#PCB design guidelines

Explore tagged Tumblr posts

Text

Tips to design High Frequency PCB for optimal performance

Best practices for high-frequency PCB design with PCB Power. Our guide provides comprehensive PCB design guidelines, material selection tips, and advanced techniques for superior performance. As a leader in PCB manufacturing in the USA, PCB Power ensures top-quality production and expert advice. Learn how to optimize impedance, grounding, and signal integrity. Visit PCB Power's Video for more details!

0 notes

Text

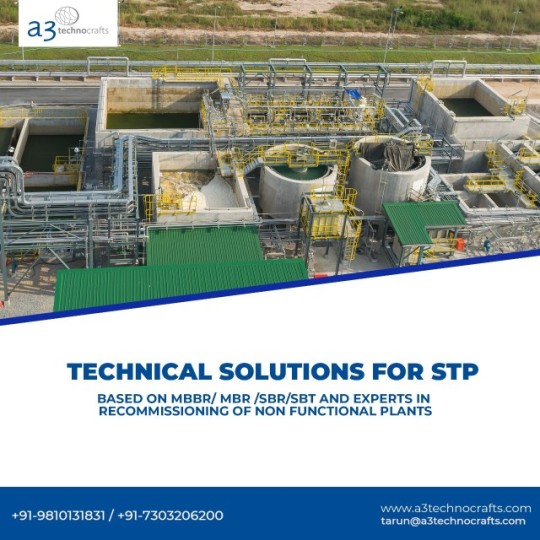

STP Plant Manufacturer and Supplier in Gurgaon

Welcome to your all-inclusive guide on STP solutions in Gurgaon. Whether you are a builder, an industry owner, or a facility manager, finding the right Sewage Treatment Plant Manufacturer in Gurgaon is important for your water treatment needs. As a rapidly growing city, Gurgaon faces increasing pressure on its water resources. Many commercial buildings, housing societies, and industries must now install STP systems to meet pollution control guidelines. Local manufacturers understand these needs and provide customized solutions fitting Gurgaon's specific requirements.

Understanding STP Plants

Netsol Water is top on Sewage Treatment Plant Manufacturers in Gurgaon, providing advance solutions of waste water management. An STP plant helps detoxify and treat wastewater arising from buildings, making the water safe for reuse purposes in gardens, cooling towers, and toilet flushing. With increasing water scarcity, as well as stringent environmental norms in Gurgaon, an efficient STP has become a must-have installation for most properties.

Key Features to Look for in an STP Manufacturer

When choosing an STP plant supplier in Gurgaon, consider these important factors:

- Experience in designing and building STPs

- Quality of materials and components used

- Technical support and maintenance services

- Cost-effectiveness and energy efficiency

- Compliance with local regulations

- Installation and commissioning expertise

Types of STP Plants Available

Gurgaon's manufacturers offer various STP technologies:

- MBBR (Moving Bed Biofilm Reactor) Systems

- SBR (Sequencing Batch Reactor) Plants

- FAB (Fluidized Aerobic Bioreactor) Systems

- MBR (Membrane Bioreactor) Technology

Each type suits different needs based on space availability, water quality requirements, and budget constraints.

Benefits of Working with Local Manufacturers

Choosing a Gurgaon-based Sewage Treatment Plant Manufacturer brings several advantages:

- Quick response time for maintenance

- Better understanding of local requirements

- Easy availability of spare parts

- Regular site visits and support

- Compliance with Haryana pollution control norms

Installation and Maintenance Services

Leading manufacturers in Gurgaon provide:

- Site assessment and planning

- Custom design services

- Complete installation support

- Regular maintenance packages

- Operator training

- Emergency repair services

Cost Considerations

STP plant costs in Gurgaon depend on:

- Treatment capacity required

- Technology chosen

- Space availability

- Level of automation needed

- Material quality selected

Most manufacturers offer flexible payment terms and annual maintenance contracts.

After-Sales Support

Quality manufacturers ensure:

- 24/7 technical support

- Regular maintenance visits

- Quick spare parts supply

- Water quality testing

- Performance optimization

- Troubleshooting assistance

Environmental Compliance

Reliable manufacturers help you:

- Meet PCB guidelines

- Maintain proper documentation

- Monitor water quality

- Submit compliance reports

- Update systems as per new rules

Netsol Water Solutions: Your Trusted STP Partner in Gurgaon

Netsol Water stands out as a leading STP plant manufacturer and supplier in Gurgaon. With years of experience, they offer complete water treatment solutions including design, manufacturing, installation, and maintenance of STP plants. Their team of experts ensures each project meets quality standards while providing cost-effective solutions.

Known for their innovative approaches and reliable after-sales service, Netsol Water has successfully installed numerous STP plants across Gurgaon. They understand local requirements and provide customized solutions that help businesses and communities manage their wastewater effectively while meeting environmental regulations.

Contact their team to discuss your STP requirements and get expert guidance on choosing the right system for your needs. With Netsol Water, you get more than just an STP plant – you get a long-term partner committed to your water treatment success.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#gurgaon#sewage#stp#stps

2 notes

·

View notes

Text

4 Crucial Things to Consider While Choosing LED PCB Manufacturer

LEDs have revolutionized lighting. At the heart of their brilliance, is the PCB assembly. Electing the right LED PCB assembly manufacturer can make or break your project. This ensures quality, performance, and ultimately, success. So, before you dive into the luminous world of LED PCBs, this article sheds some light on the key factors to consider when making your purchase:

1. Experience Matters: You should choose a manufacturer with proven expertise in LED PCB assembly. The company you choose should have a track record of successful projects similar to yours. Experience means they will understand your specific needs and deliver assemblies that meet or exceed your expectations.

2. Material Matters: The heart of your PCB is its materials. Go for manufacturers

who ensure high-quality FR4 or metal-core PCBs for optimal thermal management and longevity. They must adhere to industry standards for materials and components to guarantee reliability and safety.

3. Thermal Management: LEDs are designed to generate heat, so proper thermal management plays a crucial role. Look for manufacturers who offer solutions like aluminium heat sinks. Their expertise in thermal management can extend the lifespan of your LED PCB and prevent overheating issues.

4. Price is Not Everything: Though cost is important, its priority is not over quality.

The cheapest option might have hidden costs in the long run. Choose a manufacturer who offers budget-friendly pricing while maintaining high-quality standards and reliable service.

If you are looking for an LED PCB manufacturer near you you can count on Hitech Circuits Co., Limited. They have more than 20 years of experience in the electronics manufacturing industry. They have a talented design team who follow advanced manufacturing techniques.

These guidelines help you illuminate your path to finding the perfect LED PCB assembly manufacturer. Your choice has a direct impact on the performance, lifespan, and success of your project.

2 notes

·

View notes

Text

Complete Guide to NCR Institute of Medical Sciences, Meerut – MBBS Admission, Fees, and More

Choosing the right medical college is one of the most important steps in your journey to becoming a doctor. If you're a NEET aspirant looking for a private medical college in Uttar Pradesh, NCR Institute of Medical Sciences, Meerut is a strong option. With modern facilities, experienced faculty, and a focus on practical learning, this college is gaining popularity among students across India.

In this article, you'll find everything you need to know about NCR Institute of Medical Sciences, Meerut — from course details and admission process to fees, hostel facilities, and future opportunities. Let's get started.

About NCR Institute of Medical Sciences, Meerut

NCR Institute of Medical Sciences, Meerut is a private medical college located on the outskirts of Meerut, Uttar Pradesh. It is approved by the National Medical Commission (NMC) and affiliated with Chaudhary Charan Singh University, Meerut.

Established with the goal of providing affordable and quality medical education, the institute has a well-equipped campus, an attached teaching hospital, and a supportive environment for learning.

Why Choose NCR Institute of Medical Sciences, Meerut?

Here are a few reasons why many students are choosing NCR Institute of Medical Sciences, Meerut for their MBBS studies:

NMC recognition ensures your degree is valid across India.

A fully functional teaching hospital provides clinical training.

Modern labs, classrooms, and library with digital resources.

