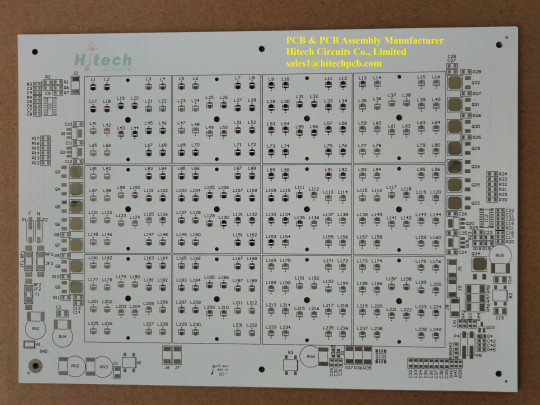

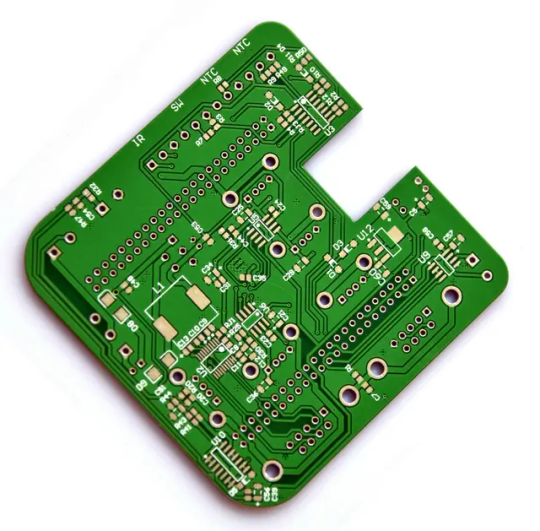

LED PCB Assembly

The utility model SMD led aluminum pcb board, simple structure, good solid crystal effect and good heat dissipation.It uses for high-brightness led printed circuit boards of led lighting equipment, the design, quality, performance, test method and related requirements of identification, packaging etc.

Technical Parameters

Product type: LED SMD PCB Board

Material: PI(polyimide) HIGH TG 170

Layer/Thickness: 2L/0.15mm

Outer Copper: H OZ + plating

Surface treatment: OSP

Min Line Width: ≥ 0.10mm

Min Line Space: ≥0.10mm

Min Hole: ≥0.20 mm

Solder Mask: White

Silkscreen: Black

Technical featuer: special materials

Application: Lamps and lanterns

Components: As Bom List

If you’re interested in our products, pls kindly email to Sandy: [email protected]

0 notes

Text

Медный сердечник PCB - медный фундамент + изоляция + медь

PCB с медным сердечником - это PCB с медной базой + изоляцией + слоем медной схемы, также известный как PCB с медной базой, PCB на медной основе и PCB с медной оболочкой.

ПХБ на основе меди - это металлический сердечник с медной пластиной. Если фундамент гибридного PCB представляет собой медную пластину, встроенную в пластину FR4, то это также PCB на основе меди.

#pcb fabrication#pcb assembly#pcb manufacturer#aluminium pcb#pcba manufacturing#pcb#flex pcb#flex circuit pcb#pcb design#led pcb#Copper core pcb

0 notes

Text

Cutting-Edge Aluminum PCBs at Affordable Price: Hitech Circuits Co., Limited

Are you searching for quality PCB circuits? It is crucial to find a well-established and stable company that delivers excellent Quality circuits at an affordable price in the market. Discover Hitech Circuits Co. Limited for cutting-edge aluminum PCBs. Hitech Circuits Co. Limited is the best PCB manufacturing company has more than ten years of experience. Our product builds with an excellent benefits like product durability, power density, minimize junctions temperatures, etc. Additionally, our aluminum pcbs will increase long-term reliability, develop durability, control temperatures, and reduce the chances of failures. For more details, call us at +86-755-29970700 or visit our website today!

