#Particle Size

Explore tagged Tumblr posts

Text

5 Advantages of Powder Processing by Rapid Mixer Granulator

Manufacturing excellence usually boils down to the smallest detail: getting the powder processing right. To the industry of powdered material, a new game in town emerged: the Rapid Mixer Granulator (RMG) - a new revolution of how granulation and mixing are done.

Why Powder Processing Matters

Anyone who has ever worked with powdered materials knows the problems: achieving a consistent particle size, maintaining uniformity in the batch, and meeting production deadlines. These become critical issues, especially in industries like pharmaceuticals, where precision isn't just desirable but rather essential. That's when the Rapid Mixer Granulator comes into play, bringing a sophisticated solution to these long-standing problems.

Let's dig deep into five major benefits of value to the RMG for efficient powder processing.

1. Lightning-Fast Processing Speed

Goodbye to time-hogging mixing cycles chewing into your production time. Well, the Rapid Mixer Granulator truly lives up to its name in hastening the granulation process for you. The intense agitation from the high-speed impeller is the most hectic, yet achieves the effect other mixers do, be it hours in your favor.

Reduces batch processing time up to 75%

Facilitates easy changes in formulas in the middle of a batch

Increases day-to-day production without the sacrifice of quality

2. More Uniformity from Every Batch

The word "professional" is stamped on every powder processor head, and that is where RMG truly shines. Their chopper and impeller systems are designed to be able to mix thoroughly while producing granules that come out quite uniform.

The impeller generates a fluidized mixing zone

Chopper breaks oversized agglomerates into smaller ones

Outcomes:

Particle size distribution is uniform

Moisture content of the entire batch is homogeneous

Quality of final product improves

Rejects decrease because of granulation differences

3. Smoothing Out the Scalability in Terms of Meeting Increased Needs

One of the most attractive benefits of modern granulation process advantages is the possibility of smooth scaling of operations. RMGs are available in a variety of sizes and can handle batch sizes ranging from a few kilograms to hundreds of kilograms, thus being suitable for pilot-scale development work, medium-sized production runs, and large-scale manufacturing operations.

The best part? The process parameters developed on smaller units can be reliably scaled up to larger machines, ensuring consistent results regardless of batch size.

4. Cost-Effective Operations

Though the investment in a Rapid Mixer Granulator may appear to be high, the return on investment is well understood with long-term operational benefits as follows:

Less labor input due to automated processes

Less energy consumption compared to multiple-unit operations

Less material waste through precise control

Lesser service needs

Robust structural design extends equipment life

5. Better Safety and Hygiene Standards

State-of-the-art powder processing strictly adheres to strict hygiene and safety requirements. With respect to the safety of man and integrity of product, the RMG has both provided for:

In-house hermetically sealed process enclosure to prevent contamination

Stainless steel finish surface avoids cross-contamination and supports easy cleaning

Features well aligned with GMP and its compliance

Clean-In and Clean-Out type cleaning, limiting operator exposure to potentially contaminated areas

Interlocked safety protection where equipment and people can’t be exposed together

Being the Smart Option for All Your Processing Needs

Higher-quality requirements, as well as heightened production efficiency, have made scalable granulation solutions critical investments for these industries. The Rapid Mixer Granulator is a perfect blend of speed, precision, and reliability in powder processing.

Whether in pharmaceuticals, food processing, or chemical manufacturing, the RMG is an intelligent choice for operations of any size due to its versatility and efficiency. It has become an industry standard because of its consistent high-quality results while upholding strict safety standards.

Align those benefits to your production goals. Improve your powder processing capabilities by utilizing a proven route for boosted productivity and product quality. This is not about staying up with industry standards; this is about setting new standards for your operation.

Manufacturing excellence usually boils down to the smallest detail: getting the powder processing right. To the industry of powdered material, a new game in town emerged: the Rapid Mixer Granulator (RMG) - a new revolution of how granulation and mixing are done.

Why Powder Processing Matters

Anyone who has ever worked with powdered materials knows the problems: achieving a consistent particle size, maintaining uniformity in the batch, and meeting production deadlines. These become critical issues, especially in industries like pharmaceuticals, where precision isn't just desirable but rather essential. That's when the Rapid Mixer Granulator comes into play, bringing a sophisticated solution to these long-standing problems.