Affordable fee structure compared to other private colleges.

Hostel and mess facilities available on campus.

A peaceful location that supports focused learning.

If you're looking for a good balance of academics, infrastructure, and affordability, this college checks all the boxes.

MBBS Course Details

The main course offered at NCR Institute of Medical Sciences, Meerut is the MBBS (Bachelor of Medicine and Bachelor of Surgery) program.

��� MBBS Course Overview:

Duration: 5.5 years (4.5 years of academic study + 1 year of internship)

Seats Available: 150 MBBS seats (as per latest NMC approval)

Language of Instruction: English

Curriculum: Follows NMC guidelines

The MBBS course focuses on both theoretical knowledge and hands-on training, ensuring students become competent and compassionate doctors.

Eligibility Criteria

To get admission into the MBBS course at NCR Institute of Medical Sciences, Meerut, students must meet the following eligibility criteria:

Must have passed 10+2 or equivalent with Physics, Chemistry, Biology/Biotechnology, and English.

Should have scored a minimum of 50% marks in PCB (40% for SC/ST/OBC candidates).

Must have qualified NEET-UG conducted by NTA.

Minimum age required is 17 years as of December 31st of the admission year.

Admission Process

The admission process at NCR Institute of Medical Sciences, Meerut is based on NEET-UG scores and follows the centralized UP NEET counselling process conducted by the Directorate of Medical Education and Training (DMET), Uttar Pradesh.

📝 Step-by-Step Admission Process:

Appear and qualify NEET-UG.

Register for UP NEET counselling at upneet.gov.in.

Choose NCR Institute of Medical Sciences, Meerut during choice filling.

If allotted, report to the college with documents and pay the admission fee.

Complete verification and secure your seat.

Students from all over India can apply under the management quota, while state domicile students can apply under the state quota.

Fee Structure

The MBBS fees at NCR Institute of Medical Sciences, Meerut are competitive and designed to be student-friendly.

💰 Estimated Fee Structure:

Tuition Fee: ₹11–13 lakhs per year (approx.)

Hostel Fee: ₹1.5–2 lakhs per year (includes mess and lodging)

Security Deposit: One-time, refundable (as per college norms)

Note: Always verify the latest fees from the official counselling portal or college website, as fee structures can change yearly.

Campus Facilities

NCR Institute of Medical Sciences, Meerut provides a student-friendly campus with all essential facilities:

🏫 Key Facilities:

Smart classrooms and digital learning aids

Fully equipped labs for anatomy, pathology, microbiology, etc.

Library with national and international medical journals

On-campus hospital with various departments and OPD services

Hostels with 24/7 security, mess, and clean living space

Recreational areas, sports grounds, and student lounges

Transportation for local students and staff

The campus promotes academic growth, personal development, and a positive student experience.

Internship and Training

The final year of the MBBS course includes a compulsory 12-month rotating internship. During this period, students work in real hospital departments such as:

General Medicine

Surgery

Pediatrics

Obstetrics and Gynecology

Emergency and ICU

This hands-on experience helps students apply what they’ve learned and prepares them for real-life medical challenges.

Career Opportunities After MBBS

After graduating from NCR Institute of Medical Sciences, Meerut, students have multiple career paths:

Appear for NEET-PG to specialize in MD/MS programs

Apply for government medical officer jobs

Start practicing in private hospitals or clinics

Prepare for exams like FMGE, UPSC CMS, or AIIMS PG

Explore careers in medical research or public health

A degree from this institute gives students a strong foundation to build their medical careers.

Final Words

If you’re a NEET-qualified student and looking for a private medical college in Uttar Pradesh with quality education, good infrastructure, and an affordable fee structure, then NCR Institute of Medical Sciences, Meerut is a solid choice.

It offers everything a future doctor needs — academic support, clinical training, and a student-friendly environment. So, start your journey today and take one step closer to your dream of wearing the white coat.

#mbbs#mbbs in india#mbbs in up#study mbbs in up#best mbbs medical college in up#NCR Institute of Medical Sciences#Meerut

0 notes

Text

Datta Meghe Medical College – A Top Choice for MBBS Aspirants in India

Are you planning to become a doctor and serve society? If yes, then choosing the right medical college is the first and most important step in your journey. One of the top private medical colleges in Maharashtra is Datta Meghe Medical College. It is a trusted name for MBBS education and offers a perfect environment for students who dream of becoming successful doctors.

In this blog, we will explore everything about Datta Meghe Medical College, including its location, facilities, MBBS course, admission process, fee structure, hostel life, and more. Let’s dive in.

About Datta Meghe Medical College

Datta Meghe Medical College is a private medical institution located in Nagpur, Maharashtra. It is part of the famous Datta Meghe Institute of Higher Education & Research (Deemed to be University). The college is approved by the National Medical Commission (NMC) and recognized by the Ministry of Health and Family Welfare, Government of India.

With world-class infrastructure, modern laboratories, experienced faculty, and advanced teaching methods, Datta Meghe Medical College offers the best medical education to students. The college follows a student-friendly approach and encourages practical learning along with theory.

Why Choose Datta Meghe Medical College for MBBS?

Here are some strong reasons why thousands of students choose Datta Meghe Medical College every year:

✅ Recognized by NMC and part of a reputed deemed university

✅ Highly experienced and qualified teaching faculty

✅ Modern infrastructure with smart classrooms and high-tech labs

✅ Exposure to clinical training in its own multi-specialty hospital

✅ Focus on research, innovation, and skill development

✅ Excellent hostel and sports facilities

✅ Safe and student-friendly campus in Nagpur

All these features make Datta Meghe Medical College a top priority for medical aspirants.

MBBS Course at Datta Meghe Medical College

The college offers the Bachelor of Medicine and Bachelor of Surgery (MBBS) program with an annual intake of 150 students. The total duration of the course is 5.5 years, which includes:

4.5 years of academic study

1 year of compulsory internship

The MBBS curriculum is designed as per the latest NMC guidelines. It covers all important medical subjects and includes early clinical exposure, hands-on training, and skill labs. Students also attend seminars, case presentations, and workshops to enhance their knowledge.

Admission Process at Datta Meghe Medical College

To get admission in Datta Meghe Medical College, students need to follow the below steps:

Qualify NEET-UG – You must appear and qualify in the National Eligibility cum Entrance Test (NEET) conducted by NTA.

Apply through MCC counseling – Admission is offered through All India Counseling conducted by the Medical Counseling Committee (MCC) for Deemed Universities.

Choose the college in counseling – After NEET results, register for MCC counseling and select Datta Meghe Medical College as your preferred option.

Document verification and admission – If selected, you must report to the college with your original documents and pay the fees to confirm your admission.

Eligibility Criteria for MBBS

To apply for Datta Meghe Medical College, you must meet these eligibility conditions:

You must be at least 17 years old as of 31st December in the year of admission.

You must have passed Class 12 with Physics, Chemistry, Biology, and English.

You must score at least 50% marks in PCB subjects (40% for reserved category).

You must qualify NEET-UG with the required cutoff marks.

MBBS Fees Structure

The MBBS fee at Datta Meghe Medical College is as per the fee structure decided by the university and NMC norms. The approximate annual tuition fee is:

Tuition Fees – ₹18,50,000 per year (subject to change)

Hostel Fees – ₹1,50,000 per year (including food and accommodation)

Other Charges – ₹75,000 (university, lab, development, etc.)

The total fees for the full course are around ₹95–100 Lakhs. The college also offers easy payment options and guidance for education loans.

Campus and Facilities

The college campus is designed with modern architecture and a peaceful environment that helps students focus on studies. Here are some of the facilities at Datta Meghe Medical College:

Smart Classrooms with AV Aids

Advanced Anatomy and Physiology Labs

Simulation and Skill Training Centers

Fully Digital Library with e-books and journals

Spacious Lecture Halls and Seminar Rooms

In-campus Hospital for clinical exposure

Separate hostels for boys and girls

Hygienic food in the mess and cafeteria

Indoor and outdoor sports facilities

24x7 security and medical support

Hostel Life at Datta Meghe Medical College

Datta Meghe Medical College offers excellent hostel facilities for students. Each hostel has:

Fully furnished rooms with attached bathrooms

Wi-Fi, common study areas, and recreation rooms

Nutritious meals served in the mess

CCTV surveillance and round-the-clock security

In-house laundry and housekeeping services

Regular health check-ups for hostel students

Hostel life here promotes discipline, safety, and academic growth. Students get a friendly and comfortable environment where they can live and study peacefully.

Internship and Career Support

After completing the MBBS course, students must undergo a 1-year compulsory internship at the attached teaching hospital. During the internship, they get real-time experience in treating patients under the guidance of senior doctors.

The college also provides support for:

NEET-PG preparation

Research opportunities

Participation in national-level medical conferences

Career counseling for specialization or overseas study

Conclusion

If you are a passionate student who dreams of becoming a skilled doctor, then Datta Meghe Medical College is a great place to begin your journey. With top-notch education, experienced faculty, excellent infrastructure, and great student support, this college prepares you to face real medical challenges with confidence.

So, start your MBBS journey at Datta Meghe Medical College and take your first step towards a successful career in medicine.

Need Help?

We at AR Group of Education offer admission support, counseling, and documentation help for MBBS aspirants across India and abroad.

Feel free to contact us at:

523, 5th Floor, Wave Silver Tower, Sec-18 Noida, UP-201301

+91–7076909090

0 notes

Text

Maintaining Your HVAC System with AC Pro-Tech Aerosol: The Ultimate AC Coil Cleaning Solution

Keeping your HVAC system operating smoothly and for a long time is very important, especially where there are lots of high humidity and corrosive substances. Cleaning your system’s AC coils with a good cleaner is very effective in protecting your system. One of the main products here is the AC Pro-Tech Aerosol which is the best from AC Products USA.

Understanding the Importance of AC Coil Maintenance

Jacobs (2023) reports that it is critical to service your HVAC regularly to ensure that it continues to operate efficiently, reliably and safely. So don't let maintenance go if you want to lose the slow and take on the low, low energy bills, that is. It also reduces dust and debris in the home, which is better for your lungs and can also increase system life and reduce your carbon footprint, helping out several good causes. Particularly, the AC cooling coils one section of your HVAC that is responsible for transferring heat. Eventually, these coils might attract all manner of garbage and dirt that will weigh them down and bust the thing loose. The machines will run well and last long, if you clean the AC coils frequently and use a good cleaner spray.

Introducing AC Pro-Tech Aerosol

The AC Pro-Tech Aerosol is a specially formulated AC coil cleaning spray designed to provide a protective coating to your HVAC system. This product not only cleans but also offers long-lasting protection against corrosion, UV rays, and other environmental factors.

Key Features:

Modified Acrylic Polymer Base: Provides a hard, clear coating that allows heat transfer while preventing corrosion.

UV Stable: Protects against material degradation due to ultraviolet rays.

Non-Conductive: Safe for use on electronic components within the HVAC system.

Flexible Barrier: Creates an oxygen barrier that remains flexible over time.

For more details and to purchase, visit the AC Pro-Tech Aerosol product page.

Why Choose AC Pro-Tech Aerosol?

When it comes to maintaining your AC Pro air conditioning system, the AC Pro-Tech Aerosol stands out for several reasons:

Comprehensive Protection: It shields the PCB, cabinet, and coils with a single application.

Ease of Use: Found in a simple spray, one can put it on easily.

Tested and Trusted: It went through a test that was very fast, but very hard, so we know it will last.

Versatility: It can work on new and old machines, making them last longer.

Application Guidelines

To achieve the best results with the AC Pro-Tech Aerosol, follow these steps:

Preparation: Ensure the HVAC system is turned off and clean the surface thoroughly.

Application: Shake the can well and spray evenly over the areas that you want, also on coils, cabinets, and PCBs.

Drying: Let the coat dry fully before you turn the system back on.

Maintenance: Check the system often and put it back on if you need to keep the best cover.

Complementary Products

For a comprehensive maintenance routine, consider using the AC Pro-Clean No Rinse Foaming HVAC Coil Cleaner in conjunction with the AC Pro-Tech Aerosol. This product is made especially to work well with machine parts with a cover on the outside. It can clean a part of the machine that makes heat and a part that gets rid of heat without taking away the cover.

Conclusion

It is important to maintain your HVAC system to guarantee it lasts and performs well. Taking on the AC Pro-Tech Aerosol is a good way to maintain your car because it cleans and protects at the same time. Because of its distinctive way of being made, it is chosen by professionals and homeowners.

More details and a range of other products are available at AC Products USA.

FAQs

1. How is AC Pro-Tech Aerosol distinguished from other coil cleaners?

While normal cleaners only clean, AC Pro-Tech Aerosol offers defense against corrosion and ultraviolet rays, which helps your HVAC equipment last longer.

2. Am I allowed to use AC Pro-Tech Aerosol on any type of HVAC system?

Yes, it is built to fit well with most HVAC systems, both in homes and commercial spaces, as well as those made by Protech AC.

3. Does AC Pro-Tech Aerosol need to be applied often?

Regularly check your system and respray it with aerosol, annually or as required by the current conditions.

4. Can the HVAC electronic parts be safely exposed to the aerosol?

Absolutely. Because it’s non-conductive, it is safe to apply to PCBs and other electronic parts.

5. Where do I find AC Pro-Tech Aerosol?

You can get the product from AC Products USA.

1 note

·

View note

Text

Rigid-Flex PCB Design Guidelines: Ensuring Reliability and Manufacturability

Designing a Rigid-Flex PCB requires more than just combining rigid and flexible sections into one board. It involves careful planning of layout, layer structure, materials, and mechanical constraints to ensure the final product is reliable, manufacturable, and cost-effective.

Below are key guidelines every engineer should follow when designing Rigid-Flex PCBs.

1. Define Rigid and Flex Zones Early

Clearly identify the rigid and flex areas during the initial layout phase. Flex regions should only exist where necessary — overdesigning with too much flex area increases cost and complexity.

Each zone should be planned based on:

Mechanical movement (bending/folding)

Component placement needs

Connector and housing locations

Avoid placing unnecessary flex areas just for routing convenience unless absolutely needed.

2. Maintain Symmetrical Layer Stack-Up

An unbalanced stack-up can lead to warping, twisting, or delamination during lamination or reflow.

Keep the number and thickness of layers symmetrical around the centerline of the rigid section.

Use dummy traces or copper balancing layers to achieve mechanical balance if needed.

Plan separate stack-ups for rigid and flex areas, but ensure transition is smooth.

3. Protect the Flex Area

The flexible section is vulnerable to cracking and wear if not designed carefully.

Never place vias, pads, or components in the flex zone.

Maintain generous spacing between traces in the flex area to reduce mechanical stress.

Avoid 90° corners and sharp transitions — use smooth curves or teardrops for trace routing.

Use coverlay (instead of solder mask) to protect the flex area from mechanical damage.

4. Follow Proper Bending Design Rules

The flex section must withstand multiple bends over its lifetime. Improper bending design can cause trace cracking, delamination, or copper fatigue.

Minimum bend radius should be 6 to 10 times the flex thickness for dynamic bends.

For static (one-time) bends, 3 to 6 times the thickness may be acceptable.

Use curved traces in the bend area to avoid concentration of stress.

Keep traces perpendicular to the bend axis wherever possible.

5. Stiffener Usage

Stiffeners are added in flex areas to provide mechanical support for connector pads or component locations.

Use FR4, polyimide, or stainless steel stiffeners depending on mechanical requirements.

Clearly define stiffener thickness and position in the mechanical drawings.

Do not overlap stiffeners with bend areas unless absolutely required.

6. Routing and Trace Layout

Trace layout impacts both electrical and mechanical performance.

In the flex region, use wide, evenly spaced traces to reduce stress.

Avoid overlapping traces on top and bottom layers in bend areas.

Do not route traces over the transition zone between rigid and flex — leave a clearance buffer.

Maintain consistent impedance and routing lengths for high-speed signals.

7. DFM Considerations

Design for Manufacturability (DFM) is critical for Rigid-Flex PCBs due to the multiple lamination cycles and tighter tolerances.

Ensure design files clearly mark flex/rigid regions and bending direction.

Avoid complex via structures (like stacked or blind/buried vias) near flex zones.

Confirm with the PCB manufacturer about acceptable layer counts, material systems, and bend performance.

Work closely with your fabricator early in the design process to avoid costly revisions.

8. Assembly Planning

Plan your PCB assembly process around the flex structure.

Use support fixtures or carrier panels during SMT to keep the board flat.

Make sure flex areas are protected during handling and soldering.

Define handling instructions clearly if the flex zone should not be bent before final assembly.

Final Thoughts

Rigid-Flex PCBs offer unmatched versatility for compact, high-performance designs — but only when designed correctly. By following key guidelines for stack-up, routing, bending, and assembly, designers can ensure their boards are reliable, manufacturable, and optimized for long-term success.

Collaborate closely with your PCB manufacturer and assembly house throughout the design process to turn your concept into a robust, production-ready product.

0 notes

Text

DY Patil Medical College – A Premier Destination for MBBS in India

DY Patil Medical College, located in Pune, Maharashtra, is one of the top private medical institutions in India. Recognized by the National Medical Commission (NMC) and affiliated with the renowned Dr. DY Patil Vidyapeeth, this college offers world-class medical education with excellent infrastructure and an experienced faculty. It is a preferred choice among MBBS aspirants for its high academic standards, clinical exposure, and overall student development.

About DY Patil Medical College

Established in 1996, DY Patil Medical College was the first private college in Maharashtra to receive approval from the Medical Council of India for an intake of 100 students. Over the years, the intake has increased, and today the college admits 250 MBBS students annually. The institution is known for its commitment to producing skilled, compassionate, and ethical medical professionals.

The campus is located in Pimpri, Pune, and is part of the DY Patil Educational Complex, which houses multiple institutions including dentistry, nursing, physiotherapy, and biotechnology colleges. This proximity offers a multidisciplinary approach to learning.

Courses Offered

MBBS (Bachelor of Medicine and Bachelor of Surgery) – 5.5 years (including a 1-year internship)

MD/MS (Postgraduate Medical Courses) – Offered in various specialties

Superspecialty Courses – DM/MCh programs in select disciplines

MBBS Admission Process

Admissions to the MBBS program are based on the NEET-UG entrance exam. Students from across India compete to secure a seat in this prestigious college. A merit list is prepared based on NEET scores, and the counseling process is conducted through the MCC (Medical Counseling Committee) for Deemed Universities.

Eligibility Criteria for MBBS

Must have passed 10+2 or equivalent with Physics, Chemistry, Biology/Biotechnology, and English

Minimum 50% aggregate marks in PCB (40% for reserved category)

Qualifying NEET-UG score as per the cut-off

Infrastructure and Facilities

DY Patil Medical College boasts modern infrastructure, well-equipped laboratories, and smart classrooms. The teaching hospital attached to the college – Dr. DY Patil Hospital & Research Centre – has over 1,500 beds, offering extensive clinical exposure to students. The hospital serves a large patient base, providing hands-on training in real-world scenarios.

Key facilities include:

Central library with over 35,000 medical books and journals

Separate hostels for boys and girls with 24x7 security

Cafeteria and mess serving hygienic meals

Indoor and outdoor sports facilities

Simulation labs for clinical skill training

Wi-Fi enabled campus

Faculty and Academics

The faculty at DY Patil Medical College includes highly qualified professors, clinicians, and researchers. They adopt innovative teaching methods such as problem-based learning, case studies, and clinical rounds. The curriculum is regularly updated in line with NMC guidelines and global best practices.

In addition to academics, students are encouraged to participate in research, conferences, seminars, and workshops. The college also promotes international collaboration through exchange programs and partnerships with reputed global medical institutions.

Hostel and Student Life

Student accommodation at DY Patil Medical College is designed for comfort and safety. Hostels are spacious, well-ventilated, and furnished with all basic amenities like study tables, wardrobes, and attached washrooms. Wi-Fi, recreation rooms, and laundry services are also available.

Student life is vibrant with several cultural and sports events organized annually. Clubs for music, dance, drama, and literary activities ensure holistic development beyond academics.

Why Choose DY Patil Medical College?

Recognized by NMC and part of a Deemed University

High NEET ranking and preference among top scorers

State-of-the-art infrastructure and 1,500+ bedded teaching hospital

Experienced faculty with a focus on research and innovation

Excellent placement and postgraduate success rate

Safe, student-friendly campus in Pune

Placement and Career Support

DY Patil Medical College supports students with career guidance, internships, and postgraduate admissions. Alumni of the college have secured placements in leading hospitals in India and abroad, while many continue to pursue MD/MS and super-specialty courses in reputed institutions.

Conclusion

DY Patil Medical College is a well-established and highly respected institution for MBBS and medical education in India. With its focus on academic excellence, clinical training, and student well-being, it stands out as an ideal choice for aspiring doctors. For those looking to build a strong foundation in medicine and enjoy a holistic college experience, DY Patil Medical College is truly a destination of opportunity.

#DY Patil Medical College#DY Patil Medical College Pune PG Fees#DY Patil Medical College is private or government

0 notes

Text

Unlock the Power of Electronics Design in Cooking Robot Hygiene

Table of Contents

Why Hygiene Matters in a Cooking Robot

How Electronics Design Improves Cooking Robot Hygiene

Sensor Integration for Real-Time Hygiene Monitoring

Sealed PCB Design for Wash-Down Protection

Built-In Cleaning Automation

Touchless Control Systems

Real-World Scenario: Electronics Design Enabling Hygiene

Meeting Global Food Safety Standards

What’s Next: Future of Hygiene in Cooking Robots

Key Takeaways

Conclusion

Smart electronics design plays a critical role in maintaining hygiene in a cooking robot. From precision control to built-in sanitation systems, advanced electronics ensure that cooking robots meet the highest cleanliness and food safety standards. Whether it’s managing temperature, automating cleaning, or preventing contamination, the secret to hygienic food automation lies in how the electronics are designed.

If you’re exploring how modern cooking robots stay clean, safe, and food-ready, the answer begins with smart, reliable electronics design. Let’s break down how this works — and why it matters.

Why Hygiene Matters in a Cooking Robot

In commercial kitchens, food factories, or even smart homes, a cooking robot handles critical tasks like chopping, frying, stirring, or mixing. Because they come into direct contact with food, hygiene isn’t just about cleanliness — it’s vital for health, compliance, and preventing cross-contamination.

Contamination risks may include:

Leftover food residues

Cross-contact between raw and cooked items

Improper temperature management

Bacteria buildup in hard-to-clean areas

How Electronics Design Improves Cooking Robot Hygiene

1. Sensor Integration for Real-Time Hygiene Monitoring

Smart sensors integrated into the cooking robot help monitor:

Surface cleanliness

Sanitization temperatures

Moisture levels that signal bacterial growth

These sensors help the robot take action — whether it’s sounding alerts or starting cleaning cycles — making electronics design a key part of hygiene management.

2. Sealed PCB Design for Wash-Down Protection

In hygiene-sensitive environments, the electronics design includes:

Waterproof PCB coatings

Isolated high-voltage components

IP67+ enclosures for safe wash-downs

This allows the cooking robot to be cleaned externally without damaging the electronics, maintaining both hygiene and reliability.

3. Built-In Cleaning Automation

Electronics power intelligent hygiene functions like:

Pre-programmed cleaning schedules

Motor control for rotating brushes and sprayers

Hot water and detergent dispensers

These automated systems reduce manual intervention and improve hygiene consistency across every cooking cycle.

4. Touchless Control Systems

Modern cooking robots feature touchless controls to avoid surface contamination. These include:

Gesture or voice recognition

Infrared sensors for non-contact operation

Capacitive proximity-based interfaces

Such innovations are only possible through thoughtful electronics design that enhances hygiene while improving user experience.

Real-World Scenario: Electronics Design Enabling Hygiene

Imagine a robotic kitchen unit preparing soups:

Sensors detect residue inside the container

A cleaning cycle is triggered automatically

Electronics control nozzles, heat, and drainage

Sealed circuits protect the system during cleaning

Here, hygiene, automation, and electronics design work together to ensure safe and sanitary operation.

Meeting Global Food Safety Standards

HACCP guidelines

FDA and EU food-grade equipment regulations

NSF/ANSI safety standards

A strong electronics design not only automates hygiene but helps manufacturers log cleaning activity and prove compliance with regulations.

What’s Next: Future of Hygiene in Cooking Robots

Emerging electronics design trends are pushing hygiene even further:

AI-Powered Hygiene Monitoring: Adaptive cleaning schedules and anomaly detection

IoT for Hygiene Reports: Remote access to logs, diagnostics, and alerts

Self-Cleaning Tech: UV light modules and antimicrobial surfaces managed by electronics

These innovations promise a future where cooking robot hygiene becomes smarter, faster, and more autonomous.

Key Takeaways

Hygiene is a critical factor in every cooking robot application

Smart electronics design enables better hygiene through sensors, automation, and protective enclosures

Sealed systems, real-time detection, and automated cleaning are only possible through modern electronics

Investing in better design reduces contamination risk and ensures compliance with food safety standards

Conclusion

A cooking robot is only as clean as its electronics allow it to be. By integrating cutting-edge sensors, sealed PCBs, and automated cleaning capabilities, electronics design plays a central role in ensuring hygiene in robotic kitchens. As the demand for automation in food preparation rises, smarter electronics will remain the backbone of safe, hygienic cooking technologies.

Hygiene isn’t optional — it’s a core feature that defines the success of any cooking robot. And it starts with smarter electronics design.

Whether you’re building the next generation of kitchen robotics or optimizing hygiene in automated food systems, the right design partner helps you move from idea to market with precision and safety built-in.

Discover how advanced electronics design can elevate hygiene in cooking robots. 🔗 Learn more at www.auckam.com

0 notes

Text

Tips to design High Frequency PCB for optimal performance

Explore optimized techniques for high-frequency PCB design. Learn how to minimize signal loss, reduce interference, and achieve peak performance in your advanced electronic projects with expert tips and strategies.

0 notes

Text

Quality Control Standards for Printed Circuit Board Suppliers

In the fast-evolving world of electronics manufacturing, reliability and precision are not optional—they are essential. For businesses that rely on printed circuit boards (PCBs) to power their devices, quality assurance must be a top priority. At Pcb-Togo Electronic, Inc., we understand this responsibility. As a trusted Printed Circuit Board Supplier, we have built our reputation on a foundation of strict quality control standards designed to meet the most demanding performance and safety requirements.

Below, we explore the comprehensive approach we take at Pcb-Togo Electronic, Inc. to ensure every PCB we deliver is tested, traceable, and built to last.

Why Quality Control Is Critical for PCB Manufacturing

Unlike many components in the electronics supply chain, PCBs are the foundation of all electrical functionality in a device. Even a minor defect—such as a poor solder connection or microscopic short—can cause device failure, product recalls, or worse, safety hazards. For that reason, choosing a Printed Circuit Board Supplier with a proven quality control system is not just important—it’s mission-critical.

Poorly controlled PCB manufacturing can lead to:

Intermittent circuit failures

Early device breakdowns

Excessive rework costs

Damaged brand reputation

This is why at Pcb-Togo Electronic, Inc., we don’t just manufacture PCBs—we verify and validate every detail throughout the production process.

Our Quality Control Process: Built for Precision

At the core of our operations is a multi-phase quality control framework designed to ensure consistency, compliance, and performance. Our system covers every stage of PCB production, from material sourcing to final delivery.

1. Verified Materials and Supplier Audits

We begin quality control long before production starts. Every PCB at Pcb-Togo Electronic, Inc. starts with certified raw materials. We conduct strict inspections and maintain detailed supplier records to ensure that copper laminates, solder masks, and surface finishes meet global standards.

Regular supplier audits help us track quality at the source. Any vendor that fails to meet our benchmarks is removed from our approved list.

To explore how material quality affects PCB performance, Find Out More on our supplier verification page.

2. In-Process Inspections

Our in-house team conducts detailed inspections at every major production checkpoint:

Etching Accuracy – To prevent shorts or open circuits

Layer Alignment – Verified via X-ray scanning for multilayer boards

Hole Wall Quality – Assessed with microsectioning techniques

Solder Mask Integrity – Checked for uniform thickness and absence of bubbles

These real-time evaluations prevent defects from carrying forward, saving both time and cost. This proactive approach distinguishes us as a forward-thinking Printed Circuit Board Supplier.

3. Final Electrical Testing

No PCB leaves our facility without undergoing 100% electrical testing. Each board is verified for:

Continuity

Shorts

Component placement (if assembly is included)

Whether you're producing high-frequency boards or standard FR4 circuits, this final validation ensures that your boards will perform flawlessly in your application.

If you're curious about our advanced testing procedures, you can find out more by contacting our engineering team or viewing our testing guidelines online.

4. Strict Packaging & ESD Protection

Even after production, PCBs must be handled with care. Our packaging process includes:

Moisture barrier bags

ESD foam and shielding

Vacuum sealing for long-distance shipments

Each order is labeled for traceability, allowing clients to track batch origin, production data, and inspection results. This complete chain-of-custody approach ensures that your PCBs arrive in top condition—no matter where in the world you are.

For more on logistics and shipping support, go right here to our delivery resource center.

Continuous Quality Improvement (CQI)

Being a Printed Circuit Board Supplier means constantly adapting to evolving industry standards and customer requirements. At Pcb-Togo Electronic, Inc., we use data from inspections and customer feedback to refine our production lines. Our engineers regularly review:

First-pass yield rates

Customer return data

Root cause analyses

This commitment to Continuous Quality Improvement helps us remain flexible and responsive, while maintaining high yield rates and low defect percentages.

Why Choose Pcb-Togo Electronic, Inc.?

With over two decades of experience, we are a leading Printed Circuit Board Supplier known for our ability to deliver reliable, high-performance boards at competitive prices. What sets us apart is our end-to-end commitment to quality—from the raw copper to the final shipment box.

Clients from industries such as medical, automotive, aerospace, and consumer electronics trust us for:

Fast lead times

Transparent communication

Flexible order quantities

Proven reliability

When you partner with Pcb-Togo Electronic, Inc., you’re choosing a supplier that backs every board with traceability, testing, and total accountability.

Final Thoughts

Selecting a reliable Printed Circuit Board Supplier is essential to the long-term success of any electronics product. At Pcb-Togo Electronic, Inc., quality isn’t a department—it’s the DNA of our entire operation. From stringent inspections and automated testing to supplier audits and proactive improvement, we take every step necessary to ensure our PCBs are ready for real-world performance.

If you’re ready to raise the bar for your electronics production, Find Out More by speaking with our technical experts or requesting a custom quote today.

Original Link: https://pcbtogo.blogspot.com/2025/06/quality-control-standards-for-printed.html

0 notes

Text

Why Choose Muzaffarnagar Medical College for Your MBBS Journey in 2025?

Choosing the right medical college is one of the biggest decisions in every medical aspirant’s life. With so many colleges across the country, it becomes difficult to pick the one that truly supports your dreams. If you're looking for a combination of quality education, top-class infrastructure, experienced faculty, and a student-first approach, then Muzaffarnagar Medical College should definitely be on your list.

🌟 About Muzaffarnagar Medical College

Muzaffarnagar Medical College is located in Muzaffarnagar, Uttar Pradesh. It is affiliated with Chaudhary Charan Singh University, Meerut, and is recognized by the National Medical Commission (NMC). Since its establishment, the college has built a solid reputation in offering world-class medical education and clinical exposure to its students.

The campus is spread over a large green area with modern academic blocks, high-tech labs, a central library, and a fully equipped hospital. The college aims to create competent and compassionate medical professionals who are ready to serve both urban and rural communities.

🎯 Why Students Prefer Muzaffarnagar Medical College

Here are the key reasons why Muzaffarnagar Medical College is a top choice for MBBS aspirants:

1. Top-Notch Infrastructure

The college offers state-of-the-art classrooms, well-maintained labs, and modern technology that helps students learn better. From anatomy dissection halls to advanced simulation labs, every facility is designed to enhance hands-on learning.

2. Dedicated Faculty

The teaching staff at Muzaffarnagar Medical College is experienced, supportive, and focused on every student's growth. Professors here don't just teach the syllabus—they mentor students, help them clear doubts, and prepare them for future exams like NEET PG, USMLE, and more.

3. Clinical Exposure

The college is attached to a 950+ bedded hospital, which sees a high patient footfall every day. This gives students real-world clinical training from the very first year. You get to observe and treat a variety of cases, which builds confidence and experience.

4. Focus on Holistic Development

Medical education is not just about books. Muzaffarnagar Medical College promotes extracurricular activities like sports, debates, research, and cultural events. The annual fests and student clubs create a balanced life and help you manage stress better.

5. Affordable Fee Structure

Compared to many private colleges in India, Muzaffarnagar Medical College offers a relatively affordable fee structure without compromising on quality. Scholarships and financial aid options are also available for deserving students.

📚 MBBS Course Overview

Here’s what you can expect from the MBBS course at Muzaffarnagar Medical College:

Duration: 5.5 years (including 1-year internship)

Eligibility: Minimum 50% marks in 12th (PCB) and qualifying NEET-UG

Seats: 150 MBBS seats (as per NMC guidelines)

Medium of Instruction: English

Annual Intake: Based on NEET rank and counselling

The curriculum is structured to provide a balance between theoretical knowledge and clinical practice. It includes subjects like Anatomy, Physiology, Biochemistry, Pathology, Microbiology, Medicine, Surgery, Pediatrics, and more.

🏥 Hospital Facilities

The college hospital is equipped with:

Emergency and trauma services

ICU and NICU units

Radiology and diagnostics labs

Operation theaters

Blood bank

Pharmacy and OPD services

This ensures that students get hands-on training in almost every medical department during their MBBS.

🧳 Hostel & Campus Life

Muzaffarnagar Medical College provides separate hostel facilities for boys and girls with 24/7 security, mess services, common rooms, and recreational spaces. The campus also features:

Sports ground

Gymnasium

Wi-Fi access

Cafeteria

Transportation for students

Students describe their college life here as enjoyable, safe, and academically productive.

🌍 Placement & Career Opportunities

After completing MBBS from Muzaffarnagar Medical College, students have multiple pathways:

NEET PG: Many students crack NEET PG and get into top government MD/MS programs.

Government Jobs: Many alumni work as government doctors in UP and other states.

Abroad Exams: The college also supports students aiming for USMLE, PLAB, and FMGE exams.

Private Practice: Graduates are confident enough to start their clinics or join reputed hospitals.

✅ Final Thoughts

If you’re an MBBS aspirant looking for the best blend of affordability, education quality, and clinical exposure, then Muzaffarnagar Medical College is worth your attention. It supports academic excellence, personal growth, and a well-rounded experience that prepares you for your future in medicine.

0 notes

Text

Tips for Maintaining Your AMB High-Speed Milling Motor

When it comes to precision PCB prototyping and small-scale manufacturing, the AMB high-speed milling motor is a top choice for designers and engineers. Known for its compact size, powerful performance, and high RPM capabilities, it’s ideal for milling fine traces, routing outlines, and drilling vias on copper clad laminates. However, like any high-precision tool, proper maintenance is essential to ensure long-lasting performance and avoid costly downtime.

In this blog, we’ll explore practical ways to extend the life of your AMB spindle motor, including best practices for cleaning, lubrication, bit handling, and operational care. Whether you're using carbide PCB drill bits or diamond-cut routers, these tips will help keep your spindle running like new.

Why Spindle Maintenance Matters

The spindle motor is the heart of your milling setup. It directly affects:

Cutting accuracy

Bit longevity

Surface finish

Machine noise and vibration

Overall production efficiency

A neglected spindle can overheat, lose precision, or fail entirely—resulting in expensive repairs or replacements. Regular care ensures your investment in equipment and tooling continues to deliver consistent, professional results.

1. Use the Right Tools for the Job

Your carbide PCB drill bits, end mills, and router bits must be compatible with the spindle’s RPM range and collet size. AMB motors typically operate at 5,000–25,000+ RPM, so only high-quality, balanced tools should be used.

Tips:

Use solid carbide bits for milling copper clad laminates, as they resist wear and minimize vibration.

Avoid using dull or chipped bits, which can create uneven loads and damage the motor’s bearings.

Choose tool lengths appropriate for your application—shorter bits generate less flex and are more stable at high speeds.

2. Keep the Spindle Clean

Dust and debris are your spindle’s worst enemies. Milling FR4 copper clad laminates produces fine fiberglass dust that can infiltrate the motor and bearings, causing long-term wear and overheating.

Maintenance Checklist:

Clean after every session: Use compressed air (gently) to blow out dust from the air vents and motor casing.

Wipe external surfaces: A microfiber cloth and isopropyl alcohol can remove buildup.

Inspect collet and nut: Clean regularly to ensure smooth tool changes and optimal grip.

Avoid using a vacuum directly on the spindle unless it has ESD protection and filtered airflow.

3. Lubricate Bearings—If Applicable

Some AMB spindle models come with sealed bearings, which are maintenance-free. However, if your model has accessible bearings, periodic lubrication may be required.

Guidelines:

Use manufacturer-recommended grease or oil.

Apply in small amounts—over-lubricating can attract dust.

Follow the service interval specified in the user manual.

If you're unsure whether your spindle requires lubrication, check your model number and consult AMB's documentation or support team.

4. Watch Your Feed and Speed

Running your spindle too fast or too slow with the wrong feed rate can strain the motor and reduce its life. Incorrect settings may also cause bit breakage, rough cuts, or overheating.

Best Practices:

Match RPM to bit size – Smaller diameter tools need higher RPMs.

Adjust feed rate for material – Softer materials need faster feeds; hard laminates like FR4 require slower, controlled passes.

Avoid stalling – Never force the tool through the material. Let the bit and spindle do the work.

Use tool manufacturers’ feed/speed charts as a baseline, and tweak settings based on results.

5. Check and Replace Collets Regularly

The collet is responsible for holding your tool securely in place. A worn or dirty collet can lead to tool slippage, vibration, or uneven cuts—all of which can strain the spindle bearings.

Inspection Tips:

Look for wear lines or discoloration.

Ensure the collet grips the bit evenly.

Replace the collet after 400–600 tool changes, or if you notice reduced performance.

Using proper torque when tightening the collet nut will also prevent undue stress on the motor shaft.

6. Avoid Overheating

High-speed milling can generate a lot of heat—especially when cutting copper clad laminates continuously. Excessive heat can degrade insulation, weaken adhesives, and shorten spindle life.

Heat Management Tips:

Take breaks between long jobs to allow the spindle to cool.

Ensure adequate airflow around the motor housing.

Consider using a cooling fan or air-assisted spindle mount if available.

Monitoring temperature during extended use is a good habit. If the spindle becomes too hot to touch, it’s time to pause and cool down.

7. Store and Handle with Care

When not in use, your AMB spindle should be stored in a clean, dry location. Protect it from dust, moisture, and accidental knocks.

Storage Tips:

Cover the motor or place it in a padded case.

Avoid laying it down on the collet or motor shaft.

Label tools and accessories to prevent mix-ups with incompatible equipment.

Proper storage prevents accidental damage and prolongs tool and motor life.

Final Thoughts

Your AMB high-speed milling motor is a precision tool designed to deliver outstanding results—but only if it’s treated with care. By following these maintenance and operation tips, you can dramatically extend spindle life, improve cutting accuracy, and reduce tool wear.

From keeping your collets clean to using premium carbide PCB drill bits and protecting your spindle from FR4 dust, each step contributes to smoother operation and long-term reliability.At Midwest Circuit Technology, we specialize in providing the tools and knowledge you need for successful PCB prototyping. Explore our full line of copper clad laminates, carbide bits, and spindle-compatible accessories designed to keep your workflow smooth and efficient.

0 notes

Text

Zero Liquid Discharge Plant Manufacturer in Delhi: Leading the Way Toward Sustainable Water Management

Zero Liquid Discharge Plant Manufacturer in Delhi

As industries continue to expand and environmental regulations become stricter, the need for sustainable and eco-friendly waste management systems is more important than ever. One such advanced technology that is transforming industrial wastewater treatment is the Zero Liquid Discharge (ZLD) system. If you're searching for a Zero Liquid Discharge Plant Manufacturer in Delhi, this article will help you understand the importance of ZLD systems and guide you in choosing the best manufacturer in the capital city of India.

What is a Zero Liquid Discharge (ZLD) System?

Zero Liquid Discharge is a water treatment process designed to eliminate all liquid waste from a system. In simple terms, ZLD ensures that no industrial effluent or wastewater is released into the environment. Instead, all water is treated, recycled, STP and reused, leaving behind solid waste that can be safely disposed of.

Why ZLD is Crucial for Industries

Industries such as textiles, pharmaceuticals, chemicals, power plants, and food processing produce a large volume of wastewater. If not treated properly, RO this can lead to environmental pollution and health hazards.

Key Benefits of ZLD Systems:

Environmental Protection: Prevents discharge of harmful chemicals into water bodies

Water Reuse: Treated water can be reused in industrial processes, saving fresh water

Regulatory Compliance: Meets strict pollution control norms from authorities like the CPCB (Central Pollution Control Board)

Cost-Efficiency: Long-term savings on water procurement and disposal

Sustainability: Supports corporate social responsibility (CSR) and green initiatives

ZLD Technology Overview

A Zero Liquid Discharge system is typically composed of:

Pre-treatment Units (for removing large particles and oil)

Evaporators (concentrate the wastewater)

Crystallizers (convert dissolved solids into crystals)

Reverse Osmosis (RO) Systems (recover water from waste streams)

Multi-Effect Evaporators (MEE) and Mechanical Vapor Recompression (MVR) for energy efficiency

Each component plays a crucial role in separating clean water from sludge and contaminants.

Growing Demand for ZLD Plants in Delhi

Delhi, being one of the most industrialized and densely populated cities in India, faces significant challenges with water scarcity and pollution. To tackle these issues, both the government and private sector are promoting the use of ZLD systems across industries.

Whether it's textile dyeing units in Bawana or pharmaceutical manufacturers in Okhla, many industries in Delhi are now looking for reliable Zero Liquid Discharge Plant Manufacturers to ensure regulatory compliance and environmental safety.

Top Qualities of a Trusted ZLD Plant Manufacturer in Delhi

If you’re in the market for a ZLD plant, it's vital to choose the right manufacturer. Here's what you should look for:

1. Experience and Expertise

Choose a manufacturer with a proven track record in designing and installing ZLD plants for a variety of industries.

2. Customized Solutions

Each industry has unique wastewater characteristics. A good manufacturer will offer tailor-made solutions based on your specific needs.

3. Advanced Technology

Check if the company uses the latest energy-efficient components like RO, MVR, and advanced membrane systems.

4. Compliance Support

A reliable manufacturer will ensure your plant meets CPCB and state PCB guidelines.

5. After-Sales Service

24/7 technical support, regular maintenance, and training services are essential for uninterrupted plant operation.

Services Offered by ZLD Plant Manufacturers in Delhi

Turnkey ZLD Solutions

Design and Engineering

Installation and Commissioning

Operation and Maintenance

ZLD Plant Upgrades

Retrofitting and Expansion

Online Monitoring Systems

Industries That Use ZLD Plants in Delhi

ZLD technology is versatile and can be adapted for various industrial sectors:

Textile and Dyeing Units

Tanneries

Pharmaceutical Plants

Chemical and Fertilizer Industries

Beverage and Food Processing Units

Power Plants

Electroplating Units

Challenges in Implementing ZLD Systems

While ZLD offers numerous benefits, it also comes with certain challenges:

High Initial Investment: ZLD systems can be capital-intensive, but the ROI is high in the long term.

Energy Consumption: Evaporators and crystallizers require substantial energy. Opting for MEE and MVR systems can reduce this burden.

Sludge Management: Handling and disposal of residual solids must be done responsibly.

Operational Expertise: Requires skilled operators for efficient functioning.

These challenges make it all the more important to choose a reputed ZLD plant manufacturer who can provide smart, efficient, and scalable solutions.

Government Regulations and ZLD

The National Green Tribunal (NGT) and Central Pollution Control Board (CPCB) have made it mandatory for highly polluting industries to adopt ZLD technologies. In Delhi NCR, industries are under pressure to treat and reuse their effluents or risk closure and penalties.

This regulatory environment is pushing demand for reliable and certified Zero Liquid Discharge Plant Manufacturers in Delhi.

How to Choose the Best ZLD Plant Manufacturer in Delhi

Here’s a step-by-step guide:

Assess Your Requirements: Know your industry’s effluent load, type of waste, and reuse objectives.

Research Vendors: Shortlist companies with certifications like ISO, CE, and CPCB approval.

Request Proposals: Compare technical offers, energy consumption, treatment efficiency, and total cost.

Visit Existing Installations: See running plants and ask for client feedback.

Check After-Sales Support: Ensure the company offers regular maintenance, training, and emergency services.

Conclusion

With Delhi’s rising industrial output and strict environmental norms, installing a Zero Liquid Discharge Plant has become more of a necessity than a choice. ZLD systems not only help industries become more environmentally responsible but also reduce long-term water costs by enabling water reuse.

Partnering with the right Zero Liquid Discharge Plant Manufacturer in Delhi ensures that your business stays compliant, eco-friendly, and future-ready. Whether you're setting up a new factory or upgrading your existing water treatment facility, now is the time to invest in ZLD for a cleaner, greener tomorrow.

FAQs

1. What is the main purpose of a Zero Liquid Discharge Plant? To treat industrial wastewater in such a way that no liquid waste is discharged, promoting complete water recycling and environmental safety.

2. Are ZLD systems mandatory for all industries in Delhi? While not all, certain high-polluting industries like textiles, tanneries, and pharmaceuticals are required to install ZLD systems by the CPCB.

3. How much does a ZLD plant cost? The cost varies based on the industry, wastewater volume, and technology used. It ranges from ₹20 lakhs to several crores.

4. What is the lifespan of a ZLD plant? With proper maintenance, a ZLD system can last 15–20 years.

5. Can a ZLD system reduce my company’s water bills? Yes. By recycling and reusing water, your dependence on fresh water is reduced, leading to lower water procurement costs.

#Zero Liquid Discharge Plant Manufacturer in Delhi#TOP Zero Liquid Discharge Plant Manufacturer in Delhi#SALE Zero Liquid Discharge Plant Manufacturer in Delhi#BEST Zero Liquid Discharge Plant Manufacturer in Delhi

0 notes

Text

Why Your Hotel Needs a Reliable Sewage Treatment Plant for Sustainable Operations

In today’s environmentally conscious world, sustainability has become a core priority for the hospitality industry. Hotels, being high water-consuming establishments, must ensure proper wastewater management to remain compliant with environmental regulations and maintain their reputation. That’s where a sewage treatment plant for hotels becomes not just important, but essential.

Understanding the Need for STPs in the Hospitality Sector

Hotels generate a significant volume of wastewater daily from guest rooms, kitchens, laundries, and other service areas. Without effective treatment, this wastewater can lead to environmental degradation and regulatory penalties. A sewage treatment plant for hotels addresses this issue by processing wastewater and converting it into environmentally safe discharge, or even reusable water for gardening, flushing, or cooling towers.