1 note

·

View note

Text

LED PCB

LED PCBs are engineered to power and control light-emitting diodes efficiently. Our LED PCBs feature thermally conductive materials for effective heat dissipation, ensuring optimal LED performance and longevity. Precision manufacturing and design expertise make our LED PCBs ideal for various lighting applications, from commercial displays to automotive lighting systems. Read More: https://sqpcb.com/products/led-pcb

#PCB Supplier#PCB Manufacturer#Custom Circuit Boards#Multi Circuit Boards#Aluminum base PCB#Multilayer PCB#aluminium pcb board#Customize Pcb#customized pcb boards#pcb board#printed circuit board#circuit board#Pcb manufacturing#Assembly pcb#pcb china#special pcb#LED PCB#rigid flex pcb

0 notes

Text

XDPCBA.cn: Exploring the Advantages and Applications of Flex PCB in Modern Electronics

Flex PCB, also known as flexible printed circuit boards, have revolutionized the world of modern electronics with their numerous advantages and wide-ranging applications. These lightweight and versatile circuit boards offer a host of benefits that traditional rigid PCBs simply cannot match.

One of the key advantages of flex PCB is its flexibility, allowing it to be bent, folded, or twisted to fit into tight spaces or unconventional shapes. This flexibility enables designers to create innovative and compact electronic devices that were previously impossible with rigid boards. From wearable technology to medical devices and automotive applications, flex PCBs have opened up new possibilities for product design.

In addition to their flexibility, flex PCBs offer enhanced durability and reliability. Their ability to withstand vibrations, shocks, and extreme temperatures makes them ideal for applications in harsh environments where traditional circuit boards may fail. This durability ensures the longevity and performance of electronic devices even in demanding conditions.

Another notable advantage of flex PCBs is their lightweight nature. Compared to rigid boards, they are significantly lighter due to their thin profile and absence of bulky connectors or cables. This weight reduction not only contributes to overall product weight savings but also allows for greater design freedom by eliminating space constraints.

The applications of flex PCBs are vast and diverse. They are widely used in consumer electronics such as smartphones, tablets, and wearables where space optimization is crucial. Additionally, industries like aerospace, automotive manufacturing, healthcare equipment, and industrial automation rely on flex PCBs for their unique properties.

In conclusion, the advantages offered by flex PCB technology have propelled it into becoming an indispensable component in modern electronics. Its flexibility, durability, lightweight nature along with its wide range of applications make it a preferred choice for designers seeking innovative solutions in electronic product development.

#pcb plate#pcb board#pcb circuit#pcb factory#circuit board#fpc#flex pcb#aluminum pcb#led pcb#led circuit board#pcb & pcba#pcb assembly#pcba board manufacture#pcba assembly manufacture#pcba service#pcb board manufacture#pcba oem#pcba shenzhen#pcba supplier#pcba pcb assembly#pcba circuit board#ems pcba#smt pcba#pcba smt assembly

0 notes

Text

The first test for our WLED board codename "Sparkle Motion" 🌈💖💡 … 🐇⏳🌌

We got our WLED-friend PCBs today, and we only made one mistake: the wrong resistor on the 3.3V feedback line. Now that it's fixed, the board seems to work great with the latest version of WLED

We are checking all 4 signal outputs with this handy 256-LED grid that sits on our desk. Next, we will test the onboard IR receiver, USB PD, I2S microphone, extra I/O pins, and I2C. We'll also do an Arduino IDE board definition in case folks want to use it as a generic ESP32-to-LED-driver board. We're calling the board "Sparkle Motion" for now, but if you have other naming ideas, let us know - if we pick your name, you get a free board

Sign up, coming soon.