Let's dig deep into five major benefits of value to the RMG for efficient powder processing.

1. Lightning-Fast Processing Speed

Goodbye to time-hogging mixing cycles chewing into your production time. Well, the Rapid Mixer Granulator truly lives up to its name in hastening the granulation process for you. The intense agitation from the high-speed impeller is the most hectic, yet achieves the effect other mixers do, be it hours in your favor.

Reduces batch processing time up to 75%

Facilitates easy changes in formulas in the middle of a batch

Increases day-to-day production without the sacrifice of quality

2. More Uniformity from Every Batch

The word "professional" is stamped on every powder processor head, and that is where RMG truly shines. Their chopper and impeller systems are designed to be able to mix thoroughly while producing granules that come out quite uniform.

The impeller generates a fluidized mixing zone

Chopper breaks oversized agglomerates into smaller ones

Outcomes:

Particle size distribution is uniform

Moisture content of the entire batch is homogeneous

Quality of final product improves

Rejects decrease because of granulation differences

3. Smoothing Out the Scalability in Terms of Meeting Increased Needs

One of the most attractive benefits of modern granulation process advantages is the possibility of smooth scaling of operations. RMGs are available in a variety of sizes and can handle batch sizes ranging from a few kilograms to hundreds of kilograms, thus being suitable for pilot-scale development work, medium-sized production runs, and large-scale manufacturing operations.

The best part? The process parameters developed on smaller units can be reliably scaled up to larger machines, ensuring consistent results regardless of batch size.

4. Cost-Effective Operations

Though the investment in a Rapid Mixer Granulator may appear to be high, the return on investment is well understood with long-term operational benefits as follows:

Less labor input due to automated processes

Less energy consumption compared to multiple-unit operations

Less material waste through precise control

Lesser service needs

Robust structural design extends equipment life

5. Better Safety and Hygiene Standards

State-of-the-art powder processing strictly adheres to strict hygiene and safety requirements. With respect to the safety of man and integrity of product, the RMG has both provided for:

In-house hermetically sealed process enclosure to prevent contamination

Stainless steel finish surface avoids cross-contamination and supports easy cleaning

Features well aligned with GMP and its compliance

Clean-In and Clean-Out type cleaning, limiting operator exposure to potentially contaminated areas

Interlocked safety protection where equipment and people can’t be exposed together

Being the Smart Option for All Your Processing Needs

Higher-quality requirements, as well as heightened production efficiency, have made scalable granulation solutions critical investments for these industries. The Rapid Mixer Granulator is a perfect blend of speed, precision, and reliability in powder processing.

Whether in pharmaceuticals, food processing, or chemical manufacturing, the RMG is an intelligent choice for operations of any size due to its versatility and efficiency. It has become an industry standard because of its consistent high-quality results while upholding strict safety standards.

Align those benefits to your production goals. Improve your powder processing capabilities by utilizing a proven route for boosted productivity and product quality. This is not about staying up with industry standards; this is about setting new standards for your operation.

#Powder processing#Rapid Mixer Granulator#Granulation#Mixing#Pharmaceutical#Uniformity#Particle size#Bulk density

0 notes

Text

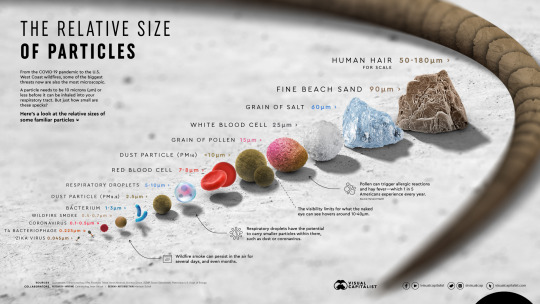

Particle size is key factor in coal mining-related respiratory disease

We found that nanoparticles have the same toxicity as silica," Liu said. “Many think progressive fibrosis is from silica, but really the coal nanoparticles may also contribute to the toxicity. This is the first study of its kind to understand nano-particulate toxicity”

0 notes

Text

undertale styled rejuv fights!

Bonus:

#pokemon rejuvenation#oc bracket#mona#art#can I just say. this was so so so fun.#I had to download a Lot of fonts and pixel brushes to find smth that Worked.#I got so excited for the upcoming del ta ru ne release i started binging many many many MANY PLAYTHROUGHS.#Help me. anyways. hopefully more upcoming! if this momentum keeps up!#I have. ideas. if I could pull them off. maybe. We Will See.#also yes the a + v fight bg is inspired by u t y cer oba’s. just laying it down there .#the gradient and particles…. very good combo .#but not petals. this is sand.#I thought about adding the Zeight but I didn’t want to overcrowd the bg#so. inspiration it is!#very good fight btw. I love. u t y.#coughs. I have many ideas. Many. MANY. ideas.#e t p. those are my ideas. Maybe c k too. hmm.#ALSO ALSO ALSO.#obliterate replacing mercy. huh. I wonder. looks to the distance.#also also also also. if the font sizes are weird I’m Sorry. I had to guess.

66 notes

·

View notes

Text

My Inktober: Day 2 - Dusttale

Dusttale by Ask-Dusttale

#zenubi-scribbles#dusttale sans#dusttale#dust tale#Sans AU#practice#inktober#art challenge#digital art#my art#digital inking#illustration#fan art#cw: scopophobia#tw: scopophobia#some of the dust particles don't show well in the thumbnail apparently#still learning tumblr image/preview sizes#looser sketching

148 notes

·

View notes

Text

If by some means you know the state of the universe right now – if you know where every particle is and how fast and in what direction each is moving – then, Newton and Einstein agree, you can, in principle, use the laws of physics to predict everything about the universe arbitrarily far into the future or to figure out what it was like arbitrarily far into the past.²

2. As we will discuss later in the book, there are realms (such as the big bang and black holes) that still present many mysteries, at least in part owing to extremes of small size and huge densities that cause even Einstein's more refined theory to break down. So, the statement here applies to all but the extreme contexts in which the known laws themselves become suspect.

"The Fabric of the Cosmos" - Brian Greene

#book quotes#the fabric of the cosmos#brian greene#nonfiction#universe#particle#direction#movement#isaac newton#albert einstein#laws of physics#prediction#future#past#big bang#black hole#exception to the rule#size#density#extremes

5 notes

·

View notes

Text

I brought up how Bruce Wayne probably has lead poisoning and Superman wouldn’t notice…

People have brought up so many points and questions that now I’m doing A SHIT TON OF MATH AND RESEARCH to see how anyone would find out about Bruce’s lead poisoning.

#looking up particle sizes#taking into consideration that Superman would probably have to search Batman on a molecular level for A LONG ASS TIME#before his vision would get blocked by a lead particle#SO MUCH MATH#Wondering what extreme of mentality unwell Batman would get to#before they realize it isn’t just a mood or only caused by stress/trauma#his sons would probably find out first bc they are detectives#most probably already know but didn’t know it could get this bad#bruce wayne#batman#dc comics

17 notes

·

View notes

Text

ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ

تخیل و فرض میتواند هم باطل باشد هم حق البته منظور این نیست که درانواحد میتواند هم درست باشد هم غلط بلکه آینده ی یک تخیل است که نشان میدهد این گربه بازیگوش تخیل زنده است یا مرده و تا مادامی که درب آینده گشوده نشده تخیل میتواند در جعبه مغز ما هم حق باشد هم باطل

.

با این مقدمه ی "علمی ادبی"🤦♂️بیاییم تخیل را وارد یک بحث جذاب علمی بکنیم آنجا که نور ، هم موج است هم ذره

.

برای ساختن این "بحث علمی تخیلی" روش به اینگونه خواهد بود که من حلقه هایی از یک زنجیر را جدا جدا بیان میکنم چگونگی بافتن زنجیر به قدرت تخیل هر کس ربط پیدا میکند

با این پیش شرط درست که تخیل و فرض لزوما باطل نیست بریم به سوی بافتن

.

خب ، بشر هرآنچه که ساخته است به نوعی ، یا مستقیم از طبیعت الهام گرفته یا غیر مستقیم از آن به طوریکه با نگاه به بی ربط ترین دستاورد های بشری باز میتوان مدلی از آن را در طبیعت مشاهده کرد

.

شاید "رد پا و خراشیدن" اولین بستر نمایشی تولید بشر بود که به وسیله آن میتوانست چیزی را ثبت و برای دیگران به نمایش درآورد

این روند طی قرن ها تلاش رسیده است به امروزی که میتواند در بستر آنالوگ یا دیجیتال اثری را ثبت و به نمایش در آورد

.

آن هنگام که ما دوربین آنالوگ عکاسی به دست گرفته ایم میتوانیم بگوییم تا حدود زیادی به سوی جنبه موجی نور میرویم و آن گاه که با دوربین دیجیتال عکاسی میکنیم در اصل وجه ذره ای نور را زنده نگه میداریم

.

با این حال که بشر میتواند با آزمایش جنبه موجی نور را مشاهده کند و بفهند اما خارج از دنیای دیجیتال نمیتواند جنبه موجی نور را حتی با دوربین آنالوگ ثبت کند ، چراکه به محض ثبت آن ، در اصل آنرا ذره ای ثبت کرده است

جوهر و کاغذ به صورت ذره ای باهم تلاقی پیدا میکنند

بزرگنمایی در یک عکس آنالوگ هرچند بهتر از بزرگنمایی در یک عکس دیجیتال است اما به دلیلی که گفتم حدی دارد بیشتر از آن باز عکس تار میشود

.

در دنیای "صفر و یک" کامپ��وتر ها میتوان این فهم های گفته شده را شبیه سازی کرد آنهم با تولید یک طرح اما به دو روش کاملا متفاوت

یک روش با محاسبه ی پیکسل ها

روش دیگر با محاسبه ی بردار ها

.

Vector & Bitmap

Wave & Particle

پیکسل و ذره ، بردار و موج

یک طرح میتواند هم پیکسلی باشد هم برداری

اول و آخر هر طرح بیتمپی ، پیکسل است

اما در عالم وکتور نهایت وجود ندارد انتها بی معنی است محدودیت اصلی این بی حدی به توان پردازشگری آن بستری دارد که پیوسته باید بردار های طراح را محاسبه کند وگرنه میتوان به راحتی مفهوم بی نهایت را اینگونه مجازی تصور کرد

Cellule or Cell

همانطور که پیکسل کوچک ترین واحد ساختمانی یک عکس دیجیتال است

سلول هم ، فهم امروزی ما از کوچک ترین واحد ساختمانی حیات است

.

بشر نیز دنیا را هم سلولی هم موجی درک و حس میکند

ولی تکیه اش به شناخت و درک و حس اطرافش ، روی بازخورد سلولی خودش میباشد اما اگر بتواند روی بازخورد موجی خودش بیشتر تکیه کند آنگاه آن جنبه ی پنهان تر آفرینش برایش آشکار میشود

بدون باز شدن دریچه این جنبه برای بشر ، ابدیت و بی نهایت فقط در حوزه مجازی قابل تصور است

.

در حوزه درمان بشر بیشتر روی درمان سلولی کار کرده است

میتواند روی درمان موجی هم پیشرفت هایی داشته باشد

.

آلبرت اینشتین برای توضیح ساده تر علمش داستانی تخیلی را اینگونه مطرح کرد که اگر دو برادر دوقلو یکی در کره زمین باشد و دیگری سفری را با موشک اما با سرعت نور آغاز کند و مسافتی را برود و برگردد هنگام دیدار دو برادر آنکه در کره زمین بود به میزان قابل محاسبهای پیر تر شده

بشر این موضوع را در ساعت های اتمی داخل ماهواره ها که به دور زمین میچرخند تجربه کرده است

اما سفر بشر با سرعت نور آیا همیشه در حد یک تخیل میماند ؟

این برمیگردد به آنکه اساس و ساختار بشر را سلولی بدانیم یا موجی یعنی کدام یک روی کدام سوار است به زبان ساده تر پایه کدام است؟

.

اساس و ساختار صفحه موبایل شما پیکسلی است حتی یک طرح وکتور که از محاسبه بردار ها رفرش میشود وقتی در صفحه ی موبایل شما بزرگ میشود پیکسلی بزرگ میشود یعنی بستر وقتی پیکسلی بود حتی تجربه بینهایت وکتوری هم پیکسلی خواهد بود به زبان فلسفی این تجربه یک توهم است

.

حال "اگر" اساس و ساختار فضازمان یعنی بستری که بشر در آن حرکت میکند موجی باشد و در کنار آن خوده بشر هم اساس و ساختارش موجی باشد و از آنجا که میدانیم اطلاعات به صورت نور قابل انتقال است آنگاه تخیل آلبرت اینشتین نه البته با موشک اما به شکلی دیگر میتواند محقق گردد

END

.

ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ

پ،ن 1️⃣: دانلود بهترین برنامه ای که میشود با آن در موبایل اشکال وکتور را مشاهده کرد

اکثر برنامه های داخل گوگلپلی را امتحان کردم ولی هیچ کدام این چنین سبک و روان در زوم نبودند

ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ

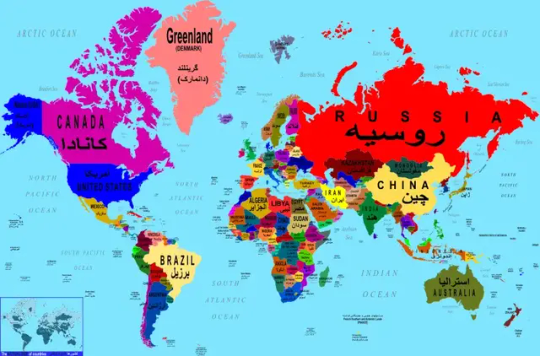

پ،ن 2️⃣: برای آنکه بهتر متوجه زوم بینهایتی بشوید نقشه ی جهانی برایتان آماده کردهام که در نقطه نون (ایرا"ن") پرچم این کشور بخت برگشته مخفی ��ده است

البته نقشه هایی که همه از آن استفاده میکنیم دو بعدی هستند اما کره زمین سه بعدی درنتیجه کشور هایی که از خط استوا دور هستند در نقشه های دو بعدی ابعادشان بزرگتر از اندازه واقعی خودشان شده است

آیا این دلیل خوبی ست برای غیرواقعی بودن نقشه ها ؟ بدون شک ، خیر

.

برای دیدن ابعاد واقعی کشورها به گوشه سمت چپ نقشه ای که گذاشتم مراجعه کنید

این نقشه اضافه شده ماهیت پیکسلی دارد که با زوم در آن به پیکسل ها خواهید رسید

ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ

پ،ن 3️⃣: نامناسب ندیدم حالا که حرف ایران و نون شد این ترانه را هم پُست کنم ، اون روزا که یاری نداشتم این ترانه خیلی میچسبید 😅ـ

نام ترانه - باغ الفبا

شاعر - همایون هوشیارنژاد

خواننده و آهنگ ساز - شهرام شبپره

تنظیم - منوچهر چشمآذر

ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ.ـ

.

.

.

#30ahchaleh#na_zzanin#ناظنین#Cell#cellule#vector#bitmap#particle#Wave#Zooming#iran#zoom#world map#maps#infinite zoom#countries#Actual size#.mp3#jetAudio#باغ الفبا#همایون هوشیارنژاد#��هرام شب پره#منوچهر چشم آذر#ایران#نقشه جهان#Bitmap Image#pixels#vector Image#mercator projection

3 notes

·

View notes

Link

3 notes

·

View notes

Text

Stuff I was shopping for today:

Kitchen table

Stuff I bought:

Really nice slingshot ($5)

MIDI drum kit ($2.50)

#could got the table if i wasn't looking for a really specific size but i ammmmm#also found that some saint vinny's have forgotten what thrift shop means#bruh no one's buying a 30 year old particle board table for $145

5 notes

·

View notes

Text

How the VJ Instruments Spheronizer Enhances Precision in Particle Shaping

Precision particle shaping stands at the core of modern pharmaceutical and chemical manufacturing excellence. When milliseconds matter and uniformity becomes the difference between success and failure, manufacturers face a critical challenge: achieving consistent, perfectly spherical particles at scale. The stakes couldn't be higher – irregular particle shapes can compromise drug efficacy, alter chemical reactions, and impact product quality.

Breaking New Ground in Particle Engineering

The VJ Instruments Spheronizer emerges as a game-changing solution in the landscape of particle engineering. This advanced equipment transforms irregular particles into uniform spheres through a precisely controlled process, addressing a fundamental challenge that has long plagued pharmaceutical and chemical manufacturers.

Traditional particle shaping methods often resulted in inconsistent outcomes, leading to:

Variable dissolution rates in pharmaceutical products

Unpredictable flow properties in powder handling

Quality control challenges and increased production costs

Higher rejection rates in final product inspection

Revolutionary Technology Meets Industry Demands

The VJ Instruments Spheronizer incorporates cutting-edge technology that sets new standards for precision particle shaping. At its heart lies a specially designed rotating friction plate with a proprietary surface pattern that ensures optimal particle movement and formation.

Key Technical Advantages:

Precision-engineered friction plate with variable speed control

Advanced particle distribution monitoring system

Automated process parameters adjustment

Temperature-controlled processing chamber

Transforming Manufacturing Excellence

In pharmaceutical manufacturing, the Spheronizer's impact is particularly profound. When processing active pharmaceutical ingredients (APIs), uniform particle shape directly influences:

Drug bioavailability

Content uniformity in final dosage forms

Manufacturing efficiency

Product stability

Chemical industry applications benefit equally from the equipment's precision:

Catalyst particle optimization

Controlled release properties

Enhanced material handling characteristics

Improved bulk density control

Cost-Efficiency Meets Performance

The VJ Instruments Spheronizer doesn't just deliver technical excellence – it transforms the economics of particle engineering:

Reduced material waste through precise control

Lower energy consumption compared to traditional methods

Minimized quality control interventions

Faster batch processing times

Integration and Support

Implementation of the VJ Instruments Spheronizer into existing manufacturing processes proves remarkably straightforward. The system features:

Modular design for flexible installation

Industry-standard connectivity protocols

Comprehensive training programs

24/7 technical support

Compliance and Quality Assurance

In highly regulated industries, compliance is non-negotiable. The Spheronizer meets and exceeds:

cGMP requirements

FDA guidelines for pharmaceutical processing equipment

International quality standards

Industry-specific validation protocols

Breaking New Ground in Particle Engineering

The VJ Instruments Spheronizer emerges as a game-changing solution in the landscape of particle engineering. This advanced equipment transforms irregular particles into uniform spheres through a precisely controlled process, addressing a fundamental challenge that has long plagued pharmaceutical and chemical manufacturers.

Traditional particle shaping methods often resulted in inconsistent outcomes, leading to: Variable dissolution rates in pharmaceutical products Unpredictable flow properties in powder handling Quality control challenges and increased production costs Higher rejection rates in final product inspection

Revolutionary Technology Meets Industry Demands

The VJ Instruments Spheronizer incorporates cutting-edge technology that sets new standards for precision particle shaping. At its heart lies a specially designed rotating friction plate with a proprietary surface pattern that ensures optimal particle movement and formation.

Key Technical Advantages: Precision-engineered friction plate with variable speed control Advanced particle distribution monitoring system Automated process parameters adjustment Temperature-controlled processing chamber

Future-Ready Manufacturing

As manufacturing continues to evolve, the VJ Instruments Spheronizer positions organizations at the forefront of particle engineering technology. Its advanced capabilities ensure:

Readiness for Industry 4.0 integration

Scalability for growing production demands

Adaptability to new material requirements

Long-term return on investment

Take the Next Step in Precision Manufacturing

The VJ Instruments Spheronizer represents more than equipment – it's an investment in manufacturing excellence. Organizations serious about precision particle shaping can't afford to compromise on capability or quality.

Ready to transform your particle engineering processes? Contact VJ Instruments today to:

Schedule a personalized demonstration

Receive a detailed ROI analysis

Discuss your specific application requirements

Begin your journey to precision particle shaping excellence

#Spheronizer#particle shaping#VJ Instruments#granule shaping#particle size#precision shaping#lab equipment#drug formulation#uniform particles#pharma tools.

0 notes

Text

I'm so excited to move out....

I can't sleep😫

#bruh#i also just realized that I forgot to pack yesterday while I was off#so ill have to pack today#start some laundry#dump my ex's clothes out of my tote#unload dishwasher#pack my clothes#prep stuff for my dad to help me move#KITCHEN TABLE?! FUCK#im definitely moving the cat last to try and avoid issues with her#i need to buy cat food and food bowl#set up the gravity water for my ex's cat (just because you dont like your ex doesn't mean you abuse their pet... I fucking love his cat...*#* She's basically my baby now... seriously I have that cat spoiled lol... If I can work out a living situation where I dont have to move in*#* with my cousin.... Im GONNA adopt another cat. i love cats)#i shouldn't have too much to move since I've downsized... a lot... sold my mini-fridge 😭 made the -easy- decision to leave my furniture*#*(an old power-lift chair that no longer works. some Mainstays shelves and entertainment center - they're almost 10 years old. cost $50 and*#*are made from particle board. they've been moved 3 too many times and they're falling apart) these were hard decisions tbh#im leaving a complete set of Mainstays dishes (cheap. i dont want them. my ex needs dishes. etc)#my mind is awake with all these plans... but I have to work tonight and i need to sleep (luckily I went to bed early)#i need a shower caddy. another (dedicated) dressing gown. a Jeep Wrangler (i hate them but they can tow mid sized campers and like. if I en*#*enjoy living like I will... Maybe I'll just make it my lifestyle) I know well-off people have made unconventional living trendy. but like.*#*Im a poor and it's more viable to live in the camper my parents bought on relatively cheap campgrounds#bro

2 notes

·

View notes

Text

#today's category is: funny signs#per arrivare a uno dei sentieri io praticamente devo passare attraverso la collina di zio paperone. è PIENO di cartelli#minacciosi tipo quelli giallo e sono pure tutti diversi 😭 la fantasia proprio#ora che ci penso anche quelli del deposito erano gialli :O magari è davvero una citazione e non sono degli psicopatici come tutti pensano :O#+ cute trees + one of the most beautiful things in the world is the shape of oak's leaves against the sky#+ tini tiny minuscole particle's size bunny :3#(hand for proportion)#passeggiatina

0 notes

Text

RADIATION NATION MAKE SOME FUCKING NOISE‼️‼️‼️

5K notes

·

View notes

Text

Everything You Need to Know About S20 Flair & Quadro Comil

High Efficiency Milling (HEM) is a modern machining strategy designed to maximise material removal rates (MRR) while minimising tool wear and heat generation. HEM involves using a lower Radial Depth of Cut (RDOC) and a higher Axial Depth of Cut (ADOC). This approach spreads wear evenly across the cutting edge, dissipates heat more effectively, and reduces the likelihood of tool failure.

0 notes

Text

youtube

#diy particle thrower#full size with lights#ghostbusters#wizardry workshop#made with cardboard#Youtube

1 note

·

View note

Text

The Latest Innovations in Dermal Filler Technology

Dermal fillers have become one of the most sought-after non-surgical cosmetic treatments due to their ability to restore volume, smooth wrinkles, and enhance facial contours. Over the past few years, significant innovations in dermal filler technology have emerged, leading to safer, longer-lasting, and more natural-looking results. In this article, we’ll explore the latest advancements in dermal filler technology and how they’re changing the aesthetics industry.

1. Biodegradable Fillers and the Push for Natural Results

One of the most significant trends in dermal filler technology is the move toward biodegradable materials. Fillers like hyaluronic acid (HA), calcium hydroxylapatite (CaHA), and poly-L-lactic acid (PLLA) are all biocompatible, meaning they break down naturally in the body over time.

The shift toward biodegradable fillers allows for safer treatments and more natural results. As these materials break down, they leave behind collagen stimulation and skin rejuvenation. This is in contrast to older filler technologies, which could sometimes feel unnatural or even cause complications in the long term.

The key benefit of biodegradable fillers is that they can provide temporary results, giving patients the option to decide if they want to continue or adjust their treatments. This has led to more personalized care and a focus on natural enhancement rather than drastic changes.

2. The Rise of Combination Fillers

Another exciting development in dermal filler technology is the use of combination fillers that combine multiple active ingredients for enhanced results. For example, Juvéderm Voluma XC combines hyaluronic acid with a unique cross-linking process that improves longevity and creates a firmer texture for deep injections, like in the cheeks.

Combination fillers offer multi-dimensional benefits by addressing various concerns at once. They may include a blend of ingredients that add volume, improve hydration, and stimulate collagen production. This multi-functional approach ensures that the filler performs well across multiple treatment areas, from the cheeks to the jawline, providing a more comprehensive treatment for facial rejuvenation.

3. Fillers Designed for Specific Areas

Innovations in dermal filler technology are also allowing for targeted treatments for specific facial areas. Newer filler formulations are designed to address the unique demands of different regions of the face, providing tailored results.

For example, under-eye fillers are now more refined, specifically designed to fill in hollow areas without causing overfilling. The soft consistency of these fillers ensures a natural look while restoring volume and minimizing dark circles.

In contrast, jawline fillers are formulated with more dense properties to provide structural support. These fillers can be injected deeper into the skin for more substantial lifting and contouring of the jaw area.

By using area-specific formulations, injectors are able to target precise concerns, such as nasolabial folds, temples, and cheeks, resulting in more customized and natural outcomes.

4. Nanotechnology in Dermal Fillers

Nanotechnology is also making waves in the dermal filler industry, particularly in how the filler particles are engineered. Nanoparticles are smaller than traditional filler particles, which means they can better integrate into the skin for a smoother, more uniform appearance.

The use of nanotechnology allows for more controlled release of the filler, providing longer-lasting and more even results. It can also reduce the risk of complications, such as lumps or migration, which are often caused by larger, less refined filler particles.

Nanoparticles can also enhance the body’s natural collagen production by being absorbed more gradually, leading to more subtle and natural improvements over time.

5. Cross-Linked Fillers for Longer Lasting Results

The process of cross-linking has revolutionized dermal filler technology by improving the strength and longevity of fillers. Cross-linking refers to the method of bonding hyaluronic acid molecules together, creating a more stable, cohesive gel that stays in place longer and provides better structural support.

Cross-linked fillers, like Restylane Lyft or Juvéderm Voluma, have a higher degree of stability, making them ideal for areas that need a firmer structure, such as the cheeks, chin, or jawline.

By increasing the degree of cross-linking, fillers become more resistant to breakdown, resulting in longer-lasting results that can persist from 6 months to 2 years depending on the type of filler used.

6. Improved Injection Techniques

Technological innovations aren’t just limited to the fillers themselves. The tools used to administer dermal fillers have also advanced, allowing for more precise and comfortable treatments. For example, micro-cannulas are becoming increasingly popular over traditional needles.

These flexible, blunt-ended tools reduce the risk of bruising and swelling by causing less tissue damage. Micro-cannulas also allow for larger areas to be treated with fewer injection sites, resulting in faster recovery times and more natural results.

7. The Role of Personalized Medicine in Dermal Filler Advancements

With the growing understanding of individual skin types, age-related changes, and genetic factors, dermal filler technology is evolving toward personalized treatments. By analyzing a patient’s unique needs—such as skin elasticity, facial volume loss, and skin texture—injectors can now choose the most appropriate filler for a patient’s specific needs.

This trend in personalized dermal filler technology is leading to tailored treatments that offer more effective results for each patient. The future of fillers may even include the use of genetic testing to predict how individuals will respond to different filler compositions, leading to even more customized solutions.

8. The Future of Dermal Fillers: What’s Next?

Looking ahead, the future of dermal filler technology holds exciting possibilities. Researchers are working on bio-stimulatory fillers that can not only add volume but also actively regenerate tissue and stimulate collagen production over time. These fillers could offer longer-lasting effects and may even reduce the need for frequent treatments.

Additionally, regenerative medicine may play a larger role in dermal filler advancements. By combining stem cell therapy and other regenerative techniques, future dermal fillers could potentially offer permanent results by stimulating the body’s own healing processes.

Conclusion: The Evolution of Dermal Fillers

Innovations in dermal filler technology have made these treatments safer, more effective, and more customizable than ever before. From biodegradable materials to nanotechnology, advancements are leading to longer-lasting results and more natural-looking enhancements. Whether through more refined injection techniques or the use of personalized filler options, the future of dermal fillers is bright and full of possibilities.

For those considering dermal fillers, staying informed about the latest innovations can help you make the best choice for achieving your desired aesthetic outcomes.

#ermal fillers#latest dermal filler technology#biodegradable dermal fillers#hyaluronic acid fillers#calcium hydroxylapatite fillers#poly-L-lactic acid fillers#cross-linked dermal fillers#nanotechnology in fillers#filler longevity#dermal filler brands#soft tissue fillers#facial volume restoration#under-eye fillers#lip enhancement fillers#cheek fillers#jawline fillers#targeted dermal fillers#filler injection techniques#micro-cannula technique#natural-looking fillers#combination dermal fillers#filler particle size#collagen stimulation with fillers#personalized filler treatments#filler safety#non-surgical facial rejuvenation#lifting and contouring fillers#hyaluronic acid vs other fillers#filler for deep wrinkles#filler for facial symmetry

0 notes