Customized Solutions for Hotel Operations

Unlike standard residential or municipal systems, hotels require customized STPs that can adapt to fluctuating loads depending on guest occupancy and seasonal demand. At A3 Technocrafts, we design sewage treatment systems that cater specifically to hotel dynamics. Our modular and scalable units ensure that the treatment process is efficient, regardless of how small or large your hotel is.

Key benefits of our hotel-specific STP solutions include:

Compact designs ideal for space-constrained hotel basements or rooftops

Odor-free operation to maintain guest comfort

Low energy consumption and maintenance requirements

Automated controls for hassle-free management

Compliance with Environmental Regulations

Environmental norms across India are becoming increasingly stringent, especially in metro cities and tourist zones. Installing a sewage treatment plant for hotels helps your establishment comply with pollution control board (PCB) guidelines. It also helps you avoid legal issues, fines, and reputation damage that could arise from untreated wastewater discharge.

A compliant STP adds value to your brand image, showing guests and stakeholders that your hotel takes its environmental responsibility seriously.

Economic and Ecological Benefits

While the initial investment in an STP might seem like a cost, it pays off in the long run. Reusing treated water can significantly reduce your freshwater consumption and water bills. Moreover, the treated sludge can be managed or repurposed effectively, reducing waste disposal costs.

By choosing an energy-efficient sewage treatment plant for hotels, your business saves resources and contributes positively to environmental conservation—aligning with the global goals of sustainable tourism.

Why Choose A3 Technocrafts for Your Hotel’s STP?

With over 12 years of experience in wastewater management, A3 Technocrafts is a trusted name in providing hotel-specific sewage treatment solutions. We offer end-to-end services from design and manufacturing to installation and maintenance. Our expert team ensures that your system runs smoothly while maintaining high-quality water treatment standards.

Conclusion

Installing a sewage treatment plant for hotels is not just about compliance—it’s a smart, future-ready investment that promotes sustainability, cost efficiency, and guest satisfaction. Trust A3 Technocrafts to deliver reliable and tailor-made STP solutions that align with your operational goals and environmental responsibilities.

Original Source:- https://a3tecnocrafts.blogspot.com/2025/05/why-your-hotel-needs-reliable-sewage.html

0 notes

Text

Why Choose Amaltas Institute of Medical Science for MBBS in 2025

If you are dreaming of becoming a doctor and are looking for the right college to kickstart your medical journey, Amaltas Institute of Medical Science can be the ideal destination for you. With a modern campus, experienced faculty, and hands-on clinical training, the institute offers a perfect blend of learning and career opportunities.

This blog will walk you through everything you need to know about Amaltas Institute of Medical Science – from admission process to fees, facilities, and career scope. So, let’s dive in.

About Amaltas Institute of Medical Science

Amaltas Institute of Medical Science, located in Dewas, Madhya Pradesh, is one of the emerging names in India’s medical education sector. Established with the mission to provide quality healthcare education and services, the institute has rapidly grown in popularity among students.

The college is affiliated with Madhya Pradesh Medical Science University (MPMSU) and approved by the National Medical Commission (NMC), which means the MBBS degree you earn here is recognized all over India.

Why Students Prefer Amaltas Institute of Medical Science

Choosing the right medical college is one of the biggest decisions in your life. Here’s why thousands of students are considering Amaltas Institute of Medical Science:

NMC-Approved MBBS Program

Affordable Tuition Fees Compared to Private Colleges

Advanced Infrastructure with Smart Classrooms & Labs

Attached 600+ Bed Teaching Hospital

Experienced and Dedicated Faculty Members

Hostel, Cafeteria, Sports, and Wi-Fi Facilities

Focus on Practical Learning & Patient Exposure

The environment is student-friendly and supports both academic and personal growth.

MBBS Course Details at Amaltas Institute of Medical Science

The institute offers a 5.5-year MBBS course, including:

4.5 years of academic study

1 year of compulsory rotating internship

The MBBS curriculum follows the Competency-Based Medical Education (CBME) model introduced by NMC. It includes subjects like:

Anatomy

Physiology

Biochemistry

Pathology

Microbiology

Pharmacology

Forensic Medicine

Community Medicine

Medicine, Surgery, Pediatrics, and more

Practical training is emphasized, and students get early exposure to clinical settings.

Eligibility Criteria for MBBS Admission

To apply for MBBS at Amaltas Institute of Medical Science, students must:

Complete 10+2 with Physics, Chemistry, and Biology

Score a minimum of 50% in PCB (40% for reserved categories)

Qualify the NEET-UG examination

Be at least 17 years old on or before December 31 of the admission year

Admission is done through counseling based on NEET rank under Madhya Pradesh state quota and all India management quota.

Fee Structure of Amaltas Institute of Medical Science

One of the most attractive features of Amaltas Institute of Medical Science is its affordable MBBS fee structure, making it accessible to more students.

Here’s a rough estimate:

Tuition Fees: ₹9–10 Lakhs per year

Hostel Charges: ₹1–1.5 Lakhs per year

Mess Fees: ₹60,000 to ₹75,000 per year

Security Deposit: ₹1–2 Lakhs (one-time, refundable)

Exact fees may vary slightly based on government guidelines or annual changes, but overall it remains a cost-effective choice compared to many private medical colleges.

Campus Facilities at Amaltas Institute of Medical Science

The college campus is designed to give students a peaceful and focused environment with all modern amenities:

Smart Lecture Theatres

Well-Equipped Laboratories

Library with Medical Journals and e-Resources

Dissection Hall and Anatomy Museum

Boys and Girls Hostels with 24/7 Security

Canteens Serving Hygienic Food

Sports Grounds and Gym Facilities

Wi-Fi Enabled Campus

Students also benefit from the Amaltas Super Speciality Hospital, which provides ample opportunities for clinical practice.

Hospital Training at Amaltas

The attached teaching hospital at Amaltas Institute of Medical Science is a 600+ bed facility that caters to thousands of patients. This ensures that MBBS students receive real-world exposure to patient care.

Emergency and Trauma Unit

Operation Theatres

ICU and NICU Units

Diagnostic Labs and Blood Bank

Outpatient and Inpatient Departments (OPD/IPD)

Community Outreach Programs

Students get to work under skilled doctors and specialists, which helps them gain confidence and skills required in the real medical world.

Hostel & Student Life

Hostel life at Amaltas Institute of Medical Science is safe, comfortable, and well-regulated. Each hostel is equipped with:

Spacious and Clean Rooms

RO Drinking Water

Laundry Facility

Common Rooms with TV & Indoor Games

Wardens and Security Staff

Separate Hostels for Boys and Girls

The college also organizes academic events, medical conferences, cultural fests, and sports tournaments to keep student life balanced and vibrant.

Career After Completing MBBS from Amaltas Institute of Medical Science

Once you complete your MBBS from Amaltas Institute of Medical Science, you can:

Appear for NEXT (National Exit Test)

Do PG in MD/MS/DNB programs

Apply for jobs in private or government hospitals

Open your own clinic after registration

Work as a junior resident or medical officer

Prepare for international exams like USMLE, PLAB, or AMC

The college provides full academic support to help students clear licensing exams and apply for higher studies.

Placement and Internship Support

During the internship, students work across various departments like medicine, surgery, pediatrics, obstetrics, and emergency care. This one-year practical experience helps them build clinical skills and prepare for real challenges.

Internship is compulsory and paid, and students receive a stipend as per government norms.

Final Thoughts: Is Amaltas Institute of Medical Science the Right Choice?

If you're a NEET-qualified student and looking for a recognized, affordable, and well-equipped medical college in central India, Amaltas Institute of Medical Science is definitely worth considering.

With a strong academic foundation, clinical exposure, and student-friendly atmosphere, the institute prepares you not just to become a doctor but a compassionate healthcare professional.

Need Help?

We at AR Group of Education offer admission support, counseling, and documentation help for MBBS aspirants across India and abroad.

Feel free to contact us at:

523, 5th Floor, Wave Silver Tower, Sec-18 Noida, UP-201301

+91–7076909090

0 notes