#wled#sparklemotion#leddriver#esp32#electronics#pcbs#arduino#makerprojects#openhardware#opensource#coding#leds#hardwaredesign#innovation#techgeeks#smartlighting#microcontrollers#hardwareengineering#esp32projects#ledmatrix#diyhardware#iotprojects#arduinoide#hardwaretesting#ledtechnology#techmakers#electronicscommunity#prototyping#hardwarehacking#adventuresintech

17 notes

·

View notes

Text

isn't it fucked how the ability to prototype hardware projects is region-locked

#deerbleats#there are no hackerspaces in my country so I can't get affordable non-industrial 3D printing/CNCing to make my own tools#and bc of ridiculous shipping times/costs just getting the right resistors for a shitty project's LEDs would take weeks of planning/waiting#meanwhile mfs in the global north will next-day-shipping order solder masks made out of custom PCBs and call it a 'budget friendly hack'#like if I were to order literally anything from PCBWay I'd have to pay over 50USD just for shipping#and if I get the wrong parts or if I break something it's fucktons of money in shipping + even more time waiting for shit yet again

7 notes

·

View notes

Text

2. Why PCBA Quality is Non-Negotiable, Hitech Circuits at your service.

The quality of PCBA directly impacts the performance, reliability, and lifespan of your electronic devices. A subpar PCBA can lead to frequent malfunctions, increased product returns, and damage to your brand reputation. On the contrary, a well-crafted PCBA ensures stable operation, reduces maintenance costs, and enhances customer satisfaction.

Our PCBA manufacturing process adheres to the highest industry standards. From material selection to final inspection, every step is meticulously monitored to guarantee that each assembly meets or exceeds your specifications. We use premium-grade PCBs, genuine electronic components, and advanced soldering techniques to ensure strong connections and optimal functionality.

Email Cynthia: [email protected] if you are interested in PCB and PCBA service.

#pcb assembly#pcb manufacturer#pcba#led pcb#pcb#fr4#flexible pcb board#aluminum pcb#electronic#ceramic pcb#flex pcb

0 notes

Text

HEY I MADE SOME LED LIGHTS (Heads up: flashing bulb, loud fan)

[Video ID: On a wooden table sits some 194 sized bulbs. Some are glass, some are LED. There are a few PCB’s of unpopulated LED 194 bulbs. There is a stand in the middle holding one LED 194. Throughout the 12 second video, the bulb is turned on and off, with a single beep for each state change. There is also a LOUD buzzing sound, which is the universal power supply fan. End ID]

I have a few things in my world that use a 12 Volt 194 Incadesant light bulb. Two automotives, a Flashlight, and some old tech. And while the original factory-designed bulbs are alright, I would prefer to have something more modern and brighter. Now, there are a lot of LED replacements on the market, but none are perfect. Some need to be angled the correct way, some are polarized, some can only go in specific 194 sockets, and most are just absolute shit quality.

SO! I set out a design goal :) I wanted to make a 194 LED bulb that was A.) Rated for 14V 0.5A (improvement on the original), was not polarized, could fit into ANY 194 socket, had a wide viewing angle, Automotive grade, and lastly, could actually last longer than a week (Goal is at least 50K hours).

And this is my first attempt! It is . .. well buggy. What do you expect for prototype number 1? But, I have already designed a second one, and once I’m sold on how efficient this one is, I’ll finalize that second one and try again. But! despite the bugs, it does still light :) And it (somewhat) does meet all my requirements as well 💙💜

Anyways, I’ll add on an update for when part two comes out, maybe late Fall 2024. The boards are NOT cheap, as they need special requirements over a regular PCB.

12 notes

·

View notes

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

J-Cube Technologies Inc.

J-Cube Technologies Inc. is an organization that specializes in the production of printed circuit boards (PCBs).

Our company is based in Montreal, Canada, and has been active in the industry for over a decade. Through our success in Asian infrastructure development and the expansion of our engineering and technical manufacturing expertise, we have grown to be a world-class provider of comprehensive and reliable electronic solutions.

#jcubetech#jcubetechca#J-Cube Technologies Inc#metal pcb#metal core pcb manufacturer#metal core printed circuit board#aluminum core pcb#mcpcb#LED MPCB#Ceramic PCB#mcpcb manufacturer#Quick turn mpcb#pcb core#Printed Circuit Board#Analog circuit#Bare board#Blind via#Component#Dip Trace#Schematic Capture#Library Pane#Schematic Pane

2 notes

·

View notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes